Full-automatic carton packing and stacking system

A palletizing system and fully automatic technology, applied in the field of automatic carton packing and palletizing system, can solve the problems of affecting the quality of palletizing, low feeding efficiency, and the stacking of cartons is not neat enough, and achieves high conveying efficiency and smashing effect. Good, improve the effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

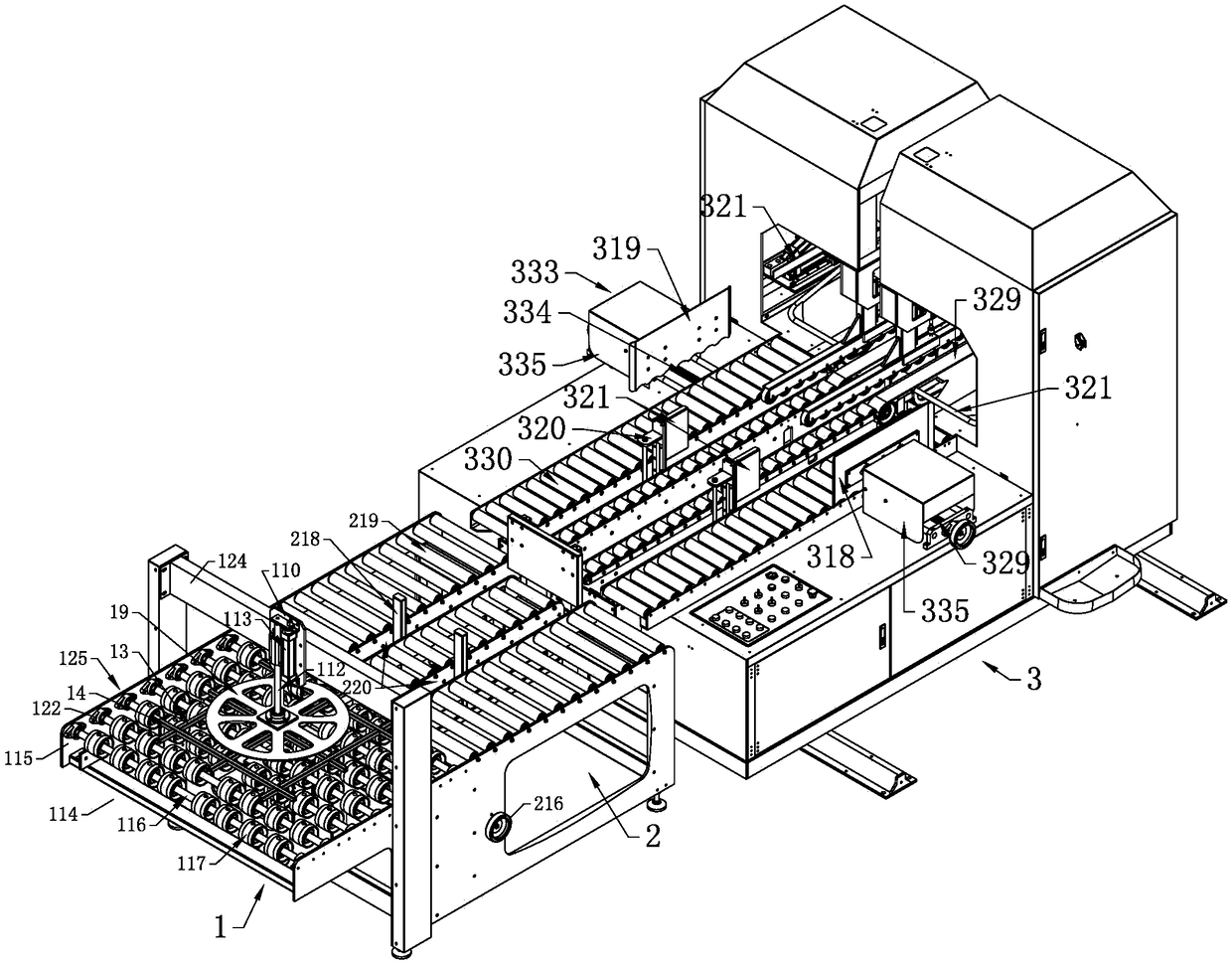

[0061] A fully automatic carton packing and palletizing system, including a packing machine and a palletizing machine 4. There is a conveying device between the baler and the palletizer, and the conveying device sends the cartons packed by the baler to the palletizer for palletizing. The conveying device can be a belt conveyor or a roller conveyor, which belongs to the prior art and will not be repeated here.

