Patents

Literature

45results about How to "Control Bend Angle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

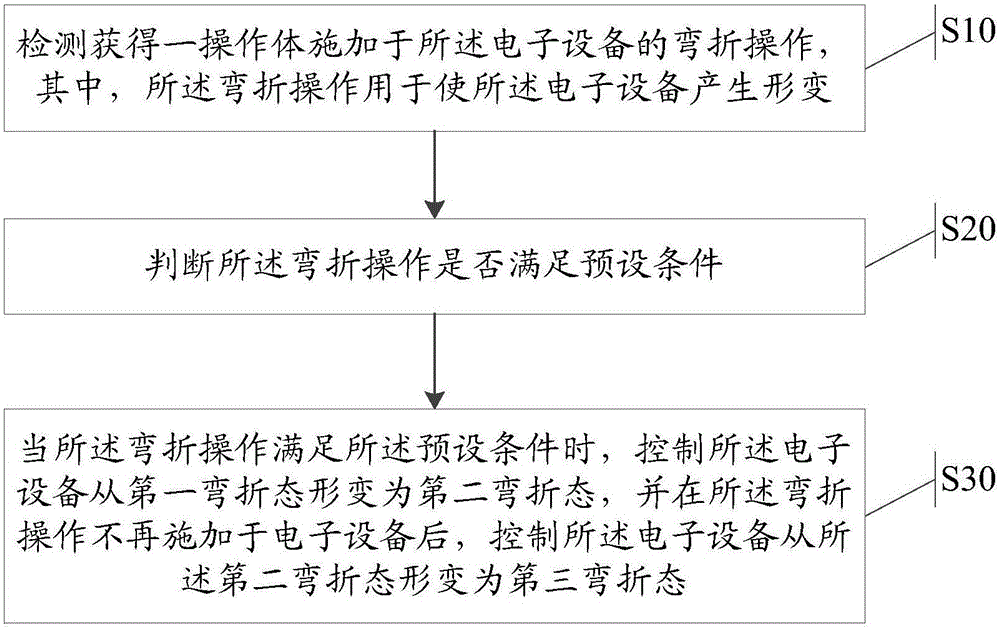

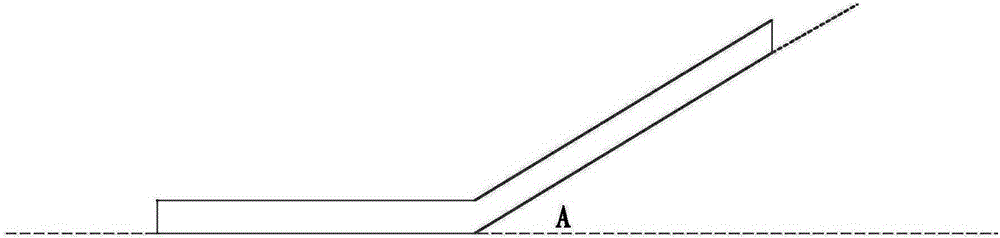

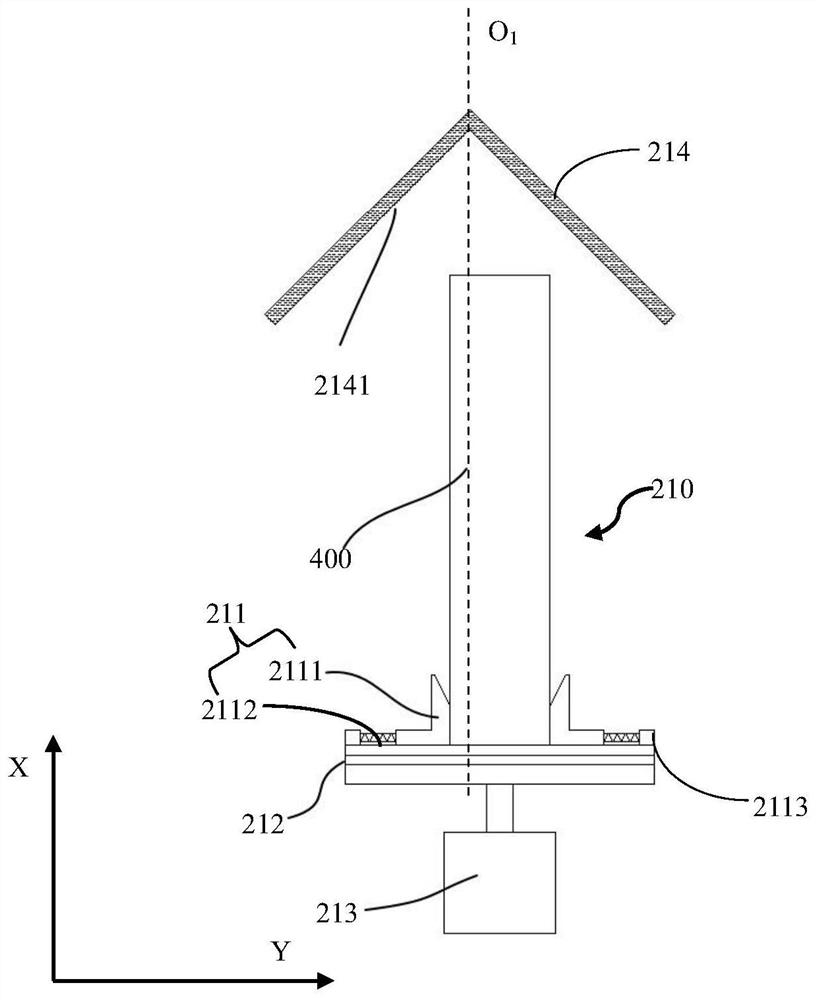

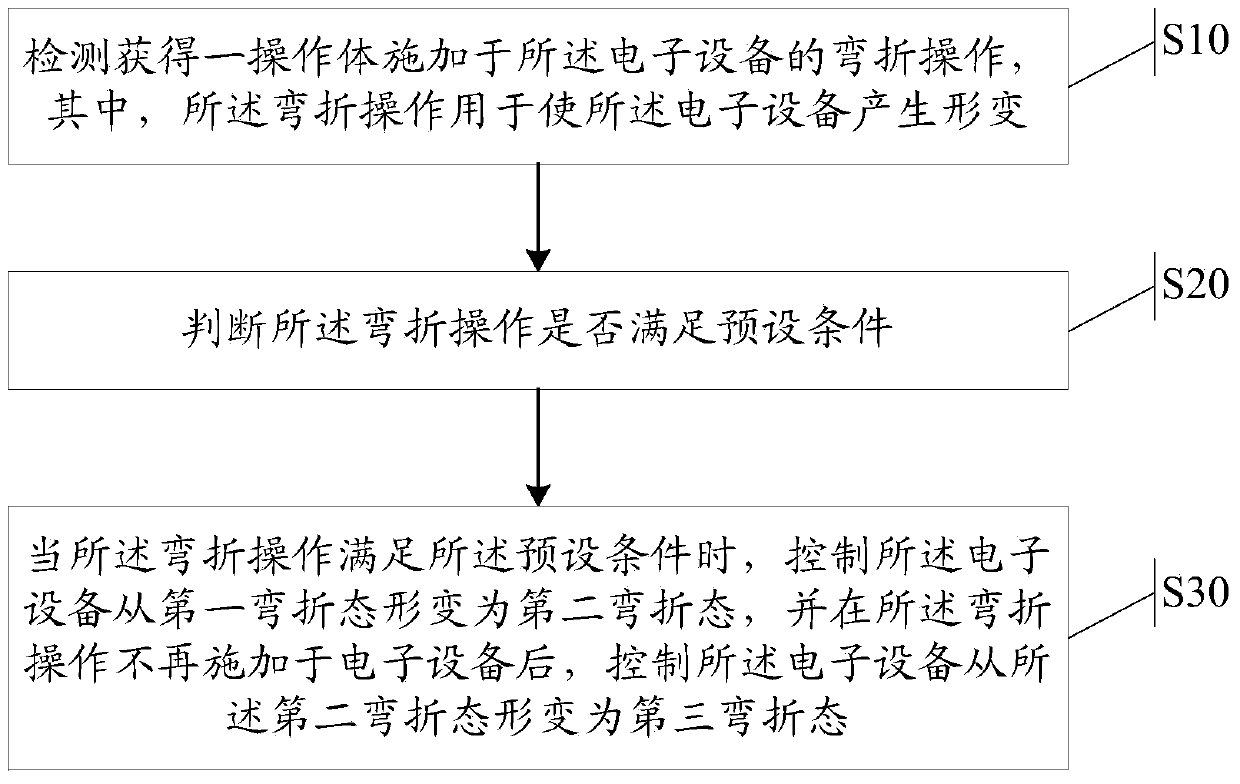

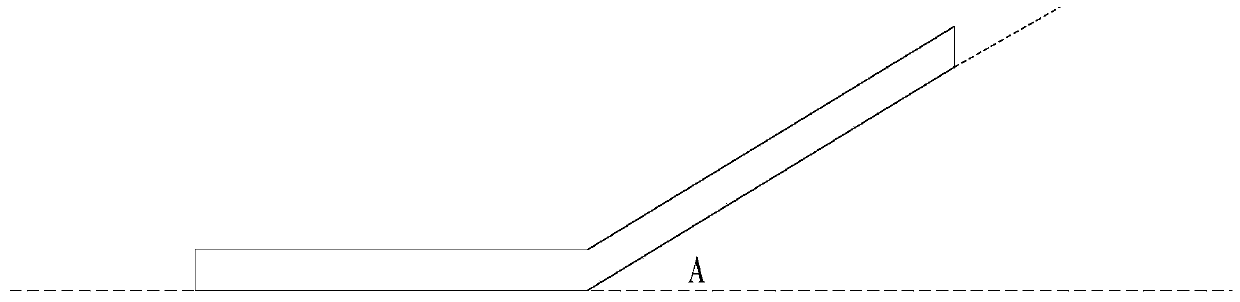

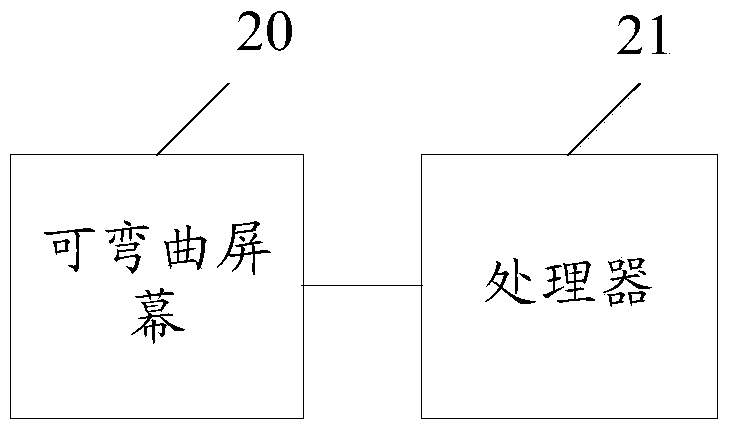

Electronic apparatus control method and electronic apparatus

ActiveCN105138076AControl bend anglePrecise bending angleInput/output for user-computer interactionDetails for portable computersControl theoryElectronic equipment

