Patents

Literature

55results about How to "Precise bending angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

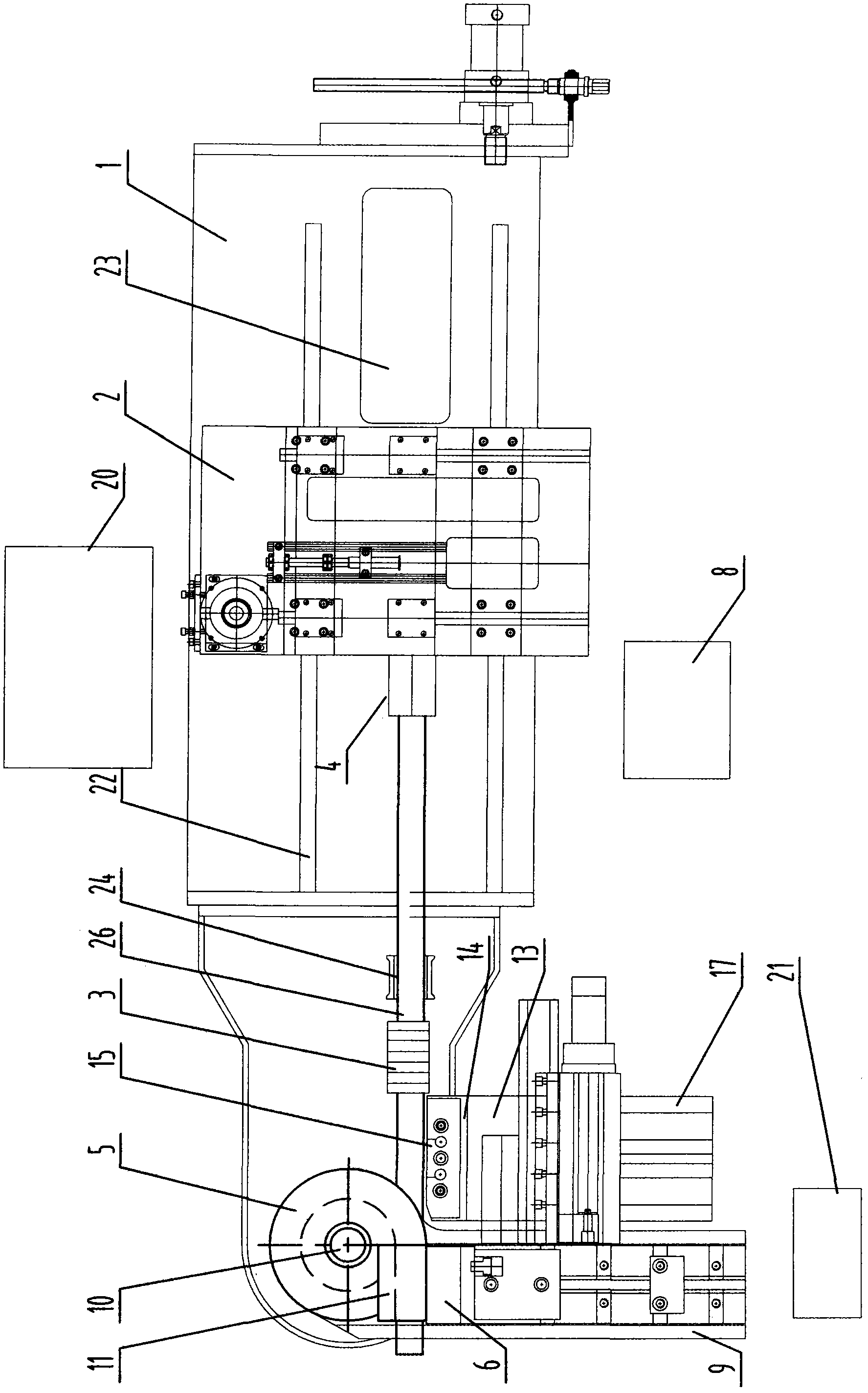

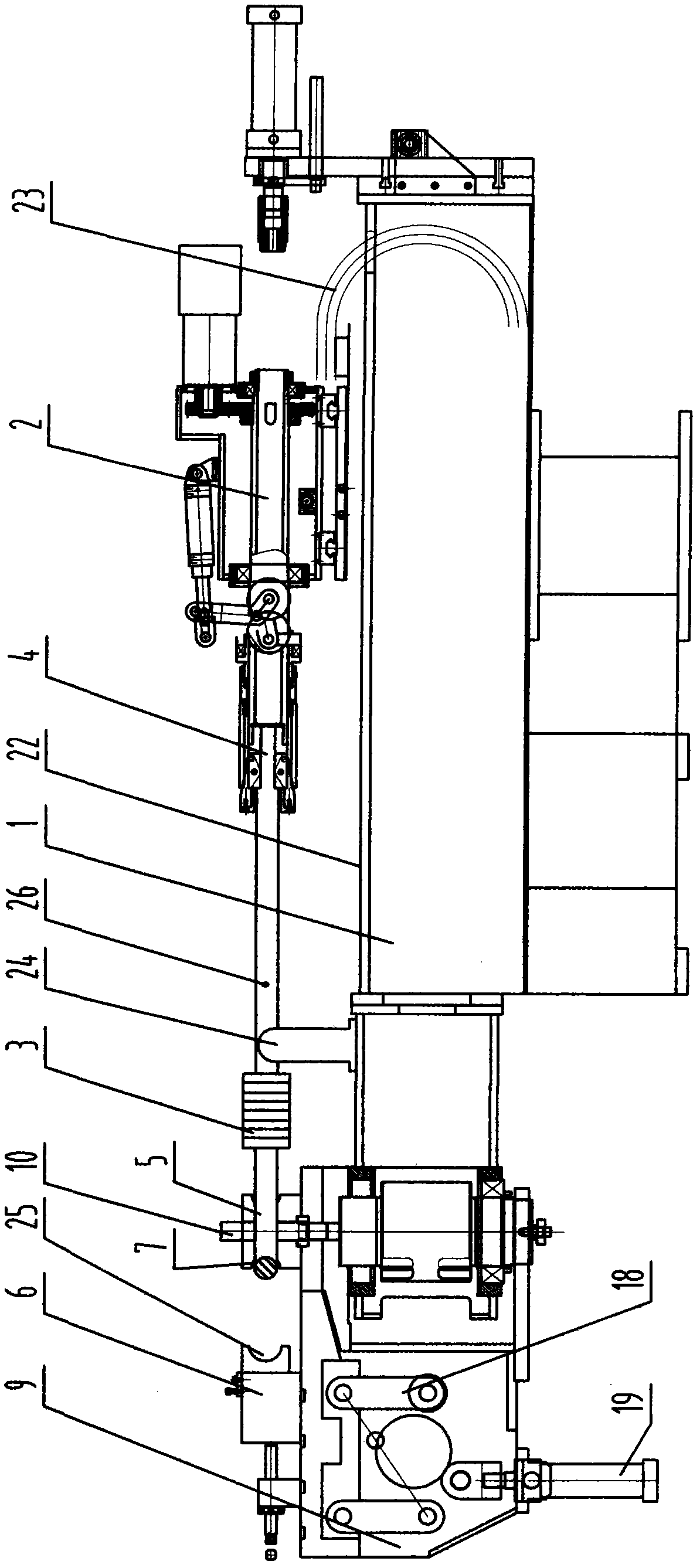

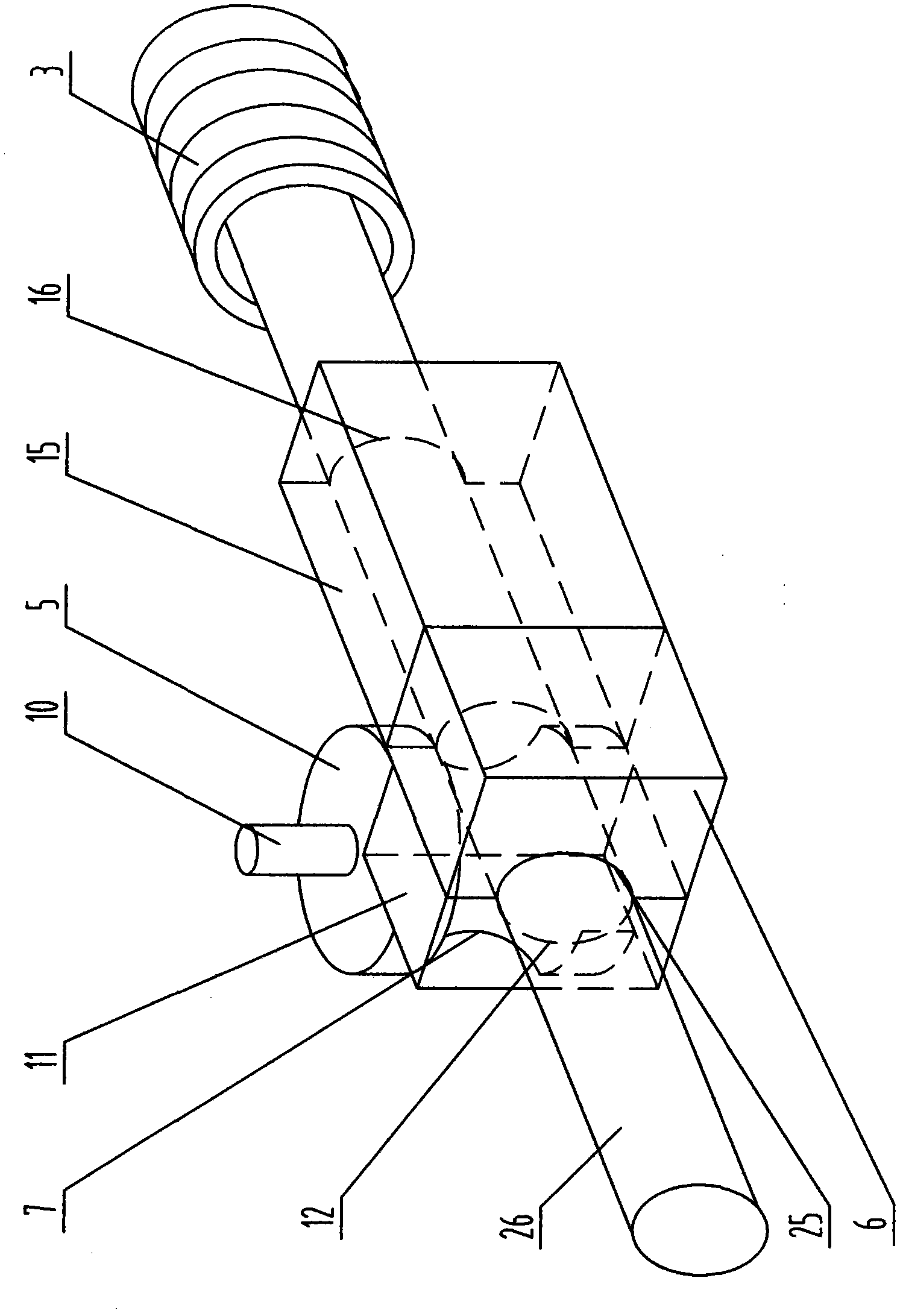

Automatic pipe bending device and pipe bending process thereof

The invention discloses an automatic pipe bending device and a pipe bending process thereof, belonging to the technical field of mechanical processing and manufacturing. The technical scheme adopted by the invention is as follows: under the automatic control of an automatic control platform, a loading claw of a pipe loading machine firstly shifts a single pipe into a rotating fixture of a pinch device, the pinch device drives the pipe to move forward through a heater, the heater heats a bent part of the pipe to 1200-1350 DEG C, the bent part is moved to a bending mold, a follower plate and a movable jaw clamp the pipe, the movable jaw and the bending mold rotate to a bending angle around a rotating shaft, the follower plate and the movable jaw are reset after the pipe is released, the above process is repeated until the bending of the whole pipe is finished, and an unloading manipulator carries out unloading operation, thus finishing the bending process. The system can automatically finish pipe operations such as loading, feeding, heating, rotating, bending, unloading and the like, so that the pipe can be automatically bent and molded, the molding process is more accurate, and theyield is high; and the number of times for transporting the pipe in the processing process is reduced, and the productivity is improved.

Owner:西安德卡汽车系统有限公司

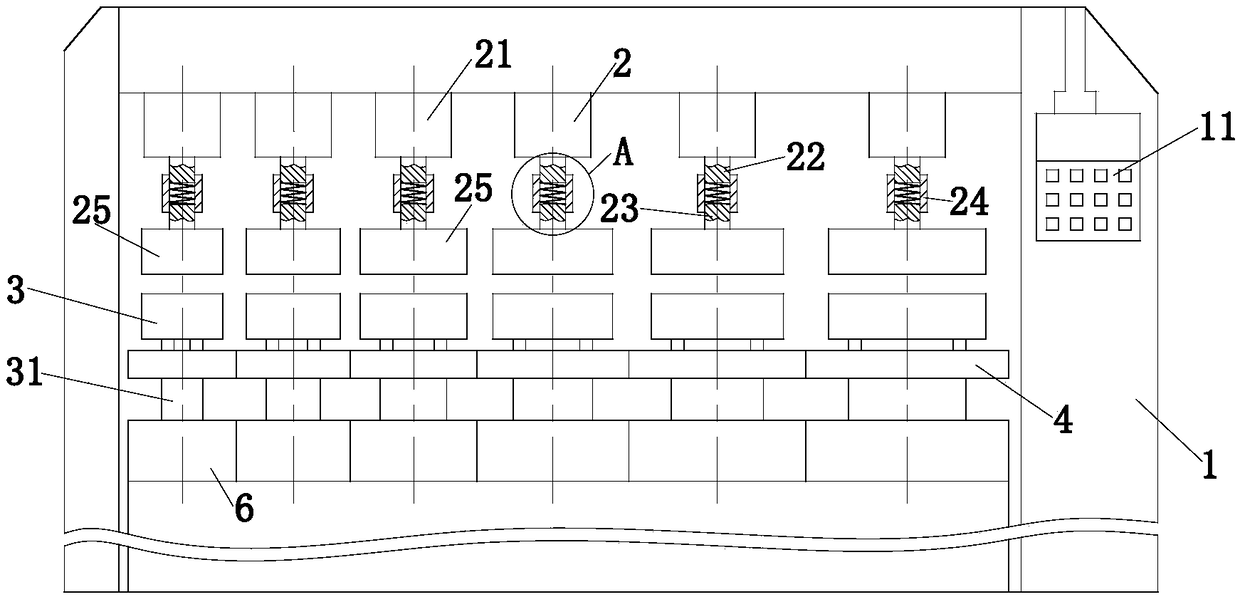

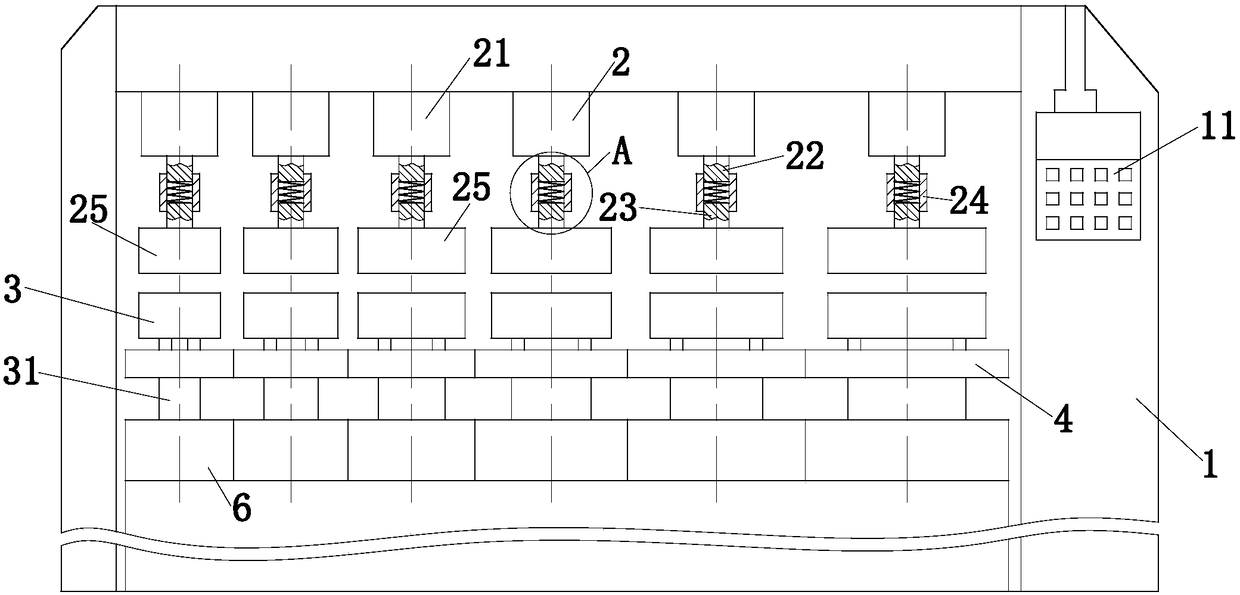

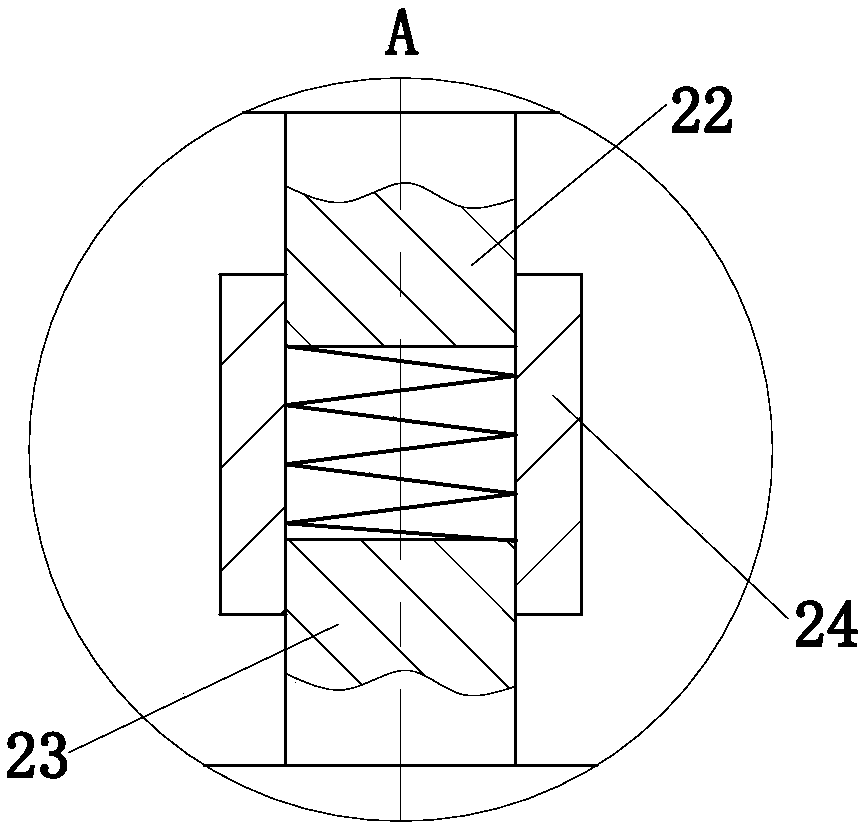

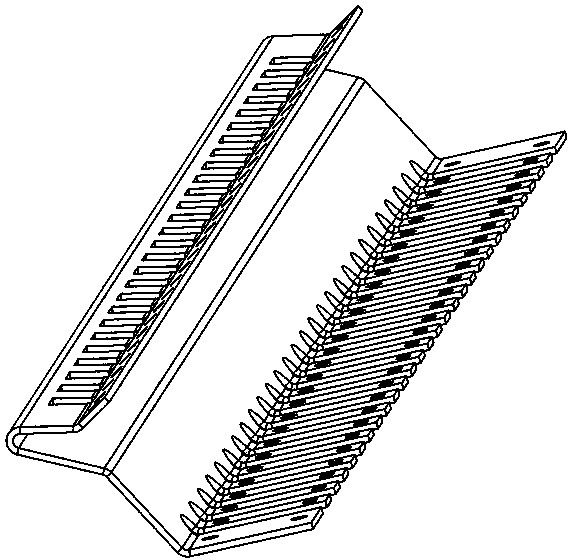

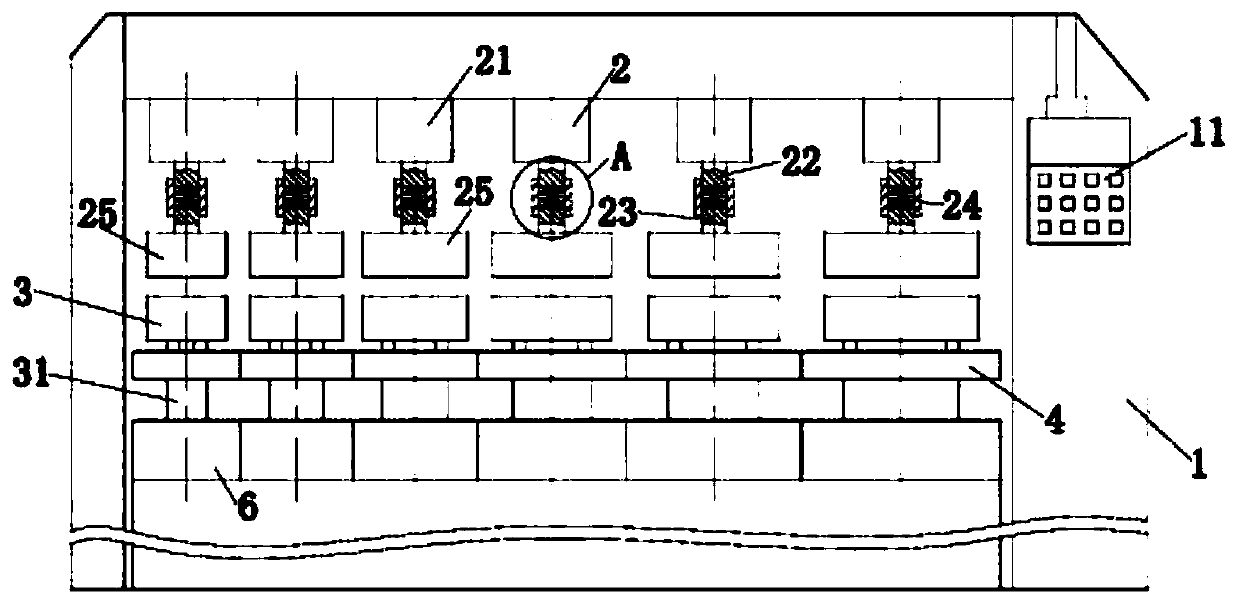

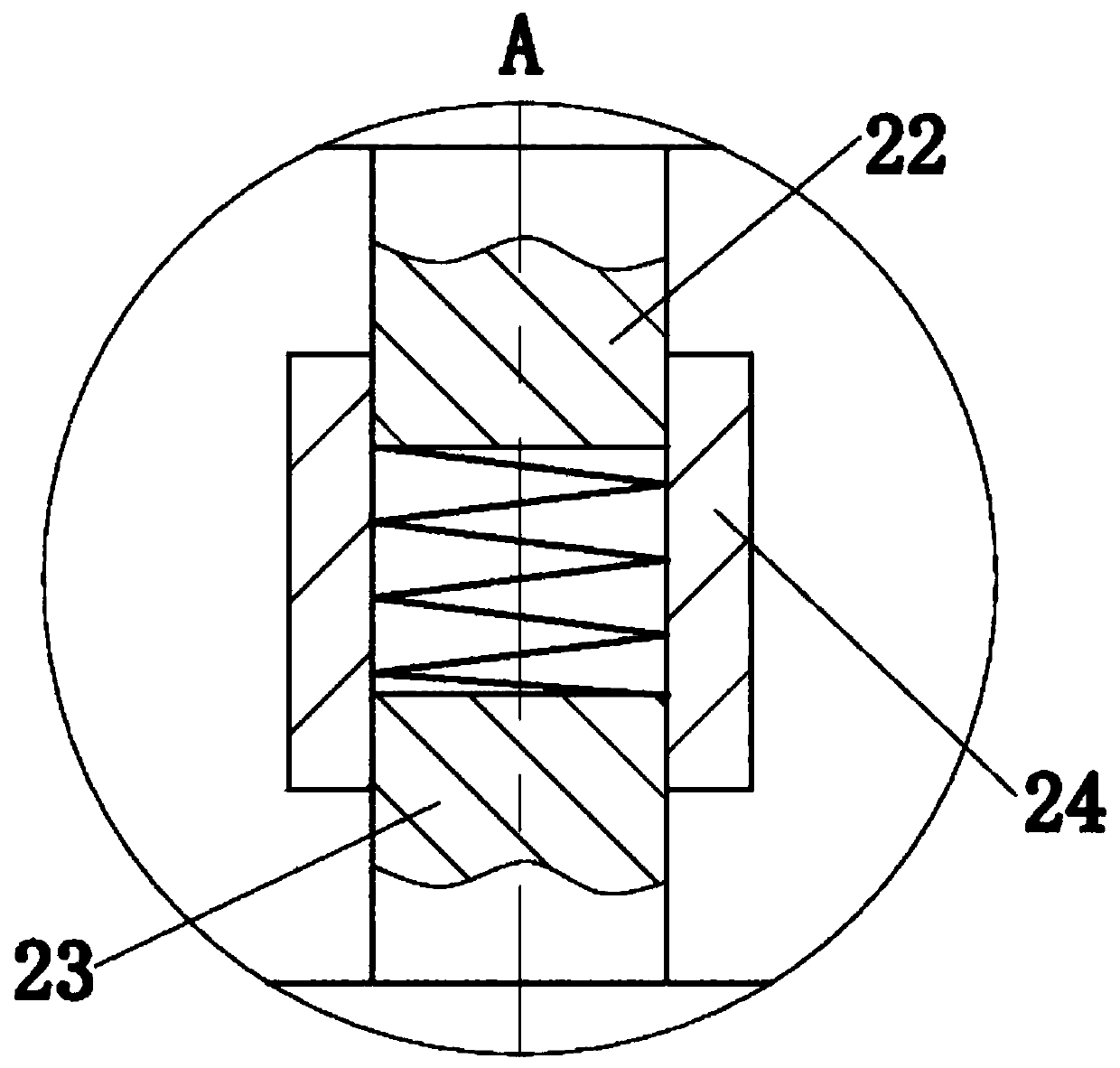

Horizontal all-purpose numerical control bending machine

The invention belongs to the technical field of board processing, in particular to a horizontal all-purpose numerical control bending machine. The horizontal all-purpose numerical control bending machine comprises a machine body, downward press die blocks, lifting die blocks, a changeable upper tool array, a detachable punch and a changeable lower tool array. The machine body is horizontally fixedto the ground. The machine body is provided with a controller. The downward press die blocks are evenly distributed on the upper part of the machine body and are used for downwards pressing the changeable upper tool array. The lifting die blocks are evenly distributed in the rear of the machine body and are used for limiting the movement direction of the changeable upper tool array as the vertical direction. The changeable upper tool array is located under the downward press die blocks. The bending angle of the changeable upper tool array is adjustable. The detachable punch is located besidethe changeable upper tool array and is used for punching boards. The changeable lower tool array is located under the downward press die blocks and is adjustable in bending angle, and the tool edges of the changeable lower tool array are matched with the tool edges of the changeable upper tool array. According to the horizontal all-purpose numerical control bending machine, by automatically adjusting the bending angles of the bent boards, the bending angles of the boards are more accurate, and the percent of pass of bent part forming is increased.

