Steam-assisted specular no-mark injection molding process for front shell of large-size LED TV

An injection molding process, a high-gloss non-marking technology, applied in the direction of coating, etc., can solve the problems of internal stress, slow flow of plastic melt, sink marks, etc., and achieve the effect of eliminating internal stress, reducing process cost and reducing pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

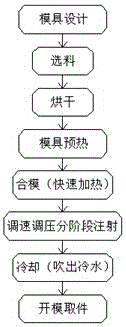

[0025] like Figure 1-2 As shown, it is the large-size LED TV front case-assisted steam high-gloss seamless injection molding process described in this embodiment, which specifically includes the following steps:

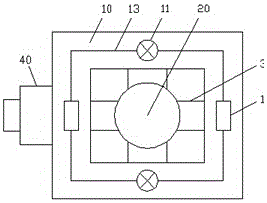

[0026] Step (1), mold design: According to the shape and structure required by the front shell of the LED TV, the hot runner and cold runner multi-point feed latent gate design is adopted. The mold includes optimized irregular water channels, mold cavities and airway;

[0027] Step (2), material selection: use PMMA or PC / ABS or high-gloss ABS material as the injection material;

[0028] Step (3), drying: Place the injection molding material in the drying box of the injection molding machine and dry it at 60°C for 4.5 hours to make the humidity less than 0.04%, and then use the automatic feeding system to continuously feed the material;

[0029] Step (4), mold preheating: correctly install the mold on the injection molding machine, preheat the mold before closing t...

specific Embodiment 2

[0040] like Figure 1-2 As shown, it is the large-size LED TV front case-assisted steam high-gloss seamless injection molding process described in this embodiment, which specifically includes the following steps:

[0041] Step (1), mold design: According to the shape and structure required by the front shell of the LED TV, the hot runner and cold runner multi-point feed latent gate design is adopted. The mold includes optimized irregular water channels, mold cavities and airway;

[0042] Step (2), material selection: use PMMA or PC / ABS or high-gloss ABS material as the injection material;

[0043] Step (3), drying: Place the injection molding material in the drying box of the injection molding machine and dry it at 70°C for 5 hours to make the humidity less than 0.04%, and then use the automatic feeding system to continuously feed the material;

[0044] Step (4), mold preheating: correctly install the mold on the injection molding machine, preheat the mold before closing the...

specific Embodiment 3

[0055] like Figure 1-2 As shown, it is the large-size LED TV front case-assisted steam high-gloss seamless injection molding process described in this embodiment, which specifically includes the following steps:

[0056] Step (1), mold design: According to the shape and structure required by the front shell of the LED TV, the hot runner and cold runner multi-point feed latent gate design is adopted. The mold includes optimized irregular water channels, mold cavities and airway;

[0057] Step (2), material selection: use PMMA or PC / ABS or high-gloss ABS material as the injection material;

[0058] Step (3), drying: Place the injection molding material in the drying box of the injection molding machine and dry it at 80°C for 5.5 hours to make the humidity less than 0.04%, and then use the automatic feeding system to continuously feed the material;

[0059] Step (4), mold preheating: correctly install the mold on the injection molding machine, preheat the mold before closing t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com