Owner:LENOVO (BEIJING) LTD

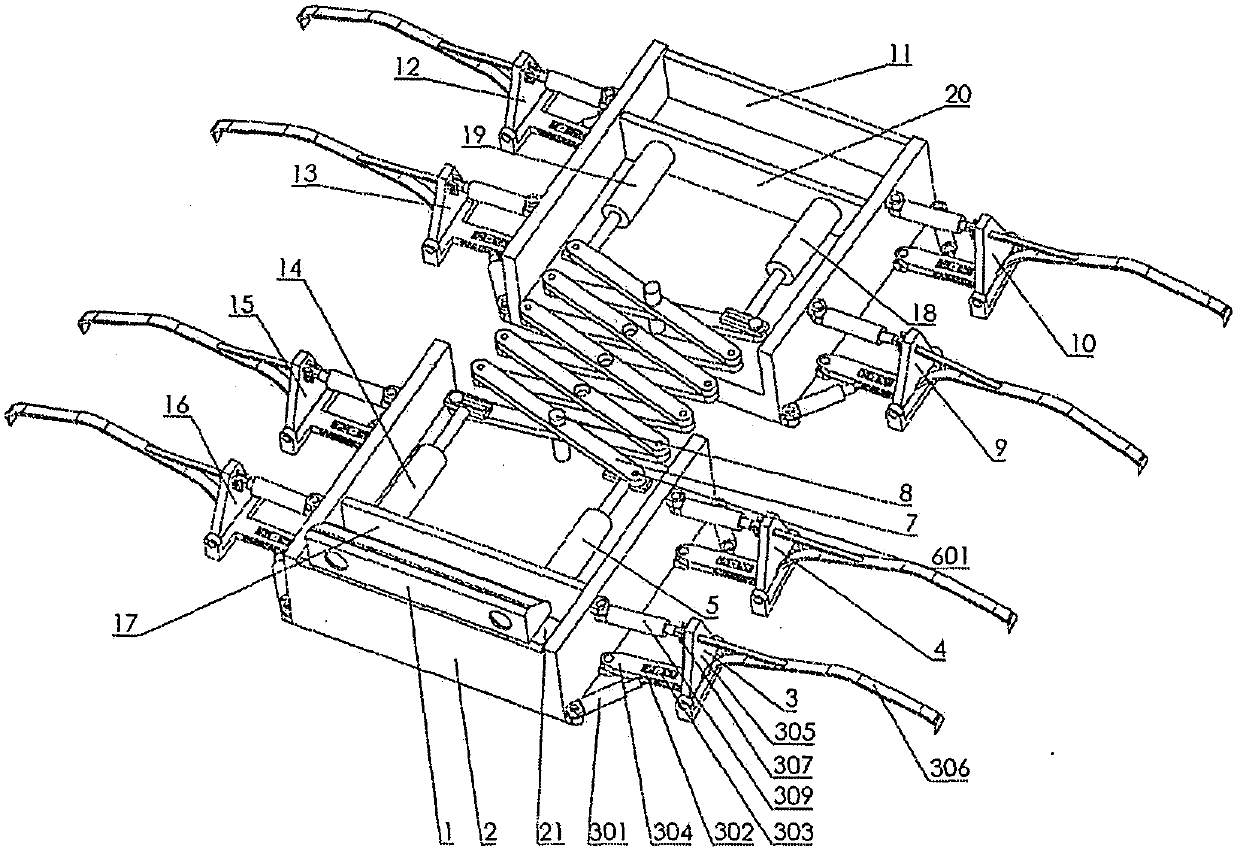

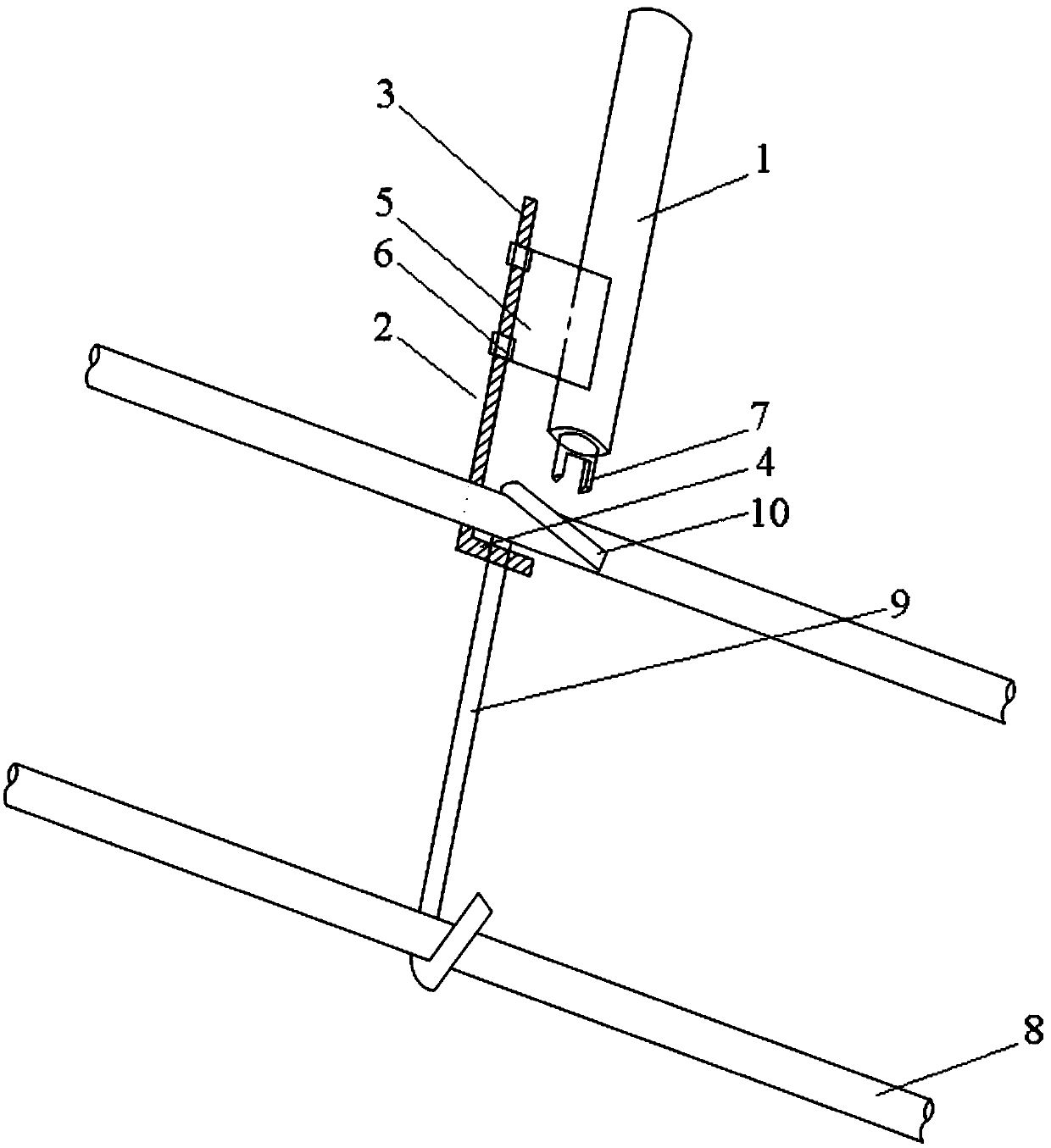

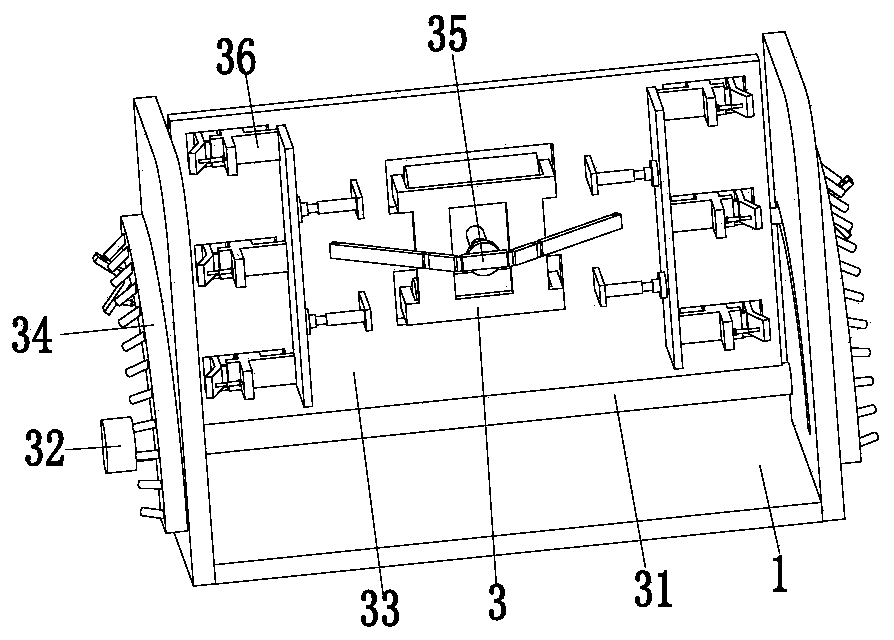

Bionic flexible tree climbing robot

The invention discloses a bionic flexible tree climbing robot. The robot comprises a trunk system, mechanical leg systems and a display and detection system. The trunk system is composed of an upper trunk and a lower trunk which are connected through a connecting rod, the body structure of an animal is simulated, the two trunks are driven by electric cylinders, and the robot is controlled to steerand move forwards; the mechanical leg systems are independently driven through the electric cylinders, front-back swinging and up-down tree trunk climbing actions of mechanical legs are achieved, andtree holding and climbing tasks are completed. In the tree climbing process of the robot, the stroke of the electric cylinders of the mechanical legs is changed, the holding angle can be changed, andthe robot can adapt to trees with different diameters; the multi-degree-of-freedom display and detection system feeds back information detected by the robot in real time, the states of the trees arechecked, and field monitoring and detection work is completed.