Owner:TAIZHOU DONGXING PRECISION MACHINERY

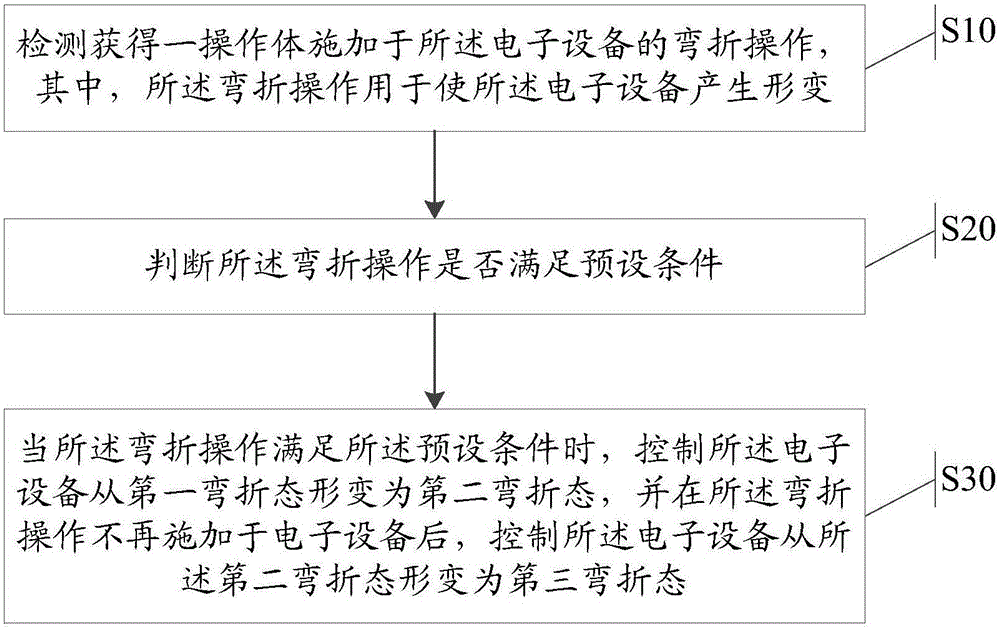

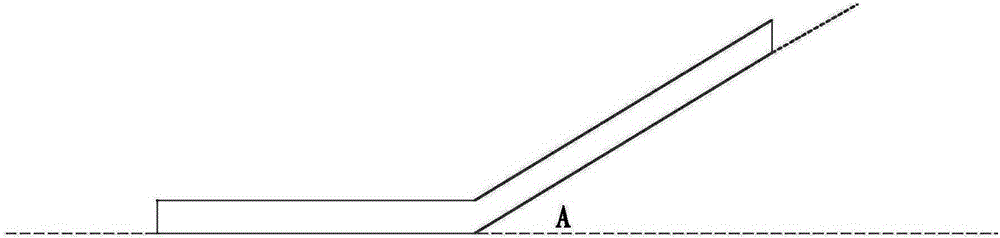

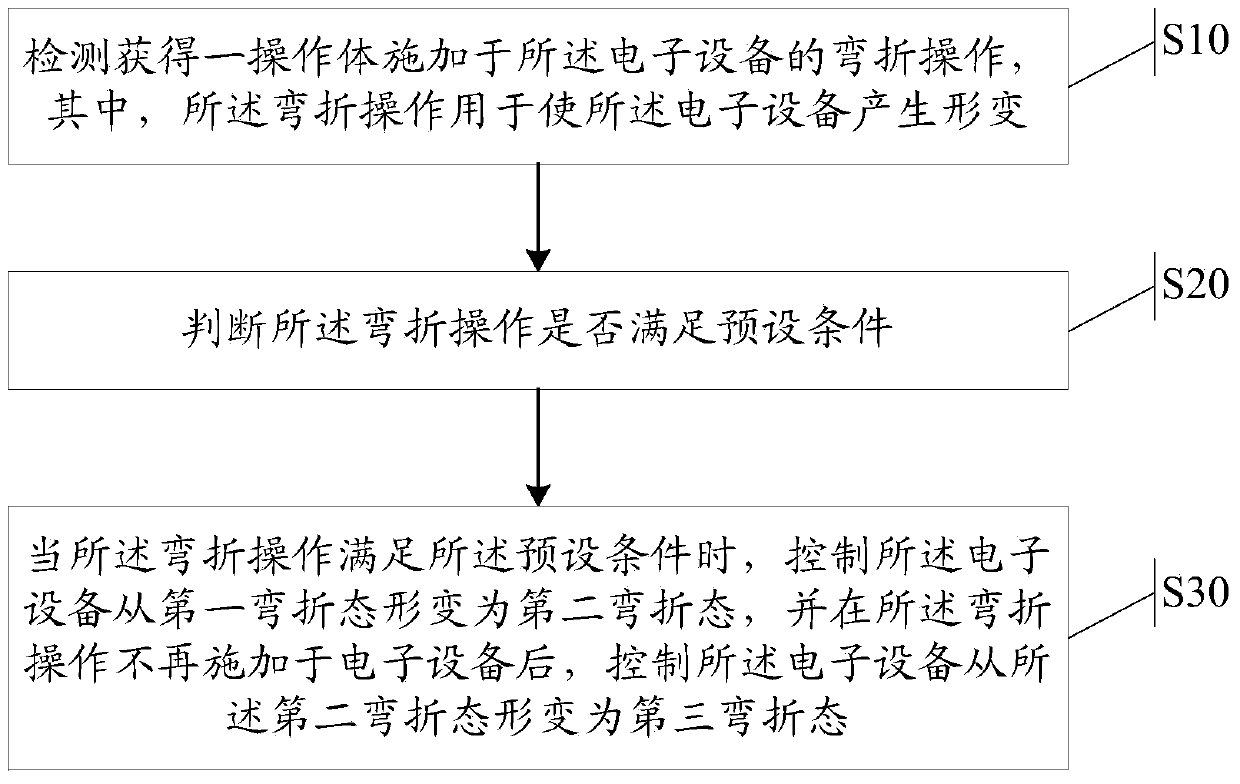

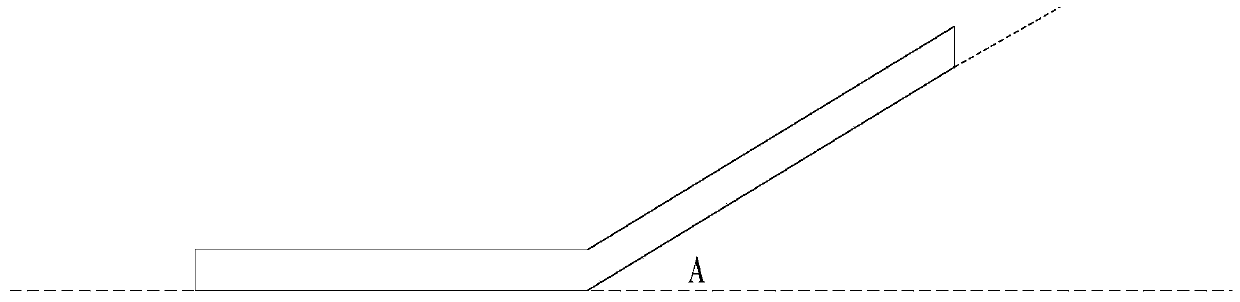

Electronic apparatus control method and electronic apparatus

ActiveCN105138076AControl bend anglePrecise bending angleInput/output for user-computer interactionDetails for portable computersControl theoryElectronic equipment

Owner:LENOVO (BEIJING) LTD

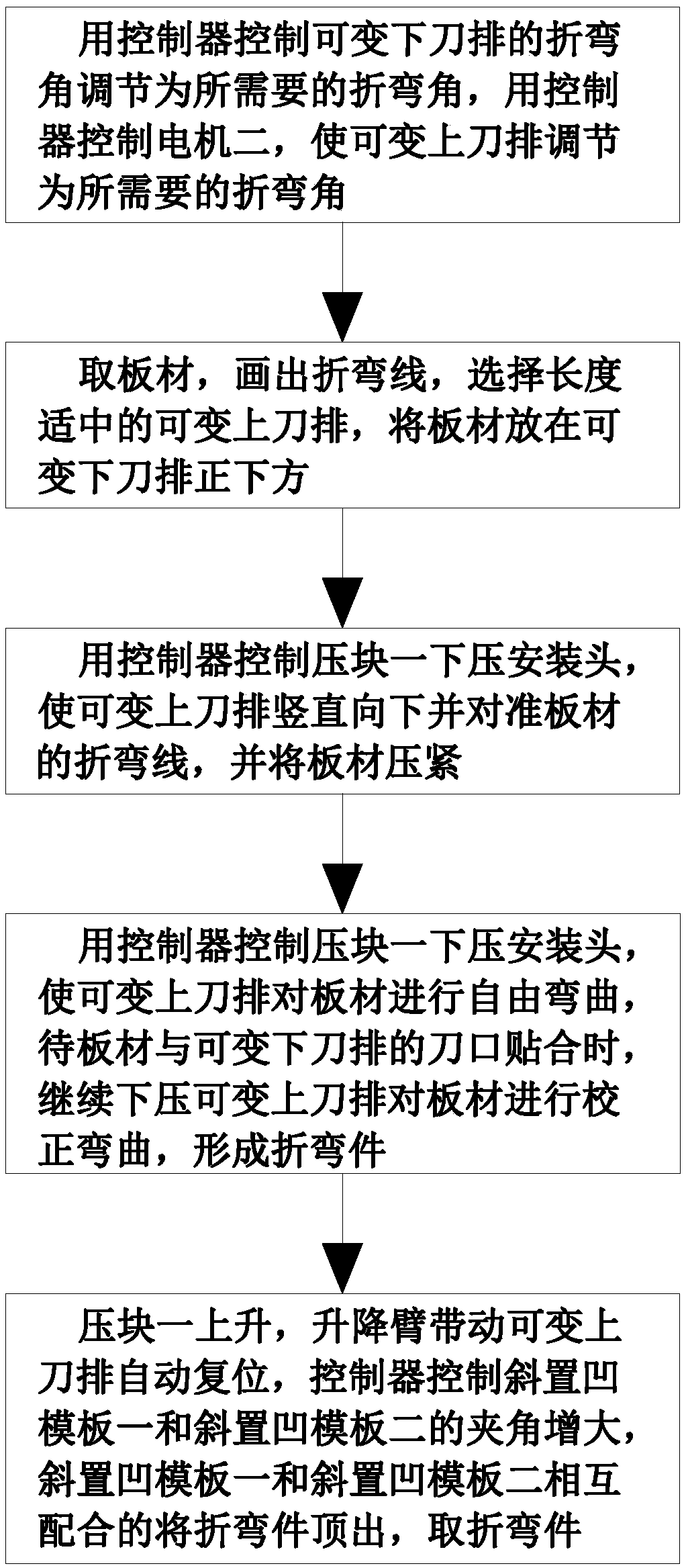

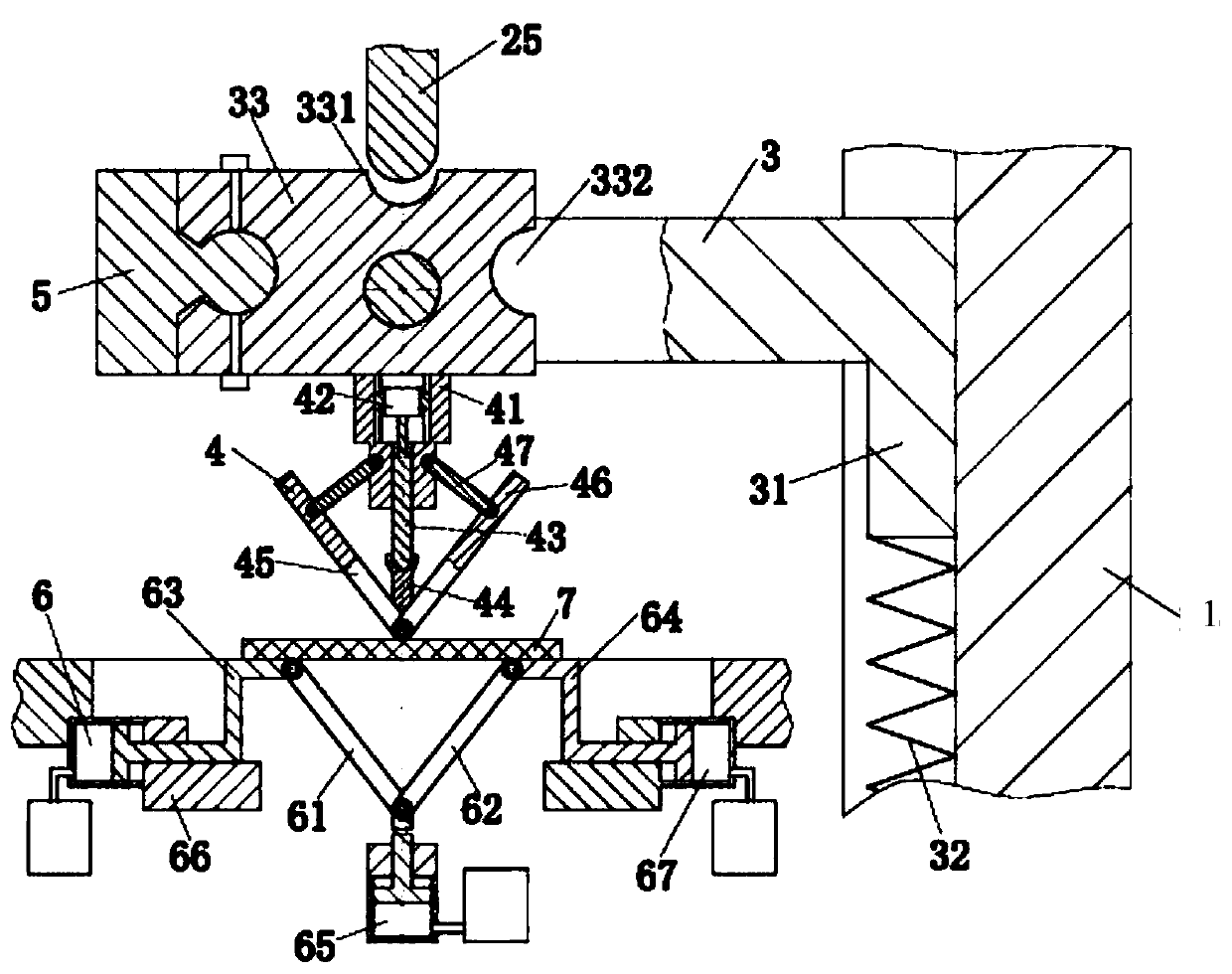

Sheet material bending and stamping integrated forming method

The invention belongs to the technical field of sheet material machining, and particularly relates to a sheet material bending and stamping integrated forming method. The sheet material bending and stamping integrated forming method comprises the following steps that a controller is used for automatically adjusting the bending angles of a variable upper tool array and a variable lower tool array to the needed bending angles; a sheet material is taken, a bending line is drawn, and the sheet material is put under the variable lower tool array; the controller is used for controlling the variableupper tool array to be aligned with the bending line of the sheet material downwards in the vertical direction and compress the sheet material; the controller is used for controlling the variable upper tool array to freely bend the sheet material, and when the sheet material and a tool edge of the variable lower tool array are attached, the variable upper tool array corrects and bends the sheet material to form a bent part; and the controller controls a pressing module to ascend, a lifting module drives the variable upper tool array to automatically reset, the controller controls the variablelower tool array to automatically expand the tool edge, and the bent part is jacked out and taken down. The bending angle of the sheet material is accurate by automatically adjusting the bending angleof the sheet material, and the forming yield of the bent part is improved.

Owner:泰州市海陵区震泽机械制造有限公司

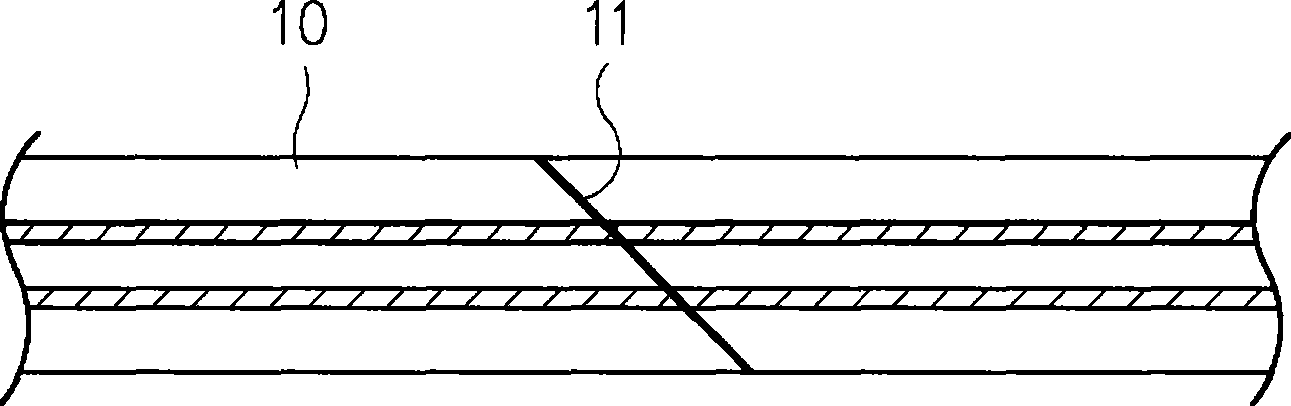

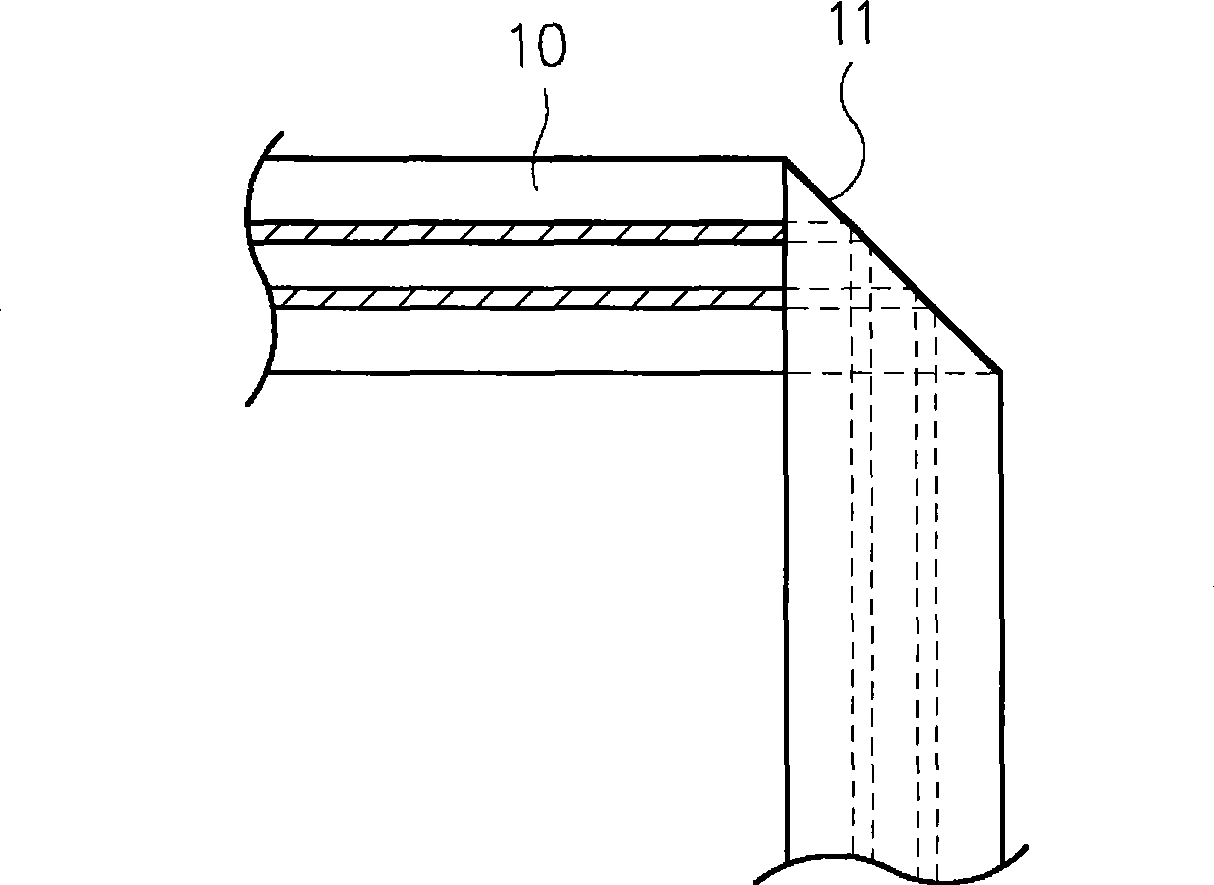

Design of bending region structure of flexible printed circuit board

The invention relates to a design of a bending region structure of a flexible printed circuit board, the flexible printed circuit board comprises a substrate, at least one printed circuit and a bending region, the bending region is staggered with at least one printed circuit, at least one groove is formed at the bending region of the printed circuit, the thickness of the groove is less than or equal to the thickness of the printed circuit, and the groove can not cut off the printed circuit; the design of the groove can effectively control the stress position at the bending region of the flexible printed circuit board, thereby achieving the purpose of precise bending angle of the flexible printed circuit board.

Owner:WINTEK CORP

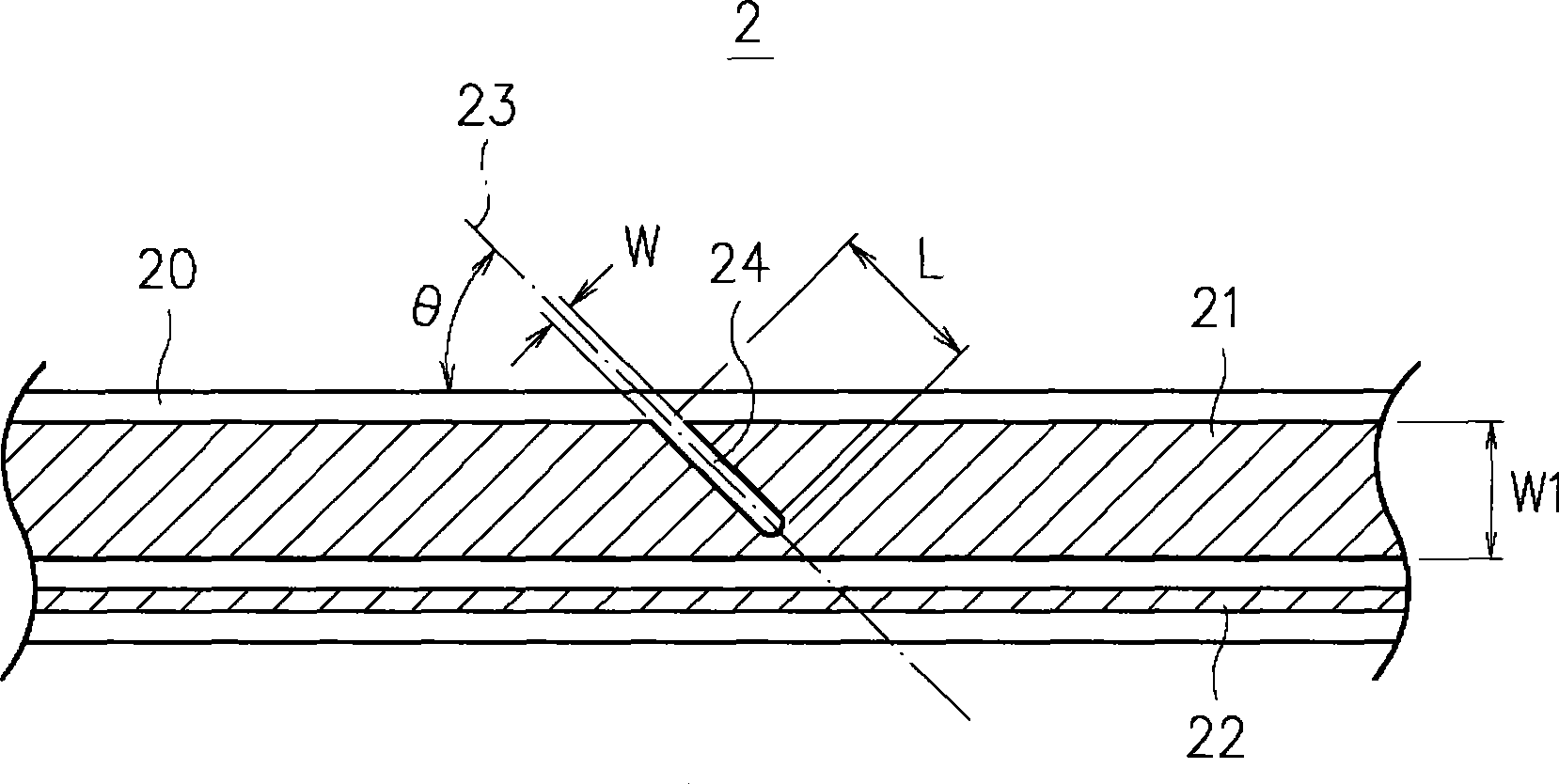

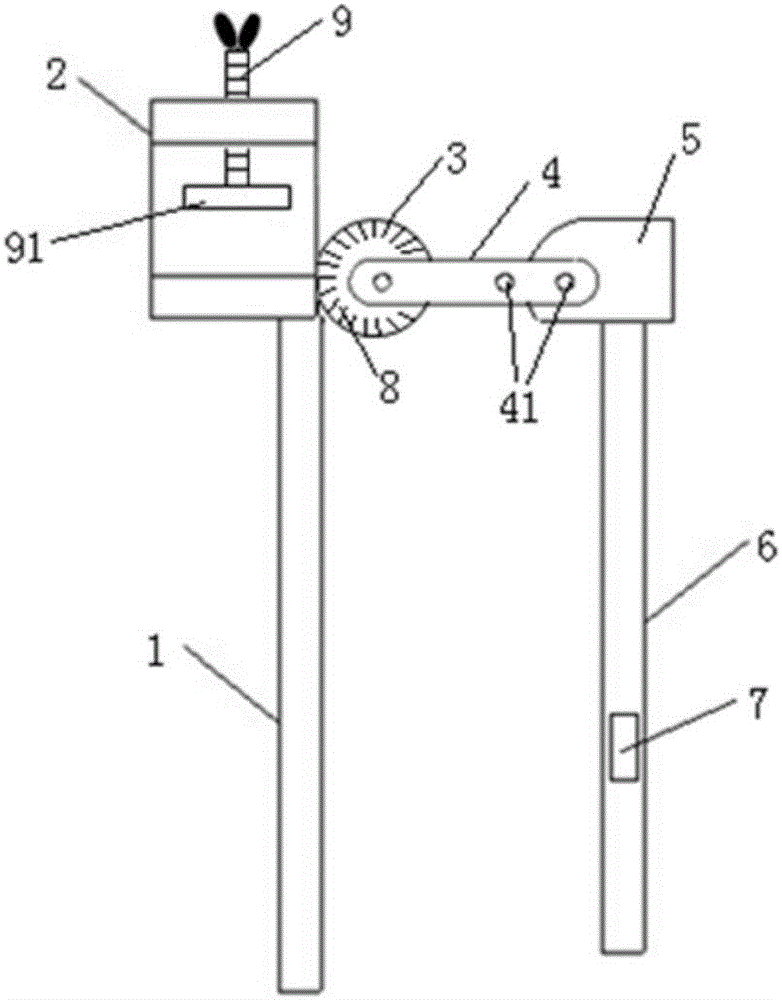

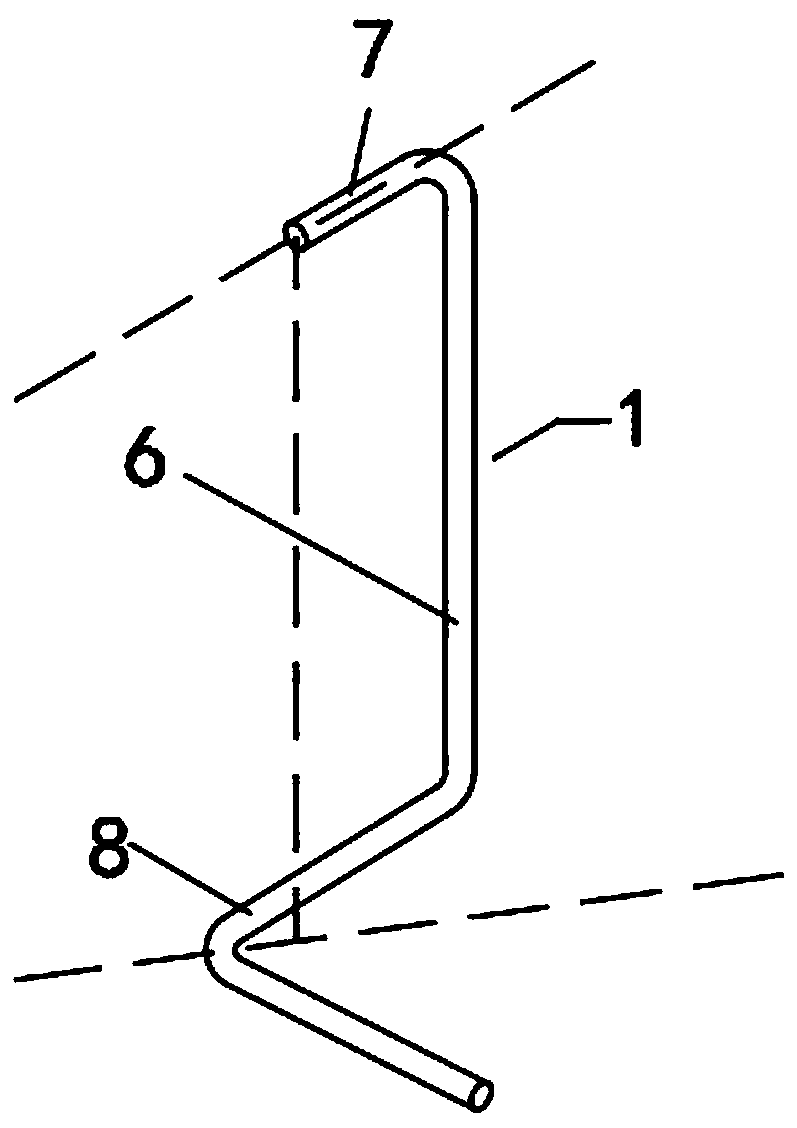

Insulating drainage wire bending tool and method

ActiveCN106684671AReal-time monitoring of bending anglePrecise bending angleLine/current collector detailsUltimate tensile strengthFlange

The invention discloses an insulating drainage wire bending tool. The tool provided by the invention includes a clamping part and a bending part. The clamping part includes a driven rod handle. The top end of the driven rod handle is provided with a C-shaped clamp base. The bending part includes a fixed wheel, a bending head, a drive rod handle and a connecting rod. When the bending part rotates around the fixed wheel, the clamp part and the bending part are in the same plane. When the drive rod handle is pushed upward so as to enable the bending part to rotate around the fixed wheel until the bending head is in contact with the right side of the C-shaped clamp base, a channel formed between the flange of the bending head and the outer edge of the fixed wheel is opposite to the opening of the C-shaped clamp base, thus an unbending insulating drainage wire passes through the channel. The invention also relates to a method using the insulating drainage wire bending tool to bend the insulating drainage wire. The insulating drainage wire bending tool utilizes the lever principle fully. Labor strength can be reduced effectively and physical power of live operation workers is saved. The insulating drainage wire bending tool and method are suitable for operation of drainage wires having different wire diameters.

