Patents

Literature

61results about How to "Good alignment effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid crystal alignment agent for photo alignment, liquid crystal alignment layer for photo alignment, and liquid crystal display element

ActiveCN103387833AHigh voltage retentionSmall amount of ionsLiquid crystal compositionsNon-linear opticsCarbon numberLiquid-crystal display

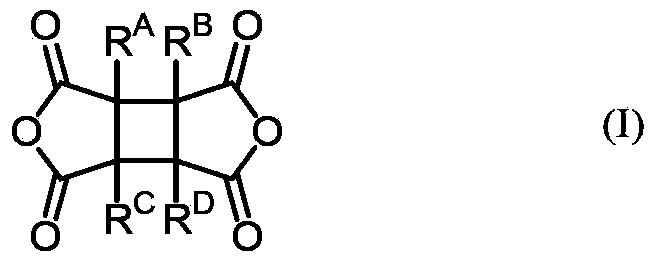

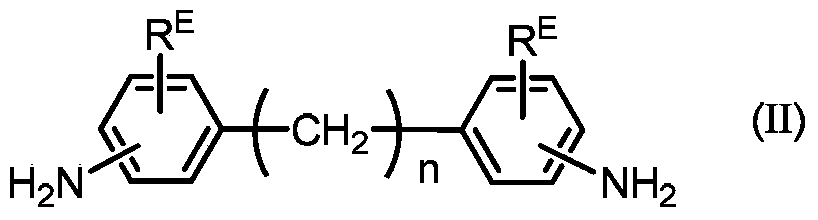

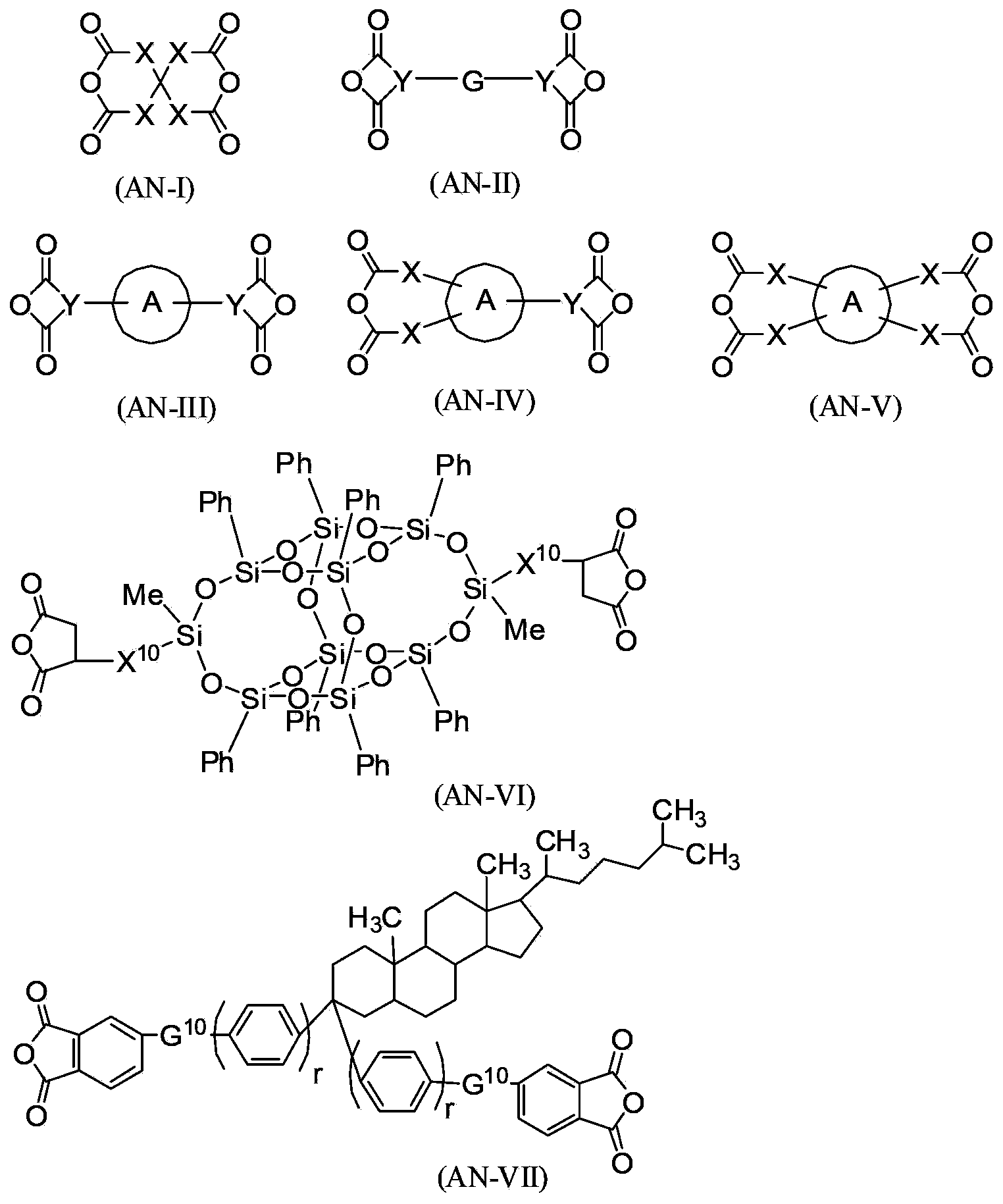

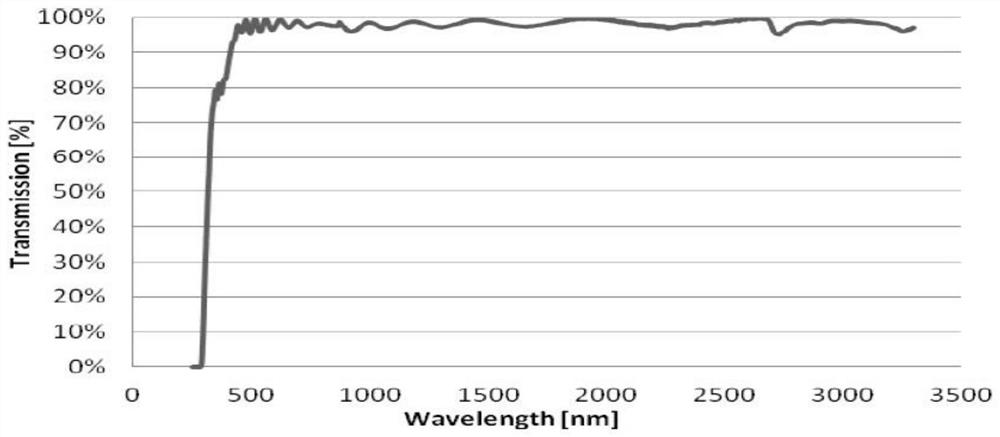

The invention provides a liquid crystal alignment agent for photo alignment, a liquid crystal alignment layer for photo alignment, and a liquid crystal display element. The liquid crystal alignment agent provided by the invention has a polyamide acid or a derivative thereof, the polyamide acid or the derivative thereof may be formed by reacting a mixer of cyclobutane tetracarboxylic dianhydride or tetracarboxylic dianhydride with specific aromatic diamine of an alkyl chain of a molecule with a carbon number larger than 4. With the adoption of the liquid crystal alignment agent, a liquid crystal alignment layer good in sensitivity of chemical change caused by light irradiation, excellent in alignment property of liquid molecule and high in optical transmittivity is formed. In addition, by applying the photo alignment layer to the liquid crystal display element, the liquid crystal display element with excellent display characteristics can be obtained.

Owner:JNC CORP +1

Liquid crystal aligning agent for photoalignment, liquid crystal alignment film and manufacturing method thereof, liquid crystal display device, compound, and polymer

ActiveCN103509563AIncreased sensitivityShao Fu ShaoLiquid crystal compositionsOrganic chemistryCrystallographyLight irradiation

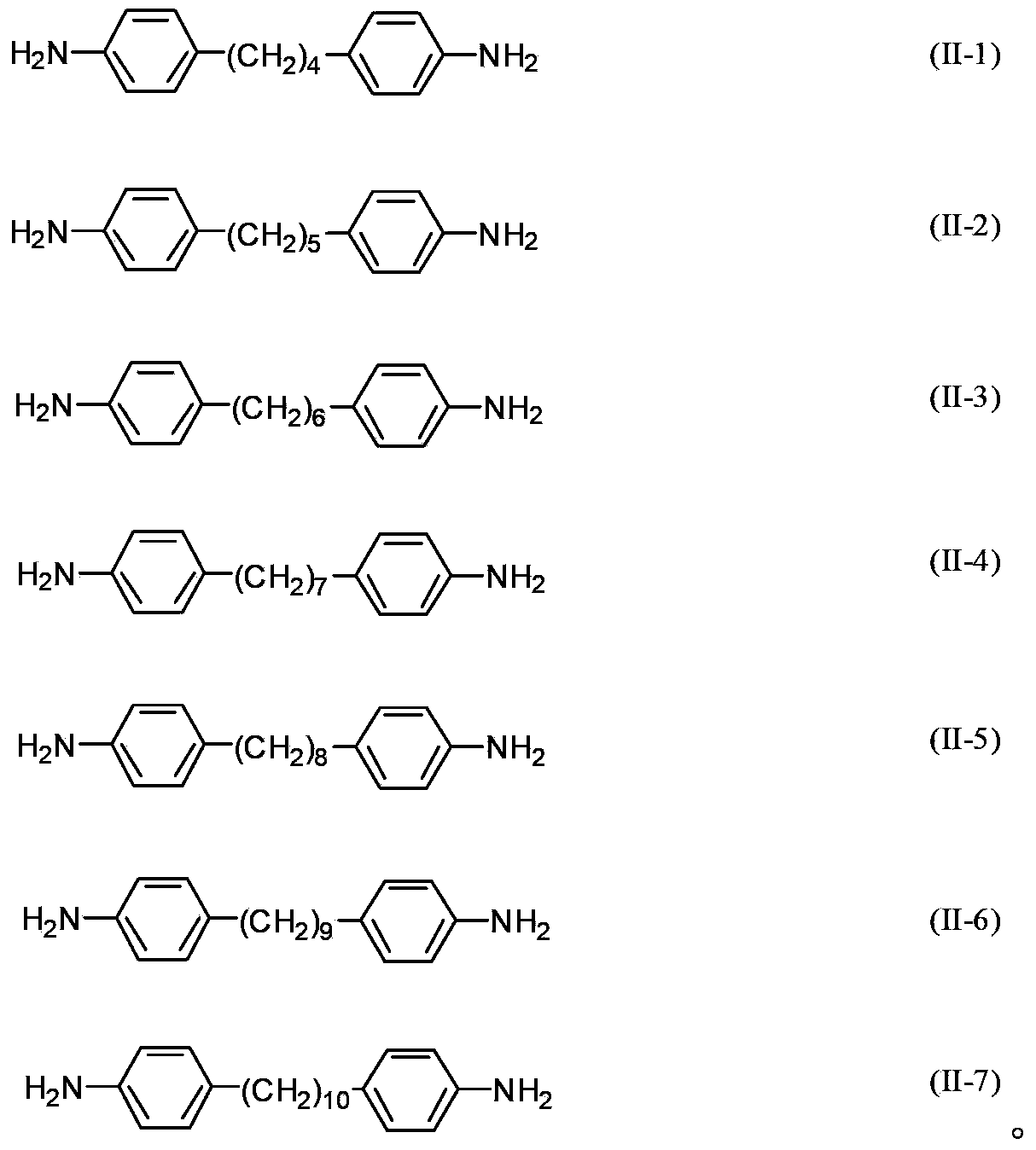

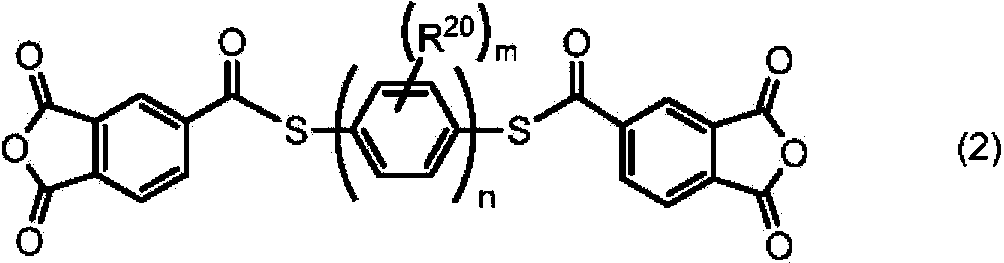

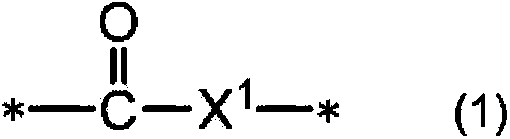

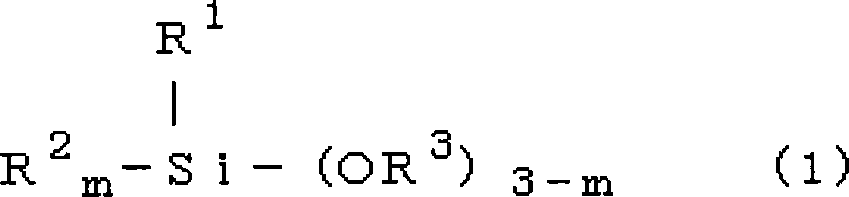

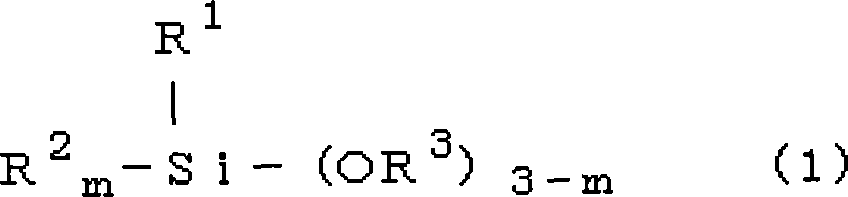

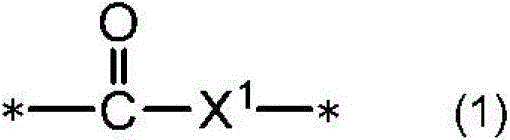

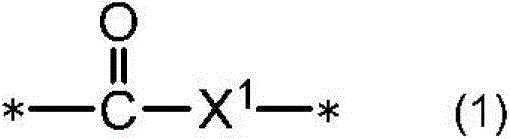

The invention provides a liquid crystal aligning agent for photoalignment, a liquid crystal alignment film and manufacturing method thereof, a liquid crystal display device, a compound, and a polymer. The liquid crystal alignment film is manufactured through the manufacturing method including the following steps: a film forming step in which a liquid crystal alignment agent for photoalignment is coated on a substrate to form a coating, the liquid crystal alignment agent for photoalignment containing at least one selected from a group consisting of polyamic acid, polyamic acid ester and polyimide and its main chain having a polymer (C) of a structure represented by formula (1); and a light irradiation step in which light irradiation is performed on the coating to manufacture the liquid crystal alignment film. (In the formula (1), X1 is sulphur atoms or oxygen atoms. * represents bonding keys. At least one of the two * is bonded on an aromatic nucleus.)

Owner:JSR CORPORATIOON

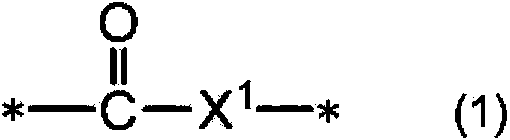

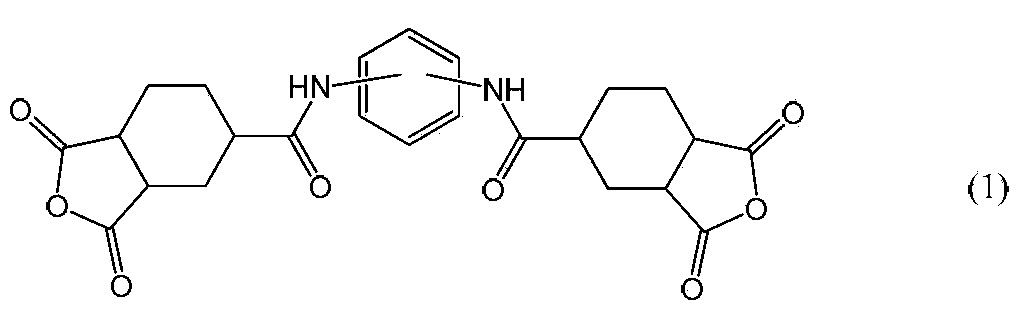

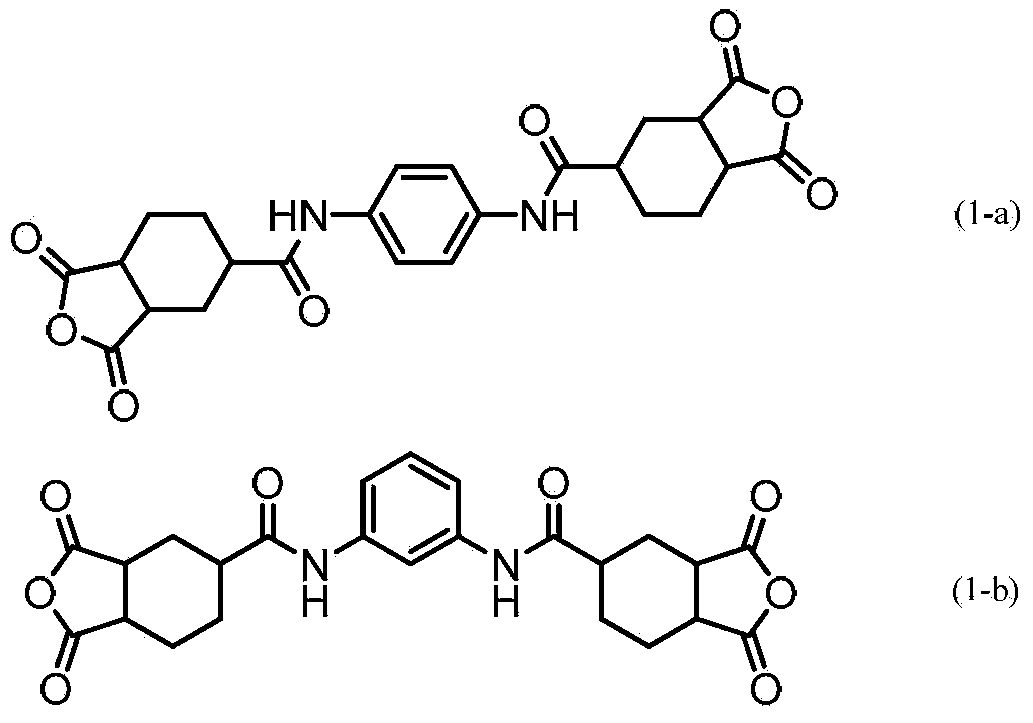

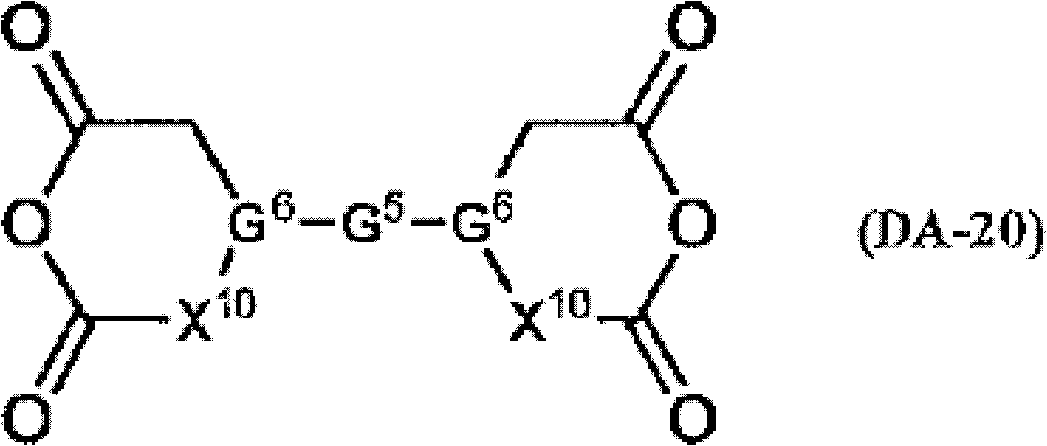

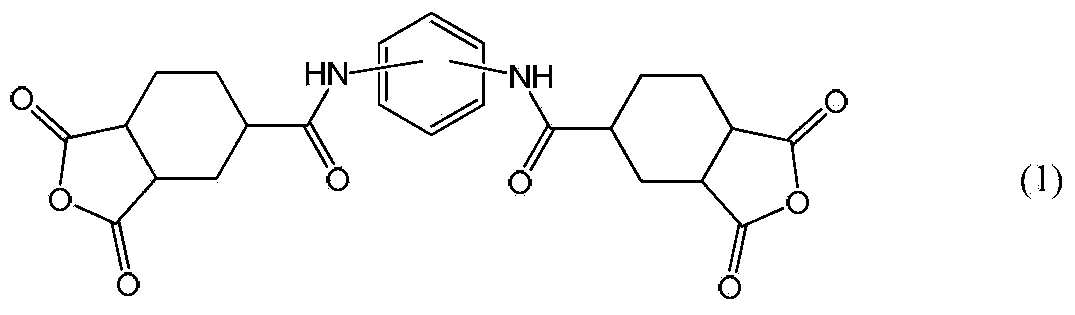

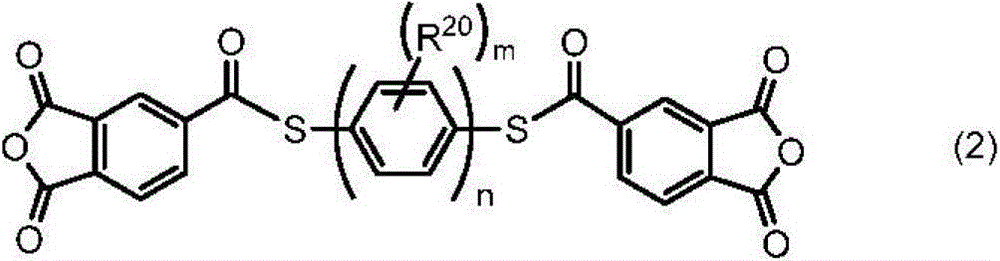

Polyamic acid or derivative thereof, liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element provided therewith