Owner:SHANGHAI UNIV

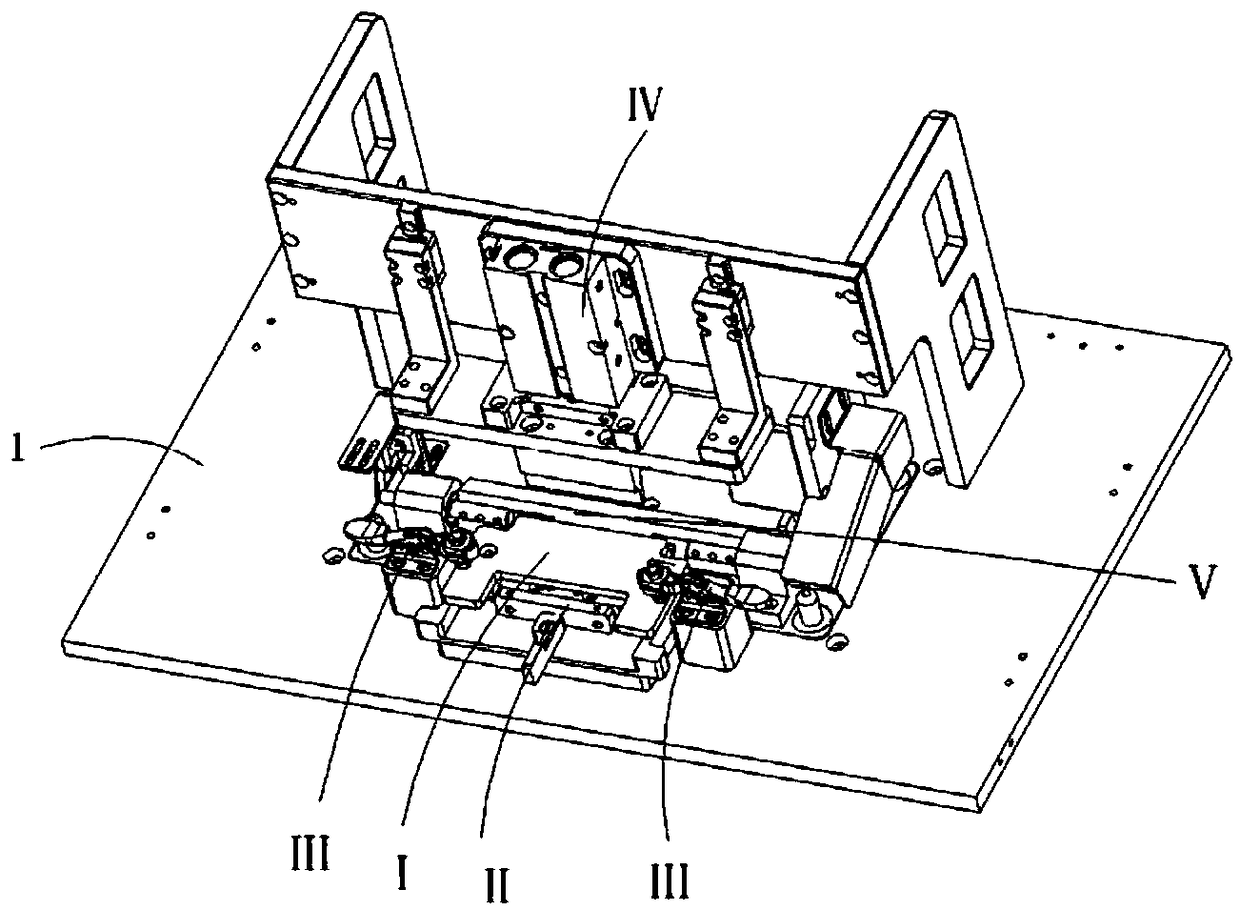

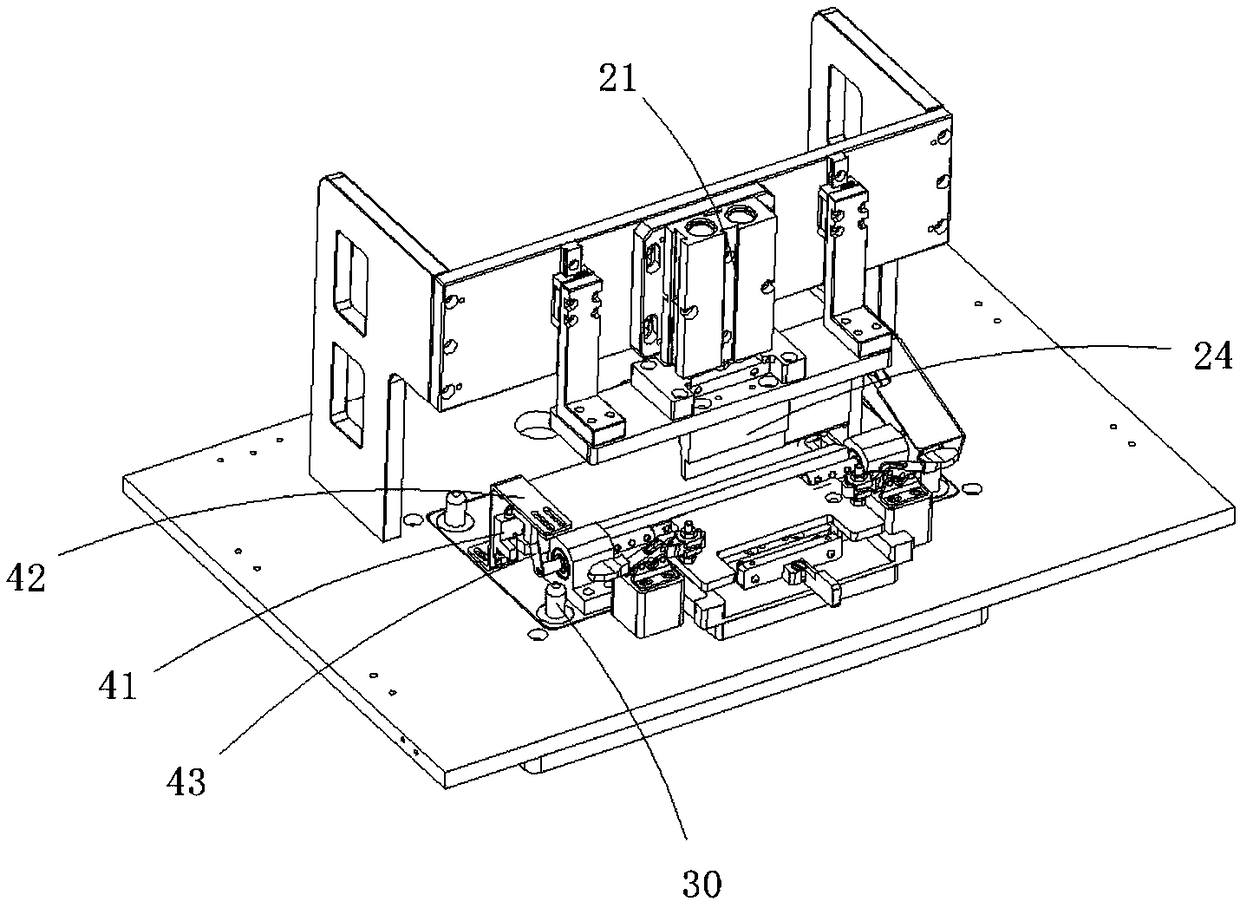

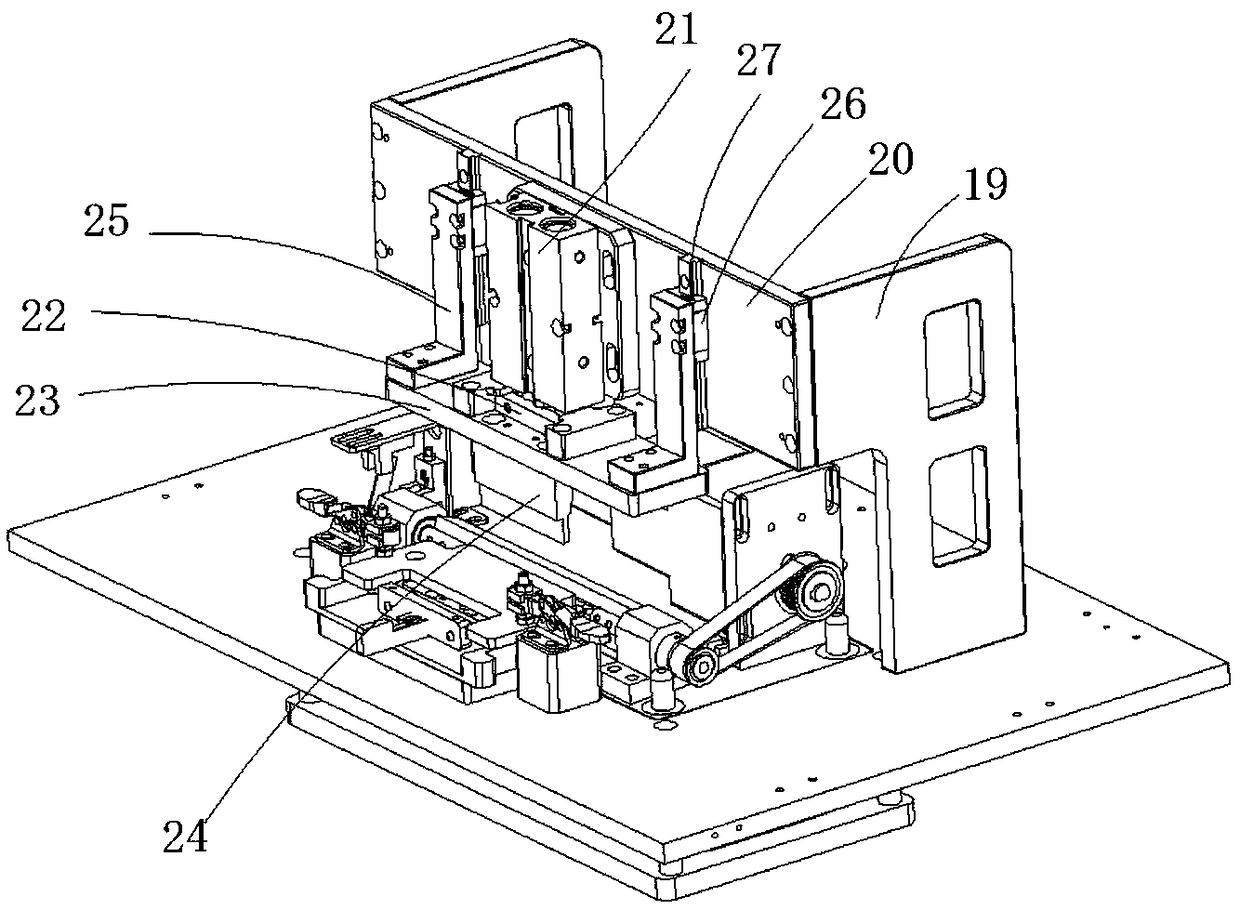

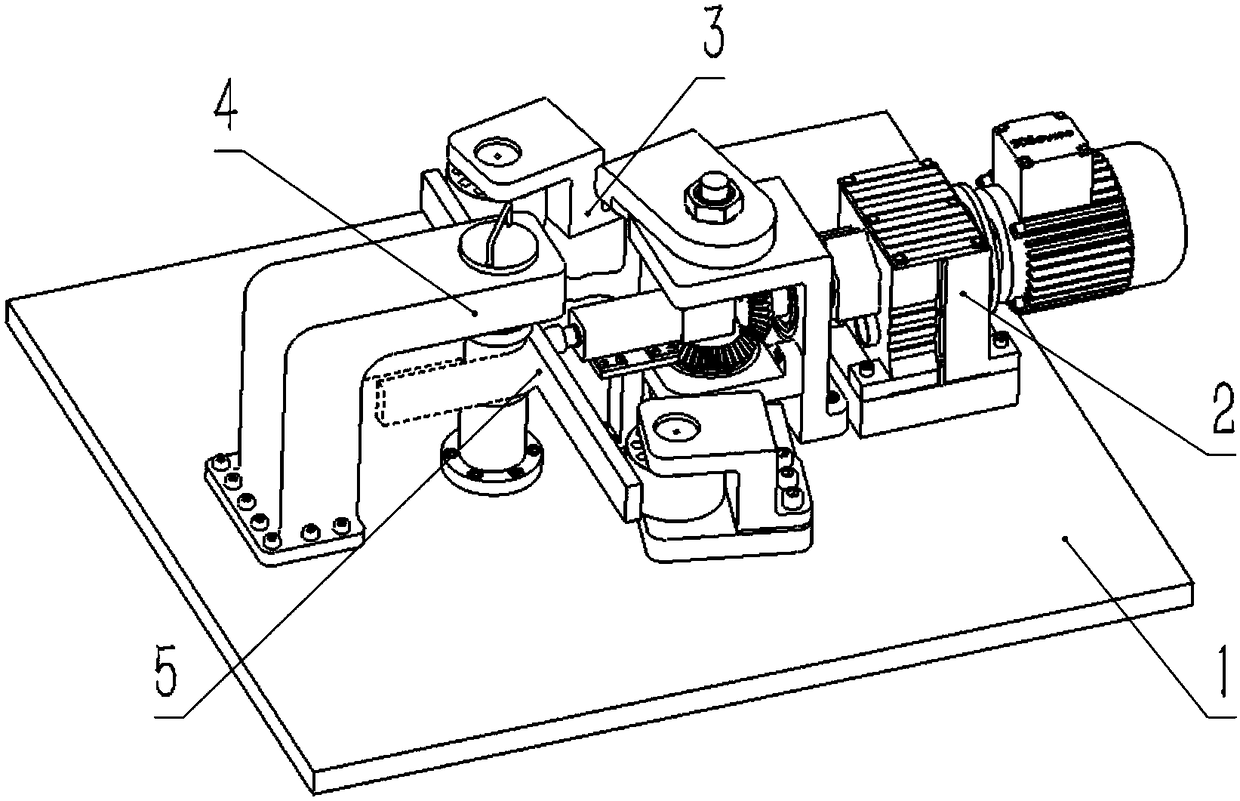

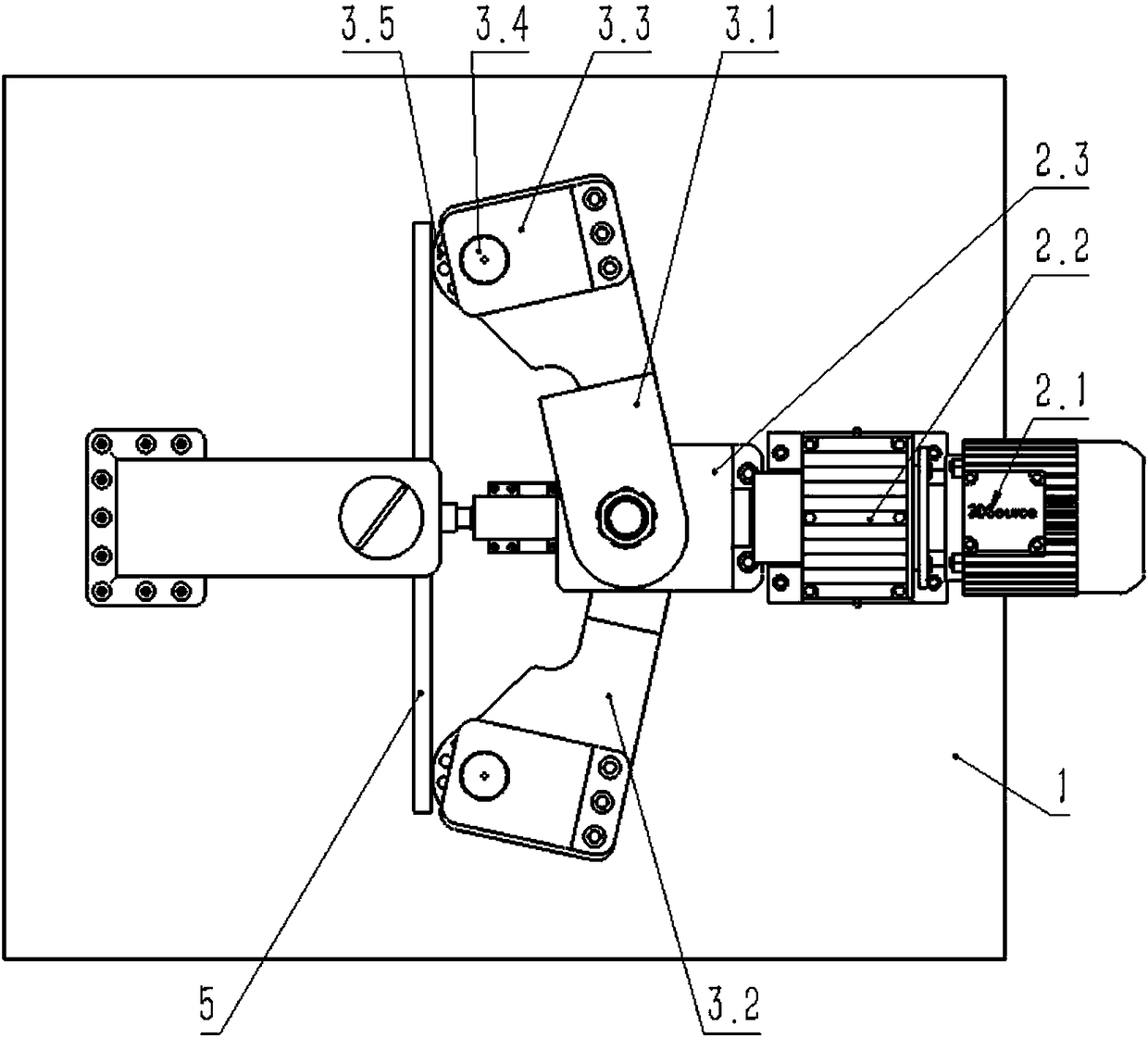

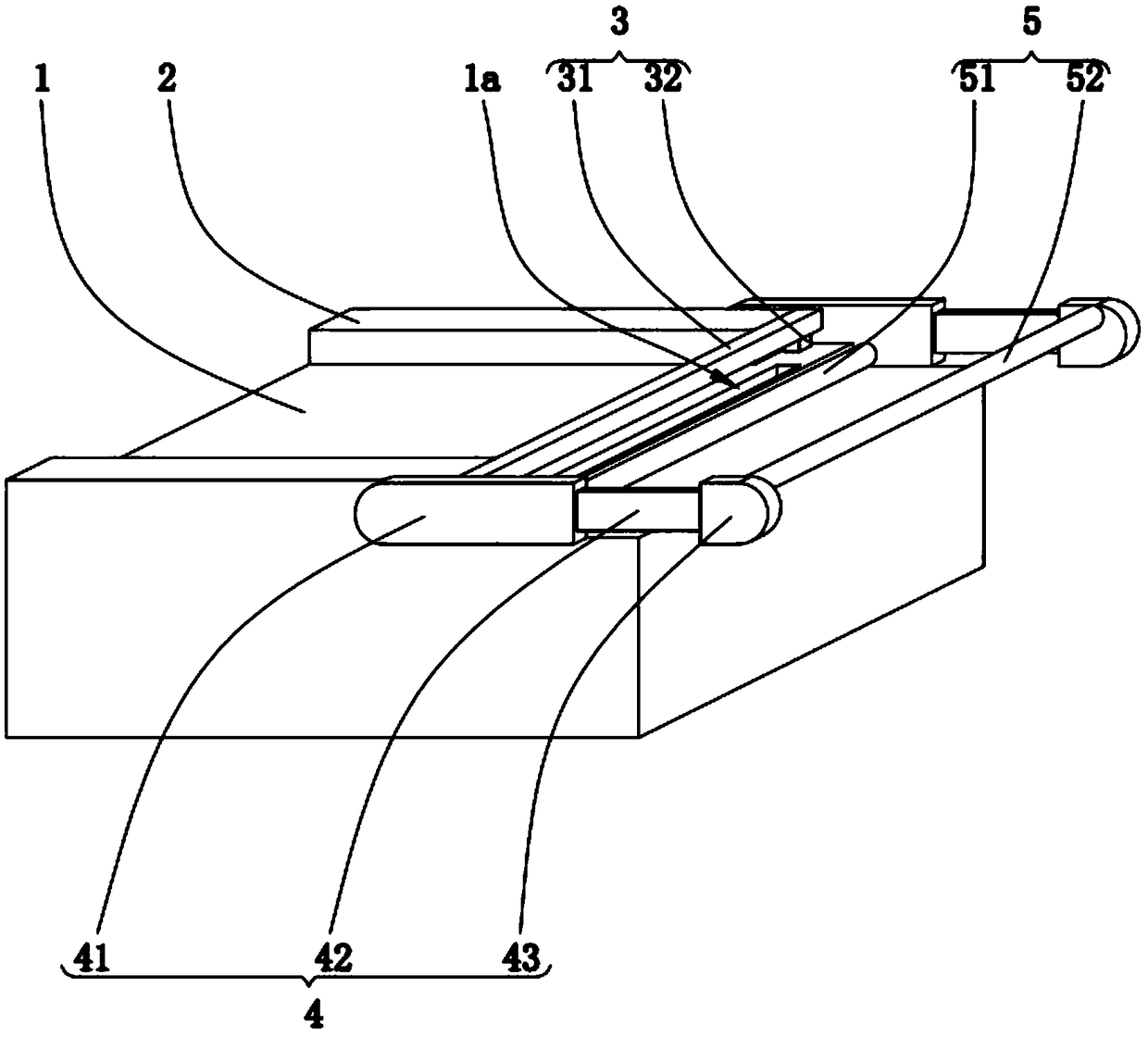

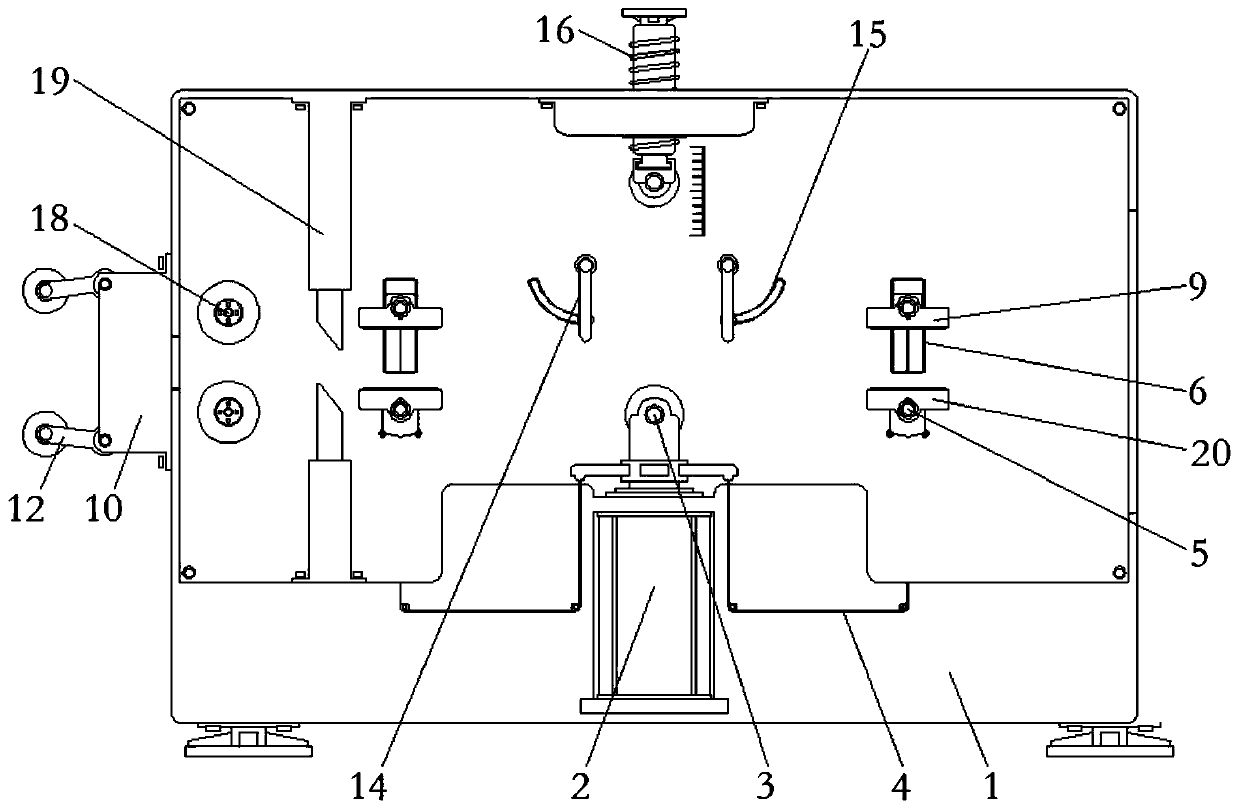

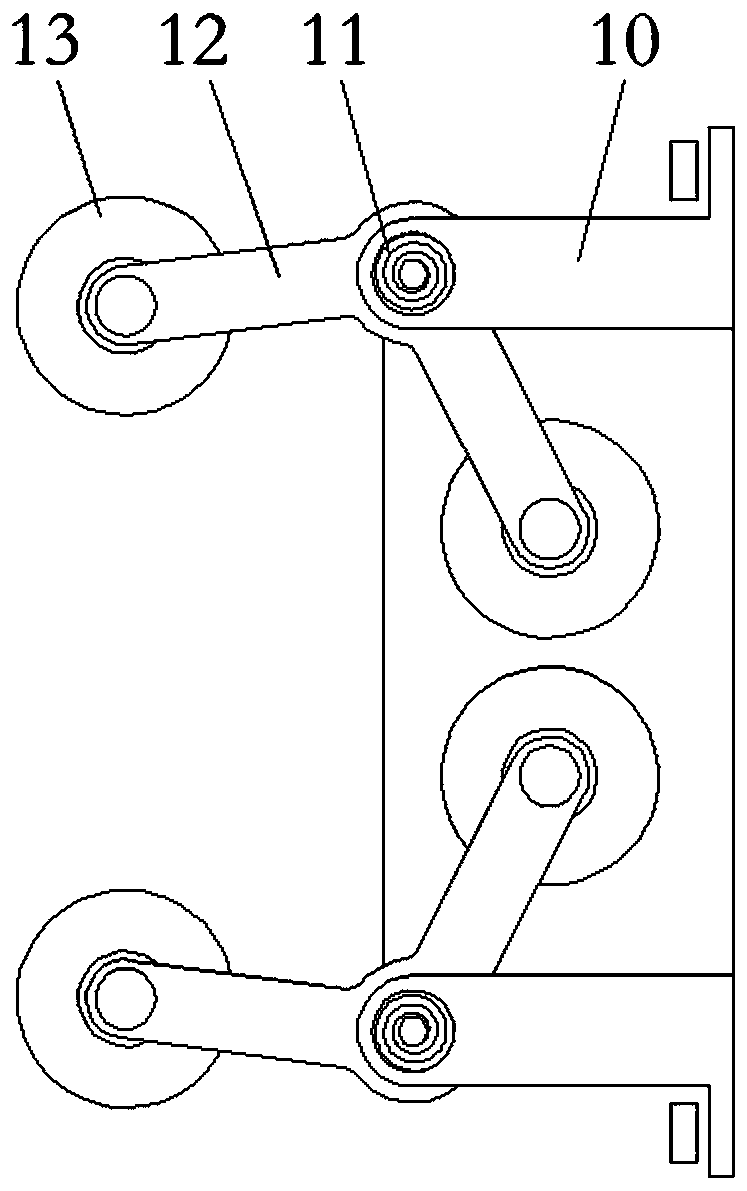

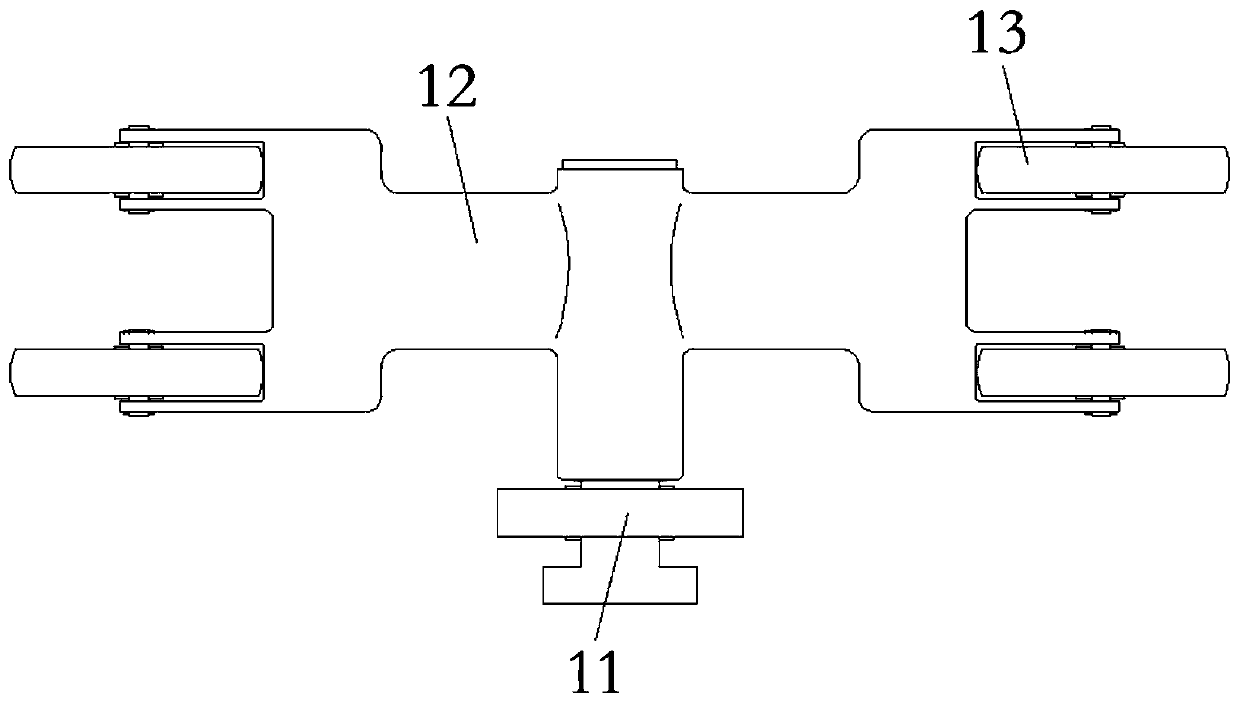

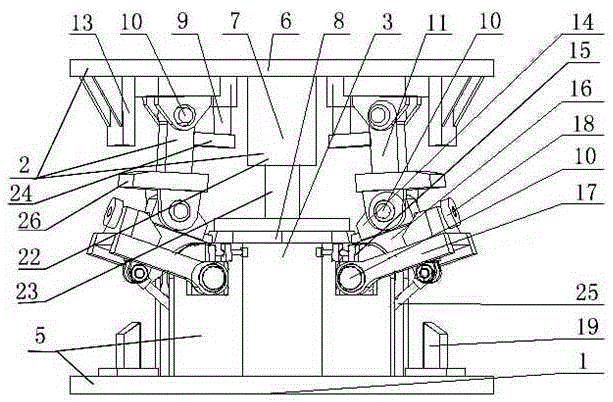

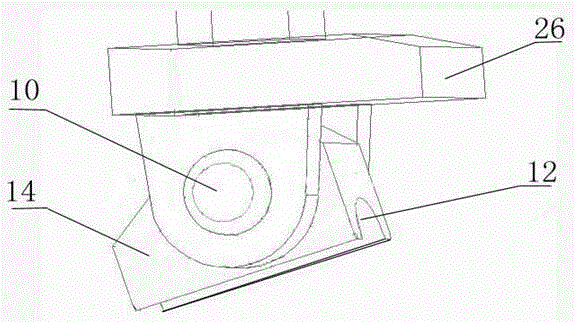

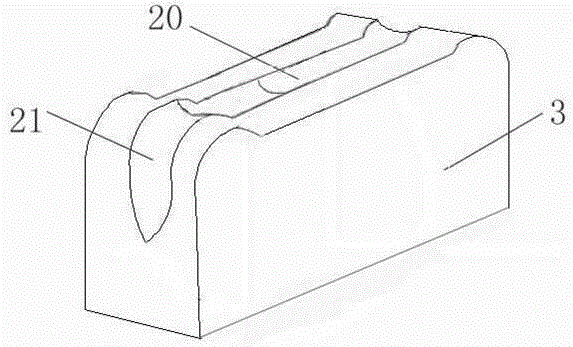

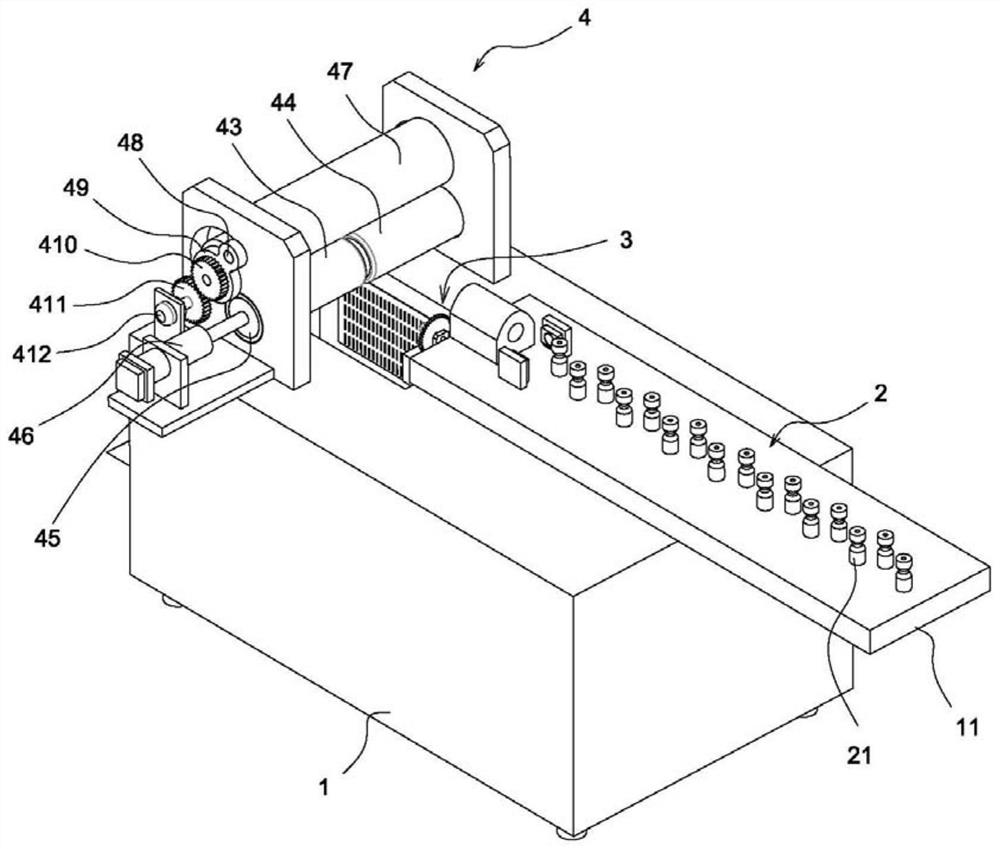

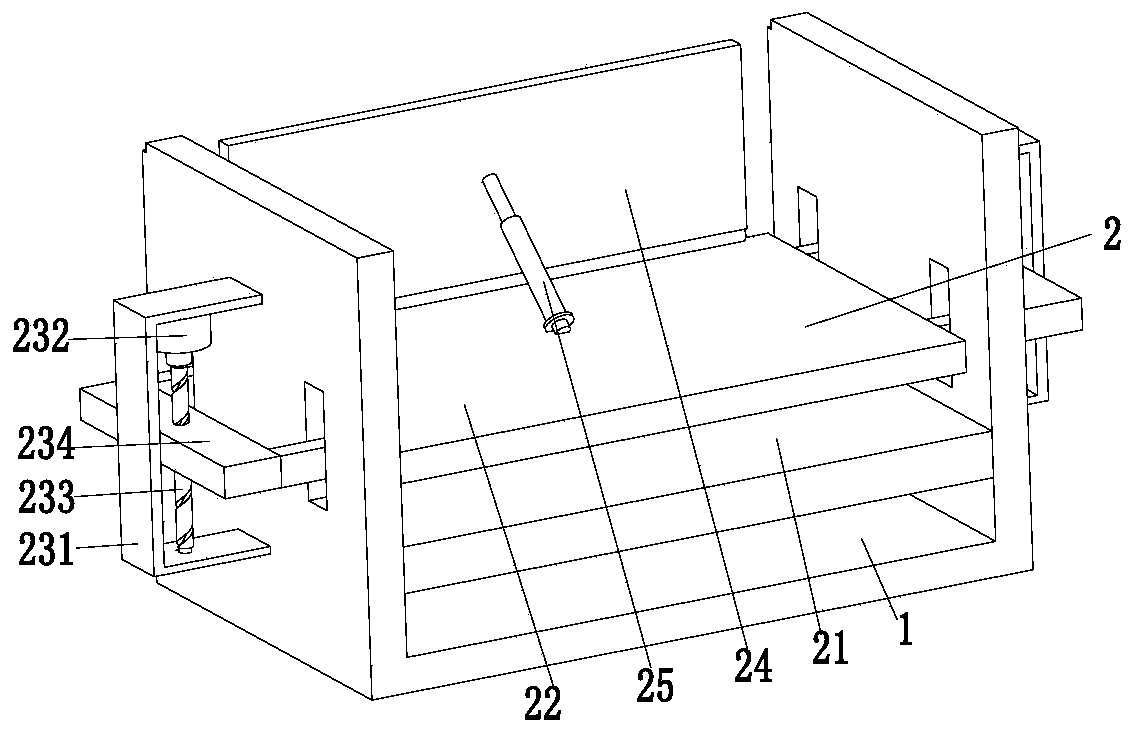

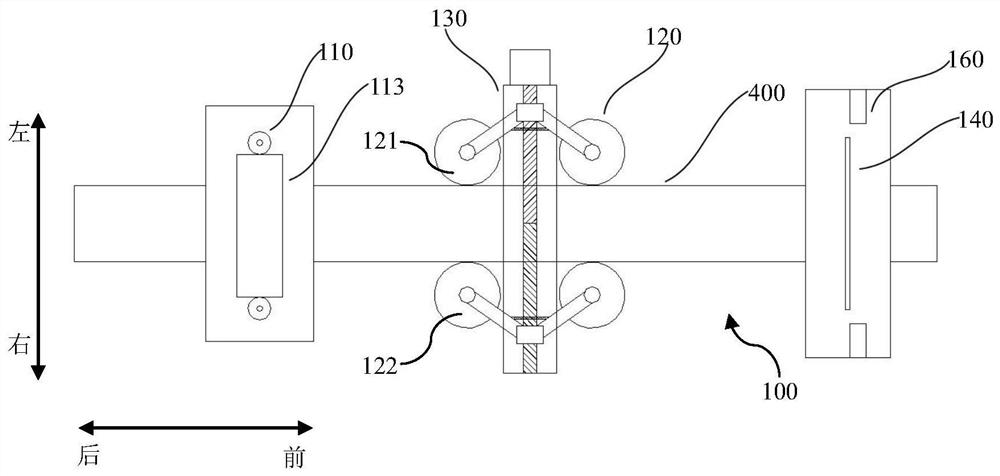

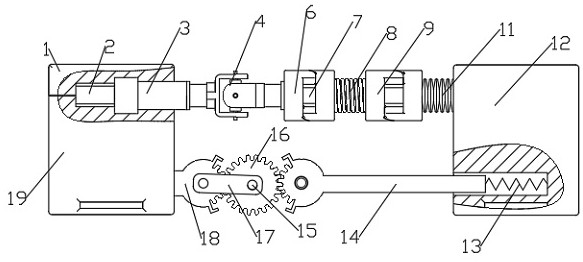

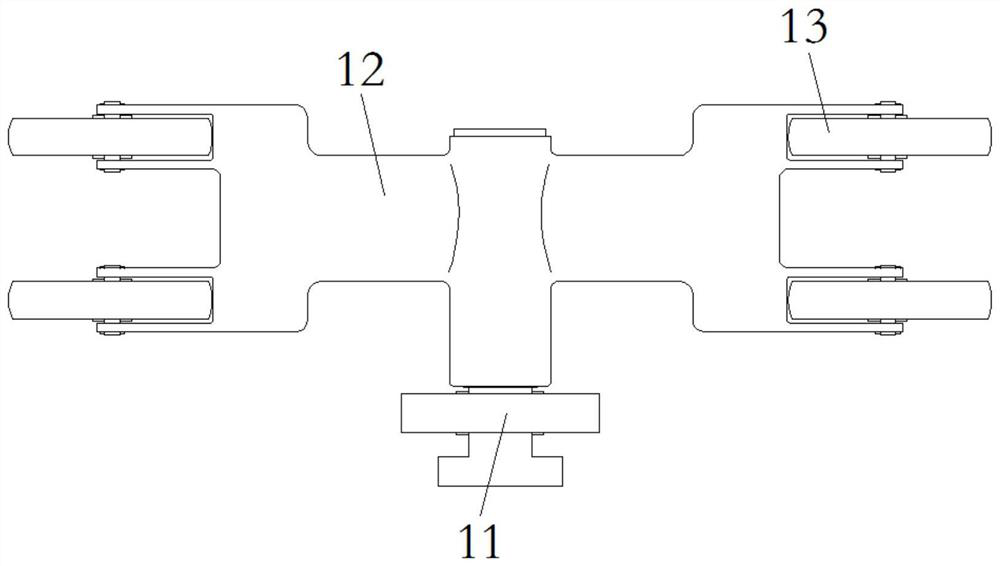

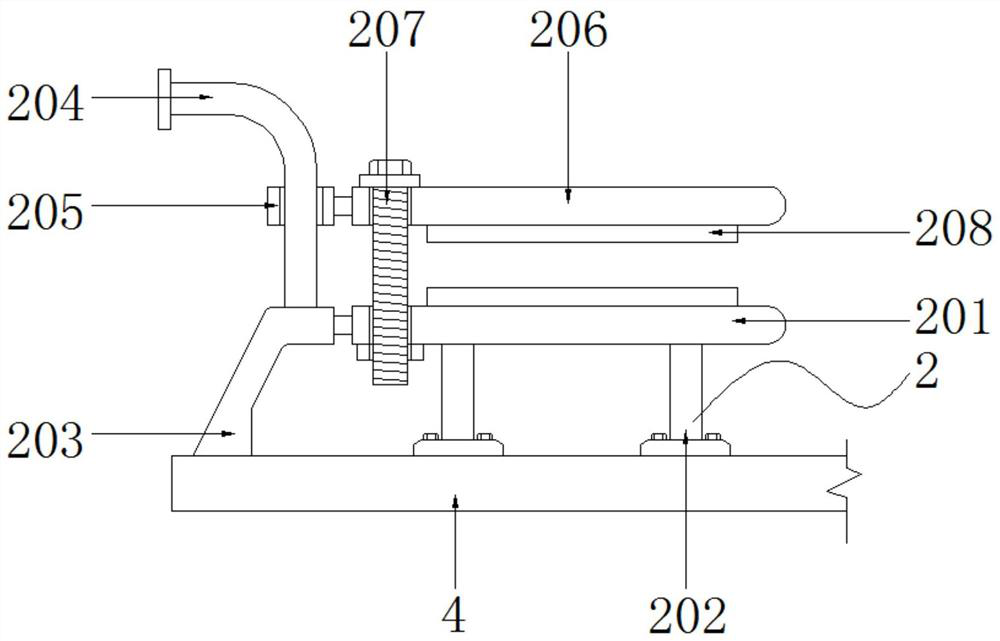

Electronic part bending mechanism

The invention relates to an electronic part bending mechanism. A carrier is placed on a base plate, a plurality of electronic components are installed in the carrier side by side, two pins which needto be bent are arranged on each electronic component, and tight press mechanisms which can tightly press the carrier and products are installed on the base plate and located on the left side and the right side of the carrier. A downward press mechanism which can press the pins is installed on the rear side of the top of the base plate. A square slotted hole is formed in the middle of the base plate, an ascending mechanism is installed at the bottom of the base plate, and an ascending plate of the ascending mechanism can pass through the square slotted hole. An upper bending mechanism is installed on the ascending plate, and comprises a rotating mechanism and a bending driving device, wherein the bending driving device can drive a rotating shaft of the rotating mechanism to rotate. An upperbending block which can conduct bending forming on the pins is installed on the rotating shaft. A sensor which can control the rotation angle of the rotating shaft is installed on the ascending plate, and an induction piece which is matched with the sensor is installed on the rotating shaft. By the adoption of the electronic part bending mechanism, bending operation of the electronic components can be achieved, the multiple products can be bent at one time, and the operation of bending with different angles can be achieved.