Owner:XINTAI POWER SUPPLY COMOANY STATE GRID SHANDONG ELECTRIC POWER CO +2

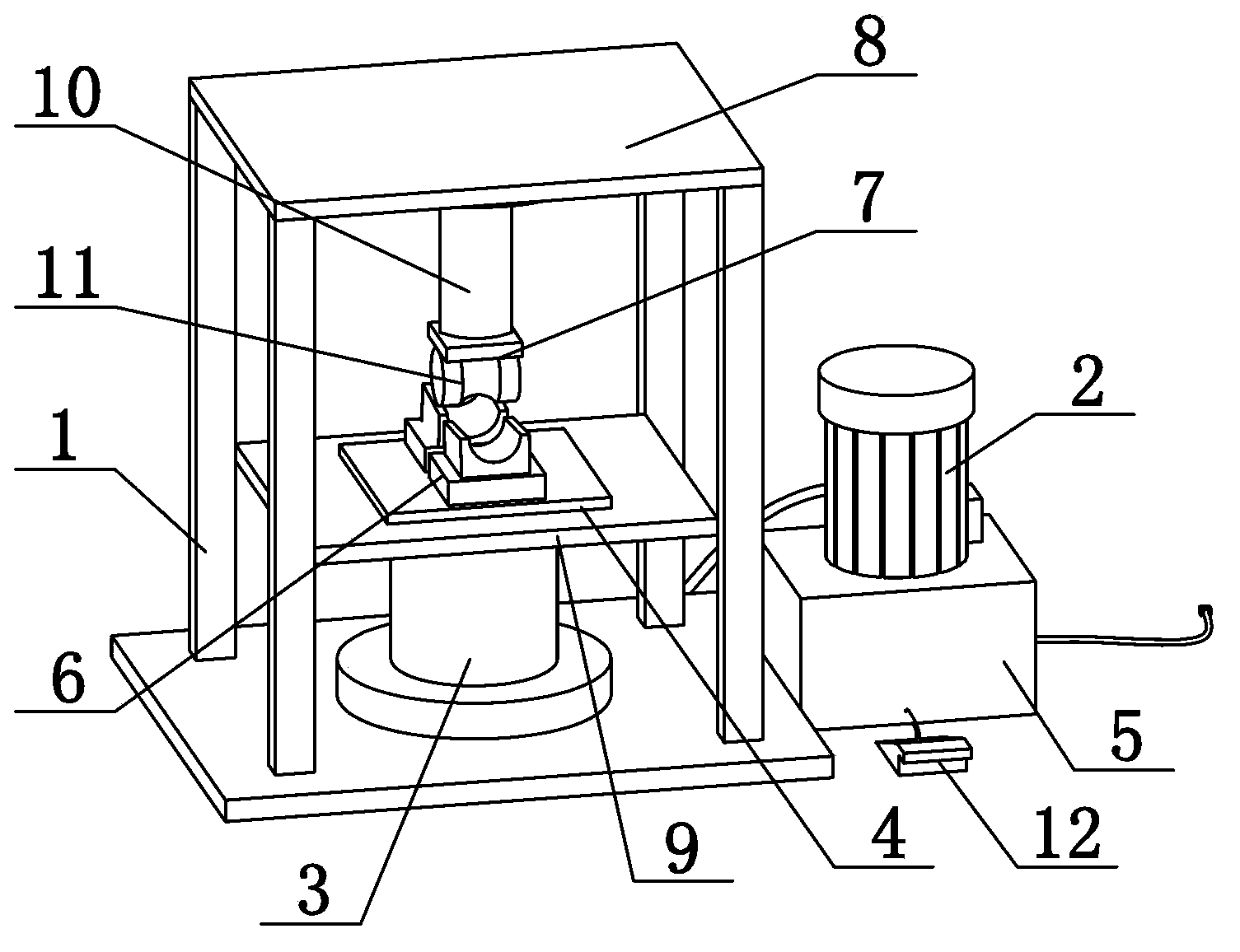

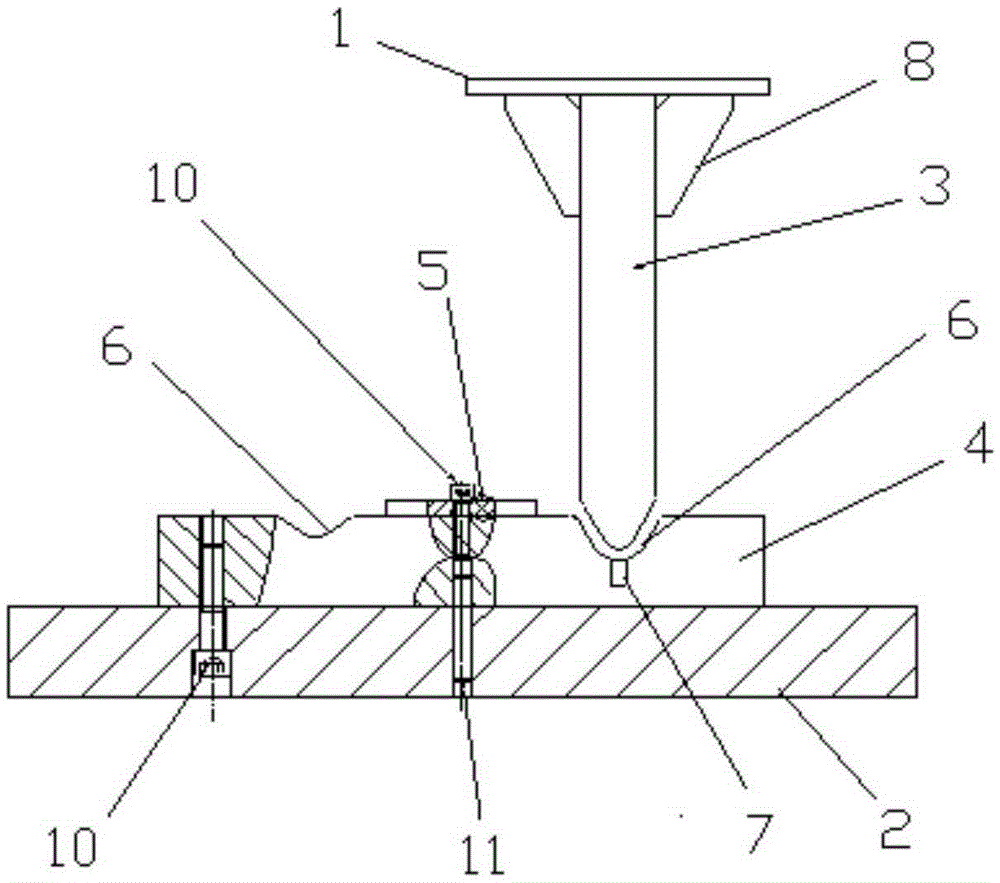

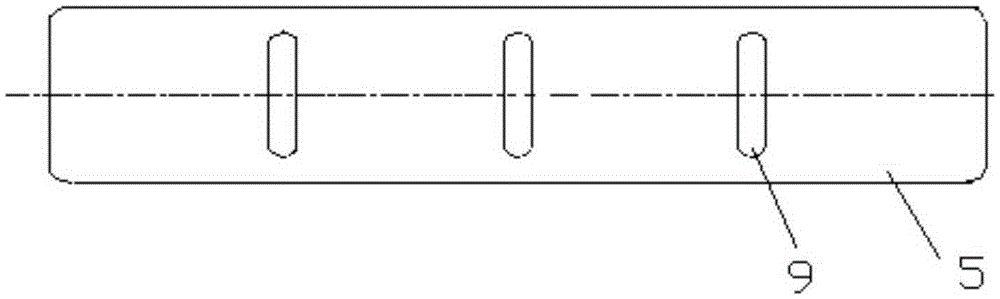

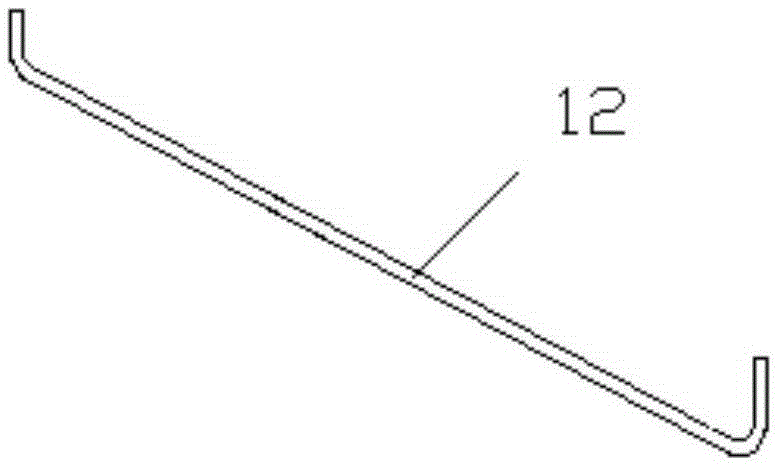

Small-sized bending device

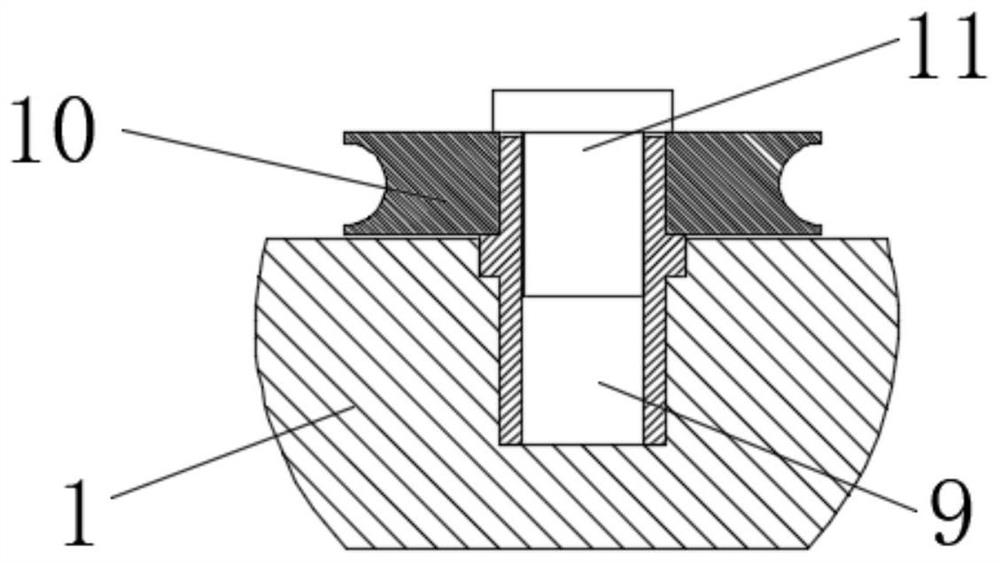

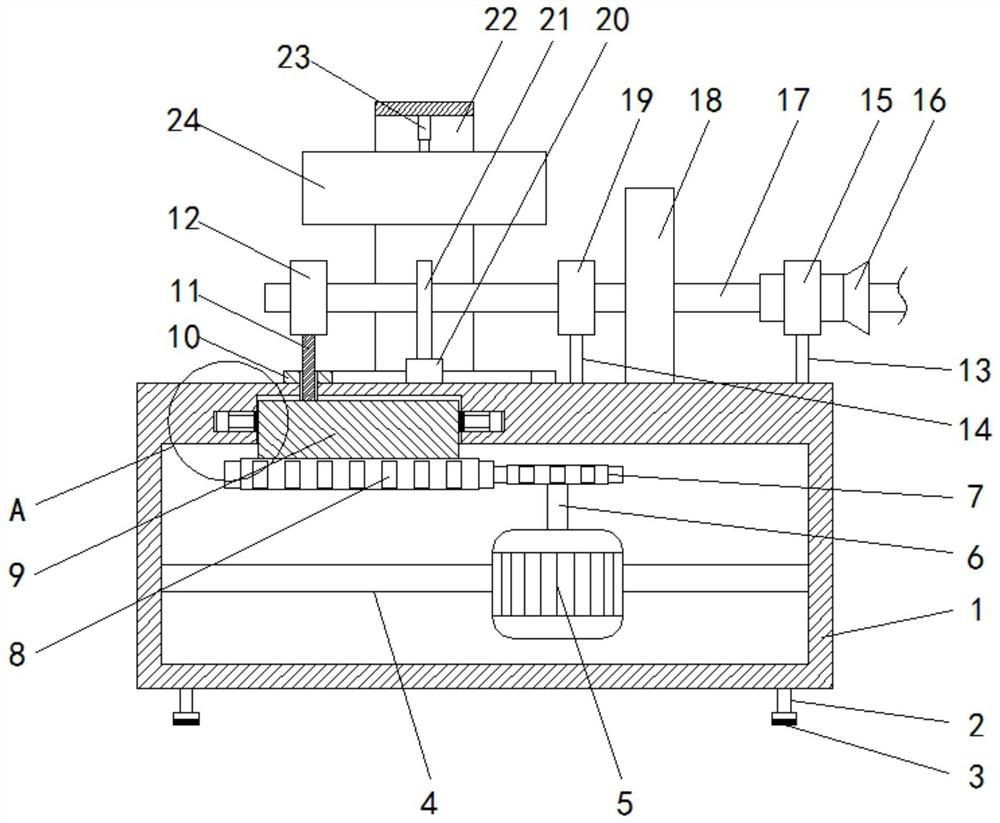

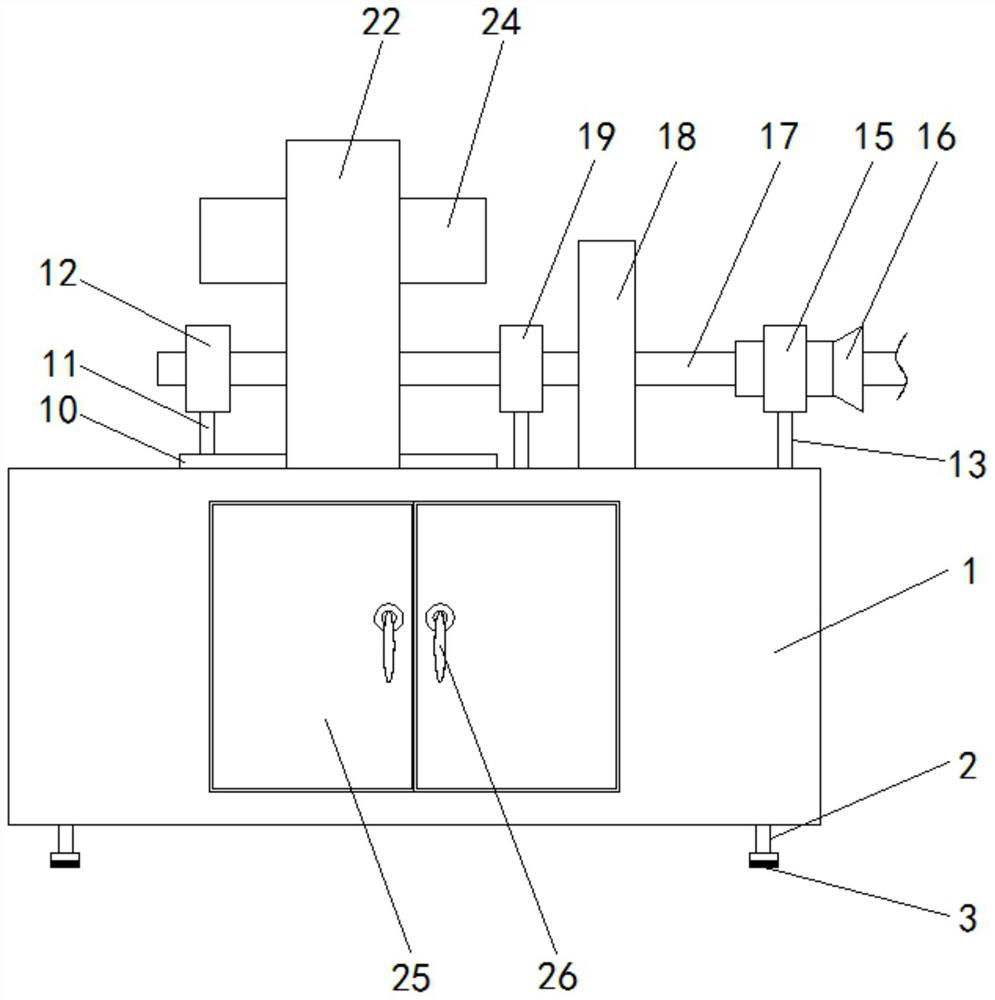

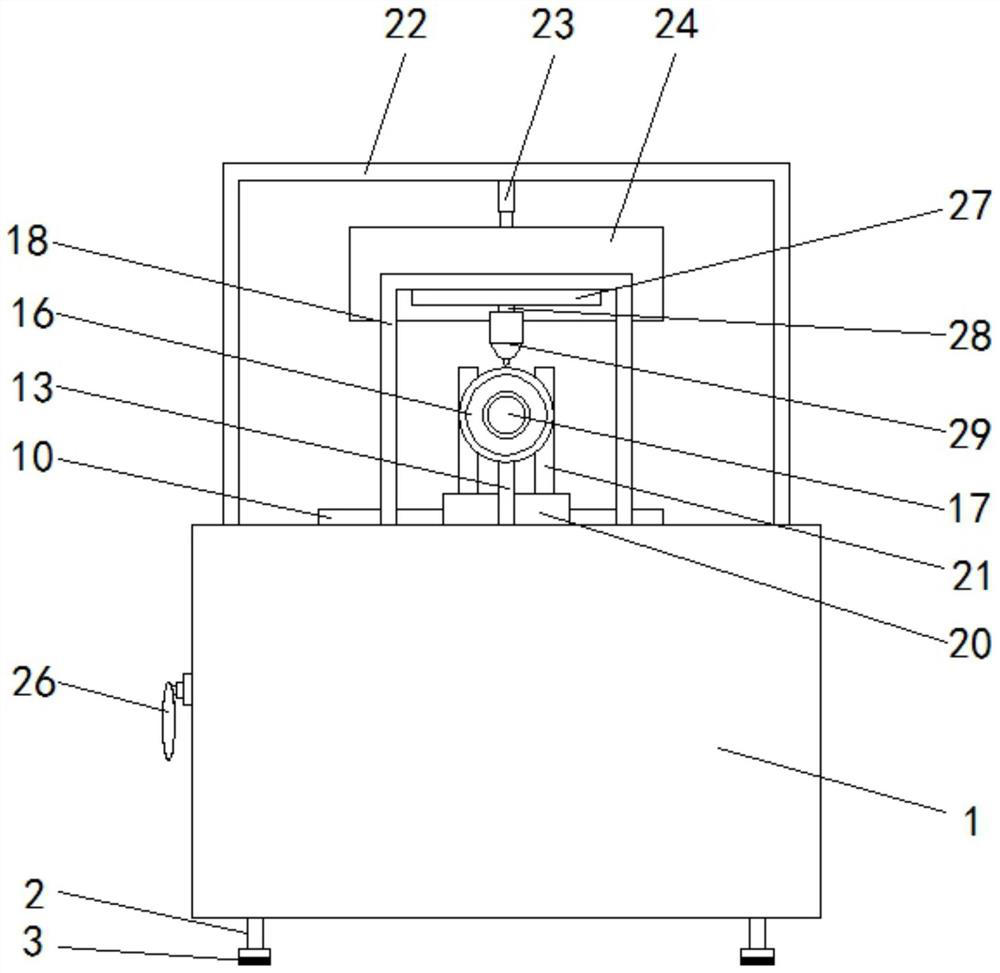

The invention discloses a small-sized bending device. The small-sized bending device is characterized by comprising a rack (1), a motor (2), a hydraulic cylinder (3), a supporting device (4) and a bending device body (7); the hydraulic cylinder (3) is arranged on the rack (1), and is connected with a hydraulic oil tank (5) through a connecting pipeline; the supporting device (4) comprises a supporting platform (9) and a carrying platform (6), and the carrying platform (6) is arranged on the supporting platform (9), and is provided with a concave angle block or an arc-shaped angle block. Hydraulic pressure is utilized for bending, and accordingly bending speed is increased, precise bending angles are guaranteed through changing of the slanting angle of the concave angle block or the arc-shaped angle block, and therefore the small-sized bending device improves working efficiency, guarantees consistent angles and saves cost.

Owner:杨国栋

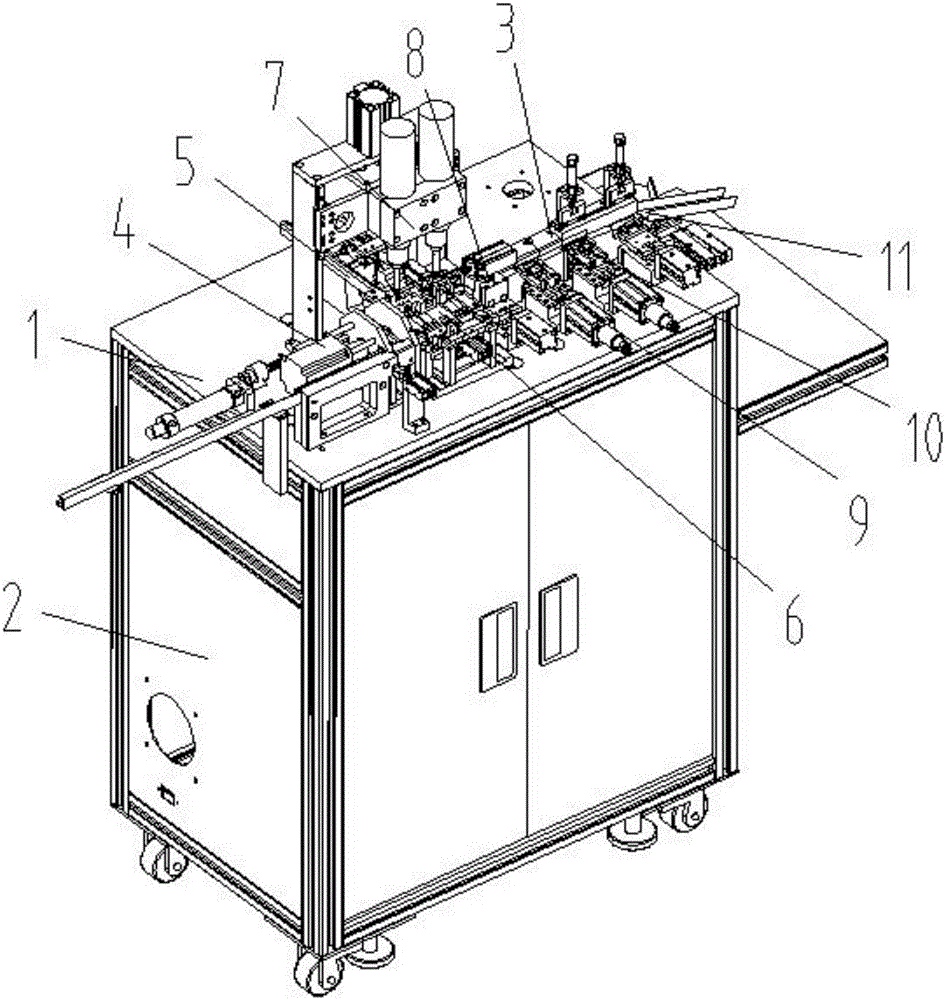

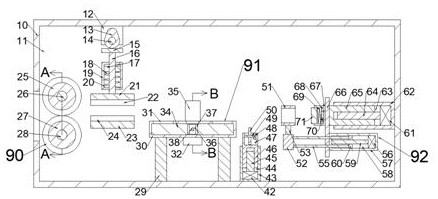

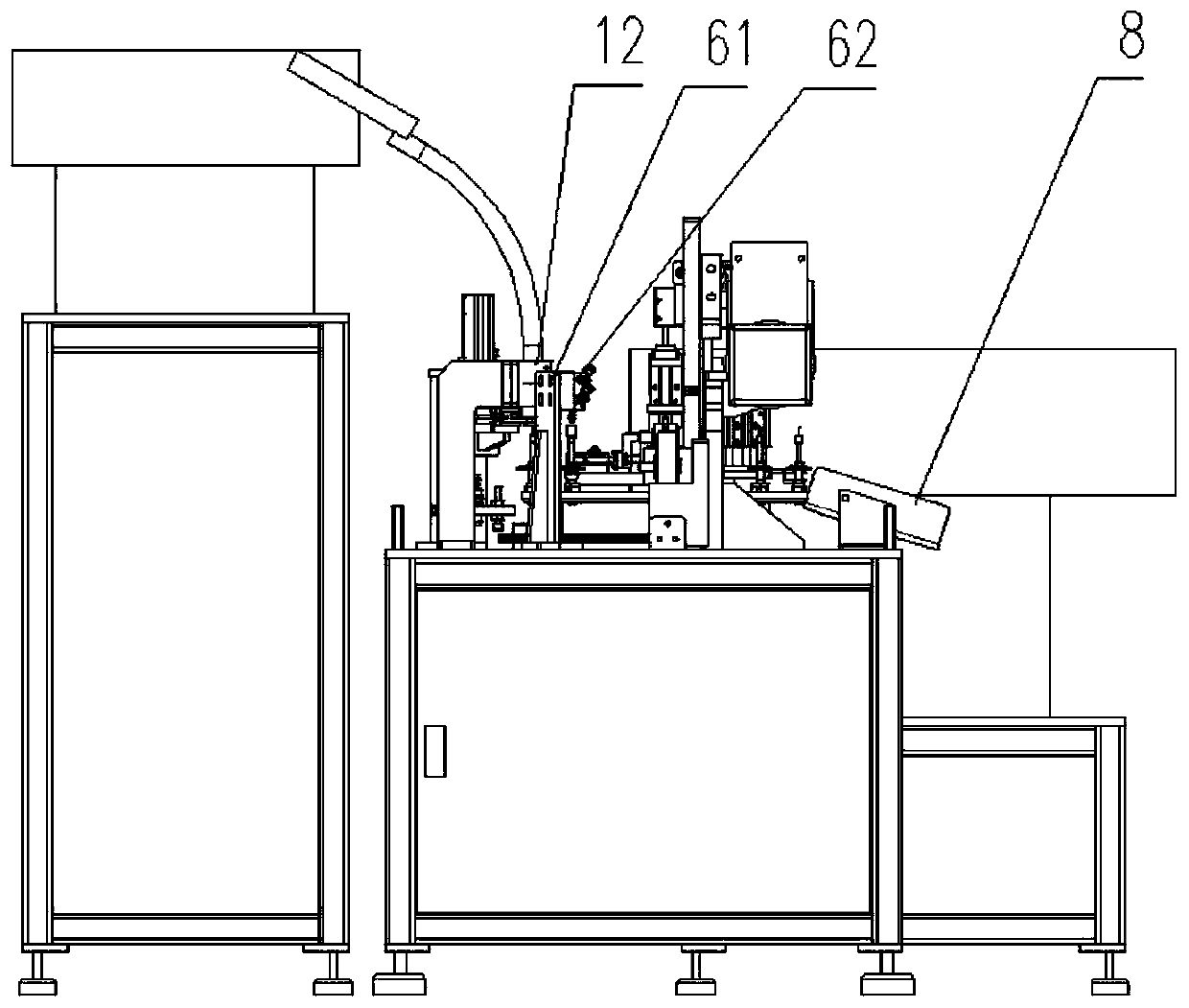

Full-automatic integrated processing machine of video graphics array (VGA) interface

ActiveCN106684669APrecise bending angleRealize automatic integrated processingContact member manufacturingContact member assembly/disassemblyGraphicsDistribution control

The invention relates to a full-automatic integrated processing machine of a video graphics array (VGA) interface. The full-automatic integrated processing machine comprises a rack and a power distribution control box, wherein a transmission groove is formed in the rack and is matched with a product, a clamping device, a bolt loading device and a bolt locking device are arranged at a left part of the transmission groove and are matched with one another, an upper bending device and a lower bending device are arranged at a right part of the transmission groove and are matched, detection devices are arranged at a left side of the upper bending device and a right side of the lower bending device, the upper bending device comprises an upper bending air cylinder, an upper bending block is connected with the upper bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an outer side, the lower bending device comprises a lower bending air cylinder, and a lower bending block is connected with the lower bending air cylinder and is provided with a bending inclined surface inclining at an angle of 45 degrees at an inner side. By the full-automatic integrated processing machine, automatic integrated processing is achieved, meanwhile, the accurate bending angle of a terminal can be ensured, detection leakage is prevented, and the processing efficiency is improved.

