Patents

Literature

98results about How to "Easy to knot" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polymer composite fiber surgical suture line capable of sustaining and controlling release of therapeutic medicaments and preparation method thereof

InactiveCN101721739AAntibacterial and anti-inflammatoryHigh mechanical strengthSuture equipmentsFiberPolymer composites

The invention belongs to the field of biomedical materials and relates to a polymer composite fiber surgical suture line capable of sustaining and controlling the release of therapeutic medicaments and a preparation method thereof. Nucleated hollow silicon dioxide submicron spheres containing the therapeutic medicaments are dispersed in aqueous solution of a polymer; the nucleated hollow silicon dioxide submicron spheres containing the therapeutic medicaments are embedded in polymer fibers by using a spinning method to form the polymer composite fiber surgical suture line of the nucleated hollow silicon dioxide submicron spheres embedded and loaded the therapeutic medicaments to obtain the polymer composite fiber surgical suture line capable of sustaining and controlling the release of the therapeutic medicaments. The embedded nucleated hollow silicon dioxide submicron spheres are dispersed in the polymer fibers and filled with the medicaments and has a sustained release function. Themedicaments are released by slow diffusion and the gradual degradation of the polymer fibers. The loaded medicaments have functions of resisting bacteria and inflammation, killing tumor cells remaining after surgery and the like.

Owner:陈东 +2

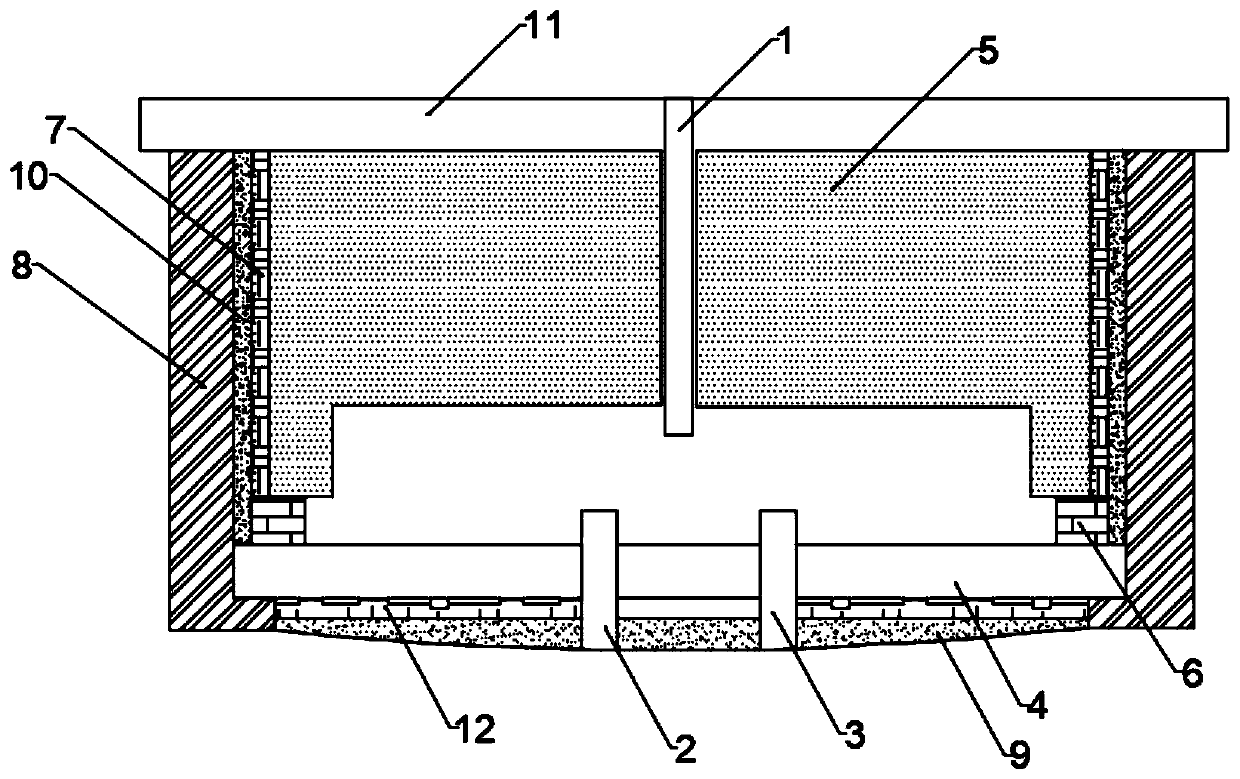

Wet process for building 3t intermediate frequency electric furnace

The invention relates to a wet process for building a 3t intermediate frequency electric furnace. By the process, 3t of materials can be melted, and the service life is prolonged. The process comprises the following steps of: (1) manufacturing a steel crucible die which has a shape of a truncated hollow cone; (2) paving an insulation layer and a thermal insulation layer by using two layers of asbestos cloth; (3) paving a furnace bottom, namely paving two layers of asbestos cloth at the furnace bottom in a staggered mode; (4) paving a furnace wall, namely paving two layers of asbestos cloth next to the inner wall of an induction coil from top to bottom, ensuring that each layer is flat and does not have any wrinkle, adhering longitudinal joints for lapping by using water glass, staggering joints of two adjacent layers, and adhering the asbestos cloth which stretches out of the upper plane to a fireproof brick plane at an upper opening of the furnace by using the water glass; (5) preparing a furnace lining material from refined quartz sand; (6) manually knotting a furnace lining, brushing a layer of water glass before filling, and tamping a filler; and (7) baking the furnace and sintering, namely baking only by using firewood after the furnace is built by the wet process, adding 50 to 60kg of firewood into a hearth for several times, and completely combusting to bake the furnace lining.

Owner:HANGZHOU ZHONGQIANG ROLLER

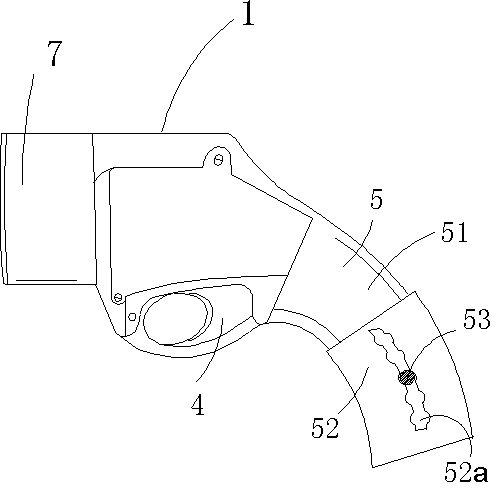

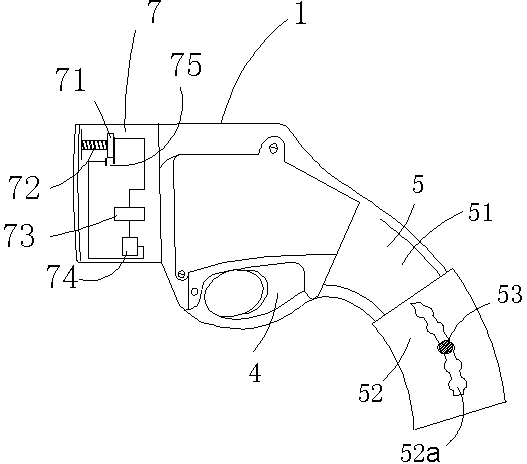

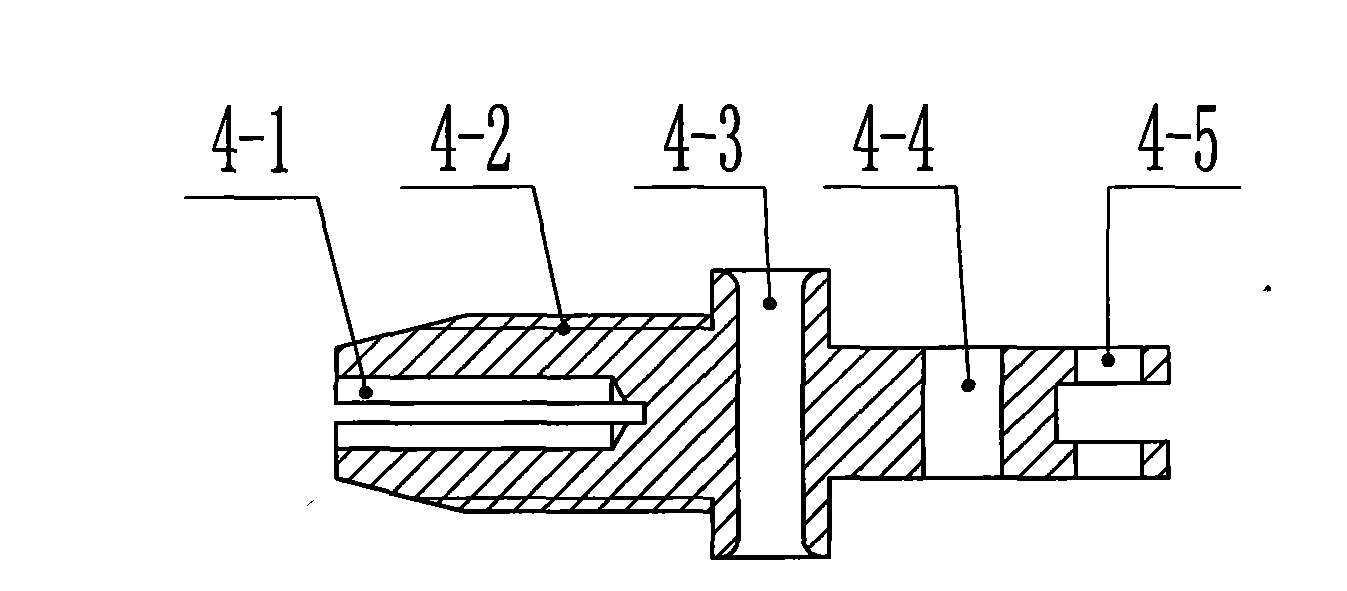

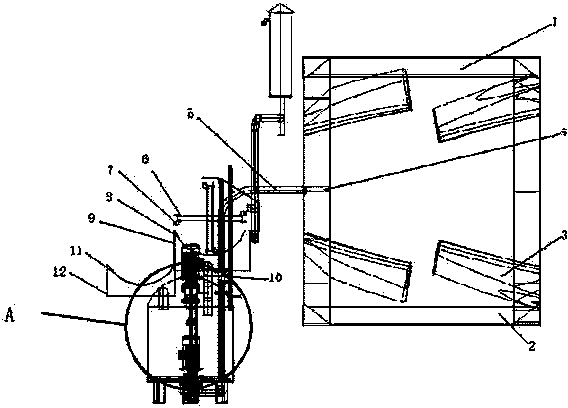

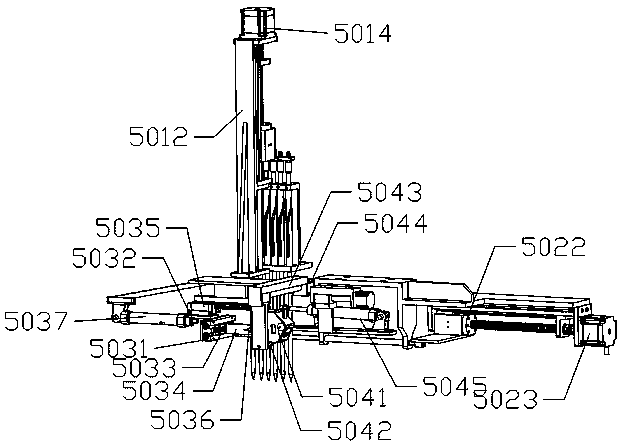

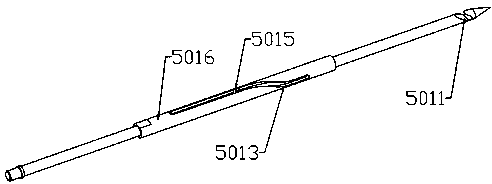

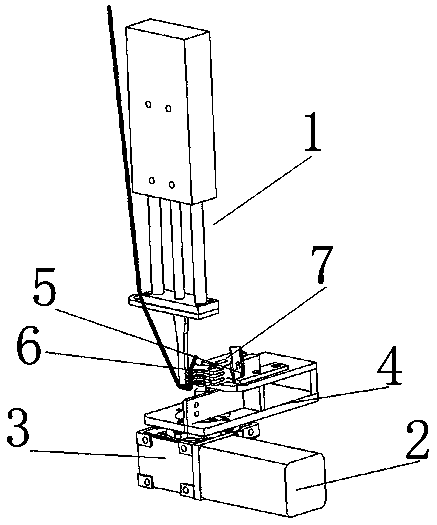

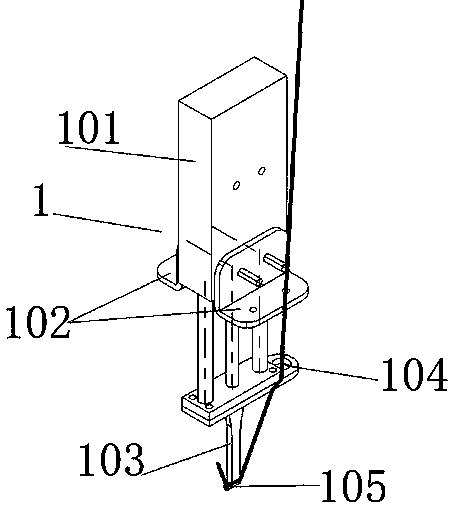

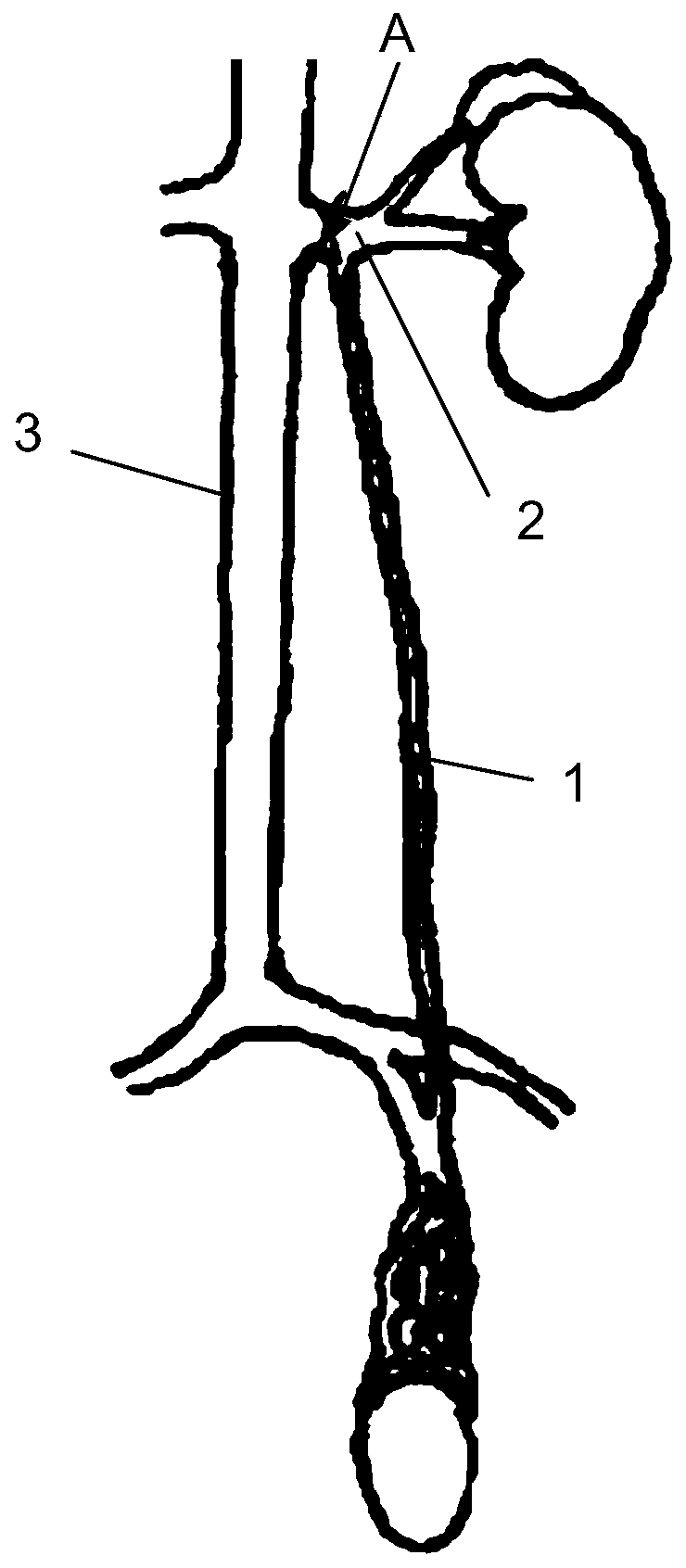

Left abomasal displacement operative reduction apparatus for cattle

InactiveCN103690268AWon't scratchIncreased surgical distanceSurgical veterinaryAbdominal wallOperative instrument

The invention discloses a left abomasal displacement operative reduction apparatus for cattle. The left abomasal displacement operative reduction apparatus is applied to the field of animal medicine and is an operative instrument for treating left abomasal displacement for the cattle. The operative reduction apparatus comprises a reduction needle transmitting device and reduction needles with line binding holes. The reduction needle transmitting device comprises three transmitting tubes and a sensing positioning device. The left abomasal displacement operative reduction apparatus has the advantages that abomasal fixing lines can be accurately, efficiently and stably conveyed to target positions on the right sides of abomasal walls of the ill cattle without opening the right sides of the abomasal walls of the cattle; the probability of injury to the cattle due to reduction needle conveying errors can be eliminated; the conveying distances of the reduction needles can be increased owing to a retractable handle, so that the abomasa of the cattle with different body sizes can be assuredly reduced to perfect positions; potential risks caused after the reduction needles penetrate the abomasal wall of the cattle and fly out can be prevented; only one operative person is required for performing left abomasal displacement on the cattle by the aid of the operative reduction apparatus and can independently complete operation without assistants.

