Large-core-diameter polarization maintaining optical fiber countershaft welding device and welding method thereof

A polarization-maintaining fiber, large core diameter technology, applied in the coupling of optical waveguides, light guides, optics, etc., can solve the problems of unsatisfactory fusion effect, different shapes and structures, inconsistent internal stress sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0090] This embodiment provides an on-axis fusion splicing device for a polarization-maintaining optical fiber with a large core diameter.

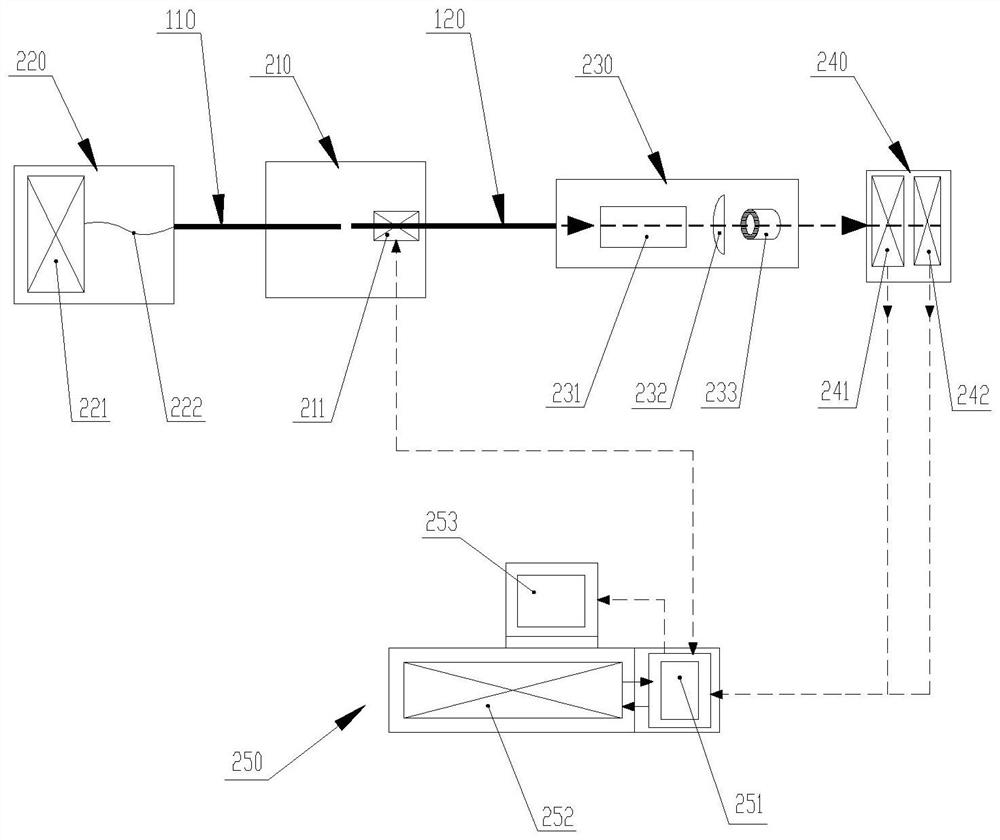

[0091] like figure 1 A schematic structural diagram of an on-axis fusion splicing device for a polarization-maintaining optical fiber with a large core provided by an embodiment of the present invention is shown:

[0092] The axial fusion splicing device for the large-core polarization-maintaining fiber provided in this embodiment is used for the pairing of the passive large-core polarization-maintaining fiber 110 and the active large-core polarization-maintaining fiber 120 with different shapes and structures and inconsistent internal stress sources. shaft welding;

[0093] The on-axis fusion splicing device of the large-core diameter polarization-maintaining optical fiber provided in this embodiment includes the existing large-core diameter polarization-maintaining optical fiber fusion splicing system 210 in the prior art, and the larg...

Embodiment 2

[0113] This embodiment provides a method for splicing a large-core-diameter polarization-maintaining fiber to a shaft by using the large-core-diameter polarization-maintaining fiber-to-shaft fusion splicing device provided in Embodiment 1 above.