Owner:秦轩汽车科技(天长)有限公司

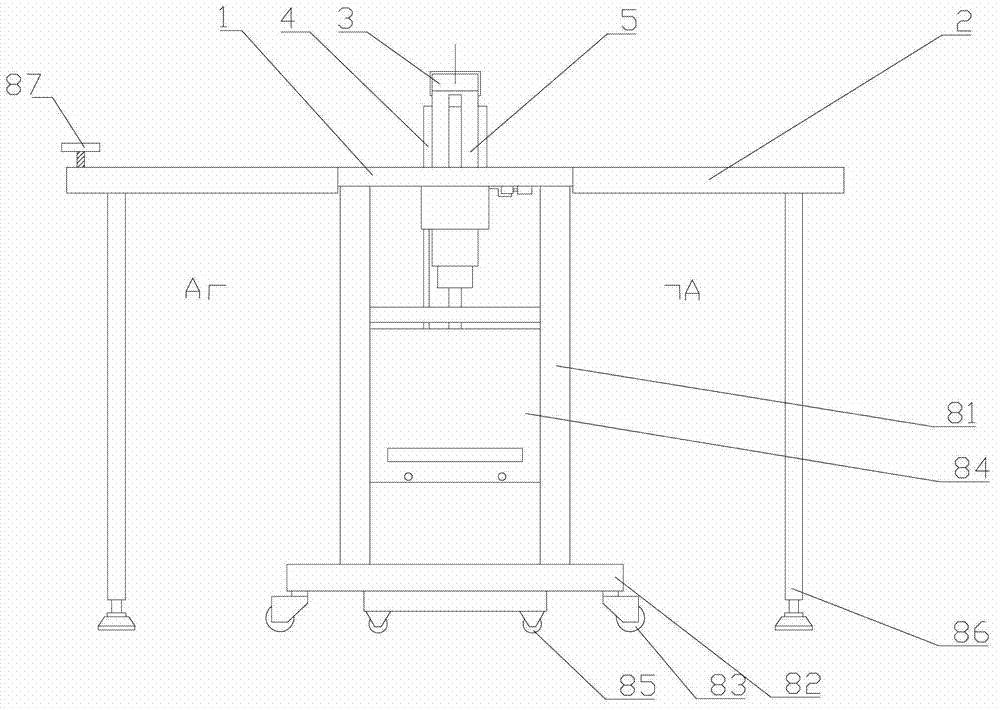

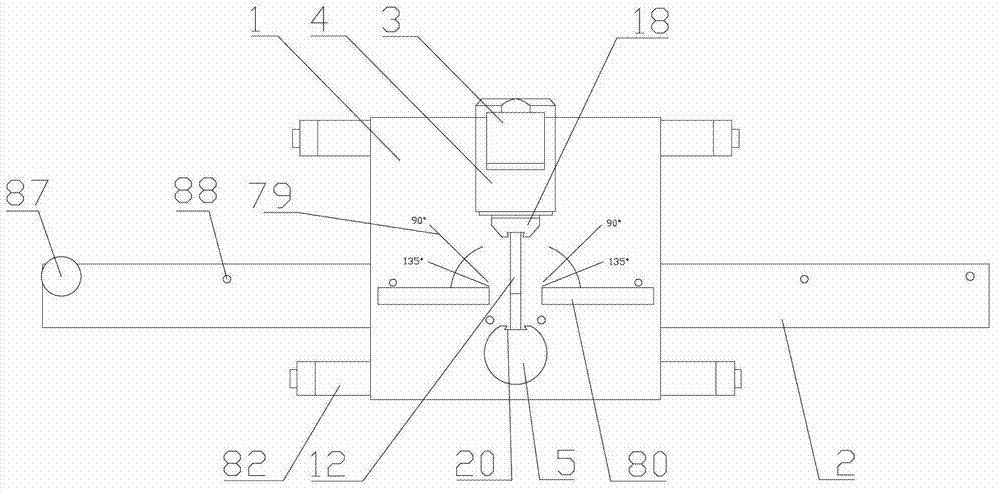

Small light numerically-controlled bus processing machine

The invention relates to a small light numerically-controlled bus processing machine. The small light numerically-controlled bus processing machine comprises a platen, supporting plates, a grating controller, an oil cylinder, a pressure head, an upright column, a shearing mold, a punching mold and a bending mold, wherein an oil cylinder insertion hole, a guide groove and an upright column fixing hole are formed in the platen respectively, the oil cylinder is inserted in the oil cylinder insertion hole and fixed on the platen, and the upright column is fixed on the platen; a strengthening plate is connected with the lower wall surface of the platen, the upright column and a strengthening sleeve; a falling object chute is formed in the strengthening plate, a section of the guide groove is correspondingly formed above the falling object chute, the pressure head is arranged at the front end of a piston rod of the oil cylinder, a first dovetail groove is formed in the pressure head, a second dovetail groove is formed in the upright column, and the supporting plates are positioned on two sides of the platen; a grating scale is connected below the pressure head, and arranged on the lower bottom surface of the platen; and a shearing stripping groove penetrating a middle shaft of the upright column and the whole upright column is formed in the side surface of the upright column, and an opening on one side of the shearing stripping groove is positioned in the second dovetail groove. The small light numerically-controlled bus processing machine has the advantages of functional diversity, simplicity, light weight, small size and the like.

Owner:陈伟民

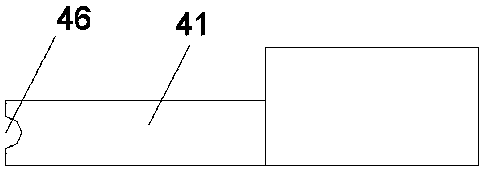

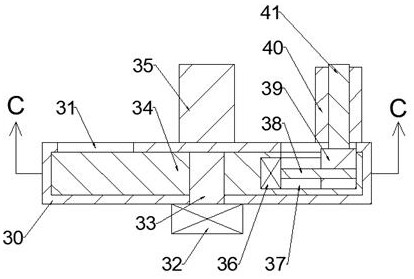

Light-small type numerical-control bus bar bending machine

The invention relates to a light-small type numerical-control bus bar bending machine, comprising a table plate, support plates, a grating controller, an oil cylinder, a press head, a vertical column and a bending die, wherein the oil cylinder and the vertical column are fixed on the table plate, a reinforcing plate is arranged on the lower wall surface of the table plate, and the reinforcing plate is connected with the vertical column and a reinforcing sleeve; a material-falling inclined groove is formed on the reinforcing plate; a section of guide groove is correspondingly formed above the material-falling inclined groove, and is through from top to bottom, the press head is arranged at the front end of the oil cylinder; a first dovetail groove is formed on the press head, and a second dovetail groove is formed on the vertical column, a slide foot is arranged below the press head, a connecting foot is connected below the slide foot, a connecting rod extending along the left side or the right side of the table plate is connected below the connecting foot, a connecting plate is connected to the other end head of the connecting rod, the connecting plate is connected to a grating ruler, and the bending die comprises a bending convex die and a bending concave die; and a swallow tail E3 is arranged on the side of the bending convex die, and a swallow tail F is arranged on the side of the bending concave die. The light-small type numerical-control bus bar bending machine disclosed by the invention has the advantages of being accurate in bending angle, high in efficiency, small in die, light in machine body, firm in table plate, easy to carry, and the like.