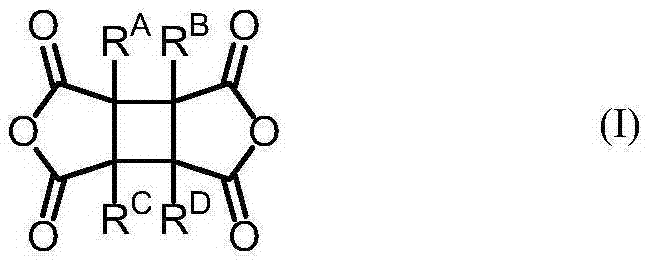

InactiveCN103374131AGood alignment effectImprove display characteristicsLiquid crystal compositionsNon-linear opticsCrystallographyTransmittance

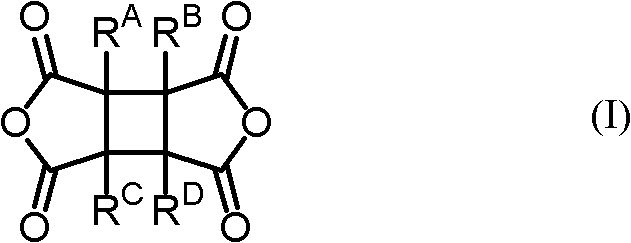

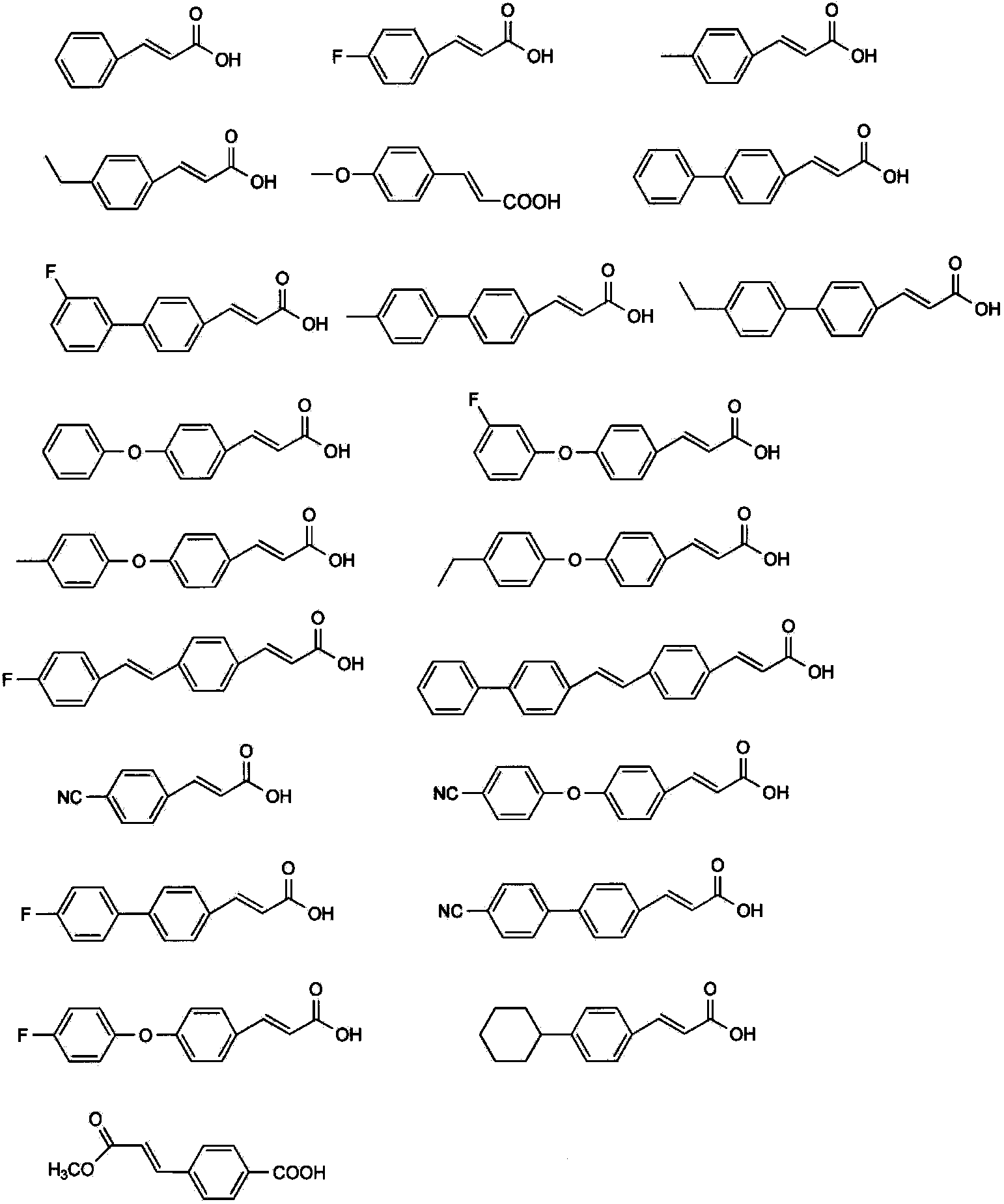

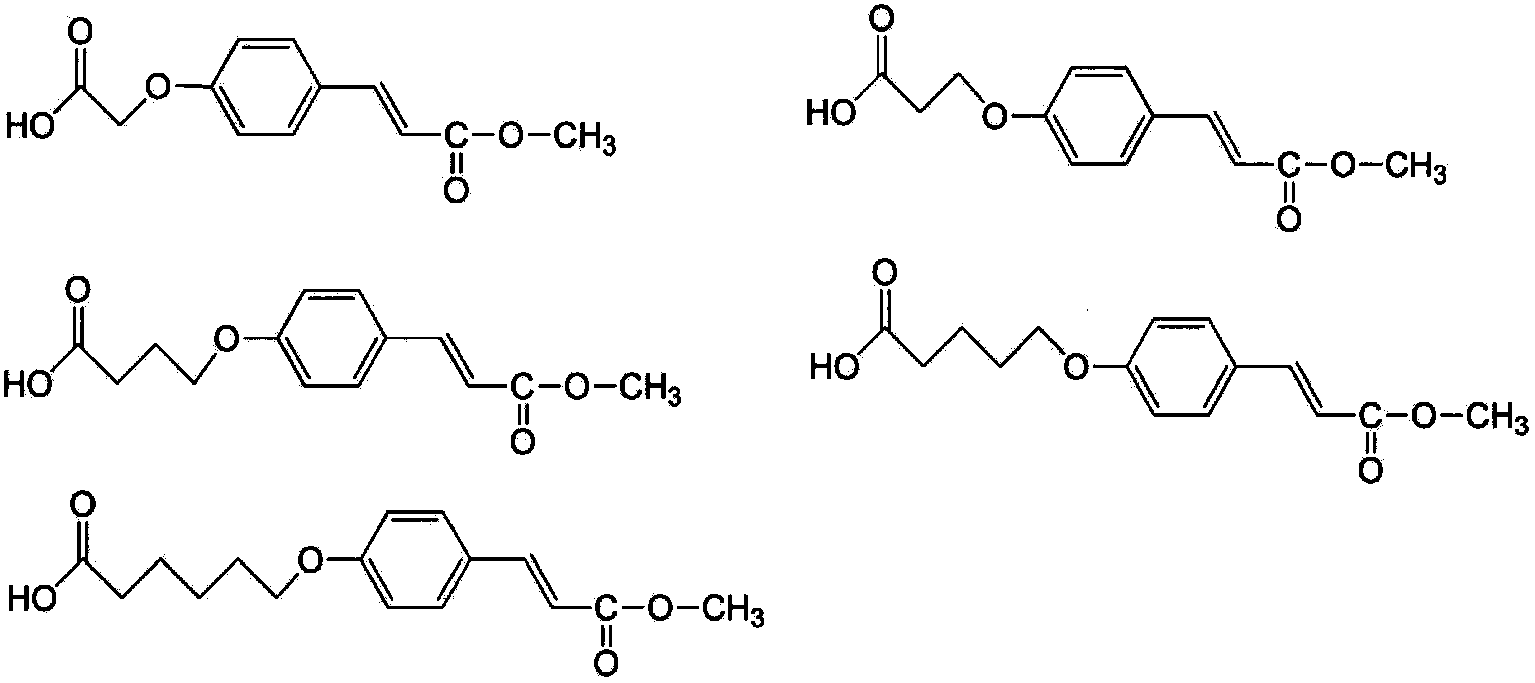

The invention provides a polyamic acid or a derivative thereof, a liquid crystal alignment agent, a liquid crystal alignment film provided with the liquid crystal alignment agent, and a liquid crystal display element provided with the liquid crystal alignment film, wherein liquid crystal molecules are excellent in alignment property and high in transmittance. The invention provides the liquid crystal alignment agent at least comprising polyamide acid obtained through the reaction of diamine with tetracarboxylic acid bi-anhydride (represented in the formula 1) or the derivative thereof, the liquid crystal alignment film, and the liquid crystal display element provided with the liquid crystal alignment film (chemical formula 1).

Owner:JNC CORP +1

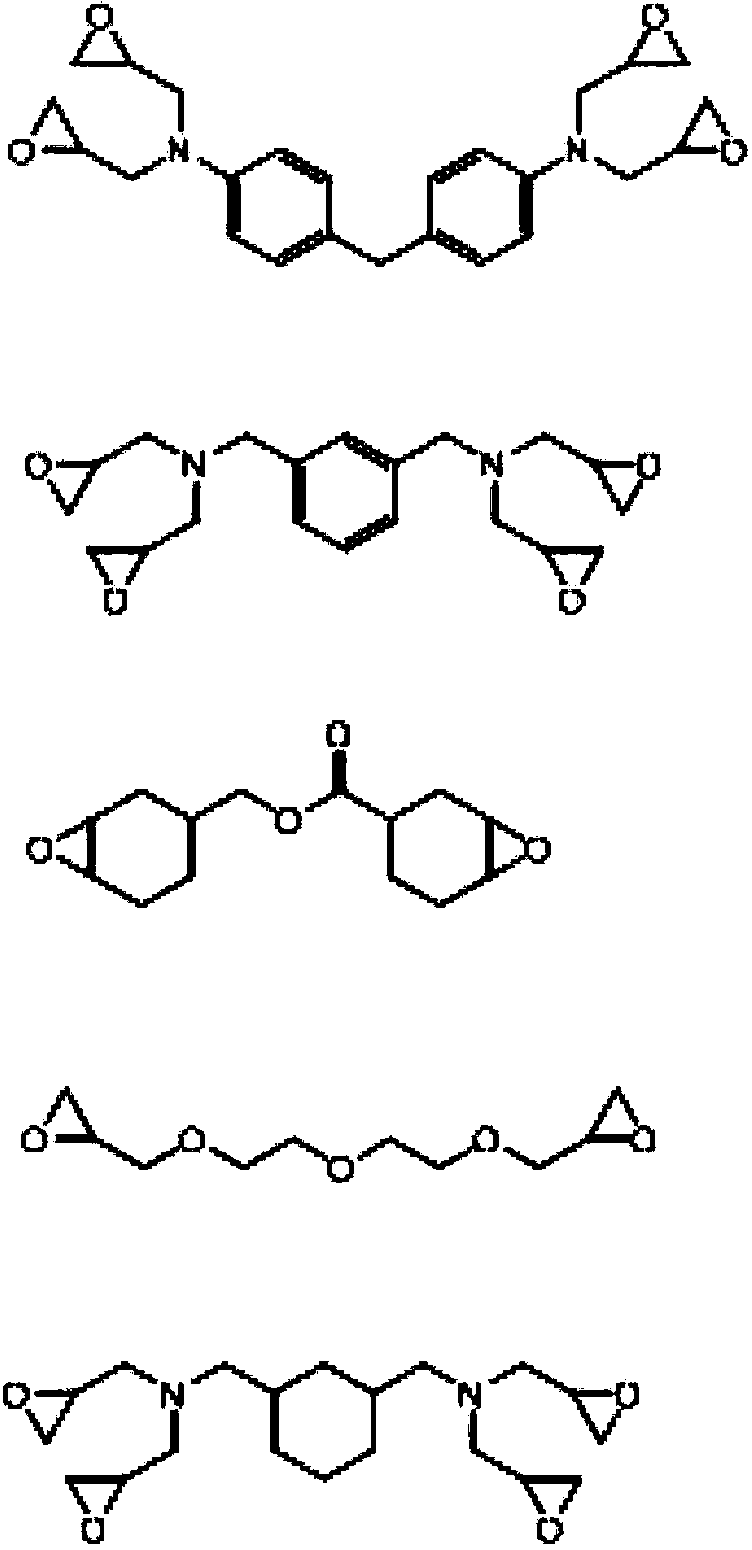

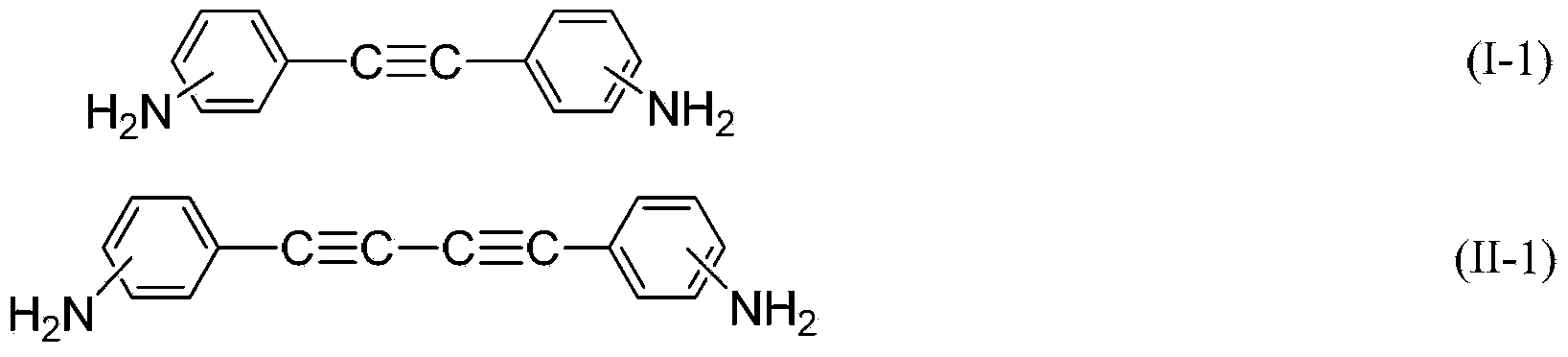

Liquid crystal alignment agents for photo-alignment, liquid crystal photo-alignment layers, and liquid crystal displays using the same

ActiveCN102585843AHigh light transmittanceGood alignment effectLiquid crystal compositionsNon-linear opticsPolyamideCarboxylic acid

The invention provides liquid crystal alignment agents for photo-alignment, liquid crystal photo-alignment layers, and liquid crystal displays using the same. The liquid crystal alignment agents contain tetracarboxylic dianhydride mixture including cyclopentane tetracarboxylic dianhydride, which is reacted with specific diamine to obtain polyamide acid or its derivatives. The liquid crystal alignment agents are applied to form a photo-alignment film with excellent alignment property and high light transmittance, because of light sensitivity of the chemical change caused by illumination. In addition, the photo-alignment film is applied in liquid crystal displays, the electrical characteristics required by liquid crystal alignment film is satisfied, the voltage maintaince ratio is high, the iron amount is little, the remained charge amount is little, etc.

Owner:长沙道安捷新材料有限公司

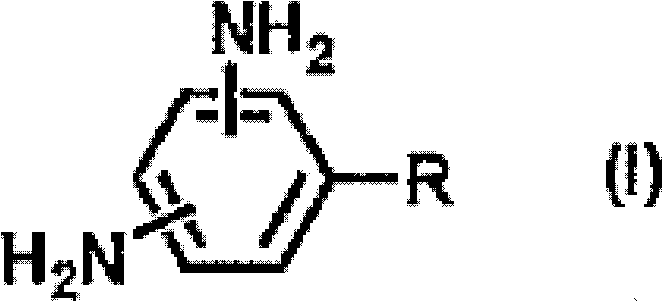

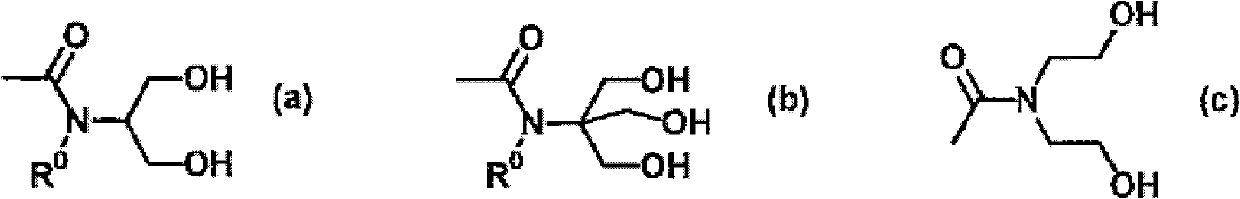

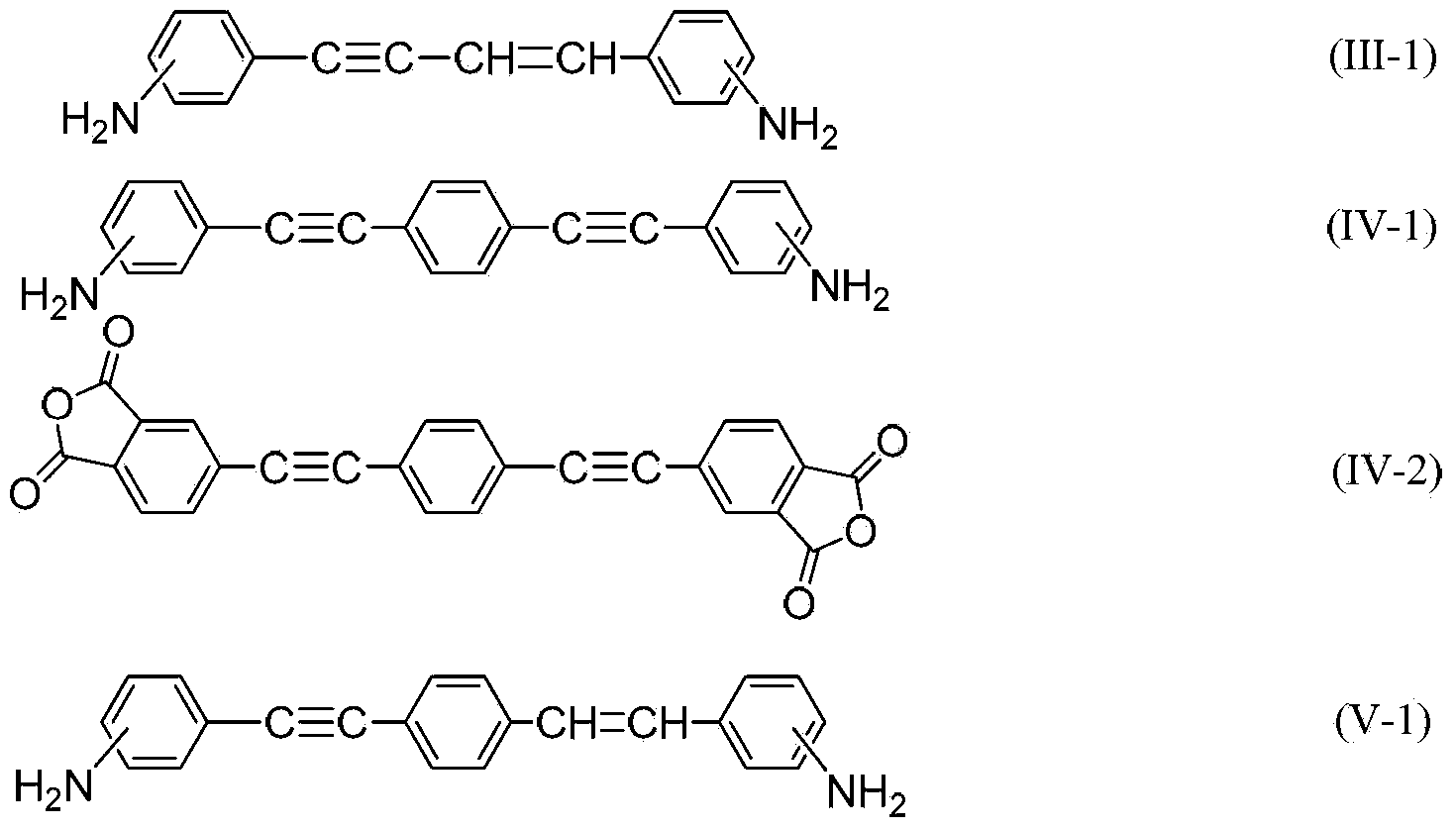

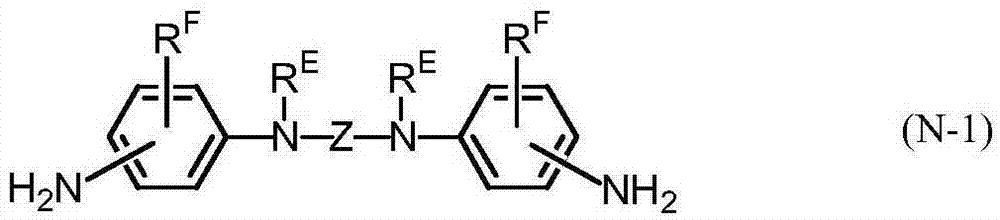

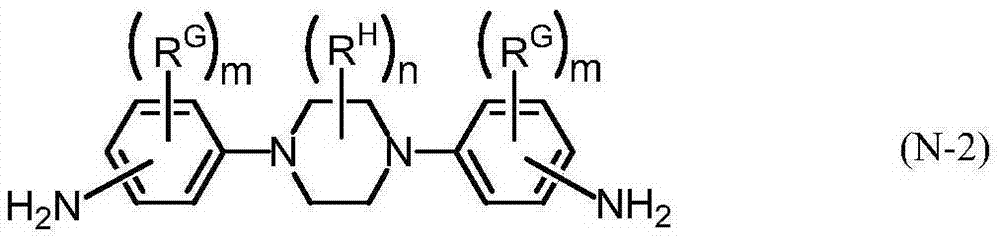

Diamine, liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display component

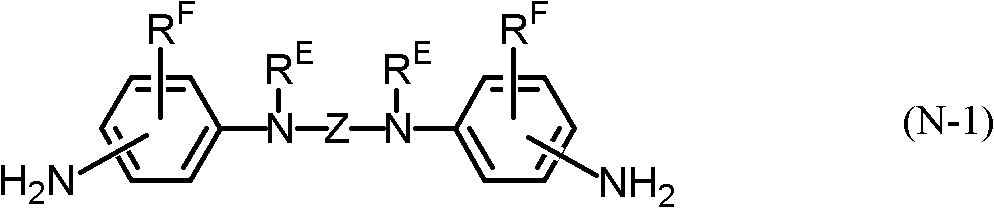

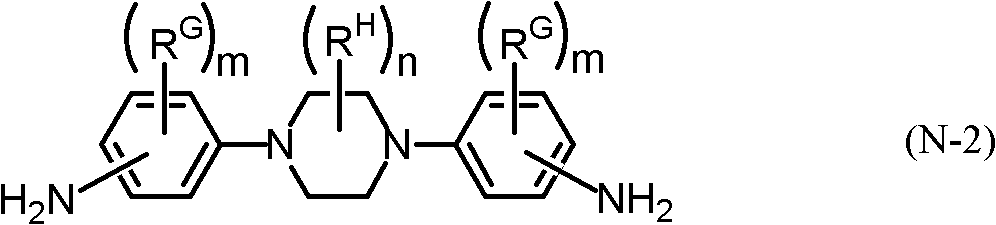

ActiveCN102372649AGood alignment effectSmall volume resistanceLiquid crystal compositionsOrganic chemistryLiquid-crystal displayNitrogen

The present invention provides a diamine, a polyamide acid and derivants thereof, a liquid crystal alignment agent for obtaining a liquid crystal alignment film and a liquid crystal display element with high liquid crystal alignment performance and good black level. At least diamine represented in the general formula (1) is used to react with tetracarboxylic acid dianhydride to obtain polyamic acid and derivants, and the liquid crystal alignment film can be prepared. In the formula 79, R is acylamino, wherein methylene is spaced on nitrogen atom and hydroxyl is bonded on the tail end.