Owner:王侨侨 +4

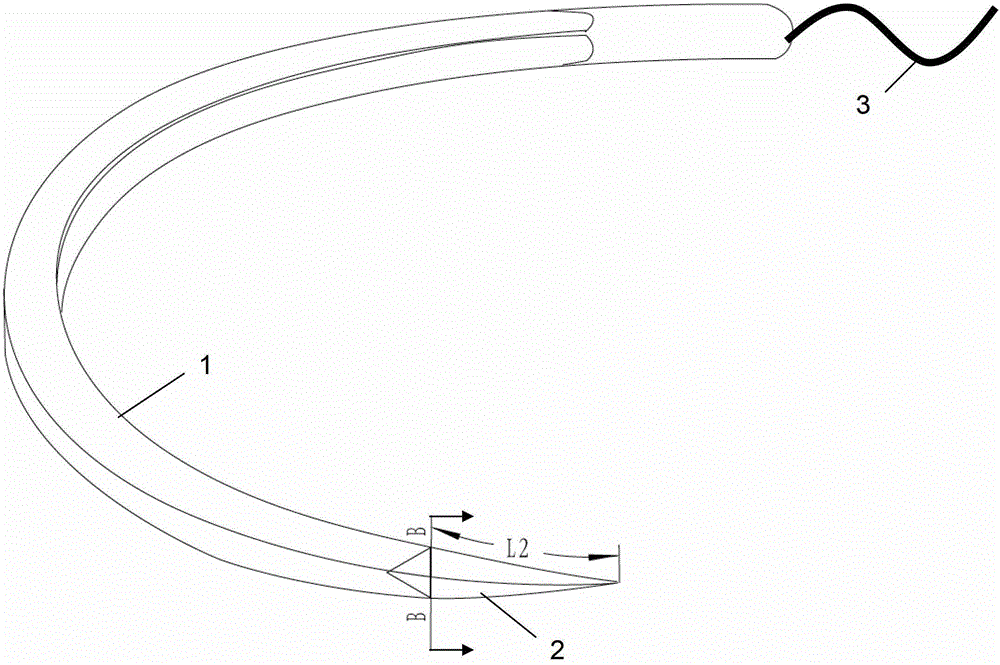

Surgical seam of yamamai silk and preparation thereof

InactiveCN101244288AHigh strengthSmooth laneSuture equipmentsAnimal materialPancreatic juiceSurgical operation

The invention relates to wild silk surgical operation suture thread and the preparation method. The wild silk yarn surgical operation suture thread adopts wild silk woven or twisting thread as thread rod and the surface is covered by wild sericin. The preparation method comprises the following steps: (1) place and immerse the wild silk into the aqueous solution, which comprises 0.1-0.3wt% sodium salt, 0.1-0.2wt% surface-active agent and 0.01-0.03wt% penetrating agent for 15 to 20 minutes; (2) after fish out and dry the wild silk, use machine to weave and twist the wild silk into the thread rod with required specification; (3) apply the wild sericin on the thread rod; and (4) heat up the silk for forming and the heating temperature should be controlled between 80 to 100 degrees centigrade. The suture thread has the advantages of high strength, smooth thread, easy knotting, good absorbing performance, good pancreatic juice and bile tolerance, easy dialyneury and capability of promotion of nerve regeneration.

Owner:深圳前海南岭天蚕科技有限公司

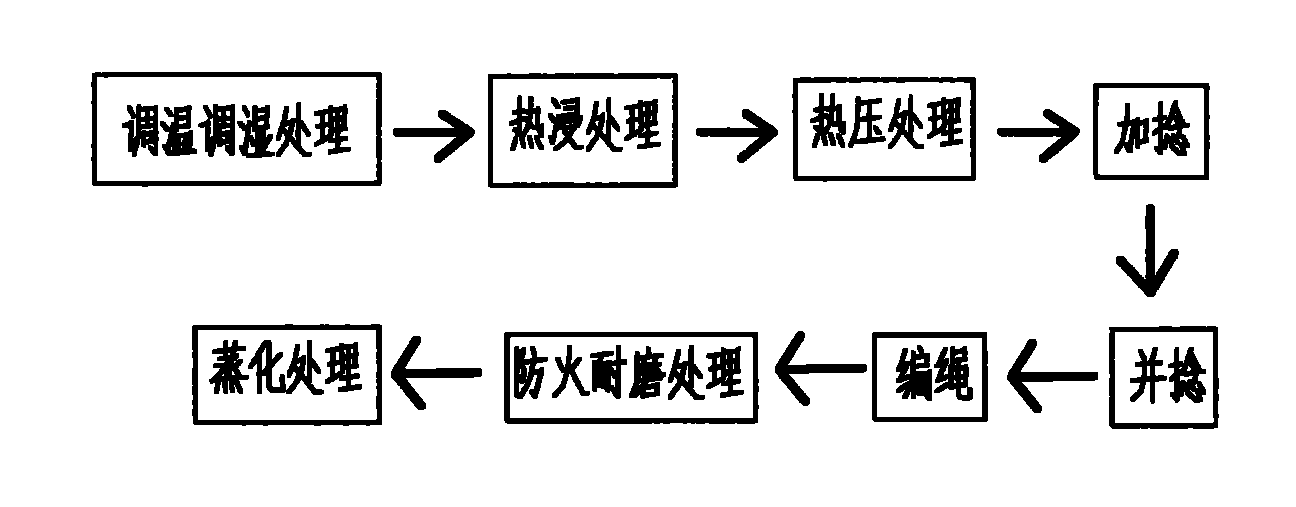

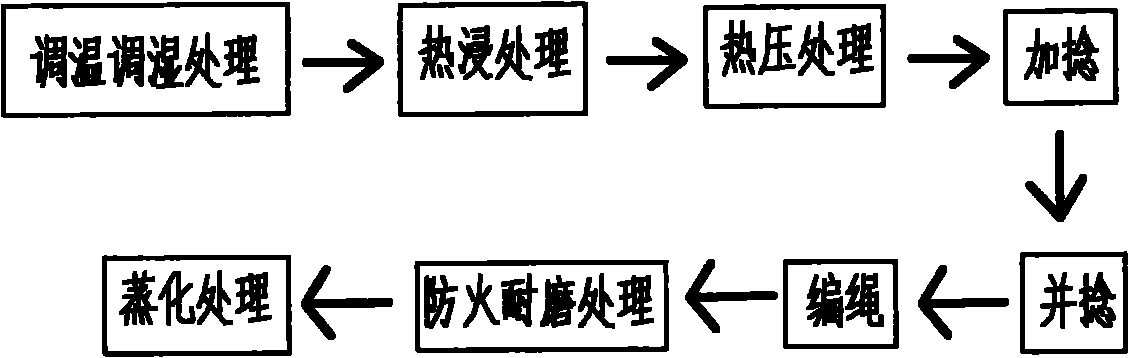

Method for producing basalt fiber rope net

ActiveCN101838885AImprove the finishHigh tensile strengthLiquid/gas/vapor removal by squeezing rollersBraidPolymer scienceActive agent

The invention discloses a method for producing basalt fiber rope nets, which comprises the following processes of: heat soaking treatment, hot-pressing treatment, weaving ropes, fireproof and wear-resistant treatment, steaming treatment, and the like. The heat soaking treatment solution contains an anionic surfactant, sodium alga acid and other aids; a tension regulation device is arranged on a high-speed braiding machine; and the fireproof and wear-resistant treatment solution contains PTFE, neutral salts, and other active agents. The method has reasonable process and advanced treatment technology and method, and the produced rope nets have the advantages of high temperature resistance, corrosion resistance, high intensity, high safety, and high cost performance.

Owner:TAIAN ROPE NET PLASTIC

Coating method of antibacterial surgical suture made of high molecular absorbable material

The invention discloses a coating method of an antibacterial surgical suture made of a high molecular absorbable material. The method comprises the following steps of: applying a dying process to a coating process; preparing a suture woven by using a warp loom; soaking a primary suture; uniformly spraying a coating liquid onto the suture by adopting a gas-free coating process; and drying and sizing. The suture is reddish violet and fresh in color, is smooth and flexible, is easy for knotting, has high knotting strength, and has the advantages of anti-inflammation, oxidation resistance, high degradability, long tension period and the like; and the safety of a knot is enhanced. The tensile strength is kept by about 70 percent two weeks after clinical suturing; slow absorption starts four weeks later; and the suture is absorbed completely 8-10 weeks later. As proved by clinical application, the antibacterial surgical suture has a wide application range and a good effect, is free from irritability, irritation and inflammatory reactions, and has the advantages of sterilization, anti-inflammation, bacteriostatic action and the like.