Owner:陈伟民

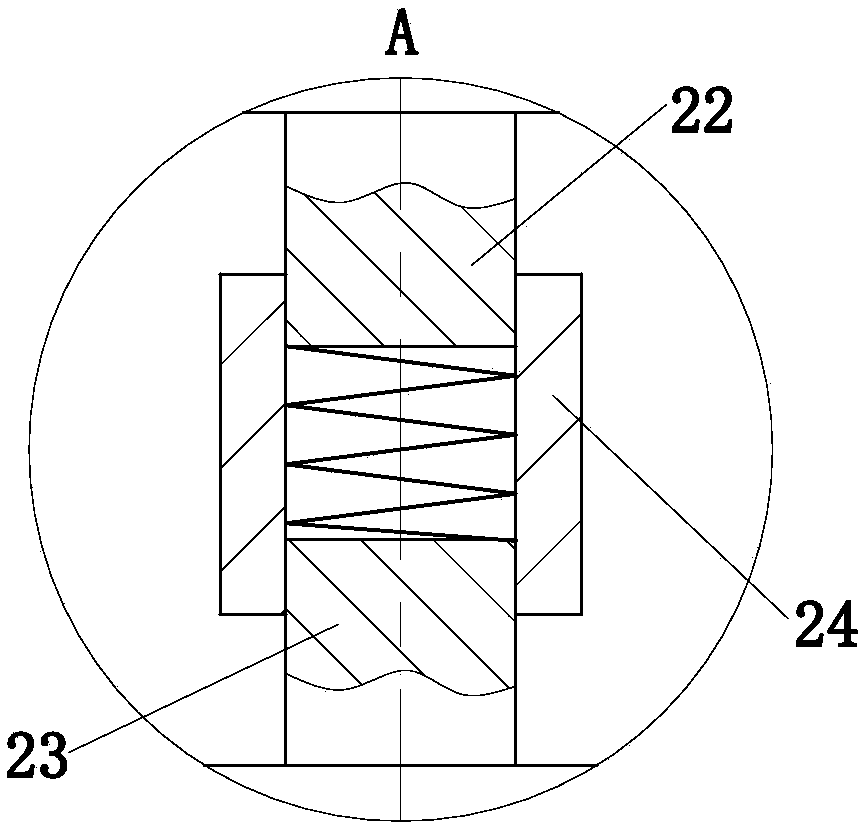

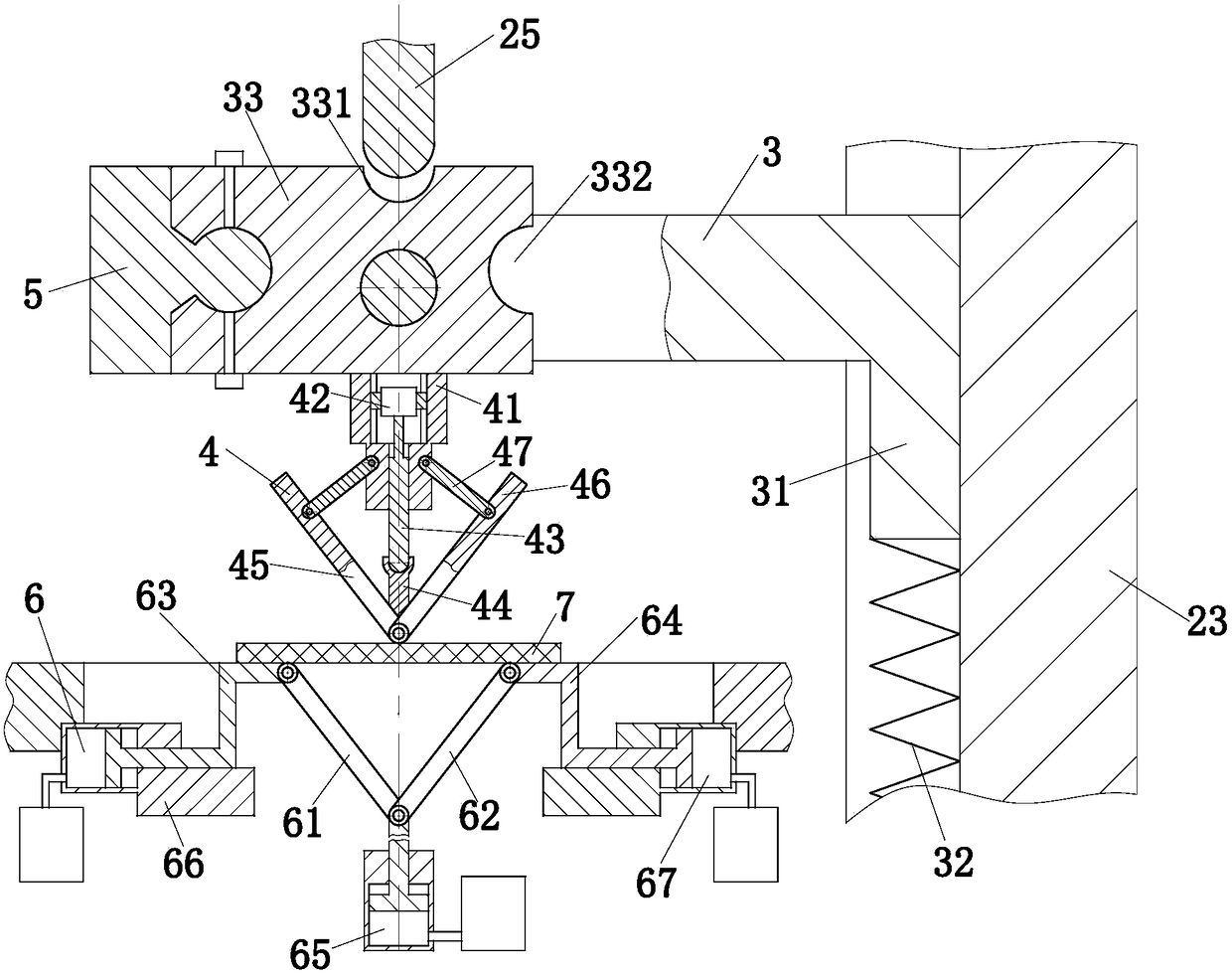

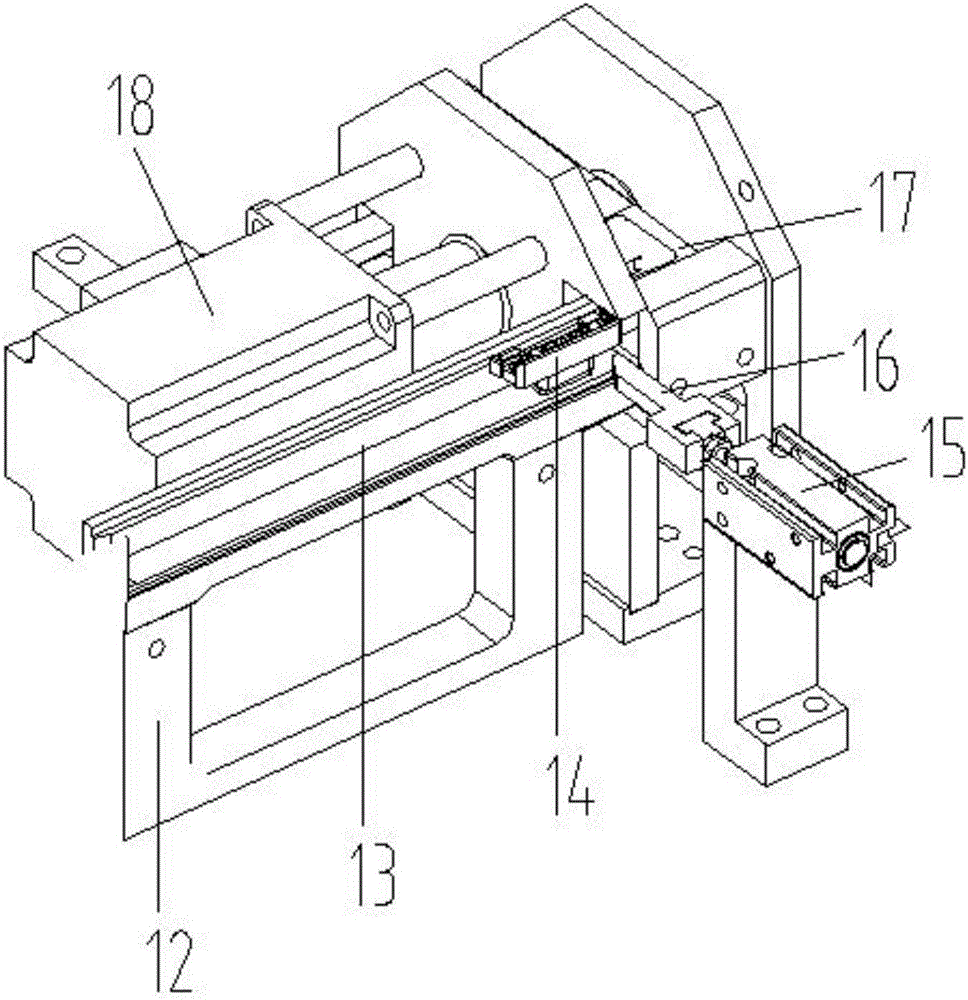

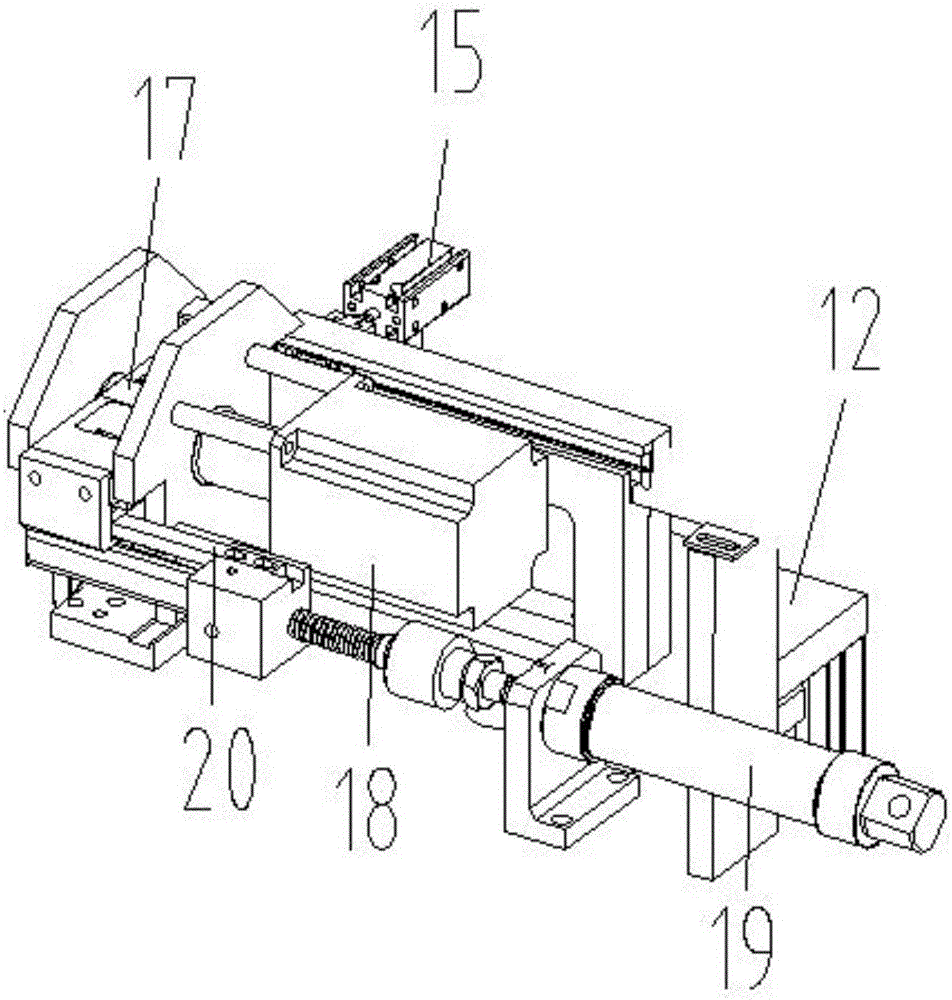

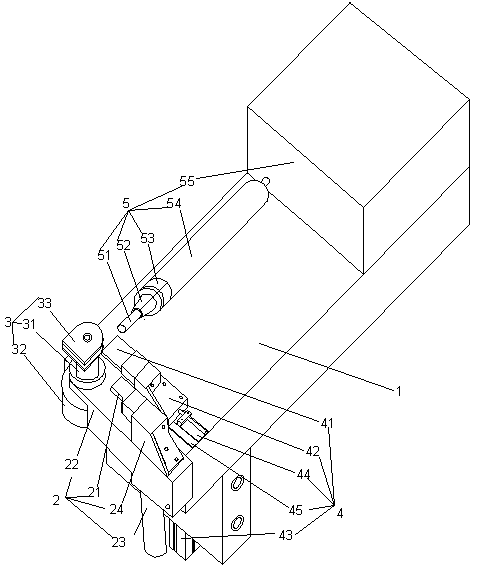

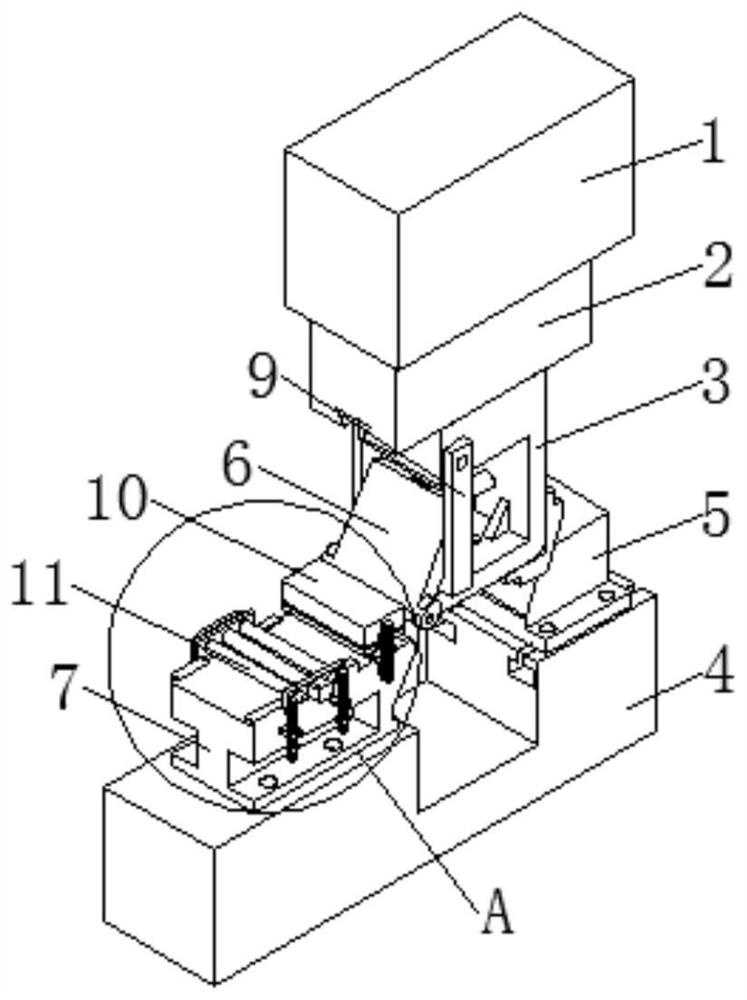

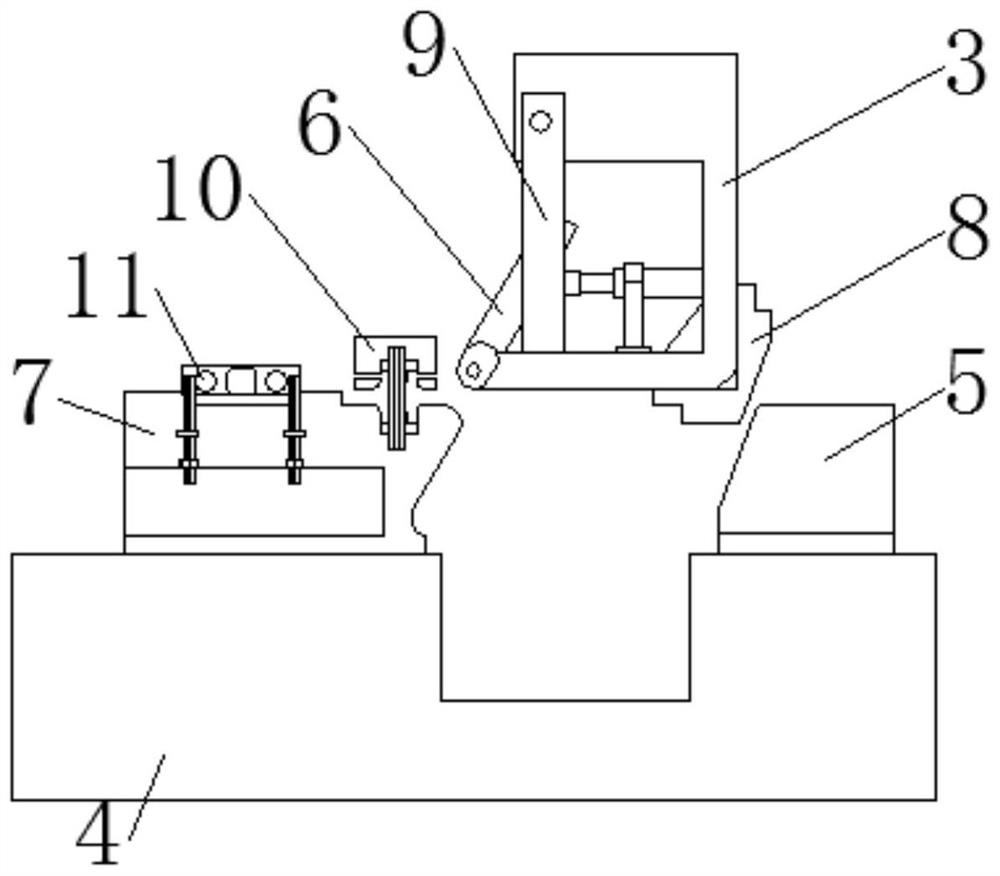

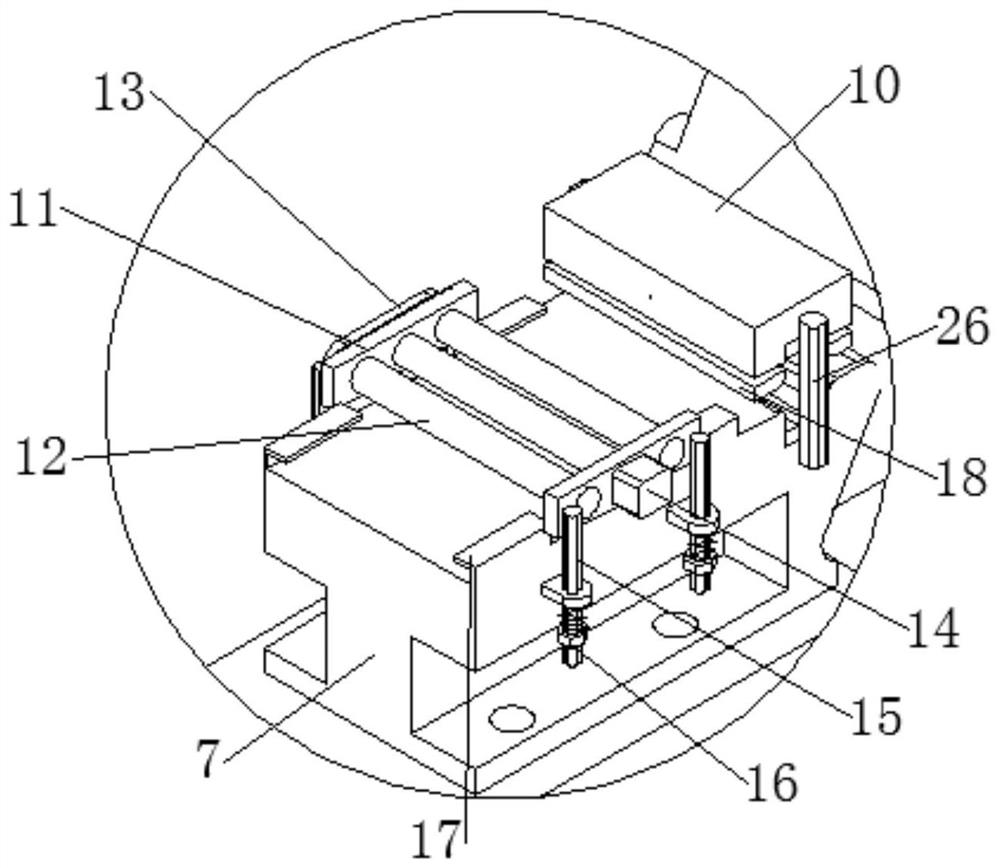

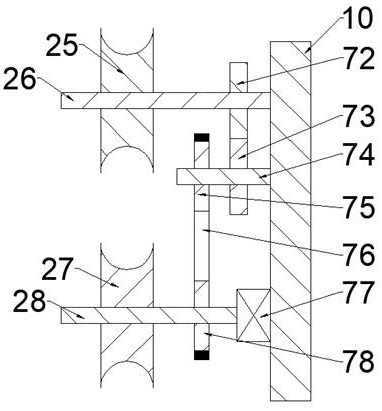

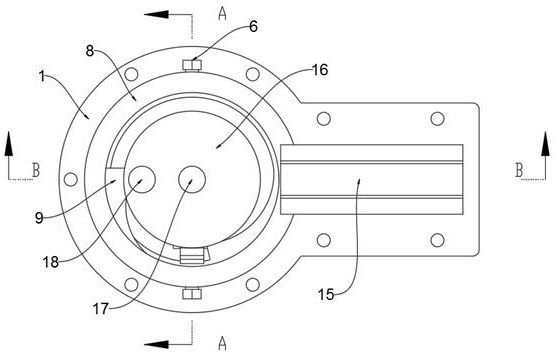

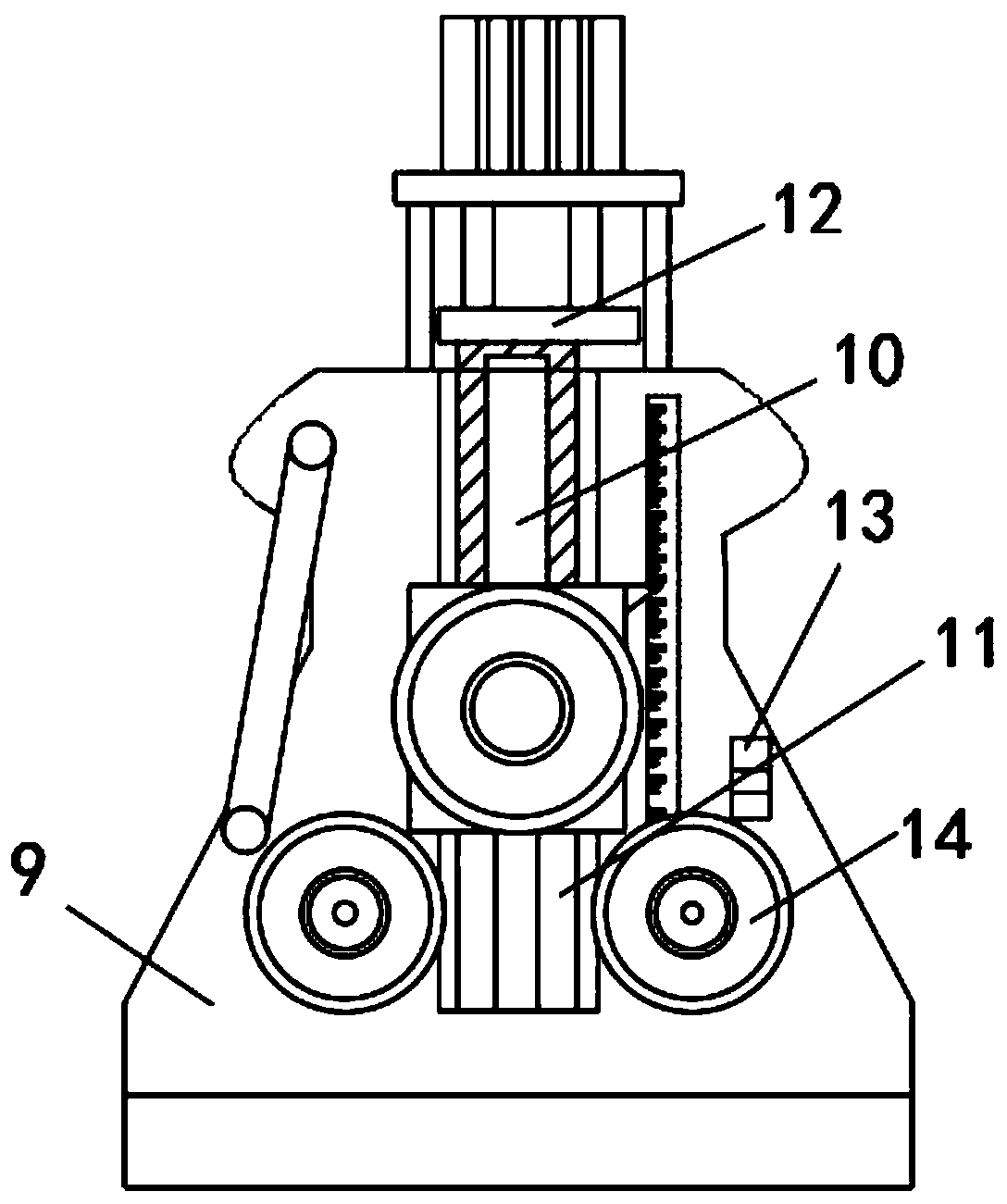

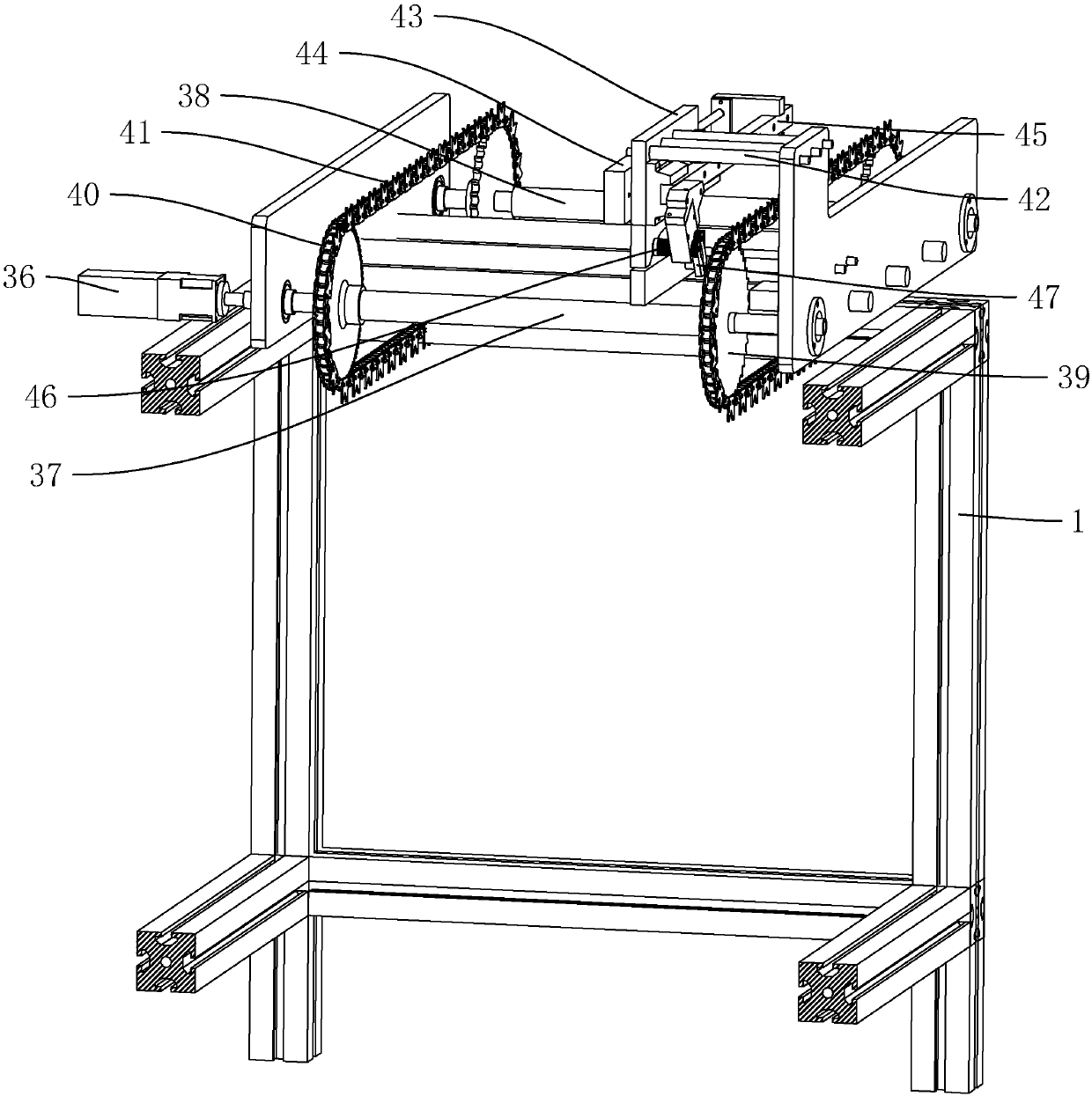

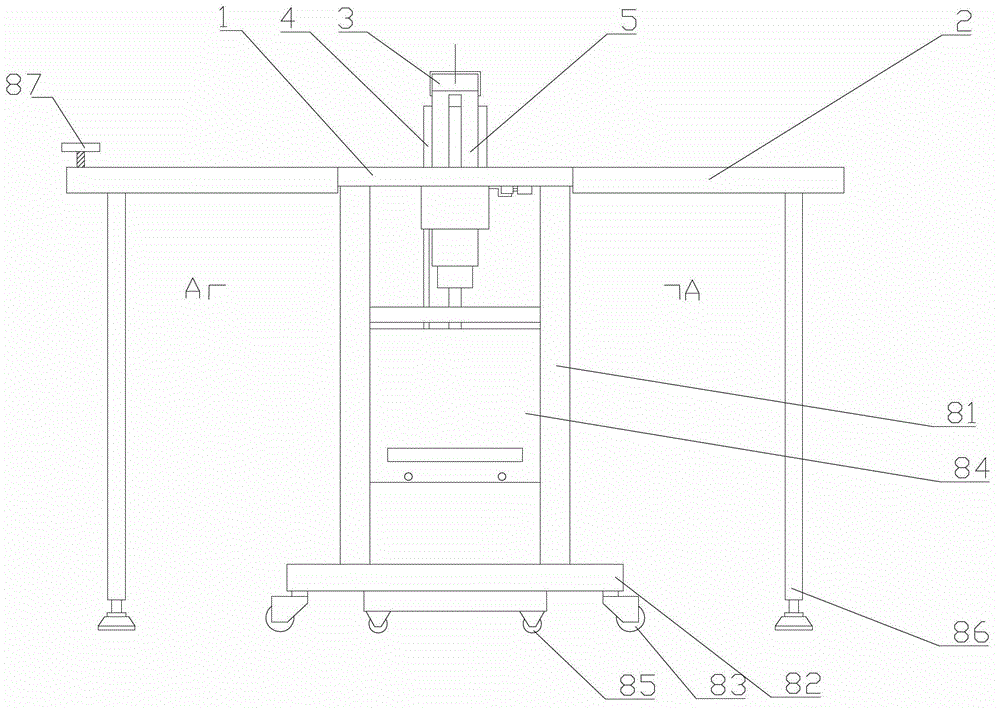

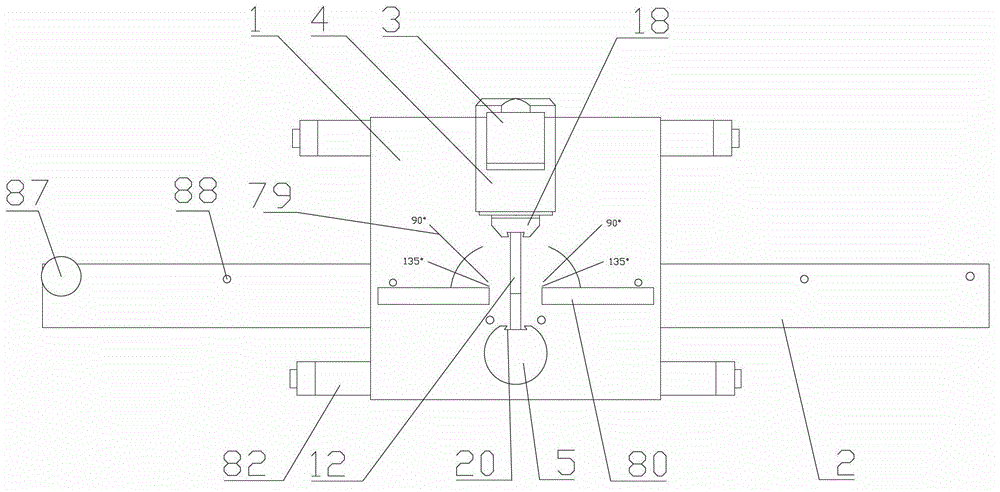

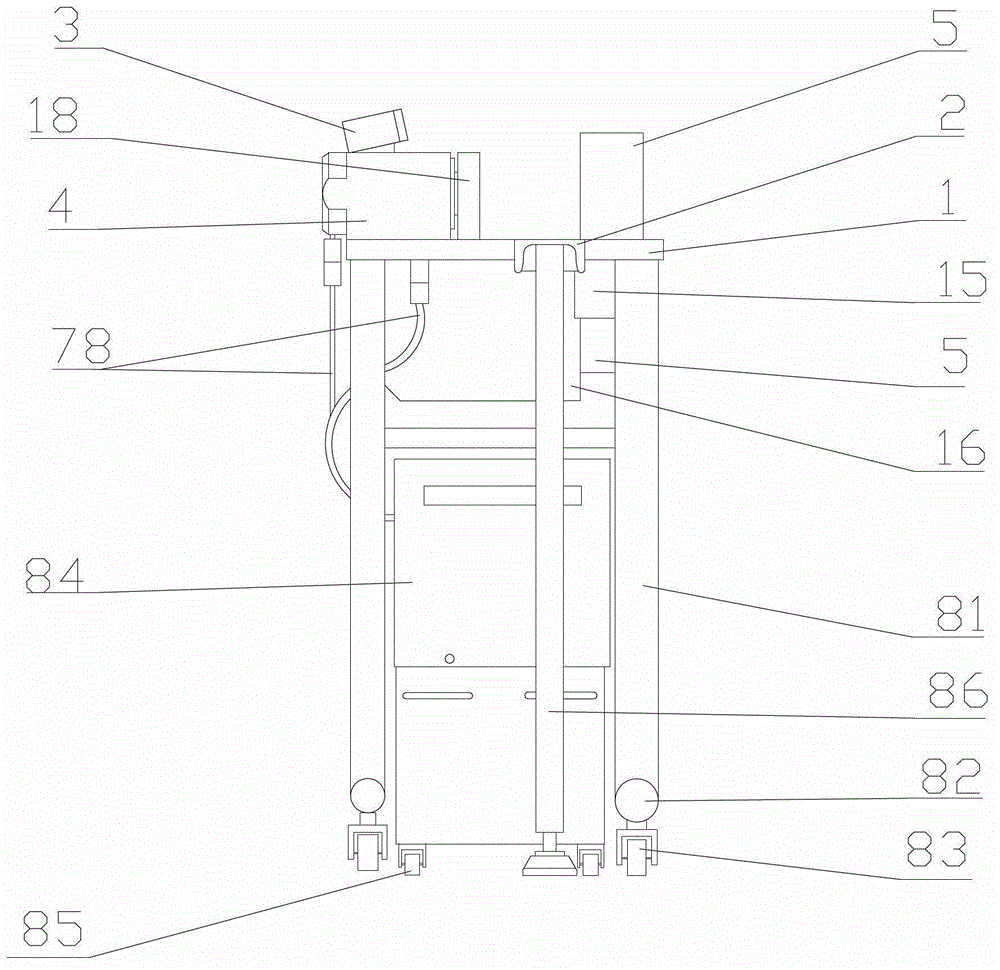

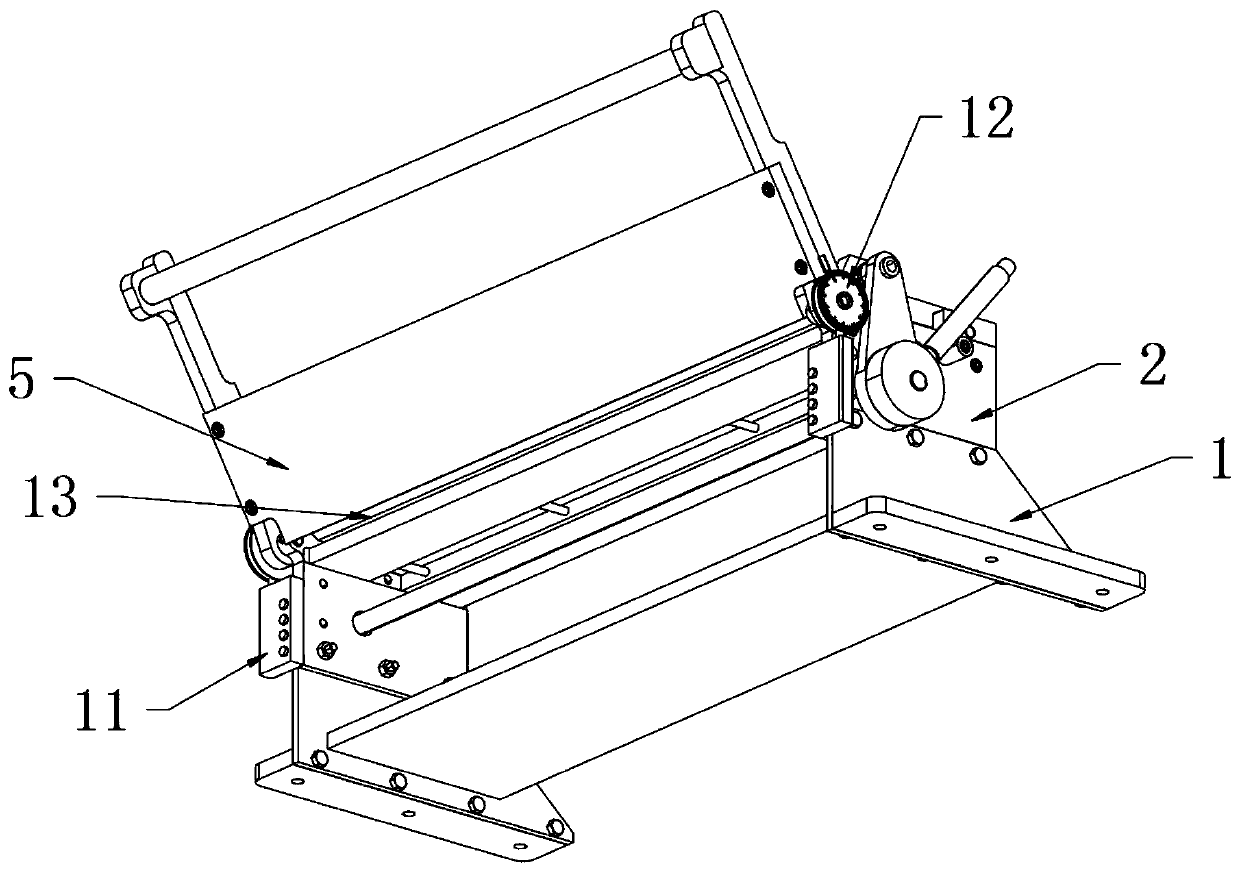

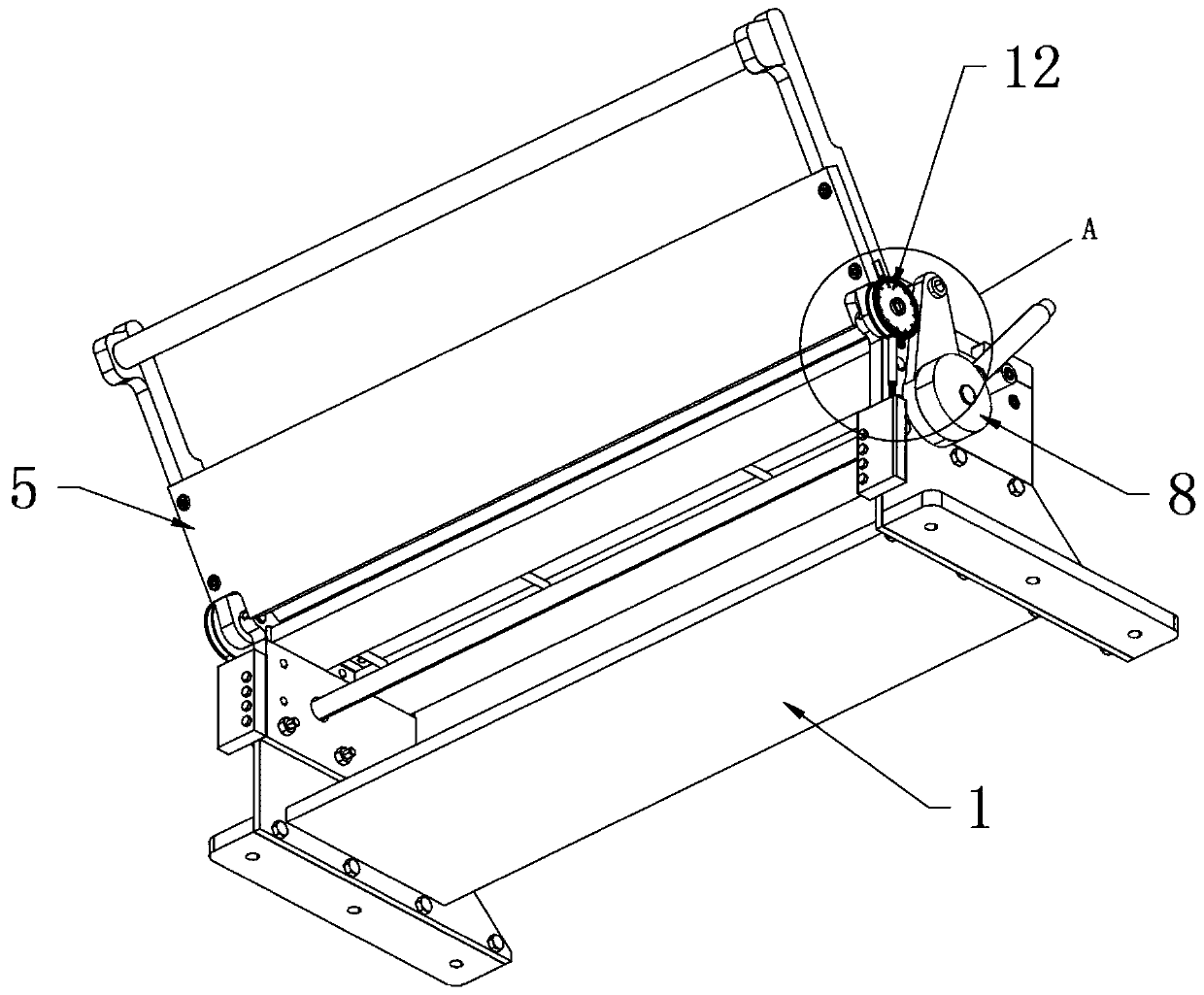

Special-shaped bending device for copper pipes

PendingCN107716648APrevent rotationPrecise bending angleMetal-working feeding devicesPositioning devicesMechanical engineeringCopper tubing

The invention provides a special-shaped bending device for copper pipes. The special-shaped bending device comprises a machine frame platform, a bending mechanism, a rotating mechanism, a positioningmechanism and a shifting mechanism, wherein the rotating mechanism, the positioning mechanism and the shifting mechanism are arranged on the rack platform. After a copper pipe is clamped and positioned on the shifting mechanism and the positioning mechanism, the bending mechanism drives the rotating mechanism to rotate to a set angle to achieve first bending, and then the bending mechanism, the rotating mechanism and the positioning mechanism return. After the shifting mechanism rotates and drives the copper pipe to rotate to a certain angle, the copper pipe is then clamped by the bending mechanism and the positioning mechanism, a clamping ring and a clamping pressing block of the shifting mechanism loose, and the bending mechanism drives the rotating mechanism to rotate to a certain angleto achieve second bending. The shifting mechanism can be used for positioning and discharging the pipe through a telescopic positioning rod, the clamping ring and the clamping pressing block are usedfor clamping the pipe to prevent rotation, and is matched with the clamping pressing block of the positioning mechanism, so that special-shaped bending for twice or even multiple times can be achieved, the bending angle is accurate, and the bending quality is good.

Owner:ZHENJIANG WANYUAN ELECTRONICS

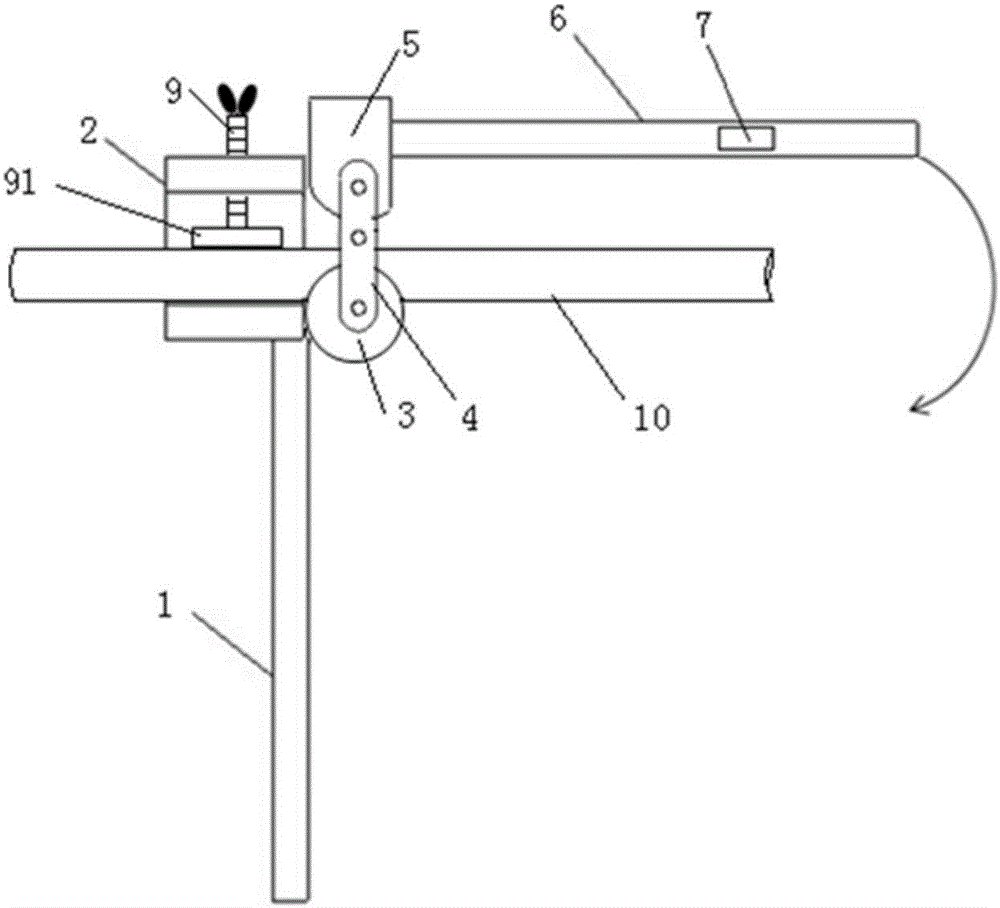

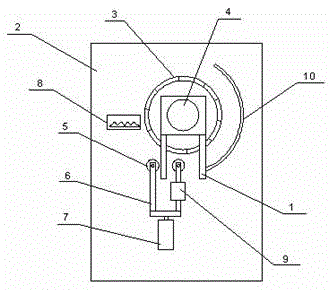

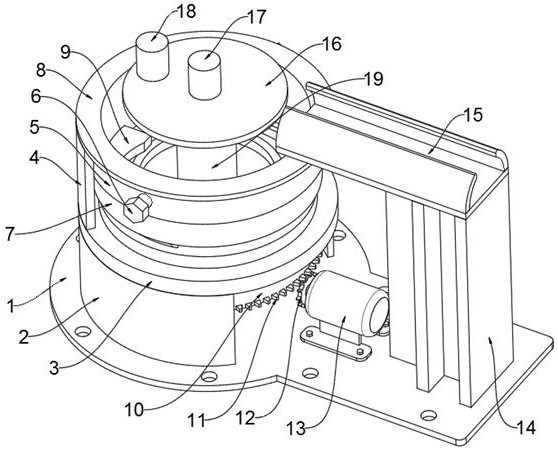

Automatic pipe bending machine

ActiveCN105478545ASimple structureReduce volumeShaping safety devicesEngineeringMechanical engineering

The invention relates to an automatic pipe bending machine which comprises an electrical system, a rack, a motor, a rotary disc, a rotary shaft, a chuck, a steam cylinder and a sliding rail. The rack comprises a base and a support. One end, penetrating the center of the rotary disc, of the rotary shaft is fixed to the base, the motor is arranged on the support above the rotary disc, and the other end of the rotary shaft is connected with the motor. The chuck is arranged on the right side of the rotary disc and fixed to the left end of the sliding rail. The steam cylinder is fixedly connected with the right end of the sliding rail. A stop block device is further arranged in front of the rotary disc and fixed to the base. The electrical system is connected with the motor and the steam cylinder. The automatic pipe bending machine has the beneficial effects of being simple in structure, small in size, convenient to use, accurate in bending angle and suitable for air conditioner pipes with various diameters.

Owner:WUHU HENGMEI ELECTRIC HEATING APPLIANCE

Bending-angle-adjustable hardware punching die structure

PendingCN111672980AChange bend angleImprove securityShaping toolsMetal-working feeding devicesStructural engineeringPunching

The invention discloses a bending-angle-adjustable hardware punching die structure. The bending-angle-adjustable hardware punching die structure comprises an upper die base and a lower die base. The lower end of the upper die base is fixedly provided with a mounting base, the lower end of the mounting base is provided with an upper die in a matched manner, the lower end of the mounting base is provided with dovetail grooves, two sides of the upper end of the upper die are fixedly provided with dovetail-shaped sliding blocks, and the sliding blocks of the upper die are mounted in the dovetail grooves of the mounting base in a matched manner. The upper die is of a C-shaped structure, the front end of a lower arm of the upper die is provided with an adjusting plate, the tip of the front end of the lower arm of the upper die is provided with a through hole, and the lower end of the adjusting plate is fixedly provided with a rotating shaft. By means of the bending-angle-adjustable hardwarepunching die structure, the bending angle of an abrasive tool can be adjusted in a stepless manner, and the adjustment manner is simple and quick, beneficial to reducing the experiment expense and accelerating the experiment progress.

Owner:杭州创融汇科技服务有限公司

Bending equipment for preventing reinforcing steel bars from rebounding

The invention discloses bending equipment for preventing reinforcing steel bars from rebounding. The bending equipment comprises a box body, a placement space is formed in the box body, a fixing mechanism is arranged in the placement space, the fixing mechanism comprises a first motor fixedly connected to the inner wall of the rear side of the placement space, a first driving shaft is rotationally connected to the front end face of the first motor, a first driving wheel is fixedly connected to the first driving shaft, and a first belt wheel fixedly connected to the first driving shaft is arranged on the rear side of the first driving wheel. According to the bending equipment, before the reinforcing steel bars are bent, an electromagnetic heating method is adopted, an electrified coil is used for heating the position needing to be bent, the reinforcing steel bars are bent after being heated, the reinforcing steel bars are prevented from rebounding after being bent through a method of removing stress through heating, the bent position is not prone to deformation after the reinforcing steel bars are heated and then cooled, a more accurate bending angle can be obtained, and the bending equipment is convenient to use in the building process.

Owner:成都俊巧峰科技有限公司

Limiting device for prefabricated part machining

The invention discloses a limiting device for prefabricated part machining, relates to the field of steel bar bending for prefabricated part machining, and aims at solving the problems that existing steel bar bending equipment adopts a complex numerical control system, stability needs to be improved, and meanwhile the production cost is too high. A first rotary connecting base is fixedly connectedto the upper end of a first fixing base, the first rotary connecting base is in a circular ring shape, a rotary cylinder is rotationally connected to the central axis position of the first rotary connecting base, a linkage pipe is arranged at the central axis position in the rotary cylinder, and a notch is formed in the side surface of the linkage pipe. A limiting block is rotationally connectedto the interior of the notch, a spring mounting block is fixedly connected to the inner wall of the linkage pipe, a supporting spring is fixedly connected to the inner wall of the spring mounting block, and the other end of the supporting spring is fixedly connected to the outer surface of the limiting block.

Owner:山东盈顺建筑科技有限公司

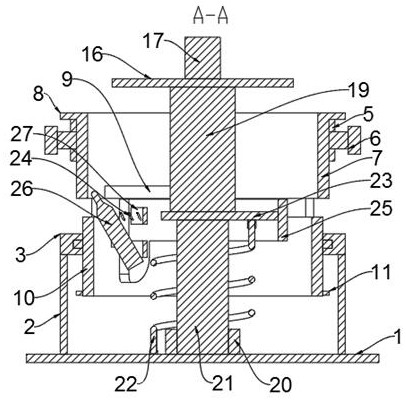

Integrated detection tool for throttle opener

ActiveCN104296623AEasy to measureImprove work efficiencyMechanical measuring arrangementsEngineeringPositioning system

The invention discloses an integrated detection tool for a throttle opener. The integrated detection tool comprises a base plate and a positioning base. The upper end face of the positioning base is a positioning datum plane attached to a support. Positioning pins are arranged on the positioning datum plane and matched with two installation holes in the support. The integrated detection tool further comprises an angle go-and-not-go gauge, a first measuring insertion block, a hole measuring positioning base, a first cable hole measuring rod and a second cable hole measuring rod. The angle go-and-not-go gauge is used for detecting the bending angle of the support, the first measuring insertion block is used for detecting the position of a pedal, the hole measuring positioning base is fixed to the bottom plate, the first cable hole measuring rod is used for detection when the throttle pedal is in the maximum uplifting state, and the second cable hole measuring rod is used for detection when the throttle pedal is in the maximum pressing state. The position of the pedal, the bending angle of the support and the position and the size of a cable connecting hole can be rapidly detected through the detection tool simultaneously, measuring is convenient, and working efficiency is high.