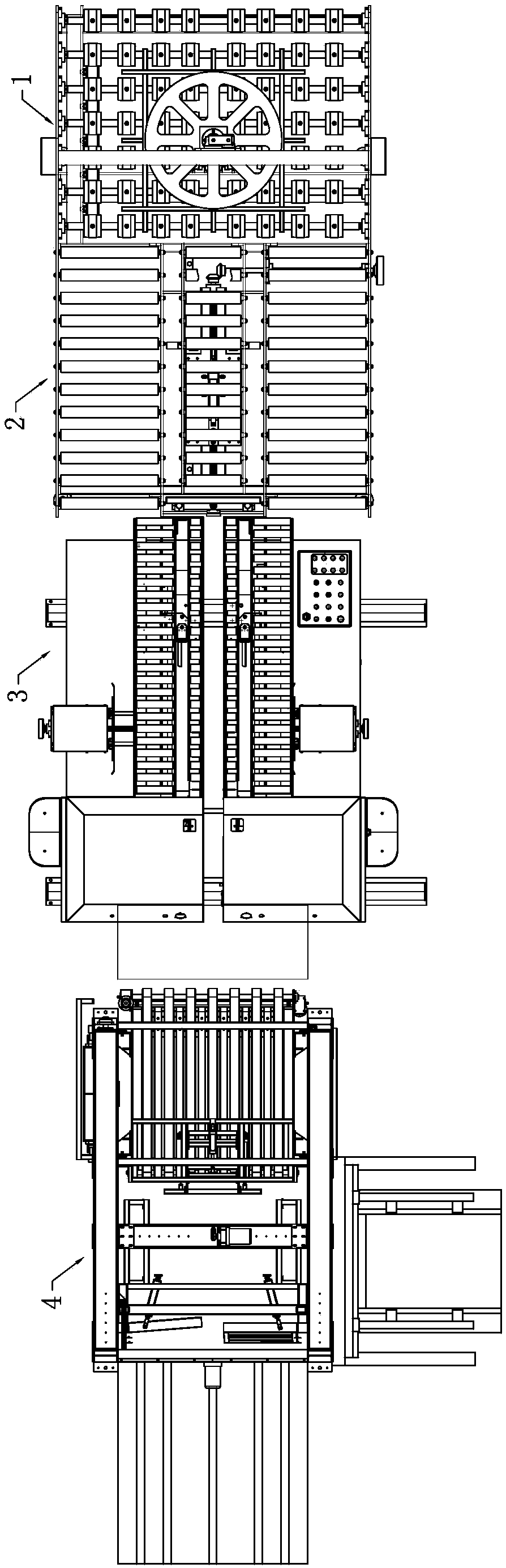

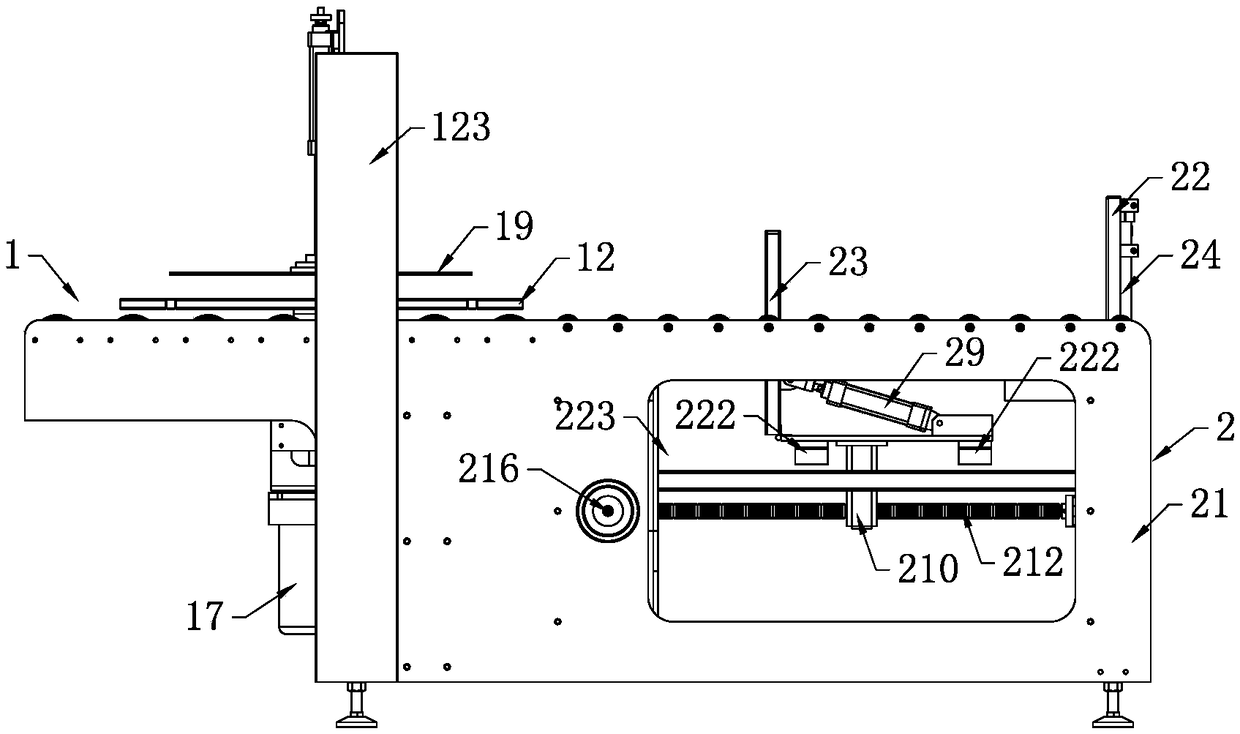

[0062] Such as figure 1 As shown, the packing machine includes an input device and a packing unit 3 which are sequentially connected. The input device includes a steering conveying unit 1 and a forward and backward clapping conveying unit 2 arranged sequentially.

[0063] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Together, the deflecting conveyor unit 1 comprises a conveying unit 114 and a deflecting unit 11 . The conveying unit 114 includes a bracket 115 and a plurality of parallel second shafts 116 rotatably mounted on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com