Owner:SHANDONG HAIDIKE MEDICAL PROD CO LTD

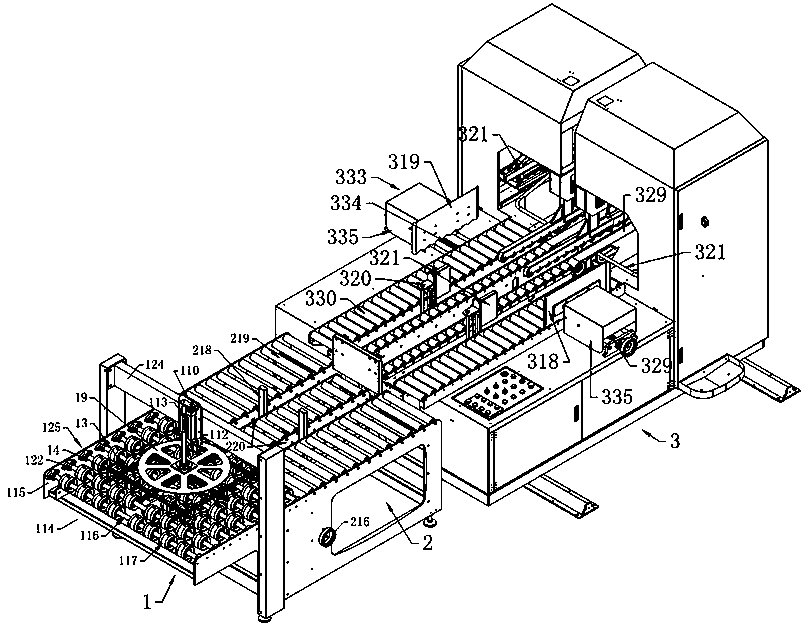

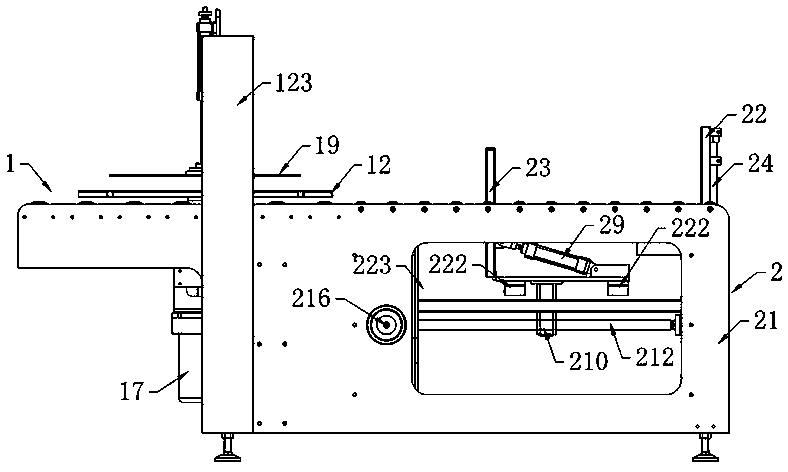

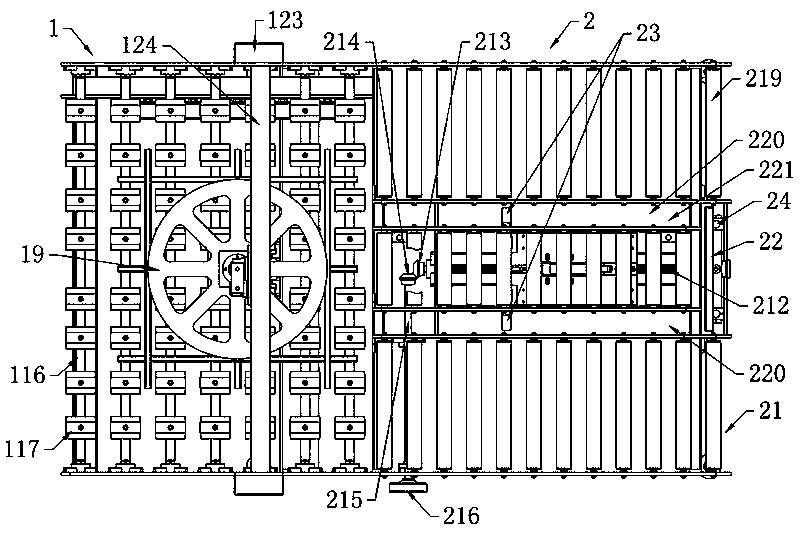

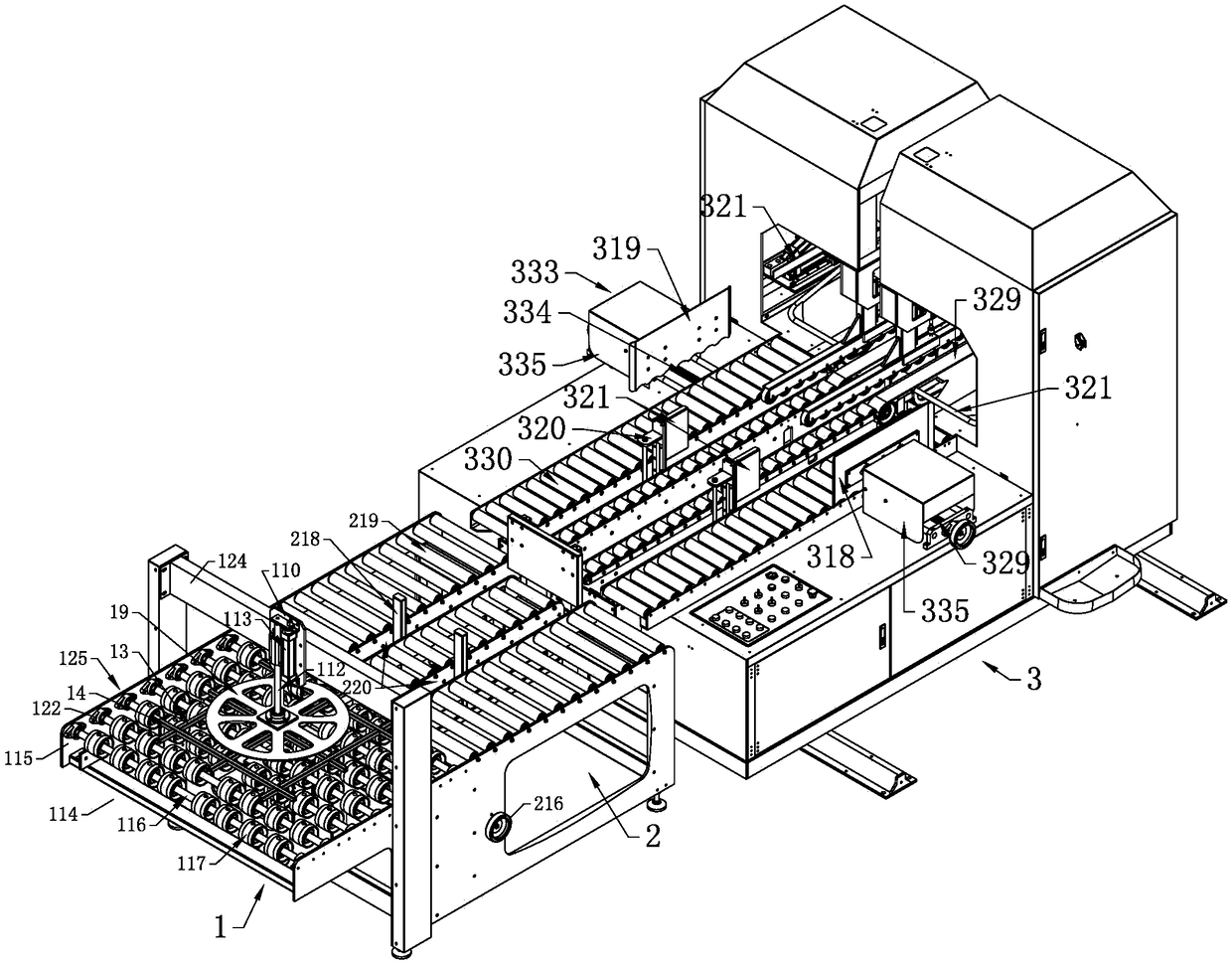

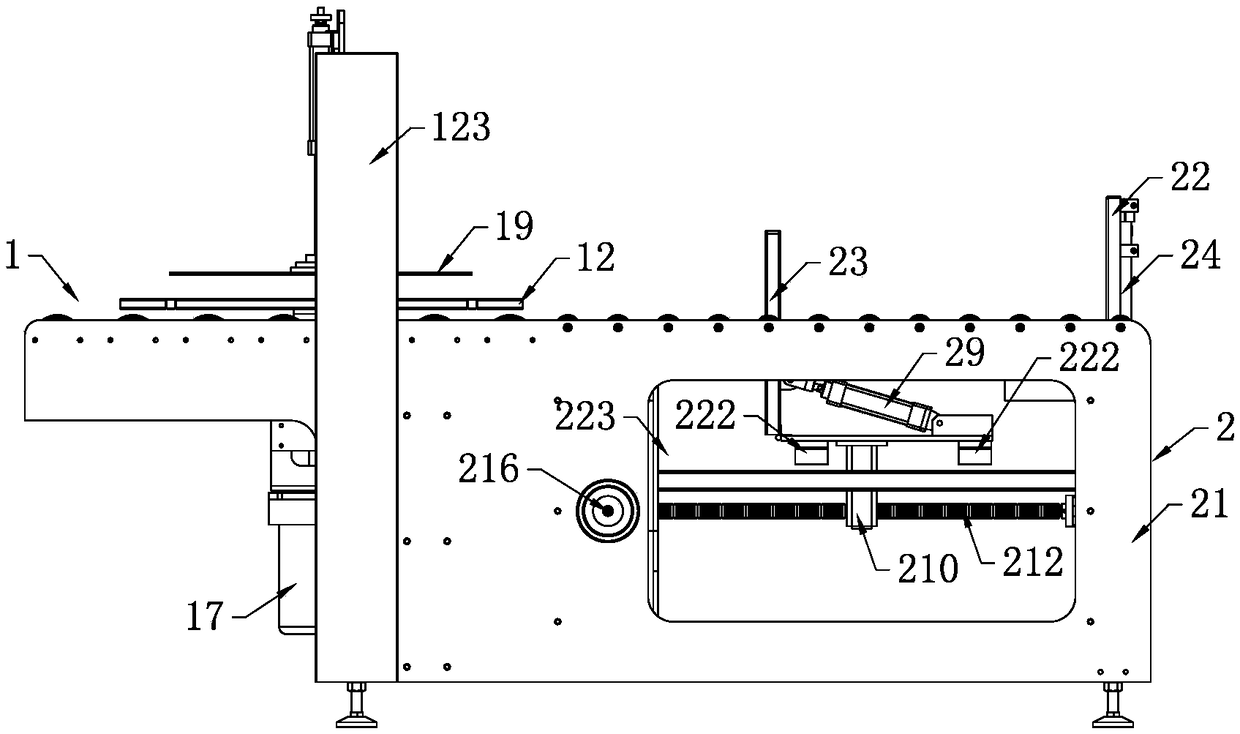

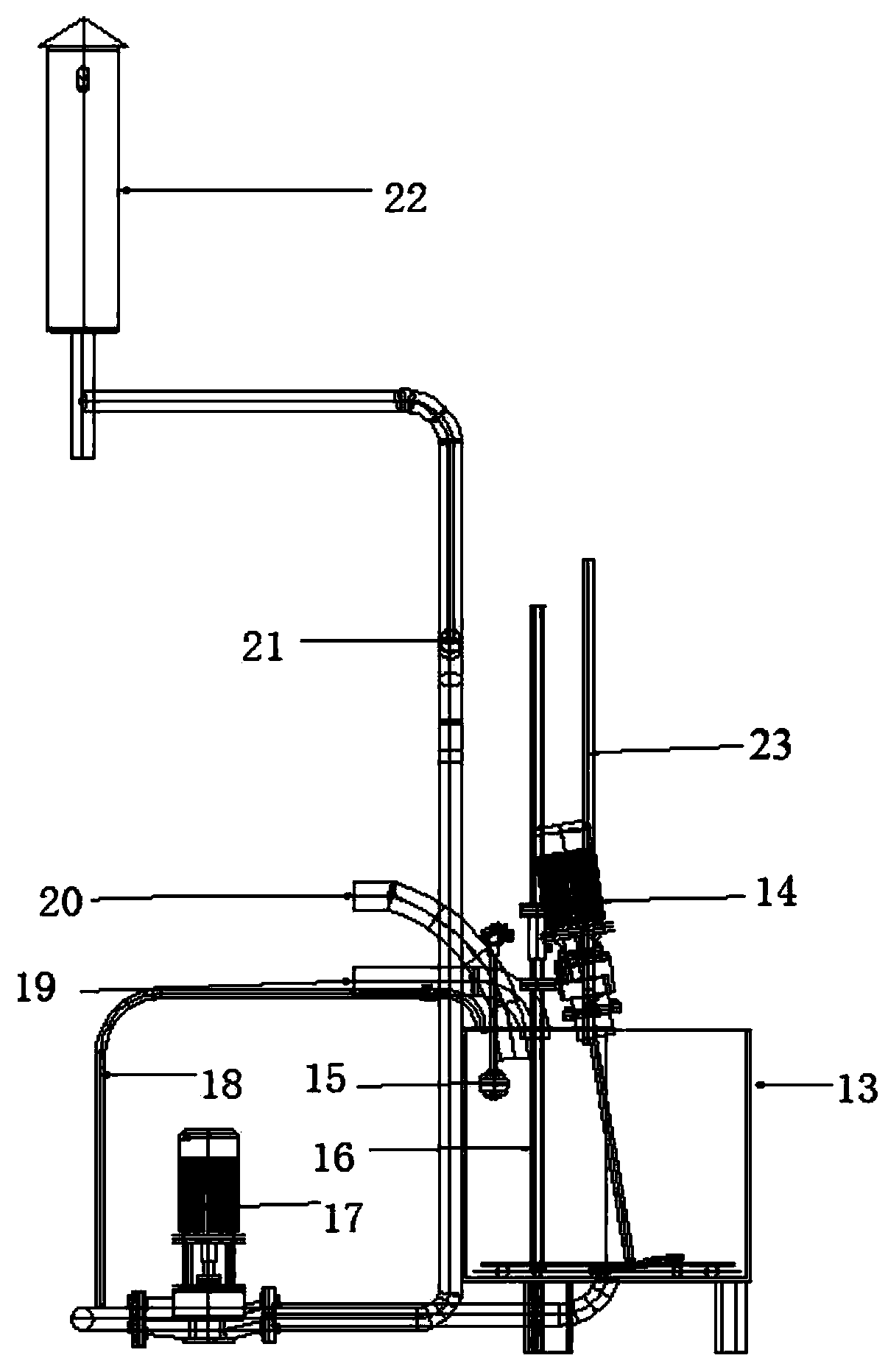

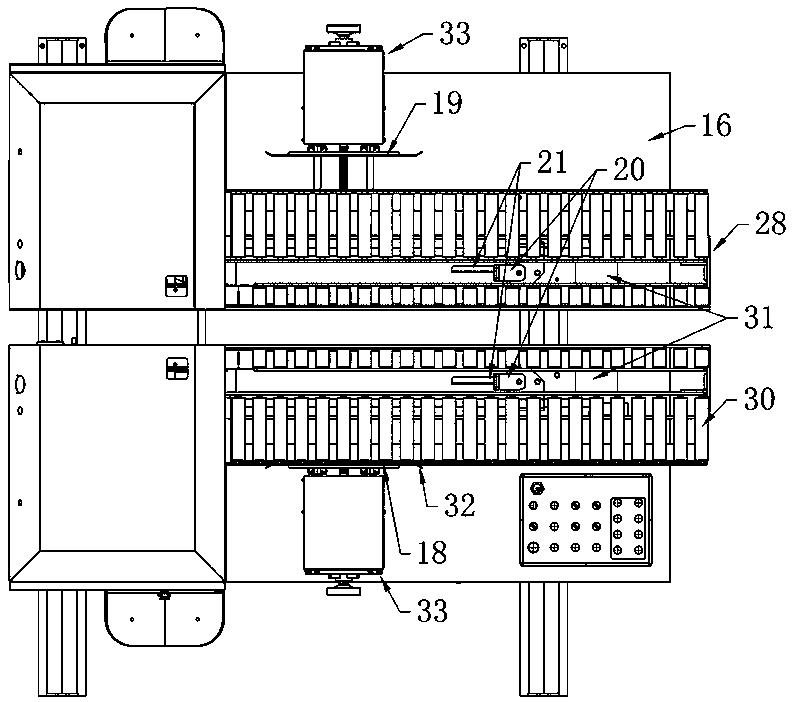

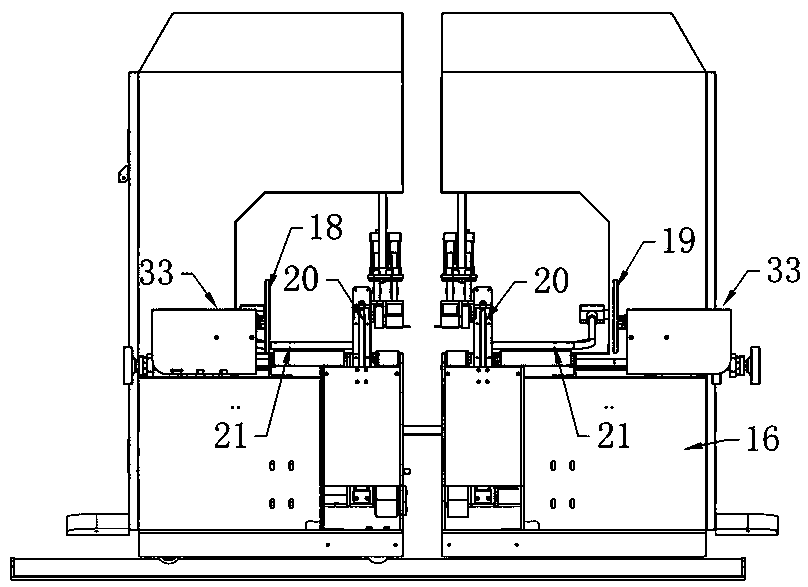

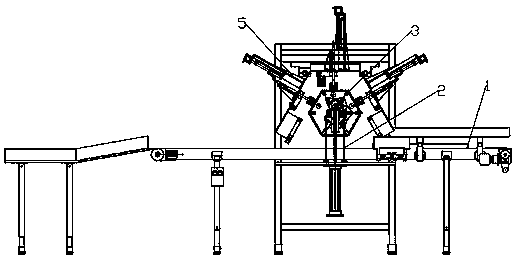

Rapid packer assembly with stable packing quality

InactiveCN108974449AImprove efficiencySimple structureBundling machine detailsEngineeringInput device

The invention discloses a rapid packer assembly with stable packing quality. The rapid packer assembly comprises an input device and a packing unit. The input device comprises a steering conveying unit and a front-back patting-aligning conveying unit. The steering conveying unit is used for preventing two stacks of cartons on the steering conveying unit from rotating and used for outputting the cartons front and back. The packing unit is used for conveying, left-right patting-aligning, packing and outputting of the cartons. The packing unit comprises a body and a knotting unit. The body is further provided with side patting-aligning units, a push rod assembly and a pressing device, wherein the side patting-aligning units are used for aligning the stacked cartons in a patting mode from sideportions, and the push rod assembly is used for pushing a packing line to line grooves of the cartons. According to the rapid packer assembly with stable packing quality, two stacks of cartons whichare fed on a conveyor side by side can be output front and back, the stacked cartons can be aligned in a patting mode front and back and left and right in the conveying process, the cartons are firmlyfixed during packing, the binding position of the packing line is precise, and the packing quality of a packer is good.

Owner:侯象洋

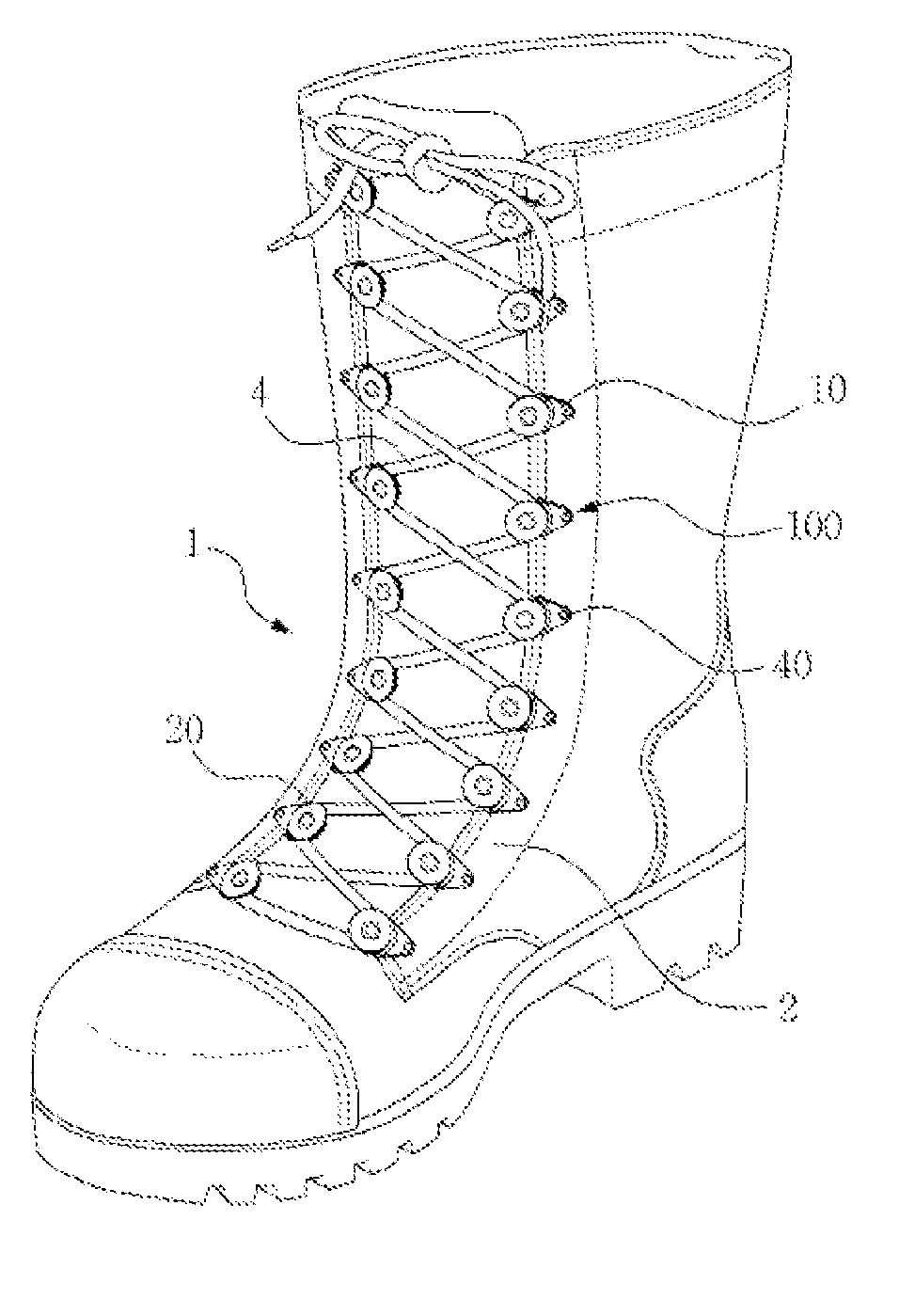

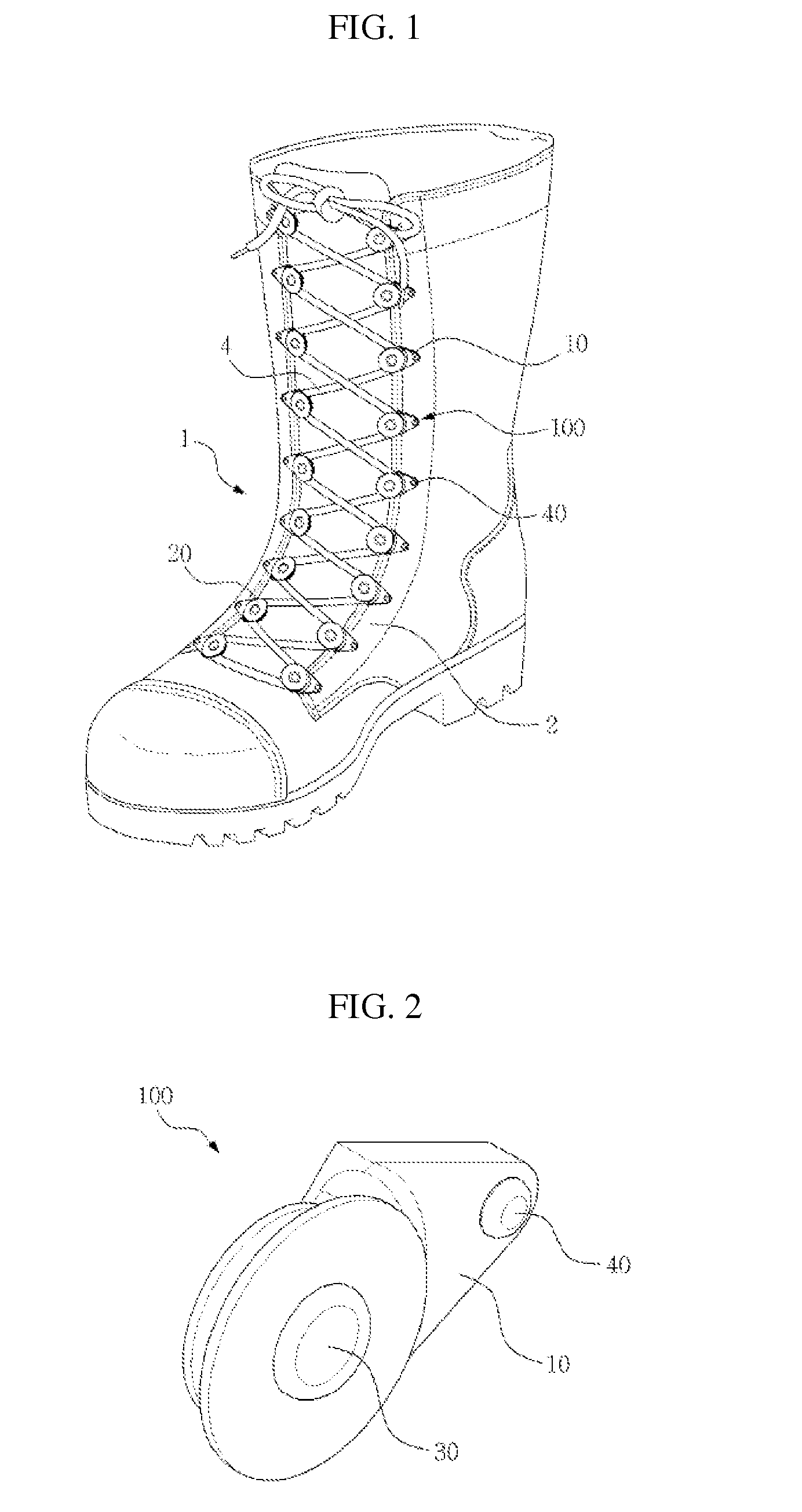

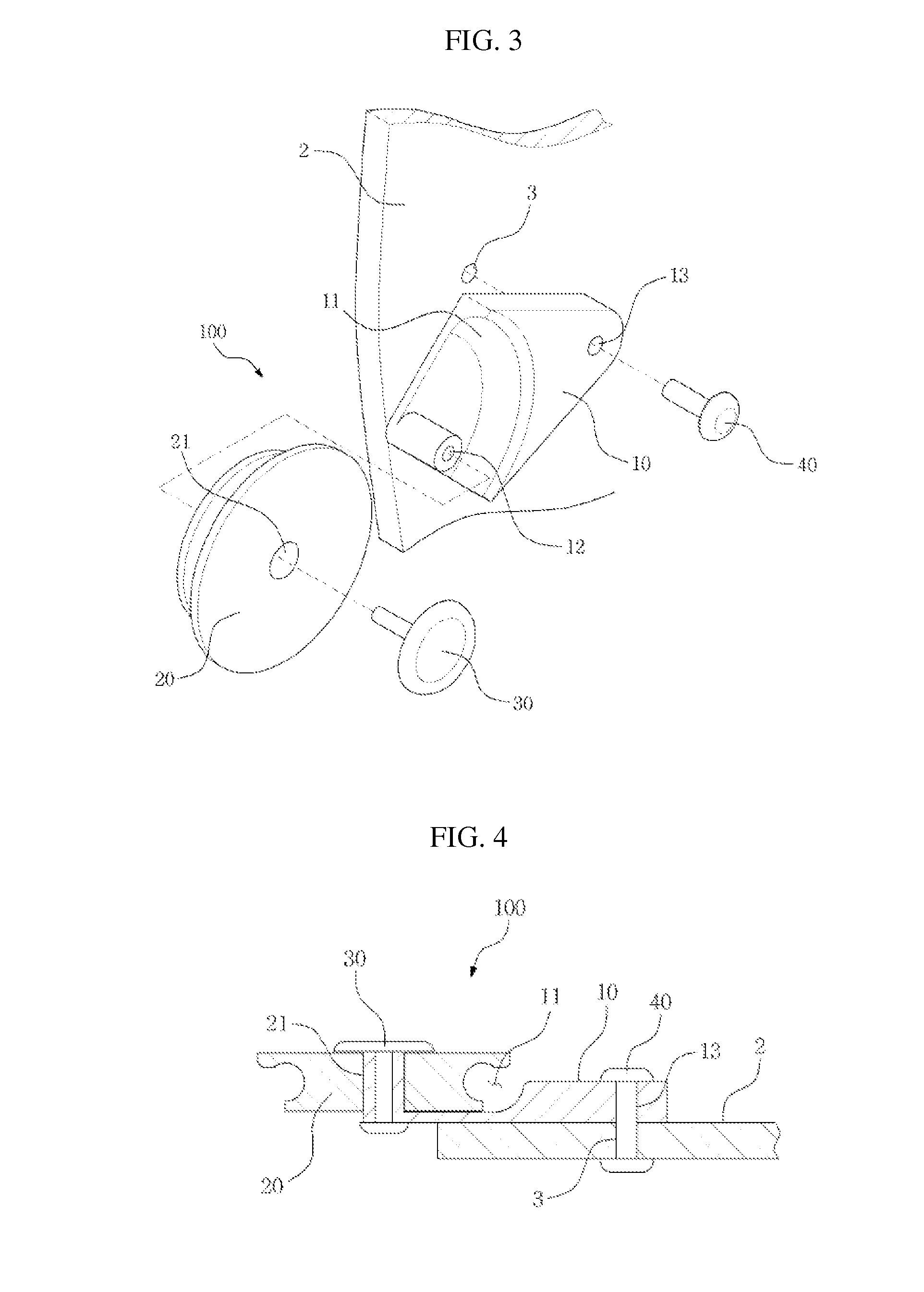

Loop for shoelace utilizing asymmetric pulley

InactiveUS20120246897A1Easy to knotImprove life expectancyLacing hooksShoe lace fasteningsEngineeringRivet

A loop for a shoelace utilizing an asymmetric pulley, including: a plurality of shoelace loops mounted to each of eyelet tabs of a shoe using respective rivets, wherein each of the shoelace loops includes: an asymmetric pulley having a pulley groove for guiding a shoelace without allowing the shoelace to be removed therefrom by itself and opposite circular side surfaces provided on opposite sides of the pulley groove, in which a diameter of a first one of the opposite side surfaces is larger than a diameter of a second one; a pulley holder having a structure suitable for sitting the pulley therein; and a rotating pin rotatably mounting the pulley to the pulley holder.

