Controlled degradable surgical suture thread and fabricating method thereof

A technology of surgical suture and manufacturing method, which is applied in the field of medical devices, can solve problems such as difficulty in synchronizing degradation absorption rate and wound healing rate, asynchronous degradation absorption rate and wound healing rate, insufficient tension strength and knot strength, etc., to achieve improvement Biocompatibility and anti-infection, good antibacterial and anti-inflammatory effects, and the effect of promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

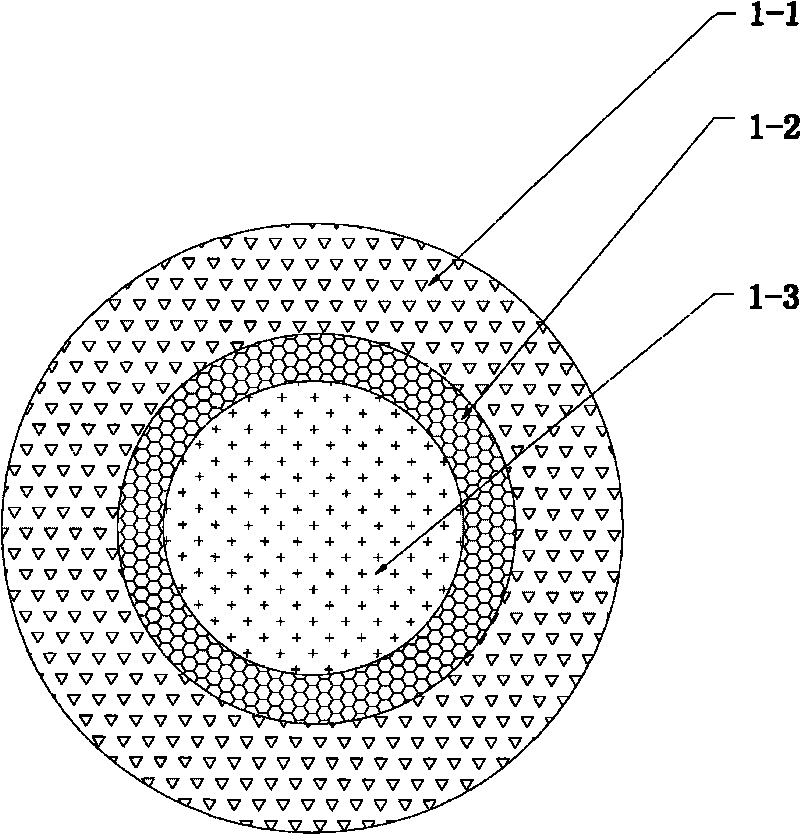

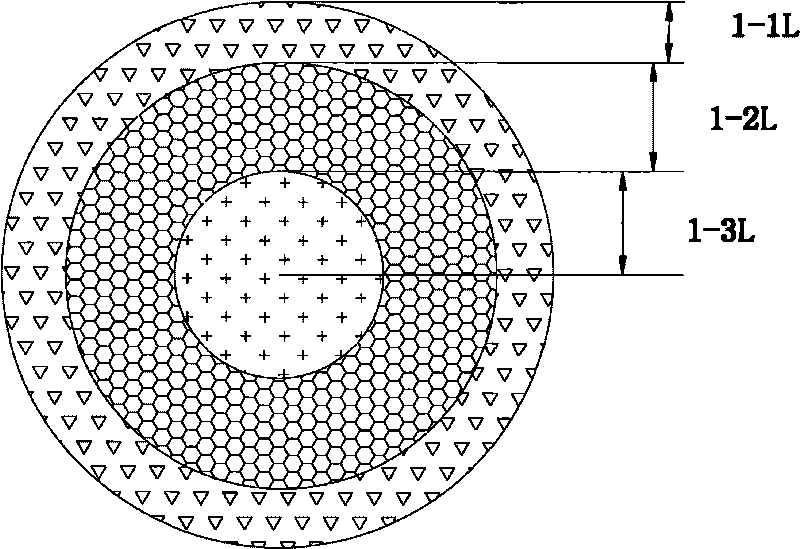

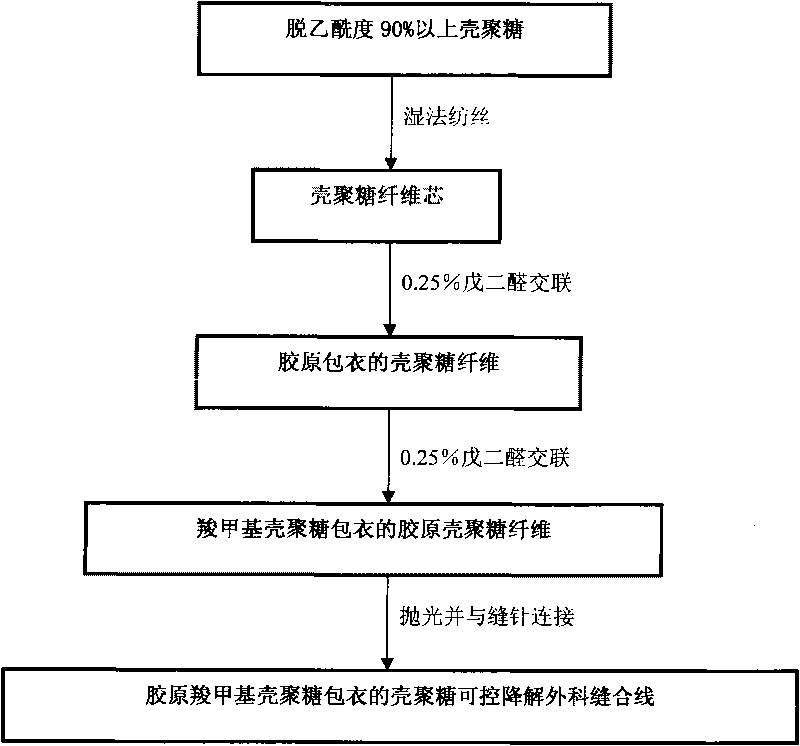

[0018] The technical scheme of the present invention is described in detail below, as shown in the figure, figure 1 It is a cross-sectional structure diagram of the controllable degradable surgical suture according to the present invention. In the figure, the structure of the controllable degradable surgical suture is, from inside to outside, sequentially, chitosan fiber core 1-3, collagen layer 1-2 and Carboxymethyl chitosan layer 1-1, each layer thickness ratio is, chitosan fiber core: collagen layer: carboxymethyl chitosan layer=2: X: (3-X), wherein 1<X<3 . The value of X is related to the degradation rate of the suture: the larger the X value, the faster the degradation rate of the suture, and the shorter the wound healing period suitable for suturing; on the contrary, the smaller the X value, the slower the degradation rate of the suture, which is suitable for suturing longer wound healing period. For example, for soft tissue laceration or surgical incision, usually 4 l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com