Photosensitive resin compsition

A technology of photosensitive resin and composition, which is applied in the field of photosensitive resin composition and protrusions for liquid crystal display elements, which can solve problems such as poor developing characteristics, and achieve the effects of excellent liquid crystal alignment and excellent voltage retention characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

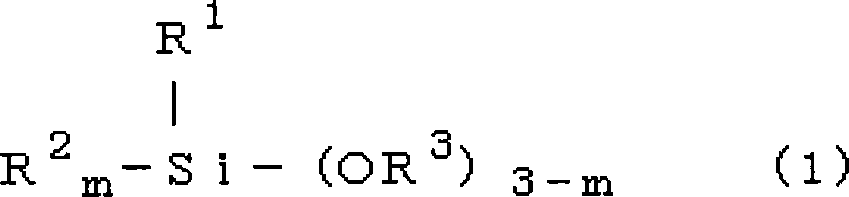

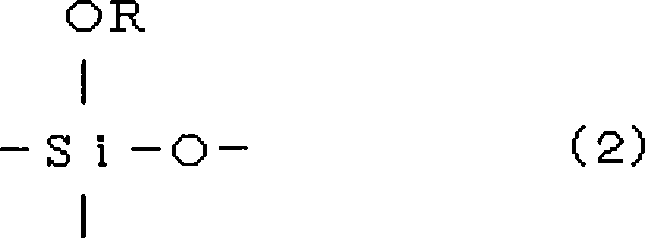

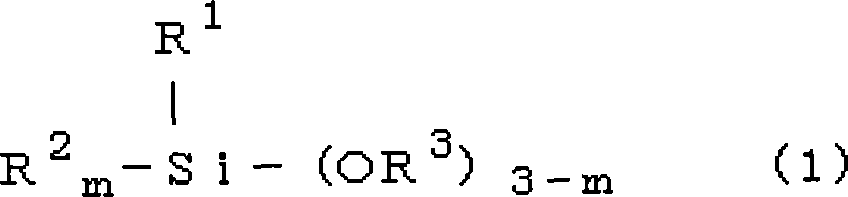

Method used

Image

Examples

preparation example Construction

[0062] Examples of the (meth)acryloyl group-containing monocarboxylic acid used for the preparation of (A1) include acrylic acid and methacrylic acid.

[0063] The polycarboxylic acid and polycarboxylic acid anhydride (e) used in the preparation of (A1) can enumerate: unsaturated polycarboxylic acid (for example, maleic acid, itaconic acid, fumaric acid and methyl maleic acid etc.) and Their anhydrides (for example, maleic anhydride, etc.) Aliphatic saturated polycarboxylic acids such as pentadecenyl succinic acid and octadecyl succinic acid; tetrahydrophthalic acid, hexahydrophthalic acid, methyltetrahydrophthalic acid, trimellitic acid, benzene Aromatic polycarboxylic acids such as pyrene tetracarboxylic acid, biphenyl tetracarboxylic acid and naphthalene tetracarboxylic acid) and their anhydrides (for example, succinic anhydride, dodecenyl succinic anhydride, pentadecenyl succinic anhydride, octadecenyl succinic anhydride, etc. Aliphatic saturated polycarboxylic acid anhyd...

Embodiment

[0203] Hereinafter, the present invention will be specifically described by way of examples and preparation examples, but the present invention is not limited thereto. Hereinafter, "part" means "part by weight".

[0204] [Preparation of Hydrophilic Resin (A)]

preparation example 1

[0206] 200 parts of cresol novolac type epoxy resin EOCN-102S (manufactured by Nippon Kayaku, epoxy equivalent 200) and Heat 245 parts of propylene glycol monomethyl ether acetate to 110°C to dissolve it evenly. Next, 76 parts of acrylic acid, 2 parts of triphenylphosphine, and 0.2 part of p-methoxyphenol were added, and it was made to react at 110 degreeC for 10 hours. Add 91 parts of tetrahydrophthalic anhydride to the reactant, react at 90°C for 5 hours, and then dilute with propylene glycol monomethyl ether acetate to make the solid content 25%, to obtain acryloyl and Propylene glycol monomethyl ether acetate solution of carboxyl hydrophilic resin (A-1: Mn: 2,200; SP value: 11.26; HLB value: 6.42; acid value: 91 mgKOH / g; acryloyl group concentration: 2.86 mmol / g) (25% solids content).

[0207] It should be noted that Mn is a polymer measured by the GPC method using a GPC analyzer (HLC-8120GPC, manufactured by TOSHO Co., Ltd.) and a chromatographic column (two pieces of T...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com