Patents

Literature

85results about How to "Improve molding pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method using 0 chromium (Cr) 17 nickel (Ni) 4 copper (Cu) 4 niobium (Nb) thin wall square pipes to machine and manufacture linkage ring guide pipe parts

InactiveCN102837159ASimple structureGuaranteed size requirementsShaping toolsNiobiumMartensitic stainless steel

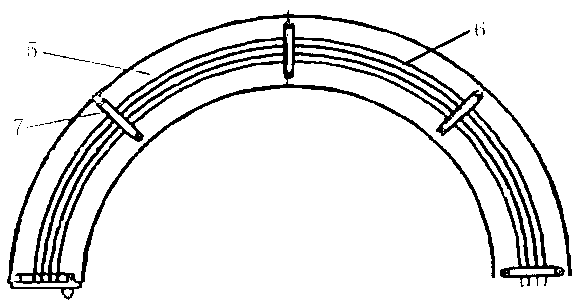

The invention belongs to the field of machining and particularly relates to a method using 0 chromium (Cr) 17 nickel (Ni) 4 copper (Cu) 4 niobium (Nb) thin wall square pipes to machine and manufacture linkage ring guide pipe parts. The method is characterized in that the 0 Cr 17 Ni 4 Cu 4 Nb thin wall square pipes with 0.6 + / - 0.03 millimeter wall thickness are used as pipe materials, after burrs are removed, rosin or sand is poured into the pipe materials which are disposed in a roll bending forming mould to be molded in a roll bending mode, the rosin or the sand in the pipe materials is removed after the pipe materials are molded in a roll bending mode, and the pipe materials are disposed on a shape rectifying mould to be rectified for 2-4 hours, and then ports of the pipe materials are cut off, after the pipe materials are in fluoroscopy examination, a heat treatment of the pipe materials at temperature of 1030-1050 DEG D under a vacuum condition for 10-30 minutes is carried out, then the pipe materials are disposed on the shape rectifying mould again to be rectified for 2-4 hours, after the pipe materials are in end cutting and the fluoroscopy examination after being rectified, the linkage ring guide pipe parts can be obtained. The technical scheme fully solves the problems that precipitation hardening type martensitic stainless steel 0 Cr 17 Ni 4 Cu 4 Nb thin wall square pipes are low in plasticity and difficult to machine, and the linkage ring guide pipe parts which meet requirements of aero-engine use are manufactured and machined.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

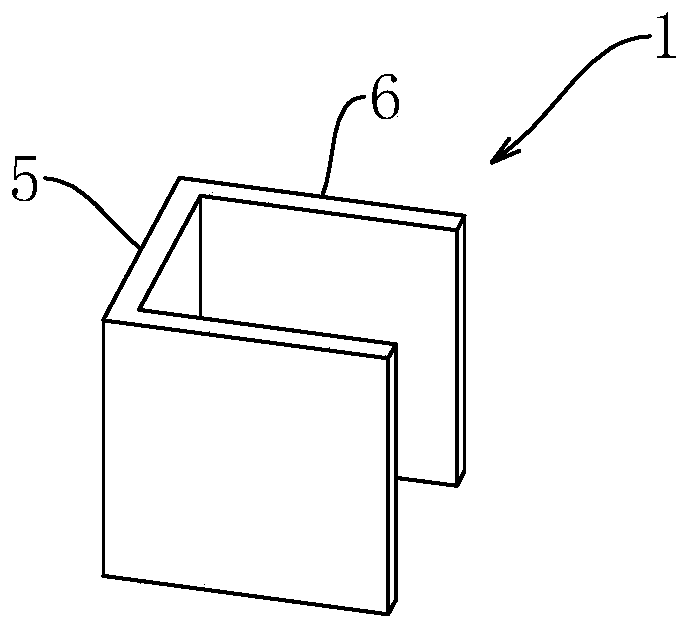

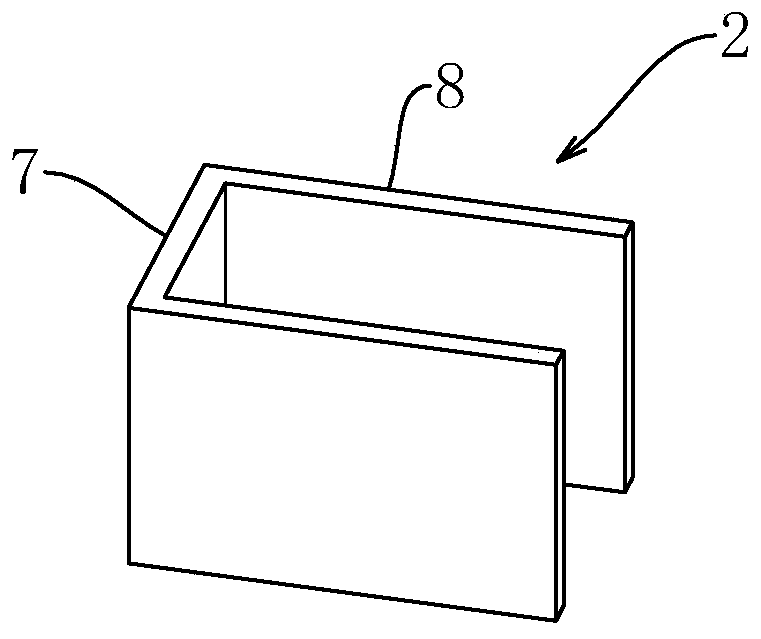

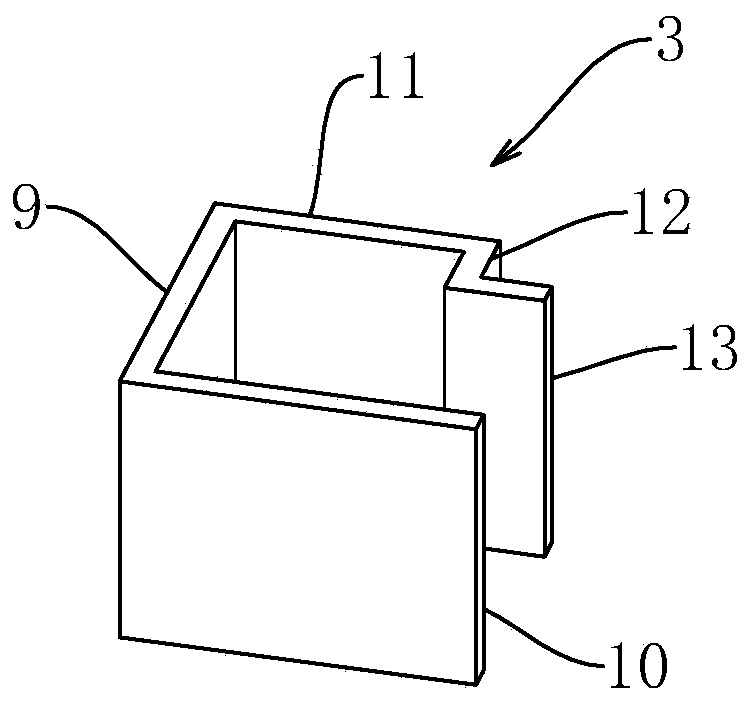

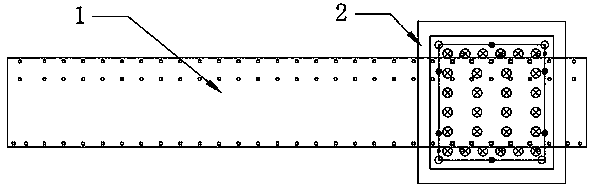

End effector, surgical operating instrument and purse-string forceps

ActiveCN104434245AImprove securityImprove molding pass rateSuture equipmentsSurgical staplesMedical equipmentPurse string suture

The invention relates to the technical field of medical equipment, and discloses an end effector, a surgical operating instrument and purse-string forceps. By means of the end effector, the surgical operating instrument and the purse-string forceps, purse-string nails can be made to be connected with lumen tissue firmly, and the risk that the lumen tissue is pierced through is completely avoided; the end effector and the surgical operating instrument can further simplify the operation process of an operation and relieve trauma brought to a surgery patient. The end effector comprises a first forceps arm, a second forceps arm, a suture mechanism, a purse-string suture mechanism and a cutting mechanism, wherein the suture mechanism is arranged on one side of the longitudinal direction of the two forceps arms, the purse-string suture mechanism is arranged on the other side of the longitudinal direction of the two forceps arms and the cutting mechanism is arranged between the suture mechanism and the purse-string suture mechanism. The purse-string suture mechanism comprises a first purse-string nail box arranged on the first forceps arm, a second purse-string nail box arranged on the second forceps arm and a double-sided nail anvil located between the two purse-string nail boxes, the purse-string nails are arranged in the two purse-string nail boxes respectively, and the surfaces, facing the double-sided nail anvil, of the two purse-string nail boxes are provided with purse-string lines.

Owner:REACH SURGICAL

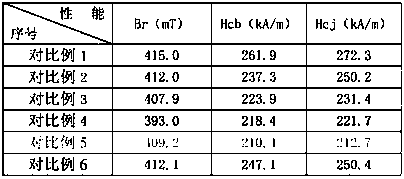

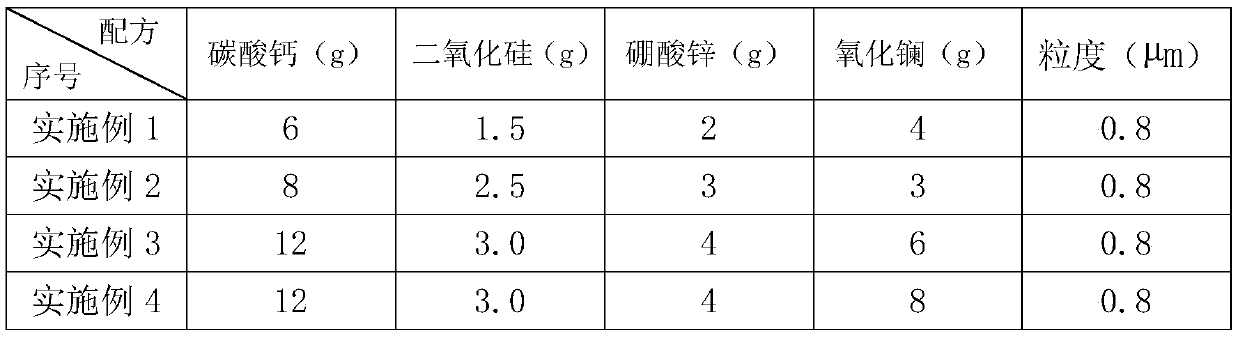

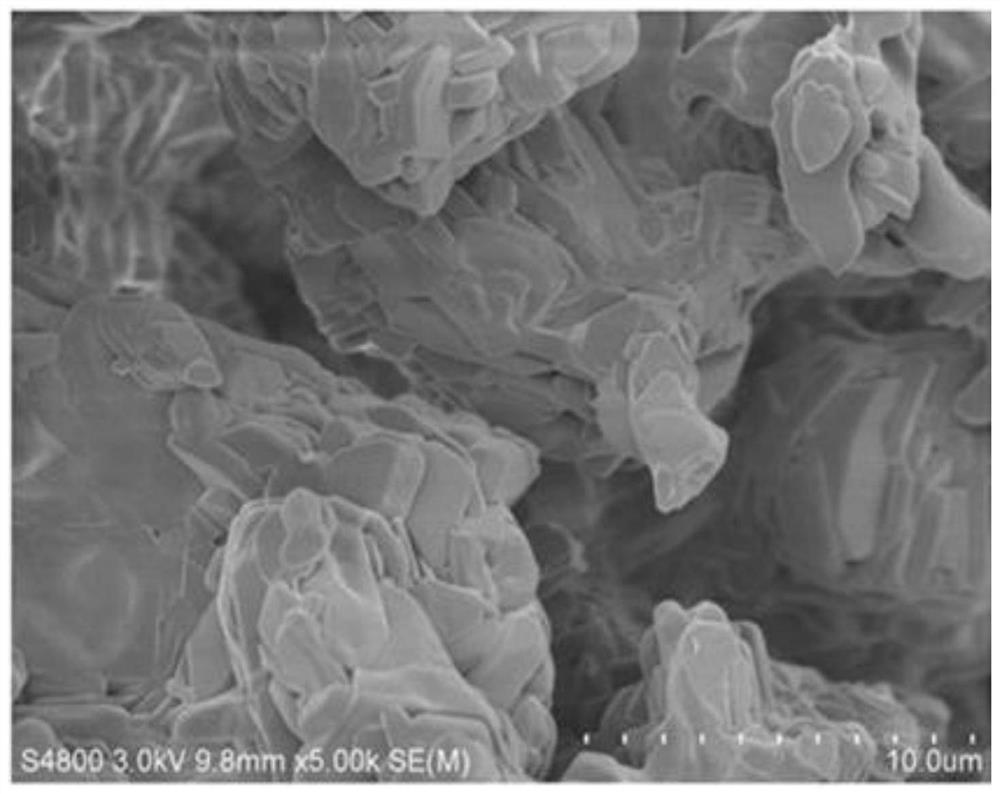

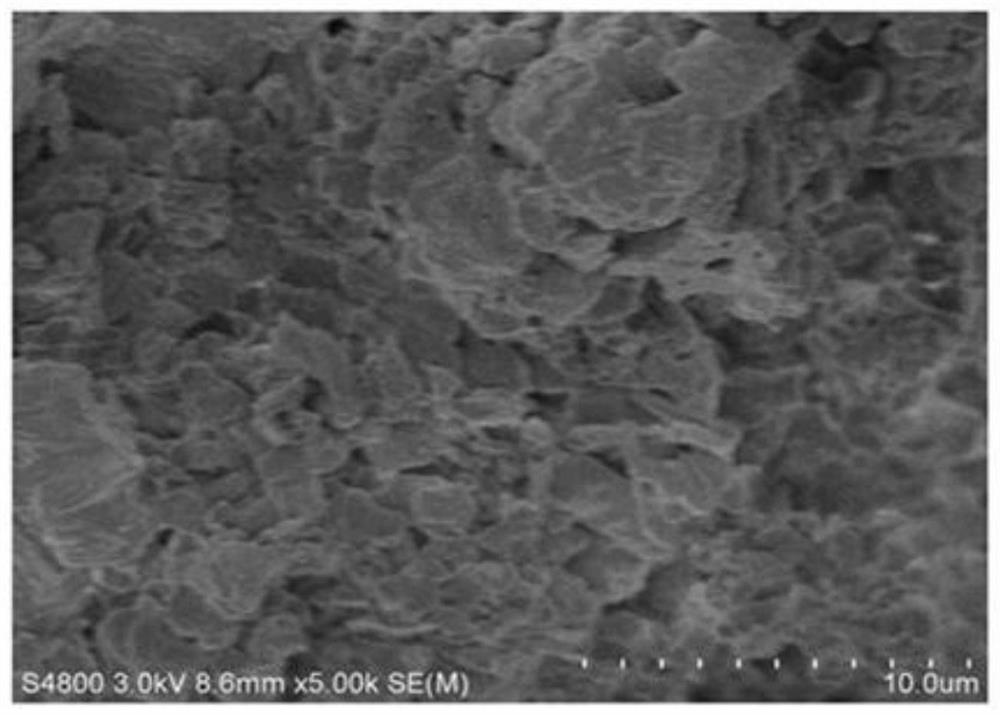

Method for improving magnetic performance of permanent magnetic ferrite

InactiveCN111099889AStrong magnetismImprove molding efficiencyInorganic material magnetismZinc borateSilicon oxide

A method for improving the magnetic property of a permanent magnetic ferrite comprises the following steps: (1) adding a permanent magnetic ferrite pre-sintered material into a ball mill, adding calcium carbonate, silicon dioxide, zinc borate and lanthanum oxide, adding water, and carrying out ball milling to obtain permanent magnetic ferrite slurry; (2) precipitating and filtering the permanent magnetic ferrite slurry obtained in the step (1) to obtain permanent magnetic ferrite filter slurry; (3) injecting the permanent magnetic ferrite filter slurry obtained in the step (2) into a mold, andcarrying out pressure molding in a magnetic field to obtain a permanent magnetic ferrite green body; and (4) sintering the permanent magnetic ferrite green body obtained in the step (3) to obtain thepermanent magnetic ferrite. Compared with the traditional process method, the technical scheme provided by the invention can obtain excellent magnetic performance under the condition that the granularity of the slurry is greater than or equal to 1.0 [mu]m, so that the forming difficulty of the slurry is reduced, the production efficiency is improved, and the method is more suitable for preparinga permanent magnet device with a complex shape.