Owner:长沙道安捷新材料有限公司

Liquid crystal aligning agent, liquid crystal alignment film, phase difference film, method for forming phase difference film, liquid crystal display device, and polymer

ActiveCN103509562AImprove qualityGood liquid crystal alignmentLiquid crystal compositionsPolarising elementsChemistryDouble bond

The present invention aims to provide a liquid crystal aligning agent which can form excellent liquid crystal aligning performance and is excellently sealed with a liquid crystal layer, a liquid crystal alignment film formed by the liquid crystal aligning agent, phase difference film including the liquid crystal alignment film and manufacturing method thereof, a liquid crystal display device including the liquid crystal alignment film, and a polymer serving as a suitable ingredient of the liquid crystal aligning agent. The liquid crystal aligning agent provided by the invention contains A, i.e., an ingredient where the same or different molecule thereof contains optical aligning radicals and radicals containing polymerism double bonds. The ingredient A is optionally a polymer ingredient. The optical aligning radicals are optionally radicals containing a cinnamic acid structure. The liquid crystal alignment film is formed by the liquid crystal aligning agent. The phase difference film contains the liquid crystal alignment film. The phase difference film is optionally used in the liquid crystal display device. The liquid crystal display device contains the phase difference film.

Owner:JSR CORPORATIOON

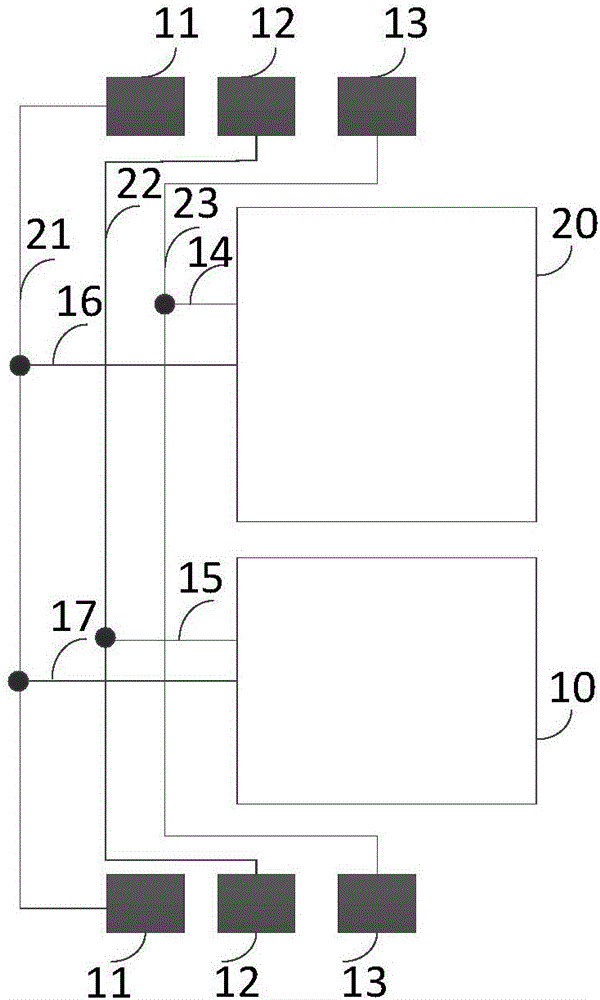

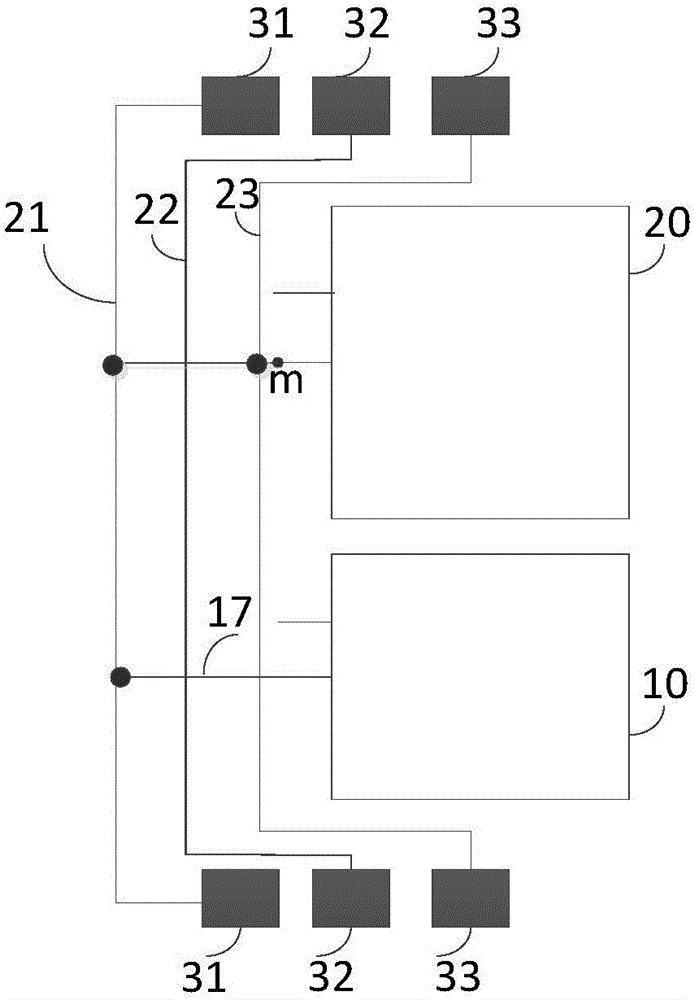

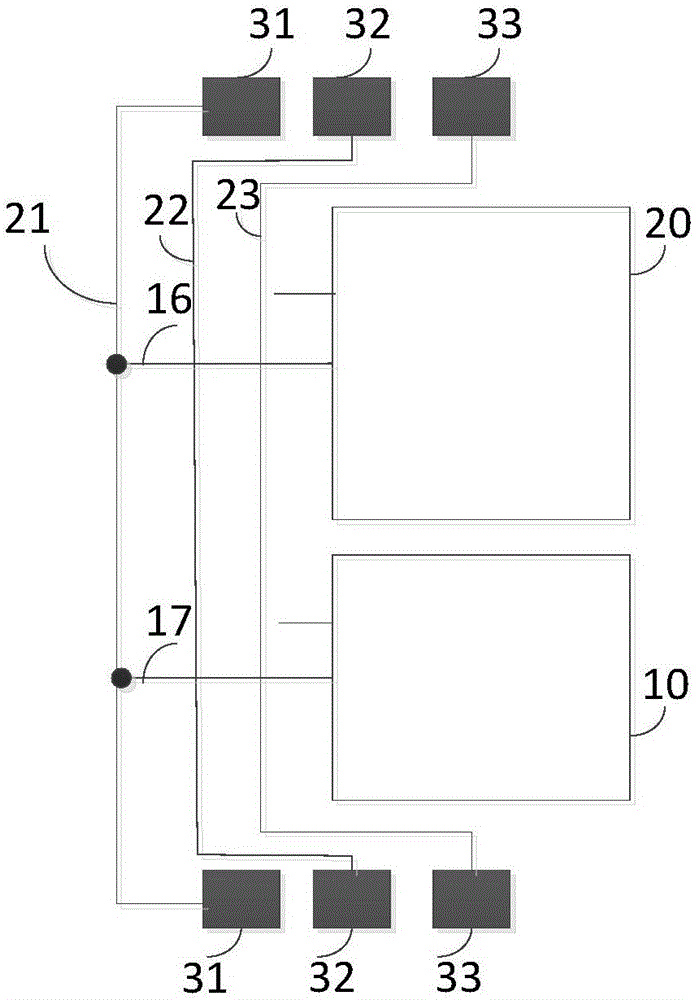

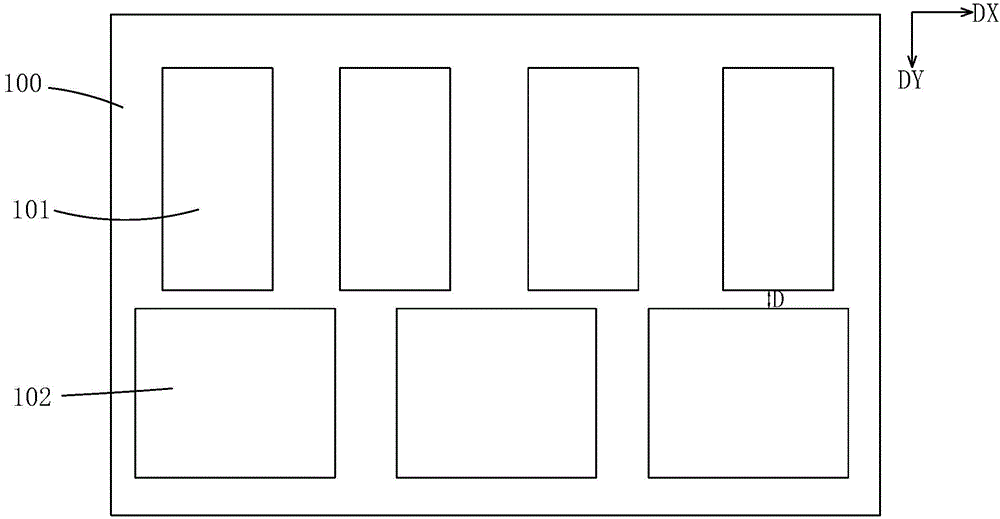

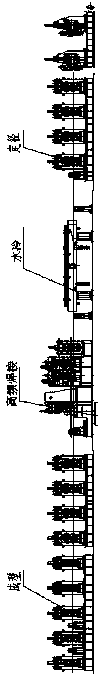

Routing structure of liquid crystal display panel and manufacture method of routing structure

InactiveCN105892176AGood alignment effectImprove the display effectNon-linear opticsLiquid-crystal displayCushion

The invention provides a routing structure of a liquid crystal display panel and a manufacture method of the routing structure. The routing structure comprises a public curing cushion, a curing bus, at least one auxiliary curing cushion, and at least one curing auxiliary line, wherein the public curing cushion is used for receiving total public voltage; the curing bus is used for transmitting the total public voltage to one liquid crystal display panel; each auxiliary curing cushion is used for receiving sub public voltage; each liquid crystal display panel in the rest liquid crystal display panels corresponds to an auxiliary curing cushion; each curing auxiliary cushion corresponds to a curing auxiliary line; the curing auxiliary line is connected with a curing bus, and is used for transmitting sub public voltage to each liquid crystal display panel in the rest liquid crystal display panels, so as to input different public voltage to each liquid crystal display panel. The routing structure of the liquid crystal display panel and the manufacture method of the routing structure can ensure that the alignment effect of each display panel is optimal.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal alignment agent for forming liquid crystal alignment film for light alignment, liquid crystal alignment film thereof, and liquid crystal display element with the same

InactiveCN103374355AIncreased sensitivityGood alignment effectLiquid crystal compositionsNon-linear opticsLiquid-crystal displayPolyamide

The present invention provides a liquid crystal alignment agent for forming a liquid crystal alignment film for light alignment, the liquid crystal alignment film thereof, and a liquid crystal display element with the same. According to the invention, the liquid crystal alignment agent comprises the components of: (A) polyamide acid with an optically reactive structure or a derivative thereof; and (B) polyamide acid which is obtained from dianhydride represented by a formula (1) and diamine as raw materials or a derivative thereof. Furthermore after the alignment film is formed, the component (A) and the component (B) are divided into two layers in the vertical direction.