Owner:CHONGQING YUJIE AUTO PARTS

Stamping die for left bent seat lining board of bulldozer

InactiveCN105328037AQuality assurancePrecise bending angleShaping toolsMetal-working feeding devicesPunching

The invention relates to a stamping die for a left bent seat lining board of a bulldozer, and belongs to the technical field of stamping dies. The stamping die for the left bent seat lining board of the bulldozer is used for conducting press forming on the left bent seat lining board of the bulldozer. According to the technical scheme, an upper die plate is connected below a punching head of stamping equipment, a convex die is fixedly connected with the lower surface of the upper die plate, and a lower die plate is fixedly connected to a workbench of the stamping equipment; a concave die is fixedly connected with the lower die plate through a bolt, the lower end of the convex die corresponds to one molding groove of the concave die in a matching mode, and a positioning plate is fixed to the upper surface of the concave die through a bolt. According to the stamping die for the left bent seat lining board of the bulldozer, the stamping equipment is used for molding bends at the two ends of the lining board, the concave die is provided with two molding grooves which are matched with the bent angles at the two ends of the lining board respectively, and thus molding is conducted on the bends at the two ends of the lining board through the two molding grooves; positioning can be conducted on a lining board plate material through the positioning plate, so that the molding position is accurate. The stamping die for the left bent seat lining board of the bulldozer is simple in structure, convenient to use, accurate in bent angle and high in stamping speed; not only is the quality of the lining board ensured, but also the production efficiency is improved greatly; the needs of the production can be met.

Owner:XUANHUA CONSTR MACHINERY

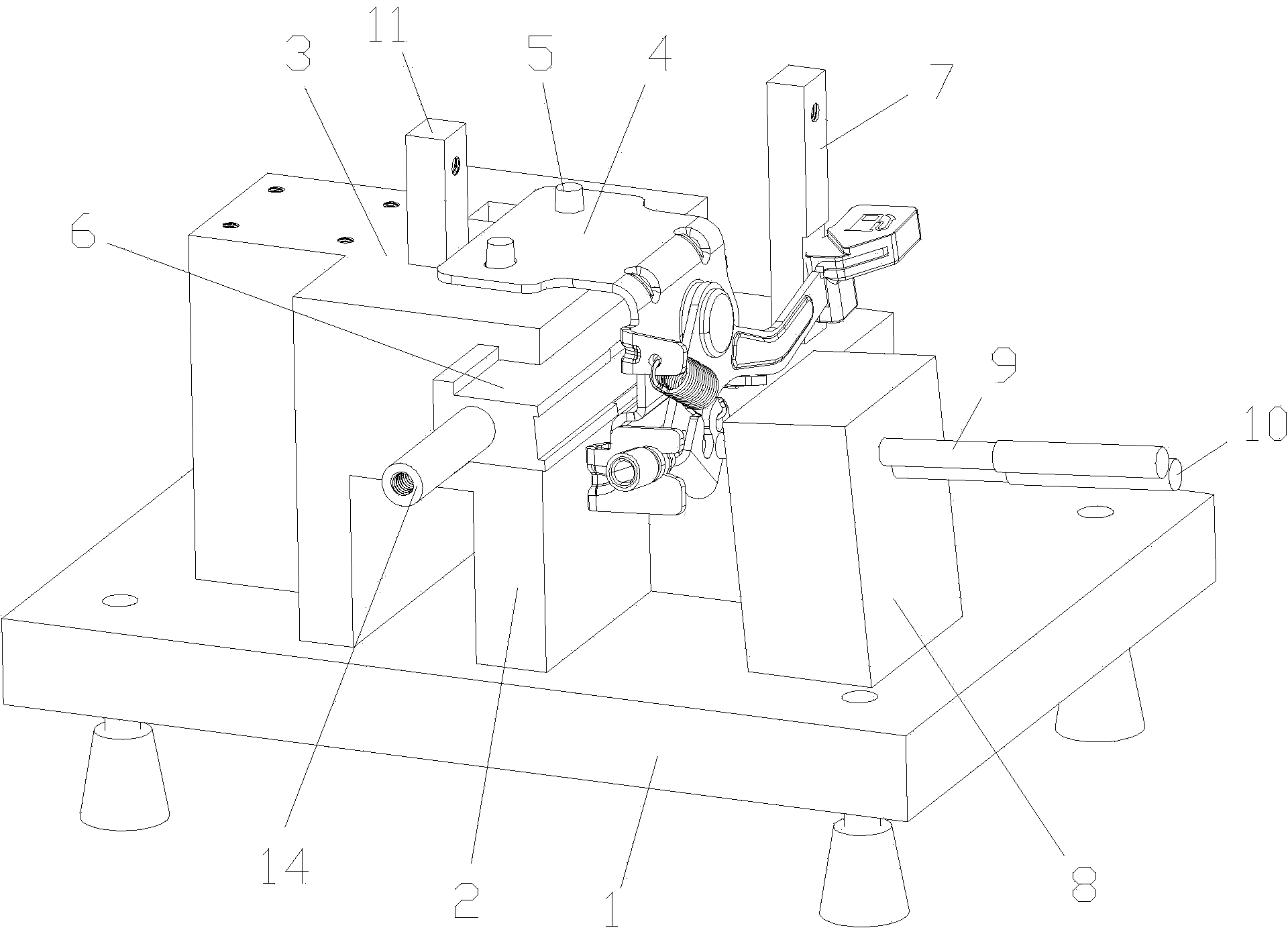

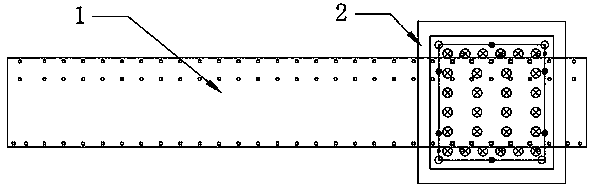

Stamping die set of harvester picker jaw

ActiveCN103736849AImprove molding pass ratePrecise bending angleShaping toolsEngineeringMachining process

The invention discloses a stamping die set of a harvester picker jaw. The stamping die set is composed of a positioning hole stamping unit, a notch stamping unit, a first bending stamping unit and a second bending stamping unit. The first bending stamping unit comprises a bending stamping block and a bending stamping base, wherein the bending stamping block and the bending stamping base are matched. The second bending stamping unit comprises a forming stamping block and a forming stamping base, the bearing surface of the forming stamping base is matched with the stamping surface of the bending stamping block, the bearing surface of the forming stamping base is provided with a groove matched with a stamping head of the forming stamping block, and a jaw machined part to be formed does not interfere with the forming stamping block when the second bending stamping unit is in a stamping state. By the application of the die set, the first bending stamping unit and the second bending stamping unit are adopted to integrally bend the jaw machined part step by step, the bending angle is accurate, the bending surface of the jaw is smooth and standard after the jaw is bent, the jaw is not prone to being bent or broken in the machining process, the forming percent of pass of the jaw machined part is increased, and the quality of the jaw is improved.

Owner:ZHANGJIAGANG LONGJING AUTOMOBILE PARTS

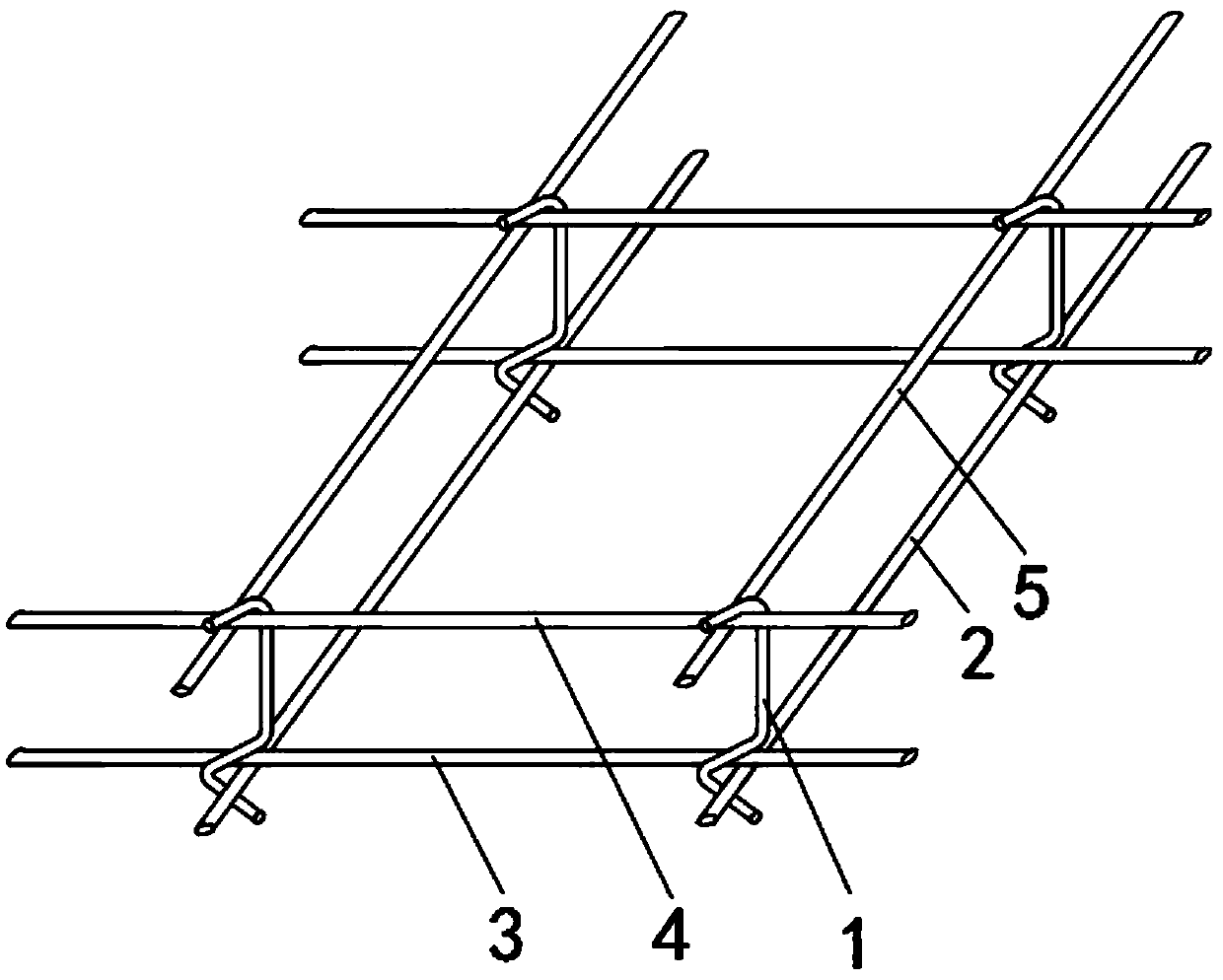

Steel bar horse stool and using method thereof

PendingCN110952722AEasy to makeShort construction periodBuilding reinforcementsStructural engineeringMechanical engineering

The invention discloses a steel bar horse stool which comprises four horse stool bar supports. The horse stool bar supports are formed by bending circular steel. The four horse stool bar supports areparallel in pairs and are arranged in a rectangular array manner. Each horse stool bar support is composed of a vertical rod, a transverse rod and a V-shaped base, wherein the transverse rod is connected to the top face of the vertical rod, and the bottom face of the vertical rod is connected with the V-shaped base. Upper layer cross bars are arranged between the connecting portions of the top faces of two vertical rods adjacent in the horizontal direction and the end portions of the transverse rods correspondingly. Two parallel upper layer longitudinal bars are arranged between the bottoms ofthe upper layer cross bars adjacent in the longitudinal direction. The intersecting portions of the two upper layer longitudinal bars and the upper layer transverse bars are located below the transverse rods of the four horse stool bar supports correspondingly. Lower layer cross bars are arranged between the positions above the middle lines of the included angles of the two V-shaped bases adjacent in the horizontal direction. The steel bar horse stool is easy to form and convenient to use, a pressing part and a bending part in a pressing device are utilized for pressing and locating the horsestool bar supports, and the forming quality and the forming precision of the horse stool bar supports are effectively improved.

Owner:CHINA CONSTR 4TH ENG BUREAU 6TH

Automatic pipe bending machine

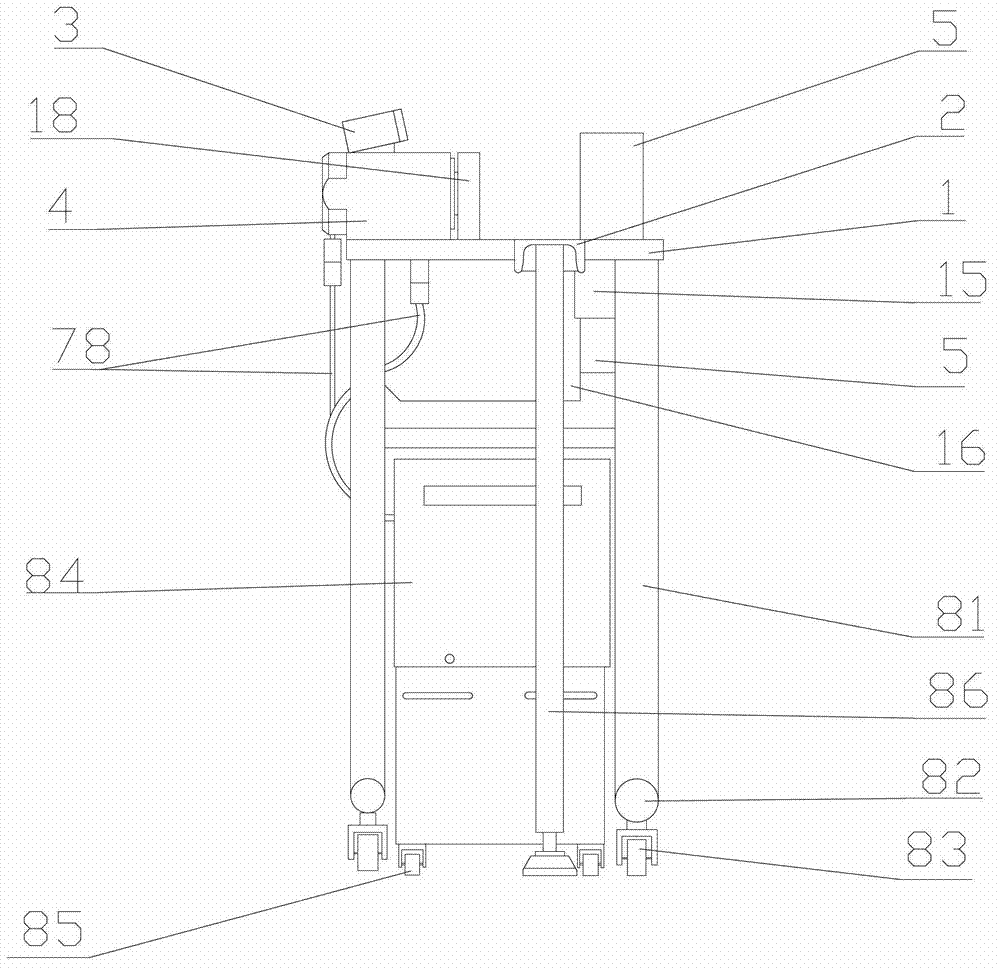

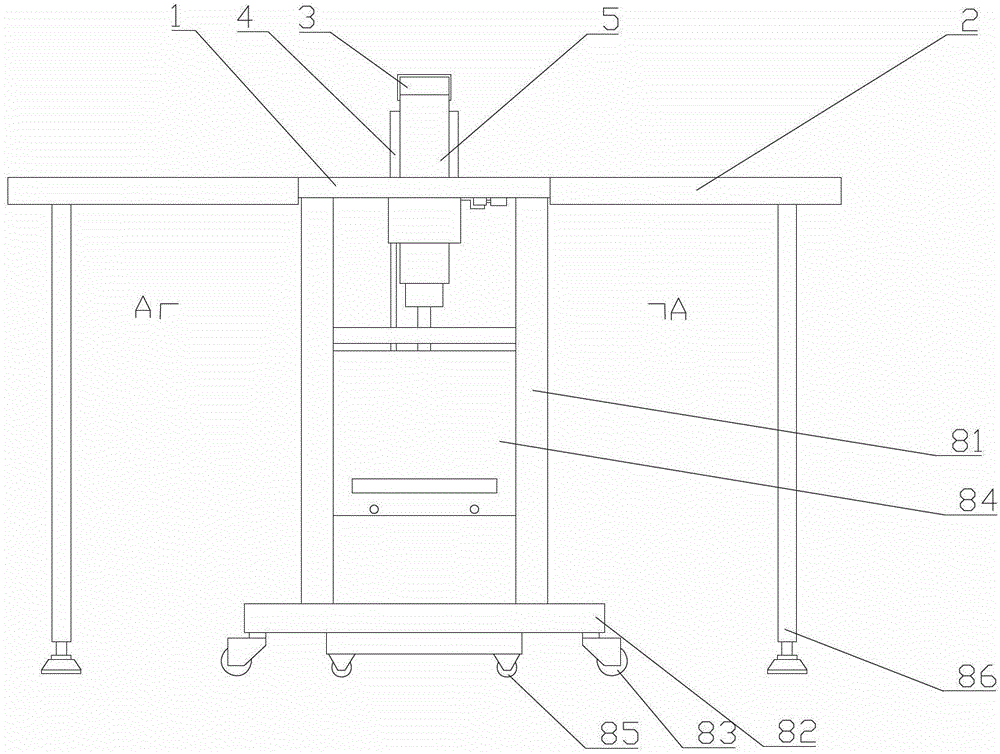

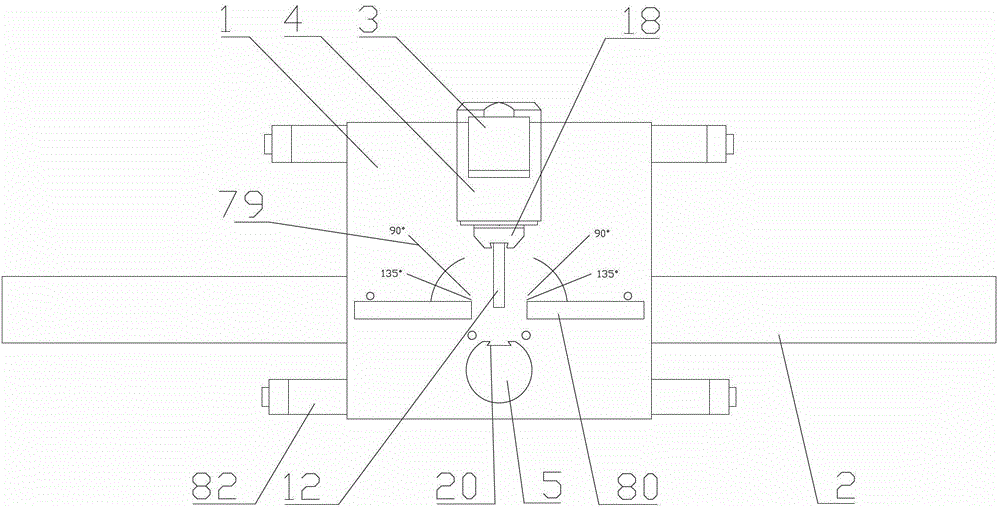

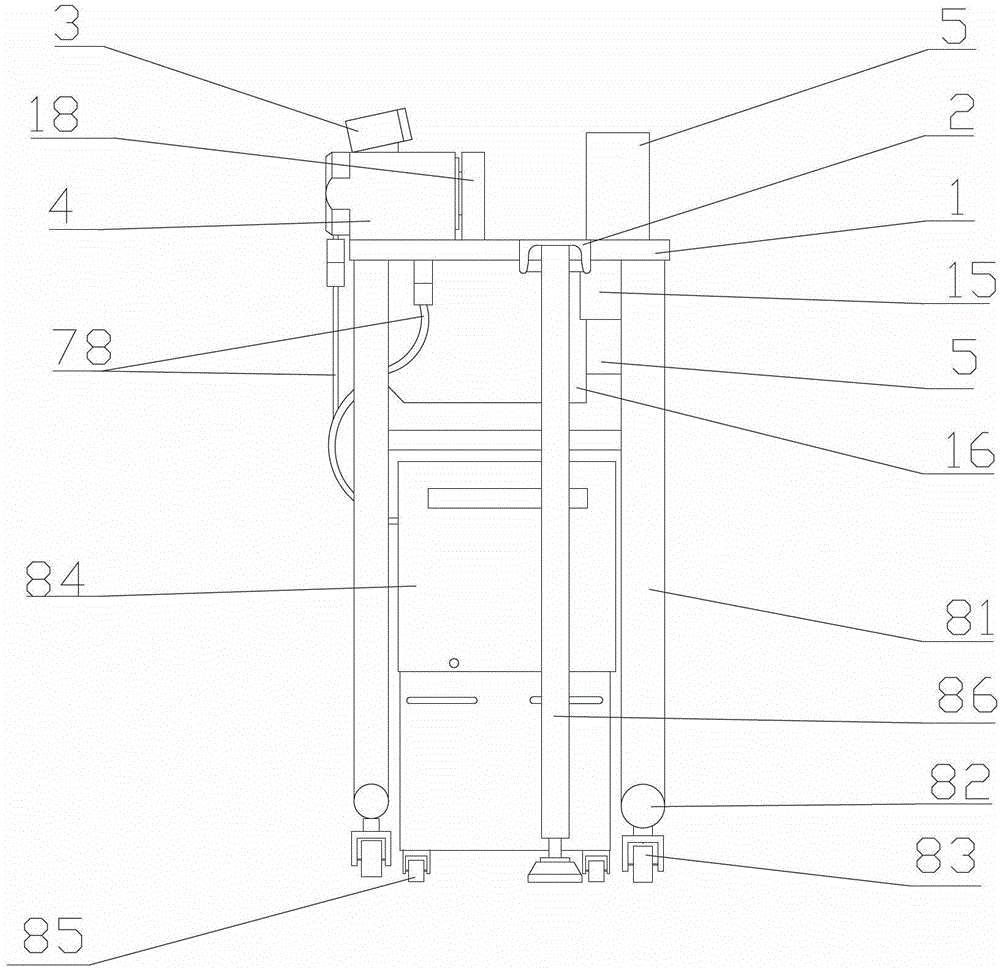

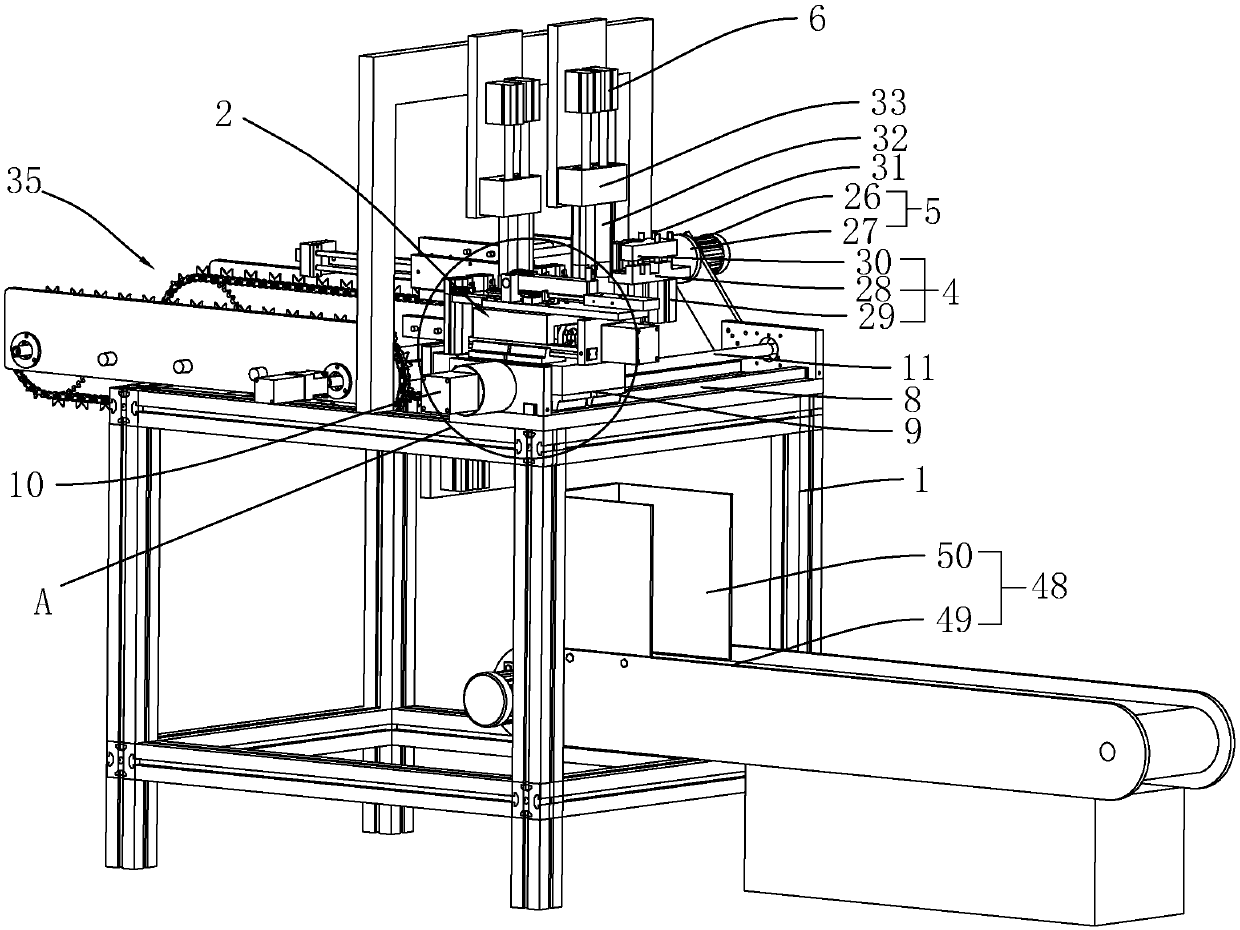

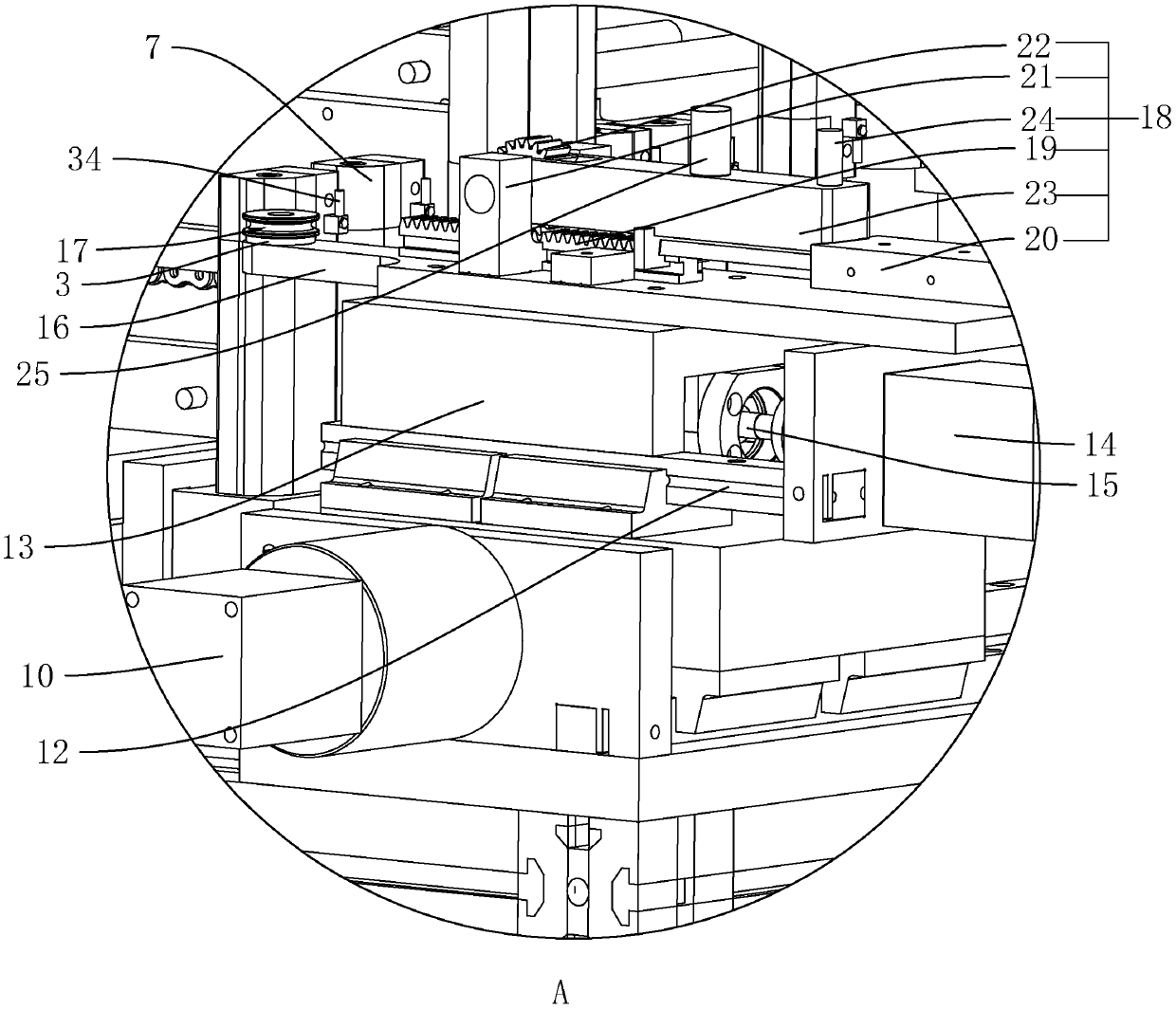

PendingCN110116154APrecise bending angleAvoid bendingMetal-working feeding devicesPositioning devicesEngineering

The invention discloses an automatic pipe bending machine, and relates to the technical field of pipe processing machinery. Thus, the problems that existing pipe bending machines cannot perform continuous bending on a same pipe with multi-angle, multi-direction and multi-size can be solved. The pipe bending machine includes a frame; the frame is provided with a pipe bending member used for bendinga pipe and a driving mechanism for driving the pipe bending member to do horizontal movement; the pipe bending member is arranged vertically; the frame is also provided with a clamping device and a rotating device; the frame is fixedly connected to multiple control air cylinders in vertical arrangement; the end parts of telescoping rods of the air cylinders are fixedly connected to molding blocksused for bearing against the pipe to cooperate with the pipe bending member to bend the pipe when the pipe bending member moves; and the arc-shaped angle of each molding block is arranged relative tothe bending angle of each part of the pipe. The pipe bending machine is reasonable in structure; and through the cooperation of the clamping device, the rotating device, the molding blocks and the pipe bending member, the continuous bending with multi-angle, multi-direction and multi-size can be performed on the pipe.