Owner:BOZHON PRECISION IND TECH CO LTD

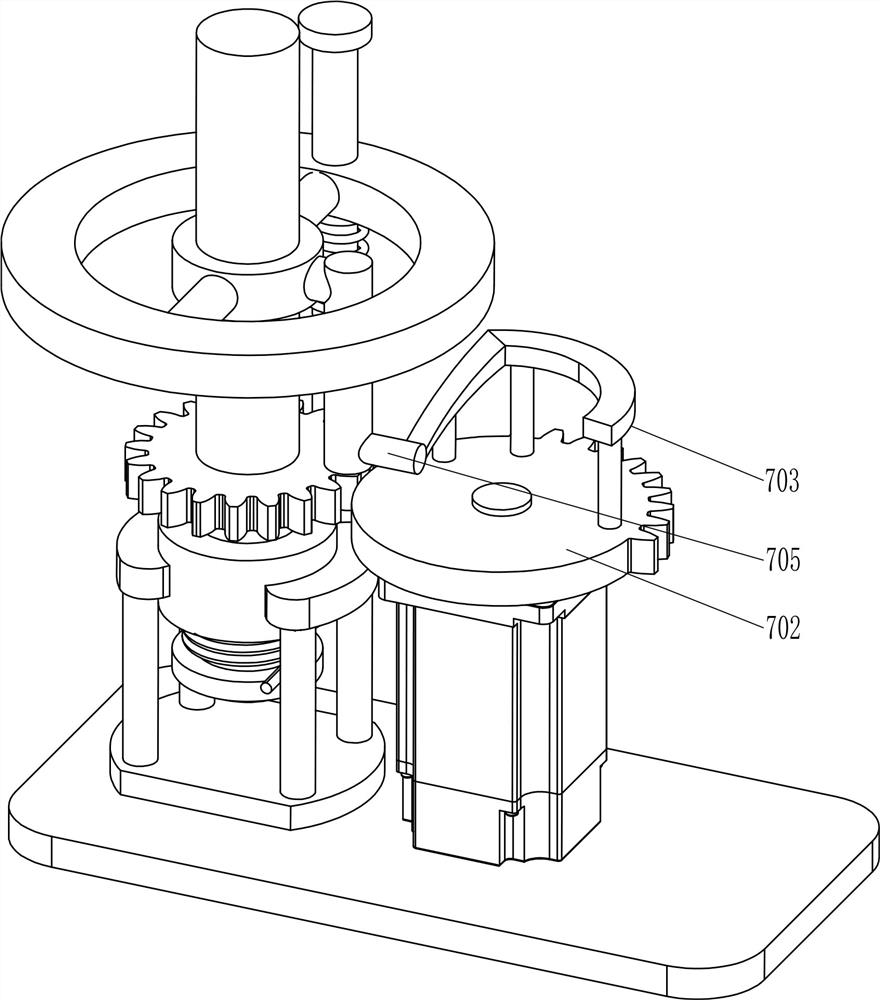

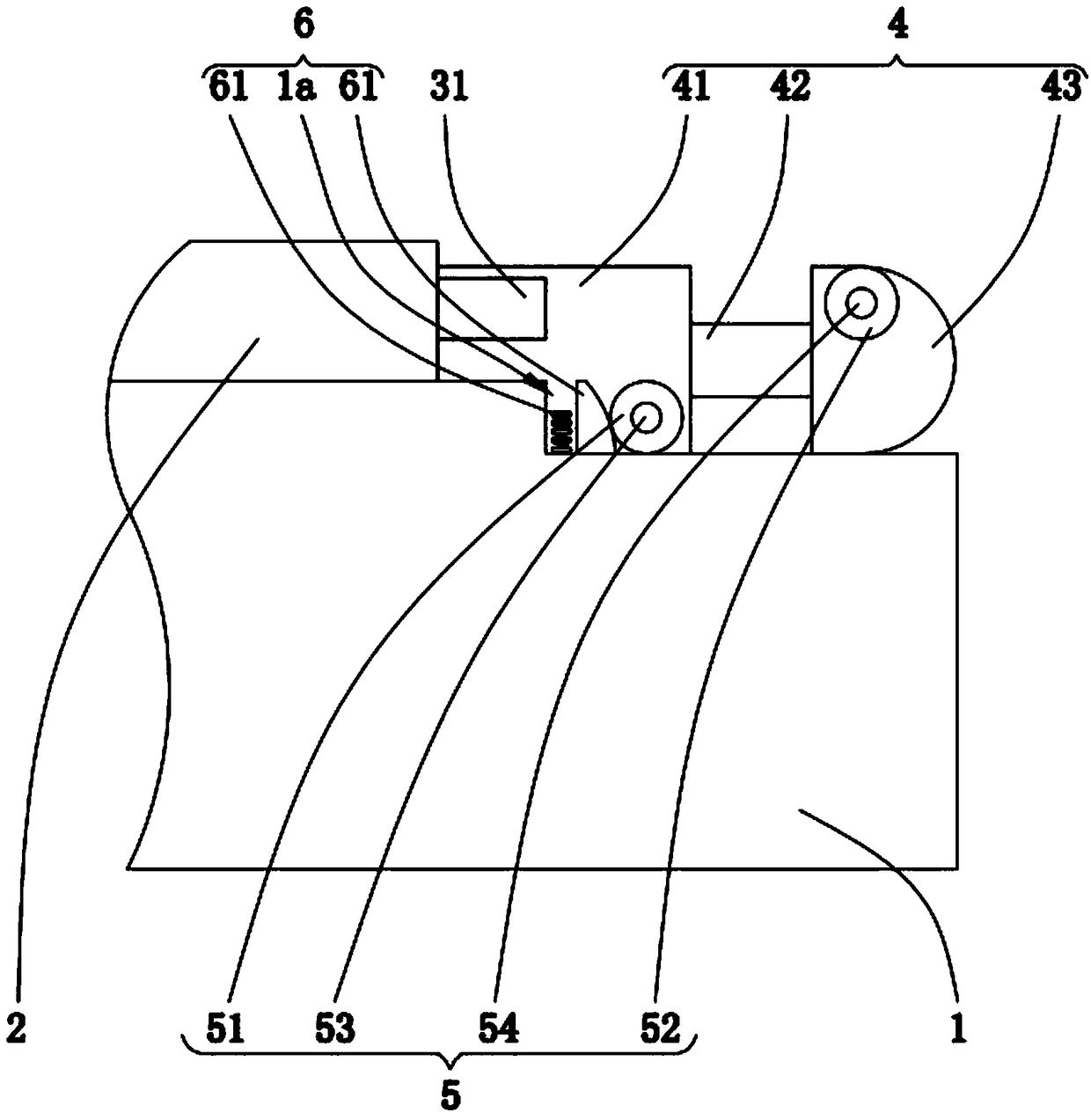

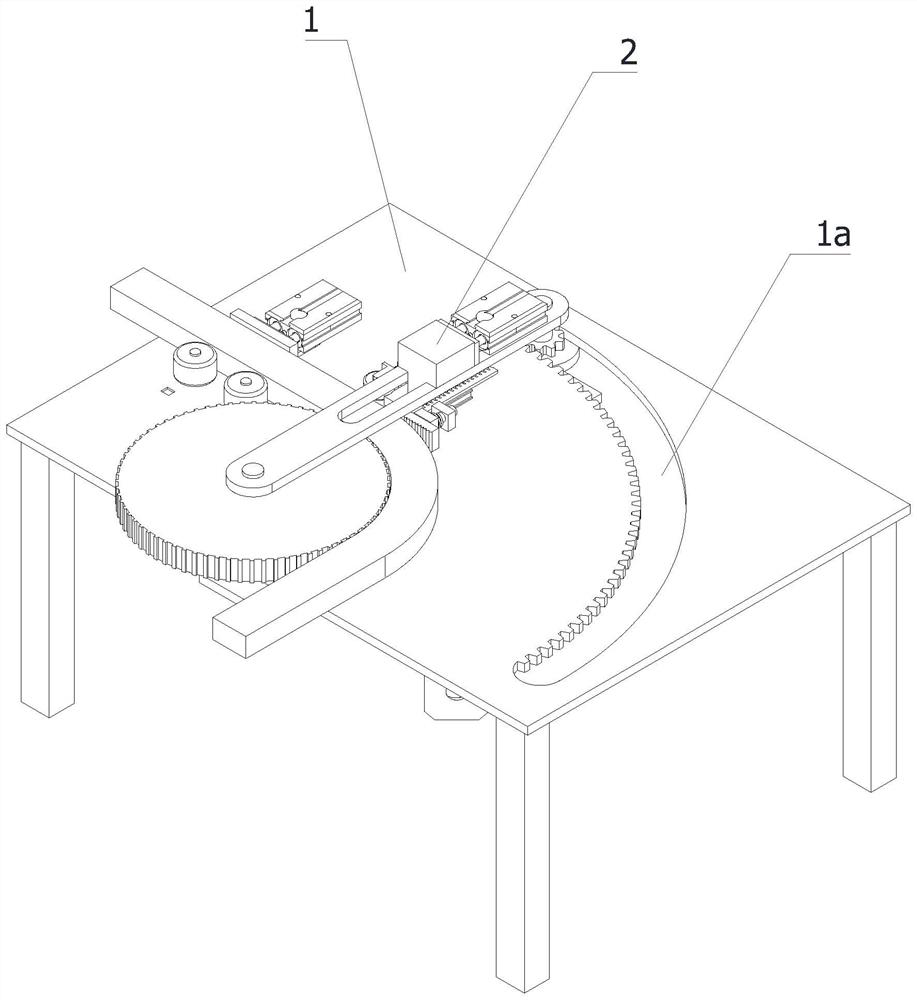

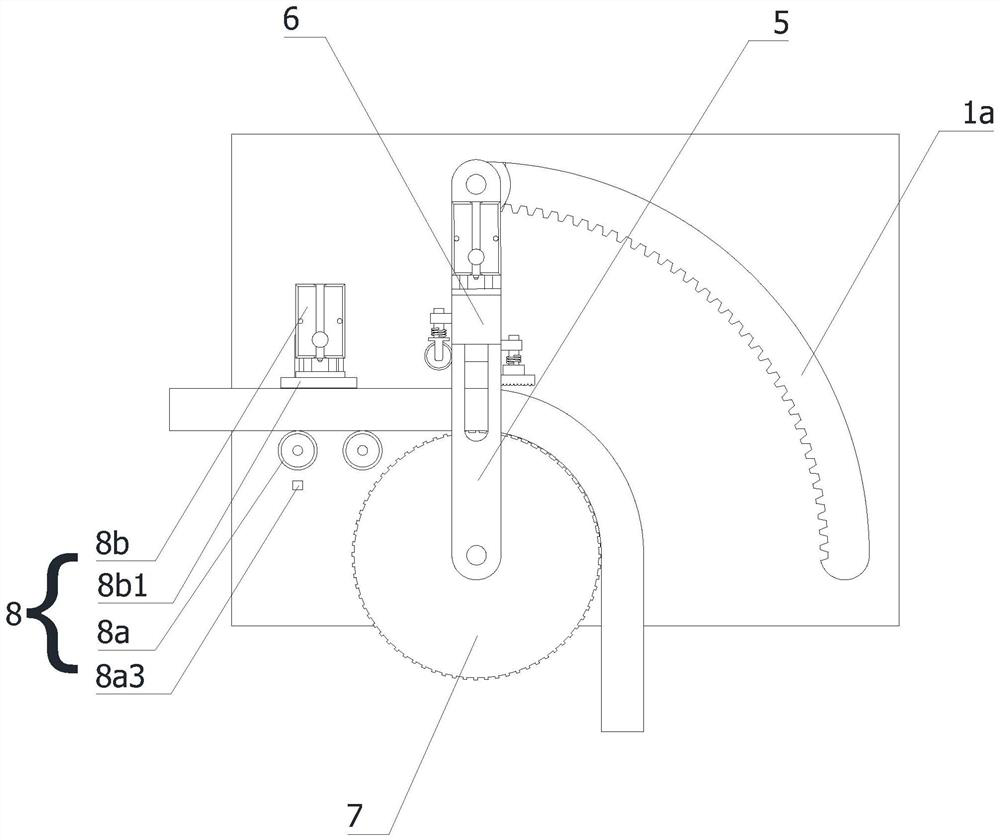

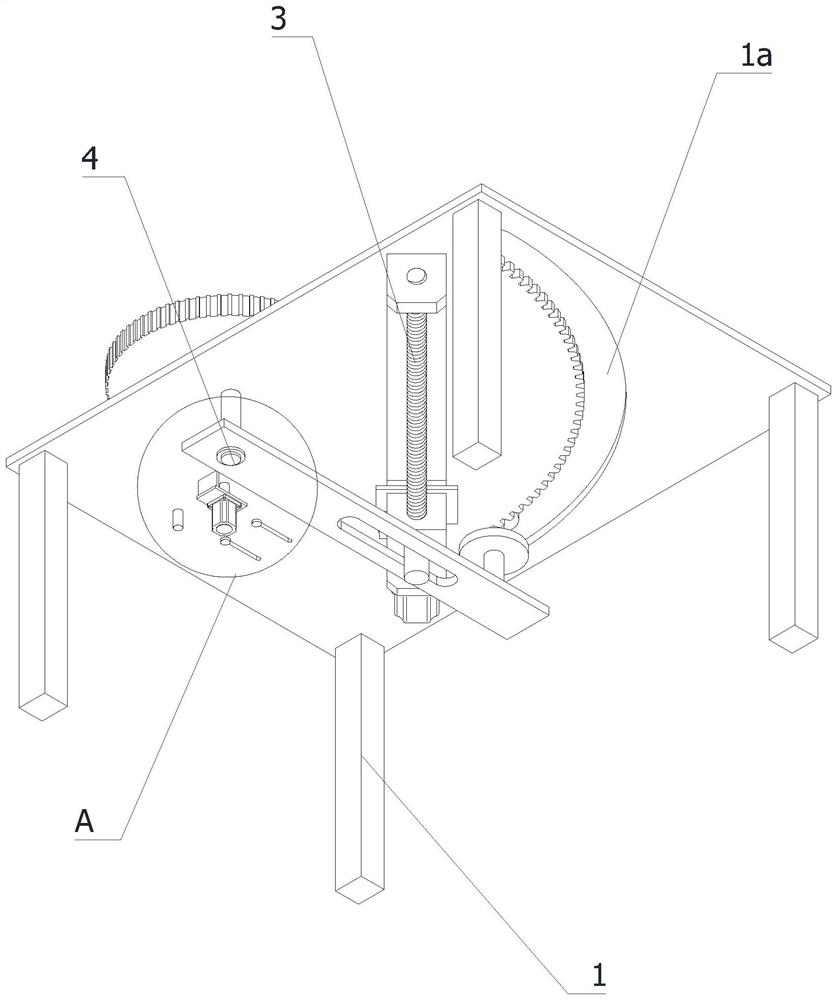

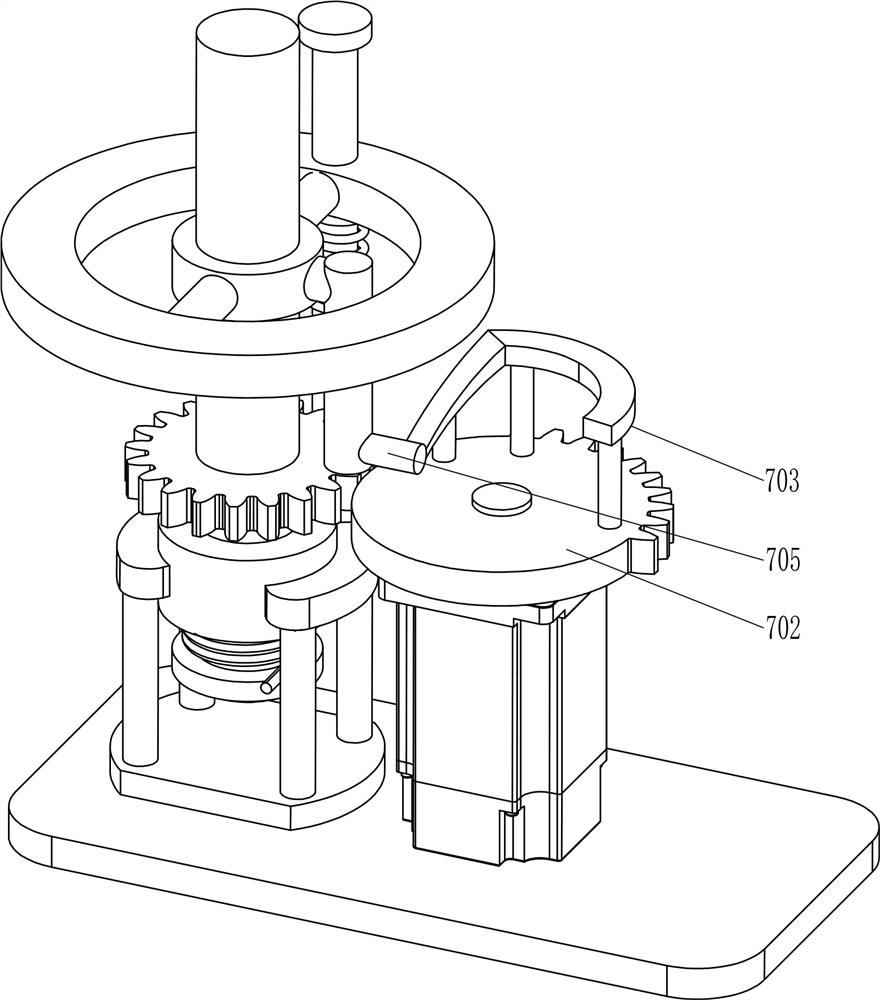

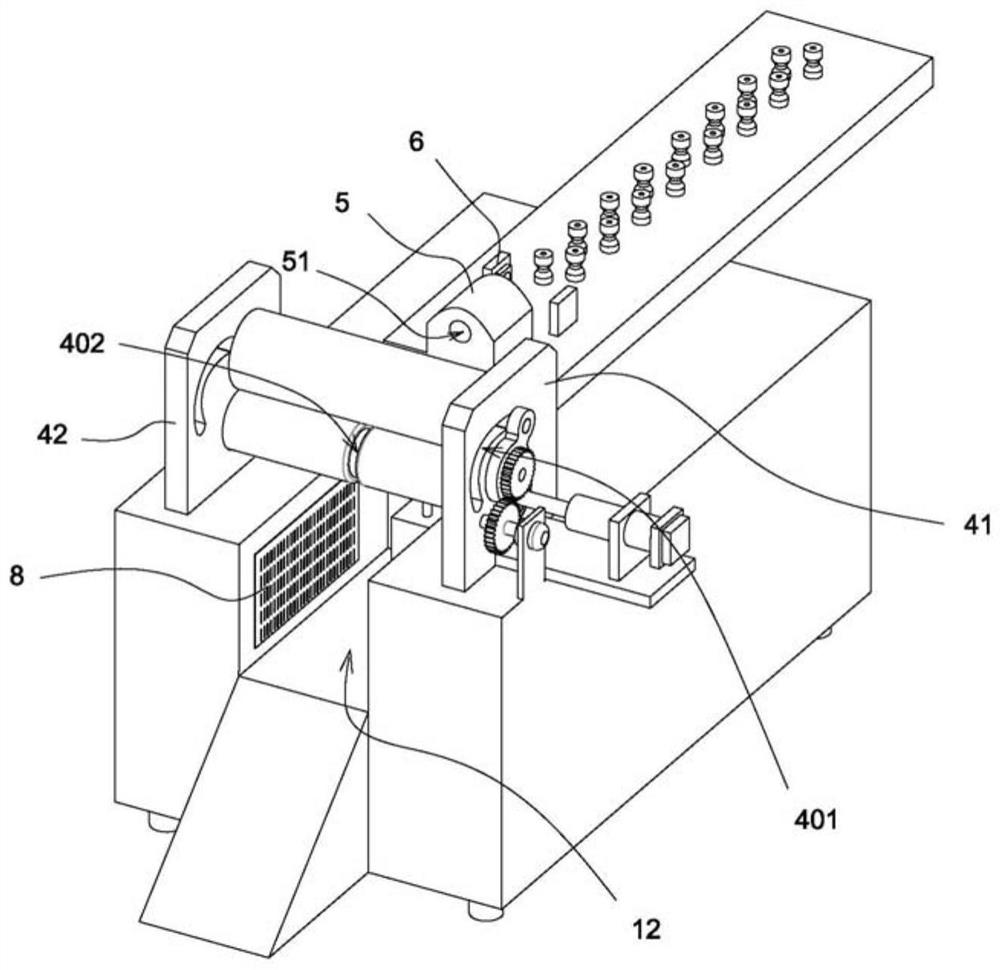

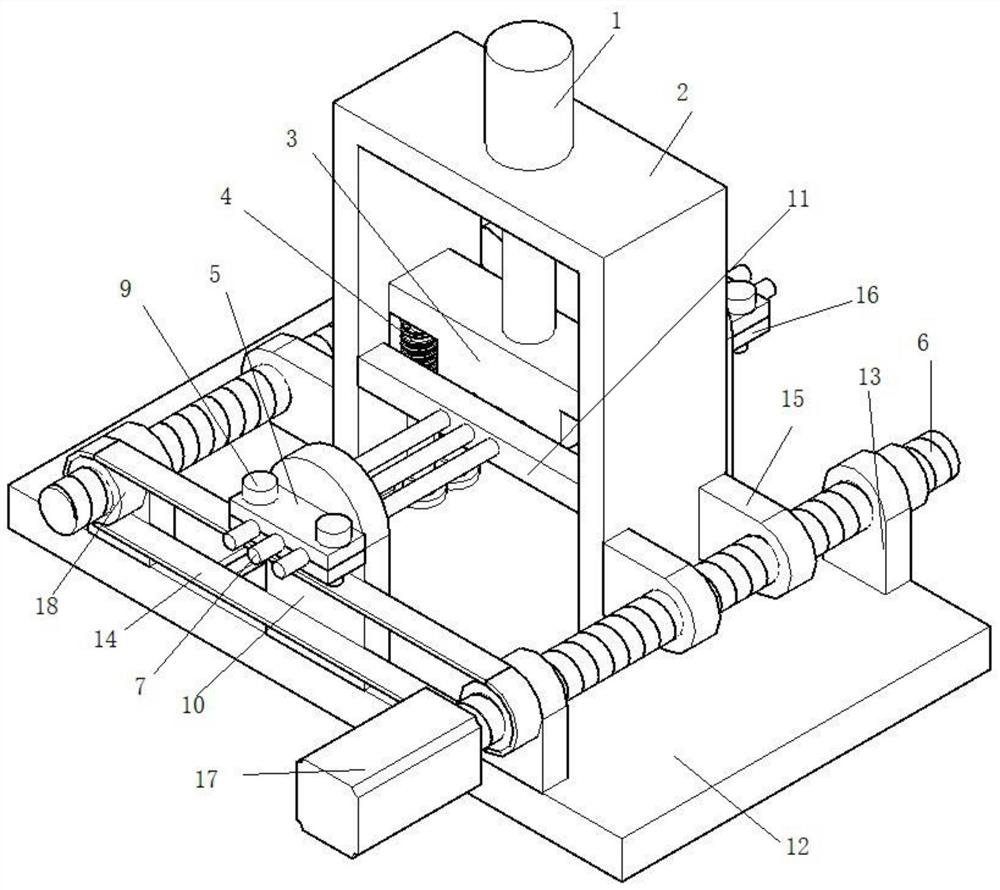

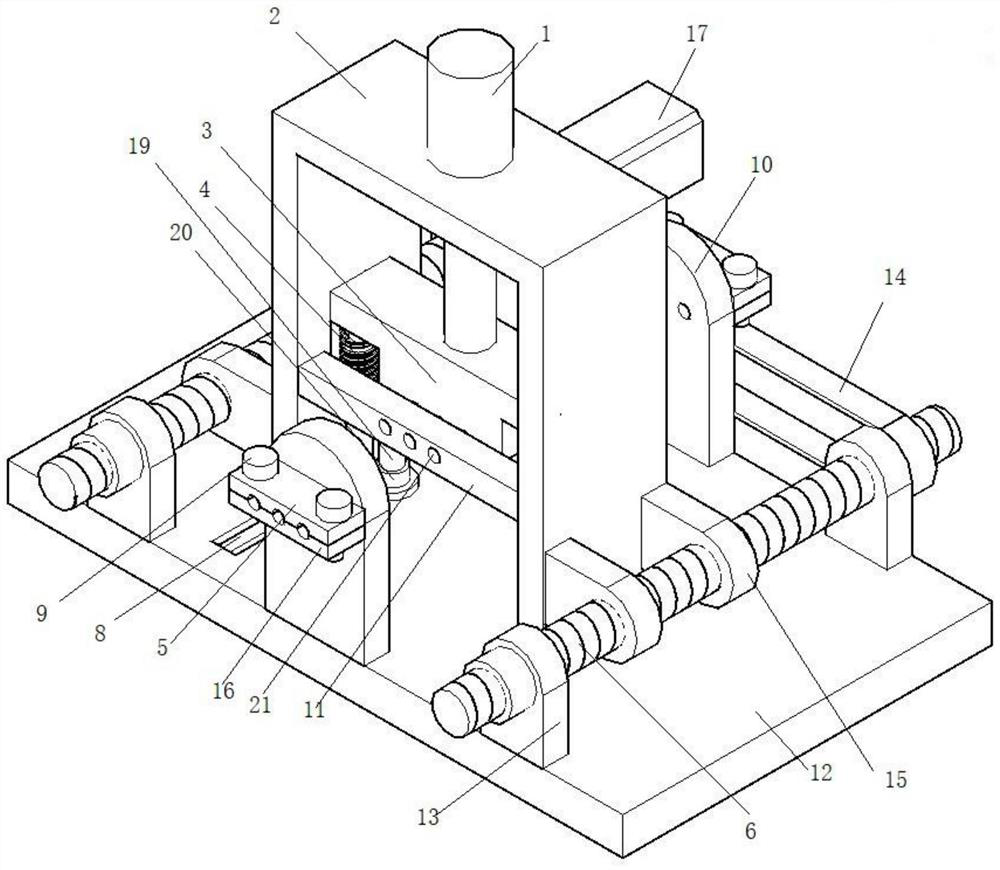

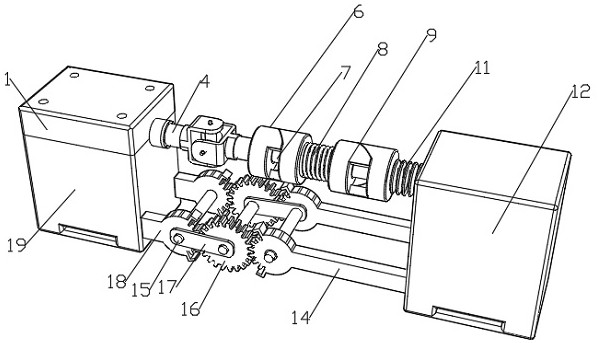

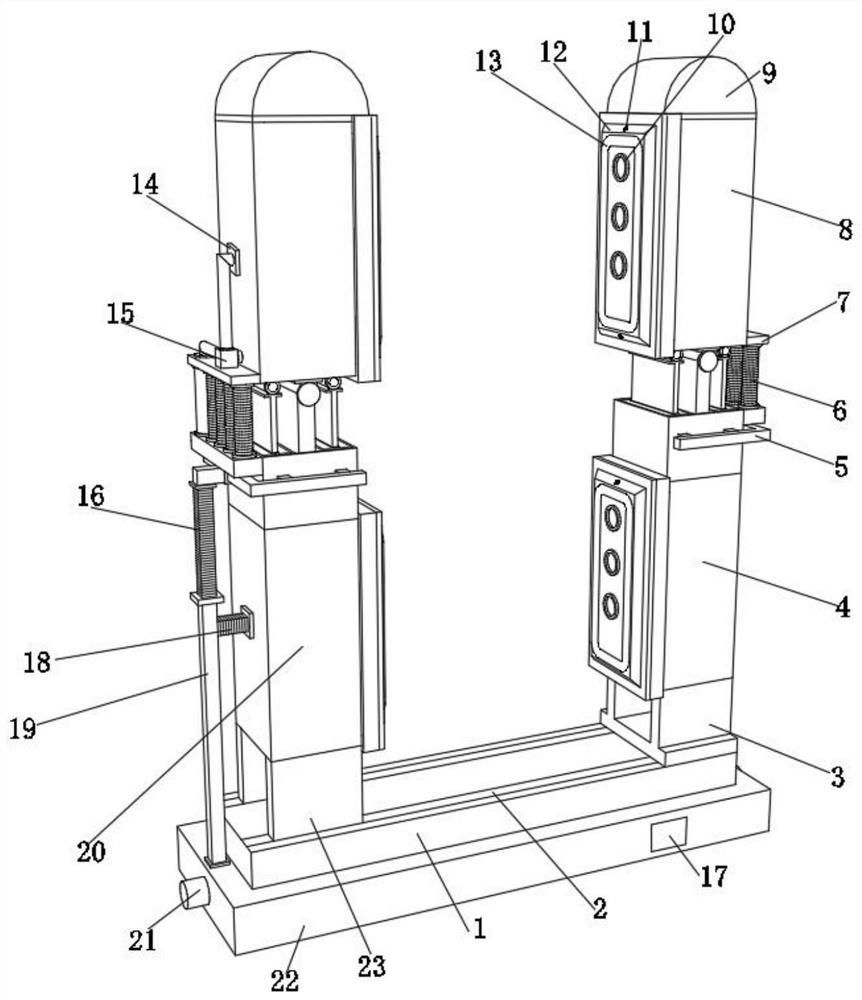

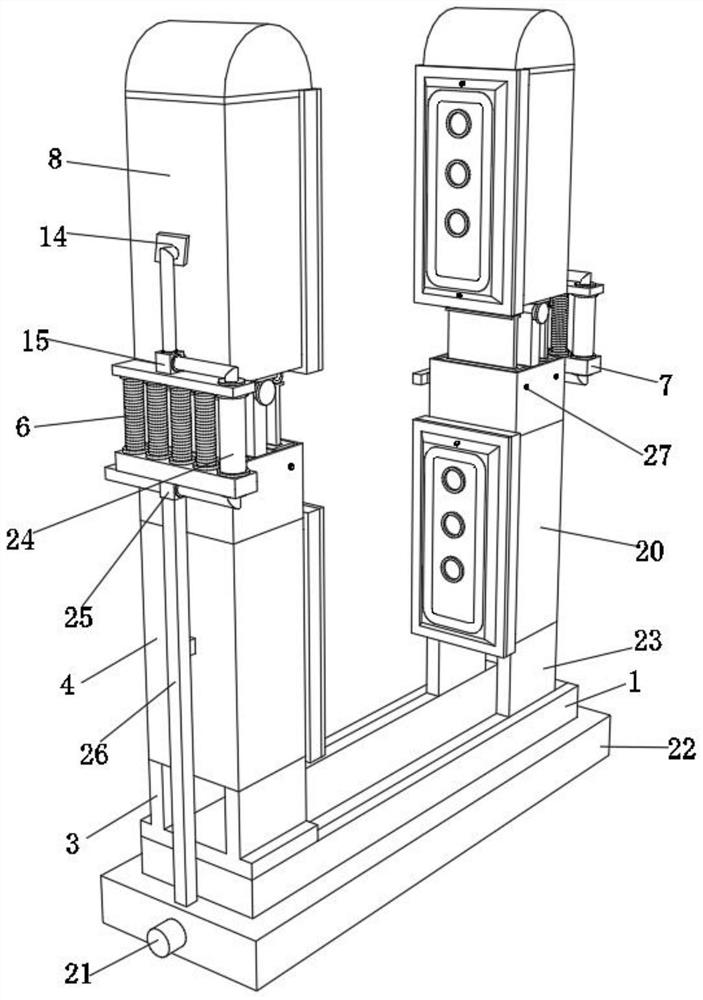

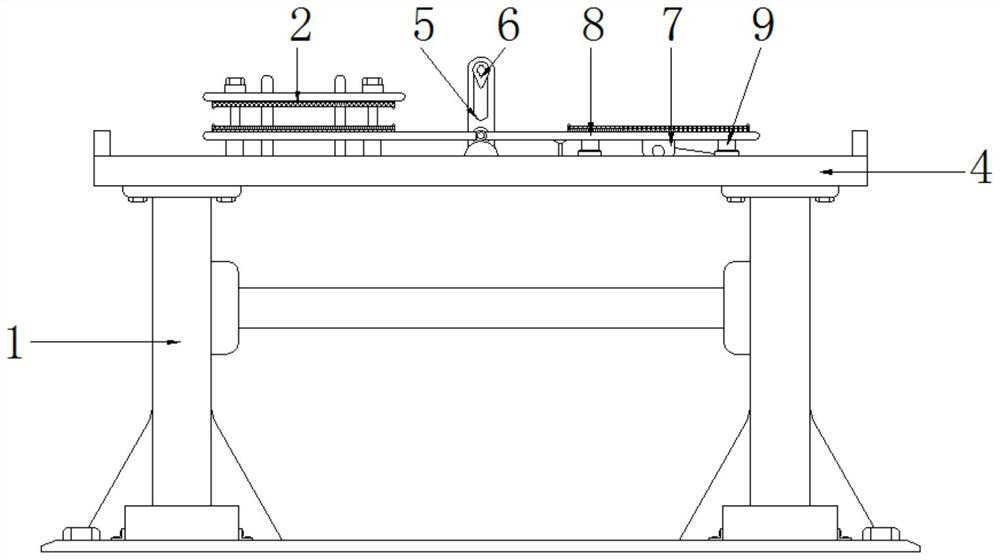

Rectangular steel pipe bending equipment

ActiveCN111644496APrecise control of bending anglesAutomatic and efficient bendingMetal-working feeding devicesPositioning devicesGear wheelClassical mechanics

The invention relates to bending equipment, in particular to rectangular steel pipe bending equipment. The technical problem needing to be solved by the invention is to provide rectangular steel pipebending equipment which can precisely control the bending angle and can automatically and efficiently bend a steel pipe. The