Owner:JNC CORP +1

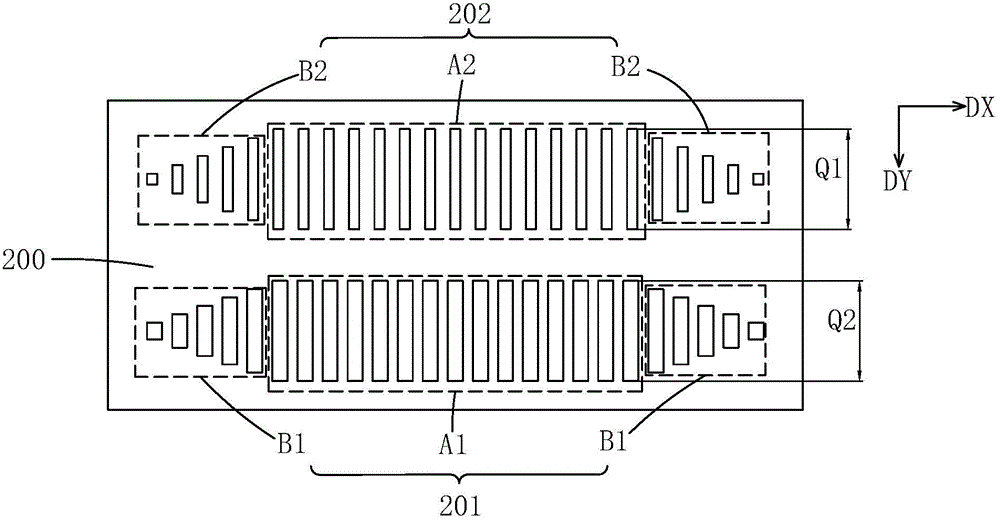

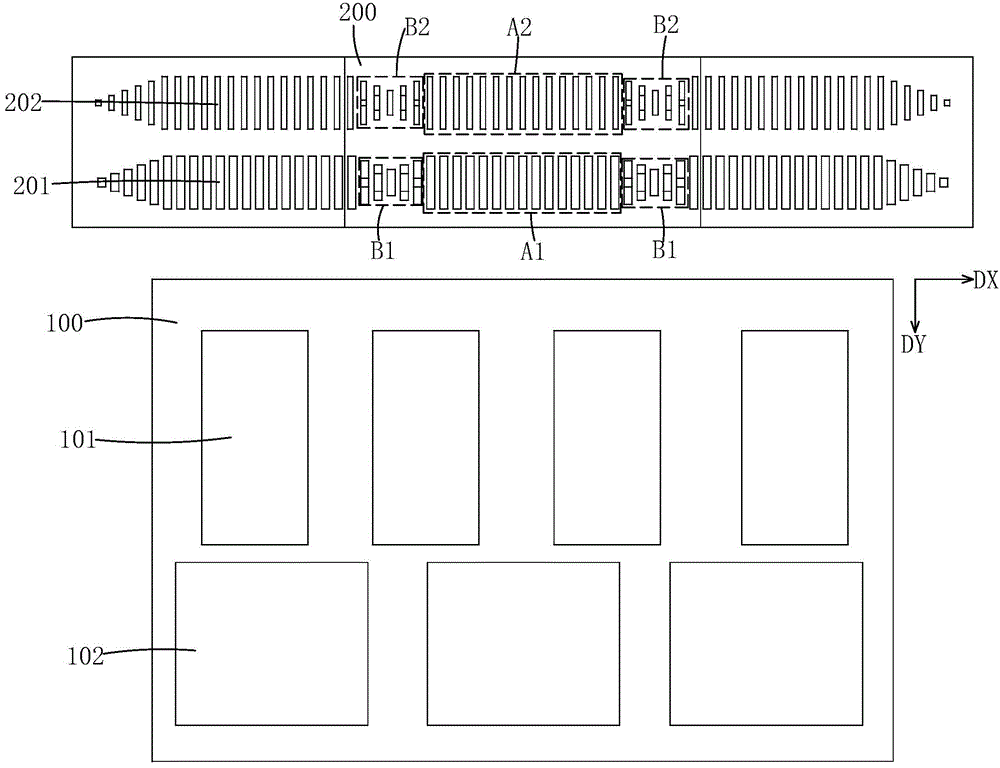

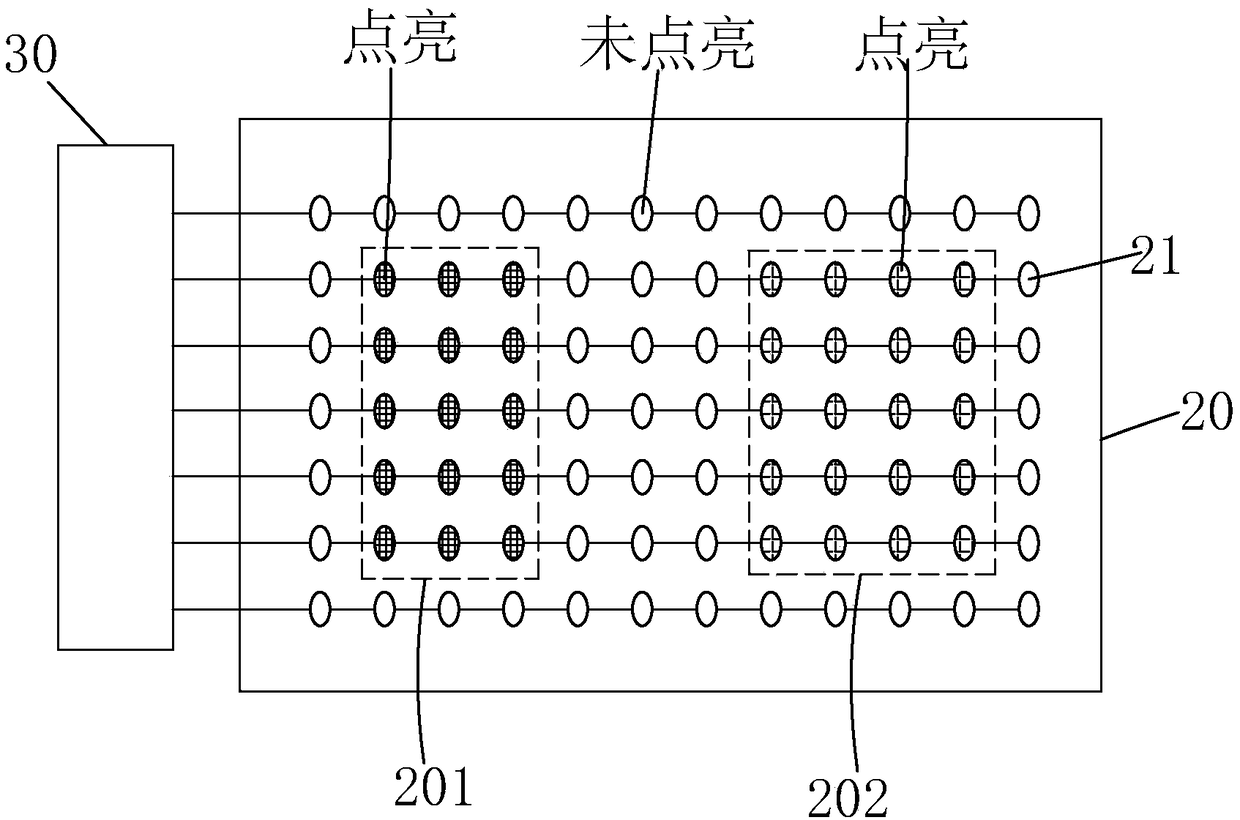

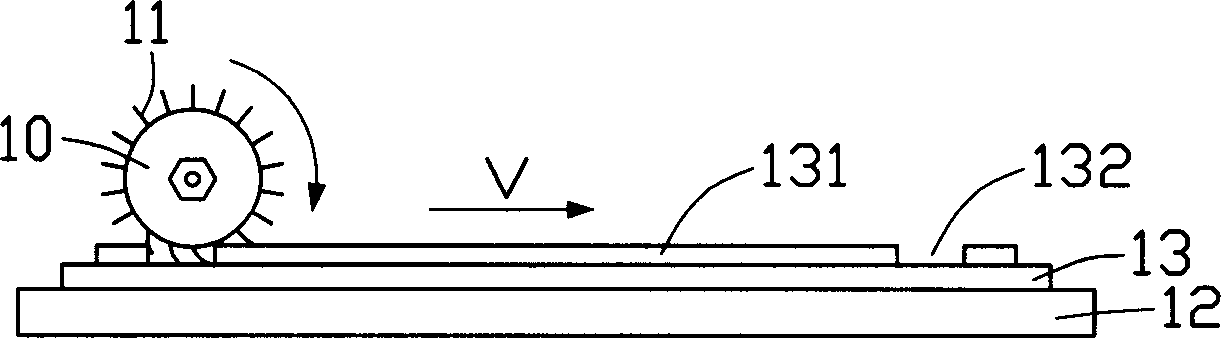

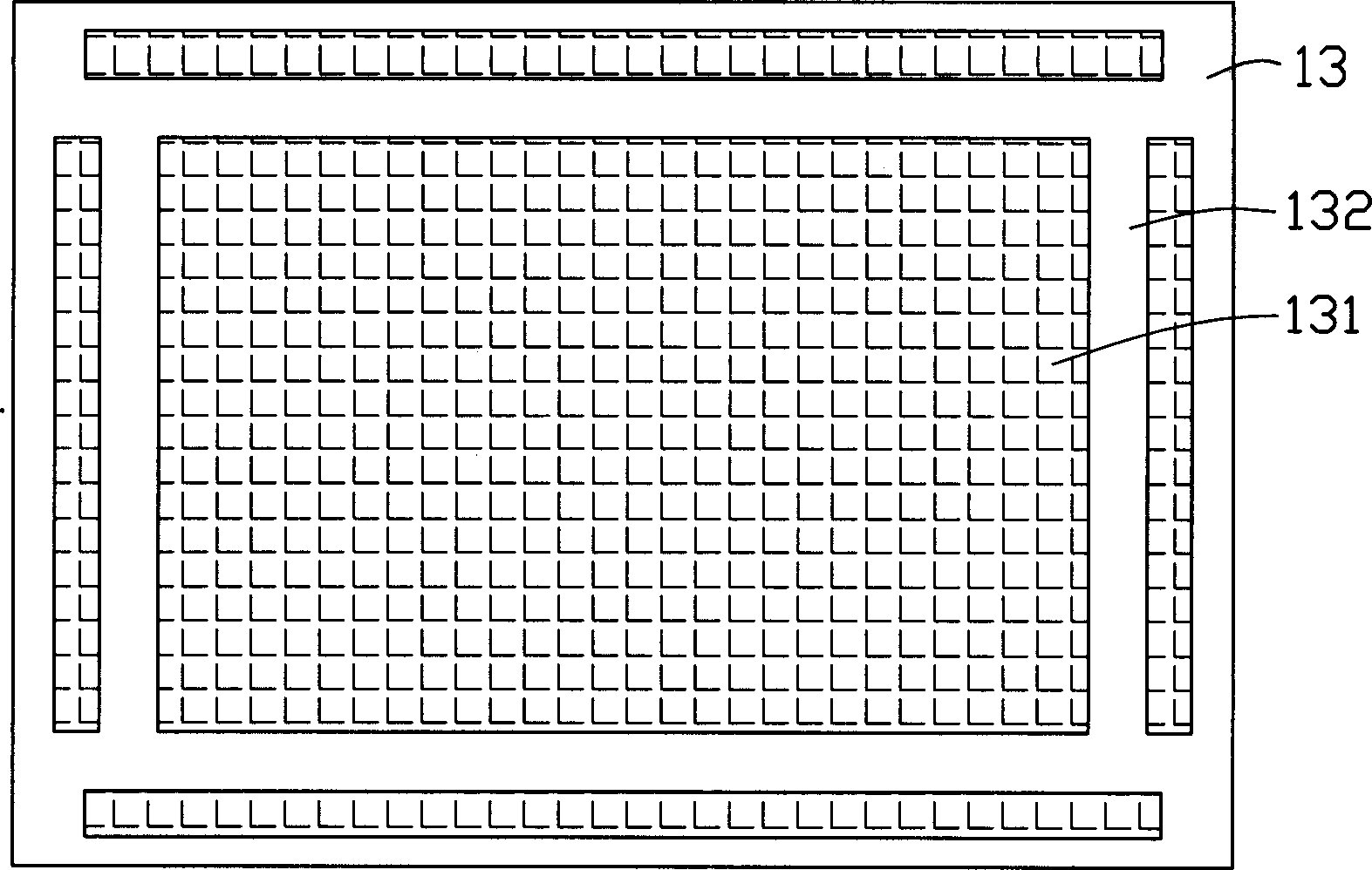

Photomask for photo alignment and photo-alignment method

ActiveCN104965388AImprove alignmentAvoid mura problemsPhotomechanical exposure apparatusMicrolithography exposure apparatusPhysicsPhotomask

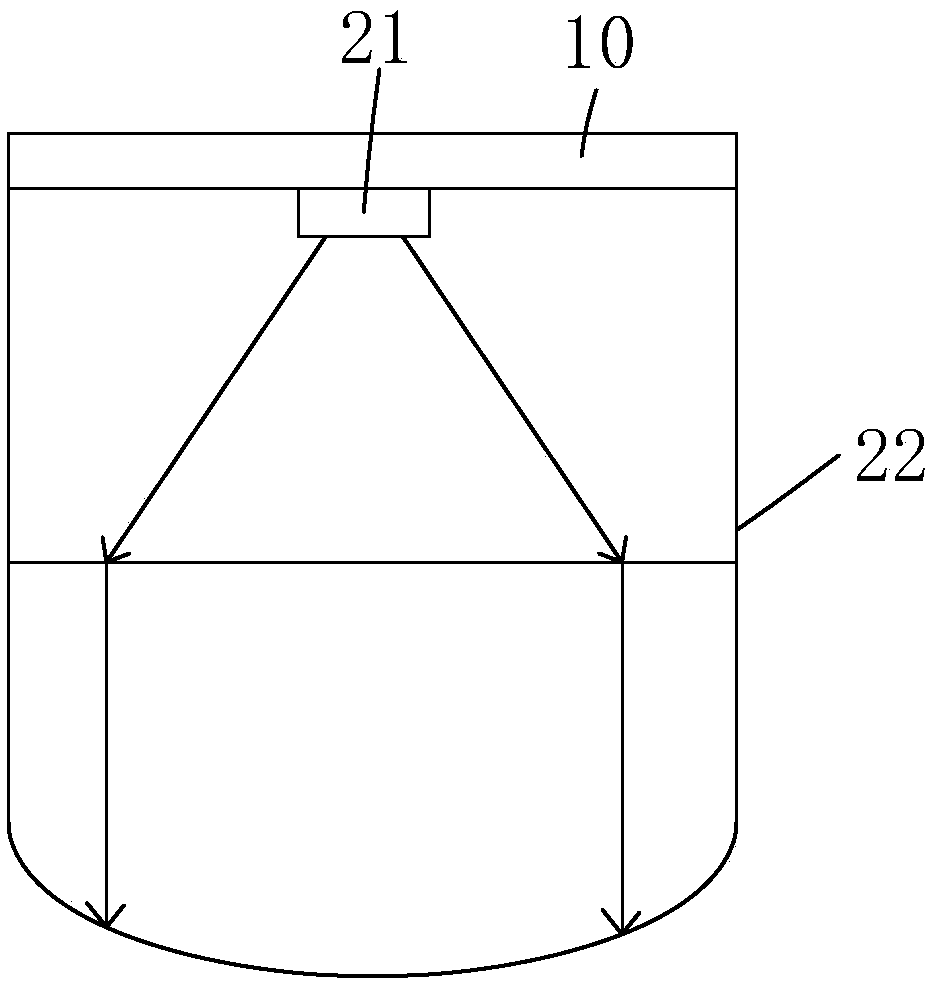

The invention provides a photomask for photo alignment and a photo-alignment method. The photomask for photo alignment comprises a photomask body (2) and a plurality of light-transmitting patterns arranged on the photomask body (2), wherein the plurality of light-transmitting patterns are arrayed along the first direction (DY) line by line and are arranged along the second direction (DX) perpendicular to the first direction (DY); each light-transmitting pattern comprises a non-overlapping domain and overlapping domains, and the non-overlapping domain is not overlapped with adjacent photomasks during use; the overlapping domains are respectively positioned on the left side and the right side of the non-overlapping domain and are overlapped with the adjacent photomasks during use; the first direction (DY) is the translation forward direction of the photomask when the phototmask is used for exposure and alignment; one ends, towards the first direction (DY), of the light-transmitting patterns positioned in the overlapping domains are aligned to one ends, towards the first direction (DY), of the light-transmitting patterns positioned in the non-overlapping domain, so that the alignment effect can be improved, and the mura problem due to the fact that the unexposed domains or insufficiently-exposed domains exist when MMG products are aligned is avoided.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

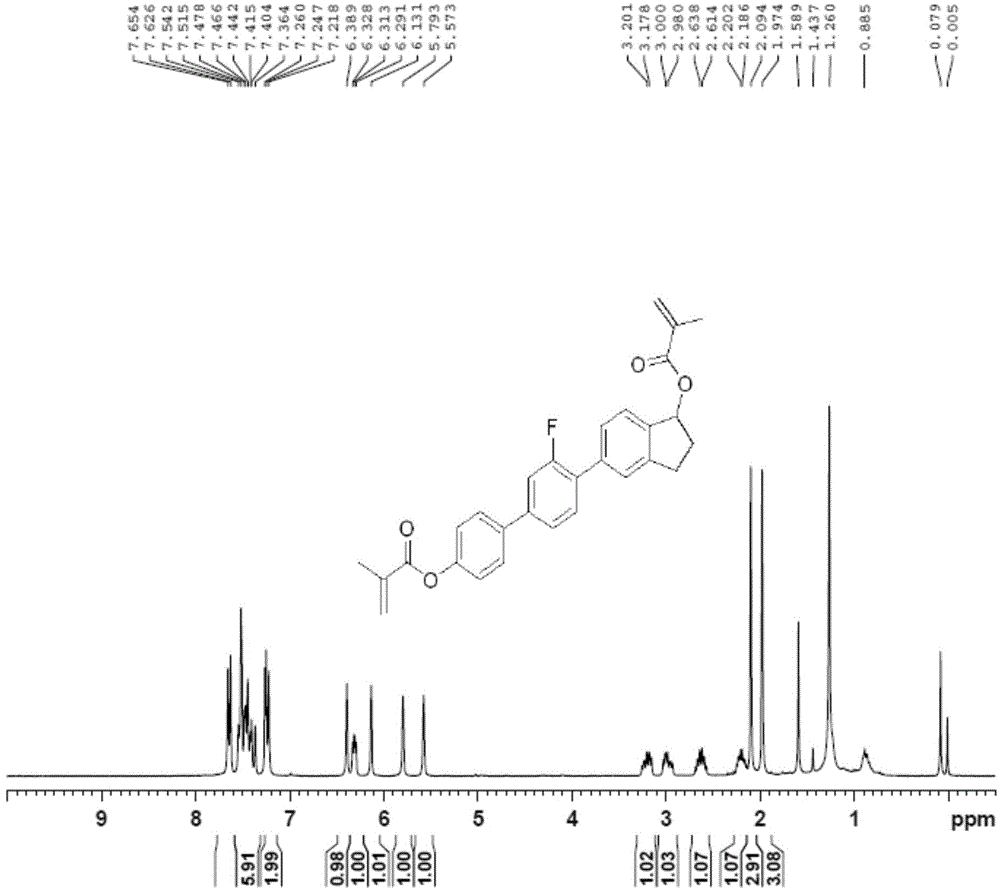

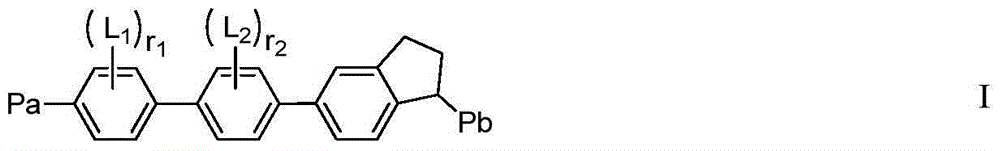

Polymerizable compound and its application in optical anisotropic body and liquid crystal display element

ActiveCN104557545AFully aggregatedImprove solubilityLiquid crystal compositionsOrganic chemistryCrystallographySolubility

The invention relates to a polymerizable compound with general formula I, also provides a polymerizable liquid crystal composition containing the polymerizable compound and a liquid crystal display element containing the polymerizable compound, and especially provides a liquid crystal display element used for PS or PSA (polymer stabilized or polymer stably-aligned) liquid crystal displays. The polymerizable liquid crystal compound has the advantages of good solubility, good orientation effect, fast polymerization rate, complete polymerization and low residue, so the bad display problem can be greatly improved.

Owner:JIANGSU HECHENG DISPLAY TECHCO

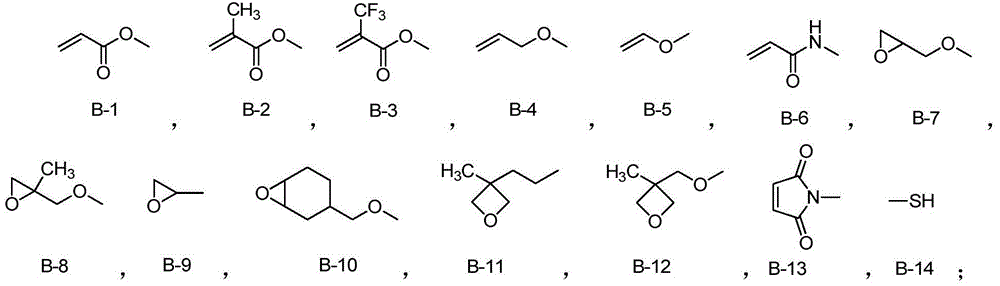

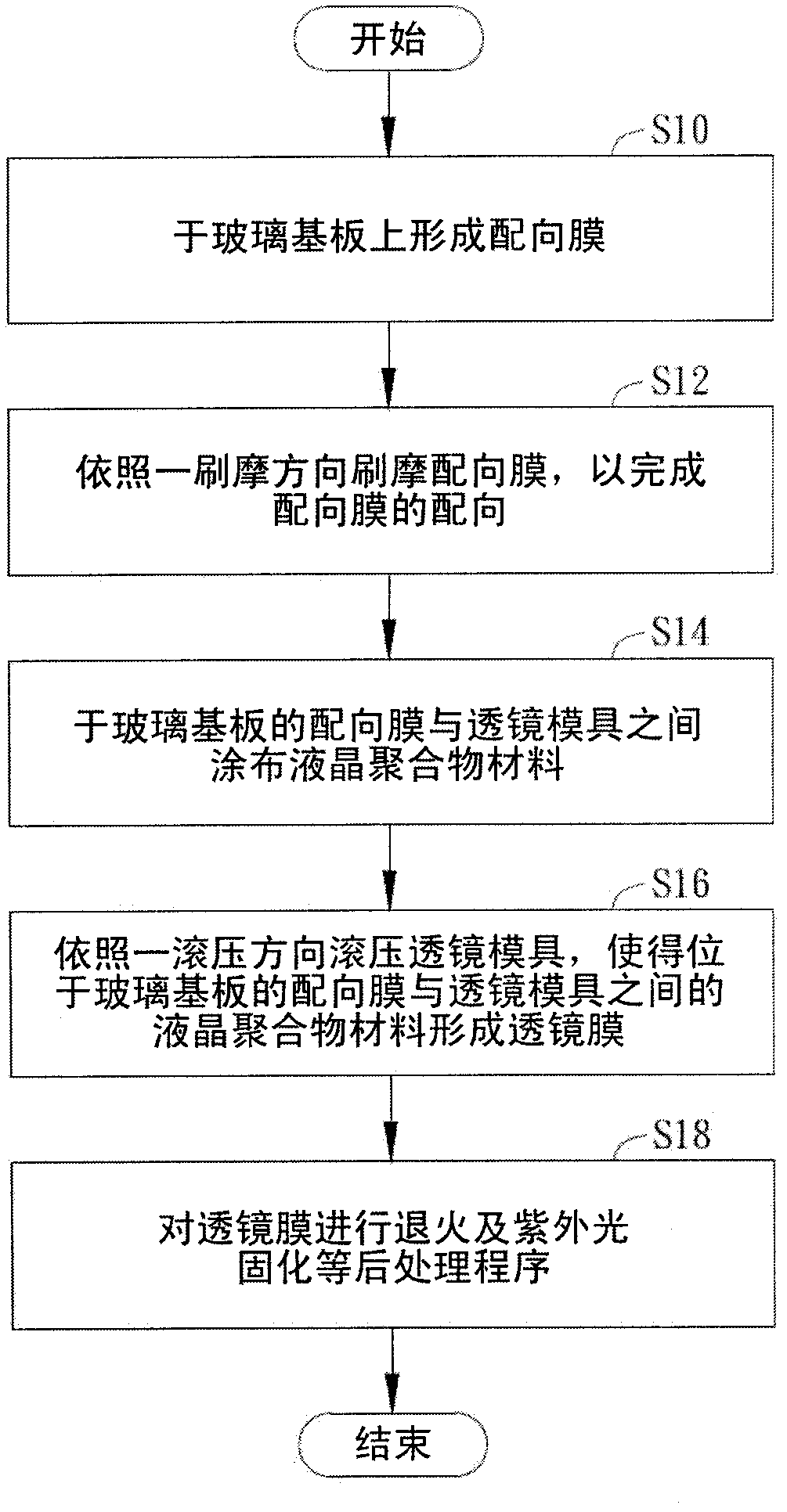

Lens membrane and manufacturing method thereof

InactiveCN102323694AGood alignment effectGood glasses-free 3D display effectStatic indicating devicesNon-linear opticsPolymerLiquid crystal molecule

The invention discloses a lens membrane and a manufacturing method thereof. The lens membrane manufacturing method comprises the steps of forming an orientation configuration membrane on a glass substrate, polishing and brushing the orientation configuration membrane according to a polishing and brushing direction, coating a liquid crystal polymers material between the orientation configuration membrane of the glass substrate and a lens mold, rolling the lens mold according to a rolling direction to make the liquid crystal polymers material form the lens membrane. A plurality of liquid crystal molecules of the lens membrane are arranged towards the polishing and brushing direction under the effects of the orientation configuration membrane, the lens membrane is cooperated with a basement panel possessing a polarization direction to be operated in a liquid crystal display device, and an included angle between the polishing and brushing direction and the polarization direction is less than 15 degrees.

Owner:AU OPTRONICS CORP

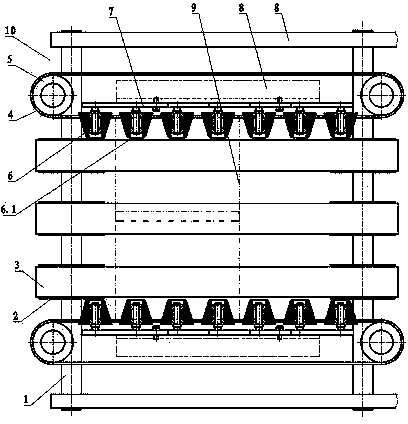

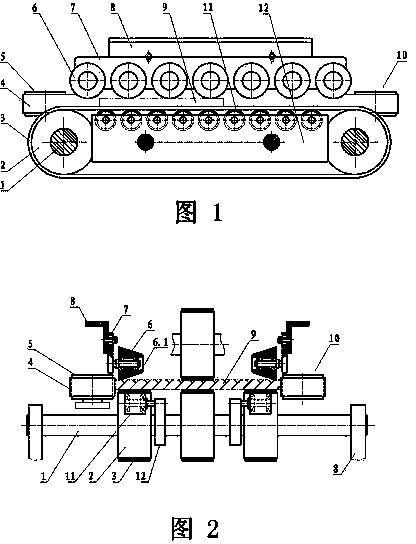

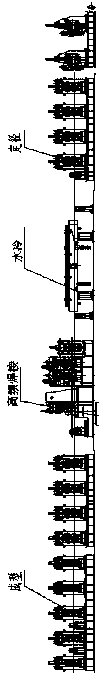

Straight seam welding special-shaped steel pipe forming process and mold changing apparatus for automobile anti-collision beam

The invention relates to a straight seam welding special-shaped steel pipe forming process for an automobile anti-collision beam. The straight seam welding special-shaped steel pipe forming process for the automobile anti-collision beam comprises the following steps of: (1) uncoiling, unrolling a steel strip coil; (2) flattening, flattening the unrolled steel strip and conveying the flattened steel strip to the next station; (3) flat cutting and butt welding, flat cutting a head portion and a tail portion of the flattened steel strip respectively, and butt welding a tail of the steel strip material after the flat cutting with a head of the next steel strip material after the flat cutting; (4) pre-storing, feeding the butt welded steel strip into a movable sleeve storage bin; (5) forming, conveying the steel strip in the movable sleeve storage bin to a forming machine, and gradually bending into a tube blank to be welded according to a certain sequence; (6) high-frequency welding, pressing the opposite ends of the tube blank to form a certain opening angle, and then to perform high-frequency welding; (7) Water cooling, cooling the high-frequency welded steel tube to room temperatureby spraying; (8) special-shaped gradient sizing, sizing the water-cooled steel tube by a sizing ; (9) profile machining, cutting the sized steel tube into specific lengths.