Owner:LEE SUK HO

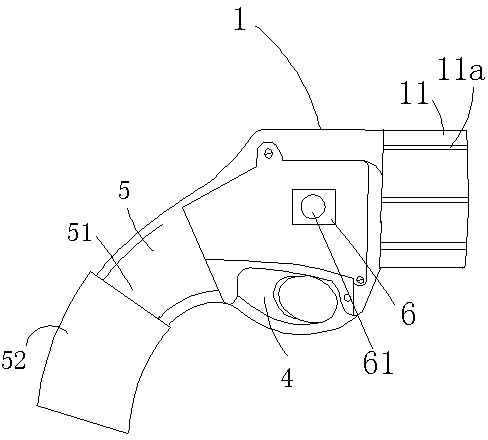

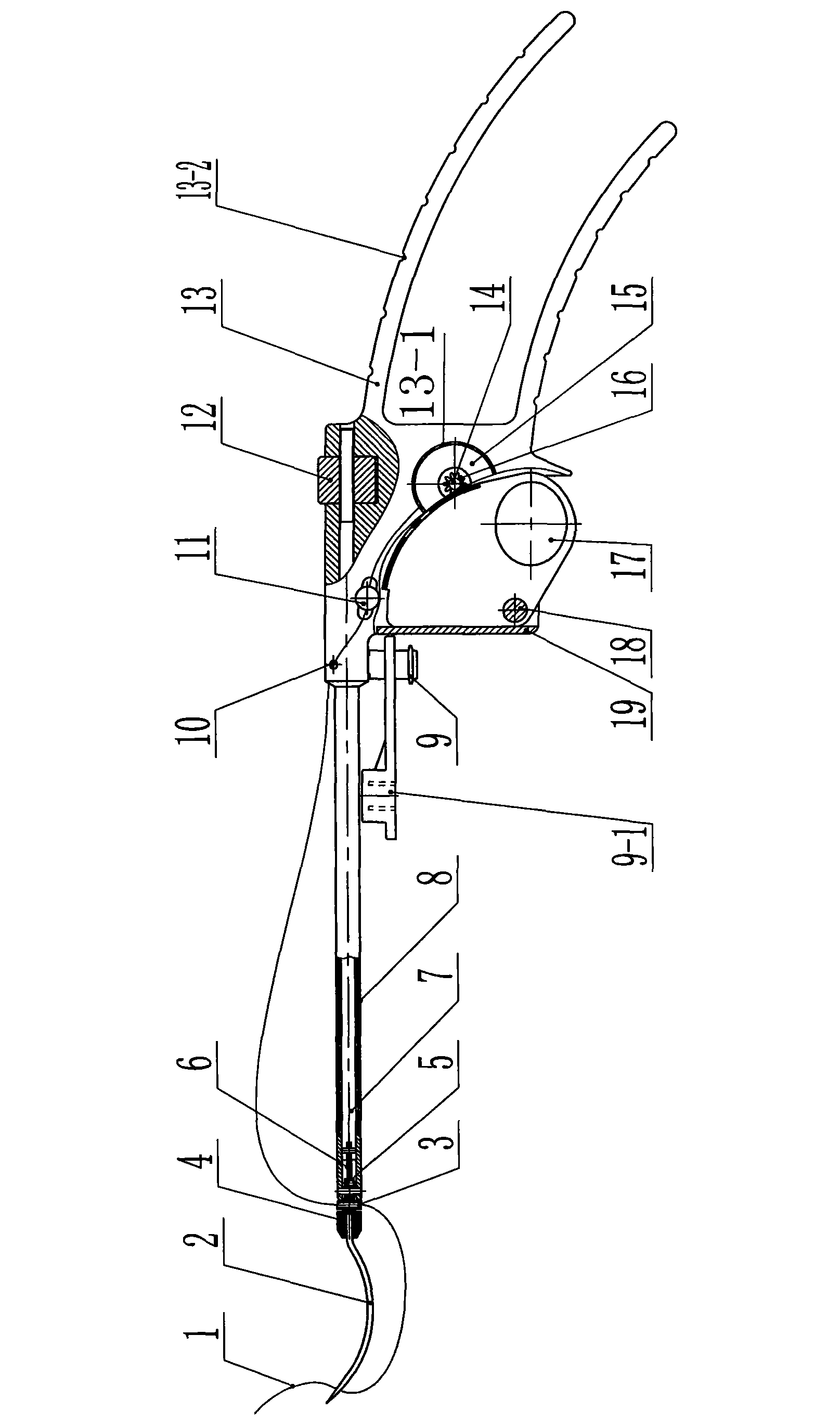

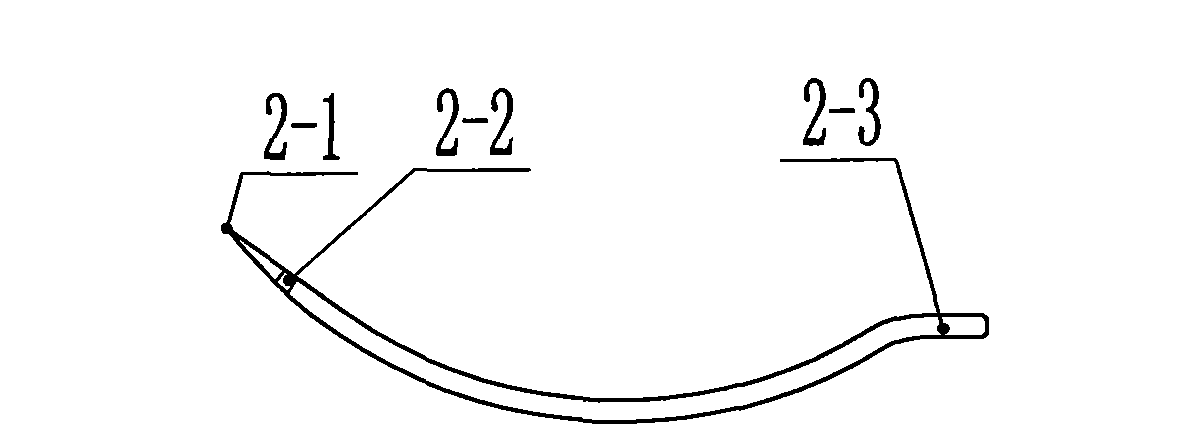

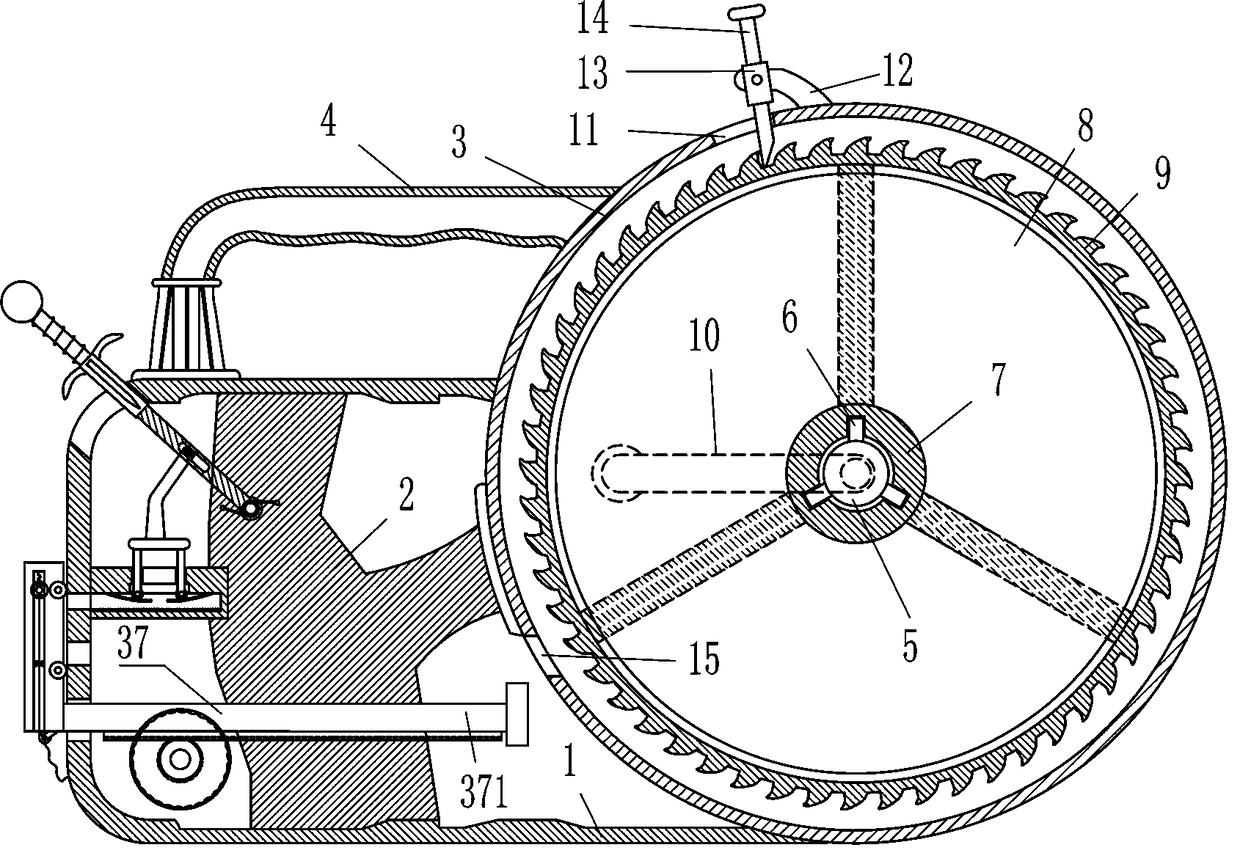

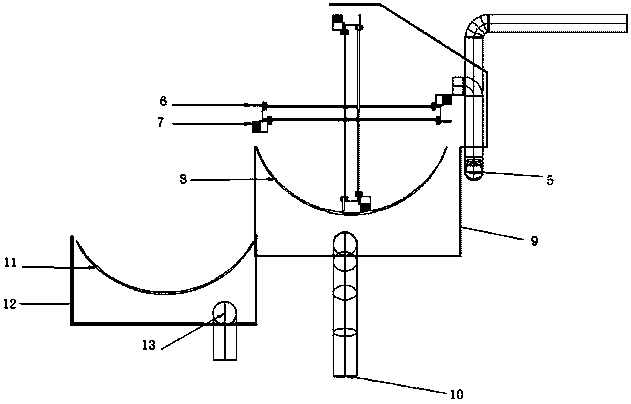

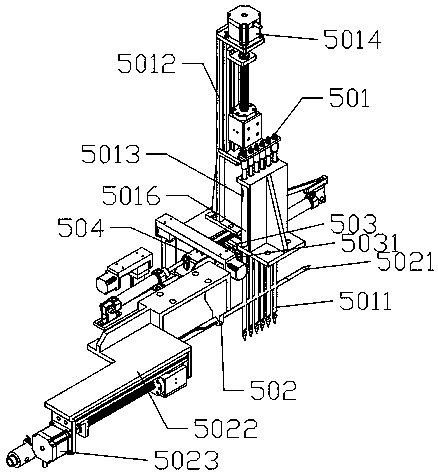

Endoscopic sewing and knot tying machine

InactiveCN102670267AEasy to knotSuture knotting facilitatesSuture equipmentsSuturing needleEngineering

The invention relates to surgical instruments and especially to an endoscopic sewing and knot tying machine comprising a suture needle, a pull rod, a main pipe, a handle, a coil, a trigger, a needle fastening nut, a rotating head, a rotating shaft, a line guide hole, a line pressing column, a needle rotating nut, a gear, a fixing shaft, a trigger shaft, a trigger groove and a handle framework, wherein the main pipe is fixed at the front end of the handle framework, and the rotating head is movably connected with the main pipe; the pull rod is arranged in the cavity of the main pipe, the front end of the pull rod is connected with the rotating head, and the back end of the pull rod is connected with the needle rotating nut; the trigger groove is arranged in the handle framework, and the trigger is fixed in the trigger groove through the trigger shaft; the tooth surface of the trigger is matched with the gear; the gear is fixed on the handle framework through the fixing shaft; the coil is movably embedded in the gear; the device utilizes the needle feeding and line guiding method of the fixed suture needle, only the line is guided and the needle is not threaded, so that the sewing operation is simple; and a principle of connecting the incomplete gear with the gear is utilized to controllably extend or shrink the suture line to facilitate the knot tying, line fastening and continuous sewing and knot tying operations.

Owner:ZIBO DONGAI MEDICAL INSTR

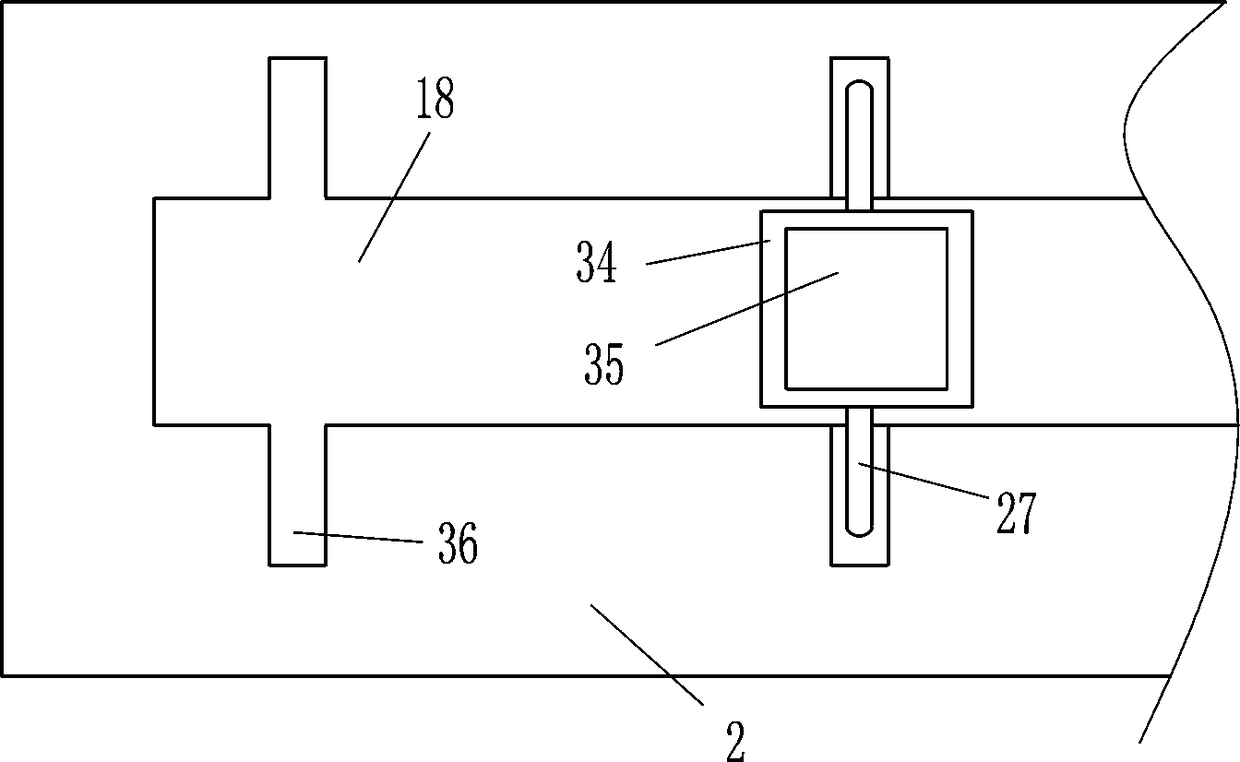

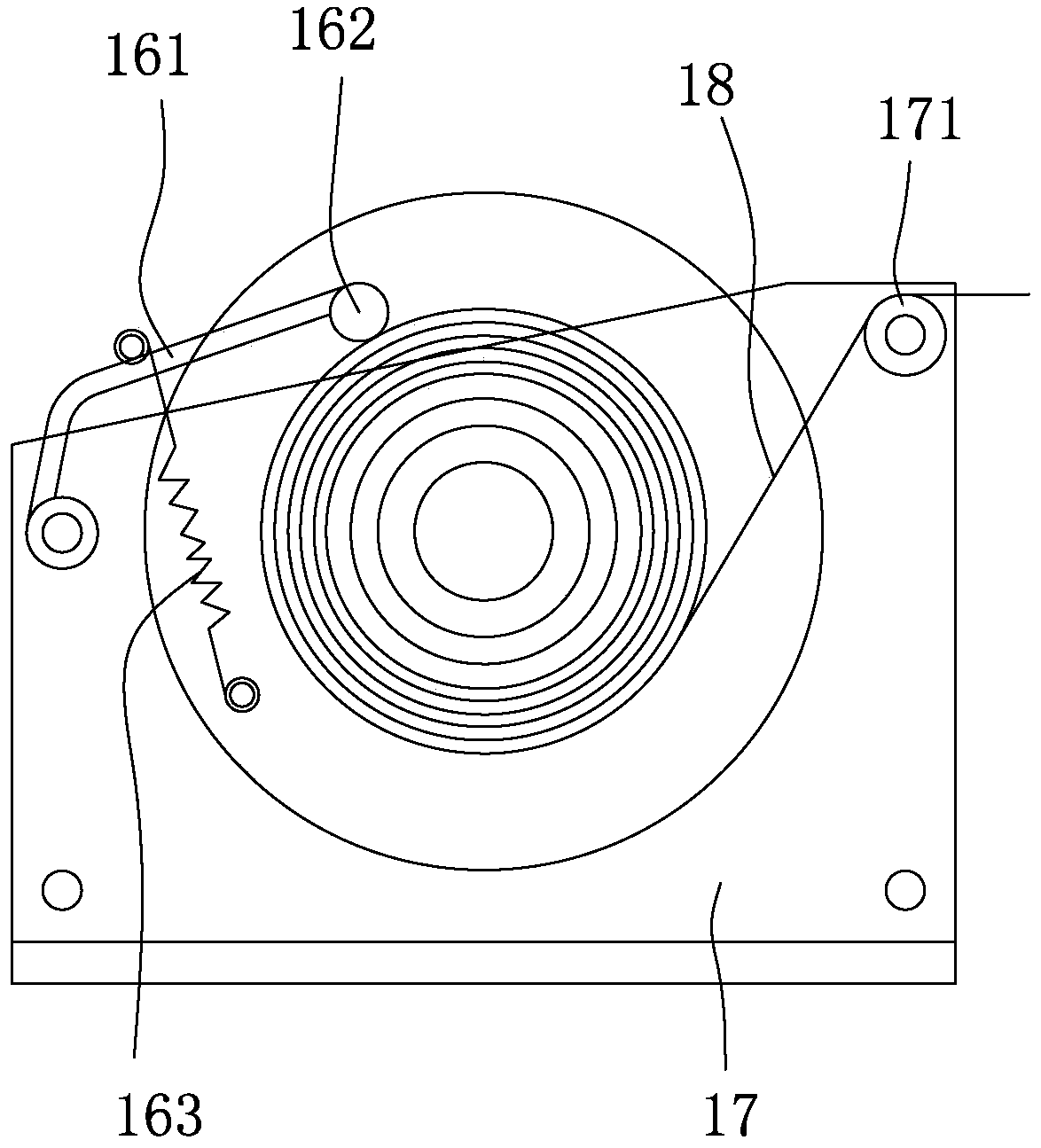

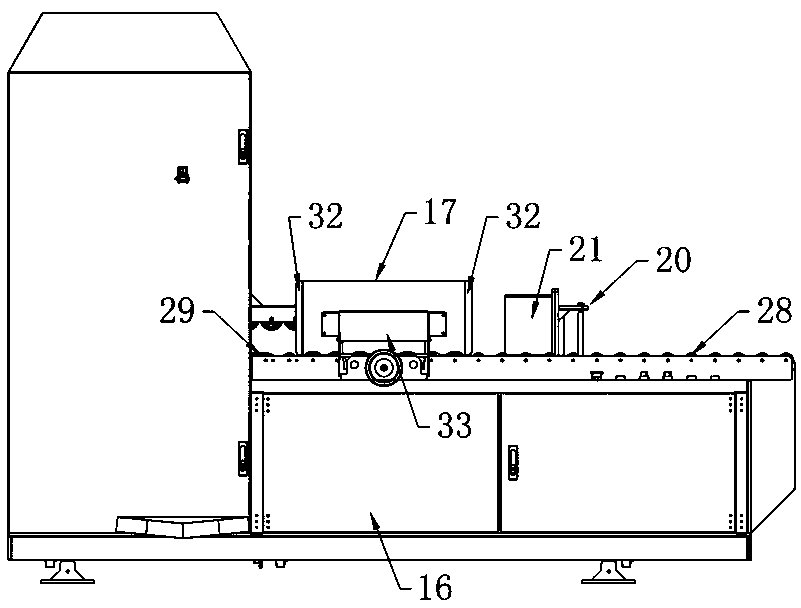

Straw bundling instrument

ActiveCN109292135AEasy to knotEasy to tieBinding material applicationBundling machine detailsEngineeringBandage