rectangular steel pipe bending equipment comprises a bottom plate which isin a cuboid shape, a workbench arranged at the top of the bottom plate, a fixing block arranged on one side of the top of the workbench, and a guide plate arranged on the side, away from the fixing block, of the top of the workbench. The rectangular steel pipe bending equipment achieves the effects of being capable of precisely controlling the bending angle, and automatically and efficiently bending a steel pipe, a quarter of the circle of a tooth lacking gear is provided with teeth, thus, a first gear and a rotary shaft can rotate only 90 degrees, a supporting block and a pressing rod can bend the rectangular steel pipe only 90 degrees, and the bending angle of the steel pipe can be effectively controlled.

Owner:郓城鸿源专用车有限公司

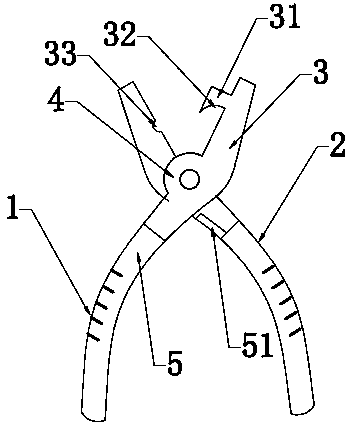

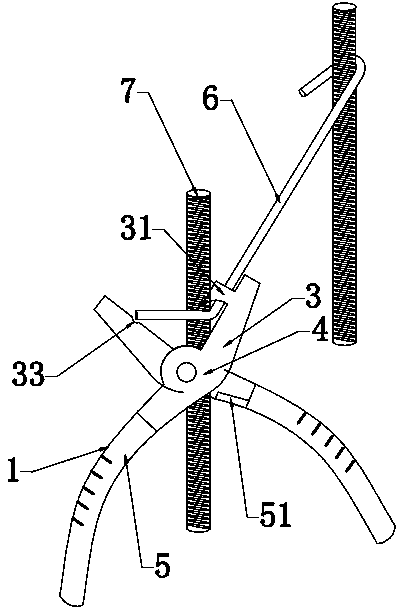

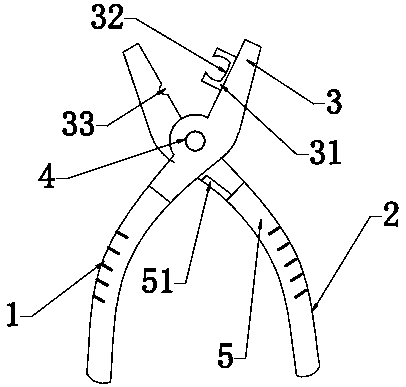

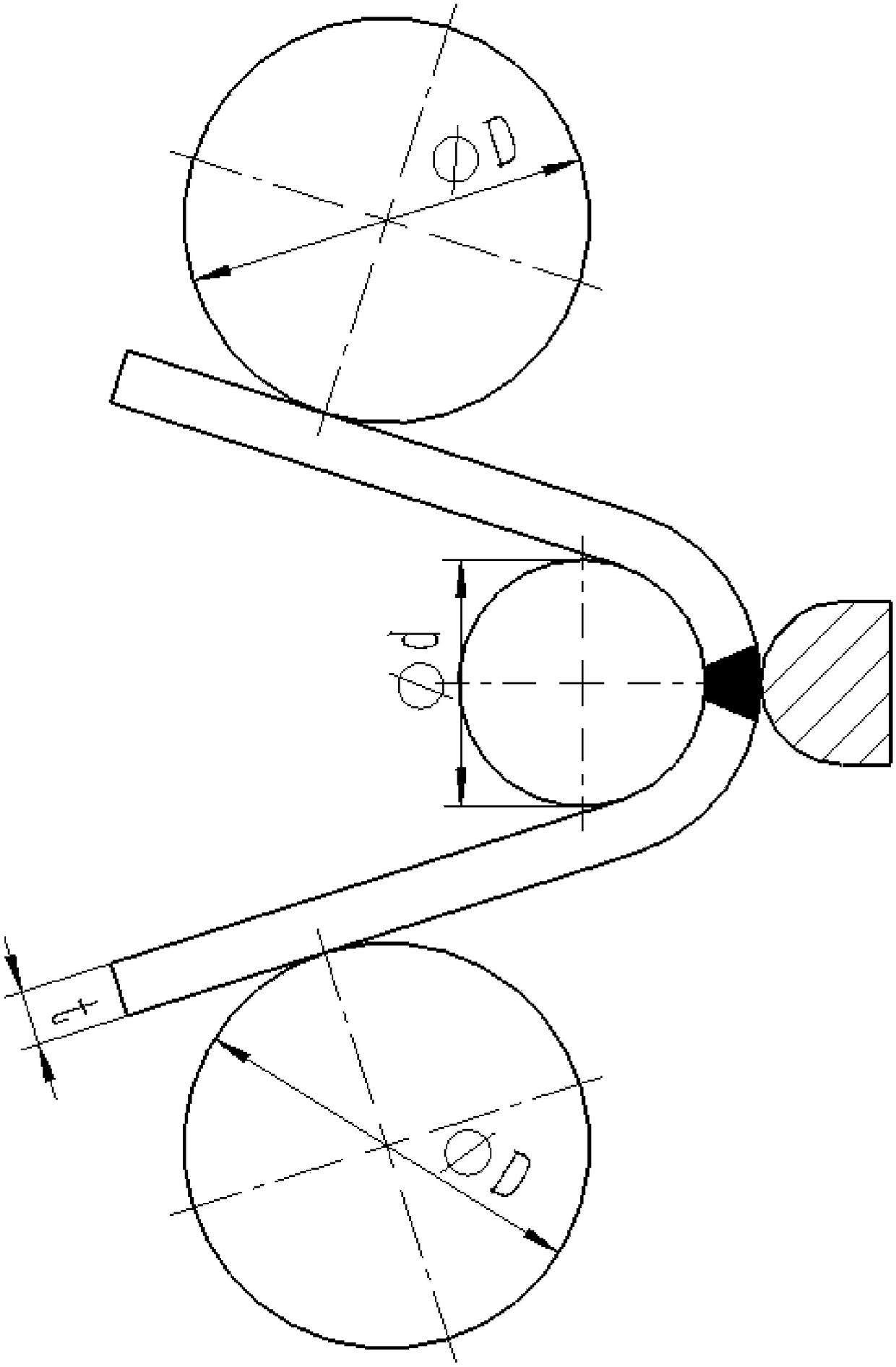

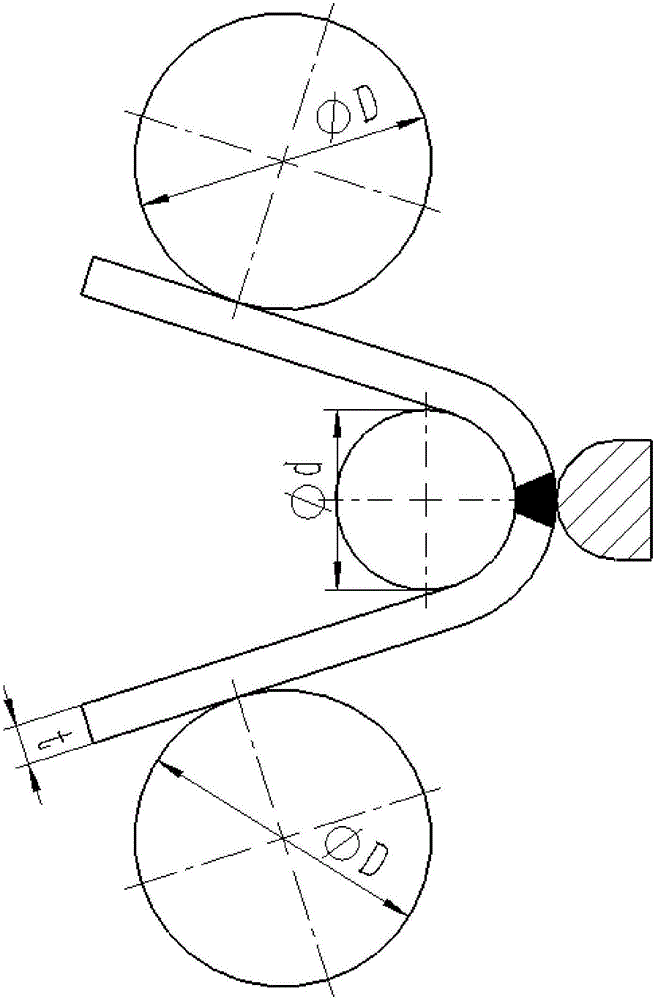

Pliers facilitating bending of rebars