Owner:山东华舜重工集团有限公司

Photosensitive resin compsition

InactiveCN101178541AGood alignment effectExcellent voltage retention characteristicsStatic indicating devicesPhotomechanical apparatusLiquid crystalVoltage

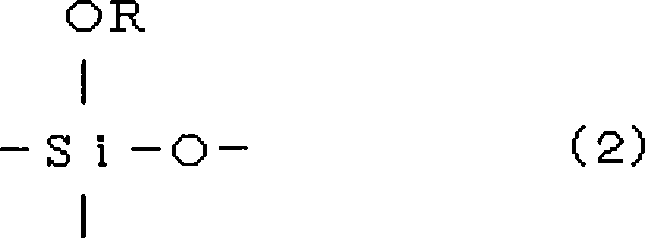

The invention provides a photosensitive resin composite for LCD element. The composite has great alkali developing property, and when the composite is solidified, the liquid crystal alignment and voltage holding property are both excellent. The photosensitive resin composite, capable of developing in alkali condition for LCD element, includes: hydrophilic resin(A) with (methyl) acroloyl and carboxylic; polysiloxane(B); and free radical polymerization initiator(C). The aforesaid polysiloxane(B) is better to be with two or more hydrolytic alkoxyl.

Owner:SANYO CHEM IND LTD

Carton correction pressing and pasting device

InactiveCN103991244ADimensionally stableThe horizontal dimension is limited and correctedContainer making machineryPulp and paper industryFolding carton

The invention discloses a carton correction pressing and pasting device. The carton correction pressing and pasting device comprises a rack, a paper conveying shaft, paper conveying wheels fixedly connected to the paper conveying shaft, paper conveying belts surrounding the paper conveying wheels in a covering mode, and paper alignment devices arranged on the outer sides of the paper conveying belts. The paper alignment devices comprise paper alignment wheels which can rotate and paper aligning belts which surround the paper aligning wheels in a covering mode. The paper conveying wheels and the corresponding paper conveying belts and paper alignment devices are respectively arranged in two sets. The two sets of paper conveying wheels and the corresponding paper conveying belts and paper conveying devices are symmetrically arranged. A row of paper pressing wheels are arranged at the positions, above the corresponding paper conveying belt, of the inner side of each paper alignment device, the paper pressing wheels are in the shape of circular truncated cones, the edges of the top faces of the paper pressing wheels are round corners, the paper pressing wheels can be arranged on a paper pressing wheel fixing plate in a rotating mode, the paper pressing wheel fixing plate is fixedly connected to the rack, and the distance between the paper pressing wheel fixing plate and the paper conveying belts can be adjusted. Folded cartons can be transversely corrected and aligned, paper faces are smooth after correction, and the carton correction pressing and pasting device is widely applied to carton forming machines.

Owner:东台江渝包装材料有限公司

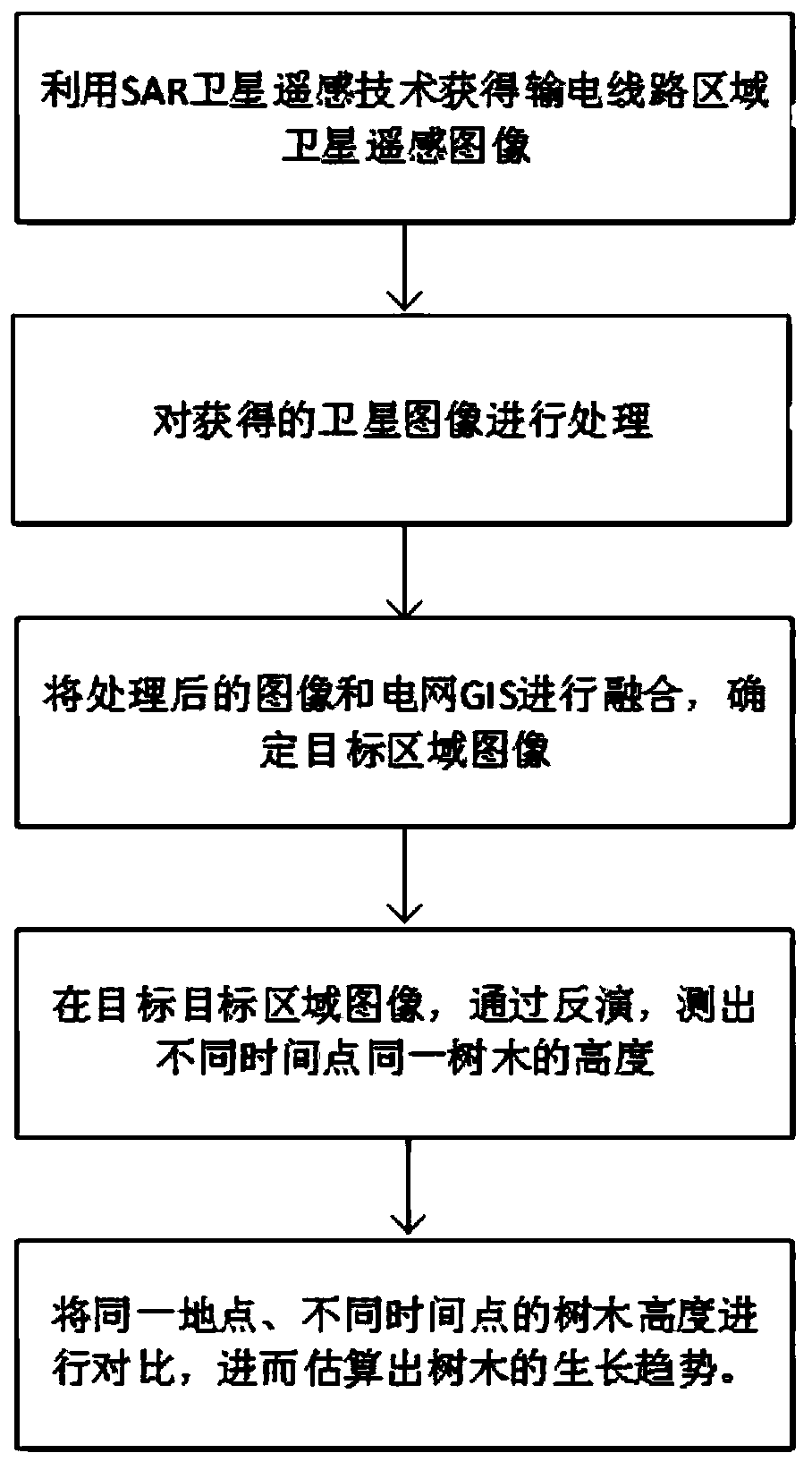

Method for predicting tree growth trend in power transmission line area based on satellite technology

PendingCN111259835ASafe and stable operationGood alignment effectData processing applicationsCharacter and pattern recognitionSatellite technologyInformation support

The invention discloses a method for predicting a tree growth trend in a power transmission line region based on a satellite technology. The method comprises the steps of obtaining a satellite remotesensing image of the power transmission line region by utilizing an SAR satellite remote sensing technology; processing the obtained satellite image; fusing the processed image with a power grid GIS,and determining a target area image; measuring the height of the same tree at different time points in the target area image through inversion; and comparing the heights of the trees at the same placeand different time points to estimate the growth trend of the trees. A tree growth trend monitoring system based on satellite wide-area remote sensing is constructed, basic information support is provided for tree barrier inspection of the power transmission line, the alignment of the inspection line is greatly improved, and safe and stable operation of the power transmission line is ensured.

Owner:YUNNAN POWER GRID CO LTD ELECTRIC POWER RES INST

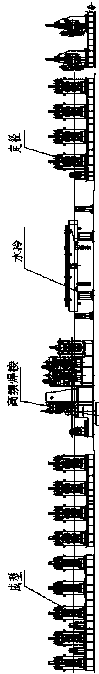

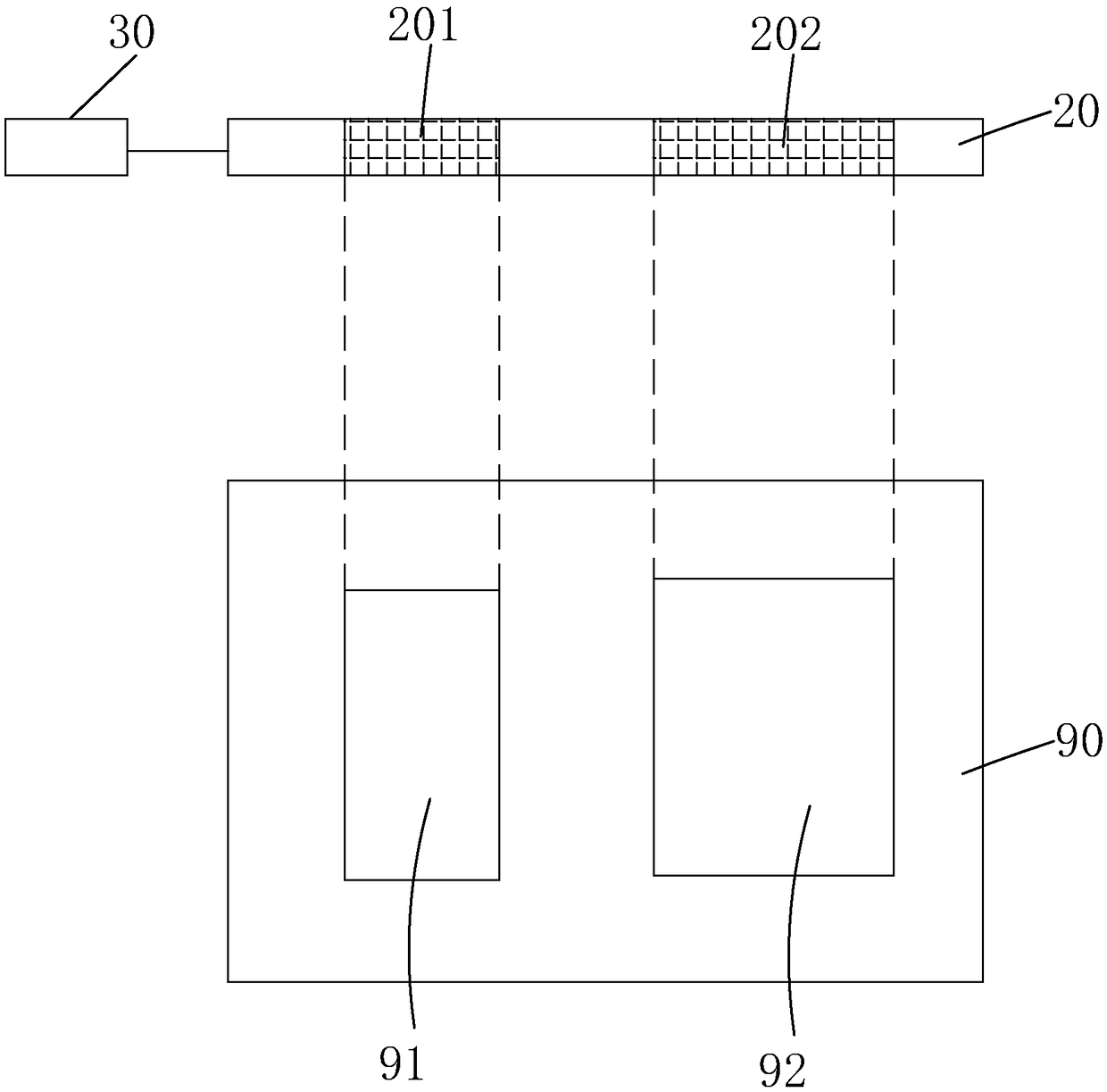

Illumination device and method for orienting MMG panel

The invention provides an illumination device and a method for orienting an MMG panel. The illumination device is used for orienting the MMG panel, and LED point light sources which are distributed inan array cooperate with a focusing collimating lens system to form a direct type collimation plane light source. In use, the illumination area, the illumination intensity and the illumination time ofthe collimation plane light source can be controlled according to the detailed design of the MMG panel, and a good orienting effect on liquid crystal display panel units with different designs on theMMG panel can be achieved.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

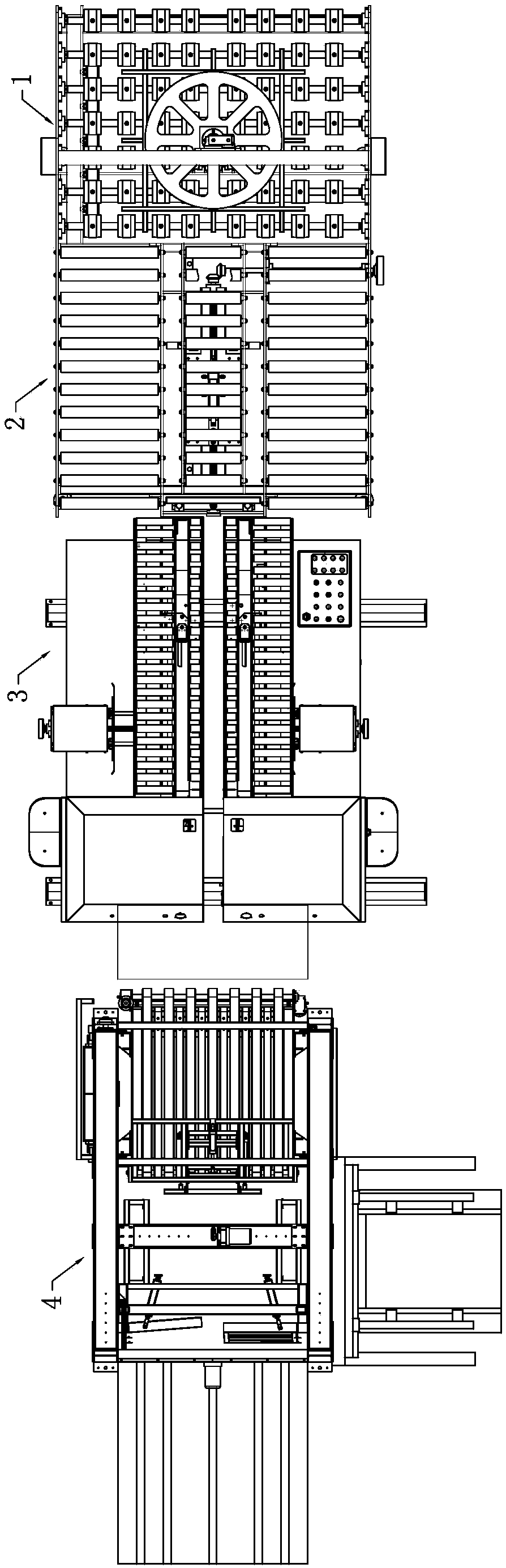

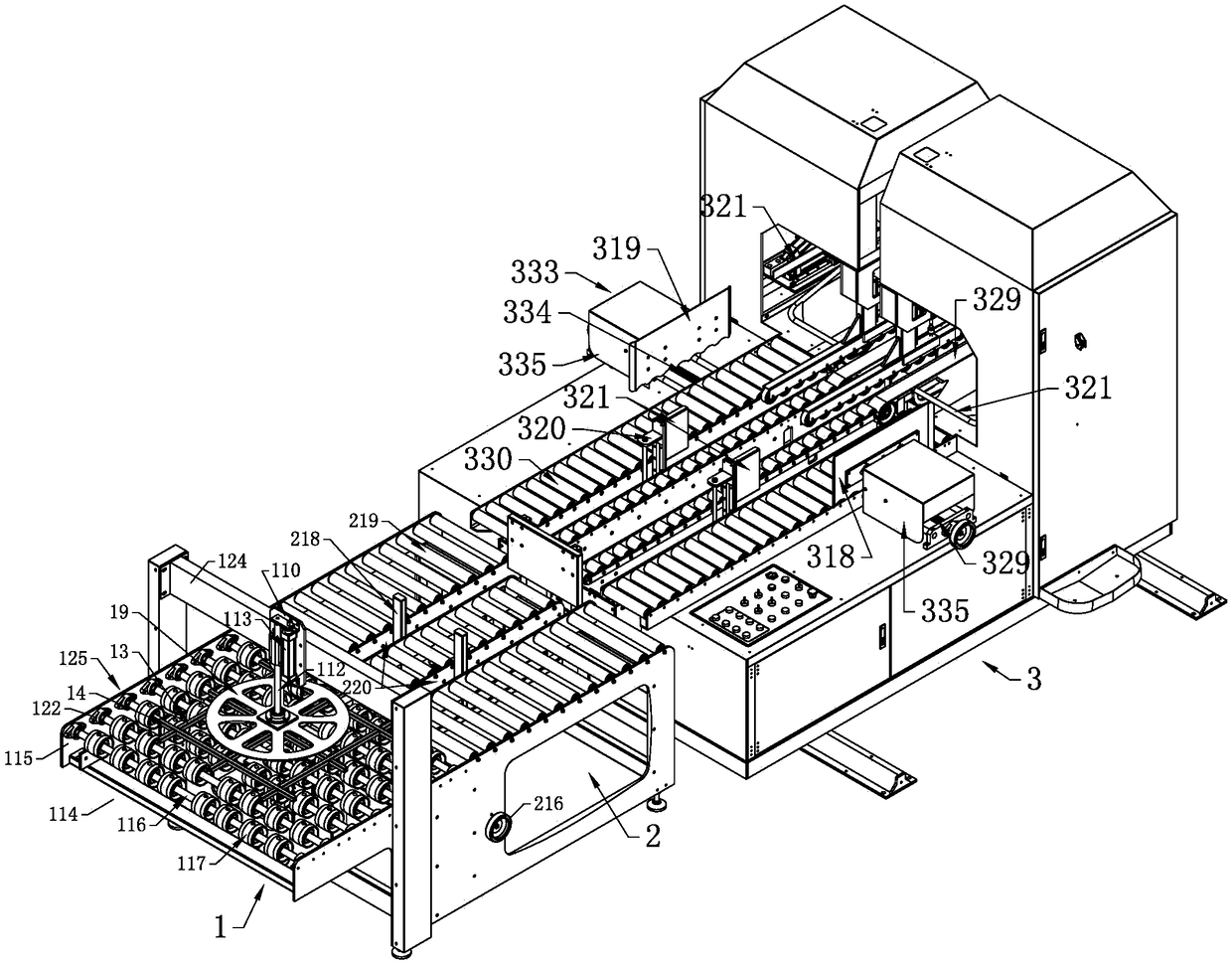

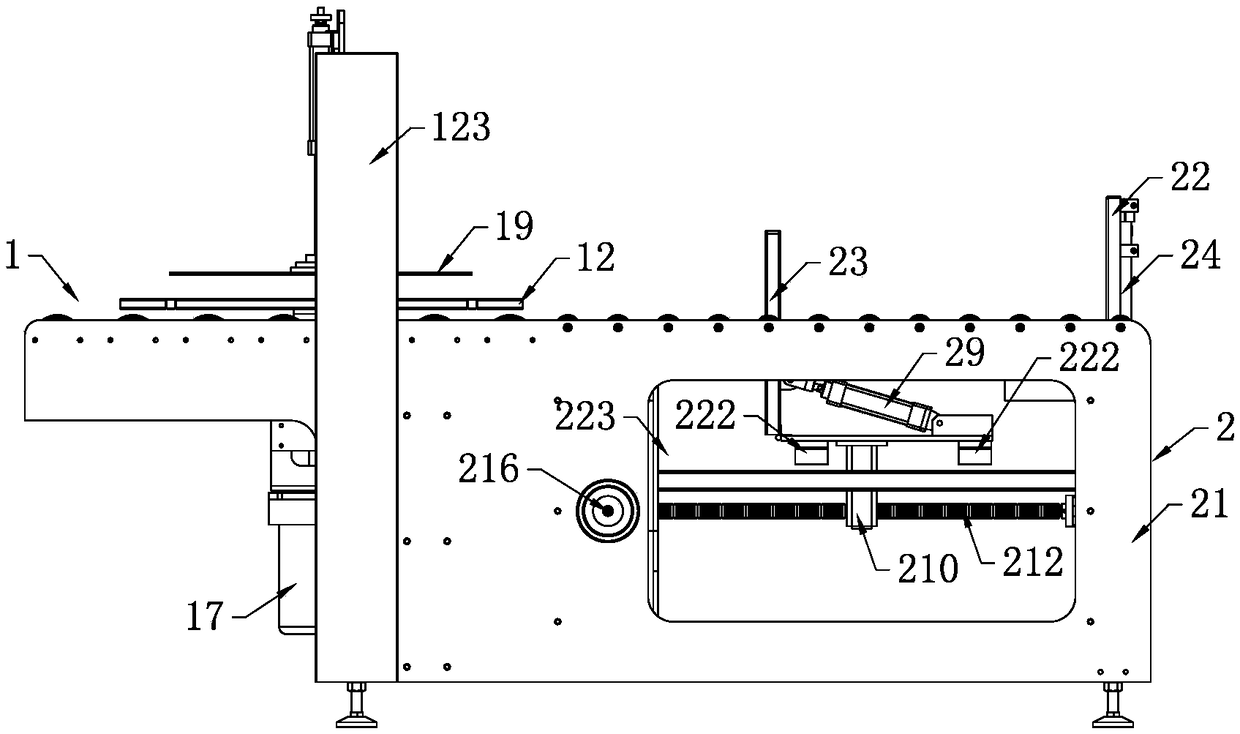

Full-automatic carton packing and stacking system

InactiveCN109398806AImprove delivery efficiencySimple structureBundling machine detailsStack machineCarton

The invention discloses a full-automatic carton packing and stacking system. The full-automatic carton packing and stacking system comprises a packing machine and a stacking machine; the packing machine comprises a steering conveying unit, a front-and-back flush conveying unit and a packing unit which are connected in sequence; the stacking machine comprises a carton input unit and a stacking unitwhich are sequentially arranged, and further comprises a tray input unit arranged on the side part of the stacking unit; and the steering conveying unit is used for outputting the two stacks of paperboxes placed on the steering conveying unit in a front-and-back mode; and the front-and-back flush conveying unit is used for carrying out input and front-and-back flush of the stacked paper boxes; the packaging unit is used for conveying cartons, left and right flush and packaging and outputting. The full-automatic carton packing and stacking system, the paper boxes can be automatically conveyed, packaged, stacked and output, achieves full automation of production, and has the advantages of being high in working efficiency, low in cost, good in packing and stacking quality and the like.

