Production method of polypropylene cooling masterbatch

A technology of cooling masterbatch and production method, applied in the direction of single-component polyolefin artificial filament, etc., can solve problems affecting product quality, equipment life and production efficiency, improving strength, lack of melting stability, and deteriorating production and labor environment , achieve the effects of shortening the molding cycle, high melt index and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

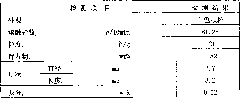

Embodiment 1

[0030] (1) Ingredients are prepared according to the following weight measurement:

[0031] 1. Polypropylene resin: 50Kg.

[0032]2. Organic peroxide: 2,5-dimethyl-2,5-di(tert-butyl peroxy)hexane: 1.1Kg; 1,1-di-tert-butyl peroxy-3,3,5 - Trimethylcycloethane: 0.2 Kg; tert-butyl peroxybenzoate: 0.4 Kg.

[0033] 3. Antioxidant: Antioxidant 1076: 0.2Kg: Antioxidant 168: 0.1Kg: Antioxidant N, N'-bis[3-(3',5'-di-tert-butyl 4'-hydroxybenzene Base) propionyl] hexamethylenediamine: 0.1Kg.

[0034] 4. Dispersant: brand name SHYS-520 polypropylene wax (PP wax): 3Kg; magnesium stearate: 0.5Kg.

[0035] 5. Light stabilizer: Light stabilizer 622: 0.15Kg: Light stabilizer 944: 0.1Kg.

[0036] 6. Surface modifier: PP surface modifier brand name PP-b-PS (downstream product of hydroxyl-terminated polylactic acid): 0.2Kg.

[0037] 7 Lubricant: Lubricant brand name RH300: 0.6Kg; XH-202B special effect bright lubricant: 0.2Kg.

[0038] 8. Flow regulator: polymer tackifier brand name LM216: 0...

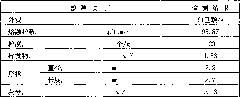

Embodiment 2

[0054] (1) The ingredients are measured and prepared according to the following proportions:

[0055] 1. Polypropylene resin: 60Kg.

[0056] 2. Organic peroxide: 2,5-dimethyl-2,5-di(tert-butyl peroxy)hexane: 1.3Kg; 1,1-di-tert-butyl peroxy-3,3,5 - Trimethylcycloethane: 0.25 Kg: tert-butyl peroxybenzoate: 0.5 Kg.

[0057] 3. Antioxidant: Antioxidant 10760.25Kg: Antioxidant 168: 0.15Kg; Antioxidant N, N'-bis[3-(3',5'-di-tert-butyl 4'-hydroxyphenyl) Propionyl] hexamethylenediamine: 0.15Kg.

[0058] 4. Dispersant: commercial brand SHYS-520 polypropylene wax (PP wax): 3.5Kg; magnesium stearate: 0.65Kg.

[0059] 5. Light stabilizer: light stabilizer 622: 0.18Kg; light stabilizer 944: 0.15Kg.

[0060] 6. Surface modifier: PP surface modifier brand name PP-b-PS (downstream product of hydroxyl-terminated polylactic acid): 0.3Kg.

[0061] 7 Lubricant: Lubricant brand name RH300: 0.8Kg: XH-202B special effect bright lubricant: 0.3Kg.

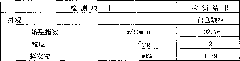

Embodiment 3

[0078] (1) The ingredients are measured and prepared according to the following proportions:

[0079] 1. Polypropylene resin: 75Kg.

[0080] 2. Organic peroxide: 2,5-dimethyl-2,5-di(tert-butyl peroxide) hexane: 1.6Kg: 1,1-di-tert-butyl peroxy-3,3,5 - Trimethylcycloethane: 0.3 Kg; tert-butyl peroxybenzoate: 0.65 Kg.

[0081] 3. Antioxidant: Antioxidant 1076: 0.35Kg: Antioxidant 168: 0.15Kg: Antioxidant N, N'-bis[3-(3',5'-di-tert-butyl 4'-hydroxybenzene Base) propionyl] hexamethylenediamine: 0.12Kg

[0082] 4. Dispersant: brand name SHYS-520 polypropylene wax (PP wax): 4.5Kg: magnesium stearate: 0.8Kg.

[0083] 5. Light stabilizer: light stabilizer 622: 0.2Kg 3; light stabilizer 944: 0.2Kg 5

[0084] 6. Surface modifier: PP surface modifier brand name PP-b-PS (downstream product of hydroxyl-terminated polylactic acid): 0.4Kg.

[0085] 7. Lubricant: Lubricant brand name RH300: 1.05Kg; XH-202B special effect bright lubricant: 0.45Kg.

[0086] 8. Flow regulator: polymer tacki...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thermal decomposition temperature | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com