Owner:HUNAN AEROSPACE MAGNET & MAGNETO

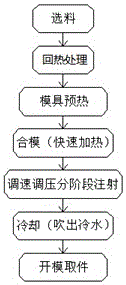

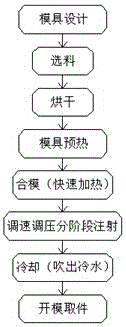

Steam type high fineness and no-weldlines injection moulding process for complex precise plastic product

The invention discloses a steam type high fineness and no-weldlines injection moulding process for a complex precise plastic product. The process comprises the following steps: (1) material selection; (2) backheating treatment; (4) mold preheating; (5) die assembly and quick heating; (6) speed-regulating and pressure-regulating injection in stages; (7) quick cooling; and (8) mold opening to take piece. According to the process disclosed by the invention, corresponding backheating treatment is performed on a material body, so that the internal stress problem of the material body is solved; then, an injection mold is of a design of a hot runner and a cold runner multipoint feeding subsurface gate, and meanwhile, the travel times of the corresponding hot runner and cold runner are added for a key portion of a product, so that the problems that a plastic melt is slow to flow at a far end to generate sink marks and the internal stress exists and the like are solved, and therefore, the appearance quality and the forming percent of pass of the product are extremely improved, the process cost and the like are reduced, and the actual using demand is met.

Owner:滁州市天悦塑胶制品有限公司

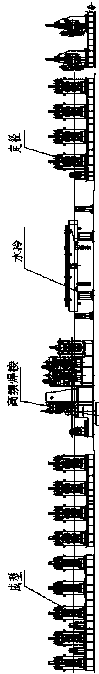

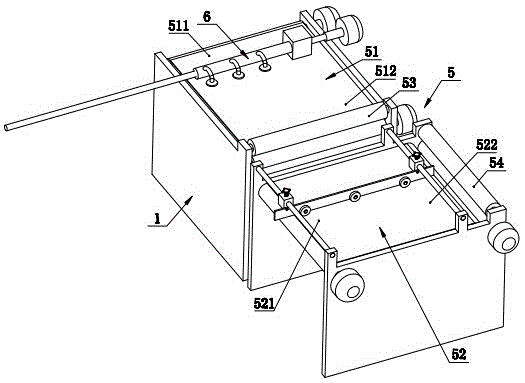

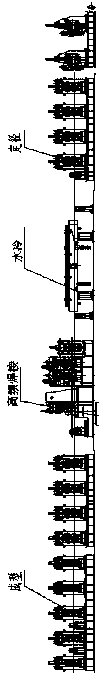

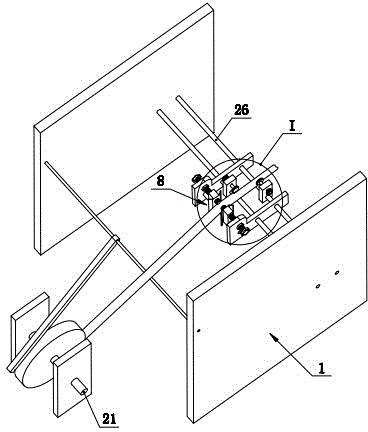

Straight seam welding special-shaped steel pipe forming process and mold changing apparatus for automobile anti-collision beam

The invention relates to a straight seam welding special-shaped steel pipe forming process for an automobile anti-collision beam. The straight seam welding special-shaped steel pipe forming process for the automobile anti-collision beam comprises the following steps of: (1) uncoiling, unrolling a steel strip coil; (2) flattening, flattening the unrolled steel strip and conveying the flattened steel strip to the next station; (3) flat cutting and butt welding, flat cutting a head portion and a tail portion of the flattened steel strip respectively, and butt welding a tail of the steel strip material after the flat cutting with a head of the next steel strip material after the flat cutting; (4) pre-storing, feeding the butt welded steel strip into a movable sleeve storage bin; (5) forming, conveying the steel strip in the movable sleeve storage bin to a forming machine, and gradually bending into a tube blank to be welded according to a certain sequence; (6) high-frequency welding, pressing the opposite ends of the tube blank to form a certain opening angle, and then to perform high-frequency welding; (7) Water cooling, cooling the high-frequency welded steel tube to room temperatureby spraying; (8) special-shaped gradient sizing, sizing the water-cooled steel tube by a sizing ; (9) profile machining, cutting the sized steel tube into specific lengths.

Owner:山东华舜重工集团有限公司

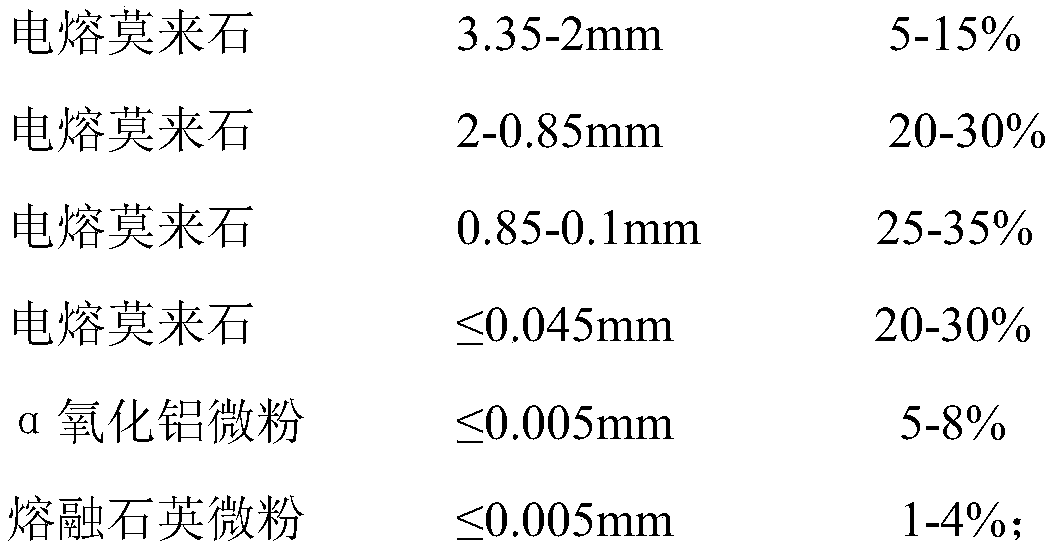

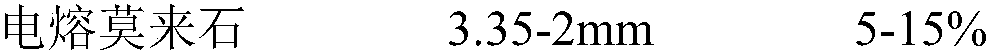

High-purity low-creep-deformation electrofused mullite brick and preparation method thereof

The invention specifically relates to a high-purity low-creep-deformation electrofused mullite brick and a preparation method thereof, belonging to the technical field of refractory materials. The high-purity low-creep-deformation electrofused mullite brick comprises the following raw materials: 5 to 15% of electrofused mullite with a particle size of 3.35 to 2 mm, 20 to 30% of electrofused mullite with a particle size of 2 to 0.85 mm, 25 to 35% of electrofused mullite with a particle size of 0.85 to 0.1 mm, 20 to 30% of electrofused mullite with a particle size of no more than 0.045 mm, 5 to8% of alpha-alumina micropowder with a particle size of no more than 0.005 mm, 1 to 4% of fused silica micropowder with a particle size of no more than 0.005 mm, and an external organic binding agentaccounting for 0.1 to 5% of the total weight of the above raw materials. The high-purity low-creep-deformation electrofused mullite brick provided by the invention is extremely low in impurity content, high in softening-point temperature under load, good volume stability at high temperature and low creep rate at high temperature. The invention also provides the preparation method which is simple,practicable, energy-saving and environment-friendly.

Owner:ZIBO GT INDAL CERAMICS

Method for preparing and constructing pipe die coating

ActiveCN102527925ALow gas productionHigh strengthFoundry mouldsFoundry coresSurface roughnessStock solution

The invention discloses a method for preparing and constructing a pipe die coating and belongs to the technical field of centrifugal casting pipes. The method for preparing the pipe die coating mainly comprises the following steps: preparing mud, preparing a stock solution, preparing a sizing liquid and preparing a final coating. The method for constructing the pipe die coating mainly comprises the following steps: heating a pipe die, cleaning the pipe die and spraying paint. The method for preparing and constructing the pipe die coating has the beneficial effect that the coating with lower gas forming amount, higher strength, stronger suspension property and better demoulding performance is successfully developed by optimizing a coating preparation process; the forming acceptability and appearance quality of the pipe are improved by optimizing a coating construction process; the forming acceptability of the pipe is maintained to be about 99.5%; and the surface roughness of the pipe is below gradient 25.

Owner:XINXING DUCTILE IRON PIPES CO LTD

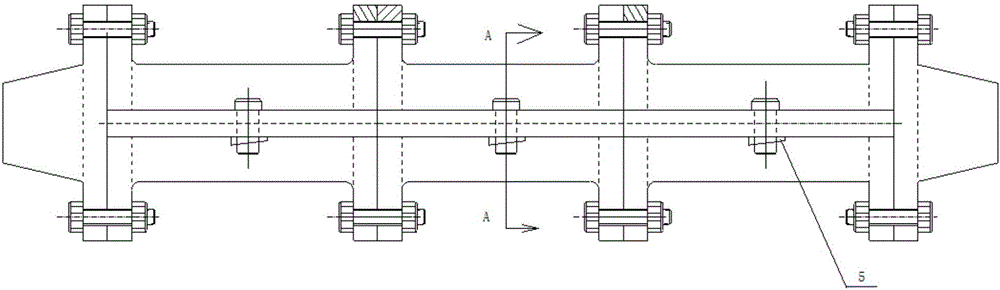

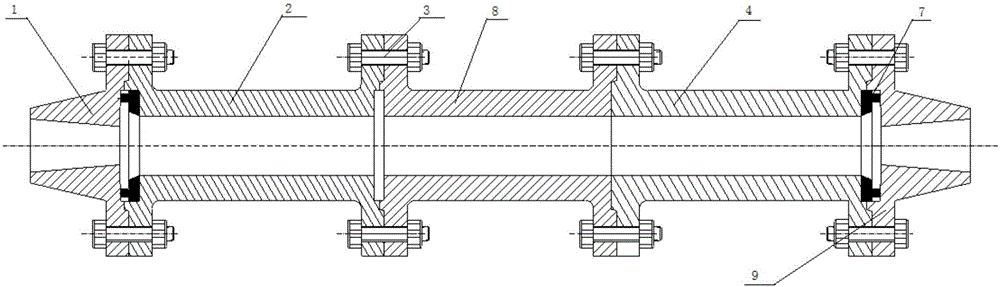

Double-disk flange and through-wall flange spheroidal graphite cast iron straight pipe integral casting technology

ActiveCN106694817AImprove protectionImprove molding pass rateFoundry mouldsFoundry coresSteel tubePressure casting

The invention discloses a double-disk flange and through-wall flange spheroidal graphite cast iron straight pipe integral casting technology. A lower section flange outer die, a through-wall flange section outer die, a transitional section outer die, an upper section flange outer die, a steel pipe framework, a transitional section core, a parting surface locating table, a through-wall flange, a screw rod and the like are involved; the screw rod is arranged on a lower pressing plate and fixed at the lower part of the lower pressing plate through a nut; a lower section core, a core connection sleeve and the through-wall flange are arranged on the lower pressing plate; the through-wall flange section outer die is arranged on the lower section flange outer die; the transitional section outer die and the upper section flange outer die are arranged on the through-wall flange section outer die; an ingate is arranged at the right middle part of the lower section core; the transitional section core and the parting surface locating table are arranged at the right part of the lower section core. According to the double-disk flange and through-wall flange spheroidal graphite cast iron straight pipe integral casting technology, by horizontal parting and vertical stepped negative pressure pouring, the molding qualification rate is increased, and the quality is more reliable; pressure casting enables an alloy structure to be more compact, so that the environmental protection is facilitated, dust can be all recycled, and environmental-friendly casting is really realized; the technology is applied to the technical field of integral casting of metals.

Owner:LIAONING EVER FOUNDRY CO LTD

ABS plastic television shell injection molding technology

The invention discloses an ABS plastic television shell injection molding technology. The technology is implemented on the basis of a corresponding injection molding system and an injection molding die. The injection molding system comprises a plurality of spiral cylinders. The injection molding die comprises a heat flow system formed by multiple heat flow channels, and a cold flow system formed by multiple cold flow channels. The technology comprises the step one of raw material pretreatment; the step two of injection molding system and injection molding die pretreatment; the step three of plastifying; the step four of injection; the step five of pressure maintaining; the step six of cooling and forming; and the step seven of die releasing. According to the technology, the steps of the technology are simplified, the period is shortened, the problem that inner stress exists in formed finished plastic products is solved, then the product quality and attractiveness are improved greatly, the forming yield and the like are increased greatly, the service life of the products is prolonged, and the requirement of actual use is met.

