Induction type automatic paving machine

A paver and inductive technology, applied in the field of inductive automatic pavers, can solve problems such as tipping, affecting throwing accuracy and throwing quality, riprap bucket offset, etc., to achieve flexible operation and improve riprap Efficiency and smooth lifting operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

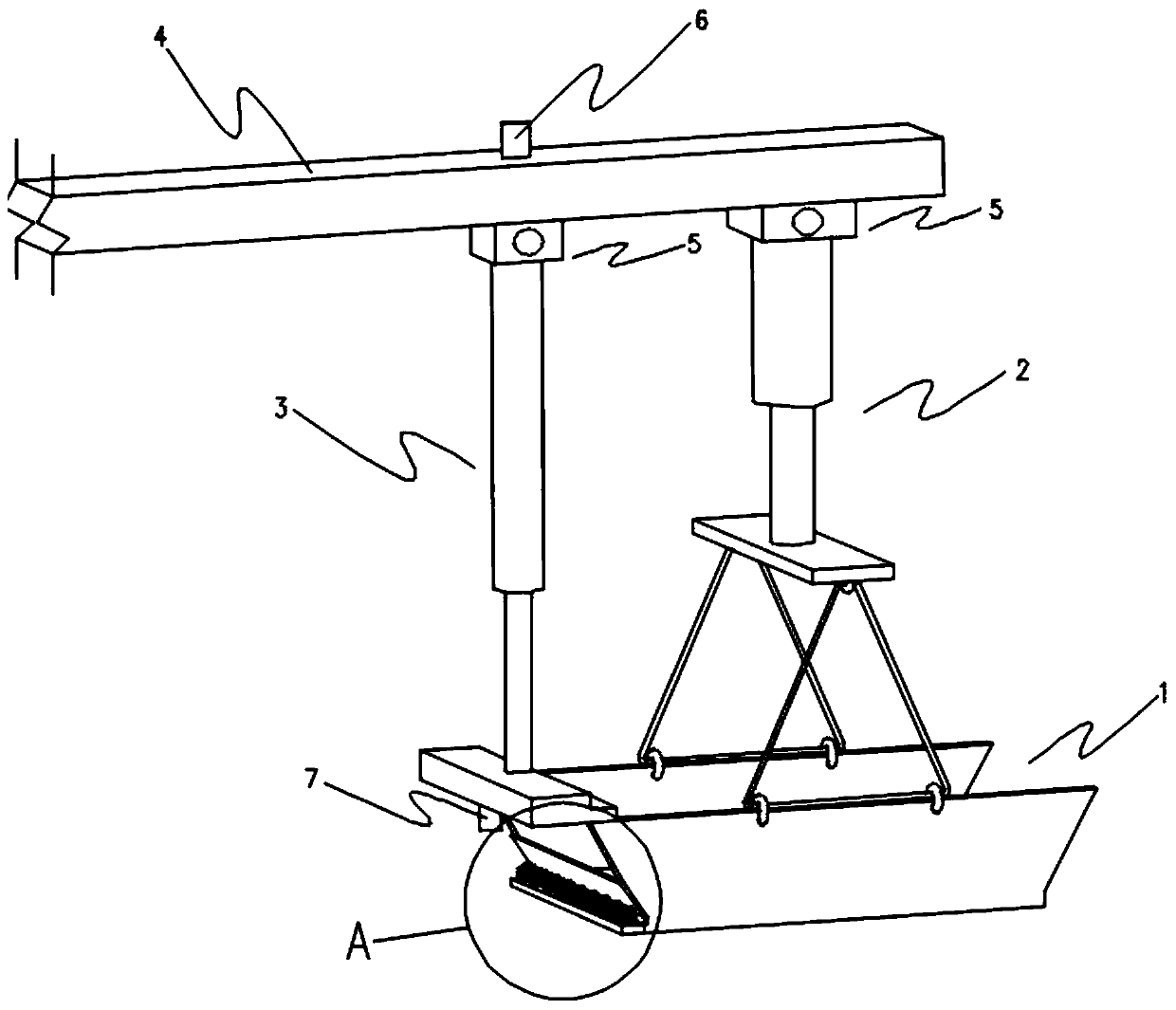

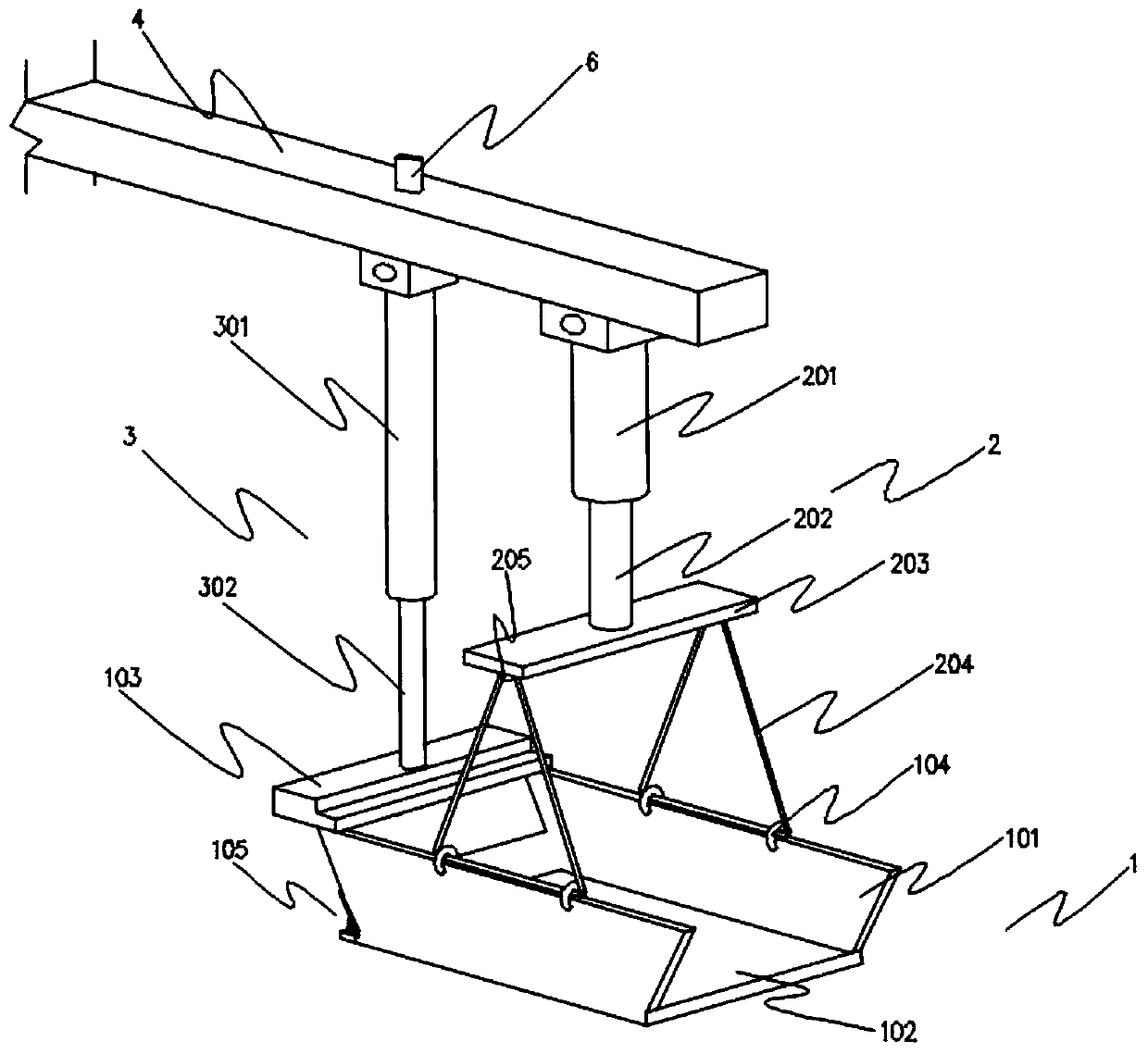

[0046] as attached figure 1 As shown, an induction type automatic spreader includes a boom 4, a bucket 1, a lifting component 2, a tipping component 3 and a positioning component, and the lifting component 2 and the tipping component 3 are all arranged in the on the boom 4.