The invention relates to a bundling instrument, in particular to a straw bundling instrument. According to the straw bundling instrument, a bandage can be fixed, straw can be bundled conveniently, thelabor cost is reduced, and the situation that the knotting is affected due to loosening of the bandage is avoided. According to the technical scheme, the straw bundling instrument comprises a frame body, a supporting plate, a round frame, a handle, a rotating shaft, clamping blocks, a casing pipe, a disc, a ratchet wheel, a rocker, a supporting rod, a guide sleeve, a clamping rod, a threaded disc, a first bearing seat and the like; the round frame is fixedly connected to the right side of the frame body, the circle center of the round frame is fixedly connected with the first bearing seat inan embedded mode, and the rotating shaft is connected with a bearing in the first bearing seat. According to the straw bundling instrument, the bandage winds the casing pipe, and the handle is held, so that the bandage can be pulled to bundle the straw; and the binding head end is fixed through the device, the rocker is rocked and reversely rotated to enable the straw to be bundled, and the strawcan be clamped through a pressing device, so that an operator can better bundle the straw.

Owner:时平元

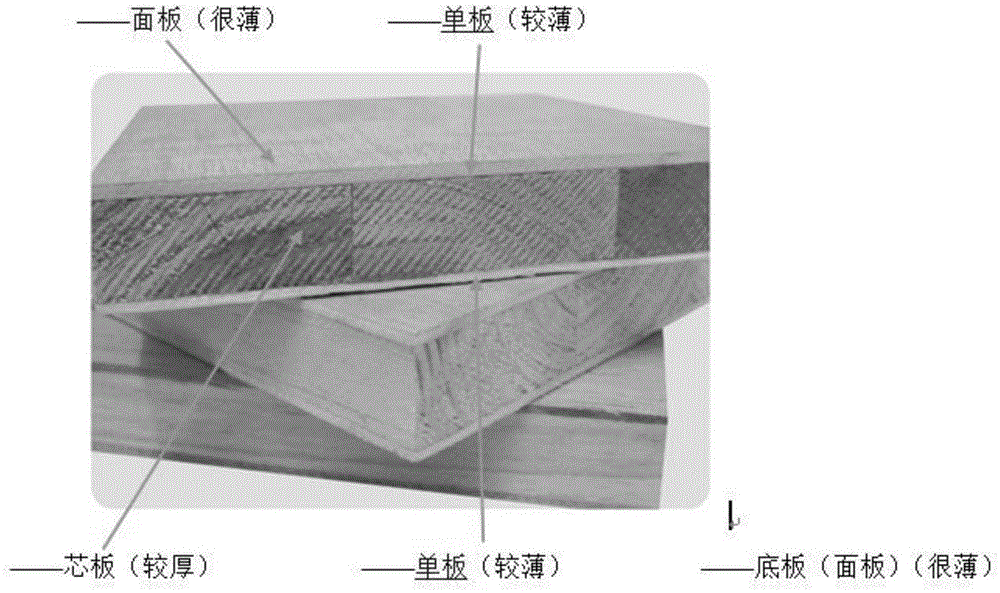

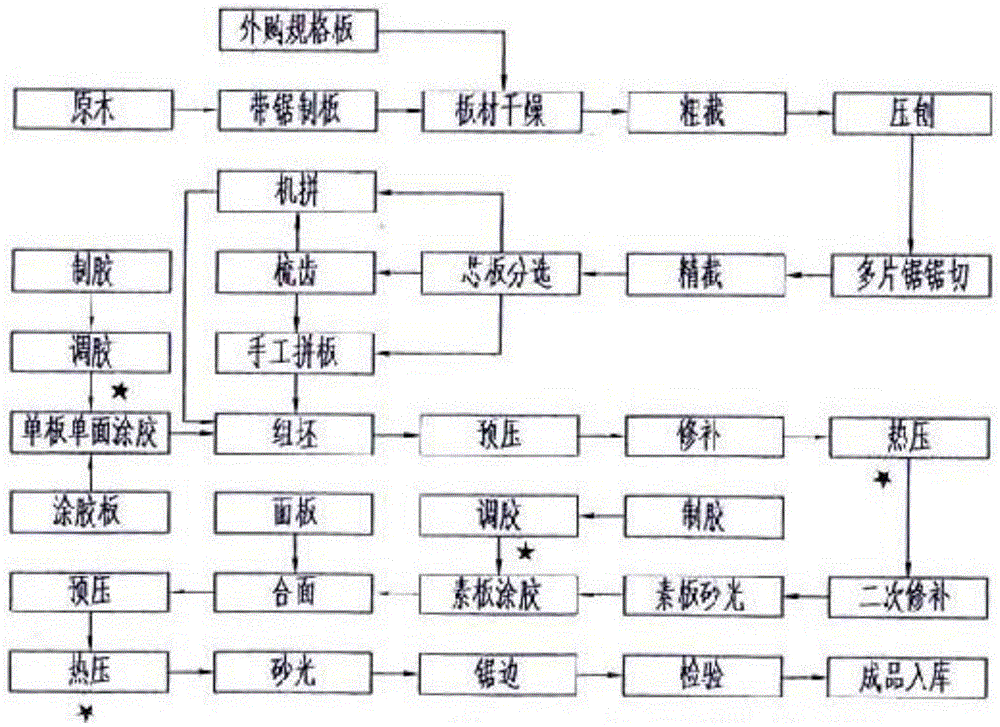

Ecological decorative paper and production method thereof

The invention provides ecological decorative paper and a production method thereof. The ecological decorative paper is prepared from the following raw materials in parts by weight: 15-20 parts of softwood pulp fiber, 15-20 parts of hardwood pulp fiber, 10-20 parts of polyester fiber, and 40-50 parts of modified thermoset resin. The ecological decorative paper is produced through steps of size degradation, beating, molding, drying, gluing, drying in a baking oven, sheeting and packaging by a fourdrinier machine. The product possesses the following advantages: 1, the product is good in eveness, stable in quality and stable in thickness, does not contain formaldehyde, melamine and other harmful substances, and is healthy and friendly to environment; 2, the product possesses good thermosetting performance, and therefore the product and a single plate and a decoration layer can be directly subjected to hot pressing for preparing a decoration sheet material, operations of sanding, glue preparation, glue blending, glue coating and the like of a single plate and a surface plate are saved, and production time, raw material cost and labor cost are saved. The product is a truly environment-friendly health product. The method of using the ecological paper for replacing the surface layer of a lumber core board is initially created in household sheet material industry, and the excellent performances of the product surly will bring revolutionary change for household sheet material industry.

Owner:SHANDONG LUNAN NEW MATERIALS

Preparation method of collagen suture lines

InactiveCN104548192AImprove flexibilityHigh tensile strengthSuture equipmentsHigh volume manufacturingMedicine

The invention relates to a preparation method of collagen suture lines, and belongs to the technical field of medical suture lines. The preparation method of the collagen suture lines comprises the following steps: stripping off a plurality of collagen tail tendons from the tail of a beaver, performing degreasing, viral inactivation, rinsing, dehydration, straightening, air drying, and screening on the collagen tail tendons, and performing oil tannage, washing, vacuum packaging and antiseptic disinfection on the collagen tail tendons which conform to requirements. The preparation method disclosed by the invention has the benefits that the production process is simple, the preparation method is scientific and reasonable, the rate of finished products is high, the collagen suture lines can be produced in batches, and the production cost of the collagen suture lines is lowered. The collagen suture lines which are prepared by the method disclosed by the invention have the advantage that the stability and the elasticity are good, the flexibility is high, the collagen suture lines are easy to knot, the tensile resistance is high, the collagen suture lines can be absorbed by human bodies, antigen-antibody reaction cannot be generated, needle holes and scars are not remained, sutures are smooth after the sutures are healed.

Owner:周峰

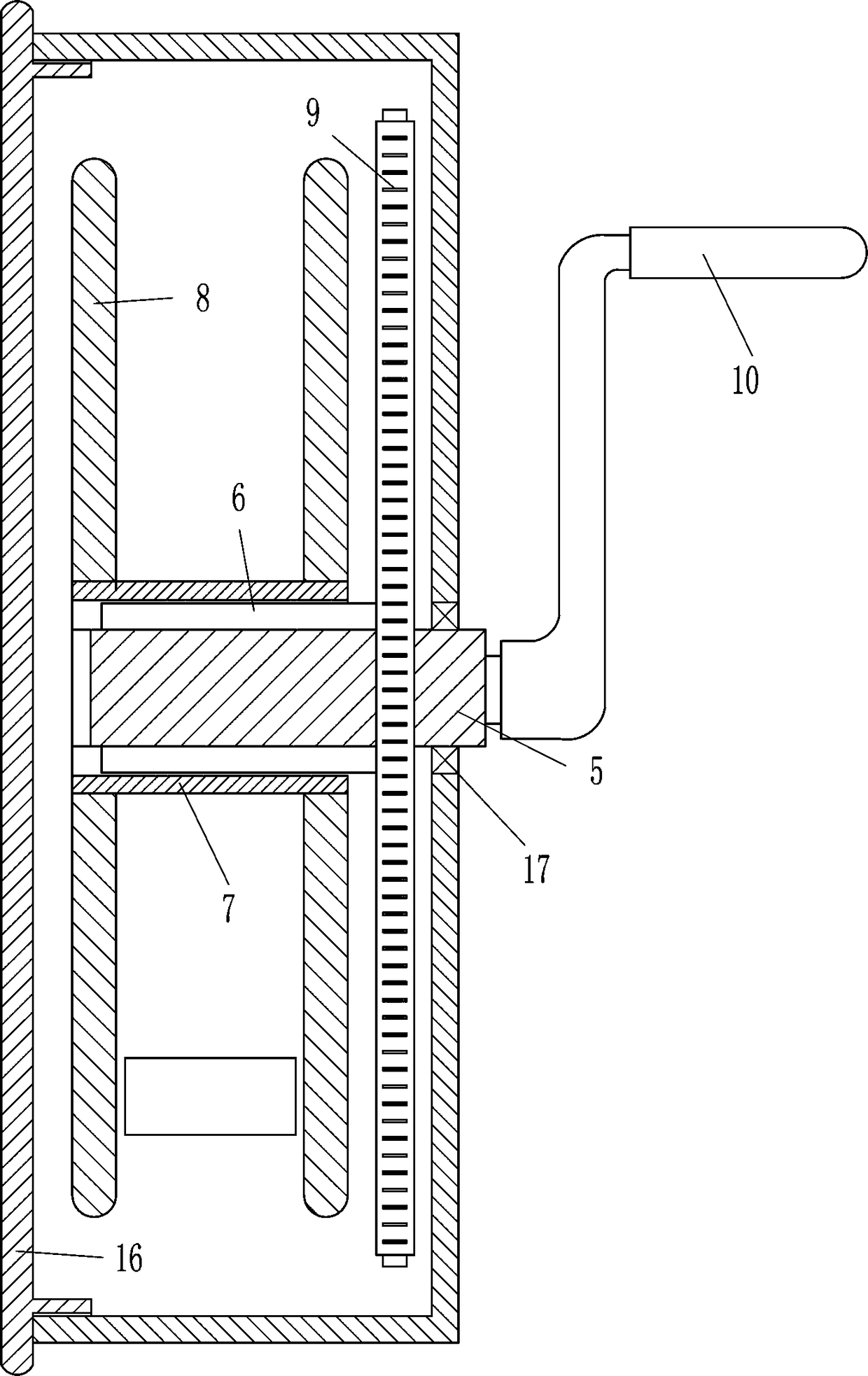

Bidirectional tractor

The invention provides a bidirectional tractor without the need of repeatedly pulling a steel wire rope by personnel. The bidirectional tractor comprises a rack, wherein an input shaft, a first drum, a second drum, the steel wire rope and a pulley are arranged on the rack; a first engagement sleeve and a first gear are arranged on the input shaft, and a first chain wheel is arranged on the first gear; a second chain wheel is arranged on a rotary shaft of the first drum, and the first chain wheel is connected with the second chain wheel through a chain; a second engagement sleeve and a second gear are arranged on a rotary shaft of the second drum, and the second gear is engaged with the first gear; and one end of the steel wire rope is fixed on the first drum, and the other end of the steel wire rope is fixed on the second drum around the pulley. According to the bidirectional tractor provided by the invention, the input shaft is capable of driving rotations with opposite rotation directions of the two drums simultaneously, the positive rotation and the reverse rotation of the input shaft drive the steel wire rope to carry out circulating travelling between the drums and the pulley, and materials are hung on the steel wire rope for being conveyed, thus a time of manually pulling the rope back to a material place is saved, the efficiency is increased, and the working intensity of the personnel is reduced.

Owner:泉州市劲力工程机械有限公司

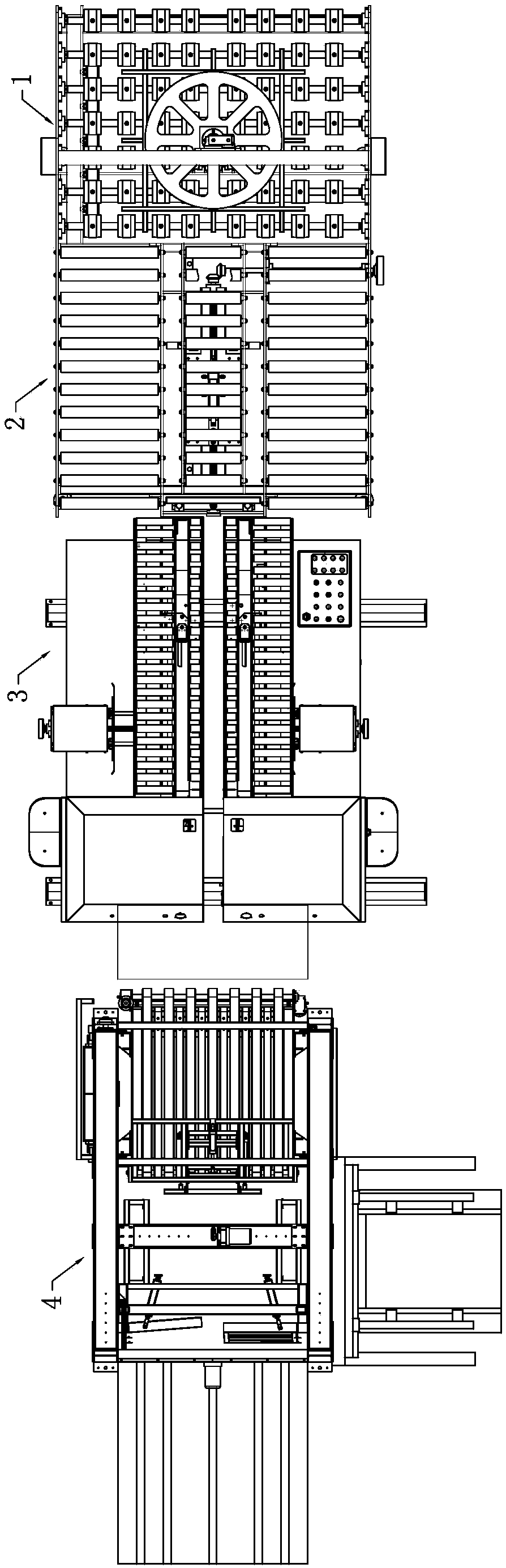

Full-automatic carton packing and stacking system

InactiveCN109398806AImprove delivery efficiencySimple structureBundling machine detailsStack machineCarton

The invention discloses a full-automatic carton packing and stacking system. The full-automatic carton packing and stacking system comprises a packing machine and a stacking machine; the packing machine comprises a steering conveying unit, a front-and-back flush conveying unit and a packing unit which are connected in sequence; the stacking machine comprises a carton input unit and a stacking unitwhich are sequentially arranged, and further comprises a tray input unit arranged on the side part of the stacking unit; and the steering conveying unit is used for outputting the two stacks of paperboxes placed on the steering conveying unit in a front-and-back mode; and the front-and-back flush conveying unit is used for carrying out input and front-and-back flush of the stacked paper boxes; the packaging unit is used for conveying cartons, left and right flush and packaging and outputting. The full-automatic carton packing and stacking system, the paper boxes can be automatically conveyed, packaged, stacked and output, achieves full automation of production, and has the advantages of being high in working efficiency, low in cost, good in packing and stacking quality and the like.