[0114] The large-core-diameter polarization-maintaining fibers to be fused to the shaft in this embodiment are passive large-core-diameter polarization-maintaining fibers and active large-core-diameter polarization-maintaining fibers with different shapes and structures and inconsistent internal stress sources.

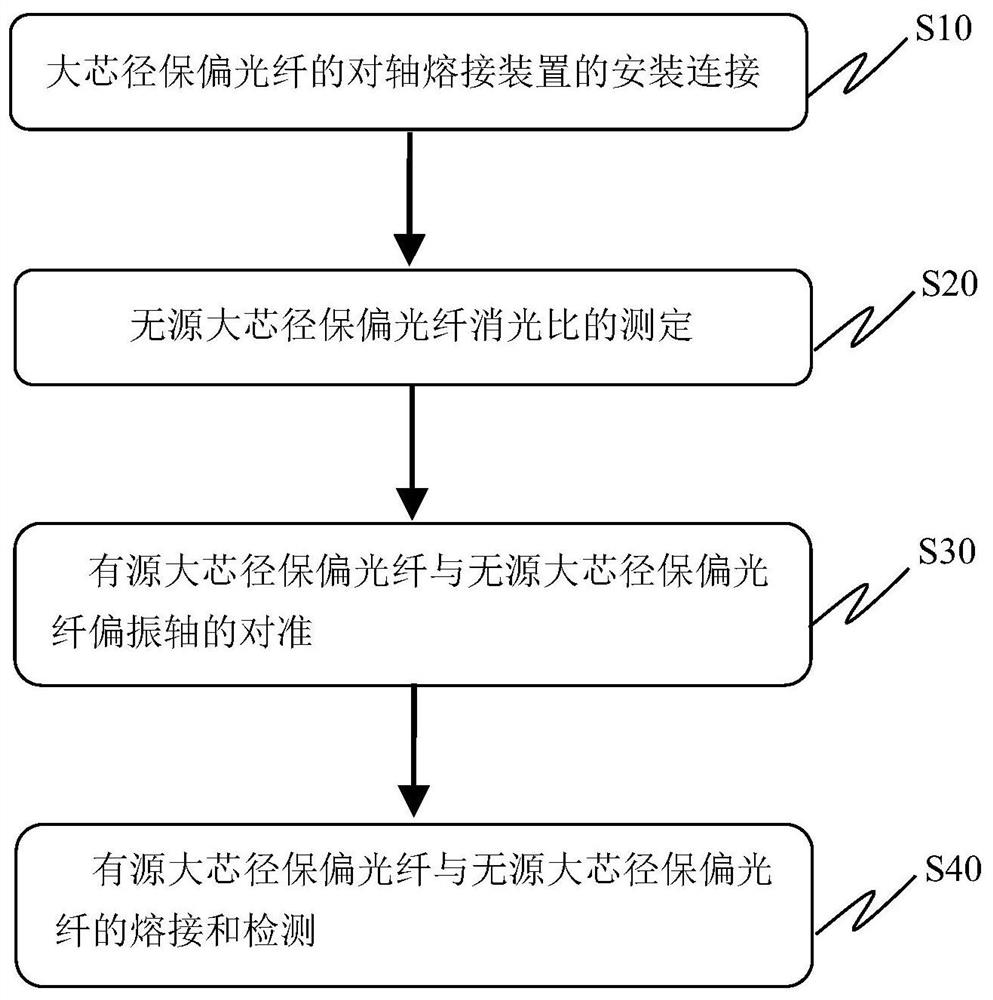

[0115] combine figure 1 , and as figure 2 A schematic block diagram of the process of splicing a large core diameter polarization maintaining fiber to a shaft using the large core diameter polarization maintaining fiber provided by the embodiment of the present invention is shown in a block diagram. The large core diameter polarization maintaining fiber provided in this embodiment Welding methods include:

[0116] S10) th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com