Owner:滁州市天悦塑胶制品有限公司

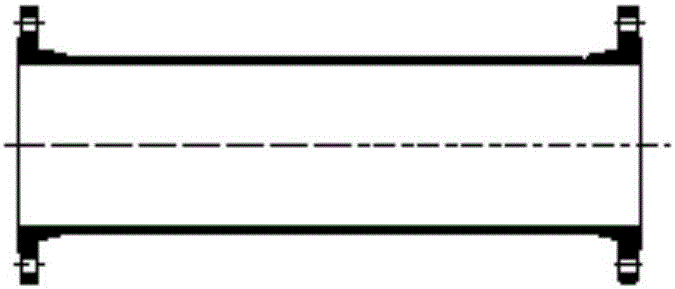

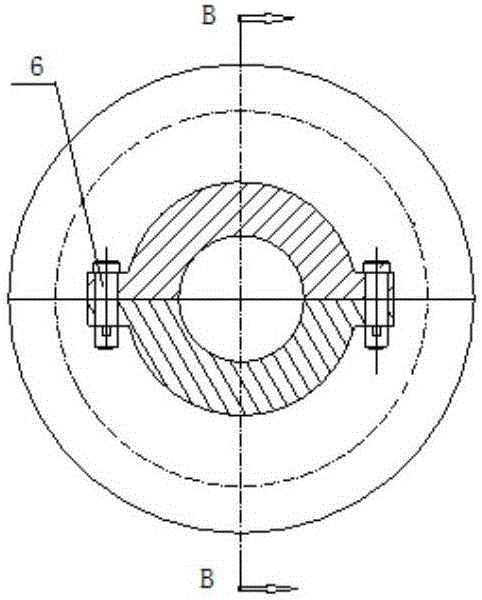

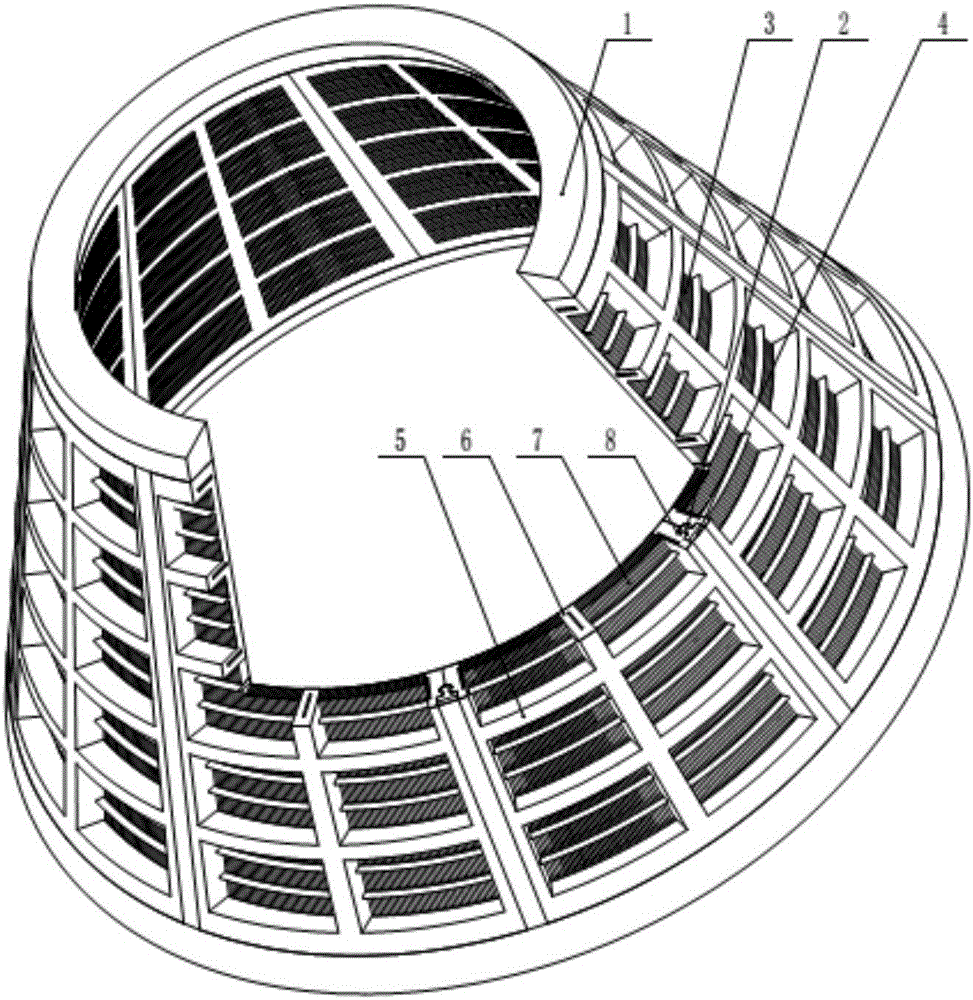

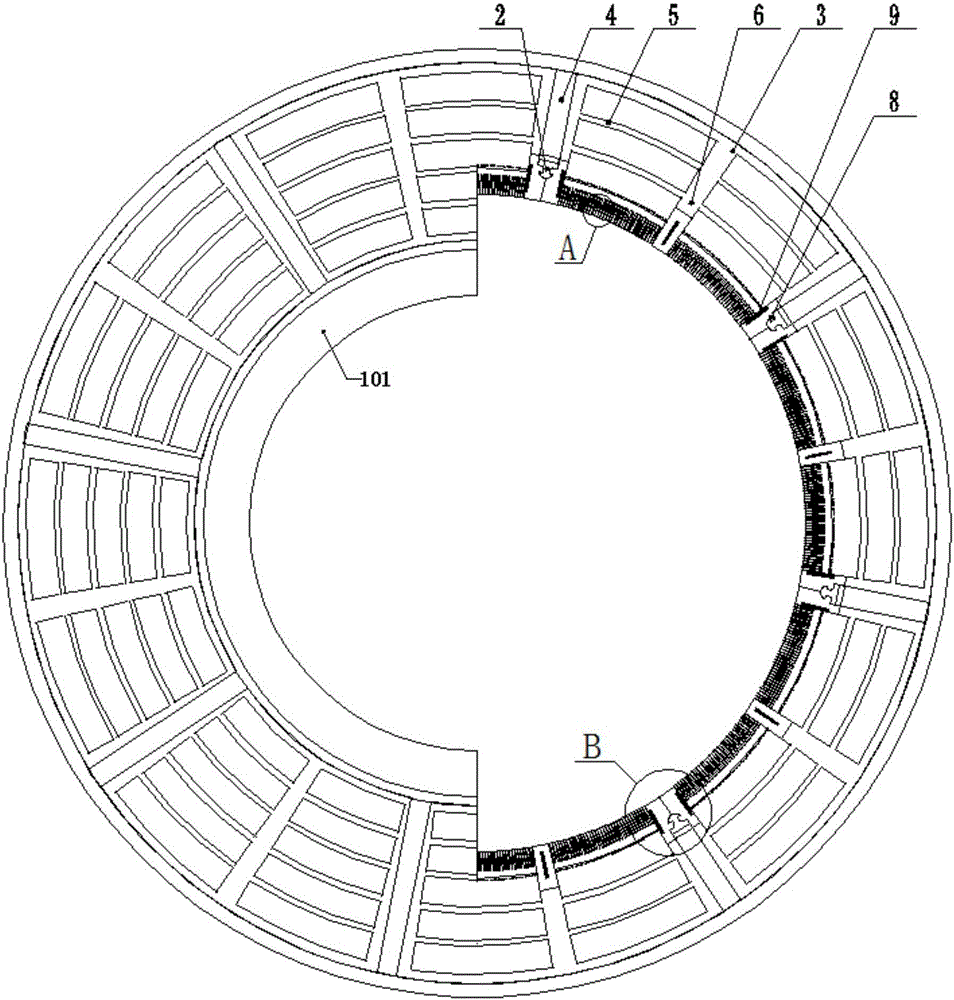

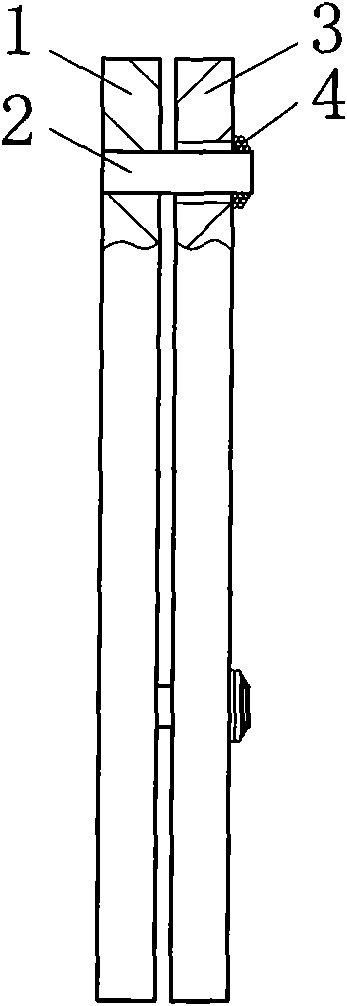

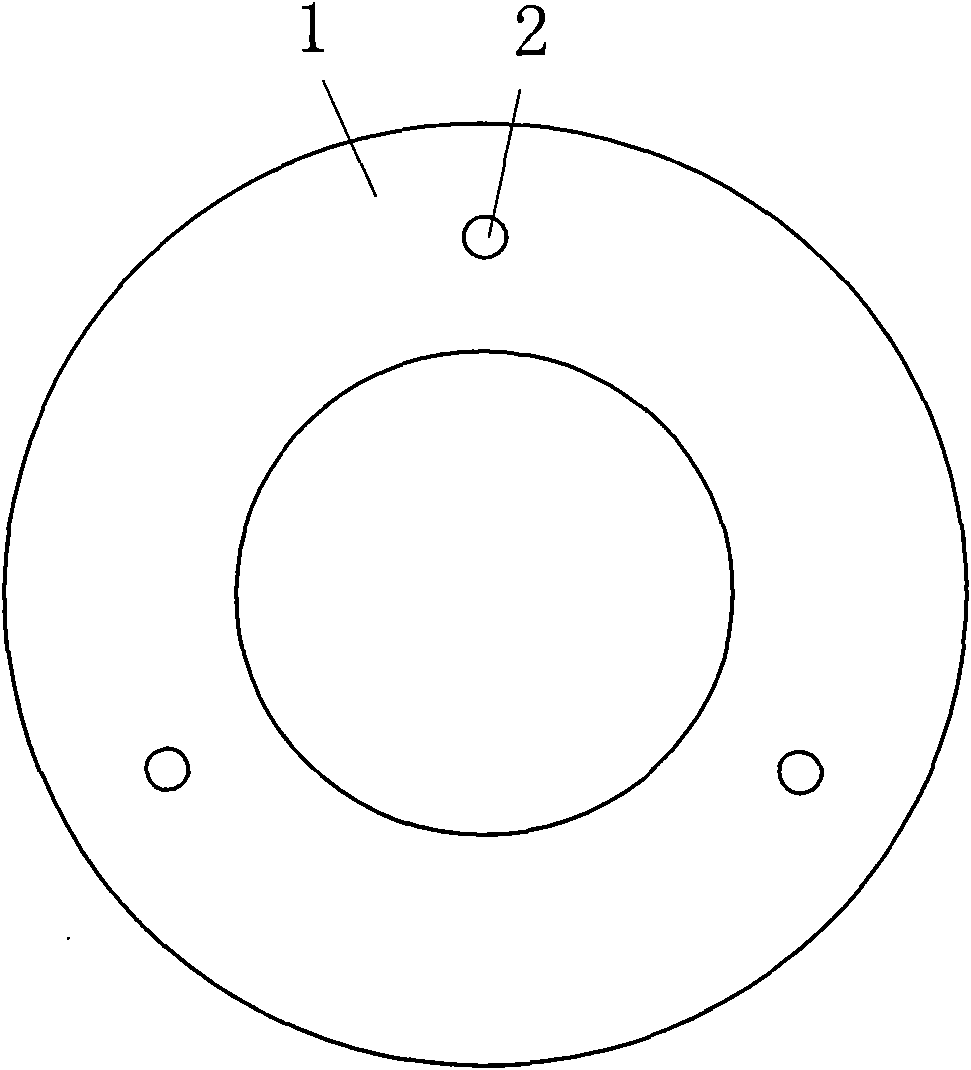

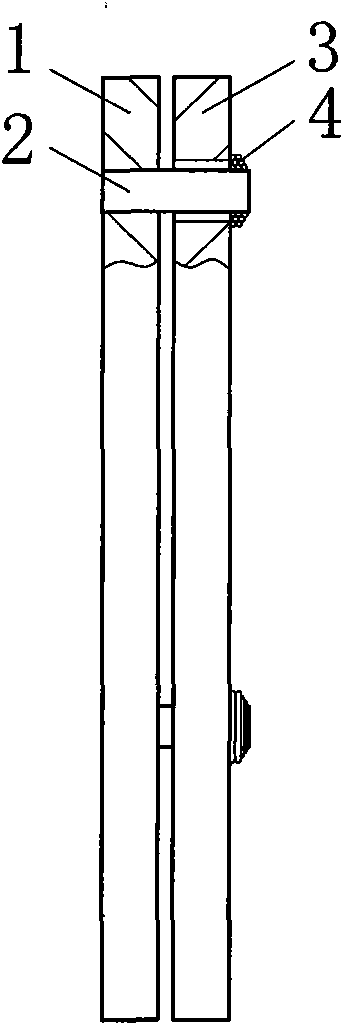

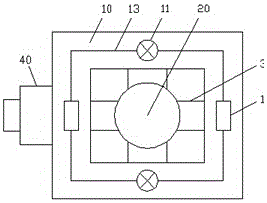

Centrifugal integral cast metal mould for dual-tray flange straight pipes

ActiveCN106735045AEffective control of pipe wall thicknessTo satisfy the market's needsEngineeringFlange

A centrifugal integral cast metal mould for dual-tray flange straight pipes comprises a left tapered plug tray, a through-wall flange pipe borne mould, fastening bolts, a non-through-wall flange pipe mould, a wedge, a fitting pin, a resin sand withdrawal core, a transition section pipe mould and a right tapered plug tray; the resin sand withdrawal core is connectively mounted between the through-wall flange pipe borne mould and the non-through-wall flange pipe mould through the fastening bolts, the through-wall flange pipe borne mould and the transition section pipe mould are connected through the fastening bolts, the transition section pipe mould and the non-through-wall flange pipe are connected through the fastening bolts, and the resin sand withdrawal core is connectively mounted between the non-through-wall flange pipe mould and the right tapered plug tray through the fastening bolts. By the arrangement, the mould is combined and assembled in design, requirements of different through-wall flanges on position are met, mass production can be realized through horizontal centrifugal casting, market requirement is met, environment protection is facilitated, dust can be fully recycled, environment friendly casting is truly realized, and the centrifugal integral cast metal mould is applied to the technical field of centrifugal casting.

Owner:营口经济技术开发区爱维尔铸业有限公司

Construction method of construction column of secondary structure

The invention relates to the technical field of construction column construction, in particular to a construction method of a construction column of a secondary structure. The construction method of the construction column of the secondary structure has the advantage that the construction yield is high. The construction method of the construction column of the secondary structure comprises the steps that 1, building blocks of the construction column are prefabricated; 2, spring wires are paid off; 3, ribs are planted; 4, a first layer of a wall is built; 5, concrete is poured; 6, the wall is built to the half height; 7, transverse steel bars are tied; 8, the upper half portion of the wall is built; and 9, the wall is maintained. The prefabricated building blocks are matched with wall building bricks to form a cavity in the rib planting portion, and the concrete is poured into the cavity to directly form the construction column. Due to the fact that the construction column is not formedthrough assisting of a wood formwork, the problem that the wood formwork is old and damaged does not need to be considered, and the yield of wall forming is high. Meanwhile, time for disassembling the wood formwork is saved, and the construction time is shortened.

