Double-disk flange and through-wall flange spheroidal graphite cast iron straight pipe integral casting technology

A ductile iron and flange technology, applied in the direction of casting mold, casting mold composition, casting molding equipment, etc., can solve the problems of difficult casting of flanged pipe, unable to meet market demand, uneven pipe wall thickness, etc. The qualified rate of molding, the improvement of the qualified rate of primary hydraulic pressure, and the effect of user satisfaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

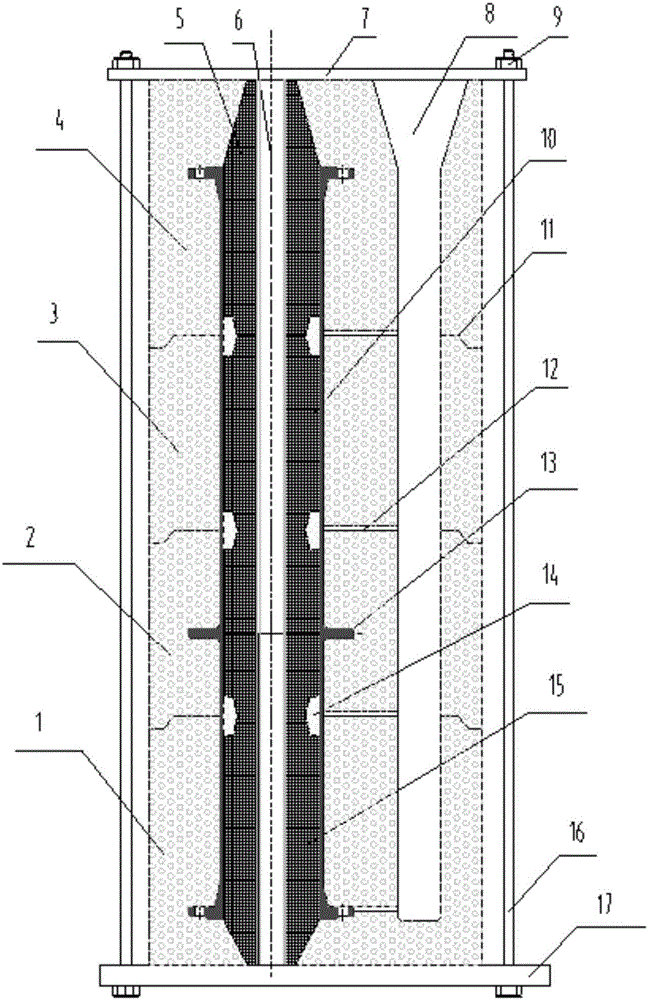

[0047] Casting PN16, length 3 meters, DN150 double disc flange straight pipe method is:

[0048] (1) Mold preparation

[0049] A. External mold preparation: Prepare DN150, PN16 lower flange outer mold, transitional outer mold, upper flange outer mold.

[0050] B. Core mold preparation; upper section core mold, transition section core mold, lower section core mold, core connection sleeve mold.

[0051] (2) Modeling and core making

[0052] The model cluster is prepared by a core shooter; the mixed phenolic resin sand is injected into the cavity of the outer mold and the core mold respectively, blown with triethylamine to solidify and form, and is ready for use after demoulding. The outer mold part includes: 1 outer mold of the upper flange, 4 outer molds of the transition section, and 1 outer mold of the upper flange. The core includes: 1 upper section core, 4 transition section cores, 1 lower section core, and 5 core connecting sleeves.

[0053] (3) Combined model clusters...

Embodiment 2

[0066] Casting PN10, length 2.5 meters, DN100 disc insert with wall-through flange straight pipe, the wall-through flange is 1 meter away from the single disc flange, the method is:

[0067] (1) Mold preparation

[0068] A. Preparation of external molds; prepare DN100, external molds for the socket of the lower section, external molds for transition sections, external molds for PN10 upper section flanges, and external molds for through-wall flanges.

[0069] B. Core mold preparation; upper section core mold, transition section core mold, lower section core mold, core connection sleeve mold.

[0070] (2) Modeling and core making

[0071] The model cluster is prepared by a core shooter; the mixed phenolic resin sand is injected into the cavity of the outer mold and the core mold respectively, blown with triethylamine to solidify and form, and is ready for use after demoulding. Among them, the outer mold part includes: 1 section of the outer mold of the upper flange, with a len...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com