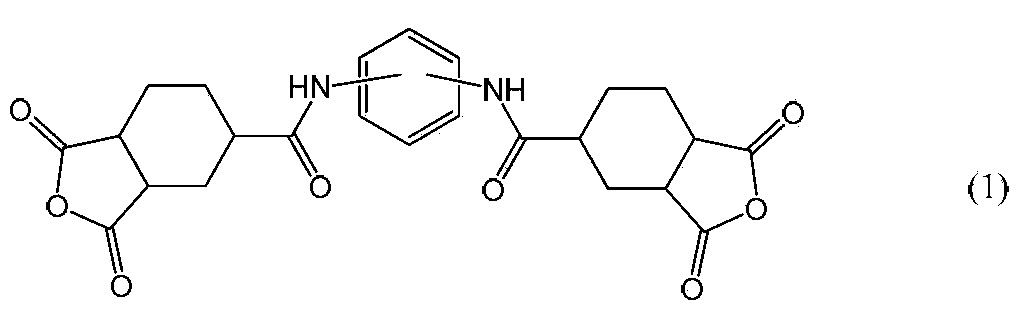

Polyamic acid or derivative thereof, liquid crystal alignment agent, liquid crystal alignment film and liquid crystal display element provided therewith

A technology of polyamic acid and derivatives, applied in liquid crystal materials, instruments, optics, etc., can solve problems such as defects, display defects, afterimages, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

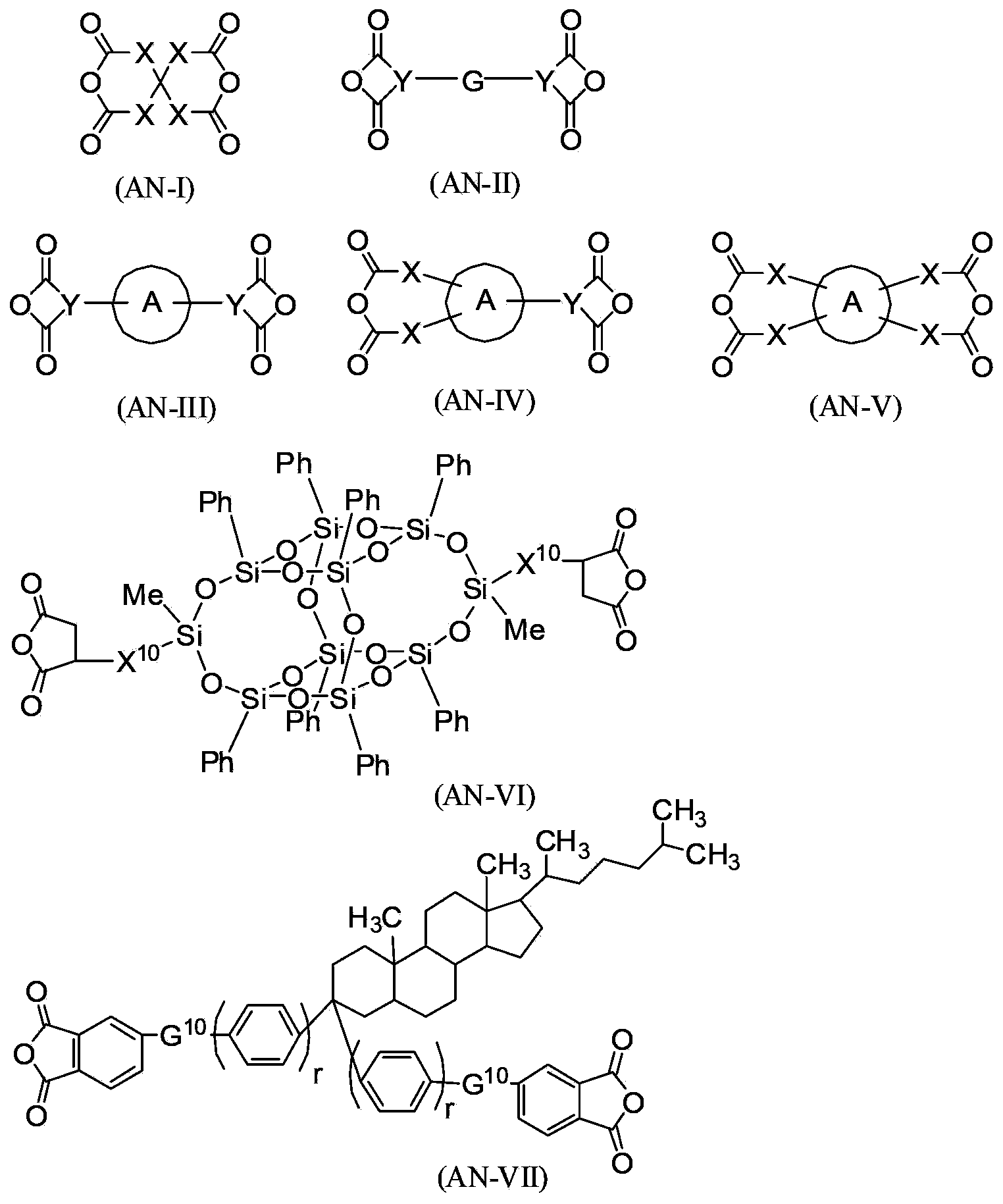

Method used

Image

Examples

Embodiment

[0642] Hereinafter, although an Example demonstrates this invention, this invention is not limited to these Examples. The evaluation method of the liquid crystal display element in an Example is as follows.