Owner:福建磊鑫(集团)有限公司

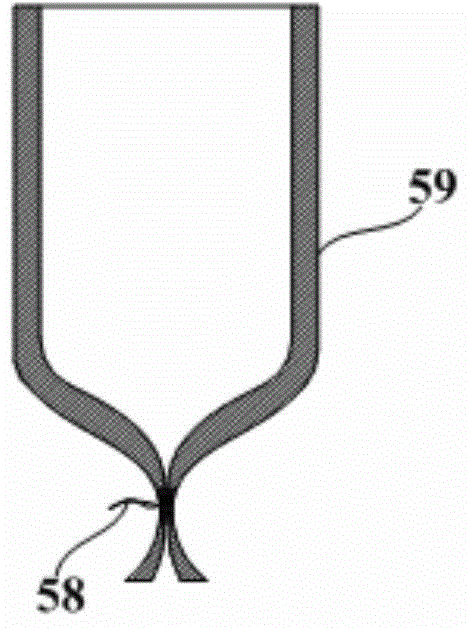

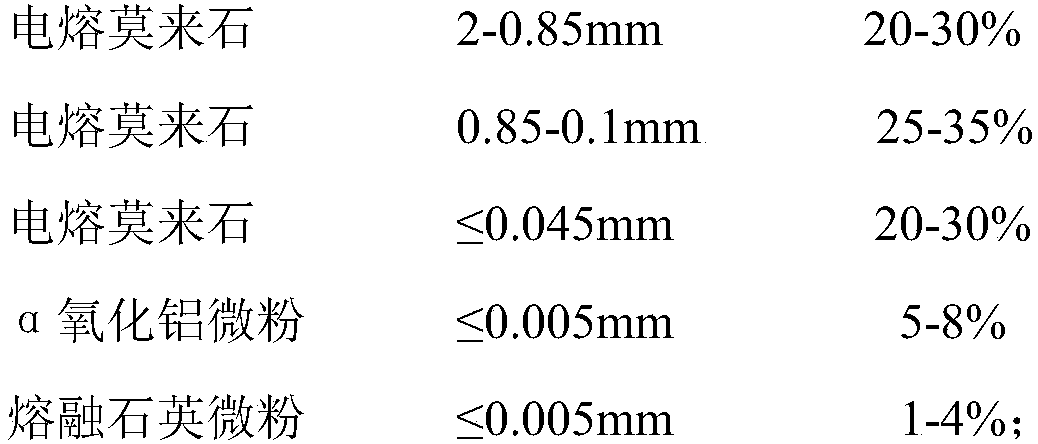

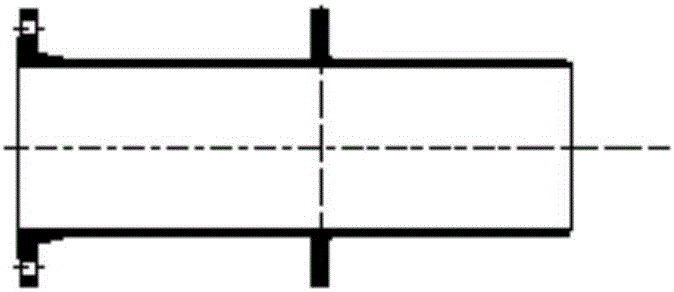

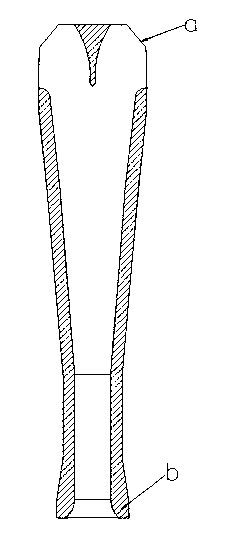

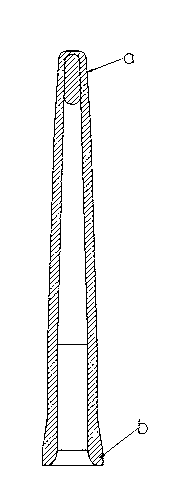

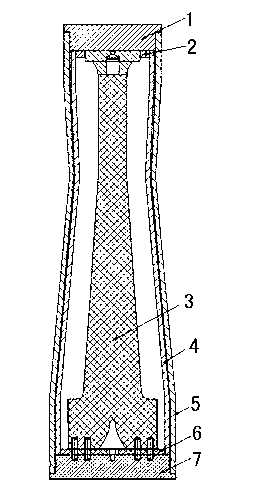

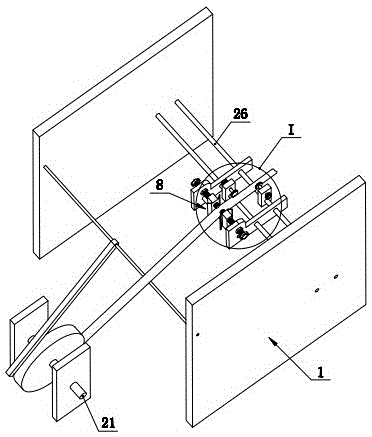

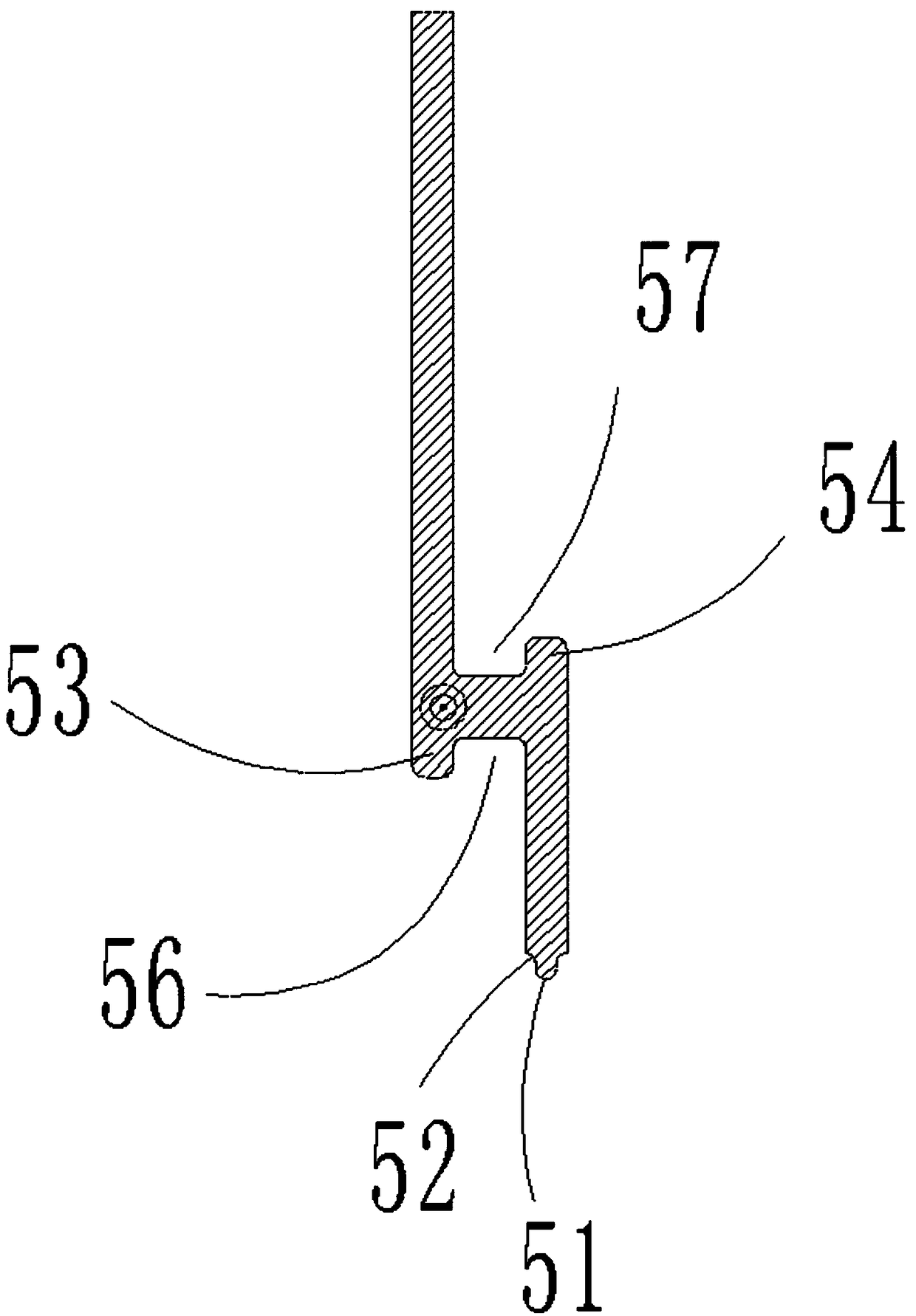

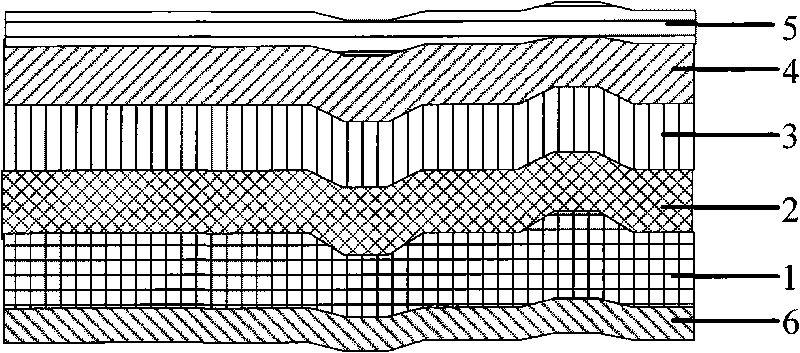

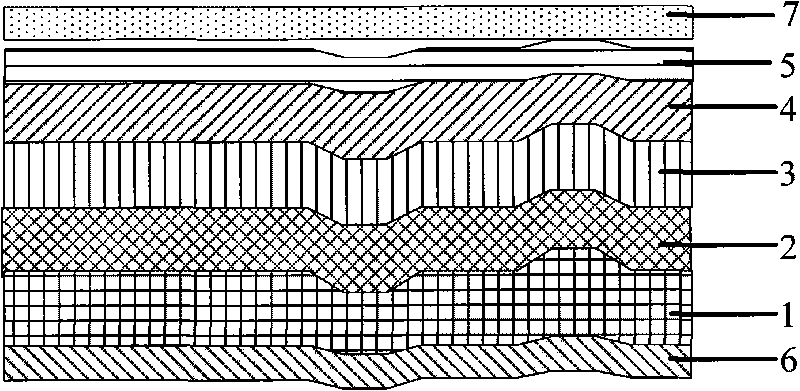

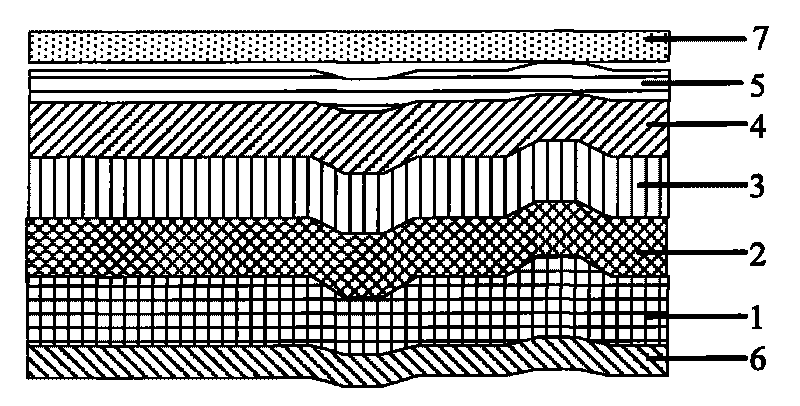

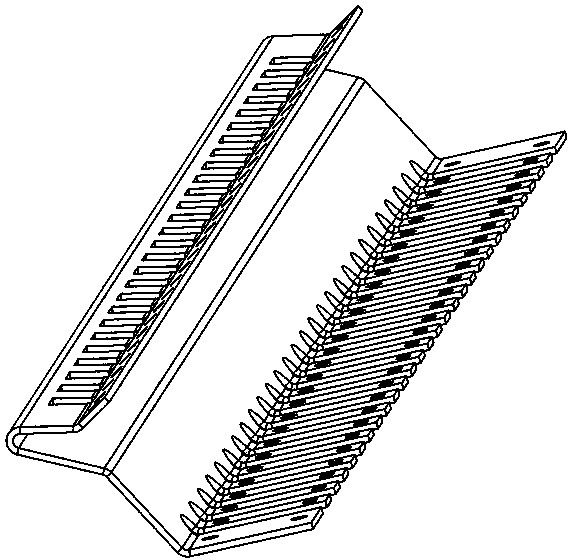

Production method for submerged nozzle of sheet billet

InactiveCN102836994AAvoid scratchesImprove molding pass rateMelt-holding vesselsPolymer scienceThin sheet

The invention discloses a production method for a submerged nozzle of a sheet billet. The production method for the submerged nozzle of the sheet billet comprises the following steps of: firstly, blending: blending raw materials according to the preset weight percentage: secondly, mixing and granulating: mixing the blended materials in the first step, adding a bonding agent and using granulating machine granules and drying granules to meet the forming conditions; thirdly, forming: adding the granules obtained in the second step into a submerged nozzle combined die of the sheet billet, closing and pressing by an isostatic pressing machine to form; fourthly, drying and sintering; and fifthly, machining: machining products obtained in the fourth step according to the requirement of the set size to obtain finished products, wherein the submerged nozzle combined die of the sheet billet in the third step comprises a base, an assembly core, an outer rubber sleeve and rubber covers, and the assembly core and the outer rubber cover are fixedly arranged on the base and the rubber covers are used for sealing the assembly core and the outer rubber cover; an inner rubber cover is arranged between the outer rubber cover and the assembly core; and an inner rubber sleeve fixing plate is arranged between the assembly core and the base.