Owner:侯象洋

Special-shaped steel tube forming technology and mold replacement device for semitrailer fence

InactiveCN108526241AGuaranteed continuous productionIncrease productivityShaping toolsButt weldingButt joint

The invention relates to a special-shaped steel tube forming technology for a semitrailer fence. The special-shaped steel tube forming technology for the semitrailer fence comprises the steps of first, uncoiling, wherein steel strip rolls are unfolded; second, leveling, wherein unfolded steel strips are leveled, and are conveyed to a next station; third, end flattening and butt welding, wherein the head portion and the tail portion of one leveled steel strip are cut to be flattened, and the material tail of the steel strip with ends cut to be flattened and the material head of a next steel strip with ends cut to be flattened are welded together; fourth, beforehand storage, wherein the steel strips subjected to butt joint are sent into a loop storage silo; fifth, forming, wherein the steelstrips in the loop storage silo are sent to a forming machine, and are sequentially bent into tube blanks to be welded; sixth, high efficiency welding, wherein high efficiency welding is carried out after the two ends, in butt joint, of every two adjacent tube blanks are pressed to form a certain open angle; seventh, water cooling, wherein the steel tubes subjected to high efficiency welding are cooled to the room temperature in a spraying manner; eighth, special shape gradual sizing, wherein the steel tubes subjected to water cooling are sized through a sizing unit; and ninth, profile machining, wherein the sized steel tubes are segmented into steel tube bodies of specific lengths.

Owner:山东舜世高科实业有限公司

Substrate and LCD device using the same

ActiveCN1834734AGood alignment effectImprove adhesionStatic indicating devicesNon-linear opticsLiquid-crystal displayEngineering

The invention discloses is a substrate, comprising an active region, an edge region and a frame glue adhesion region between them, where the active region is coated with an aligning film layer, the frame glue adhesion region has fillings with close friction coefficient to that of the aligning film, and the aligning effect is better and the adhesion between the frame glue and the substrate can not be influenced. Besides, the invention provides a LCD using the substrate.

Owner:INNOCOM TECH SHENZHEN +1

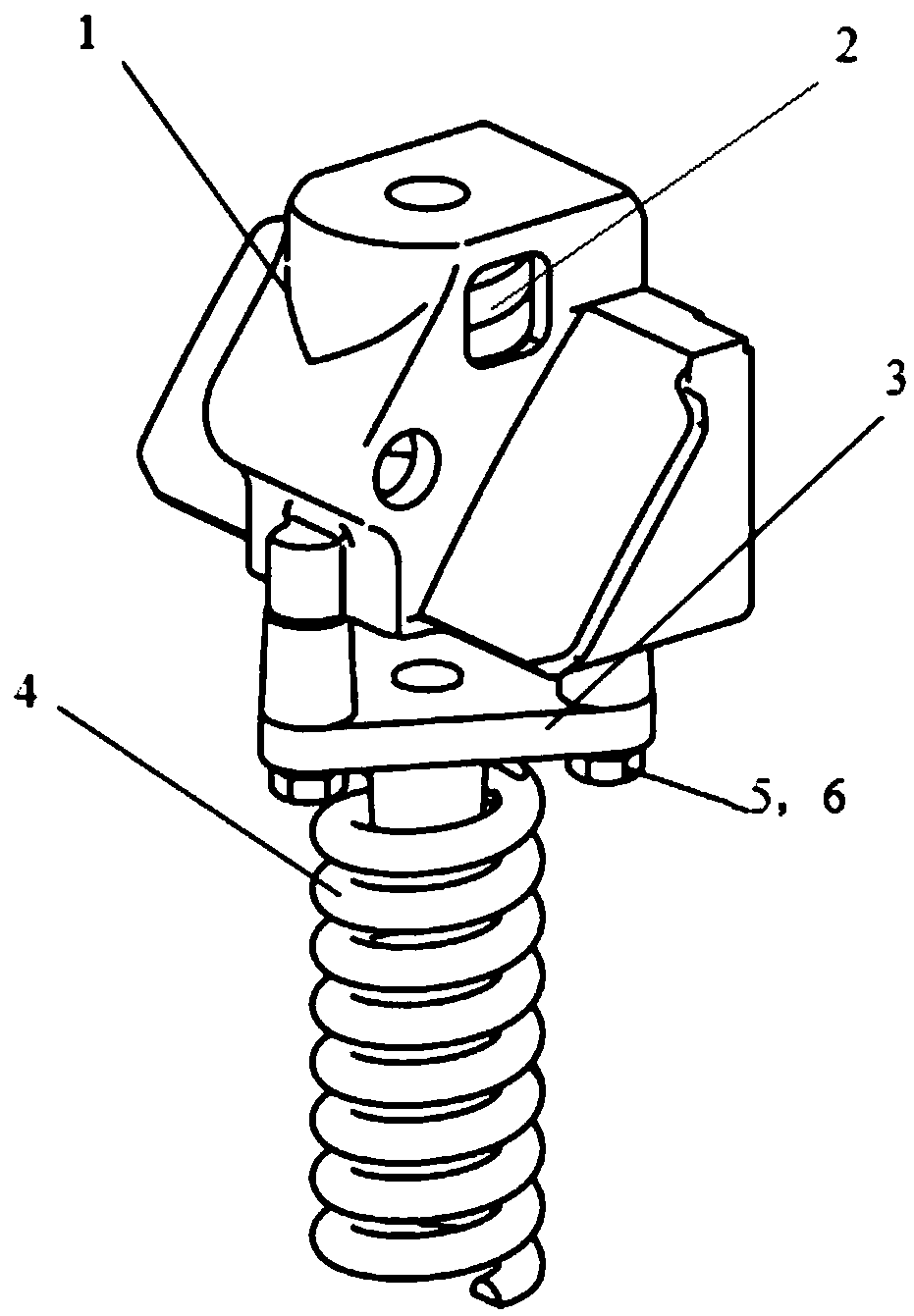

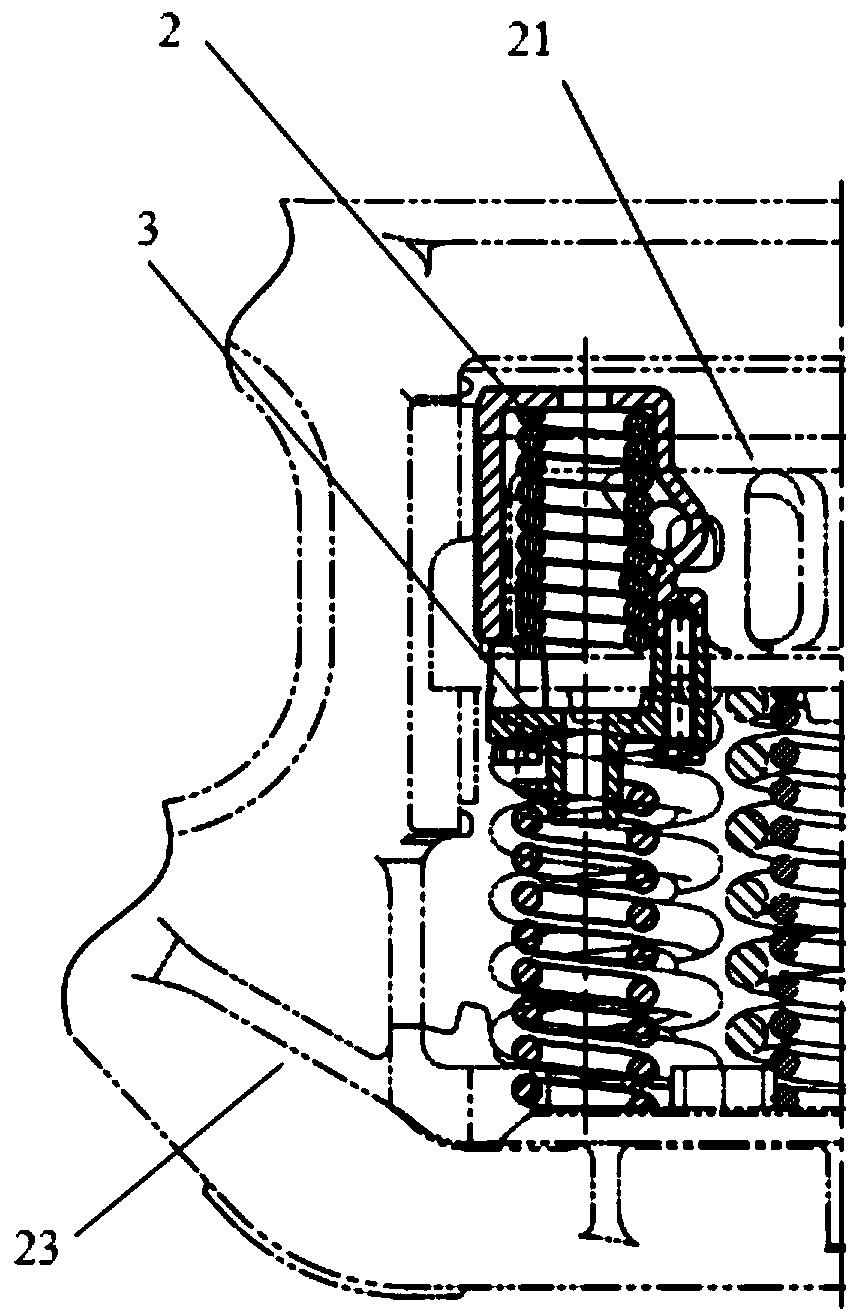

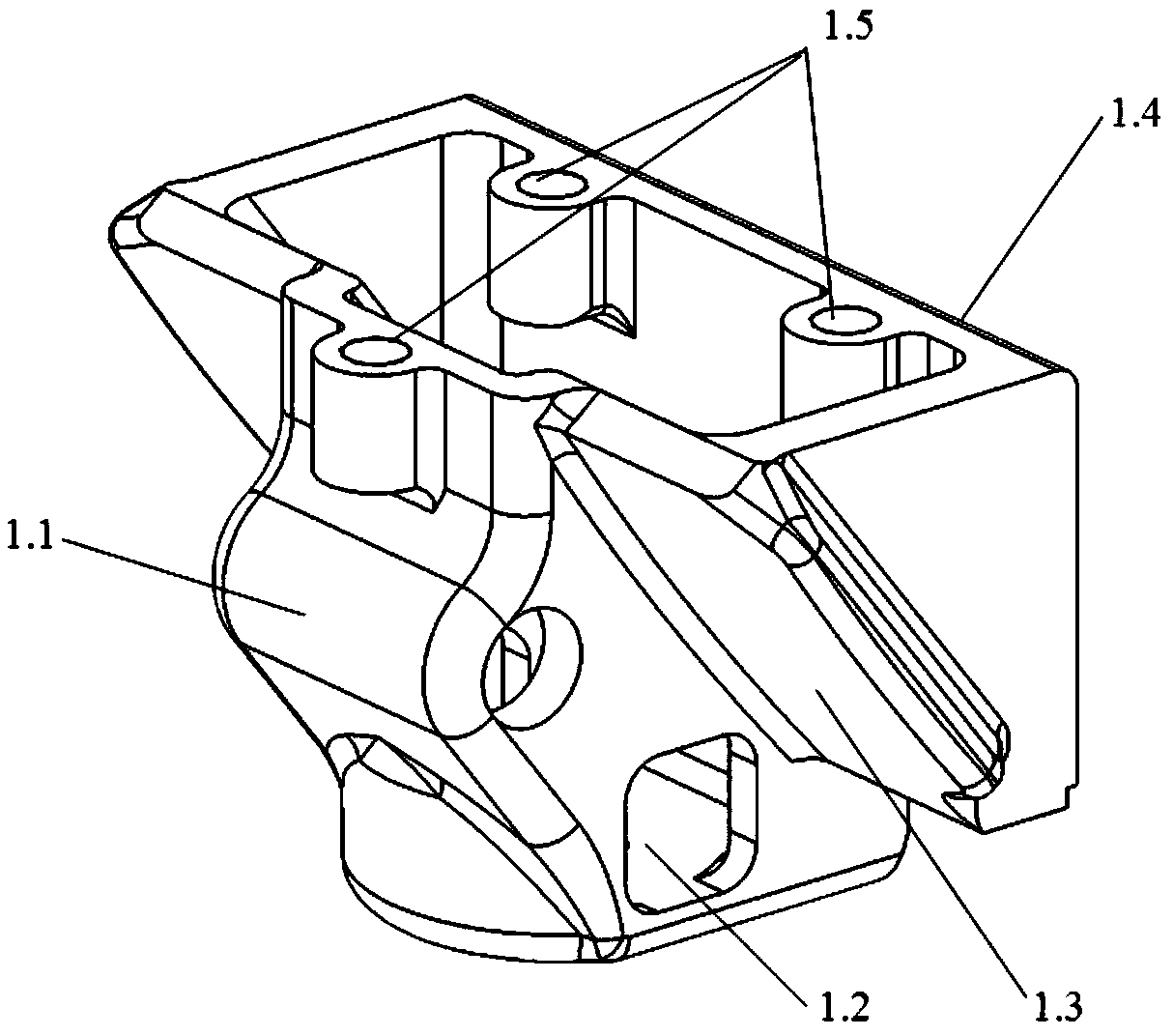

A railway freight car bogie vibration damping device which can provide composite vibration damping force

The invention discloses a railway freight car bogie vibration damping device which can provide composite vibration damping force. A large-body incline wedge vibration damping part is arrange on that upper plane of the bottom of the inclined wedge groove at the end of the bolster and a spring vibration damping part is arrange on the lower plane of the bottom of the inclined wedge groove at the endof the bolster, and the inclined wedge vibration damping part and the spring vibration damping part are connected through a guide seat. The inclined wedge vibration damping part is arranged on the bottom of the inclined wedge groove at the end of the bolster. As that contact friction area of the incline wedge is large, A low damping spring is arranged between that incline wedge and the side frame,the friction resistance of the vehicle at full load is increased, An upper damp spring and a low damper spring are used in different vertical spaces, the advantage of that invention are simple structure, Compact and easy to manufacture, installation and maintenance, Maintenance, both no-load and full-load damping performance stable characteristics, It also has the characteristics of better control bogie rhombus deformation ability and better snake movement stability, which will play an important role in improving and improving the technical performance and running quality of the three-piece bogie of railway freight cars, reducing the wear of vehicle parts, and reducing the cost of vehicle manufacturing, operation and maintenance.