Owner:海盐县铭新机械有限公司

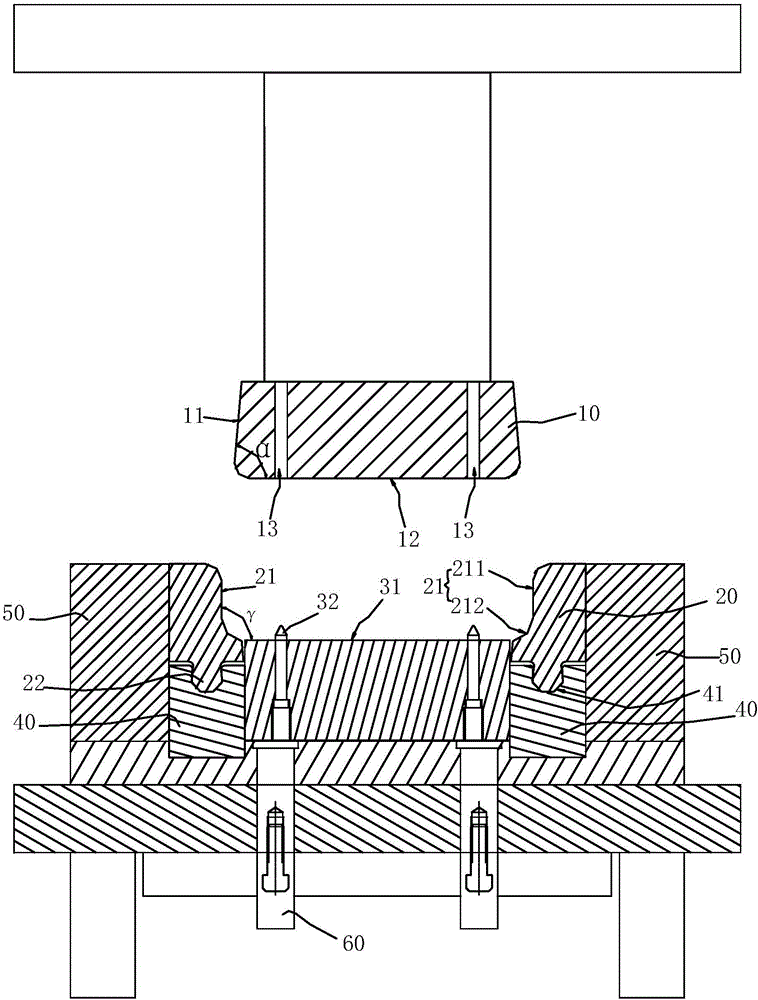

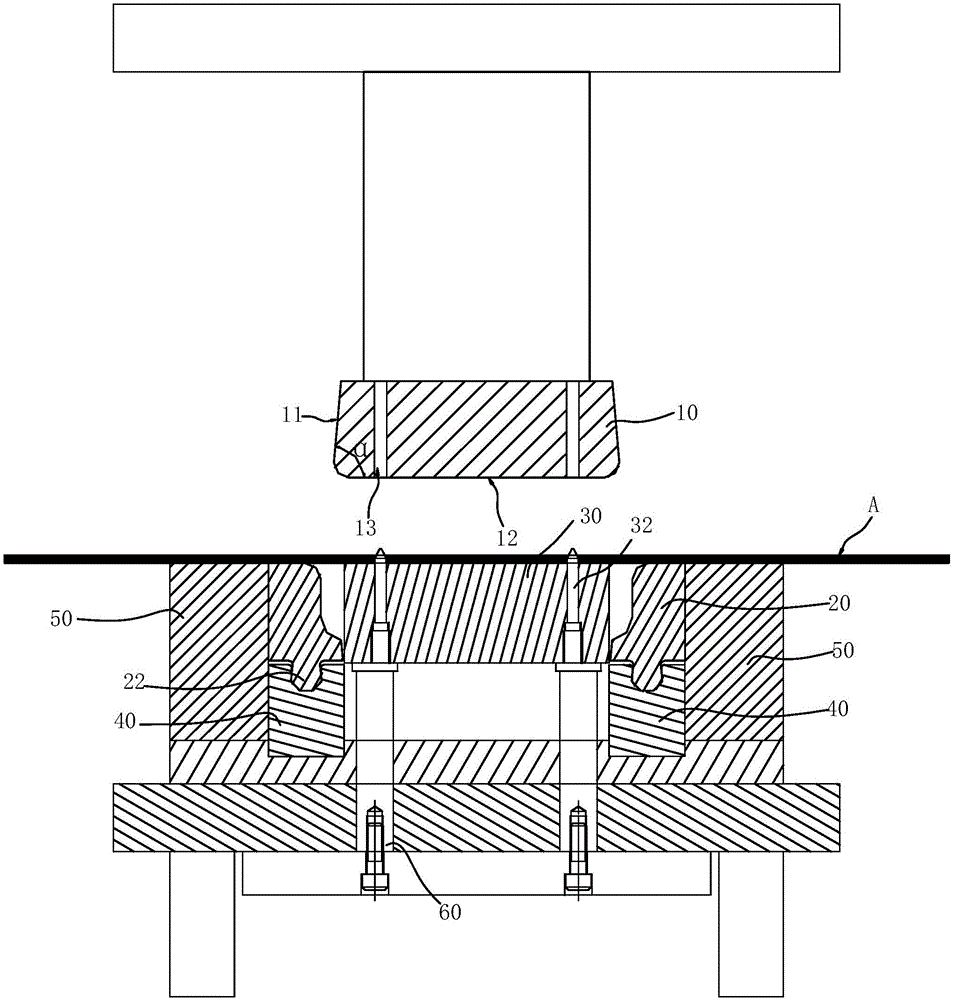

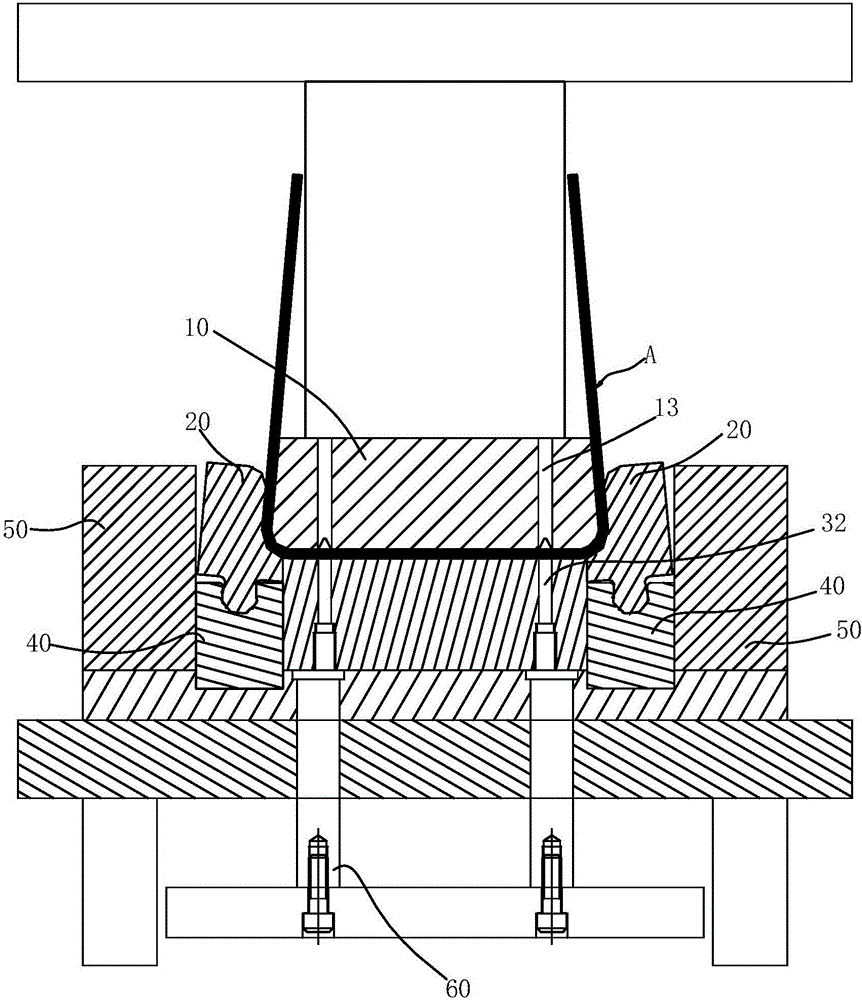

Punching mold for preventing rebound of bent piece

The invention relates to the field of punching molds, in particular to a movable punching mold. The punching mold comprises a convex mold; an included angle between a side forming surface and a bottom forming surface of the convex mold forms an anti-rebound included angle alpha; a concave mold matched with the convex mold includes a side mold and a bottom mold; the outer side of the side mold and a side mold bracket are hinged by a hinge shaft; when the side mold rotates, an included angle between an inner side forming surface of the side mold and a bottom mold forming surface of the bottom mold forms a bent angle gamma; and the bent angle gamma is positioned between the anti-rebound included angle alpha and a demolding included angle beta. A rebound angle delta alpha is considered when the upper mold is designed; an actual bent angle of a piece A to be bent when molding in a mold cavity is consistent with the anti-rebound included angle alpha; and after the piece A to be bent is taken out from the mold cavity, the actual bent angle of the piece A to be bent after less rebound is equal to a theoretic bent angle, so that the influence on the bent piece by elastic deformation is thoroughly solved, the precision of the bent angle of the bent piece is guaranteed, and the product quality is improved.

Owner:HEFEI HUALIN MOLD

Small light numerically-controlled bus processing machine

The invention relates to a small light numerically-controlled bus processing machine. The small light numerically-controlled bus processing machine comprises a platen, supporting plates, a grating controller, an oil cylinder, a pressure head, an upright column, a shearing mold, a punching mold and a bending mold, wherein an oil cylinder insertion hole, a guide groove and an upright column fixing hole are formed in the platen respectively, the oil cylinder is inserted in the oil cylinder insertion hole and fixed on the platen, and the upright column is fixed on the platen; a strengthening plate is connected with the lower wall surface of the platen, the upright column and a strengthening sleeve; a falling object chute is formed in the strengthening plate, a section of the guide groove is correspondingly formed above the falling object chute, the pressure head is arranged at the front end of a piston rod of the oil cylinder, a first dovetail groove is formed in the pressure head, a second dovetail groove is formed in the upright column, and the supporting plates are positioned on two sides of the platen; a grating scale is connected below the pressure head, and arranged on the lower bottom surface of the platen; and a shearing stripping groove penetrating a middle shaft of the upright column and the whole upright column is formed in the side surface of the upright column, and an opening on one side of the shearing stripping groove is positioned in the second dovetail groove. The small light numerically-controlled bus processing machine has the advantages of functional diversity, simplicity, light weight, small size and the like.

Owner:陈伟民

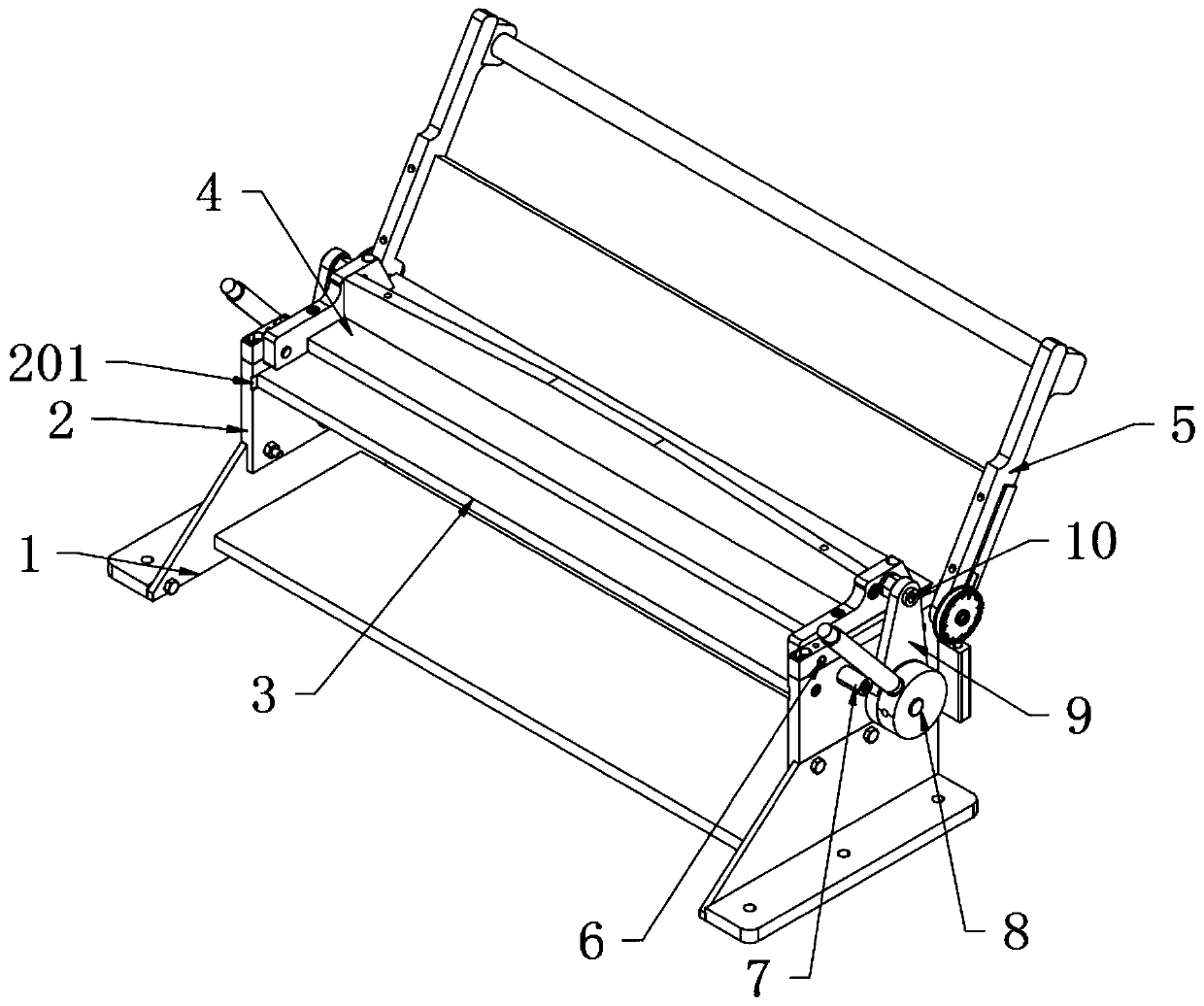

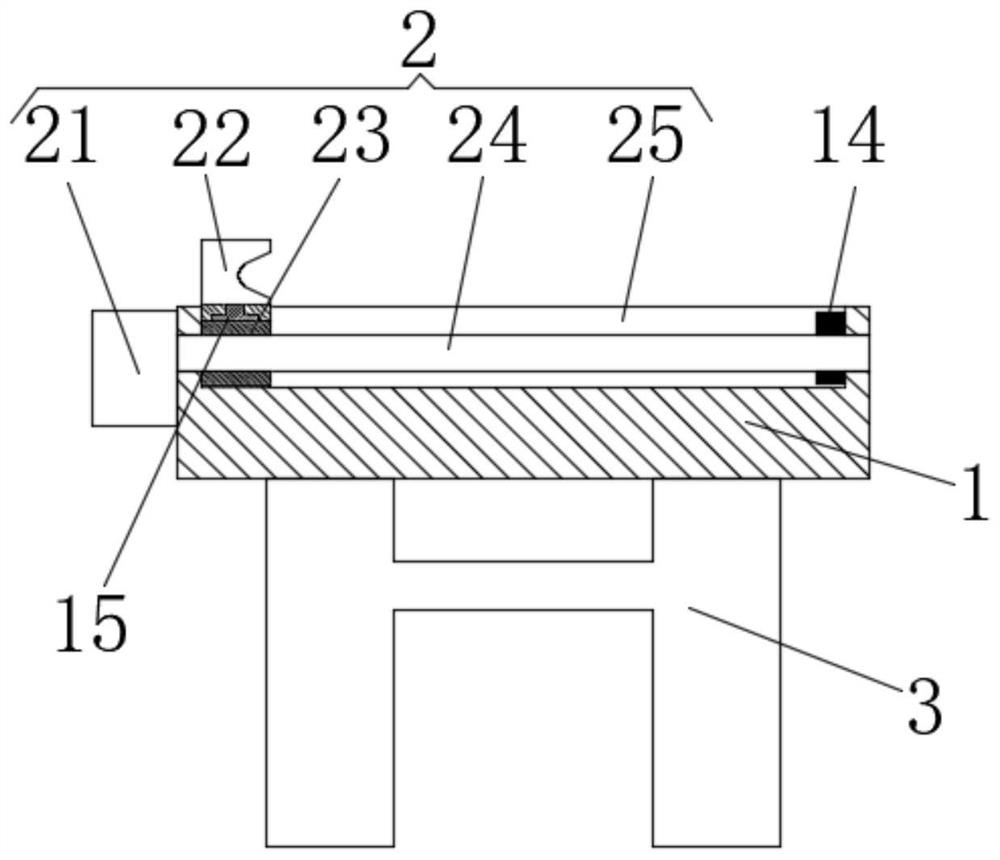

Precise portable type manual sheet bending machine and operating method thereof

The invention provides a precise portable type manual sheet bending machine. The precise portable type manual sheet bending machine comprises a base, a locating pillar and a spring. Side plates are fixedly mounted at the left side and the right side of the base through bolts. A base plate is inlaid into the upper ends of the opposite side walls of the inner sides of the two parallel side plates through grooves. According to the precise portable type manual sheet bending machine, an angle scale is provided with an edge groove and the locating pillar, the outer wall of the angle scale is provided with scales, and a pointer pointing to the angle scale is arranged in the central axis of the side wall of a bending plate; in addition, the edge groove is formed in the side wall of the curved surface of the angle scale; when the upper end of the locating pillar abuts against the angle scale, the spring is in the compressed state, and it is guaranteed that the locating pillar can be located inthe edge groove all the time; when passing through an insertion hole, the locating pillar can be precisely inserted therein for locating; and the precise portable type manual sheet bending machine isapplicable to sheet bending operation in a family style small factory, low in cost and high in product precision.

Owner:GUIZHOU UNIV

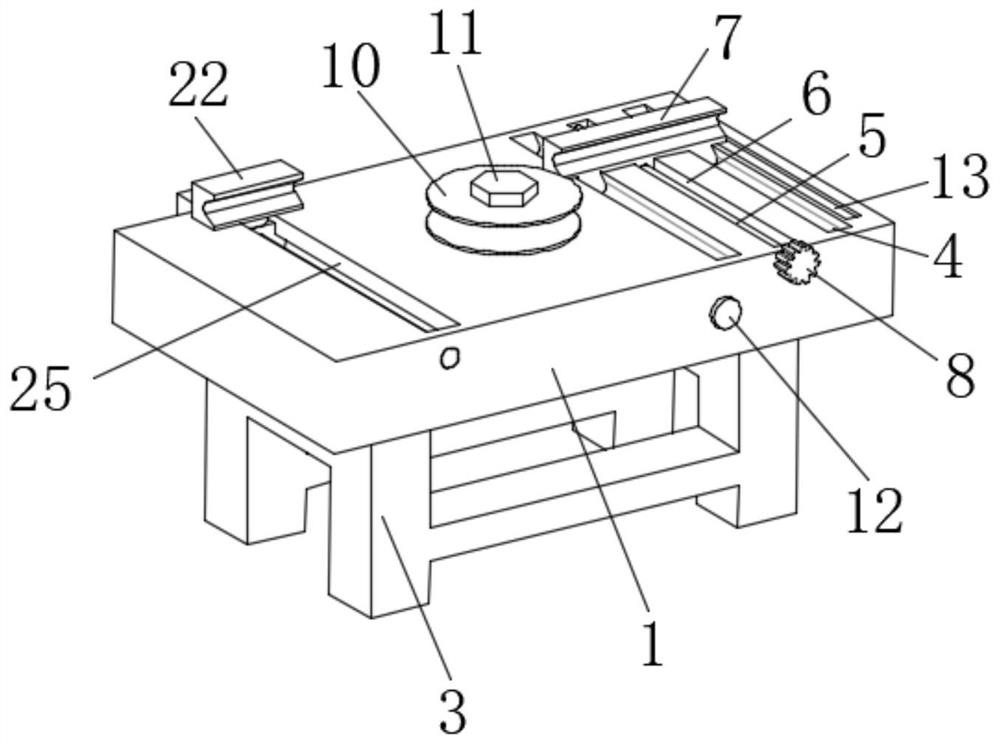

Bending-degree-adjustable pipe bending device for stainless steel pipe production

The invention discloses a bending-degree-adjustable pipe bending device for stainless steel pipe production. The device comprises a working plate table, an inner threaded cylinder and a bending mechanism. A support is arranged on the lower surface of the working plate table, two dovetail grooves and a strip-shaped groove are formed in the right side of the upper surface of the working plate table,the strip-shaped groove is formed between the two dovetail grooves, a first lead screw is longitudinally and rotatably connected into the strip-shaped groove, the two dovetail grooves are in slidingconnection with dovetail blocks symmetrically arranged on the lower surface of a check block, a threaded hole formed in the middle of the lower surface of the check block is in threaded connection with the first lead screw, a knob is arranged at the front end of the first lead screw, the inner threaded cylinder is rotatably connected to the inside of a circular hole at the center of the upper surface of the working plate table, according to the bending-degree-adjustable pipe bending device for the stainless steel pipe production, the bending angle can be automatically controlled according to needs, the bending angle is more accurate, and the bending efficiency is higher.

Owner:泰州市易达非机电制造有限公司

Intelligent horseshoe bending device

PendingCN113857306APrecise bending angleAvoid damageMetal-working feeding devicesMetal working apparatusRotational axisGear drive

The invention provides an intelligent horseshoe bending device which comprises a shell. A fixing part is fixedly mounted in the shell, a motor is fixedly mounted on the fixing part, a rotating shaft is movably mounted at the upper side of the motor, a driving gear is fixedly mounted at the upper end of the rotating shaft, the driving gear is connected with a driven gear in an engaged mode, and a fixing block is fixedly installed at the upper side of the driven gear. Through cooperative use of the motor, the driving gear, the driven gear, a movable rod, a third fixing mechanism, a positioning rod and a workpiece, the motor generates kinetic energy and drives the driving gear to rotate through the rotating shaft, the driving gear drives the driven gear to rotate through meshing connection, and the driven gear drives the third fixing mechanism through the movable rod to bend the workpiece; and after bending, a bending degree detection mechanism detects the bending degree of the workpiece, the workpiece is continuously bent if the bending degree does not reach a set value, and therefore the effect that the bending angle of the equipment is accurate is achieved.