Owner:侯象洋

Fur niter-dyeing machine

ActiveCN104388607AIncrease heightReduce strong mechanical actionLeather/skins/hides/pelt chemical treatment apparatusTemperature controlScrub brushes

The invention discloses a fur niter-dyeing machine. The fur niter-dyeing machine comprises a rotary drum structure, a filtering device and a stirring device. The rotary drum structure comprises a flat and straight baffle plate arranged at the inner surface of the drum body along an axis direction, an inclined baffle plate structure and inlet and outlet water pipes. The filtering device comprises a liquid inlet pipe, a primary filtering device and a secondary filtering device. The opening of a liquid outlet pipe is arranged above the primary filtering device. The primary filtering device comprises a rubber scrubbing brush, a hairbrush and a primary filtering screen. The rubber scrubbing brush is located in front of the hairbrush. The secondary filtering device comprises a secondary filtering screen and a secondary liquid outlet pipe. The stirring device comprises a temperature control device, a steam heating device and an inclined stirring device arranged in the cylindrical shell of the stirring device. A water outlet of the rotary drum structure is connected to the liquid inlet pipe of the stirring device. The primary liquid outlet pipe and the secondary liquid outlet pipe of the filtering device are respectively connected to the primary liquid inlet pipe and the secondary liquid inlet pipe of the stirring device. The fur niter-dyeing machine can be used in fur niter-dyeing and guarantees finished fur quality.

Owner:桐乡市鑫诺皮草有限公司

Novel carton packer

The invention discloses a novel carton packer which comprises a body and a knotting unit arranged on the body. The body is further provided with side patting-aligning units and a push rod assembly, the side patting-aligning units are used for aligning stacked cartons from side portions in a patting mode, and the push rod assembly is used for pushing a packing line to line grooves of the cartons. The novel carton packer further comprises a swing rod assembly and a pressing device both arranged on the body. The pressing device is used for fixing the cartons during packing, and when a swing rod of the swing rod assembly swings, a line hooking block can drive the packing line to wind the packing line around the stacked cartons so that the knotting unit can conveniently carry out knotting. According to the novel carton packer, the conveyed cartons can be aligned by patting from left and right sides, the cartons are firmly fixed during packing, the binding position of the packing line is precise, and the packing quality of the packer is good.

Owner:侯象洋

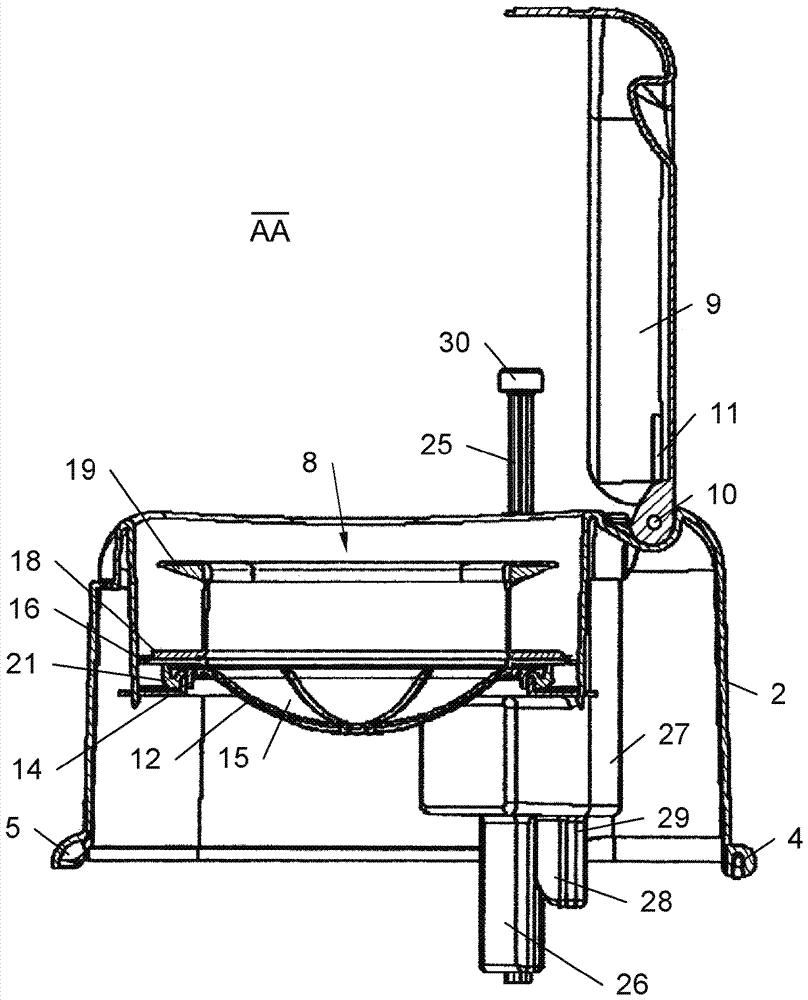

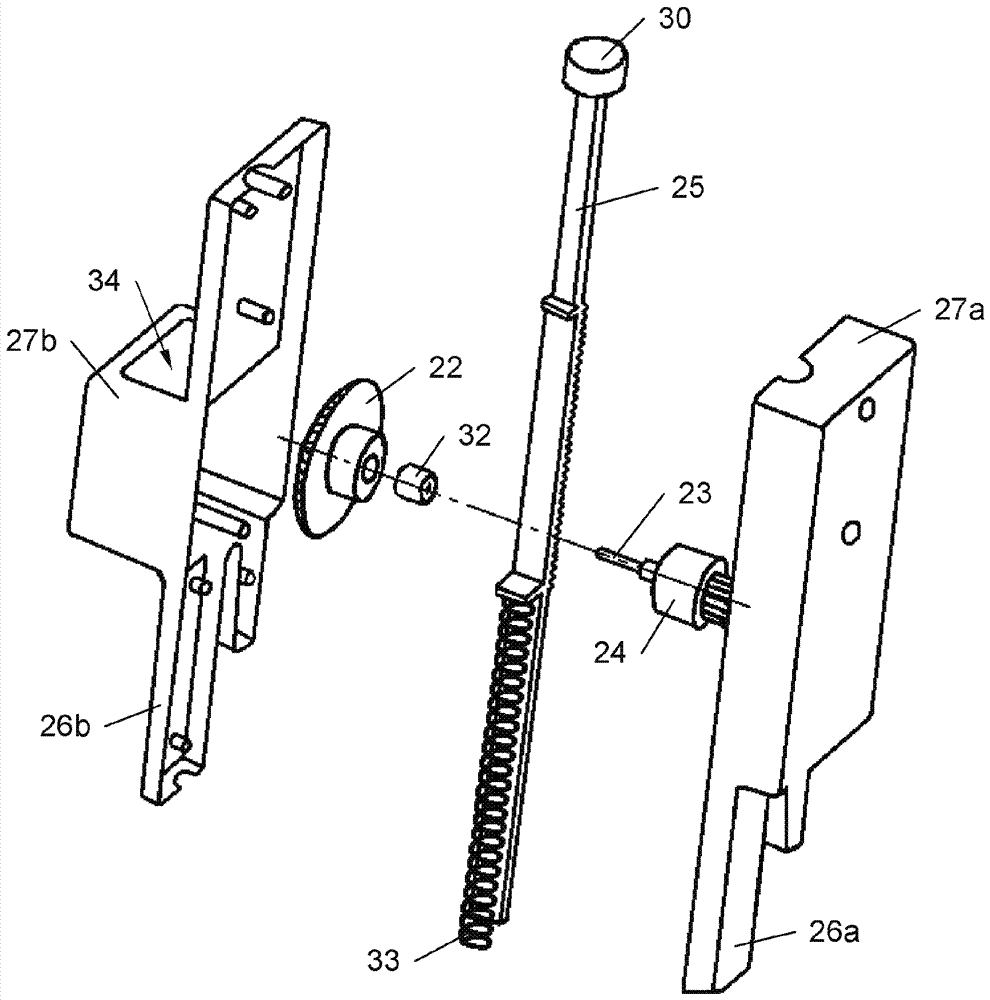

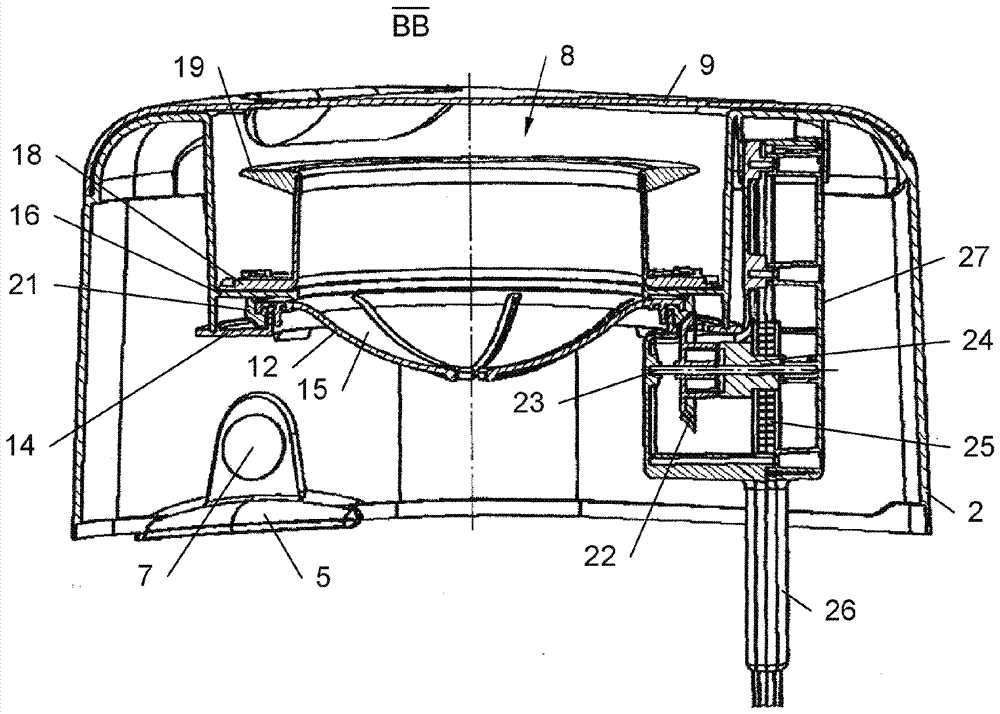

Waste storage device with smell protection

The invention relates to a waste storage device with smell protection. The invention relates to a waste storage device (1), comprising a container (2, 3) with a container opening (8) and a driver ring (12), which is rotatably mounted to the container (2, 3) in the region of the container opening (8). The driver ring (12) is also designed to catch a waste storage bag or waste storage hose (13) guided through a center opening of the driver ring (12). The waste storage device (1) also comprises a gear rod (25), which is movably guided in the container (2, 3) at its first end, which is coupled to the driver ring (17) and which faces the lid (9) respectively cooperates with the lid (9) on its free second end. Furthermore, the invention relates to a waste storage system (20), comprising a waste storage device (1) of said kind and a storage cassette (17) containing the waste storage bag or waste storage hose (13).

Owner:GLOBAL MARK PLASTIC LTD

Self-made hair conditioner

InactiveCN103494757AEasy to knotKnot won'tCosmetic preparationsHair cosmeticsBiotechnologyNutrients substances

A self-made hair conditioner is disclosed. The preparation method of the self-made hair conditioner comprises: uniformly mixing crushed mung bean, black sesame and yolk, then mixing with chrysanthemum water obtained by immersing dried chrysanthemum and stirring uniformly to obtain the hair conditioner. The self-made hair conditioner not only keeps the nutrients possessed by raw materials selves, but also helps to reduce hair friction and prevent split ends, dryness and yellowness of hair.

Owner:陈家振

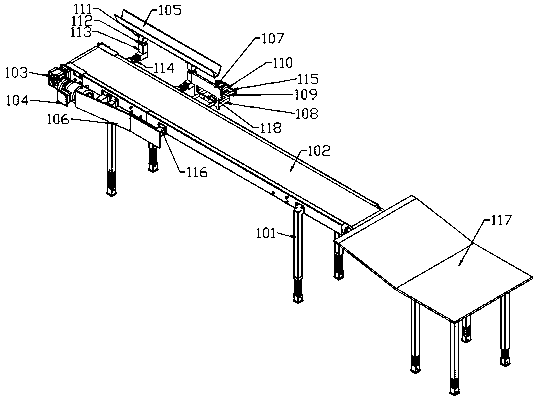

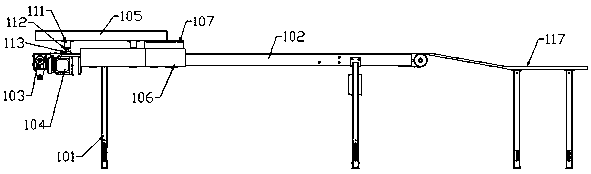

Multi-station weaving and twisting machine

The embodiment of the invention discloses a multi-station weaving and twisting machine and belongs to the technical field of spinning and twisting. Existing automatic weaving and twisting machines areautomatic in working processes after twisting frames are placed to regulated positions. The problem of how to transport the twisting frame and adjust the placing direction of the twisting frame is not solved as well by a mounting seat of the twisting frame. The multi-station weaving and twisting machine comprises a twisting frame transporting station, a twisting frame lifting station, a twistingframe rotating station and a twisting station. The twisting frame can be transported to the weaving and twisting position automatically and automatic weaving and twisting work is carried out automatically.

Owner:YIBIN HIEST FIBER +1

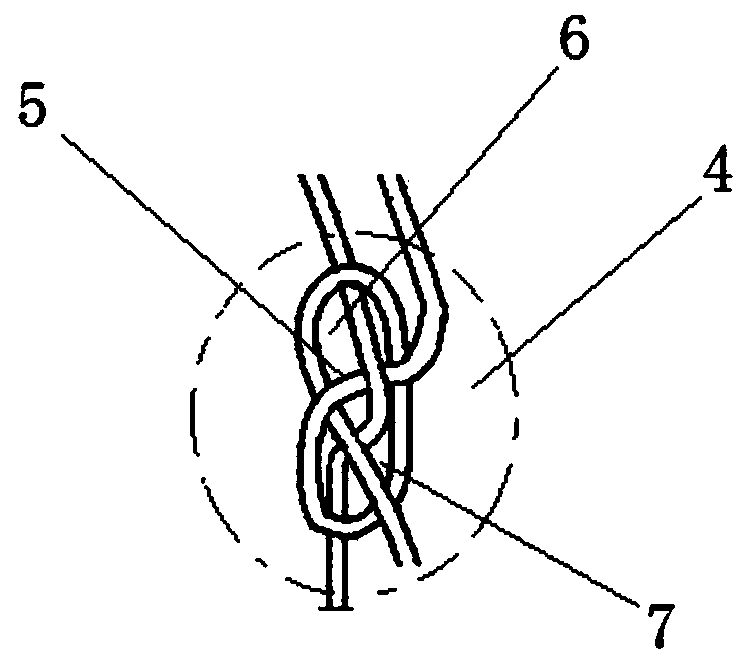

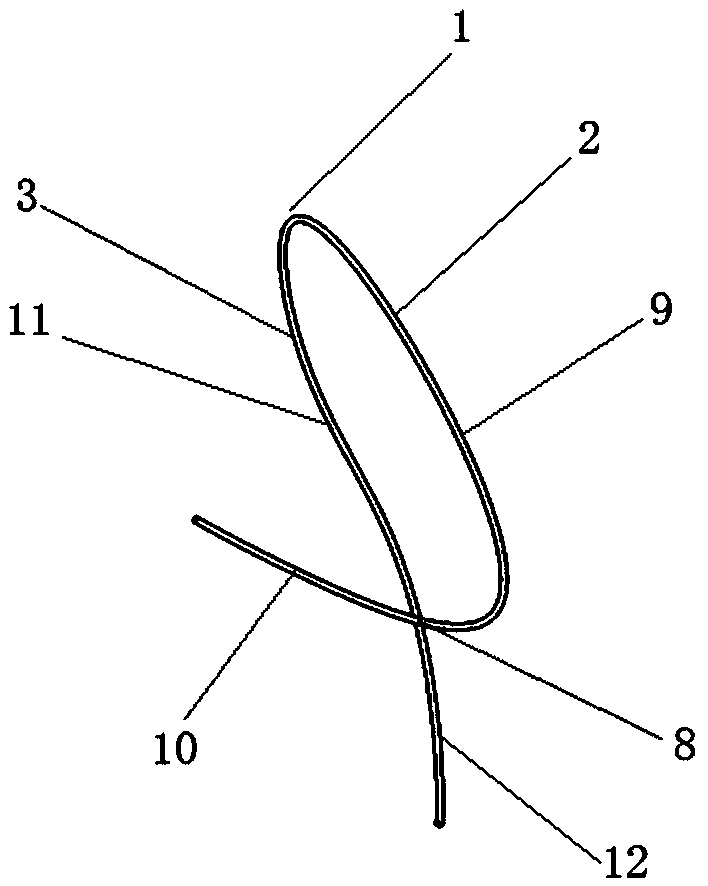

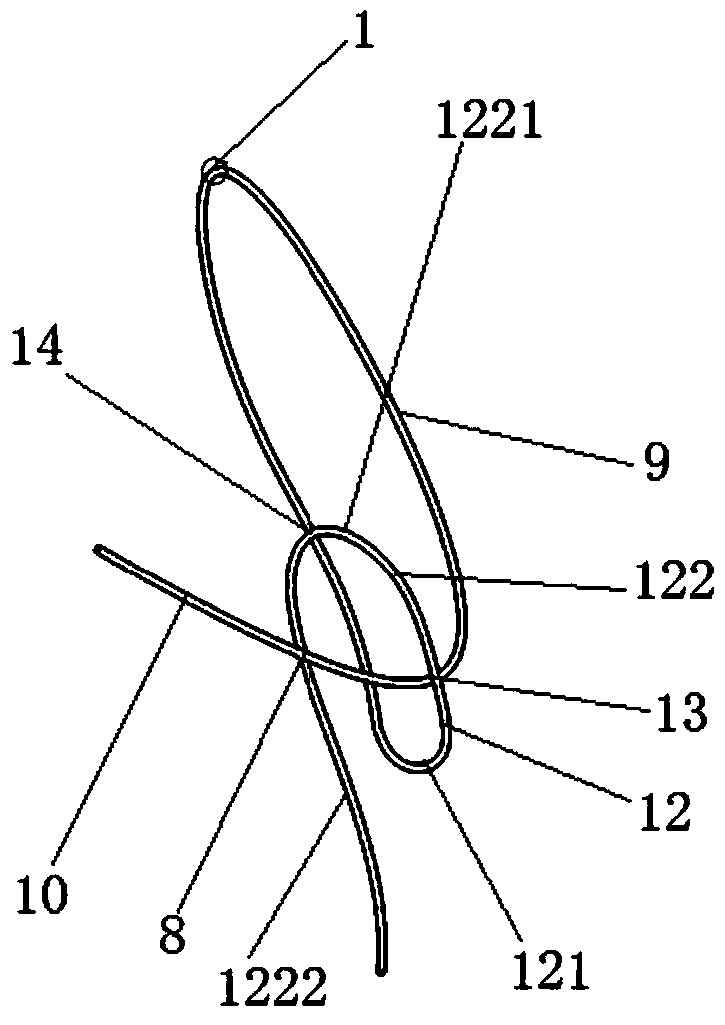

Knot making and buckling method for protection wire of low-speed wind tunnel flutter testing model

The invention discloses a know making and buckling method for a protection wire of a low-speed wind tunnel flutter testing model. The method comprises: step one, a knotting position and a connecting point position of a protection wire are determined; step two, the protection wire is processed to form a first segment and a second segment; step three, the first segment and the second segment are overlapped and wound to enable the first segment and the second segment to form a knot in an overlapping and winding mode, wherein the know is located at the knotting position and has a circular ring and a watershed line overlapped on the circular ring, the circular ring is segmented into a first half ring and a second half ring by the projection of the watershed line on the circular ring, and the second segment passes through the first half ring, crosses over the watershed line and extends out of the second half ring. With the method, the knotting position of the knotted protection wire is prevented from shifting due to mutual pressing, buckling and friction of wire parts in the knot and the friction is increased when the wire is stretched tightly; and when the protection wire is loosened, the knot releasing becomes convenient. Therefore, the length of the protection wire can be adjusted easily to adapt to the change of the model balancing position.