Owner:SHANGHAI BAOMING REFRACTORIES CO LTD

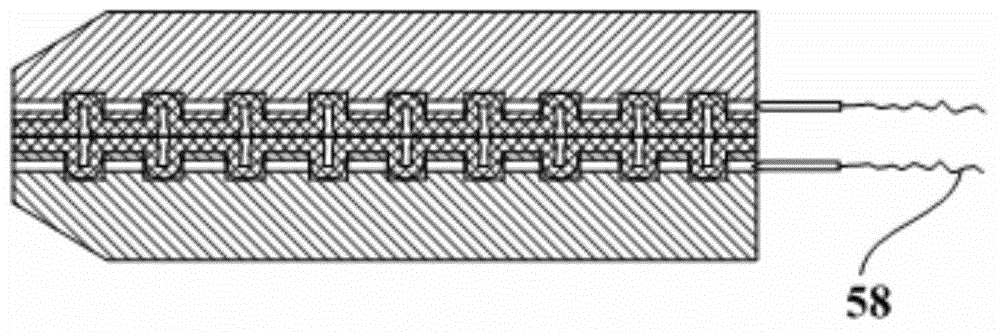

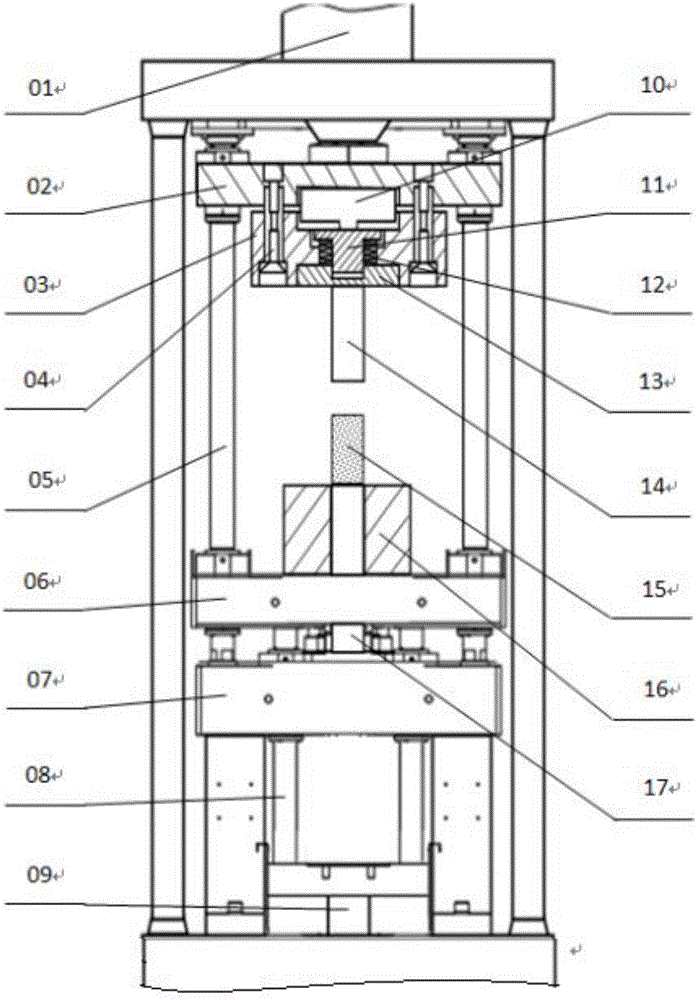

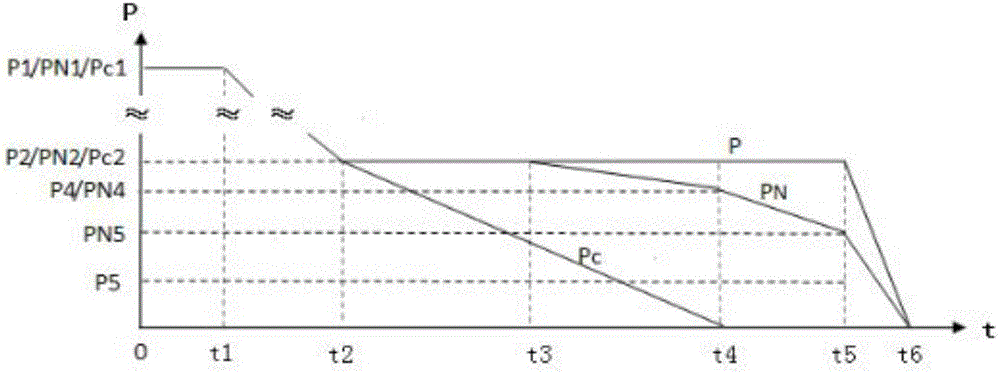

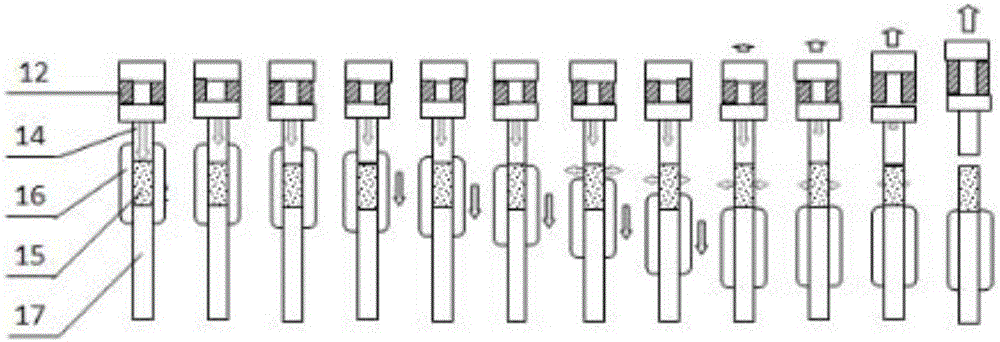

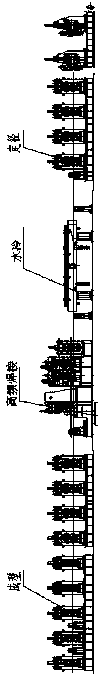

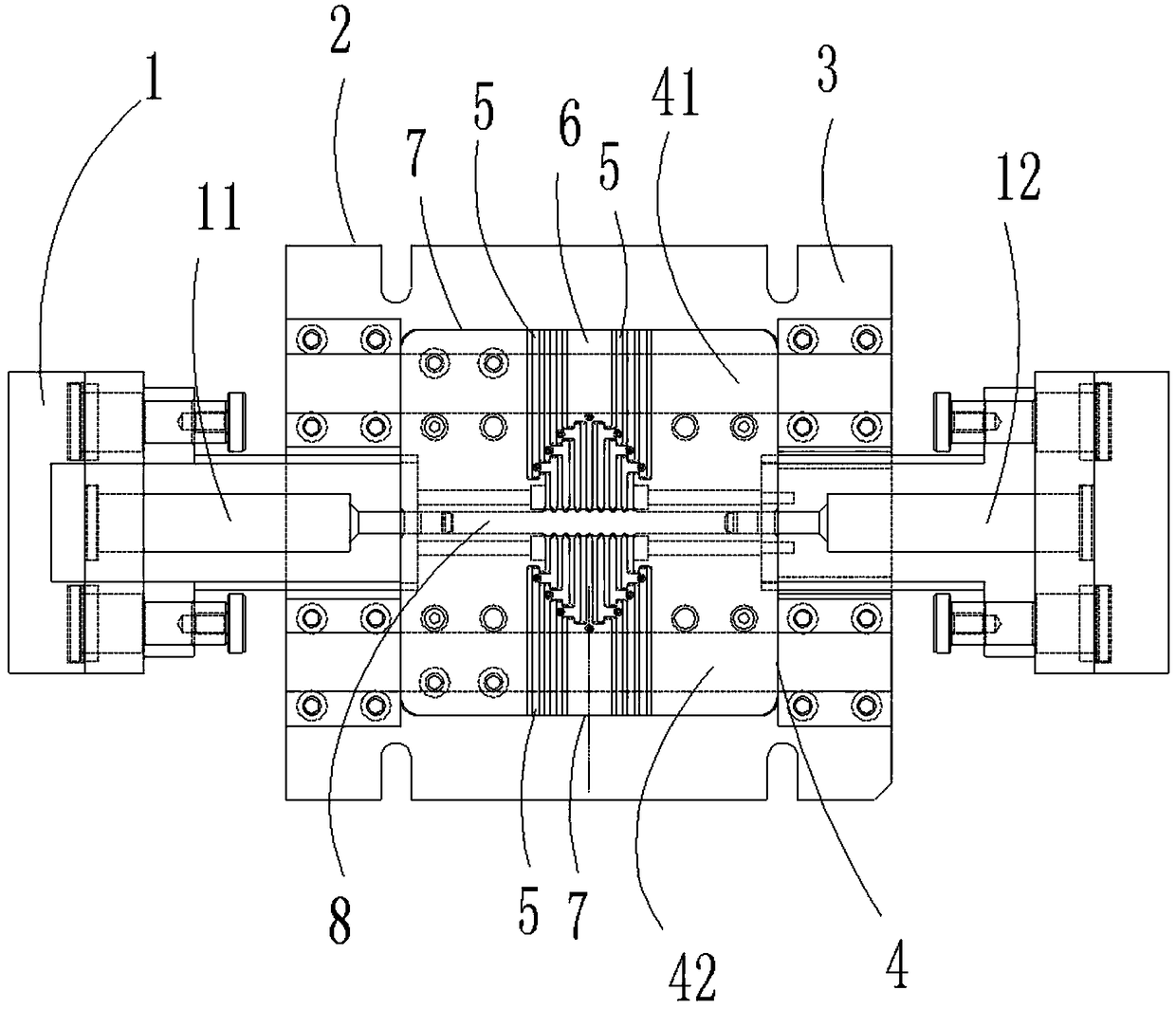

Pressing device and method of full-automatic magnetic powder molding press

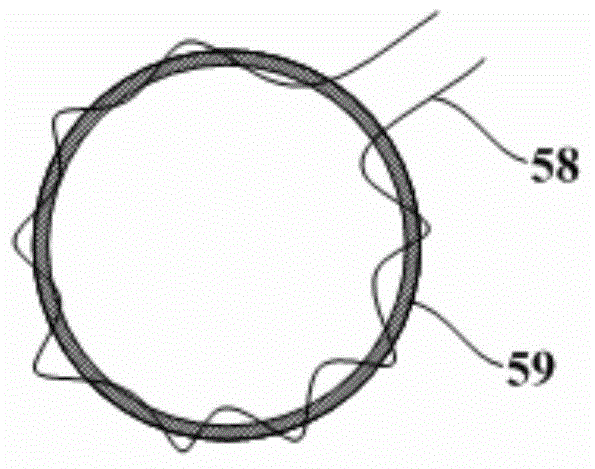

The invention discloses a pressing device and method of a full-automatic magnetic powder molding press. The pressing device comprises a pressure rack, wherein two ends of the pressure rack are respectively a rack top plate and a rack tabletop plate; the pressing device further comprises an upper mold trace releasing pressure retention device, a lower mold device and a guide column frame transmission mechanism; the upper mold trace releasing pressure retention device comprises an upper template and a pressure retention mounting module; the upper template is provided with an upper template cavity with a downward opening; a sensor is arranged in the upper template cavity; the pressure retention mounting module is provided with a steplike cavity which runs through in the vertical direction; a mounting plate is encapsulated at the lower part of the steplike cavity; and a guide mandril and a spring are embedded in the steplike cavity in a sliding manner. The pressing device of the full-automatic magnetic powder molding press realizes real-time monitoring and control for the whole molding process of a magnet blank; and when the pressing device is applied to a magnet blank manufacturing method provided by the invention, the springback tension in the magnetic blank can be effectively reduced or eliminated, so that the molding qualification rate of the magnet blank is increased.

Owner:上海平野磁气有限公司 +1

Special-shaped steel tube forming technology and mold replacement device for semitrailer fence

InactiveCN108526241AGuaranteed continuous productionIncrease productivityShaping toolsButt weldingButt joint

The invention relates to a special-shaped steel tube forming technology for a semitrailer fence. The special-shaped steel tube forming technology for the semitrailer fence comprises the steps of first, uncoiling, wherein steel strip rolls are unfolded; second, leveling, wherein unfolded steel strips are leveled, and are conveyed to a next station; third, end flattening and butt welding, wherein the head portion and the tail portion of one leveled steel strip are cut to be flattened, and the material tail of the steel strip with ends cut to be flattened and the material head of a next steel strip with ends cut to be flattened are welded together; fourth, beforehand storage, wherein the steel strips subjected to butt joint are sent into a loop storage silo; fifth, forming, wherein the steelstrips in the loop storage silo are sent to a forming machine, and are sequentially bent into tube blanks to be welded; sixth, high efficiency welding, wherein high efficiency welding is carried out after the two ends, in butt joint, of every two adjacent tube blanks are pressed to form a certain open angle; seventh, water cooling, wherein the steel tubes subjected to high efficiency welding are cooled to the room temperature in a spraying manner; eighth, special shape gradual sizing, wherein the steel tubes subjected to water cooling are sized through a sizing unit; and ninth, profile machining, wherein the sized steel tubes are segmented into steel tube bodies of specific lengths.

Owner:山东舜世高科实业有限公司

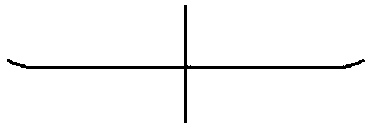

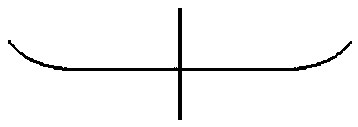

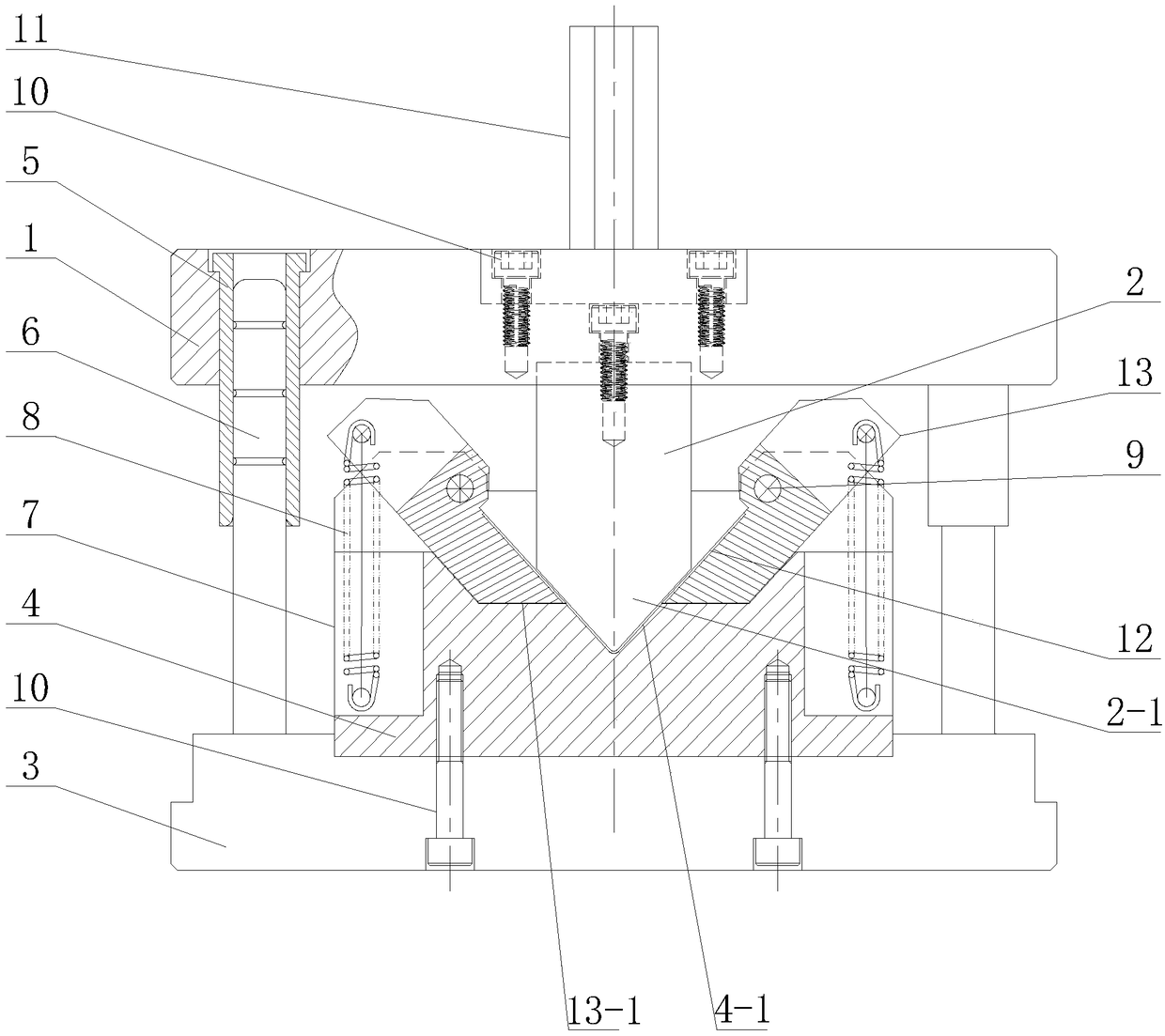

V-shaped workpiece bending-forming mold and forming method

InactiveCN108637048AImprove molding pass rateImprove molding efficiencyShaping toolsEjection devicesPunch pressEconomic benefits

The invention discloses a V-shaped workpiece bending-forming mold and a forming method, and belongs to the field of mold processing. The V-shaped workpiece bending-forming mold and the forming methodaim to solve the problems that existing V-shaped workpiece processing techniques are high in rejection rate and economic benefits are affected. The V-shaped workpiece bending-forming mold comprises anupper mold holder, a male mold, a lower mold holder and a female mold, wherein the upper mold holder and the lower mold holder are sequentially arranged from top to bottom, the upper end of the malemold is connected with the upper mold holder, and the lower surface of the female mold is connected with the upper surface of the lower mold holder; and a downwards-convex V-shaped protrusion is arranged at the lower end of the male mold, a V-shaped groove matched with the V-shaped protrusion is formed in the upper surface of the female mold, and the V-shaped groove is located under the V-shaped protrusion. The bending forming of a V-shaped workpiece is achieved through the mode that the male mold and the female mold are matched, the forming qualified rate of the V-shaped workpiece is effectively improved, and the economic benefit is increased; the two turnover plates can quickly and automatically take out the formed V-shaped workpiece, and the forming efficiency of the V-shaped workpiececan be effectively improved; the mold is simple in structure and can adapt to various power equipment, not limited to a punch press.

Owner:FOSHAN ENCI TECH CO LTD

Polyurethane sieve basket and forming method thereof

The invention relates to a polyurethane sieve basket suitable for the industry of screening of black metal, non-ferrous metal, coal, building materials, petrochemical engineering, abrasive material and the like, and a forming method of the polyurethane sieve basket. The polyurethane sieve basket comprises a frame body and n sieve plates arranged on the frame body. The frame body comprises a bottom frame, a top frame and n spokes connecting the bottom frame and the top frame. The sieve plates are arranged between every two adjacent spokes. The two sides of each sieve plate are fixedly connected with the corresponding spokes; and n is a natural number equal to or larger than two. According to the polyurethane sieve basket, an assembly type structure is adopted, the integrally-formed sieve plates are adopted and all installed on the frame body of the sieve basket, and the sieve basket is simple in overall structure and convenient to form; when one sieve plate is abraded, the abraded sieve plate can be replaced independently, so that the maintenance cost is greatly reduced; and the aperture ratio is high, and the service life is long. Meanwhile, the invention further discloses the forming method of the polyurethane sieve basket.

Owner:北京斯克瑞科技有限公司

Follower baffle plate for centrifugal casting by hot mold method

The invention relates to a baffle plate for centrifugal casting by hot mold method, which comprises a fixed plate, sliding small shafts and a follower plate, 2-6 sliding small shafts are fixed on the end surface of the fixed plate, sliding holes which correspond to the sliding small shafts are arranged on the follower plate, the sliding holes are in clearance fit with the sliding small shafts, the follower plate is fixed with the fixed plate through the sliding small shafts, and fine aluminum line cliques are wound at the tail ends of the sliding small shafts for compressing the follower plate and the fixed plate. The baffle plate can effectively solve the quality problems of cracks and the like caused by resistance when a pipe shrinks during the pouring by the hot mold method, and realize high molding qualification rate.

