Position adjustable internal nozzle device of quench machining tool

A quenching machine tool and inner nozzle technology, applied in quenching devices, heat treatment equipment, furnaces, etc., can solve the problems of poor hardening effect, cumbersome installation and operation, inconvenient installation and adjustment for workers, and achieve good structure and performance uniformity and process design Reasonable, the effect of reducing the number of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] The technical solution of this patent will be described in further detail below in conjunction with specific embodiments.

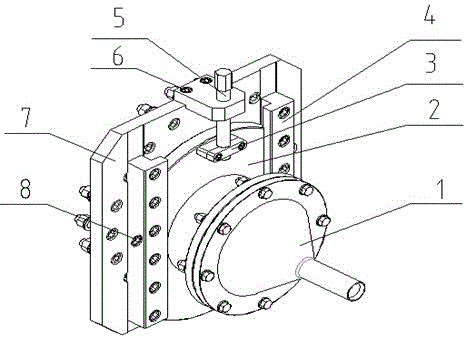

[0011] See figure 1 , A position-adjustable internal nozzle device of a quenching machine tool, comprising an internal nozzle 1, a sliding seat 2, a sliding seat rail 4, a screw rod 5 and a base flange 7; the sliding seat rail 4 is fixed on the base flange 7, There are two sliding seat rails 4, which are arranged in parallel and spaced apart. The sliding seat 2 is slidably installed between the two sliding seat rails 4. The gap between the two sliding seat rails 4 is greater than the width of the sliding seat 2, and the side of the sliding seat rail 4 There are bolt jacks 8 for adjusting the left and right positions of the sliding seat 2; the upper end of the base flange 7 is provided with a screw nut 6 for fixing and fixing the screw 5, the screw 5 is installed on the screw nut 6, sliding The seat 2 is provided with a positioning block 3, and the lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com