[0047] The hanging bucket 1 is an open structure, and the hanging bucket 1 is fixed on the hanging arm 4 through the hoisting assembly 2 .

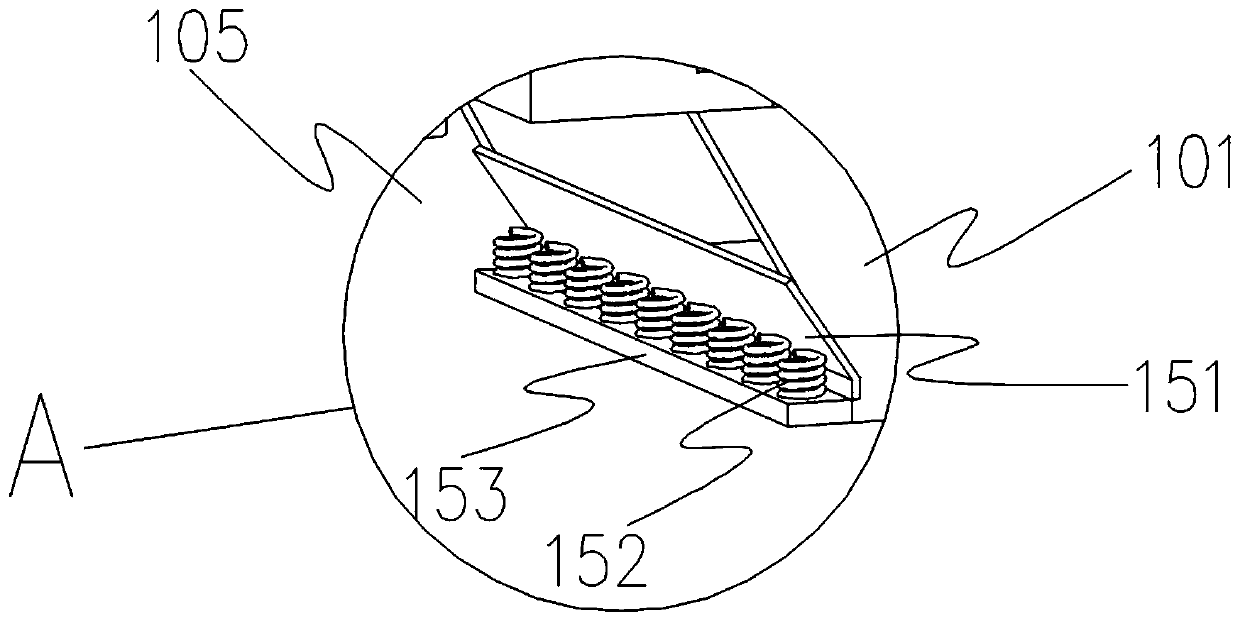

[0048] as attached image 3 As shown, the hanging bucket 1 includes a side plate 101 , a bottom plate 102 and a hanging plate 103 .

[0049] The side plate 101 includes a first side plate 101 and a second side plate 101, the first side plate 101 and the second side plate 101 are respectively fixed on opposite sides of the bottom plate 102, and the hanger plate 103 is fixed on the The upper part of the side plate 101 is fixedly connected with the first side plate 101 and the second side plate 101 respectively.

[0050] Preferably, the first side plate 101 and the ...

Embodiment 2

[0073] Based on the above-mentioned Embodiment 1, the similarities will not be repeated, and the differences are as follows: Figure 5 and 6 As shown, the number of the tilting assemblies 3 is a group, and each of the tilting assemblies 3 is located on opposite sides of the bucket 1 respectively; the number of the stopper assemblies 105 is a group, and each The stopper assemblies 105 are respectively located on opposite sides of the bucket 1 . On the one hand, the bucket 1 can be tipped and thrown in two directions, and on the other hand, the bucket 1 can be transported smoothly and the stability of the equipment operation can be improved.

[0074] When throwing rocks, the tipping assembly 3 on one side of the bucket 1 drives the second telescopic rod 302 to shrink, and the tipping assembly 3 on the other side drives the second telescopic rod 302 to extend, so that the bucket 1 rotates around the lifting ring 205 to realize the lifting The inclination of the bucket 1 causes ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com