Liquid crystal aligning agent for photoalignment, liquid crystal alignment film and manufacturing method thereof, liquid crystal display device, compound, and polymer

A liquid crystal alignment agent and liquid crystal alignment technology, applied in liquid crystal materials, chemical instruments and methods, optics, etc., can solve the problems of easy drop in voltage retention rate, increase of impurity ions, poor electrical characteristics, etc., and achieve good sensitivity, burn-in Less, good liquid crystal alignment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0169] As the solvent used in the preparation of the photoalignment agent of the present invention, a solvent capable of dissolving the polymer contained in the photoalignment agent can be used. In addition, a poor solvent for the polymer may be used in combination within the range in which the polymer contained in the photoalignment agent does not precipitate. As the solvent used in the preparation of the photoalignment agent of the present invention, specifically, at least one of the first solvent shown in the following [A] and the second solvent shown in the following [B] is preferred , and more preferably contain both the first solvent and the second solvent.

[0170] [A] As at least one selected from the group consisting of a compound represented by the following formula (4), a compound represented by the following formula (5), and 1,3-dimethyl-2-imidazolidinone The first solvent of the species.

[0171]

[0172] (In formula (4), R 11 It is a monovalent hydrocarbon ...

Embodiment 1

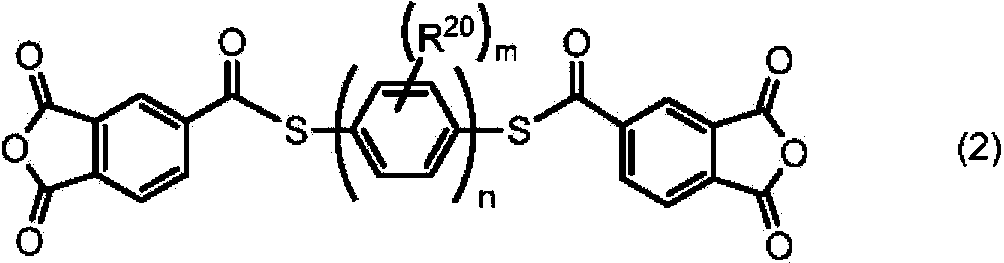

[0252] In a 2000 mL three-necked flask equipped with a stirring bar, 93.3 g of trimellitic acid chloride was taken, and 450 g of tetrahydrofuran was added thereto, followed by stirring and dissolving. Thereafter, it was cooled to 0° C., 30.0 g of 1,4-benzenedithiol dissolved in 200 g of pyridine was slowly added dropwise thereto, and stirred at room temperature for 20 hours. The solid deposited at this time was removed by filtration, and the filtrate was poured into 500 g of hexane for reprecipitation, and the precipitate (white solid) was recovered by filtration. By recrystallizing this white solid with 200 g of acetic anhydride, 21.2 g of a compound (A-3) represented by the formula (a-3) was obtained.

Embodiment 2

[0254] The above synthesis was carried out except that 46.1 g of 4,4'-biphenyldithiol was used instead of 1,4-benzenedithiol, and the amount of hexane during reprecipitation was changed to 2,500 g. In the same manner as in Example 1, 26.3 g of the compound (A-4) represented by the formula (a-4) was thus obtained.

[0255]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com