Owner:CRRC MEISHAN

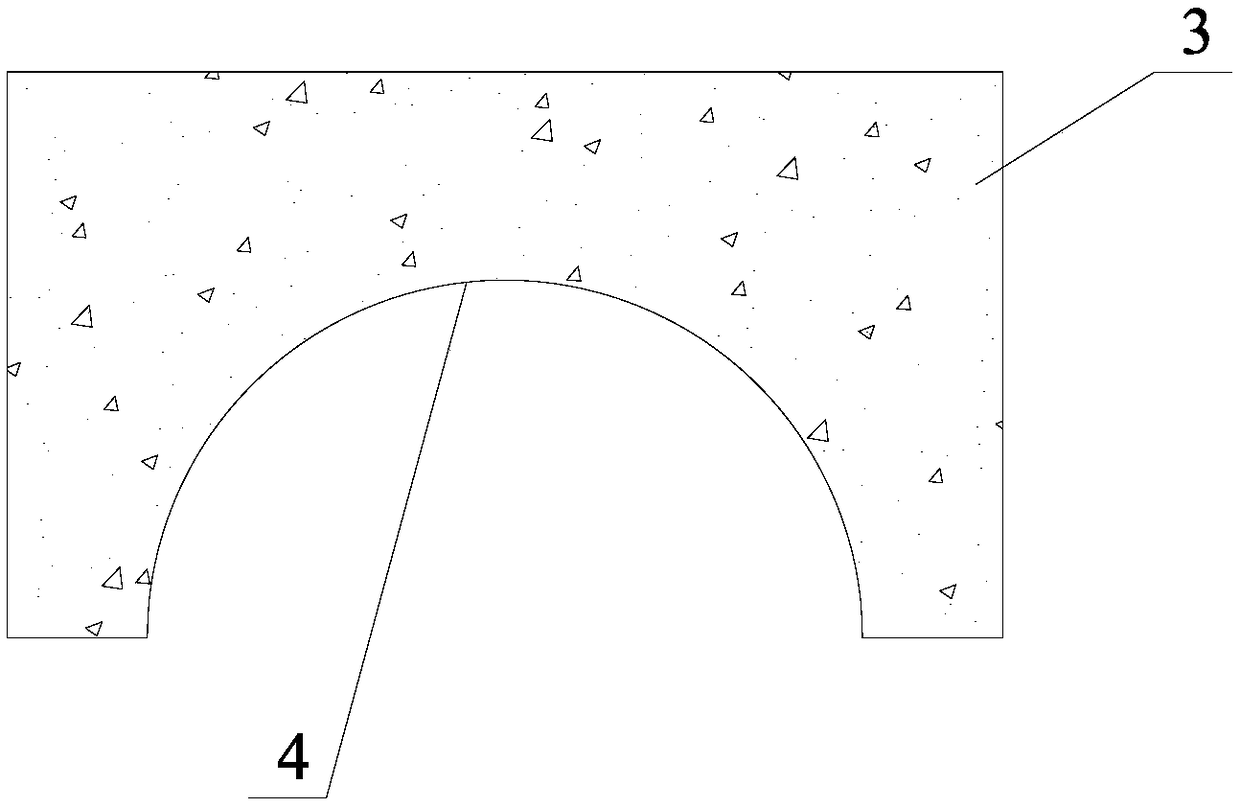

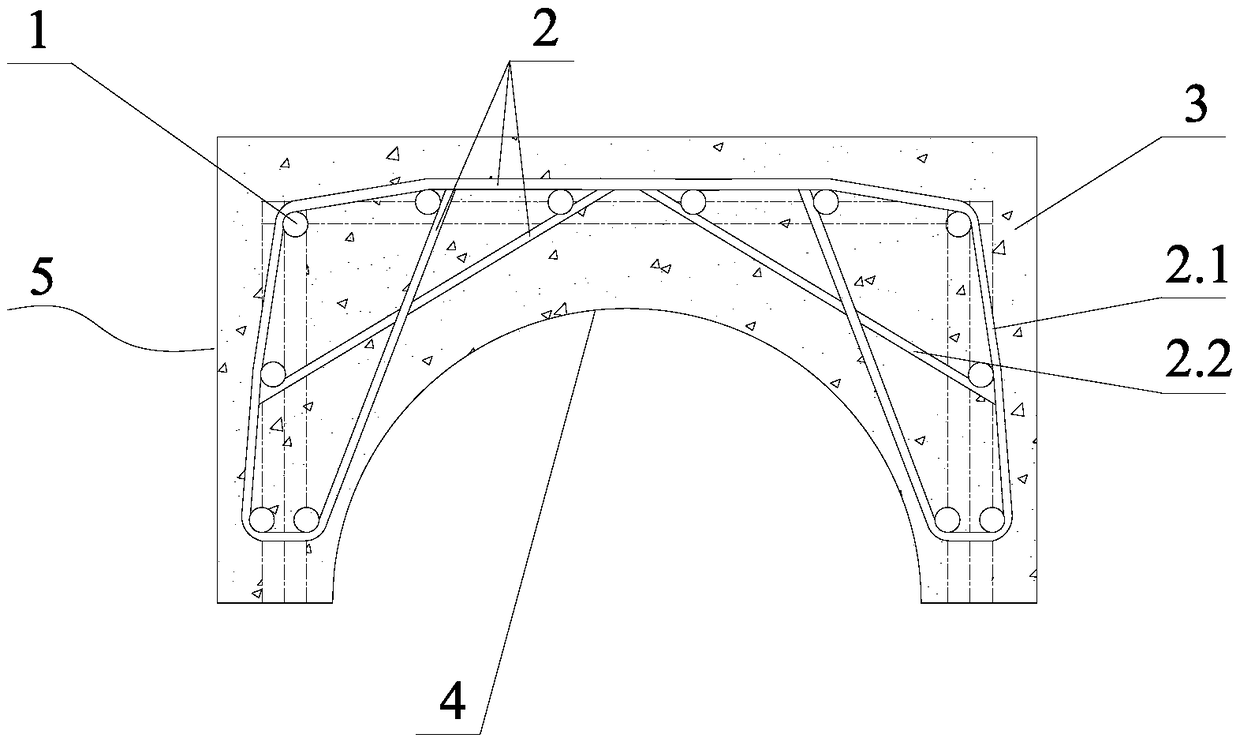

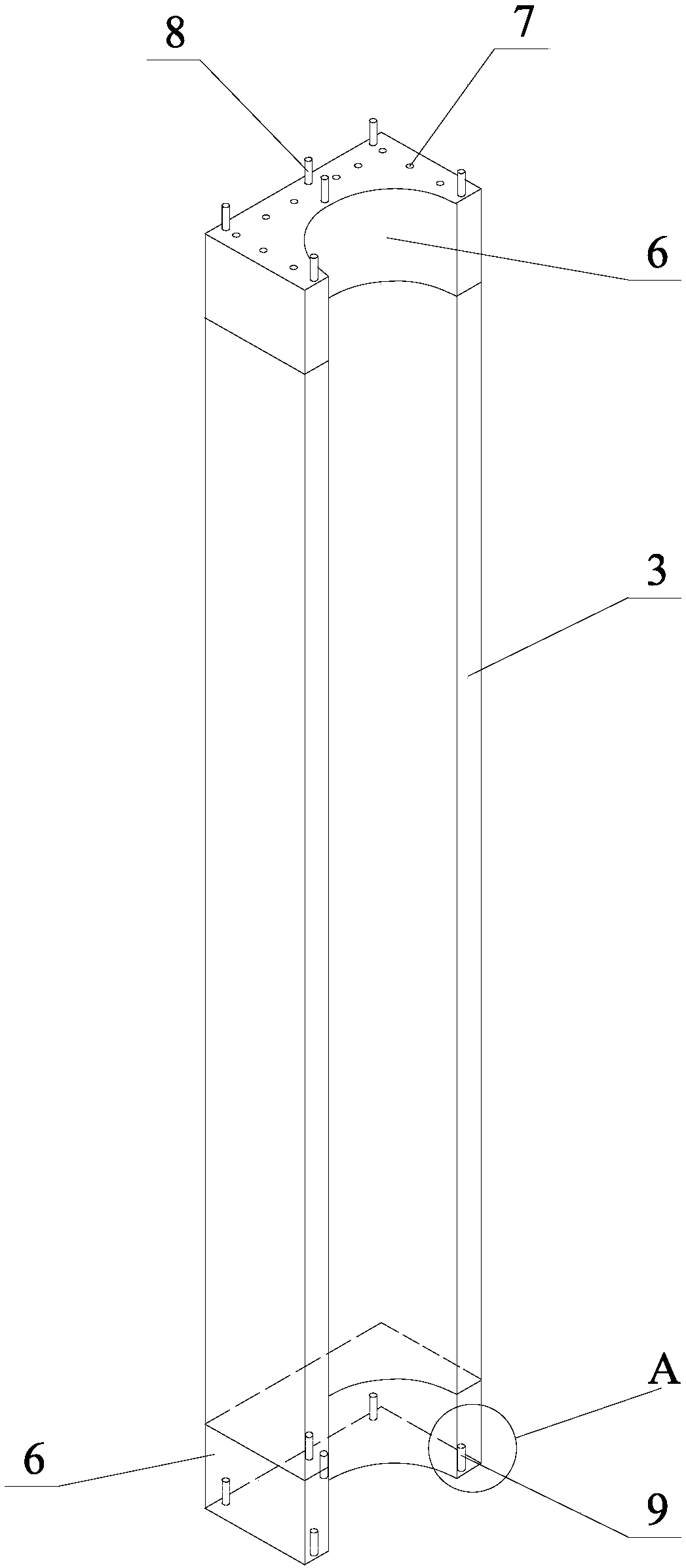

Supporting and protecting pile and composed supporting and protecting row pile

The invention discloses a supporting and protecting pile and a composed supporting and protecting row pile. The supporting and protecting pile comprises a precast concrete pile body with a reinforcingsteel bar cage composed of multiple vertical prestressed reinforcing steel bars and multiple transverse stirrups, and the cross section of the pile body is in a first rectangular shape with a first semicircular groove in one side. The supporting and protecting pile further comprises metal end plates at the two ends. Multiple through holes allowing the multiple vertical prestressed reinforcing steel bars to penetrate are formed in the metal end plates. Multiple guide insertion connection columns are arranged on one end plate, insertion connection blind holes which are in one-to-one correspondence with the multiple guide insertion connection columns are formed in the other end plate, horn mouth clamp rings with the large upper portions and the small lower portions are arranged in the holes,and each horn mouth clamp ring is composed of multiple metal elastic pieces. The long side of the supporting and protecting pile is close to the contact face of the foundation pit inner side around afoundation pit and the supporting and protecting pile and forms a ceaseless connection line extending in the length direction. The supporting and protecting pile and the composed supporting and protecting row pile have a small earth squeezing effect, are good in compactness, are large in contact area of the contact face of the foundation pit inner side around the foundation pit and the supportingand protecting pile, and are high in bending resistance.

Owner:浙江华展工程研究设计院有限公司

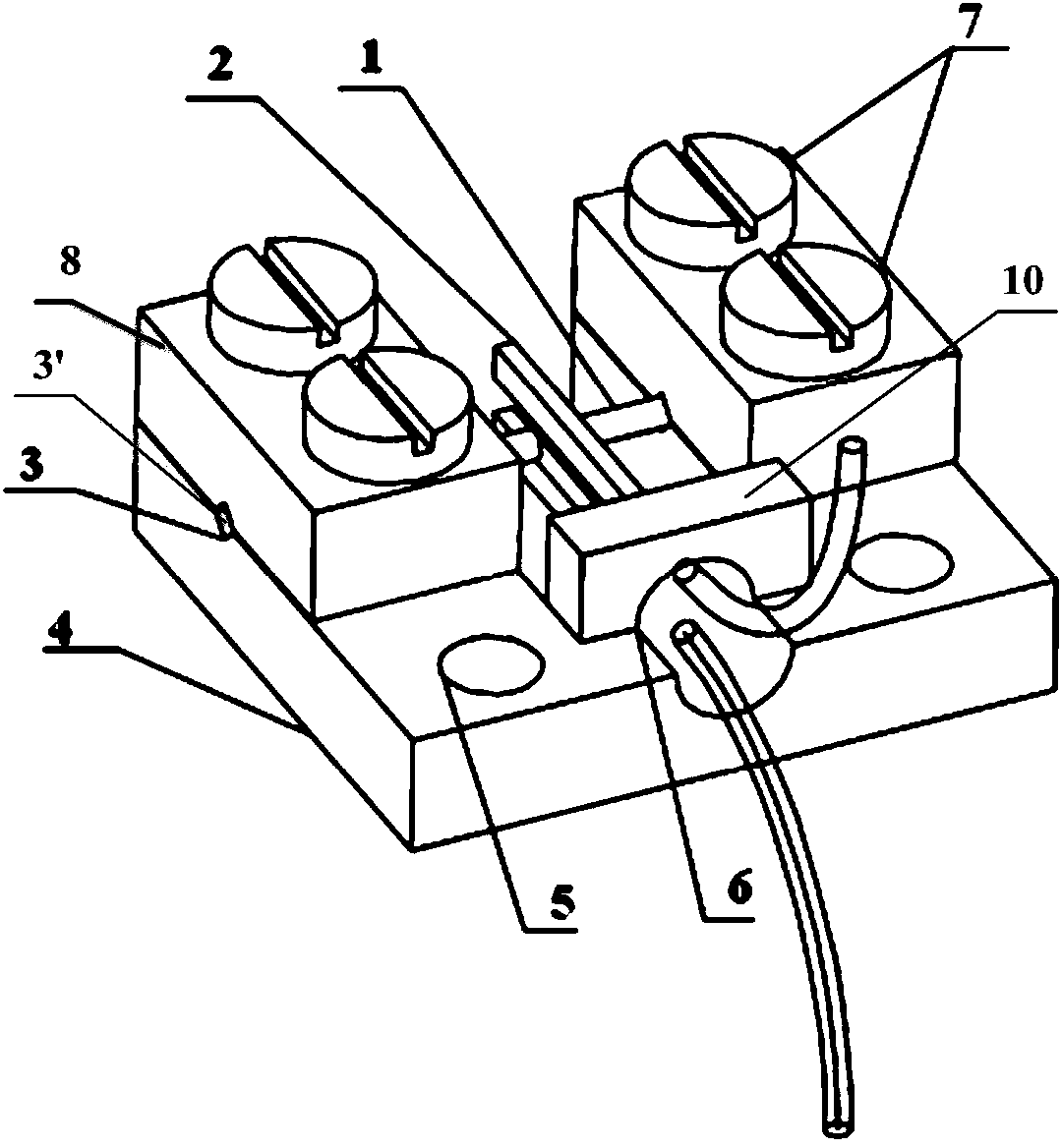

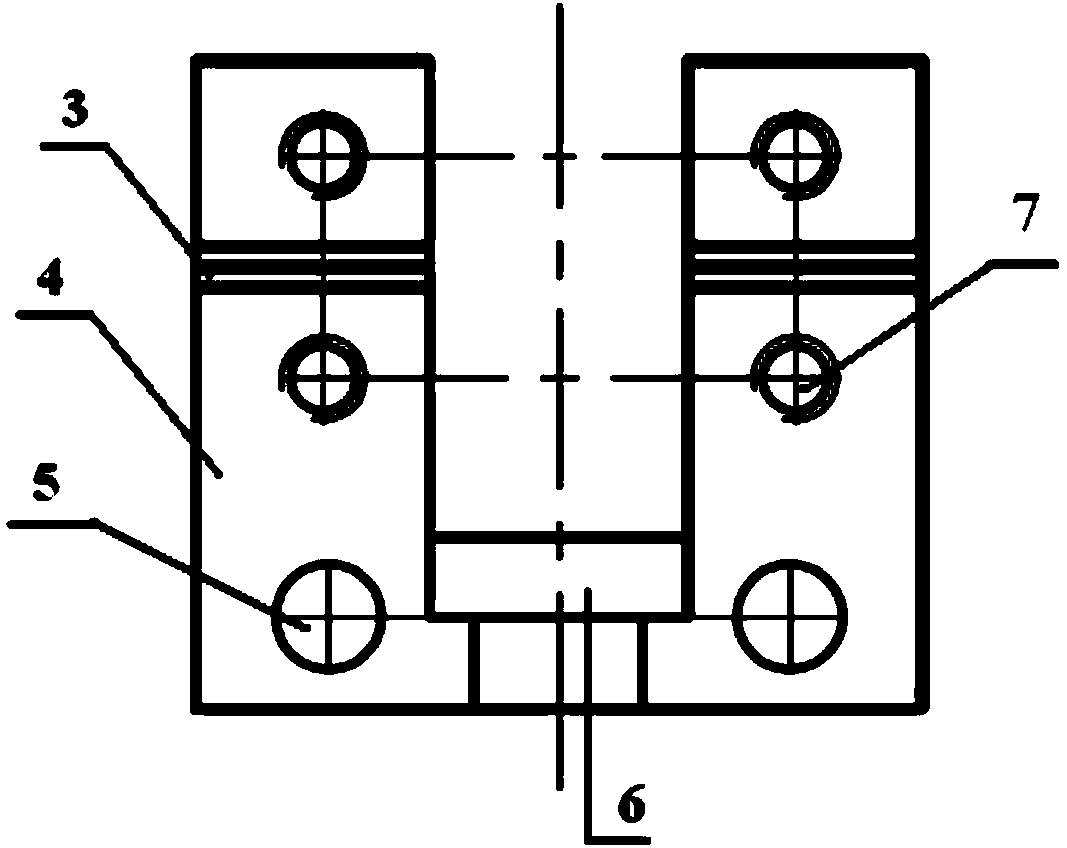

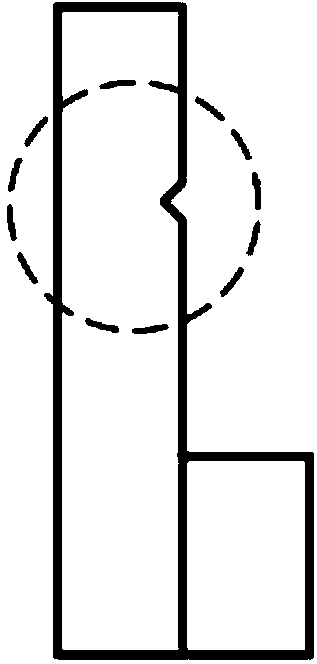

Enhancement type quartz tuning fork encapsulating device

ActiveCN103795367AEasy to fixIncreased Resonance Enhancement StrengthImpedence networksSignal-to-noise ratio (imaging)Miniaturization

The invention relates to an enhancement type quartz tuning fork encapsulating device which comprises a base, a screw and fixing blocks, wherein the base is of a U-shaped structure, a positioning hole is formed in the center of the base, a quartz tuning fork is fixed in the positioning hole, two pins of the quartz tuning fork penetrate through the positioning hole, lower V-shaped grooves are formed in two lateral walls of the U-shaped base, upper V-shaped grooves are formed in the two fixing blocks respectively, the two fixing blocks are placed on the two lateral walls of the base to enable the upper V-shaped grooves to be aligned with the lower V-shaped grooves, two resonating tubes are fixed through the fully-constrained clamping between the upper V-shaped grooves and the lower V-shaped grooves, the quartz tuning fork is made to be located between the two resonating tubes without making contact with the two resonating tubes, and the screw penetrates through the fixing blocks to be fixed on the two lateral walls of the base. According to the device, miniaturization of an encapsulating structure can be achieved, the enhancing effect of the resonating tubes, the sensitivity of the quartz tuning fork and the signal to noise ratio can be improved, and the optimum applicability of the whole structure can be improved.

Owner:BEIJING AEROSPACE TIMES OPTICAL ELECTRONICS TECH

Forming process and mold replacement device for straight seam welded special-shaped steel pipes for automobile anti-collision beams

The invention relates to a straight seam welding special-shaped steel pipe forming process for an automobile anti-collision beam. The straight seam welding special-shaped steel pipe forming process for the automobile anti-collision beam comprises the following steps of: (1) uncoiling, unrolling a steel strip coil; (2) flattening, flattening the unrolled steel strip and conveying the flattened steel strip to the next station; (3) flat cutting and butt welding, flat cutting a head portion and a tail portion of the flattened steel strip respectively, and butt welding a tail of the steel strip material after the flat cutting with a head of the next steel strip material after the flat cutting; (4) pre-storing, feeding the butt welded steel strip into a movable sleeve storage bin; (5) forming, conveying the steel strip in the movable sleeve storage bin to a forming machine, and gradually bending into a tube blank to be welded according to a certain sequence; (6) high-frequency welding, pressing the opposite ends of the tube blank to form a certain opening angle, and then to perform high-frequency welding; (7) Water cooling, cooling the high-frequency welded steel tube to room temperatureby spraying; (8) special-shaped gradient sizing, sizing the water-cooled steel tube by a sizing ; (9) profile machining, cutting the sized steel tube into specific lengths.

Owner:山东华舜重工集团有限公司

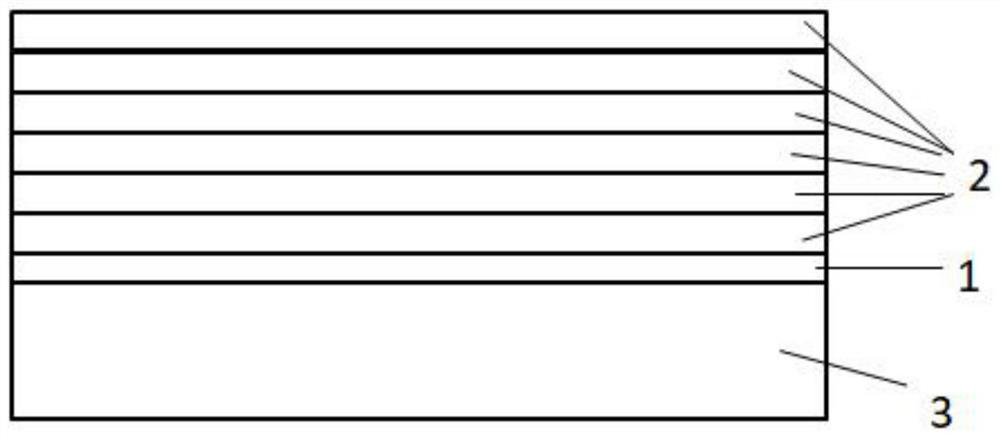

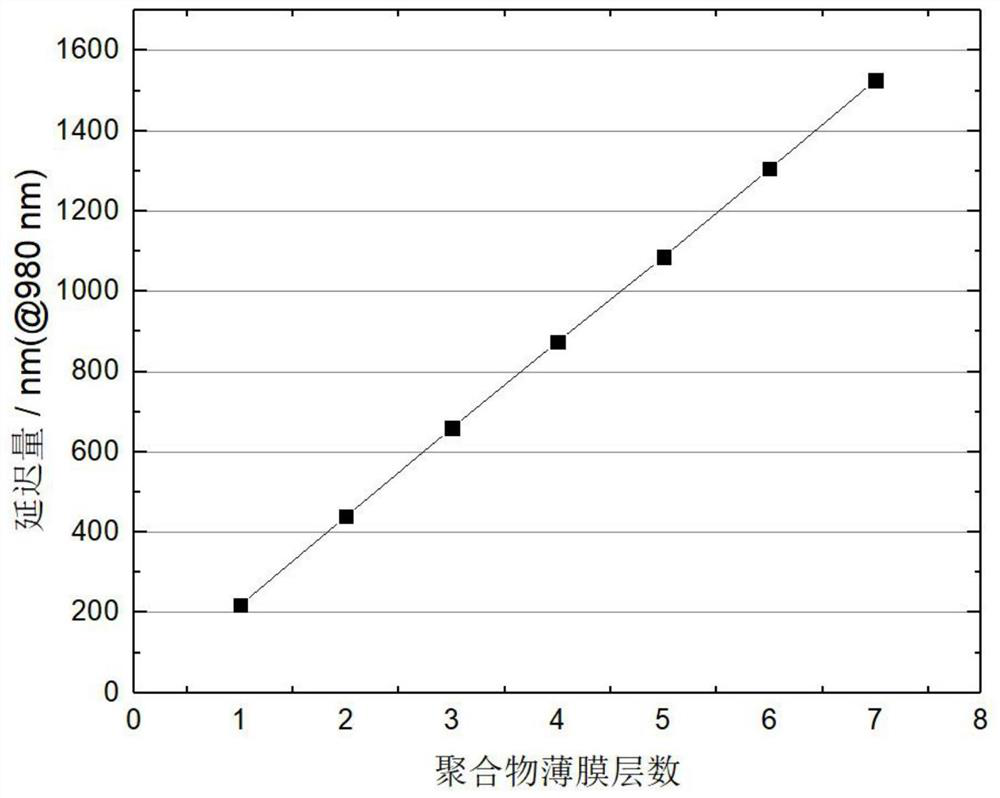

Novel polymerizable mesocrystal mixture coating and application thereof in near-infrared band

InactiveCN113004729AImprove solubilityHigh solid contentPolarising elementsDiffraction gratingsAlkanePolymer science

The invention provides a novel polymerizable mesogenic mixture coating. The novel polymerizable mesogenic mixture coating comprises one or more single-reactive mesogenic compounds; one or more monoreactive mesogenic compounds include a polymerizable backbone body structure and a polar functional group derived from the polymerizable backbone body structure; the polymerizable skeleton body structure is composed of a benzene ring or biphenyl structure and a flexible alkane chain, the tail end of the alkane chain is provided with unsaturated C = C double bonds or acrylate, and the polar functional groups do not comprise alcohols, phenols, amines and amides. The invention also discloses an application of the novel polymerizable mesocrystal mixture coating in preparation of an anisotropic polymer film of a polymerized liquid crystal material. The mesogenic compound coating with high solid content can be prepared at the same time, and molecules are arranged in order after film formation; the formed polymer film is formed by stacking multiple layers, and good alignment can be carried out on the next layer of polymer film.

Owner:张家港莱拓新材料科技有限公司

Method for forming liquid crystal alignment film for photo-alignment and liquid crystal display element

ActiveCN102585843BHigh light transmittanceGood alignment effectLiquid crystal compositionsNon-linear opticsLiquid-crystal displayTransmittance

The invention provides liquid crystal alignment agents for photo-alignment, liquid crystal photo-alignment layers, and liquid crystal displays using the same. The liquid crystal alignment agents contain tetracarboxylic dianhydride mixture including cyclopentane tetracarboxylic dianhydride, which is reacted with specific diamine to obtain polyamide acid or its derivatives. The liquid crystal alignment agents are applied to form a photo-alignment film with excellent alignment property and high light transmittance, because of light sensitivity of the chemical change caused by illumination. In addition, the photo-alignment film is applied in liquid crystal displays, the electrical characteristics required by liquid crystal alignment film is satisfied, the voltage maintaince ratio is high, the iron amount is little, the remained charge amount is little, etc.