Owner:SHENYANG AIRCRAFT DESIGN INST AVIATION IND CORP OF CHINA

Weaving and twisting head and weaving and twisting method thereof

ActiveCN109680403ASimple structureThe braided style is simple and strongCrochetingPunchingEngineering

The invention discloses a weaving and twisting head and a weaving and twisting method thereof, and belongs to the technical field of textile twisting. Corresponding needles are arranged on X, Y and Zaxes, and are used for hooking the same weaving and twisting thread. The whole weaving and twisting process is completed under driving of multiple liner modules and a weaving and twisting finger cylinder, a needle punching mechanism, a needle hooking mechanism and a knotting mechanism are driven by the linear modules to respectively move in different directions, so that weaving and twisting threads are transformed into twisted threads. The weaving and twisting head has a relatively simple structure. According to the method, a manual weaving and twisting process is simulated, and the weaving and twisting models are relatively simple and firm.

Owner:YIBIN HIEST FIBER +1

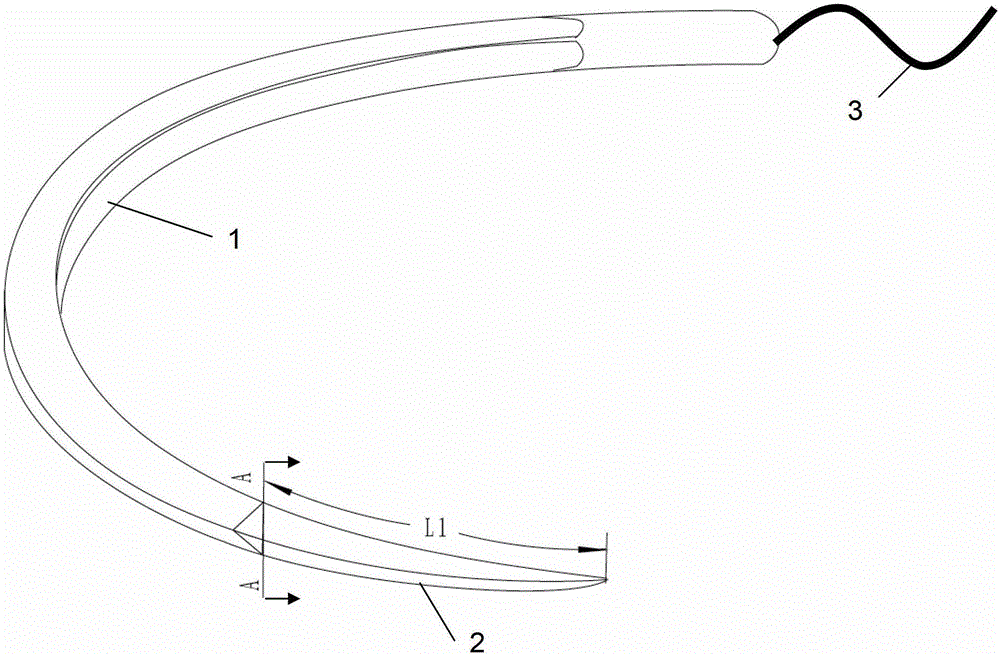

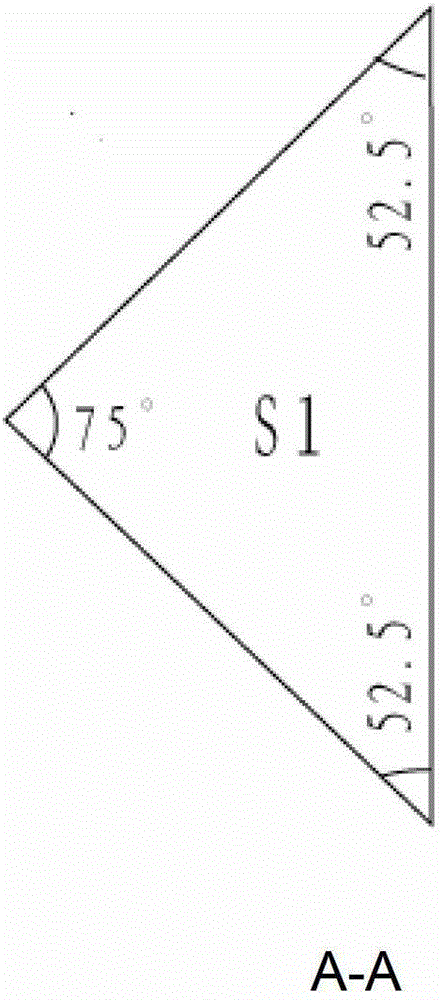

Suture needle with suture line and suture line coating

InactiveCN103142263AHigh strengthImprove stabilitySuture equipmentsSurgical needlesSuturing needleIsoetes triquetra

The invention discloses a suture needle with a suture line and a suture line coating. The suture needle consists of a suture needle and a suture line, wherein the suture needle comprises a needle body and a needle tip at the front end of the needle body; the coating layer is arranged on the surface of the suture line; and the longitudinal section of the needle tip is an equilateral triangle with each angle being 60 degrees. The strength of the needle tip is effectively improved through the needle tip with the shape, puncturing is facilitated, and the trauma to the surface is relatively low, so that the suture needle enjoys exceptional advantage and is worth of being applied and popularized. The invention also discloses the suture needle with the suture line, and a mixture of hydroxyacetic acid-hydracrylic acid copolymer and calcium stearate is adopted. The coating is higher in strength, stability and surface smoothness and more facilitates piercing in tissues of a human body, the resistance and the tearing degree of a wound surface are reduced, the suture line is easier to knot and not easy to disperse after a suture surgery is finished, and the firmness of knotting is further improved.

Owner:上海浦东金环医疗用品股份有限公司

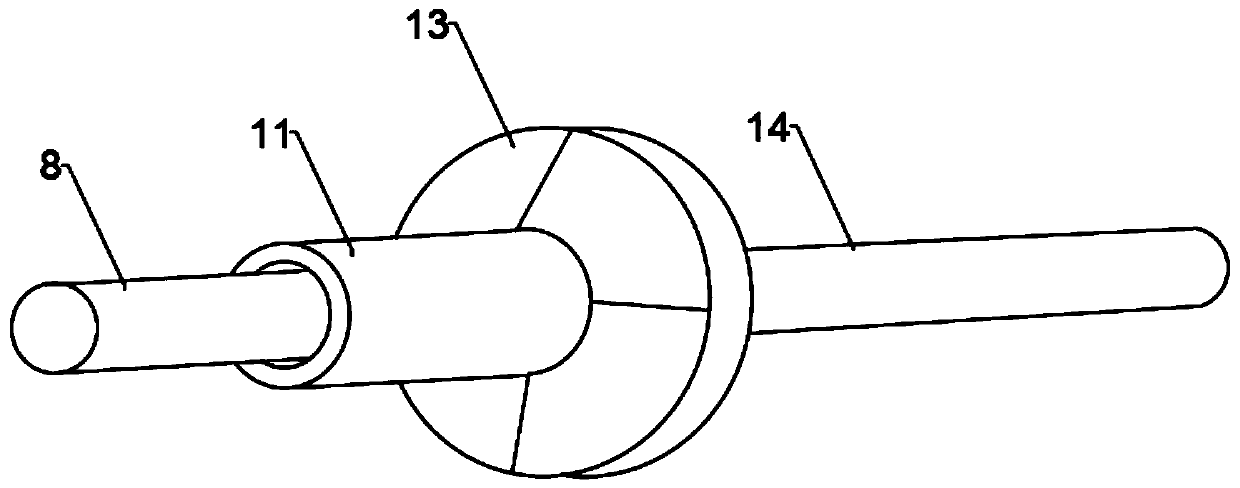

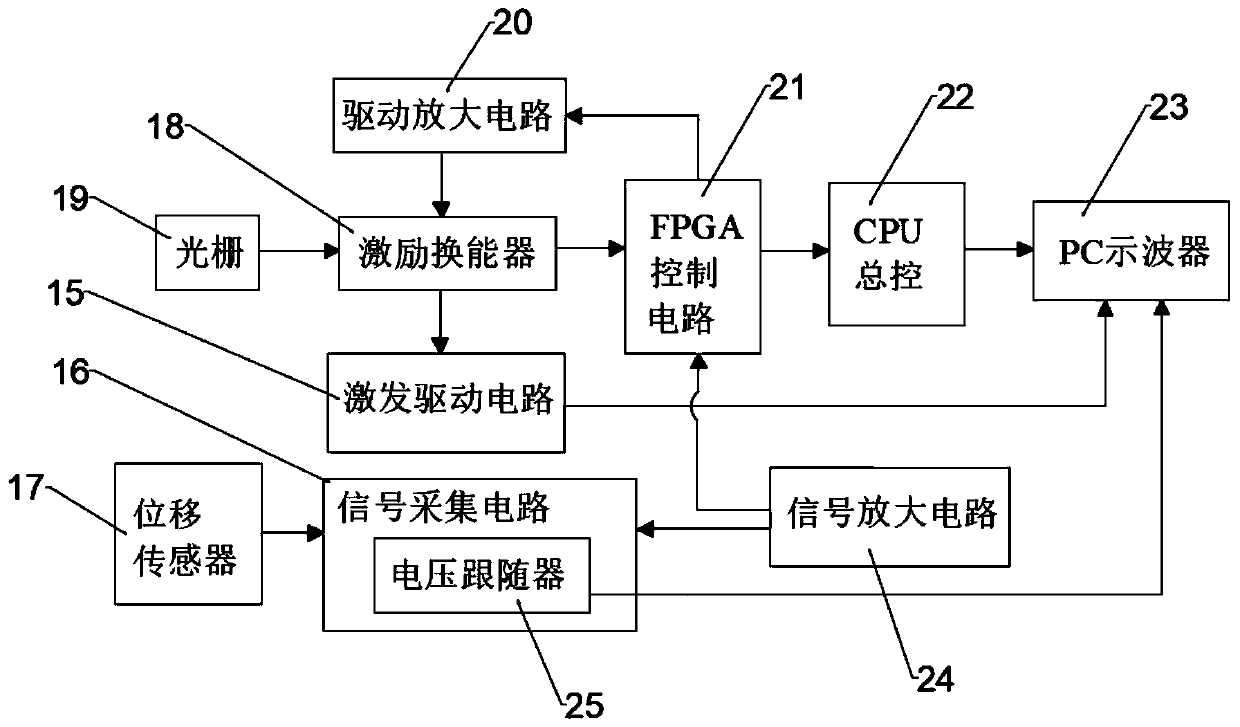

Orbital septum fat fixing thread knot pusher and control system

The embodiment of the invention discloses an orbital septum fat fixing thread knot pusher and a control system. The orbital septum fat fixing thread knot pusher comprises a wire connecting lead shaftprovided with internal threads on the surface and a first penetrating conductor rod and a second penetrating conductor rod which are attached to an aluminum oxide ceramic substrate. Screw-in metal covers are tightly connected to the upper surfaces of the two sides of the aluminum oxide ceramic substrate through seal rings; through an excitation drive circuit and a signal acquisition circuit installed at the left end and the right end of the waveguide wire, the signal acquisition circuit receives displacement information from a displacement sensor, a control end of the excitation driving circuit is connected with an excitation transducer, a magnetostrictive transducer is combined with the displacement sensor to obtain the linear displacement to be measured; the knotting position wound on the inner thread wall of the knotting thread leading shaft can be effectively controlled, knotting threads are pulled through magnetic field force, knots are pushed to a suture fixing position, and therefore knotting thread displacement can be accurately and effectively controlled, deep knotting of an eye bag operation becomes easy, and an incision in the eye conjunctiva can be properly reduced.

Owner:XIEHE HOSPITAL ATTACHED TO TONGJI MEDICAL COLLEGE HUAZHONG SCI & TECH UNIV

Novel medical suture material and preparation method thereof

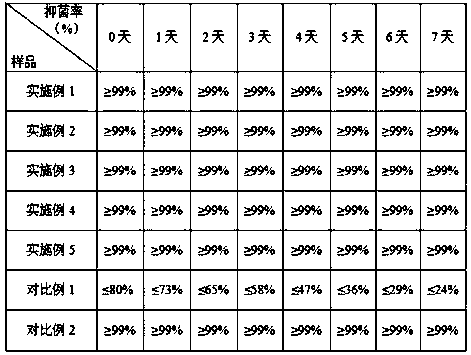

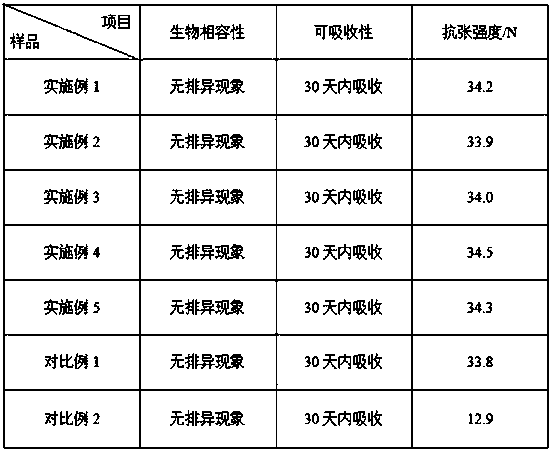

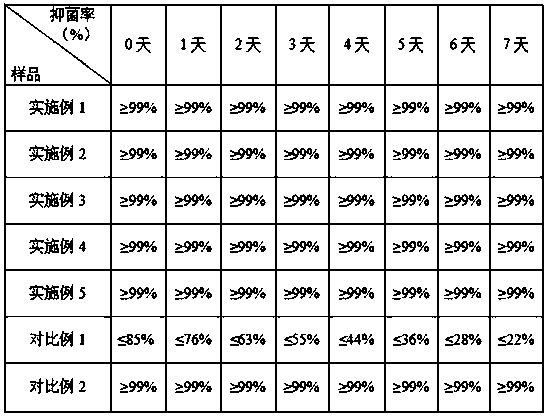

ActiveCN109876177AHigh tensile strengthEasy to knotSuture equipmentsSpinning solution filteringAcetic acidBiocompatibility Testing

The invention discloses a novel medical suture material and a preparation method thereof. The novel medical suture material is prepared from the following raw materials: yamamai silk, polyglycollide,collagen, chitosan, an antibacterial agent, acetic acid, urea, glycerin, pretreatment liquid and coagulation bath; the preparation method of the medical suture material comprises the following steps:preparation of a spinning solution; preparation of spinning thread; pretreatment of yamamai silk; preparation of an antibacterial agent solution; antibacterial coating treatment of spinning thread andyamamai silk respectively; braiding of the spinning thread and the silk; shaping of the braided wire, sterilizing, package, and acquisition of the novel medical suture material. The medical suture material has high tensile strength and good biocompatibility, and can be completely absorbed and degraded in biological tissues; the antibacterial effect is excellent and durable; the preparation process is short, the cost is low, the use is safe, and the production efficiency is high.