[0643]

[0644] The weight average molecular weight of a polyamic acid was calculated|required by the GPC method using 2695 separation module · 2414 differential refractometers (made by Waters), and performed polystyrene conversion. The obtained polyamic acid was diluted with a phosphoric acid-dimethylformamide (DMF) mixed solution (phosphoric acid / DMF=0.6 / 100: weight ratio) so that the polyamic acid concentration became about 2 wt%. HSPgel RT MB-M (manufactured by Waters) was used as a column, and the mixed solution was used as a developing solvent, and the measurement was performed under the conditions of a column temperature of 50° C. and a flow rate of 0.40 mL / min. As the standard polystyrene, TSK standard polystyrene manufactured by Tosoh Co., Ltd. was used.

[0...

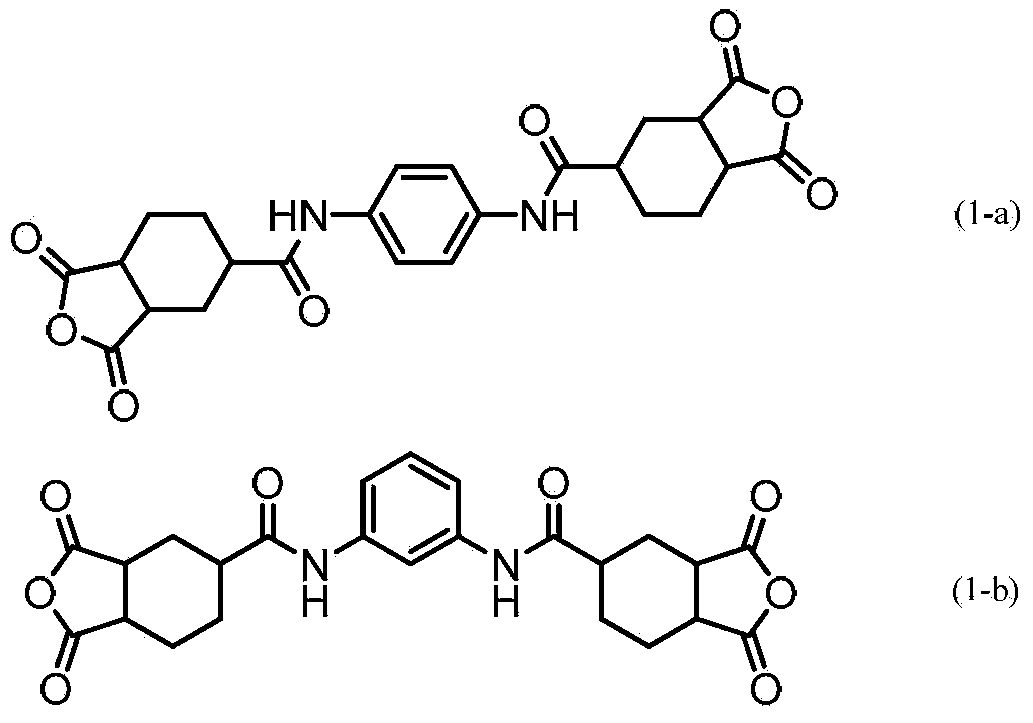

Synthetic example 1

[0661] Add 0.446 g of diamine in formula (DI-5-1) where m is 1, and 13.5 g of dehydrated NMP into a 50 mL brown four-neck flask equipped with a thermometer, a stirrer, a raw material input port, and a nitrogen gas inlet port, and dry ammonia Stir to dissolve under air flow. Then, 1.054 g of acid dianhydrides (1-a) (manufactured by Nippon Seika Co., Ltd.) and dehydrated NMP5.0g were added, and stirring was continued at room temperature for 24 hours. BC5.0g was added to this reaction solution, and the polyamic-acid solution whose polymer solid content concentration was 6 wt% was obtained. Let this polyamic-acid solution be PA1. The weight average molecular weight of the polyamic acid contained in PA1 was 74,000.

[0662] [Synthesis Example 2~Synthesis Example 37]

[0663] Except for changing the tetracarboxylic dianhydride and diamine as shown in Table 1-1 and Table 1-2, prepare a polyamic acid solution (PA2)~polyamic acid with a polymer solid content concentration of 6wt% ac...

Embodiment 1

[0675] Add the mixed solvent of NMP / BC=4 / 1 (weight ratio) in the polyamic acid solution (PA1) that the polymer solid content concentration prepared in Synthetic Example 1 is 1wt%, and be diluted to the polymer solid content concentration of 4wt% to make liquid crystal alignment agent. The liquid crystal alignment agent was coated on the glass substrate using a spinner (manufactured by Mikasa Co., Ltd., spin coater (1H-DX2)). In addition, including the following examples and comparative examples, the rotational speed of the spinner was adjusted according to the viscosity of the liquid crystal alignment agent, so that the alignment film had the following film thickness. After coating, heat and dry on a heating plate (manufactured by ASONE Co., Ltd., EC heating plate (EC-1200N)) at 70°C for 80 seconds, and then dry it in a clean oven (Espec) Co., Ltd., in a clean oven (PVHC-231), heat treatment was performed at 230° C. for 15 minutes to form an alignment film with a film thickne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com