A railway freight car bogie vibration damping device which can provide composite vibration damping force

A vibration damping device and a technology for railway freight cars, which are applied in the direction of the device for lateral relative movement between the underframe and the bogie, can solve the problems of insufficient bogie capacity, inability to design a wide-body wedge, and inability to effectively suppress amplitude growth, etc. , to achieve the effect of reducing vehicle manufacturing and operation and maintenance costs, improving technical performance and operating quality, and improving technical performance and operating quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention is further described below in conjunction with specific embodiment, and specific embodiment is the further description of the principle of the present invention, does not limit the present invention in any way, and the identical or similar technology of the present invention all does not exceed the scope of protection of the present invention.

[0032] In conjunction with the accompanying drawings.

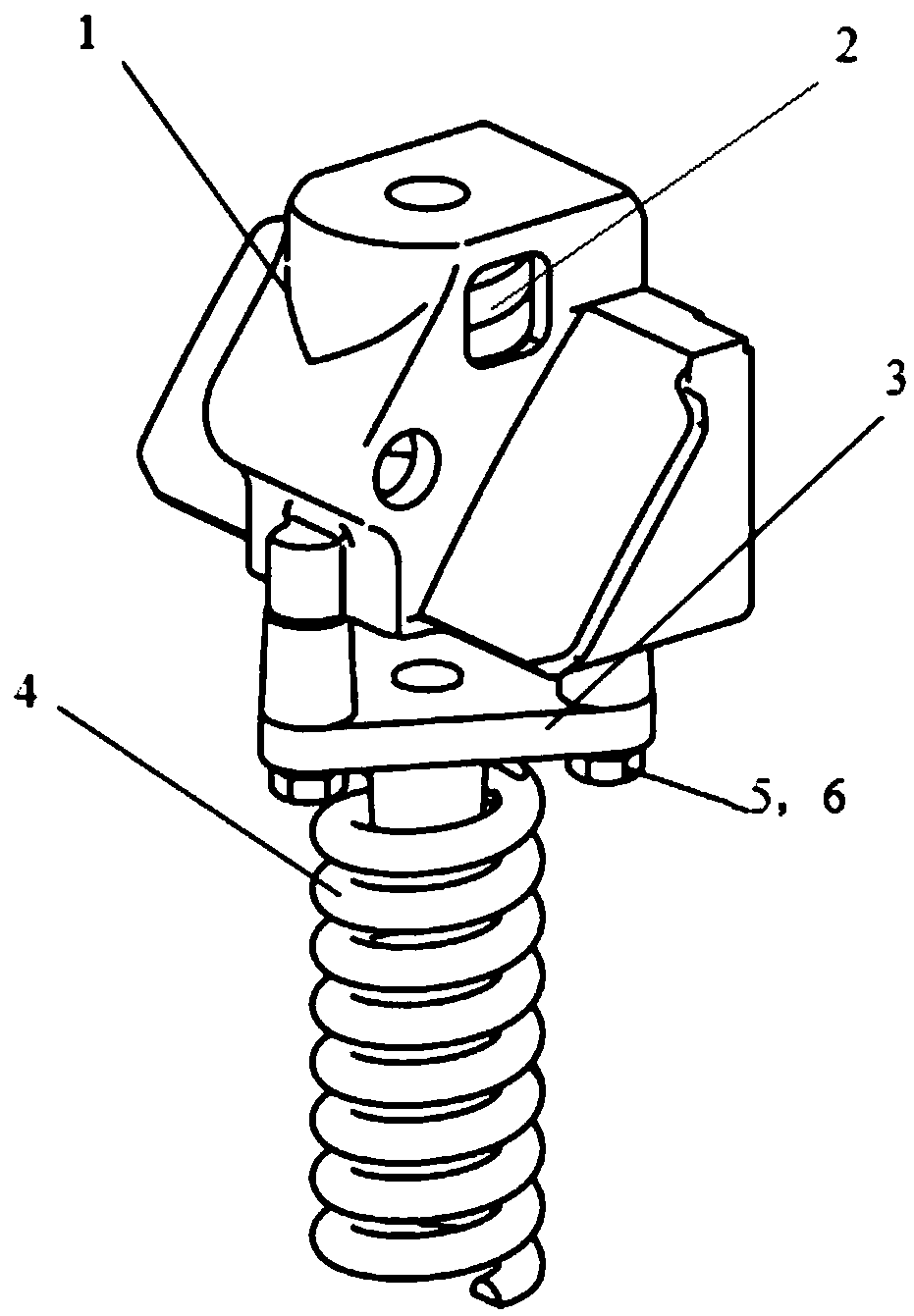

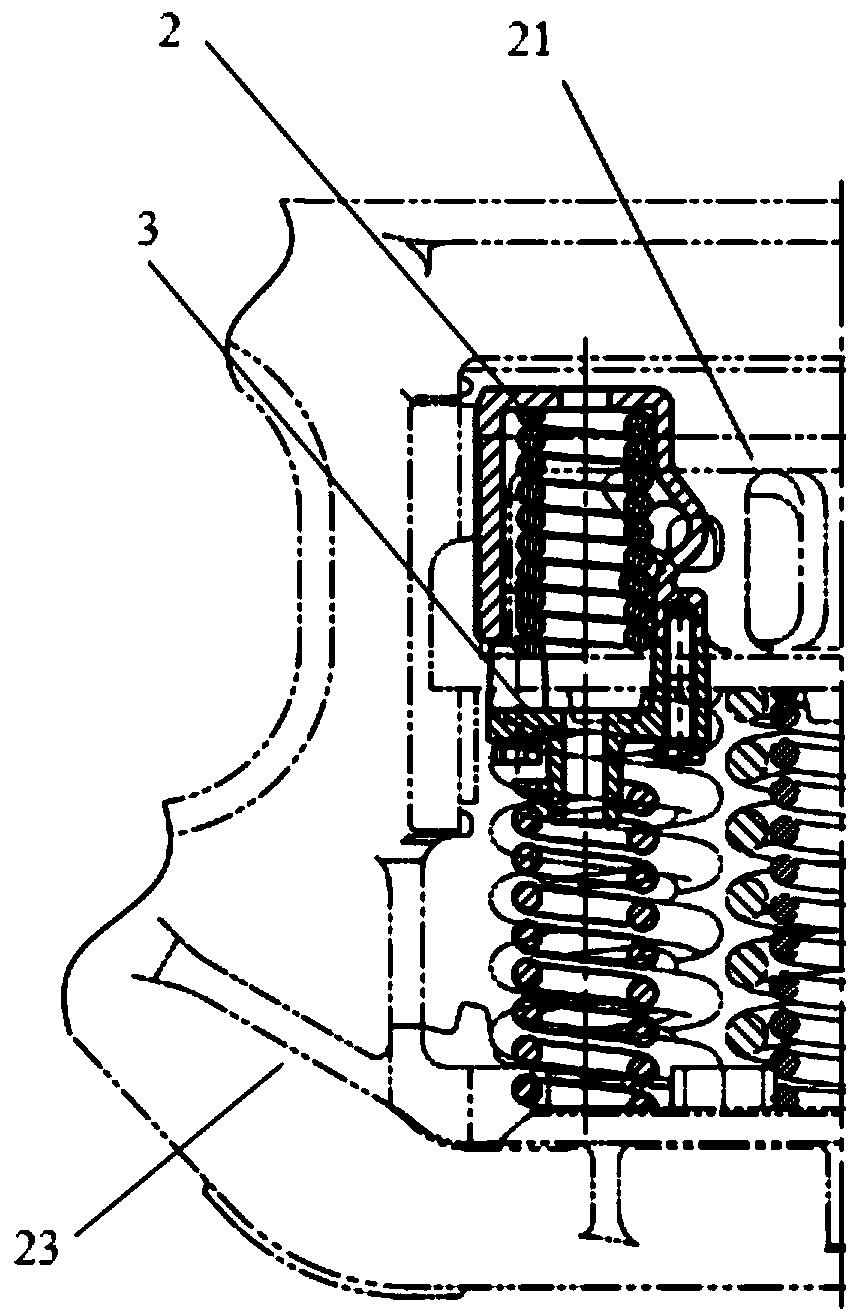

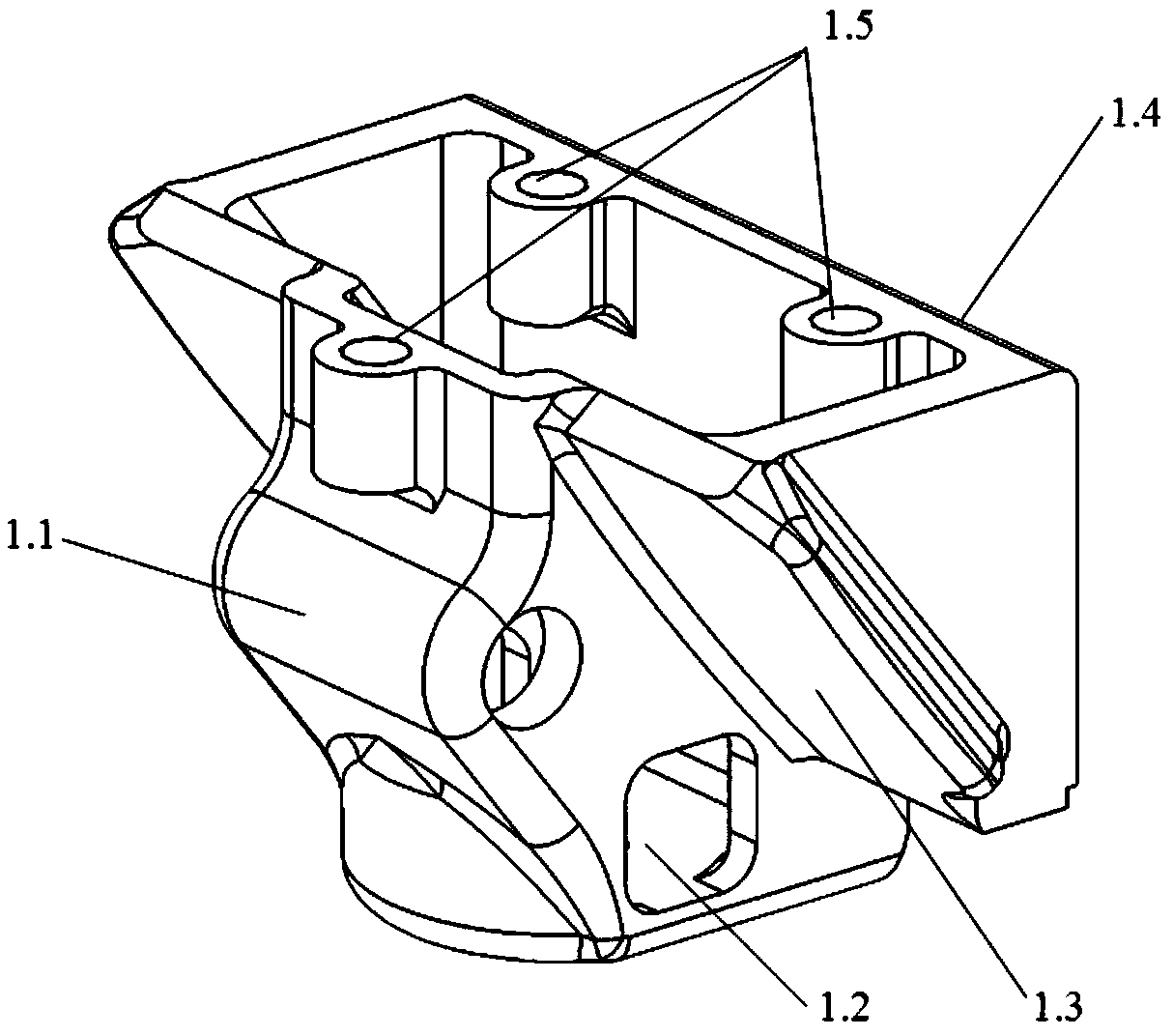

[0033]The railway freight car bogie vibration damping device that can provide composite vibration damping force. The bogie includes a bolster 21 and is placed on the side frame 23 through the central suspension spring 22. The vibration damping device is installed at the end of the bolster 21. The vibration damping device consists of two Partial composition, the wide-body wedge damping part installed on the upper plane 12 of the bottom of the wedge groove at the end of the bolster and the spring damping part installed on the lower plane 13 of the bottom ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com