Lens membrane and manufacturing method thereof

A manufacturing method and lens film technology, applied in the fields of lenses, optics, instruments, etc., can solve problems such as poor alignment ability and poor 3D display effect, and achieve the effect of improving alignment ability and good naked-eye 3D display effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0059] A preferred embodiment of the present invention is a method for manufacturing a lens film. In this embodiment, the lens film manufacturing method is used to manufacture a lens film applied in a liquid crystal display device, and the lens film cooperates with a base panel (base panel) having a polarization direction (polarization direction) to operate in the liquid crystal display device , but not limited to this.

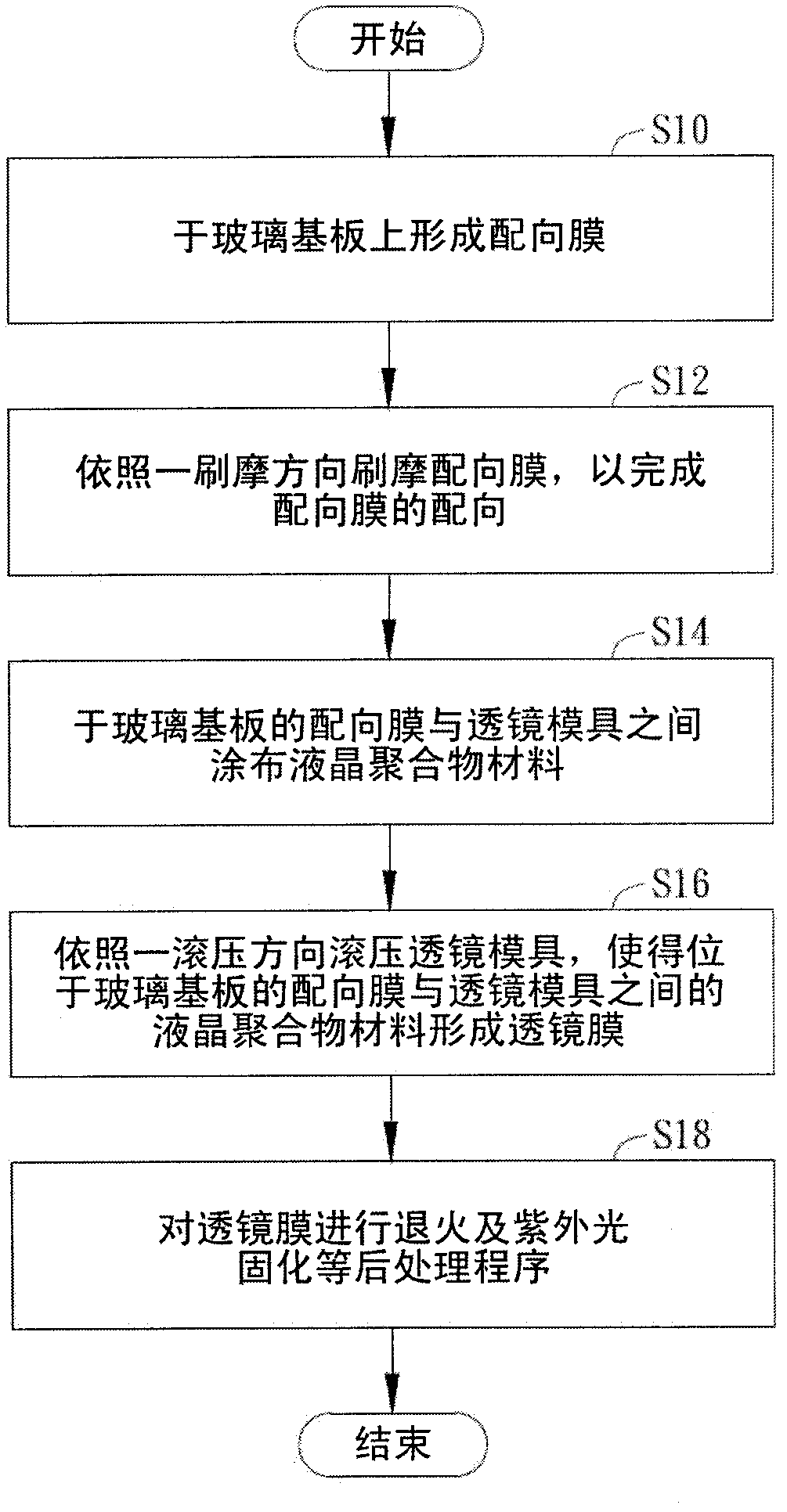

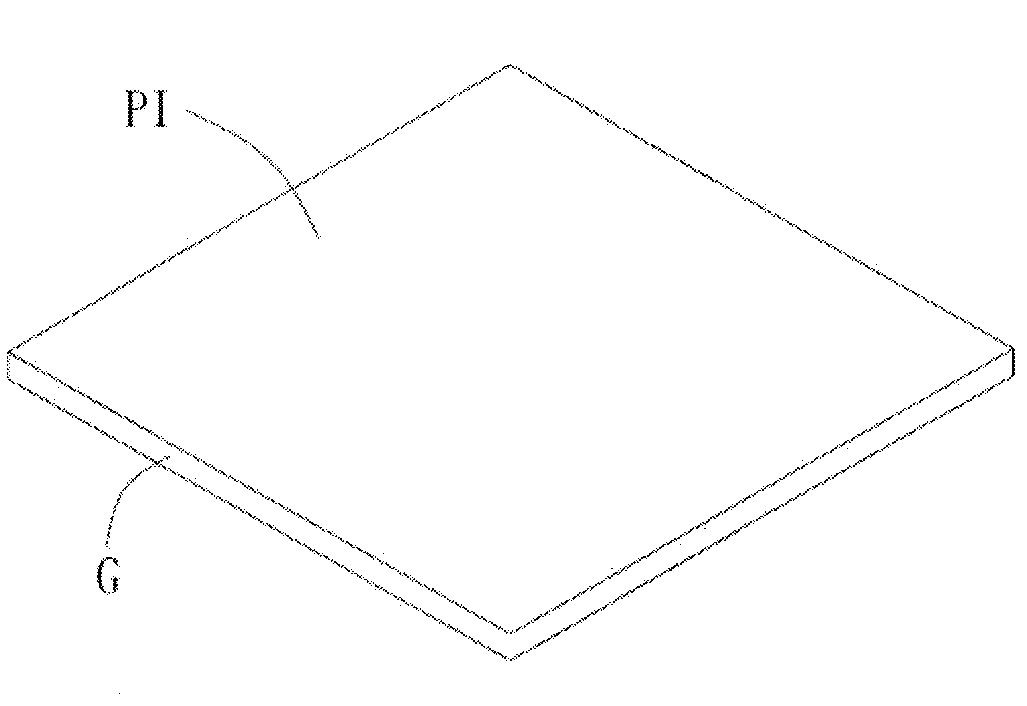

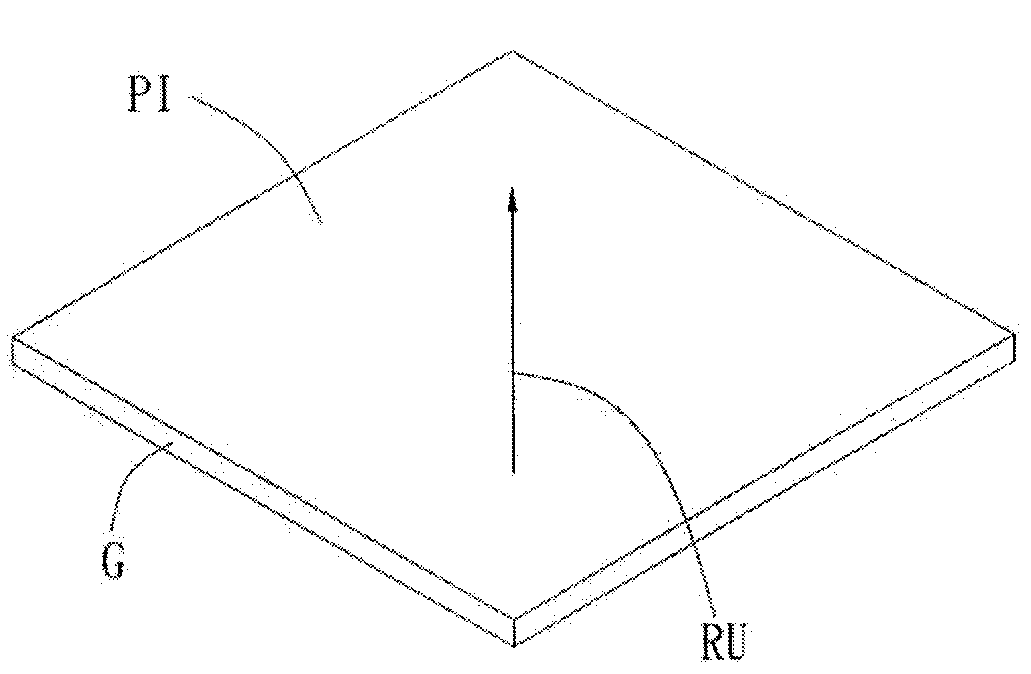

[0060] Please refer to figure 1 , figure 1 A flow chart of the manufacturing method of the lens film is shown. Such as figure 1 As shown, at first, the method executes step S10 to form an alignment film PI on the glass substrate G (for the schematic diagram, please refer to Figure 2A ). In practical applications, the glass substrate G is ITO conductive glass. The alignment film PI formed on the glass substrate G by this method can be made of polyimide (PI), and this method can form the alignment film PI on the glass substrate G by evaporation, inkjet p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com