A polystyrene imitation wood profile and its preparation method

A technology of polystyrene and profiles, applied in the field of polystyrene micro-foaming co-extruded wood-like materials and its preparation, which can solve the problems of easy peeling of plaster, large waste of stickers, and easy peeling of paint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1——4

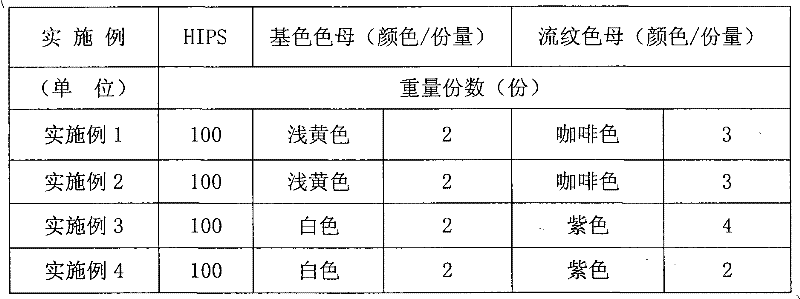

[0011] 1. Prepare high-impact polystyrene material (HIPS), base color masterbatch, and flow pattern masterbatch according to the proportions, and mix them with a low-speed mixer as the surface material raw materials. The material formula is shown in Table 1 (1 part by weight 1 kg)

[0012] Table I

[0013]

[0014] 2. Combine 100 parts of polystyrene material, 2 parts of foaming agent, 1 part of color masterbatch (Example 1-2 uses yellow color masterbatch, Example 3-4 uses white color masterbatch), 2 parts plasticizer , Add a high-speed mixer and mix evenly as the core material.

[0015] Among them, the foaming agent can use the AK-8 foaming agent of Hangzhou Dingyue Chemical Co., Ltd.;

[0016] Color masterbatch can use H series masterbatch of New Particle Chemical Pigment Co., Ltd.;

[0017] As the plasticizer, dioctyl phthalate can be used.

[0018] The core layer polystyrene material can use recycled polystyrene material.

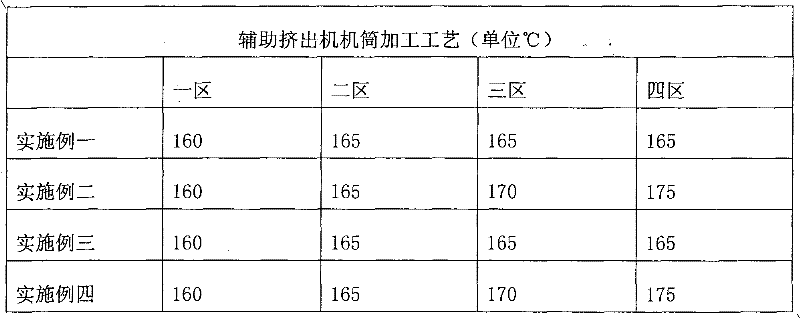

[0019] Co-extrusion molding: The processing equipment inclu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com