Owner:XINXING DUCTILE IRON PIPES CO LTD

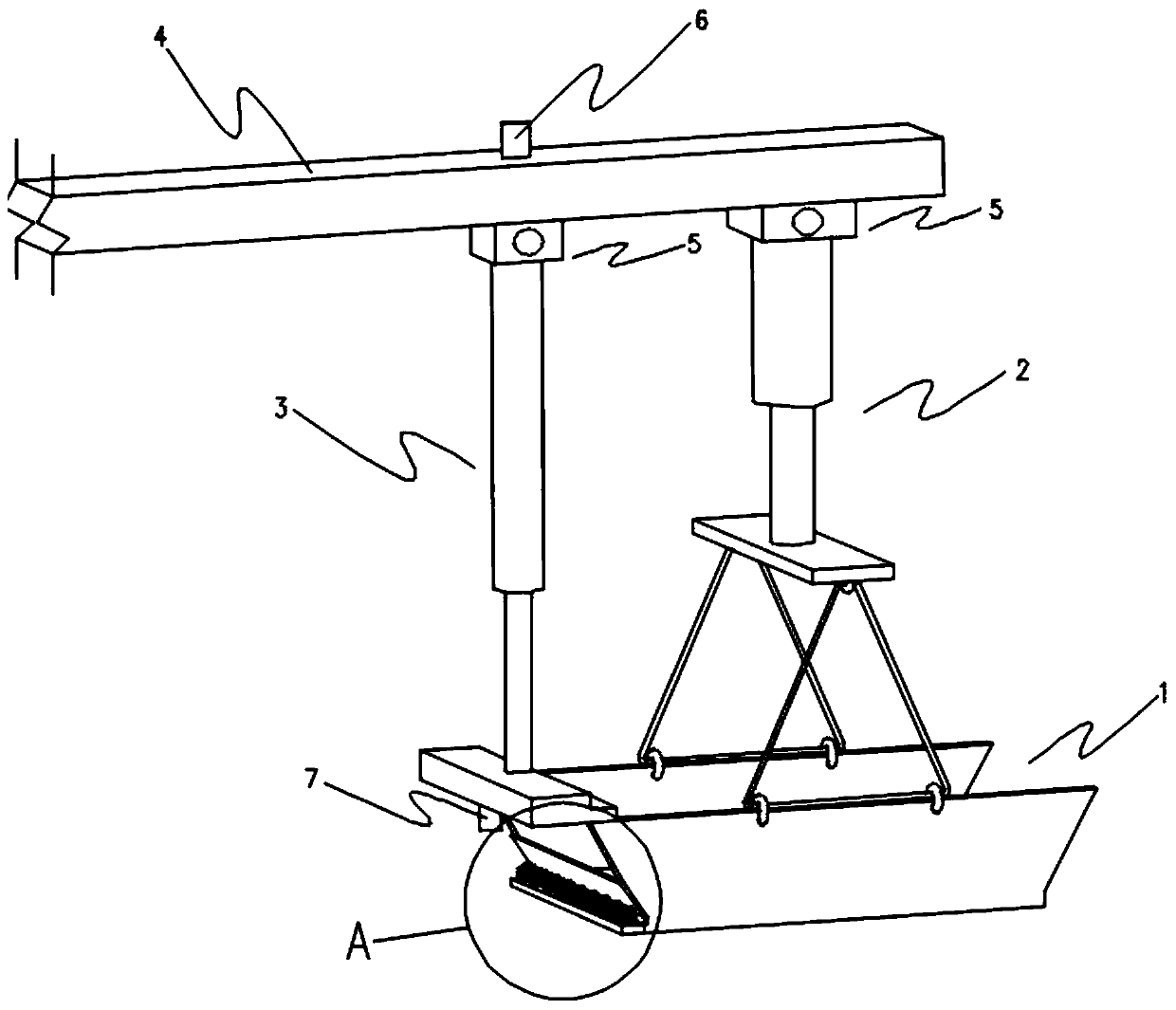

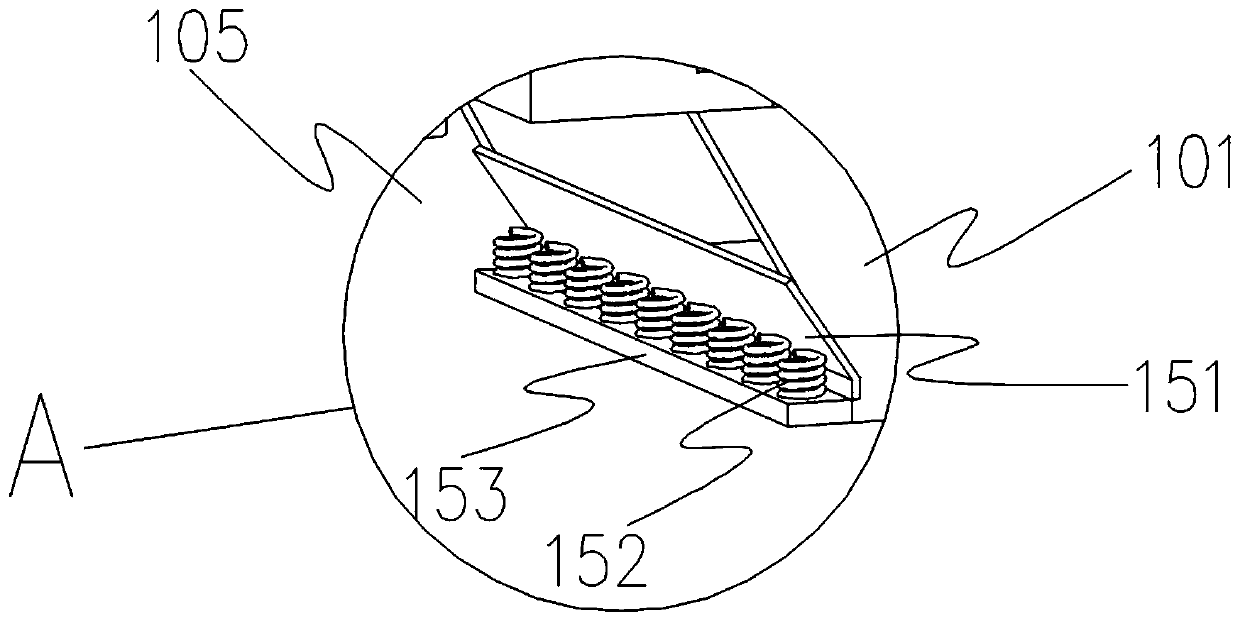

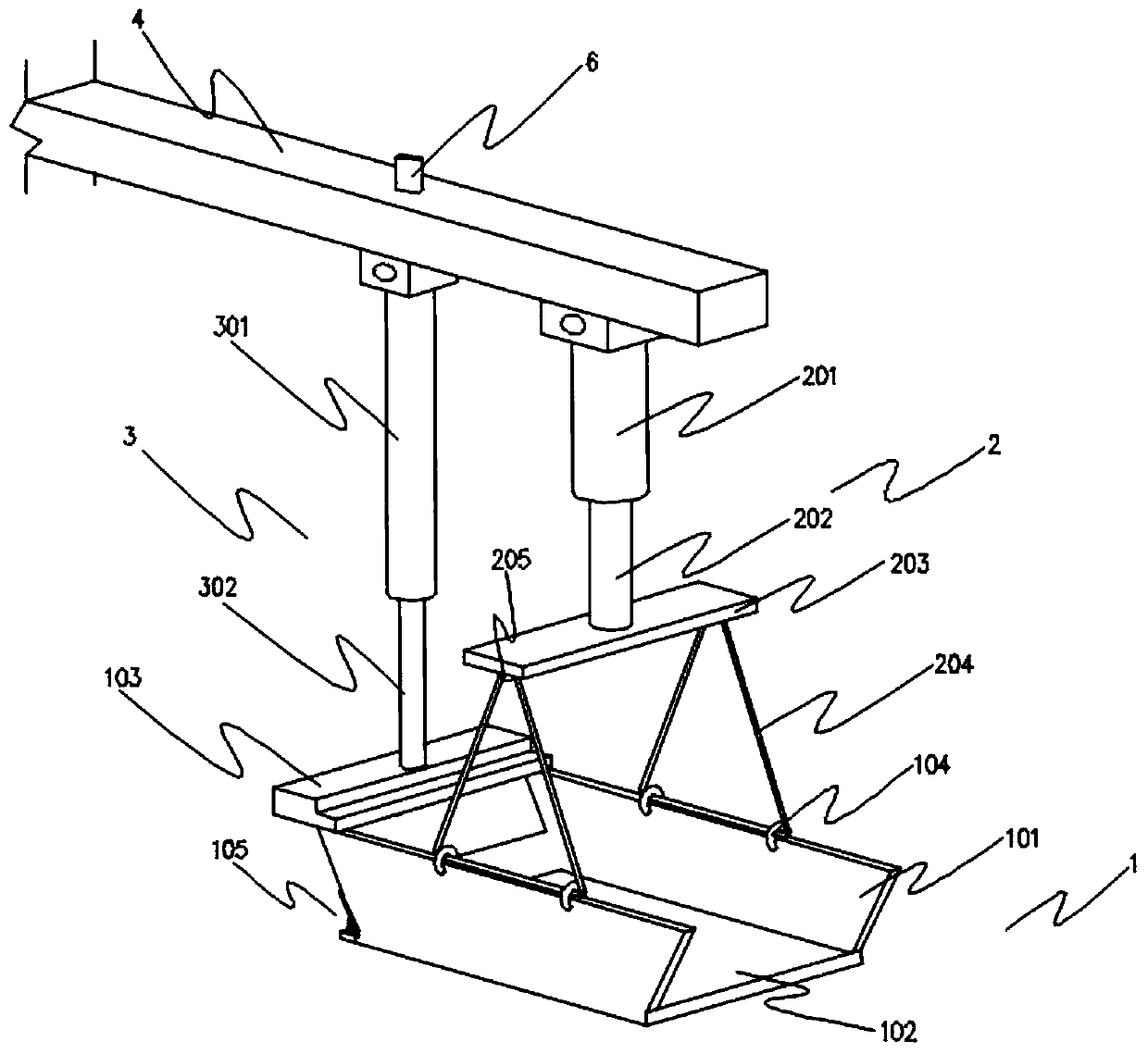

Induction type automatic paving machine

ActiveCN111119190AImprove molding pass rateSimple structureFoundation engineeringControl engineeringStructural engineering

The invention relates to an induction type automatic paving machine. The induction type automatic paving machine comprises a lifting arm, a lifting bucket, a lifting assembly, a tipping assembly and apositioning assembly; the lifting assembly and the tipping assembly are all arranged on the lifting arm; the lifting bucket is of an open structure, and the lifting bucket comprises a side plate, a bottom plate and a lifting plate; the lifting bucket is fixed to the lifting arm through the lifting assembly; and the positioning assembly comprises a GPS position finder and a distance monitor. According to the induction type automatic paving machine, the defects that riprap is uneven, local missing is happened, local stacking is high, supplement riprap is need to be carried out repeatedly and the construction cost is increased due to the fact that existing riprap equipment is prone to being affected by human or environmental factors are overcome. The induction type automatic paving machine is simple in structure, flexible in operation, stable in lifting operation, can avoid the occurrence of lifting bucket deviation and tipping, is conducive to accurate riprap positioning, improving theriprap accuracy, improving the qualified rate of riprap section forming of a dam body, reducing the construction cost, and improving the construction quality and efficiency.

Owner:CCCC SHANGHAI DREDGING

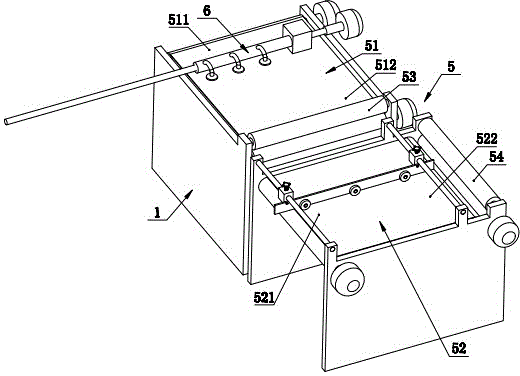

A fully automatic leather machine

ActiveCN103818094BSimple structureEasy to operateLamination ancillary operationsLaminationCardboardFully automatic

The invention discloses a full-automatic hard outer shell machine. The full-automatic hard outer shell machine comprises a machine body, wherein a cardboard conveying device, a cover seal conveying device, a hard outer shell edge covering and moulding device and a hard outer shell moulding and discharging device are arranged on the machine body; the cardboard conveying device and the cover seal conveying device are correspondingly arranged at the two ends of the hard outer shell edge covering and moulding device; the hard outer shell moulding and discharging device is arranged on one side of the hard outer shell edge covering and moulding device; the hard outer shell moulding and discharging device is connected with the hard outer shell edge covering and moulding device through a transferring sucker; the hard outer shell edge covering and moulding device comprises a rotating main shaft and a rotating arm; the middle of the rotating arm is mounted at the upper end of the rotating main shaft in a sleeving manner; two groups of paper sucking mechanisms are symmetrically installed at the left end and the right end of the rotating arm; one group of the paper sucking mechanism is correspondingly arranged above the discharging end of the cardboard conveying device; the other group of the paper sucking mechanism is correspondingly arranged above the discharging end of the cover seal conveying device. By adopting the structure, the full-automatic hard outer shell machine is simple in structure and relatively high in production efficiency.

Owner:瑞安市国安印刷机械厂

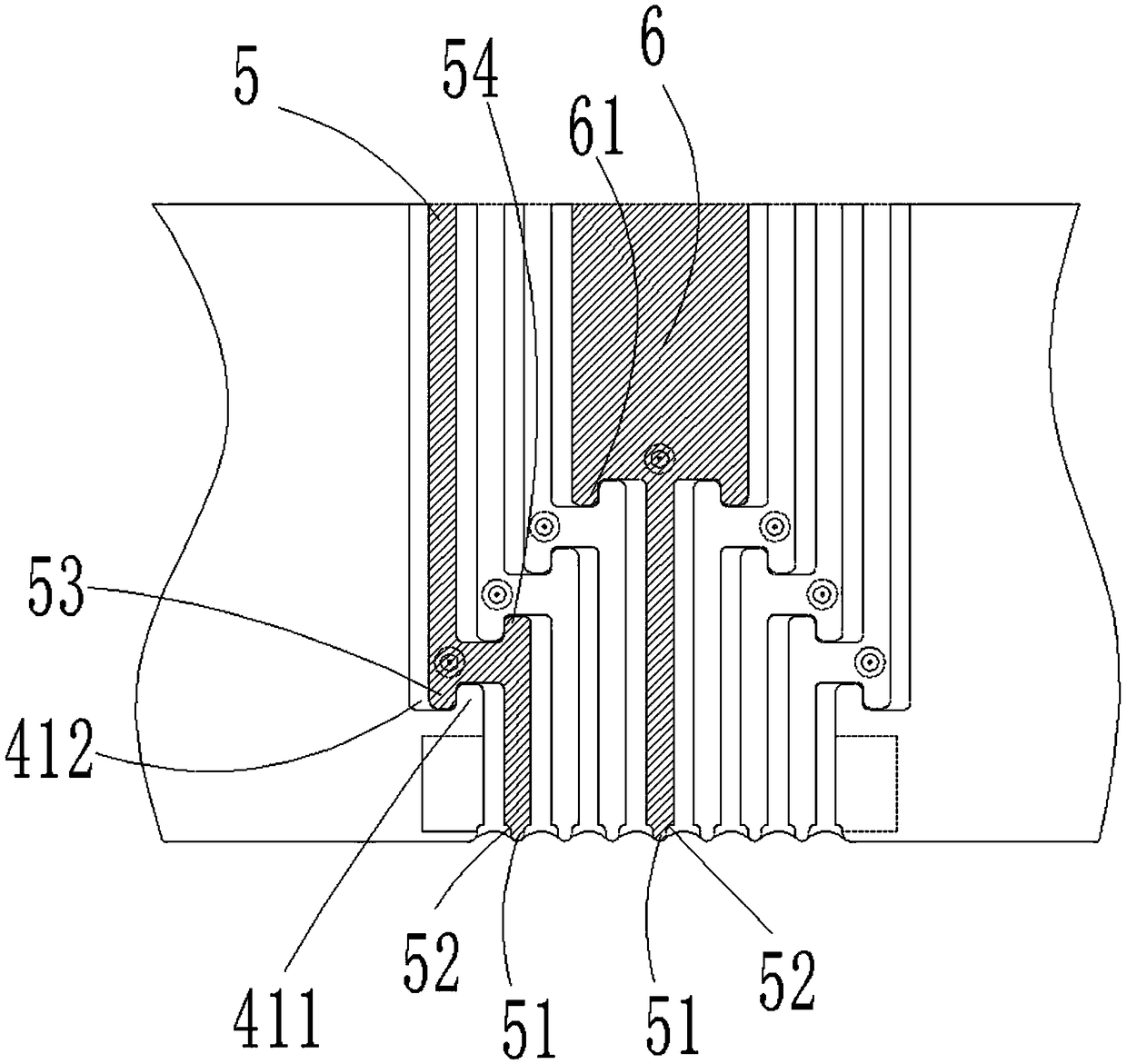

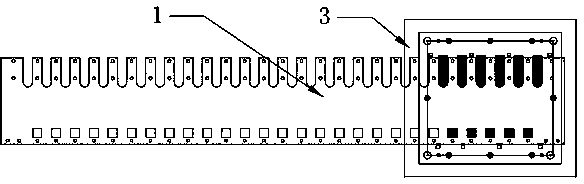

Corrugated pipe water swelling forming device and technology

PendingCN109420697AFill the gap in the marketImprove molding pass rateShaping toolsPipe waterEngineering