Owner:冯建华

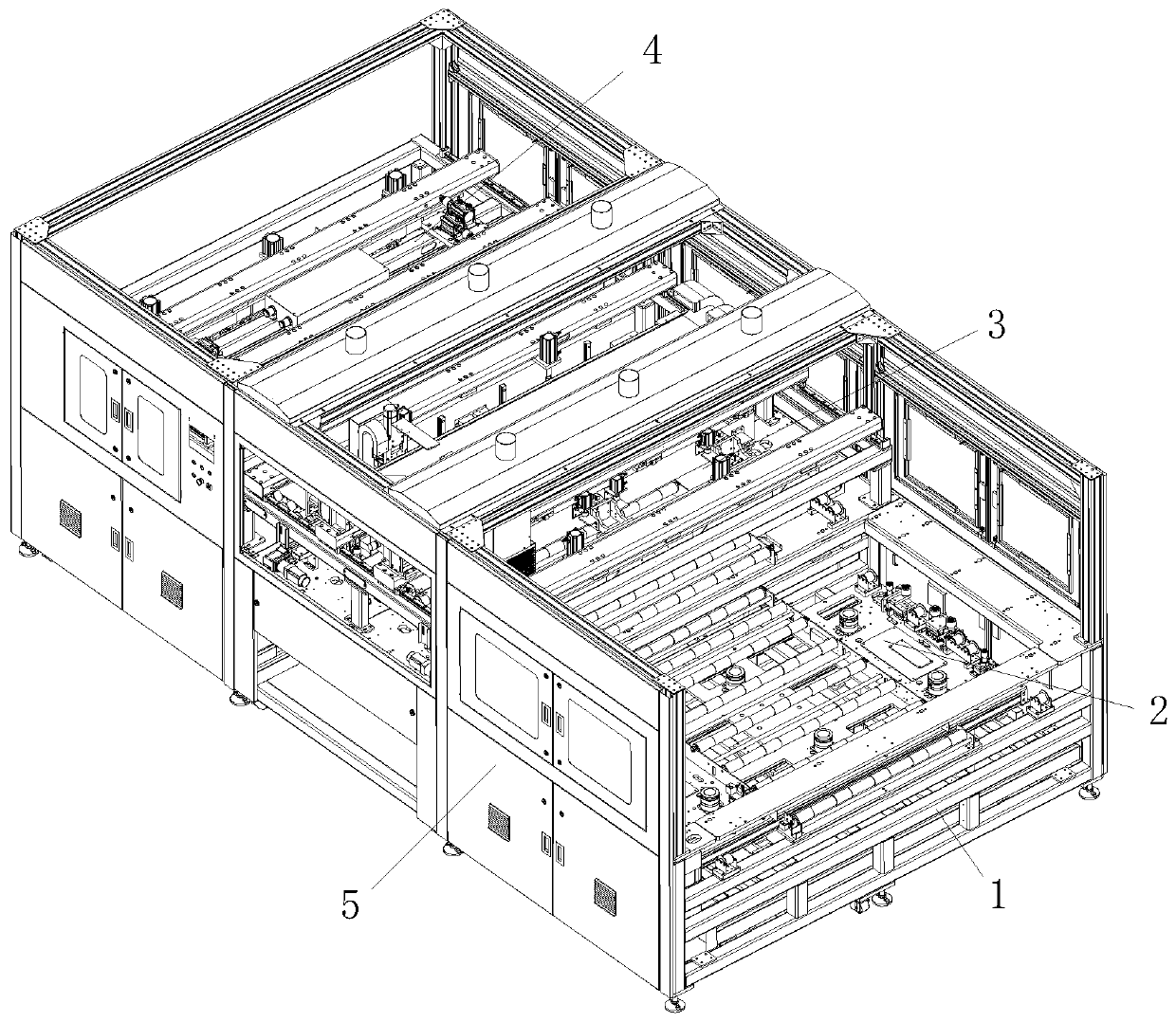

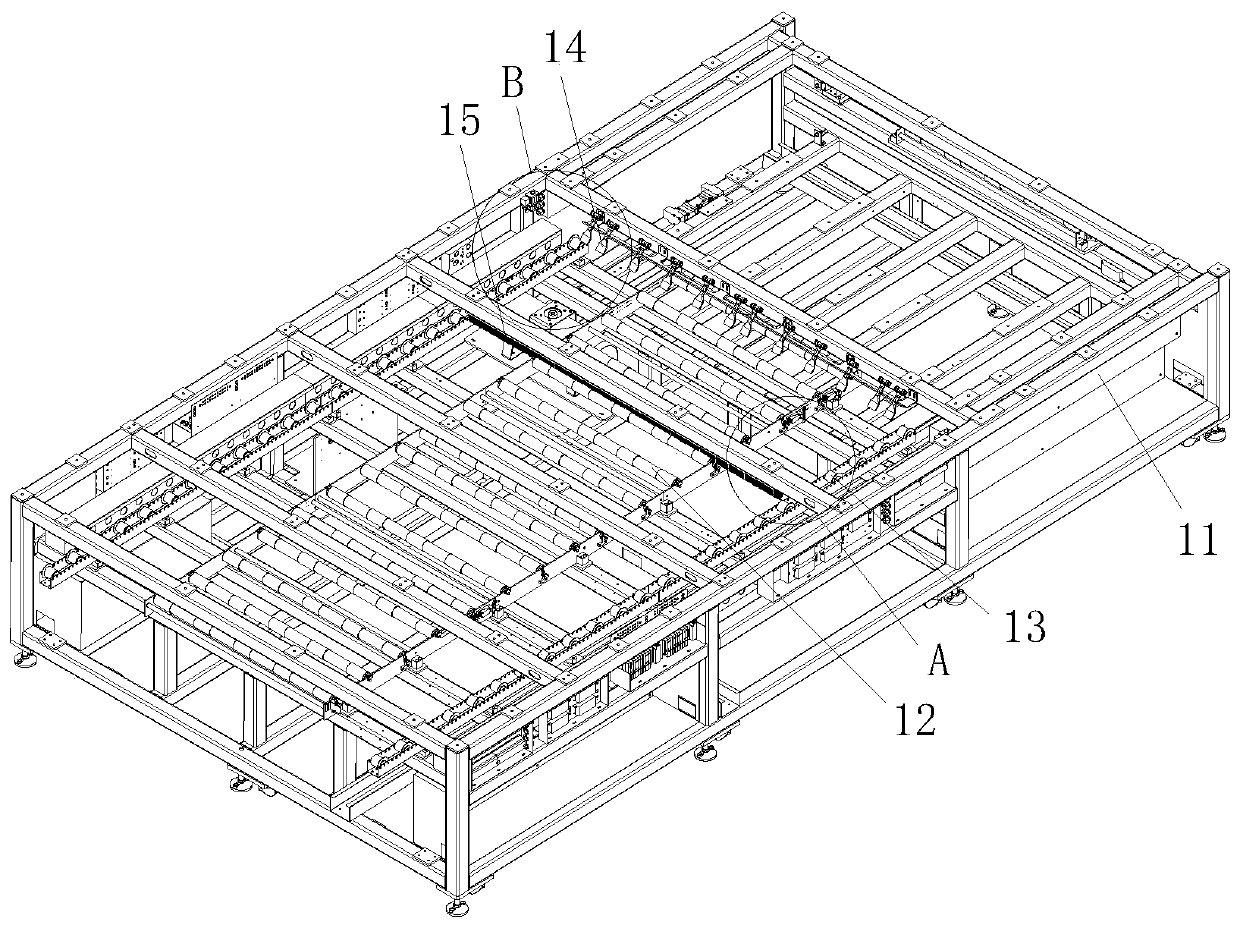

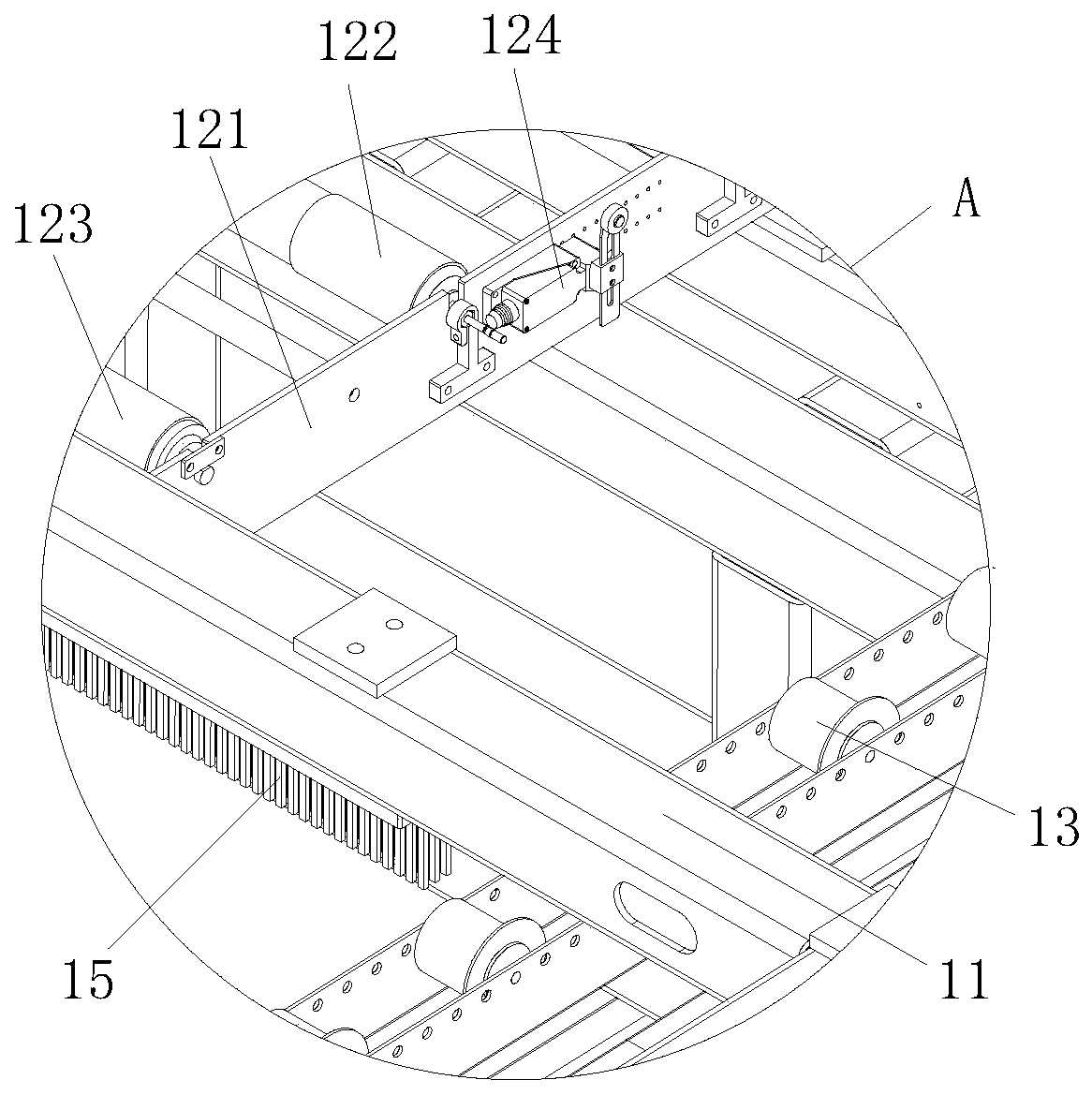

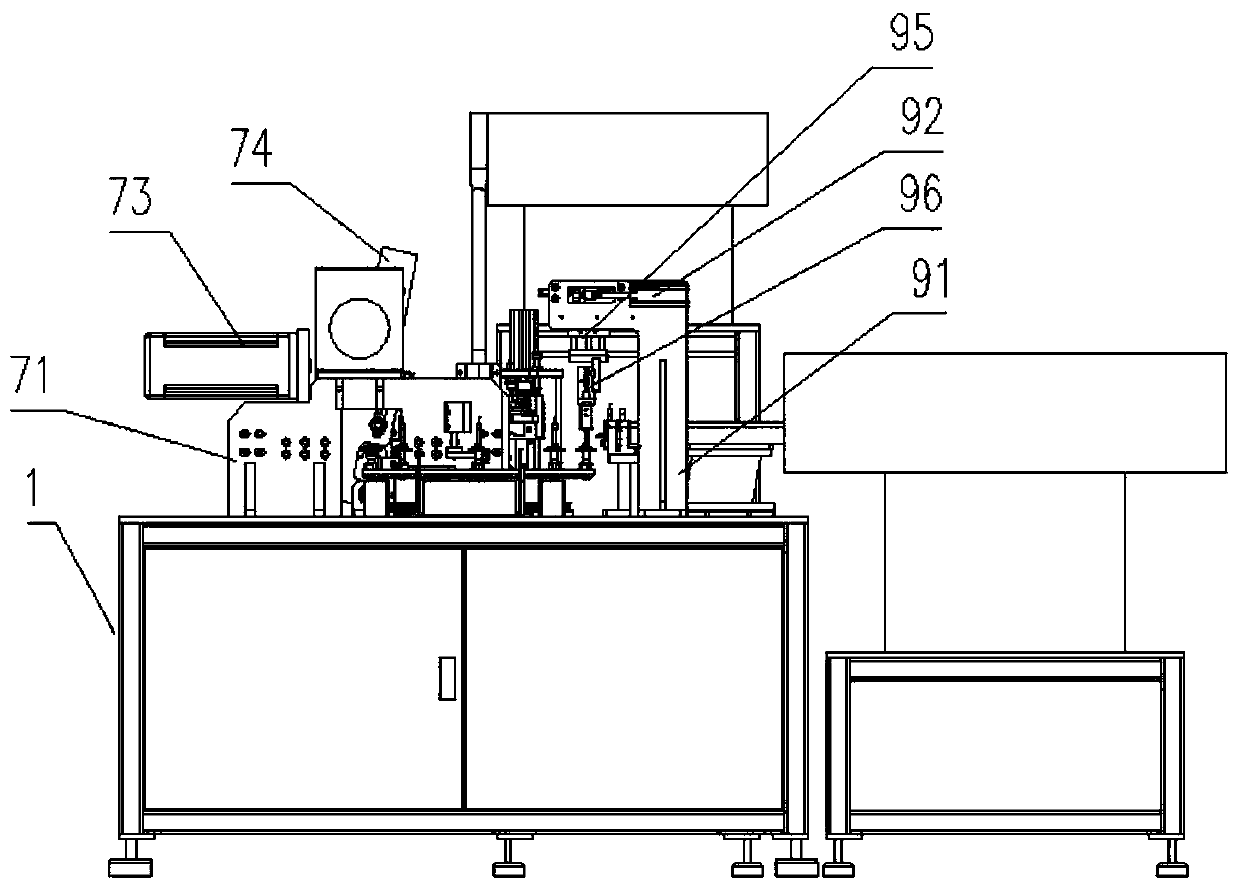

Transverse plate imbricating and welding integrated machine

PendingCN109759842AAvoid WeldingCompact structureFinal product manufactureOther manufacturing equipments/toolsSlagTransverse plane

The invention discloses a transverse plate imbricating and welding integrated machine. The transverse plate imbricating and welding integrated machine comprises a conveying mechanism, a lifting rollerline, a welding mechanism, a bending mechanism and a shield, the lifting roller line, the welding mechanism and the bending mechanism are sequentially arranged on the conveying mechanism from right to left and all located in the shield, the shield is arranged on the conveying mechanism, products are conveyed from the lifting roller line to a roller conveying line of the conveying mechanism, the products on the roller conveying line pass through the welding mechanism for bus bar welding, and the products on the roller conveying line pass through the bending mechanism for outgoing line bendingtreatment. In this way, the transverse plate imbricating and welding integrated machine is compact in structure and stable in operation, battery strings can be welded and bent fully automatically, short time-consuming is achieved, automatic noncontact hot air welding is achieved, and pseudo welding or remaining of excess welding slag is avoided; and automatic bending is achieved, rapid bending isachieved, the same accurate bending angle is obtained, and product consistency is ensured.

Owner:SUZHOU SHENGCHENG SOLAR EQUIP

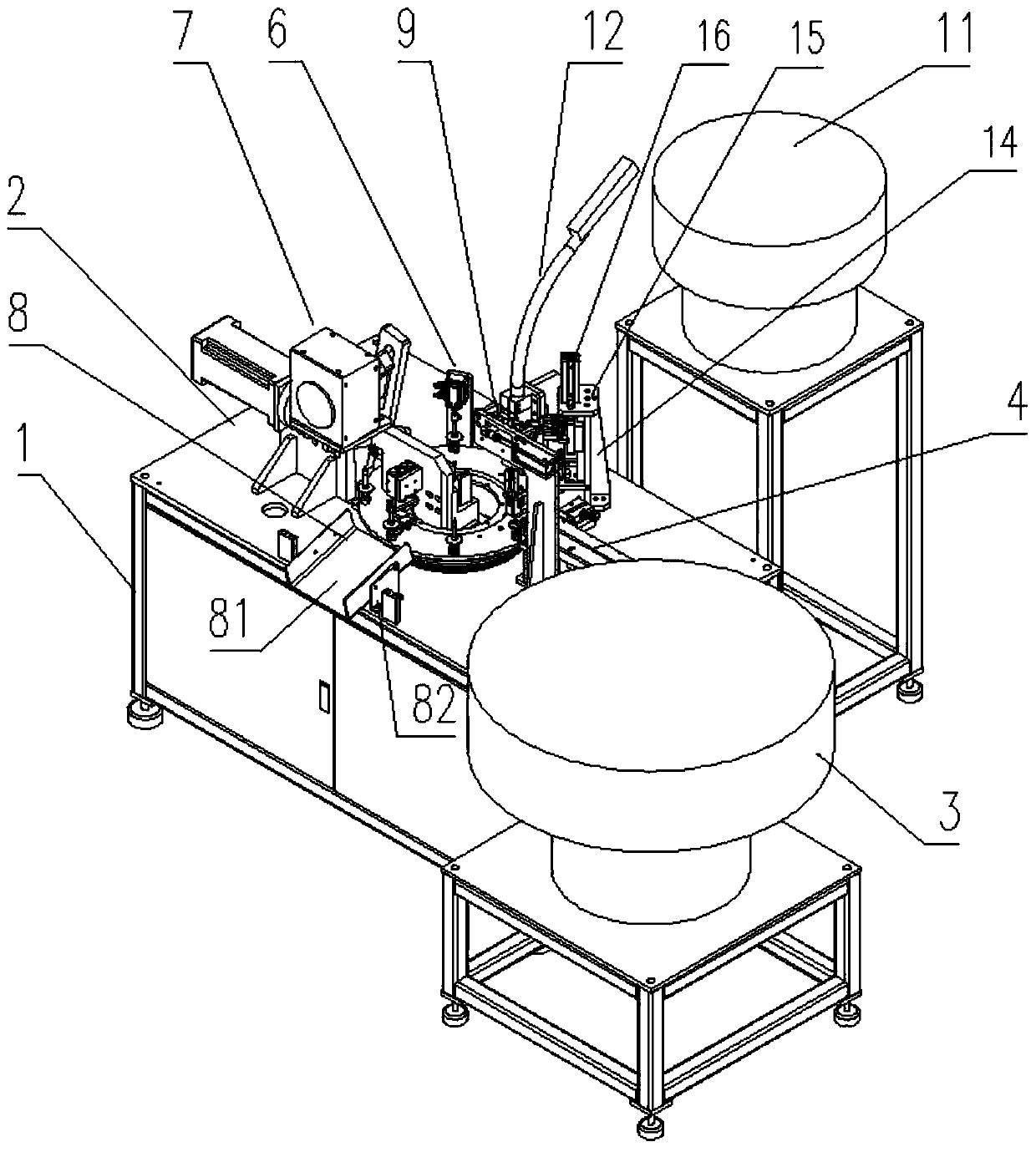

A kind of pan head bending equipment

ActiveCN108160768BSimple structureLow costMetal-working feeding devicesPositioning devicesEngineeringDevice failure

The invention discloses disc head bending equipment. The disc head bending equipment comprises a bracket; a worktable surface is arranged above the bracket; a vibration disc is arranged on the outer side of the bracket, and is connected with a direct vibration feeding device arranged on the worktable surface; a positioning tool is arranged at the end part of the direct vibration feeding device; acutter turntable device is arranged on the outer side of the positioning tool; a pressing device, a bending device and an unloading device are arranged on the outer side of the cutter turntable in sequence; and a loading device is arranged between the cutter turntable and the direct vibration feeding device. The disc head bending equipment is simple in structure, can bend products with different types, reduces the cost, saves the energy, is simple and convenient to replace tools for equipment, is low in fault rate of the equipment, improves the production efficiency, adopts servo control for bending angles, is precise in bending angle, and improves the product quality.

Owner:WUXI ZHONGWANG 4D TECH

Method for controlling electronic equipment and electronic equipment

ActiveCN105138076BControl bend anglePrecise bending angleInput/output for user-computer interactionDetails for portable computersStructural engineeringBending force

Owner:LENOVO (BEIJING) LTD

A horizontal universal CNC bending machine

The invention belongs to the technical field of board processing, in particular to a horizontal all-purpose numerical control bending machine. The horizontal all-purpose numerical control bending machine comprises a machine body, downward press die blocks, lifting die blocks, a changeable upper tool array, a detachable punch and a changeable lower tool array. The machine body is horizontally fixedto the ground. The machine body is provided with a controller. The downward press die blocks are evenly distributed on the upper part of the machine body and are used for downwards pressing the changeable upper tool array. The lifting die blocks are evenly distributed in the rear of the machine body and are used for limiting the movement direction of the changeable upper tool array as the vertical direction. The changeable upper tool array is located under the downward press die blocks. The bending angle of the changeable upper tool array is adjustable. The detachable punch is located besidethe changeable upper tool array and is used for punching boards. The changeable lower tool array is located under the downward press die blocks and is adjustable in bending angle, and the tool edges of the changeable lower tool array are matched with the tool edges of the changeable upper tool array. According to the horizontal all-purpose numerical control bending machine, by automatically adjusting the bending angles of the bent boards, the bending angles of the boards are more accurate, and the percent of pass of bent part forming is increased.

Owner:TAIZHOU DONGXING PRECISION MACHINERY

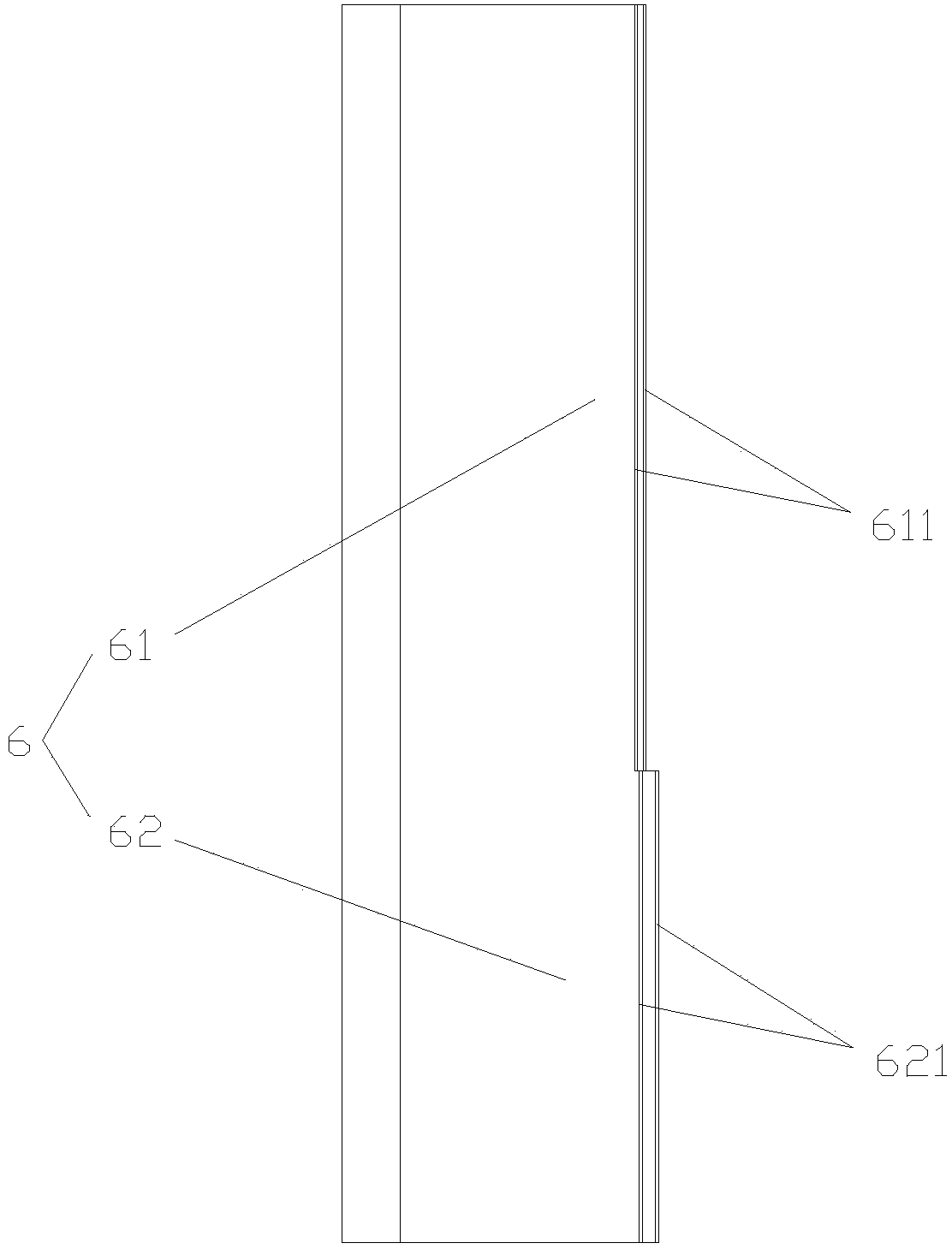

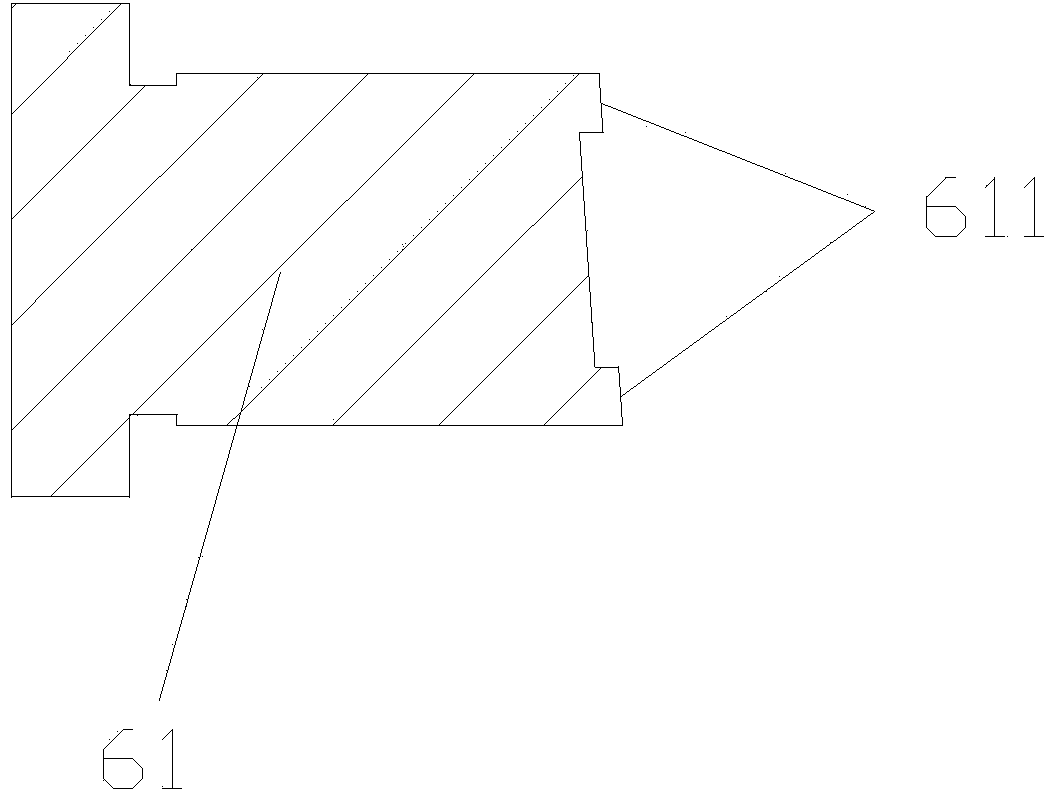

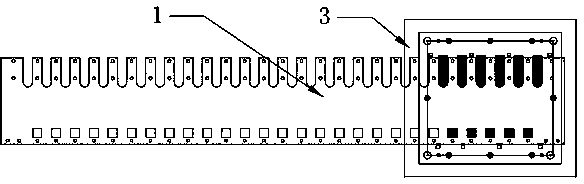

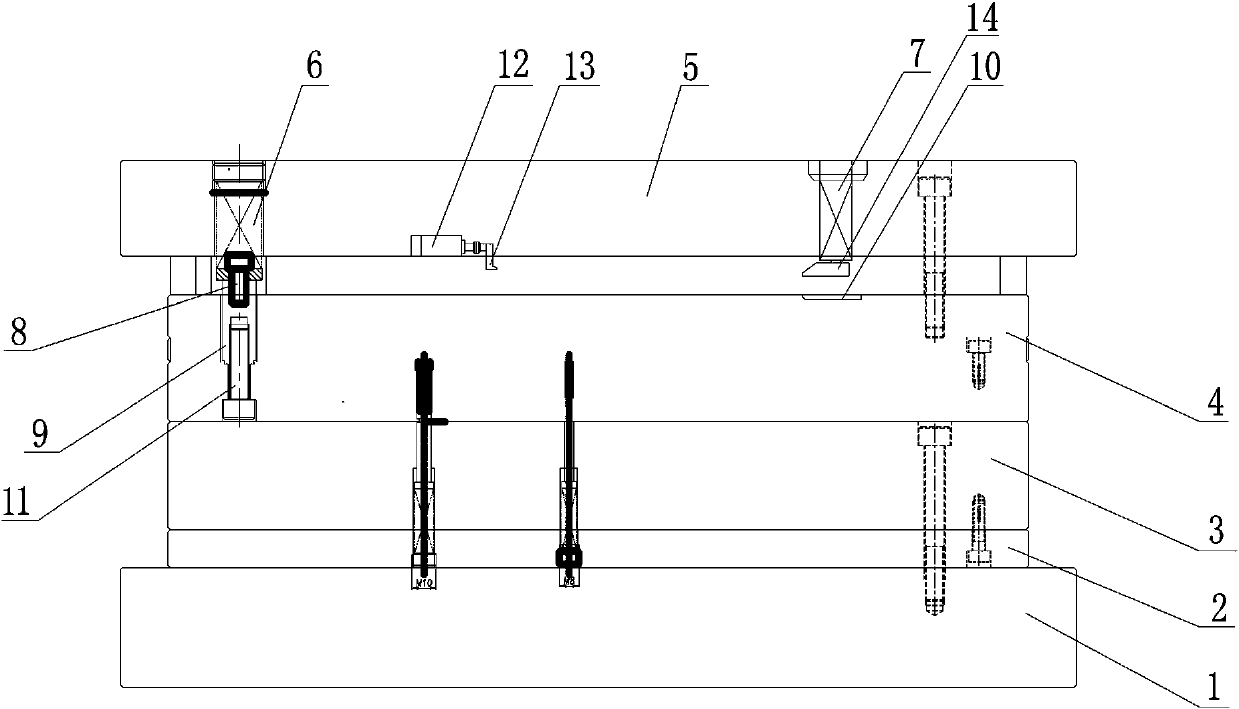

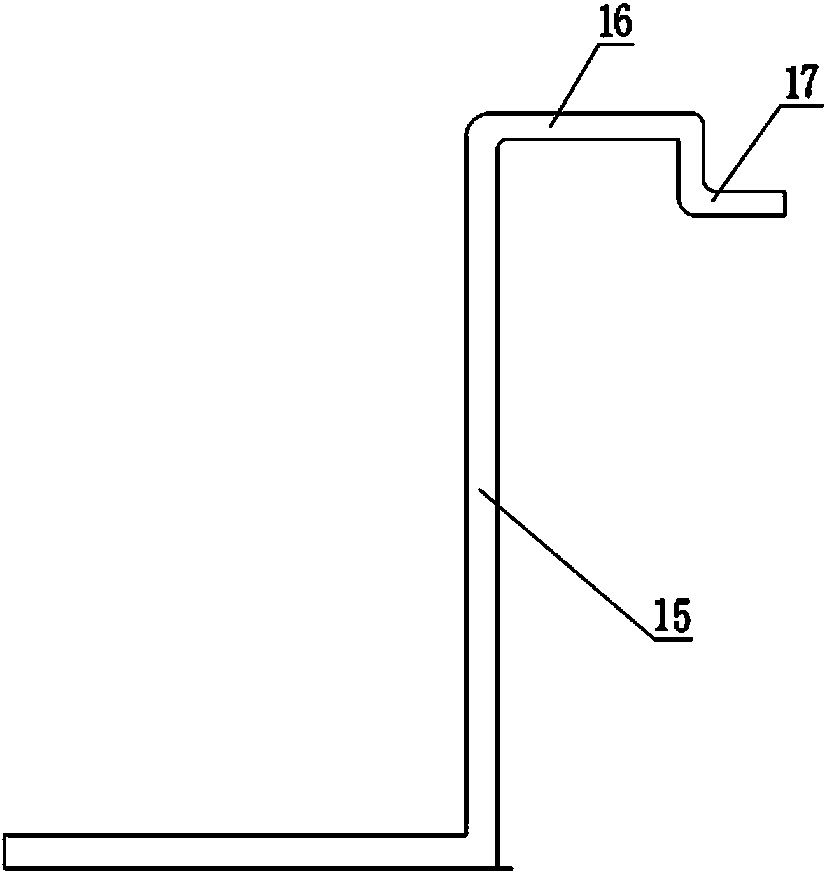

A precision progressive die for multi-bending forming

ActiveCN106180383BCompact structurePrecise bending angleShaping toolsMechanical engineeringSquare cavity

The invention discloses a precision progressive die with a multi-bending forming function. The precision progressive die comprises a base (1), a lower cushion plate (2), an upper cushion plate (3) and a female die body (4), wherein the lower cushion plate (2), the upper cushion plate (3) and the female die body (4) are arranged on the base (1) and sequentially connected from bottom to top. An upper support (5) is arranged above the female die body (4) and internally provided with a female die insert A (6) and a female die insert B (7). The lower end of the female die insert A (6) is connected with a pressing die body (8), and an ejector rod (11) located under the pressing die (8) is arranged in a square cavity (9). The lower end of the female die insert B (7) is connected with a wedge B (14), a circular bead is arranged on the left side of the wedge B (14), and the wedge B (14) is located over a cavity (10). An arc chamfer matched with the circular bead is arranged on the left side wall of the cavity (10). The precision progressive die has the beneficial effects that the structure is compact, the bending angle is precise, continuous bending is achieved, bending efficiency is improved, and the production output is increased.

Owner:CHENGDU HOMIN TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com