Owner:SHANDONG ZHUSHI PHARMA GRP CO LTD

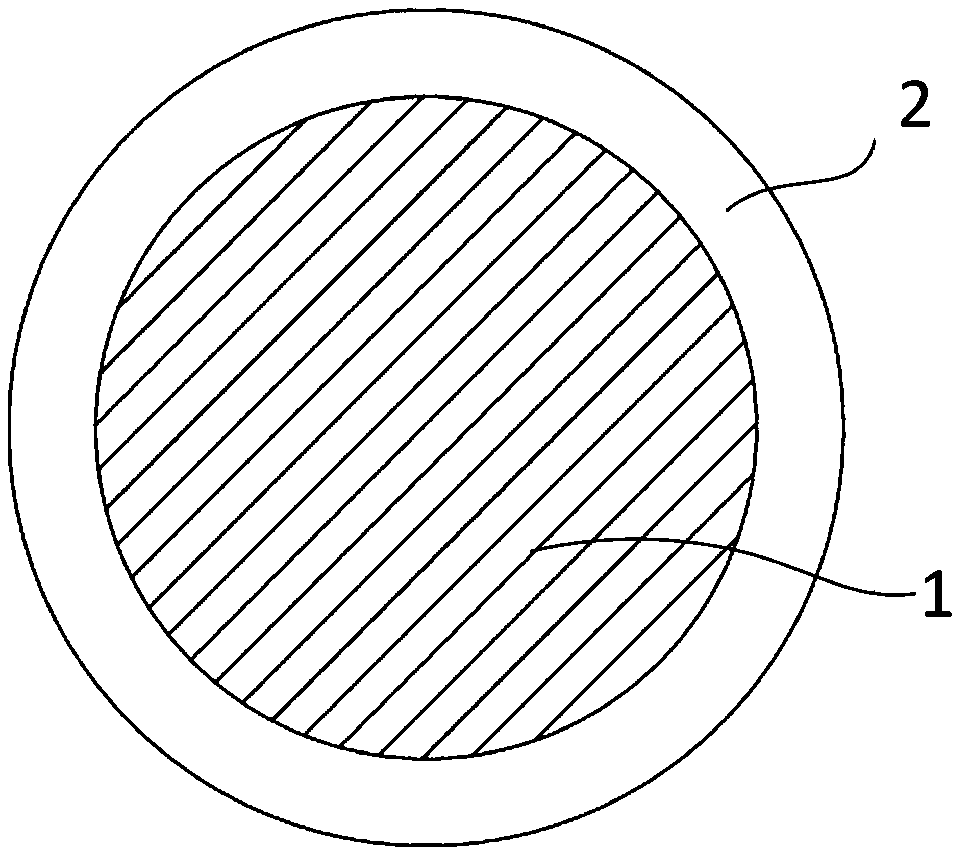

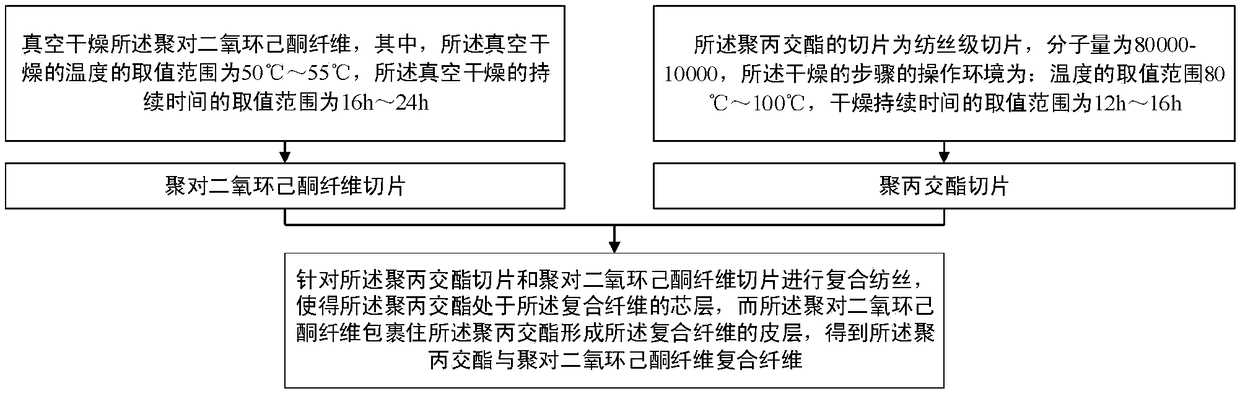

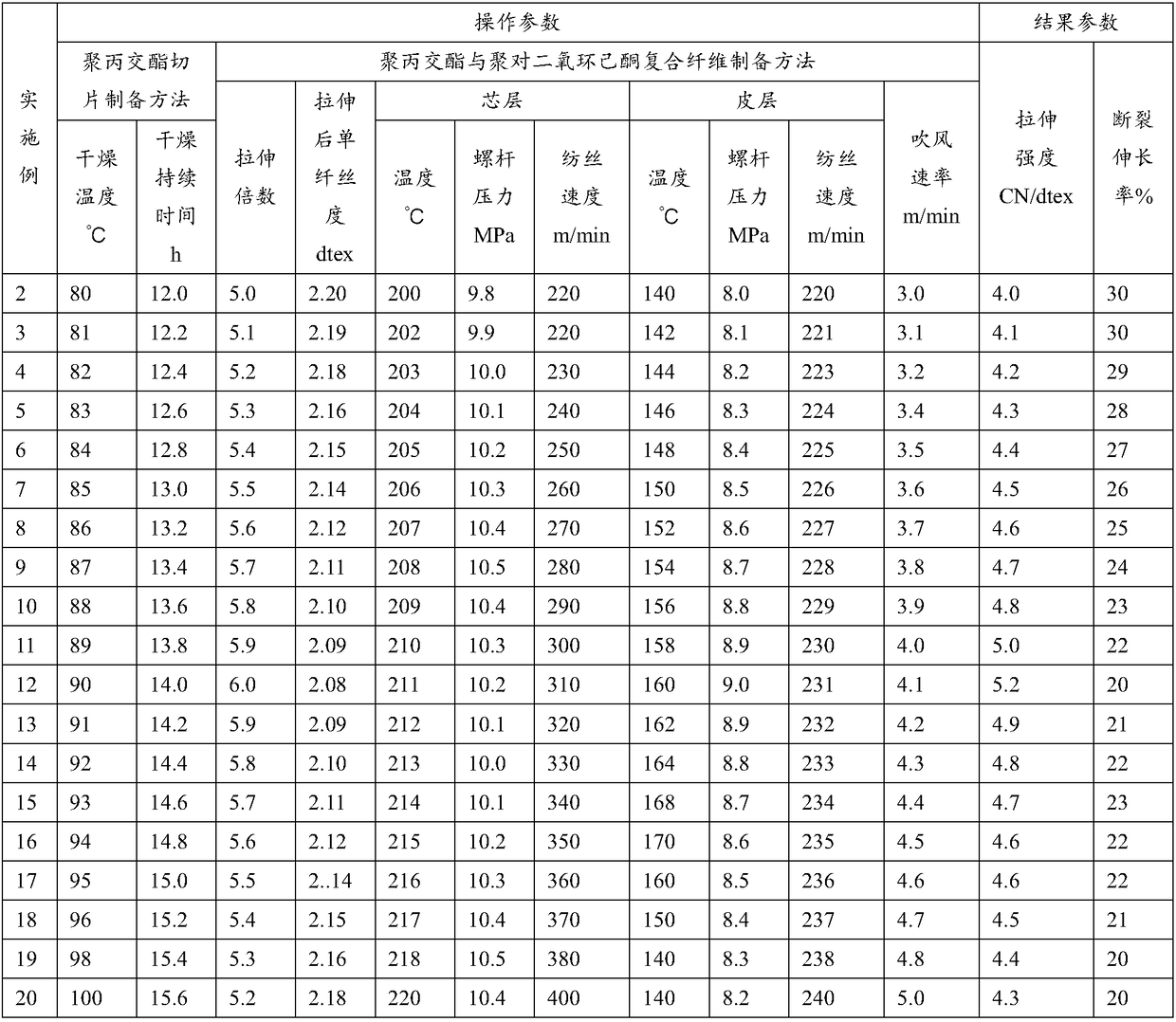

Polylactide-p-dioxanone composite fiber, preparation method thereof, application and surgical suture

ActiveCN109234843AIncreased biodegradation rateGood biocompatibilitySuture equipmentsFilament/thread formingP-dioxanoneFiber

The invention discloses a polylactide-p-dioxanone composite fiber, a preparation method thereof, application and a surgical suture. In the composite fiber, a polylactide fiber serves as a core layer of the composite fiber, and p-dioxanone serves as a skin layer of the composite fiber. The preparation method comprises the following steps: respectively obtaining a polylactide slice and a p-dioxanoneslice; performing composite spinning on the polylactide slice and the p-dioxanone slice, so that polylactide is located at the core layer of the composite fiber, and the p-dioxanone is used for packaging the polylactide to form the skin layer of the composite fiber, so as to obtain the polylactide-p-dioxanone composite fiber. The composite fiber can be used for the surgical suture. The surgical suture is prepared from the composite fiber. The value range of the tensile strength of the composite fiber is 4.0CN / dtex-5.2CN / dtex, and the value range of the breakage elongation is 20%-30%, so thatthe composite fiber can meet the requirements of the surgical suture and is low in manufacturing cost.

Owner:CHINESE TEXTILE ACAD

Binding packing machine rope gripper

PendingCN111003243AImprove stabilityEasy to operateBundling machine detailsElectric machineryStructural engineering

The invention belongs to the technical field of rope grippers and particularly relates to a binding packing machine rope gripper. The binding packing machine rope gripper comprises a rope feeding device. A motor is arranged below the rope feeding device. An output shaft of the motor is in driving connection with a speed reducer. A support is arranged above the speed reducer. The top of the supportis fixedly connected with a cutter rest. A passive pressing part is arranged on one side of the cutter rest. An active rotary pressing part is arranged on the front side of the passive pressing part.The rope feeding device comprises a rope feeding cylinder, fixed plates, a connecting plate, a round port and a penetration pipe. The front and rear sides of the fixed plates are fixedly connected with the rope feeding cylinder through screws. The binding packing machine rope gripper is provided with the rope feeding device and has the advantages of being higher in stability, easy to operate andcontrol, simple in installation and capable of saving time, labor, cost and material resources. Through cooperation of the active rotary pressing part and the passive pressing part, the binding packing machine rope gripper makes knotting easier and more accurate and increases the knotting success rate remarkably.

Owner:常州超研机械有限公司

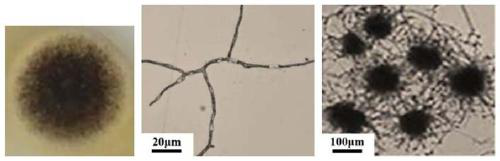

Construction method of mutant strain for increasing metabolism yield of filamentous fungi through form optimization and orientation

ActiveCN110066741ALow viscosityIncrease productionFungiMicroorganism based processesMicroscopic observationBottle

The invention relates to a construction method of a mutant strain for increasing the metabolism yield of filamentous fungi through form optimization and orientation. The method comprises the steps that the filamentous fungi are cultured in a liquid culture medium; whole genomes are extracted; an amplification-aim form gene segment of a primer in the whole genomes of the filamentous fungi is designed; the aim gene segment is connected with a carrier for constructing a carrier for regulating and controlling form gene expression; the filamentous fungi are converted through the carrier, and resistance genes on the carrier are used for screening converters; the mutant strain is inoculated into a seed bottle, after culture is conducted for a time period, filtering is conducted for collecting hyphae, and after dyeing, the form is observed through a microscope; after seeds are transferred into a fermentation culture medium, sampling is conducted at certain time intervals, filtering is conducted for collecting hyphae, and after dyeing, the form is observed through the microscope; the titer of the product is measured, and the high-yield strain is screened. The hyphae of transformed fungi have multiple branches, the branches wind and gather into balls, the branches of extraglomerular hyphae are short, the balls of the fungi are compact and even in size, and the viscosity of a fermentationsolution is low.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

Operation suture line for gastrointestinal surgery and preparation method thereof

ActiveCN108273119AControllable degradation rateControl degradation rateSuture equipmentsCoatingsBiopolymerAntibacterial property

The invention relates to an operation suture line for gastrointestinal surgery and a preparation method thereof. The operation suture line is characterized in that an innermost layer is an alloy core,a second layer to the outside is a deacetylation chitin fiber layer, a third layer is a biopolymer layer, and an outermost layer is a polyglycolic acid layer; the thickness ratio of the deacetylationchitin fiber layer to the biopolymer layer to the polyglycolic acid layer is (2 to 2.5):(1 to 1.5):(1 to 1.5); the diameter of the alloy core is 3 to 5mm, the alloy core adopts zinc, lithium and magnesium alloy, and the weight percentage ratio of zinc to lithium to magnesium is 92:5:3; the deacetylation chitin is prepared by mixing with acetic acid, the biopolymer layer is prepared by degreasinganimal casings, the polyglycolic acid is prepared by polymerizing glycolic acid, and the outer surface of the polyglycolic acid layer is coated with a sterilant. The operation suture line prepared bythe method has the advantages that the antibacterial property is better, the probability of wound infection is greatly decreased, the wound healing speed is quick, the strength is high, the easiness in breaking is avoided, and the prospect is broad in clinical application.

Owner:戴庆涛

Surgical operation suturing material and preparation method thereof

The invention discloses a surgical operation suturing material and a preparation method thereof. The surgical operation suturing material comprises the following raw materials in parts by weight: 15-23 parts of polyglycolic acid, 5-8 parts of ossein, 11-14 parts of polylactic acid, 0.5-0.9 part of tryptophan, 0.4-0.8 part of fish collagen protein, 2-4 parts of radix achyranthis bidentatae and 0.01-0.05 part of nisin. The surgical operation suturing material disclosed by the invention is free of toxin, harm and accumulation, easy to process and mold, high in strength, easy to tie and good in properties such as flexibility and sterilization and disinfection resistance, capable of promoting heal of a wound, and can be completely absorbed and degraded in biological tissue within 15-25 days.

Owner:ZHENGZHOU YUANRAN BIOLOGY TECH CO LTD

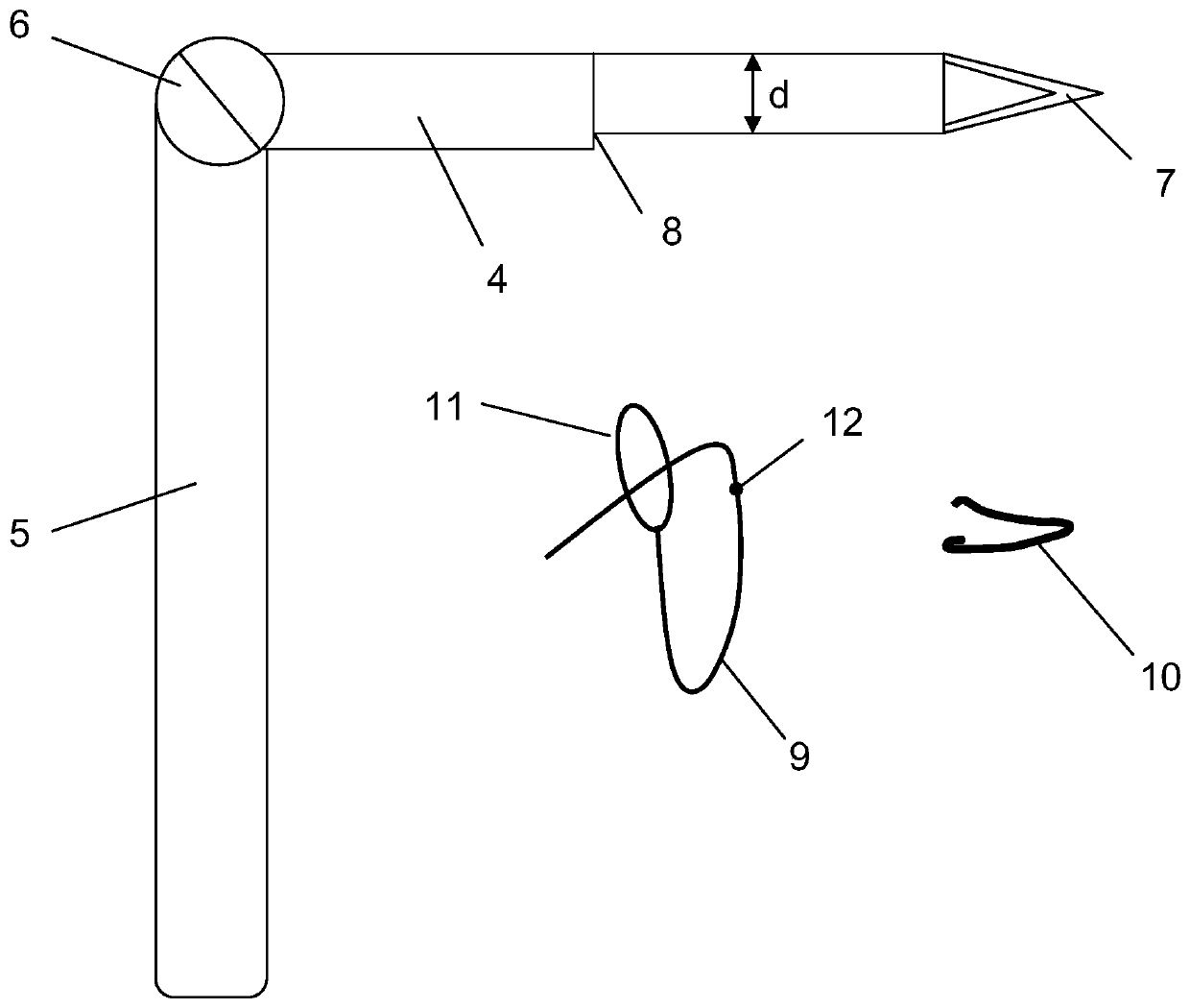

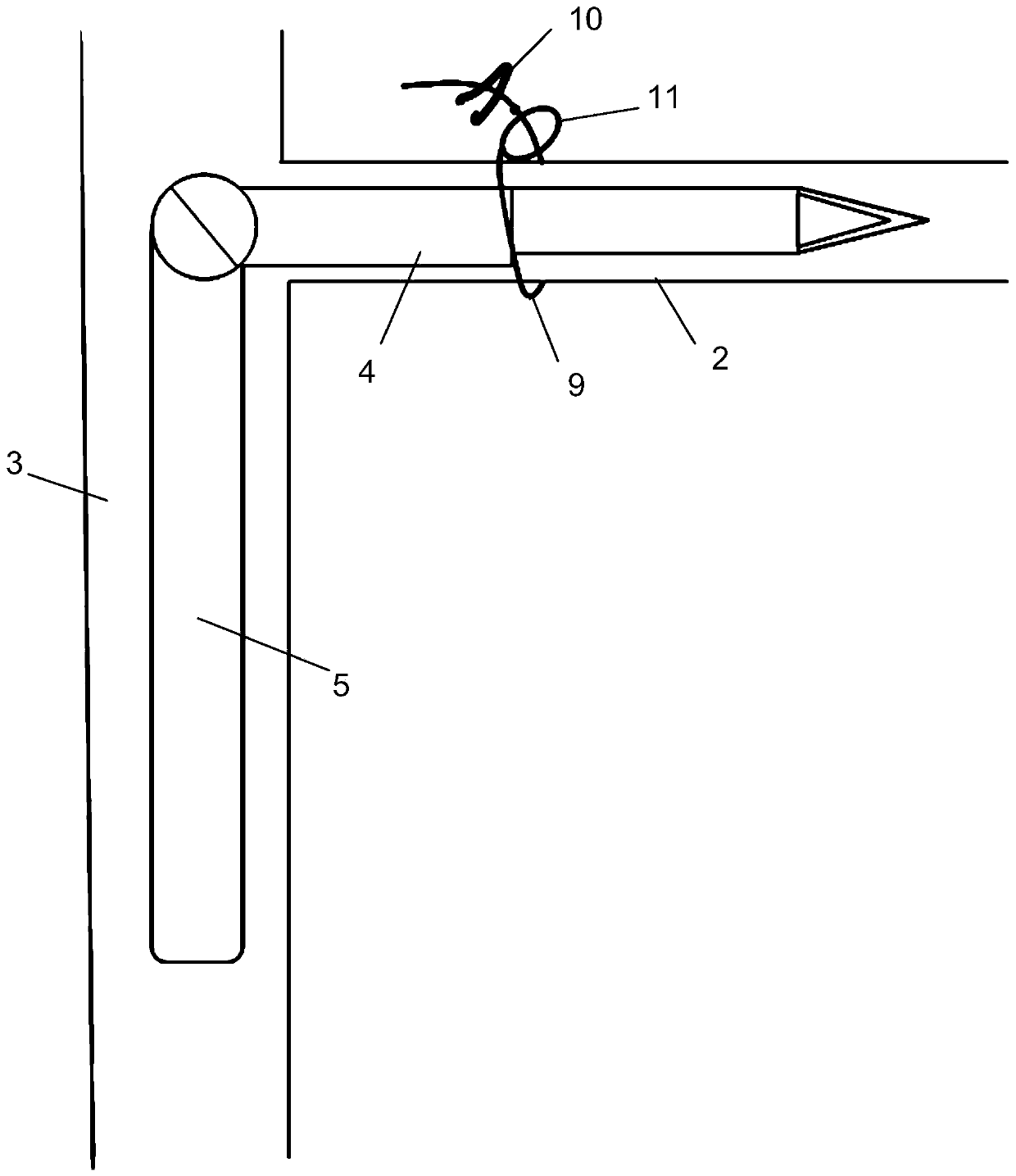

Rat varicocele model building tool and use method thereof

PendingCN109730797AAvoid compromising accuracyPrecise positioningSurgical veterinaryOrthodontic ligatureEngineering

The invention discloses a rat varicocele model building tool. The tool comprises a tool body and tool accessories; the tool body comprises a handle and a narrowing rod, the tail end of the narrowing rod is connected with the upper end of the handle through a movable joint, the head end of the narrowing rod is conical, a flexible protective layer is arranged outside the narrowing rod, and a step isarranged on a rod body of the narrowing rod; the tool accessories comprise a ligature and a ligature clamping buckle. The invention further discloses a use method of the rat varicocele model buildingtool. The rat varicocele model building tool and the use method thereof have the following advantages that the ligature is positioned, the phenomenon that due to slipping, the final accuracy is affected is avoided; the rebound diameter can be effectively controlled, and the narrowing effect is more precise; damage to organs can be avoided during operation; knotting is better facilitated, and slippage or tightening can be prevented.

Owner:SHANGHAI TONGJI HOSPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com