The invention discloses a corrugated pipe water swelling forming device. The corrugated pipe water swelling forming device comprises a water swelling machine and a water swelling die. The water swelling machine comprises a left punch and a right punch. The corrugated pipe water swelling forming device is characterized in that the water swelling die comprises a die frame, a die core, first movableinserts and second movable inserts, the die core is divided into an upper die core body and a lower die core body, and each of the upper die core body and the lower die core body is provided with onesecond movable insert and the multiple first movable inserts; the first movable inserts and the second movable insert on the upper die core body are symmetric to the first movable inserts and the second movable insert on the lower die core body; the corresponding first movable inserts are symmetrically distributed on the two sides of each second movable insert; each of the first movable inserts and the second movable inserts is provided with a male die; two female dies are symmetrically arranged on the two sides of each male die; each first movable insert is further provided with a first protruding part, a second protruding part, a first groove part and a second groove part; and each second movable insert is provided with a third protruding part and a third groove part.

Owner:广东思豪内高压科技有限公司

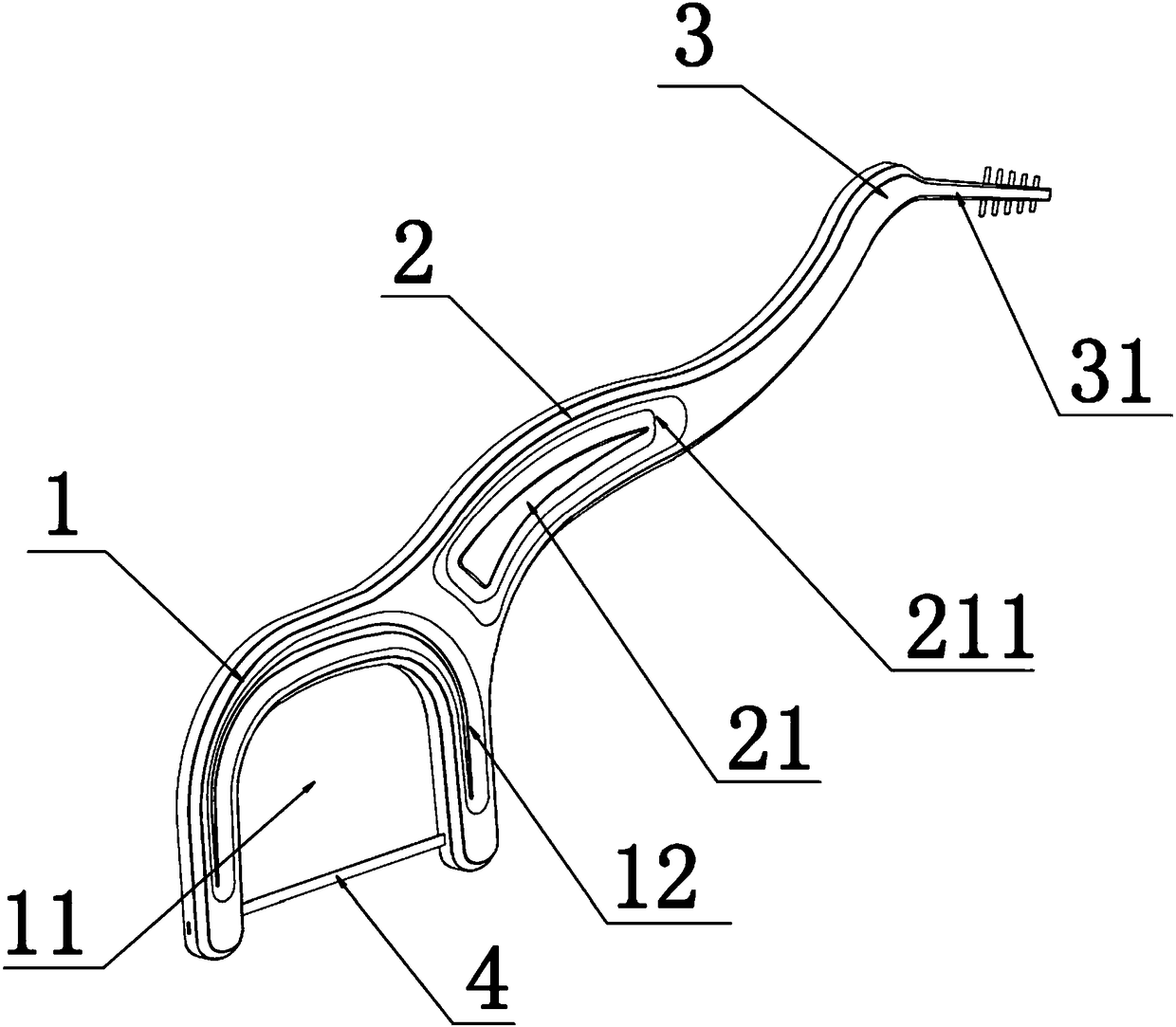

Floss pick and preparation process thereof

ActiveCN108186143AReduce cut resistanceReduce bleeding riskGum massageDental flossEngineeringDental floss

The invention discloses a floss pick which comprises a floss part (1), a handhold part (2) and a toothpick part (3) which are sequentially integrally connected, wherein the floss part (1) is distributed at the front end of the handhold part (2), and the toothpick part (3) is distributed at the rear end of the handhold part (2); a U-shaped groove (11) is formed in the lower end of the floss part (1), and a floss (4) is mounted at an opening of the U-shaped groove (11) in a matched manner; a tooth gap brush (31) integrally connected with the toothpick part (3) is arranged at the tail end of thetoothpick part (3). With the adoption of the structure, the floss can be used for clearing positions, where a toothbrush cannot brush, in teeth, the tooth gap brush can be used for cleaning residues left in gaps between teeth, and the floss pick is simple to use and comprehensive in cleaning.

Owner:余姚市科琳日用品有限公司

Forming process and mold replacement device for straight seam welded special-shaped steel pipes for automobile anti-collision beams

The invention relates to a straight seam welding special-shaped steel pipe forming process for an automobile anti-collision beam. The straight seam welding special-shaped steel pipe forming process for the automobile anti-collision beam comprises the following steps of: (1) uncoiling, unrolling a steel strip coil; (2) flattening, flattening the unrolled steel strip and conveying the flattened steel strip to the next station; (3) flat cutting and butt welding, flat cutting a head portion and a tail portion of the flattened steel strip respectively, and butt welding a tail of the steel strip material after the flat cutting with a head of the next steel strip material after the flat cutting; (4) pre-storing, feeding the butt welded steel strip into a movable sleeve storage bin; (5) forming, conveying the steel strip in the movable sleeve storage bin to a forming machine, and gradually bending into a tube blank to be welded according to a certain sequence; (6) high-frequency welding, pressing the opposite ends of the tube blank to form a certain opening angle, and then to perform high-frequency welding; (7) Water cooling, cooling the high-frequency welded steel tube to room temperatureby spraying; (8) special-shaped gradient sizing, sizing the water-cooled steel tube by a sizing ; (9) profile machining, cutting the sized steel tube into specific lengths.

Owner:山东华舜重工集团有限公司

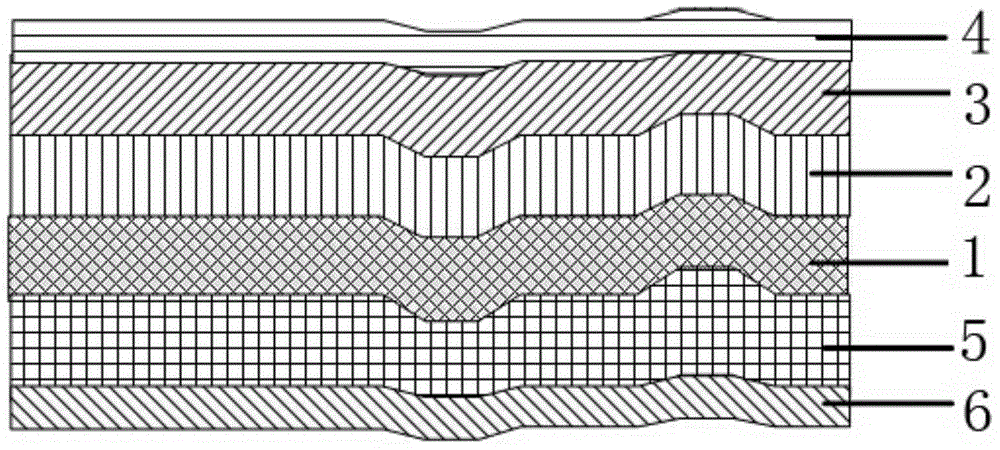

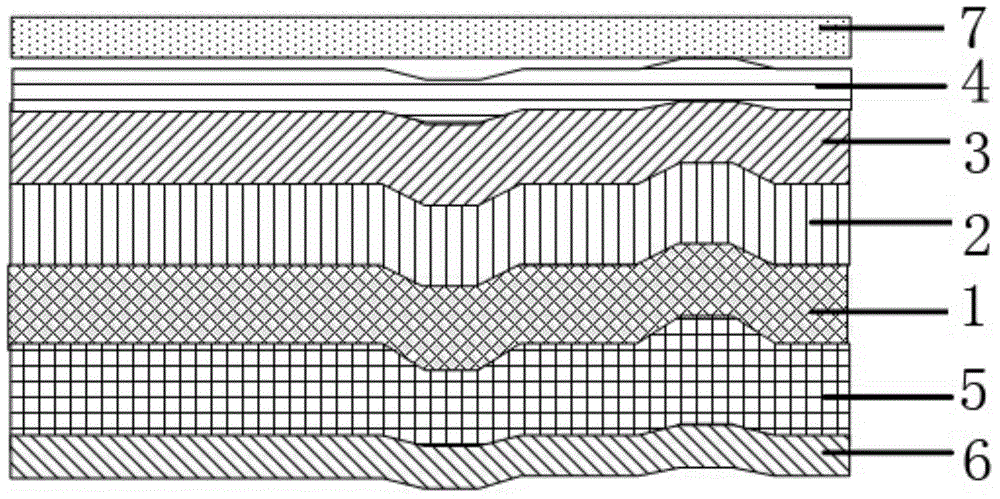

Printing color management (PCM) compound steel plate

InactiveCN101758737AImprove rigidityImprove molding pass rateSpecial ornamental structuresSheet steelLacquer

The invention provides a PCM compound steel plate. The front face of the steel plate is coated with a primer layer, an upper roller of the primer layer is coated with a finish layer, an upper roller of the finish layer is coated with a pattern printing layer, the surface of which is embossed with a decorative pattern, and an upper roller of the pattern printing layer embossed with the decorative pattern is coated with a protective paint layer. The pattern printing layer realizes the visual effect of various colors and patterns, the surface embossing forms concavo-convex stereoscopic impression, the rigidity of the steel plate is increased, the rigidity requirement can be satisfied through selecting a thin base material so that the cost is reduced, the forming qualification rate of a finished product is enhanced, and the PCM compound steel plate is extensively used for the industries of home appliances, decoration and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

Aorthite lightweight refractory material with uniform pores and preparation method thereof

ActiveCN114195532AUniform stateEffective adjustment statusCeramic materials productionClaywaresPyrophylliteFoaming agent

The invention provides an anorthite lightweight refractory material with uniform pores and a preparation method thereof.The mixing sequence of different raw materials is adjusted, coal gangue powder and pyrophyllite are added firstly, then refractory clay and calcium carbonate are added, and finally high-alumina cement, a coagulation accelerator and a foaming agent are added, so that the state of slurry can be effectively adjusted, and the uniform-pore anorthite lightweight refractory material is prepared. And bubbles of the slurry are distributed more uniformly in a cast blank, so that the heat conductivity coefficient of a product is reduced. Test results show that the heat conductivity coefficient of the anorthite lightweight refractory material is reduced from 0.18 W / (m.K) to 0.12 W / (m.K), the strength of a wet blank is improved from 0.1 MPa to 0.4 MPa, and the forming qualification rate of the wet blank is improved. The volume weight is controlled to be 450-530 kg / m < 3 >, and the product percent of pass is increased to 96% from 87% and is increased by 9%.

Owner:山东鲁阳浩特高技术纤维有限公司

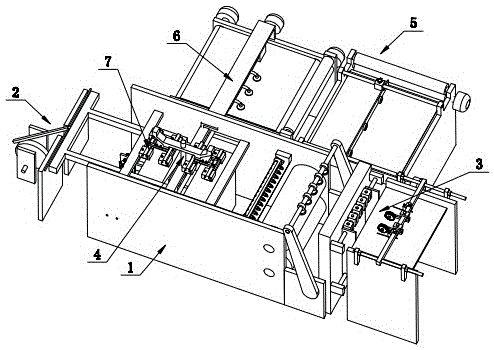

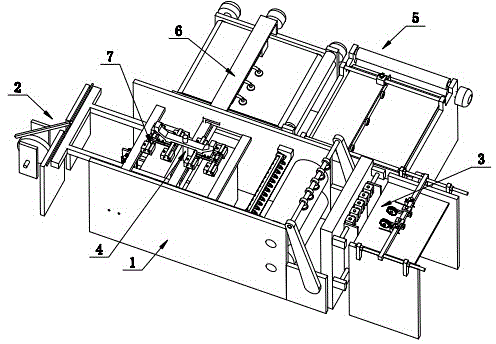

Full-automatic hard outer shell machine

ActiveCN103818094ASimple structureEasy to operateLamination ancillary operationsLaminationCardboardEngineering

The invention discloses a full-automatic hard outer shell machine. The full-automatic hard outer shell machine comprises a machine body, wherein a cardboard conveying device, a cover seal conveying device, a hard outer shell edge covering and moulding device and a hard outer shell moulding and discharging device are arranged on the machine body; the cardboard conveying device and the cover seal conveying device are correspondingly arranged at the two ends of the hard outer shell edge covering and moulding device; the hard outer shell moulding and discharging device is arranged on one side of the hard outer shell edge covering and moulding device; the hard outer shell moulding and discharging device is connected with the hard outer shell edge covering and moulding device through a transferring sucker; the hard outer shell edge covering and moulding device comprises a rotating main shaft and a rotating arm; the middle of the rotating arm is mounted at the upper end of the rotating main shaft in a sleeving manner; two groups of paper sucking mechanisms are symmetrically installed at the left end and the right end of the rotating arm; one group of the paper sucking mechanism is correspondingly arranged above the discharging end of the cardboard conveying device; the other group of the paper sucking mechanism is correspondingly arranged above the discharging end of the cover seal conveying device. By adopting the structure, the full-automatic hard outer shell machine is simple in structure and relatively high in production efficiency.