Owner:长沙道安捷新材料有限公司

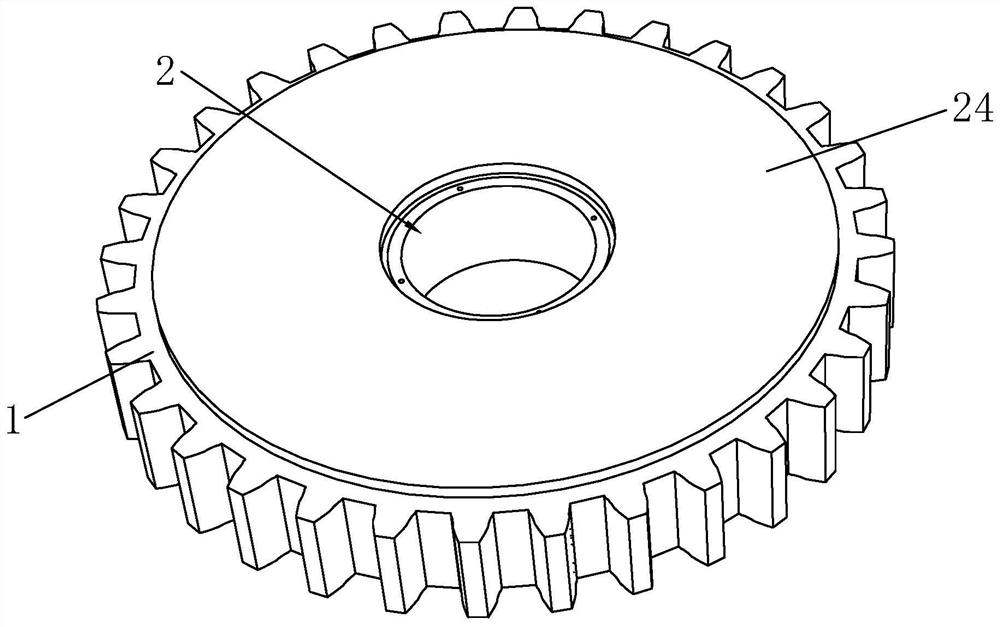

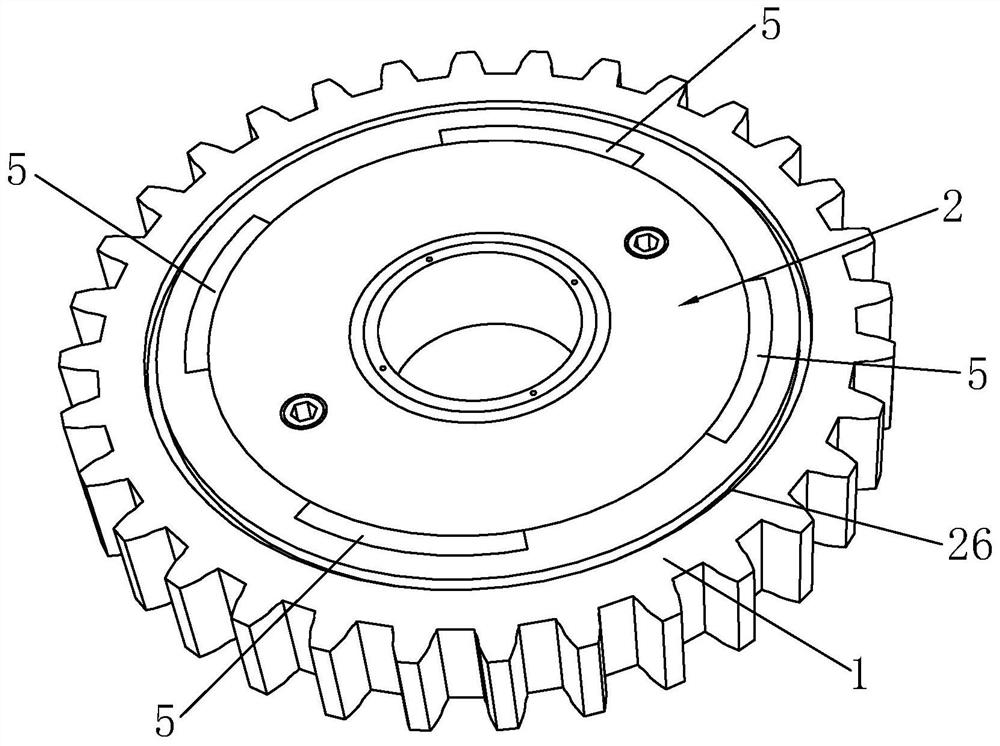

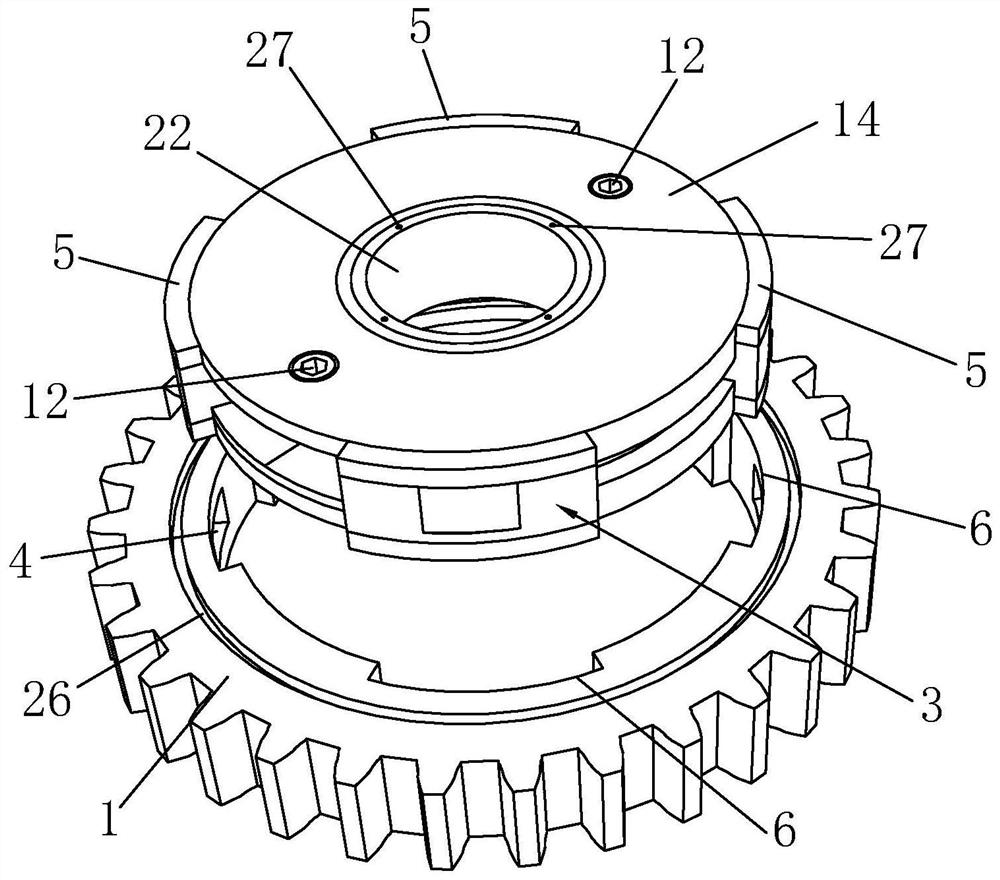

High-strength straight gear and manufacturing method thereof

ActiveCN112065951AEasy to manufactureEasy to manufacture and facilitate the processing of the gear hubPortable liftingGearing elementsGear wheelManufacturing engineering

The invention discloses a high-strength straight gear and a manufacturing method thereof. The high-strength straight gear comprises a gear ring and a gear hub, wherein the gear hub is arranged in thegear ring and provided with a fixing mechanism, the gear ring is provided with a fixing groove, the fixing mechanism is clamped in the fixing groove, the gear hub is provided with a positioning protruding part, the gear ring is provided with a positioning groove, and the positioning protruding part is arranged in the positioning groove; and the method adopts five steps of a, part manufacturing, b,fixing mechanism assembling, c, gear ring machining, d, gear assembling, and e, gear detection. According to the gear and the method, replacement time of the gear ring can be saved, the gear ring isconvenient to replace, the installation precision of the gear is ensured, slipping between the gear ring and the gear hub is avoided, and the reliability of the gear in the working process is ensured;and by means of the method, gear manufacturing can be facilitated, the gear quality is improved, time needed for gear manufacturing is saved, the production efficiency is improved, and the gear strength is ensured.

Owner:新昌县金鹰齿轮箱有限公司

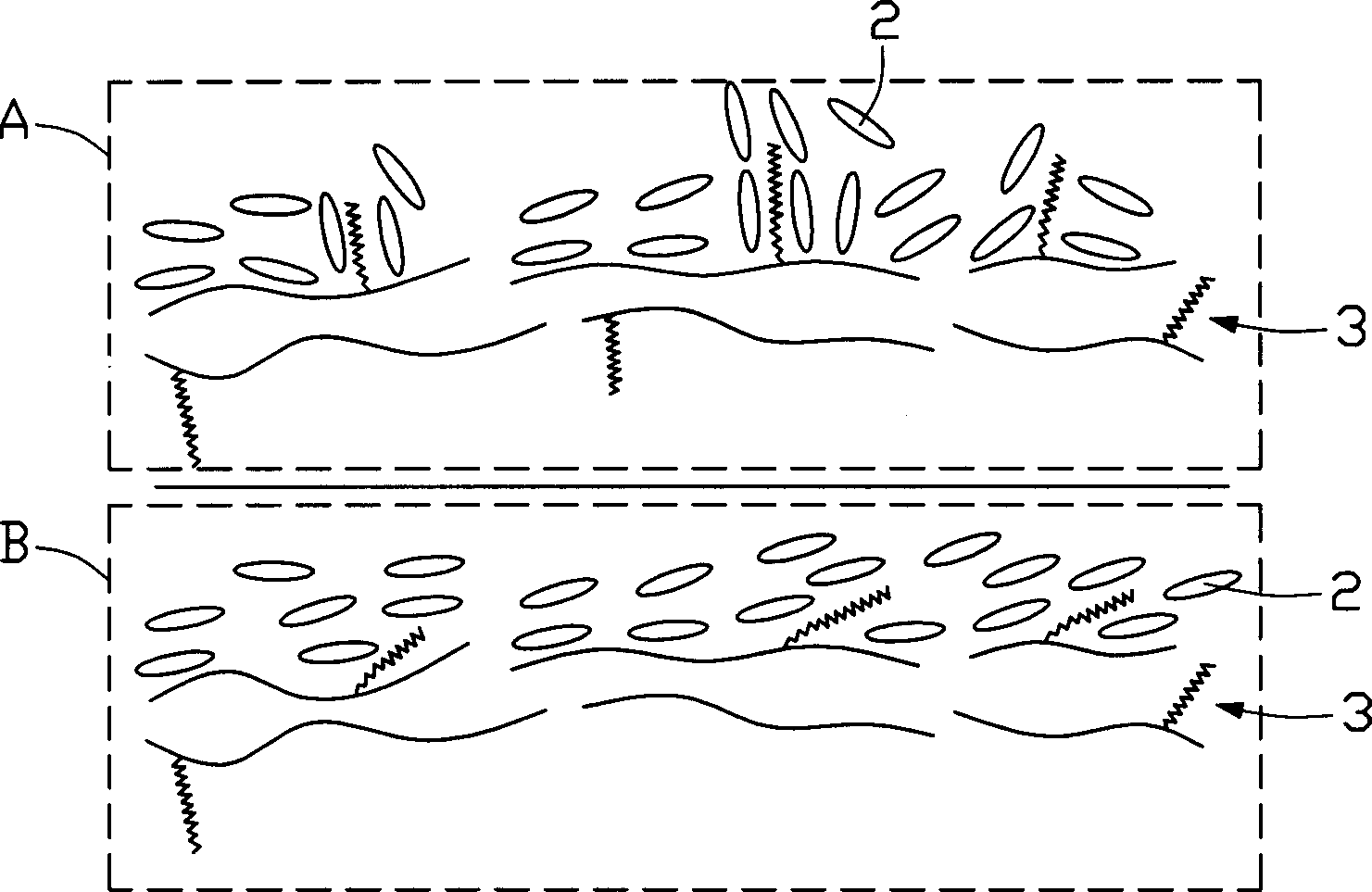

Method for improving alignment effect of self-aligned liquid crystals

InactiveCN108267898AImprove misalignmentGood alignment effectNon-linear opticsLiquid-crystal displayLiquid crystal

The invention discloses a method for improving the alignment effect of self-aligned liquid crystals and applies to a liquid crystal display panel. The liquid crystal display panel comprises an array substrate, a color filter substrate arranged in parallel to the array substrate and at an interval as well as a liquid crystal molecular layer clamped between the array substrate and the color filter substrate. According to the method, the liquid crystals are solidified by only powering up a common electrode in the color filter substrate, or a common electrode in the array substrate is arranged ina non-display area of the array substrate. Compared with the uncertainty and complexity by changing the material of a self-aligned liquid crystal system, the method for improving the alignment effectof the self-aligned liquid crystals has the advantages that the problem of poor alignment of self-aligned liquid crystal display can be effectively solved on the premise that the material of the self-aligned liquid crystal system keeps unchanged, and has great significance in further application of the self-aligned liquid crystal display.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Liquid crystal alignment agent for photoalignment, liquid crystal alignment film and manufacturing method thereof, liquid crystal display element, compound, and polymer

ActiveCN103509563BGood alignment effectShao Fu ShaoLiquid crystal compositionsOrganic chemistryLight irradiationLiquid-crystal display

The present invention provides a method for manufacturing a liquid crystal alignment film capable of producing a liquid crystal display device which shows excellent liquid crystal alignment properties by light irradiation on a coating layer, has low element causing burn-in and exhibits high voltage holding ratio. The method for manufacturing a liquid crystal alignment film comprises: a film formation process of spraying a liquid crystal aligning agent for photoalignment including polymers (c) having a structure (Y), which is represented by a formula 1 in a main chain and is at least one selected from the group consisting of polyamic acid, polyamic acid ester and polyimide, on a substrate and forming a coating layer; and a light irradiation process of forming a liquid alignment film by irradiating light on the coating layer. In the formula, X1 is a sulfur atom or an oxygen atom. * represents a bond. And at least one among two * is combined to a direction ring.

Owner:JSR CORPORATIOON

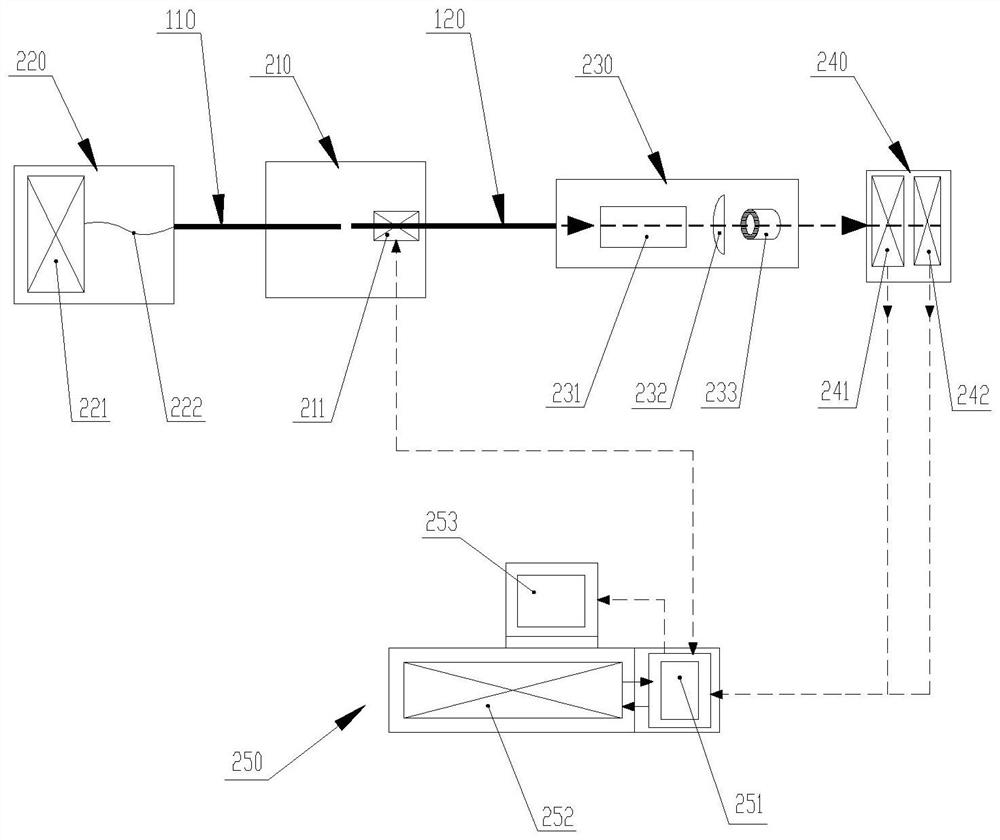

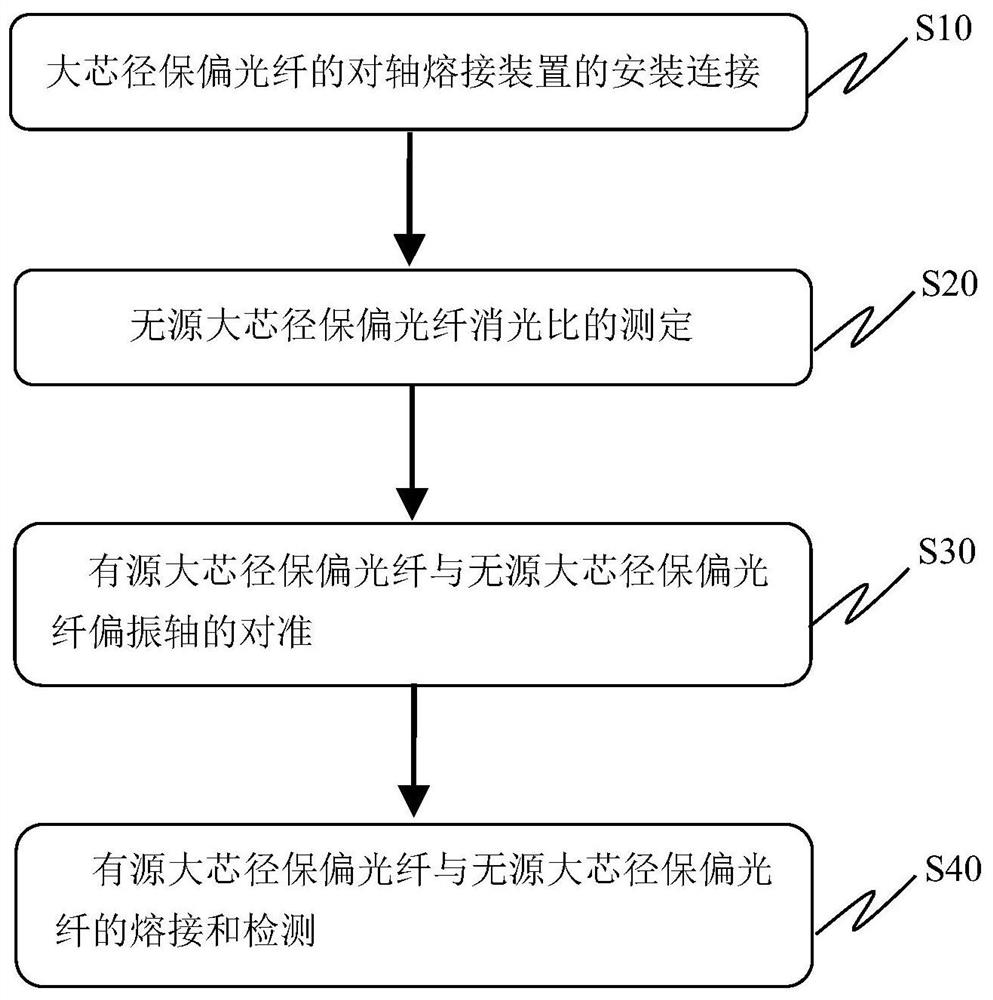

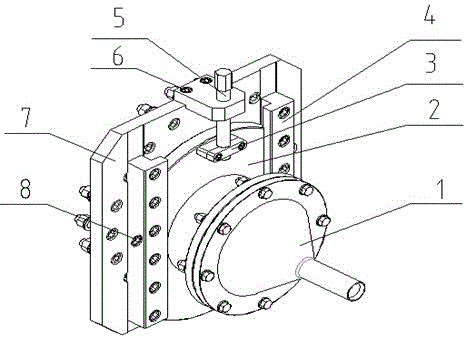

Large-core-diameter polarization maintaining optical fiber countershaft welding device and welding method thereof

PendingCN111830632AGuaranteed communication qualityAdaptableCoupling light guidesPolarization-maintaining optical fiberOptical power

The invention discloses a large-core-diameter polarization maintaining optical fiber countershaft welding device and a welding method thereof. The welding device is additionally provided with a high-efficiency linearly polarized light injection system, an output light collimation filtering system, an optical power and extinction ratio detection system and a data collection processing display system on the basis of a conventional large-core-diameter polarization maintaining optical fiber welding system. The welding method comprises the following steps of firstly, measuring an optical power value and an extinction ratio of the passive large-core-diameter polarization maintaining optical fiber to be welded; measuring an optical power value and an extinction ratio after the active large-core-diameter polarization maintaining optical fiber and the passive large-core-diameter polarization maintaining optical fiber are welded; through comparative analysis of the two groups of data, the polarization axis of the active large-core-diameter polarization maintaining optical fiber being continuously adjusted to be matched with the polarization axis of the passive large-core-diameter polarization maintaining optical fiber, and when comparison of the two groups of data reaches the optimal result, countershaft welding of the two large-core-diameter polarization maintaining optical fibers withdifferent appearance structures and inconsistent internal stress sources being completed. The welding device is advantaged in that the optical fiber is accurate in alignment, and the welded large-core-diameter polarization maintaining optical fiber is high in optical power and extinction ratio and good in communication quality.

Owner:THE 23RD RES INST OF CHINA ELECTRONICS TECH GRP CORP

Position adjustable internal nozzle device of quench machining tool

InactiveCN105018695ASimple structureEasy to operateFurnace typesHeat treatment furnacesJackscrewEngineering

The invention discloses a position adjustable internal nozzle device of a quench machining tool. The internal nozzle device comprises an internal nozzle, a sliding seat, sliding seat tracks, a screw rod and a base flange, wherein the two sliding seat tracks are fixed on the base flange in parallel at an interval, the sliding seat is glidingly mounted between the two sliding seat tracks, the interval between the two sliding seat tracks is larger than the width of the sliding seat, and bolt jackscrews for adjusting the left-right position of the sliding seat are arranged on the side surfaces of the sliding seat tracks; a screw rod nut for mounting and fixing the screw rod is arranged at the upper end of the base flange, the screw rod is mounted on the screw rod nut, a positioning block is arranged on the sliding seat, the lower end of the screw rod is connected to the positioning block, and a threaded hole in threaded fit with the screw rod is formed in the positioning block; the internal nozzle is assembled on the sliding seat. The position adjustable internal nozzle device of the quench machining tool is simple in structure, convenient to operate and wide in application range, and internal nozzles with different specifications can be replaced to meet quenching requirements of steel pipes with different specifications.

Owner:HANDAN XINXING SPECIAL TUBING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com