Owner:瑞安市国安印刷机械厂

Embossing enhanced PCM galvanized sheet

InactiveCN104354385AImprove visual effectsImprove rigiditySpecial ornamental structuresDecorative articlesFrontageAnti ageing

The invention provides an embossing enhanced PCM galvanized sheet. The base material is a galvanized sheet, a second passivation layer is formed on the back of the galvanized sheet the second passivation layer is subjected to roll-coating by a back paint layer, a first passivation layer is formed on the frontage of the galvanized plate, the first passivation layer is subjected to roll-coating by a primer layer, the primer layer is subjected to roll-coating by an anti-ageing paint coating, and patterns are pressed on the surface of the anti-ageing paint coating. The embossed anti-ageing coating is enhanced to achieve the visual effect of various colors and patterns, the surface embossing has concavo-convex stereoscopic impression, the rigidity of the galvanized sheet is enhanced, thinner base materials can be selected to meet the rigidity requirement, the cost is lowered, the finished product forming pass percent is improved, and the galvanized sheet is widely applied to the industries of household appliances, decoration and the like.

Owner:SUZHOU HESHENG NEW MATERIALS

Steam-assisted specular no-mark injection molding process for front shell of large-size LED TV

InactiveCN106393560ASolve the prone to sink marksAddress stressCoatingsHot runnerInjection molding machine

The present invention discloses a steam-assisted specular no-mark injection molding process for a front shell of a large-size LED TV. The process comprises the following steps: step (1), mold design; step (2), choice of a material; step (3), drying; step (4), mold preheating: correctly mounting the mold on an injection molding machine, preheating the mold before production mold clamping at a set preheating temperature within a range of 80-90 DEG C; step (5), mold clamping and rapid heating; step (6), speed-regulating and pressure regulating staged injection; step (7), rapid cooling; and step (8), mold opening for taking out the molded part. According to the present invention, by using the design of a multiple-feed subsurface gate with a hot runner and a cold runner, the problems of easy formation of sink marks and existing of internal stress due to slow remote flow of plastic melt, and the like are solved; meanwhile, corresponding travel time for the hot runner and the cold runner is added to the key portion of the product, thereby greatly improving the appearance quality of the product and increasing the molding yield, etc.; and the requirements of actual use are met.

Owner:滁州市荣康塑料制品有限公司

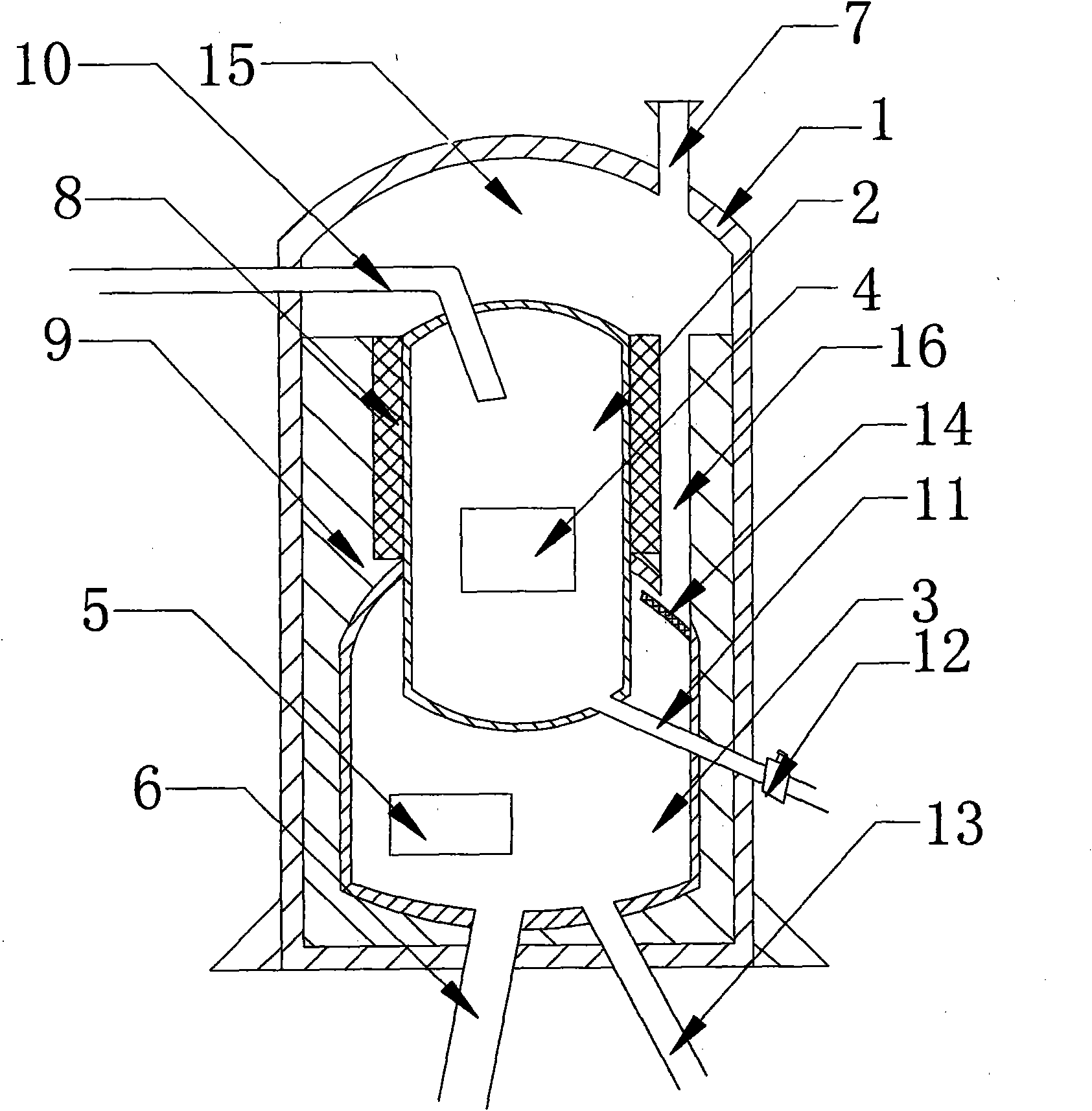

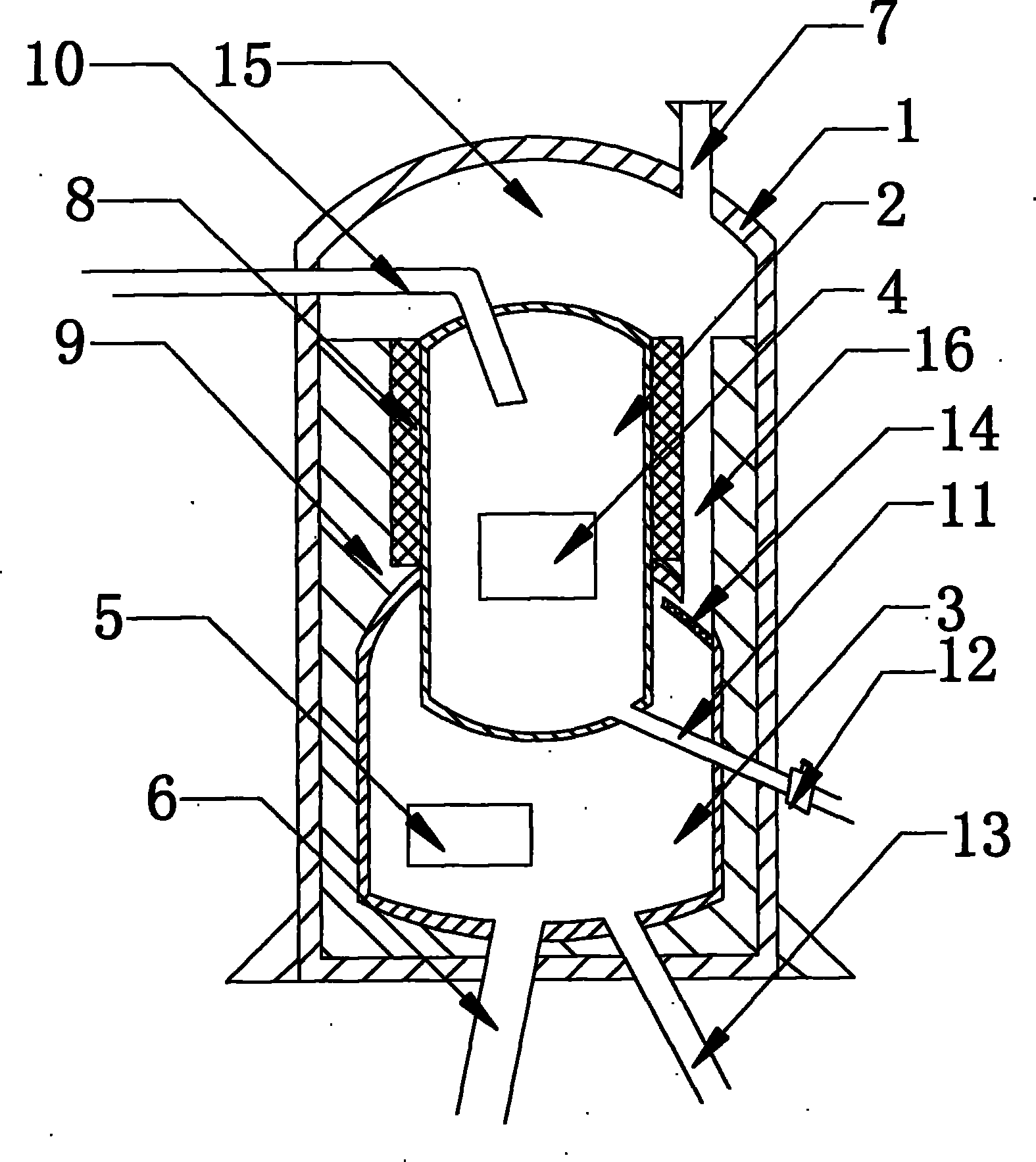

Pouring melting furnace

InactiveCN102692128AImprove molding pass rateThe process is convenient and fastCrucible furnacesCombustion chamberSlag

The invention relates to a pouring melting furnace comprising a shell, a melting chamber and a combustion chamber. The melting chamber is of a closed barrel-shaped structure; an observing port is arranged at the side wall of the top of the melting chamber; the lower end of the melting chamber is arranged in the combustion chamber; a feeding port is arranged at the side wall of the combustion chamber; a slag discharging port is arranged at the bottom of the combustion chamber; ports which are corresponding to the observing port, the feeding port and the slag discharging port are formed at the shell; a chimney which extends out of the shell is arranged at the top of the combustion chamber; the outer wall of the melting chamber outside the combustion chamber is covered with a thermal insulating layer; and a fire-resisting thermal-protective layer is arranged among the thermal insulating layer, the combustion chamber and the shell body respectively. The pouring melting furnace is characterized in that a smoke storing chamber is formed between the top of the shell and the melting chamber; a smoke channel which is communicated with the smoke storing chamber is arranged between the thermal insulating layer and the fire-resisting thermal-protective layer; a baffle is arranged at the bottom of the smoke channel and fixed at the side wall of the combustion chamber. The pouring melting furnace has the advantages of continuous pouring, convenient and rapid process, safety, reliability and improved qualified rate of casting molding.

Owner:陈瑜

Polytrimethylene terephthalate toughened color master batch and preparing method thereof

InactiveCN106589848AGood dispersionImprove thermal stabilityPolyethylene terephthalatePolytrimethylene terephthalate

The invention discloses a polytrimethylene terephthalate toughened color master batch. The polytrimethylene terephthalate toughened color master batch comprises, by mass percent, 20%-50% of PPT resin, 15%-40% of pigment, 10%-25% of ACR, 5%-30% of nano barium sulfate, 2%-4% of a cold-resistant toughening agent, 2%-4% of an enhanced modifying agent, 2%-4% of a coupling agent, 2%-8% of a heat stabilizer, 1%-3% of antioxidant and 1%-3% of a dispersing agent. According to the polytrimethylene terephthalate toughened color master batch, the technology process is improved, the polytrimethylene terephthalate toughened color master batch has the beneficial effects of being environment-friendly, free of pollution, high in dispersibility, good in heat stability, high in dyeing property, good in impact resistance and the like, and the actual using requirement is met.

Owner:CHUZHOU MADIL PLASTIC

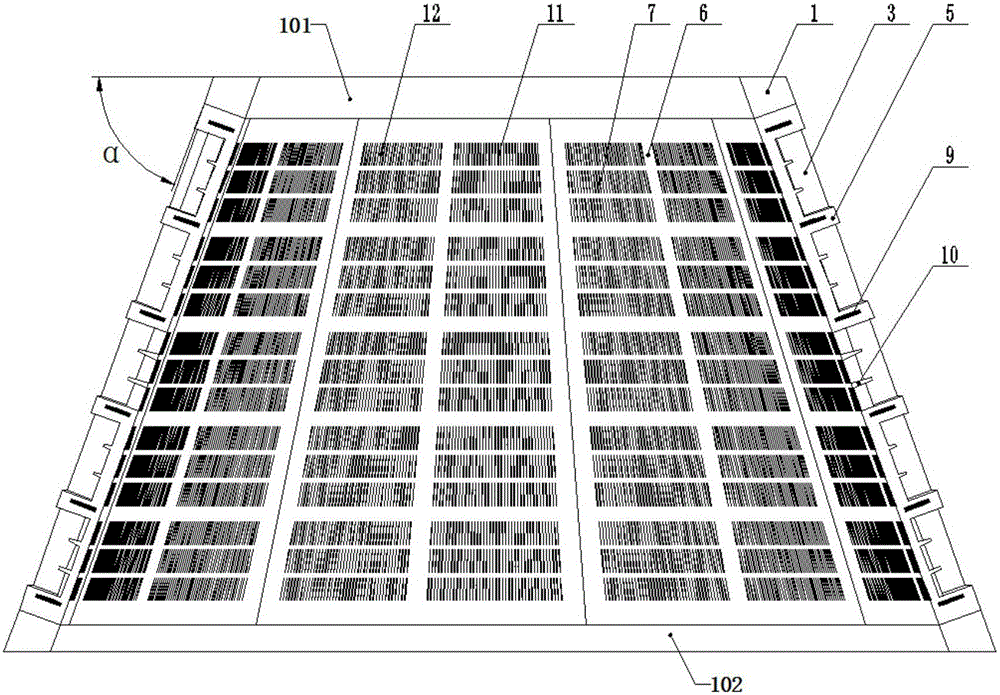

Stamping die set of harvester picker jaw

ActiveCN103736849AImprove molding pass ratePrecise bending angleShaping toolsEngineeringMachining process

The invention discloses a stamping die set of a harvester picker jaw. The stamping die set is composed of a positioning hole stamping unit, a notch stamping unit, a first bending stamping unit and a second bending stamping unit. The first bending stamping unit comprises a bending stamping block and a bending stamping base, wherein the bending stamping block and the bending stamping base are matched. The second bending stamping unit comprises a forming stamping block and a forming stamping base, the bearing surface of the forming stamping base is matched with the stamping surface of the bending stamping block, the bearing surface of the forming stamping base is provided with a groove matched with a stamping head of the forming stamping block, and a jaw machined part to be formed does not interfere with the forming stamping block when the second bending stamping unit is in a stamping state. By the application of the die set, the first bending stamping unit and the second bending stamping unit are adopted to integrally bend the jaw machined part step by step, the bending angle is accurate, the bending surface of the jaw is smooth and standard after the jaw is bent, the jaw is not prone to being bent or broken in the machining process, the forming percent of pass of the jaw machined part is increased, and the quality of the jaw is improved.

Owner:ZHANGJIAGANG LONGJING AUTOMOBILE PARTS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com