The invention discloses a pliers facilitating bending of rebars. The pliers comprise a main plier part and a plier part arranged in mutual intersection and rotatably fixed together, and each of the main plier part and the auxiliary plier part is composed of a plier head, a connection portion and a handle. The pliers are characterized in that the inner side of the plier head of the main plier part is provided with a fastening portion used for holding a longitudinal bar, the upper end of the handle of the auxiliary plier part is provided with a limiter protrusion that is higher than the upper end of the handle of the main plier part and the connection portion, a gap is formed between the end of the limiter protrusion close to the connection portion and the connection portion when the corresponding handle is not moved, and the limiter protrusion abuts to the adjacent handle and stops rotate after the handle is turned by a certain angle. The pliers obtained by the invention have the advantages of simple structure, bending effectiveness and high bending precision.

Owner:CHINA METALLURGICAL CONSTR ENG GRP

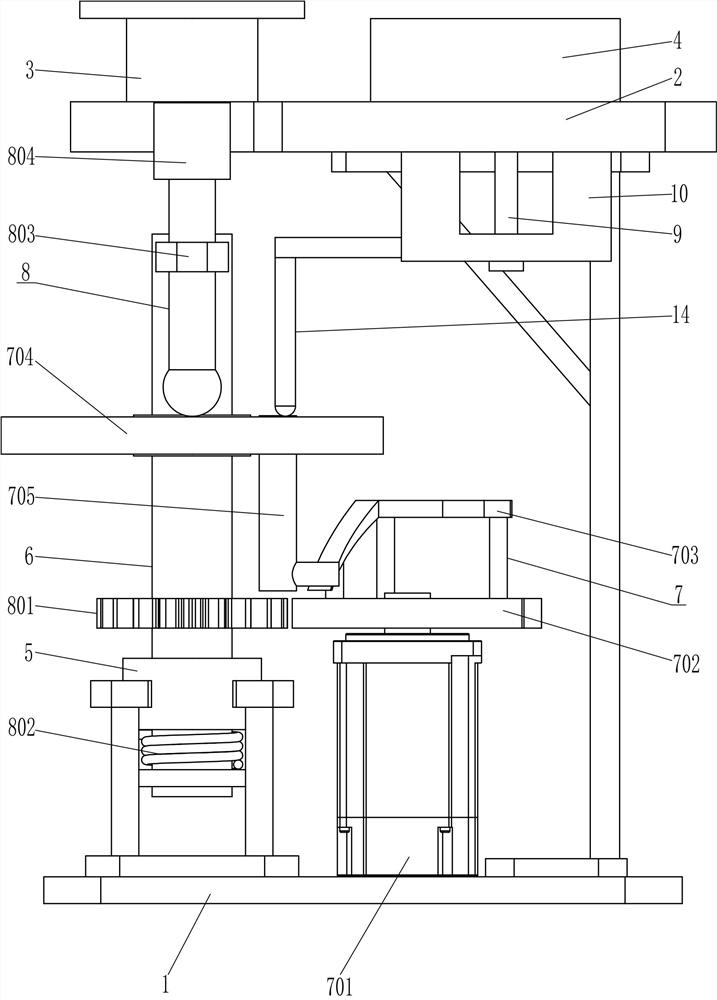

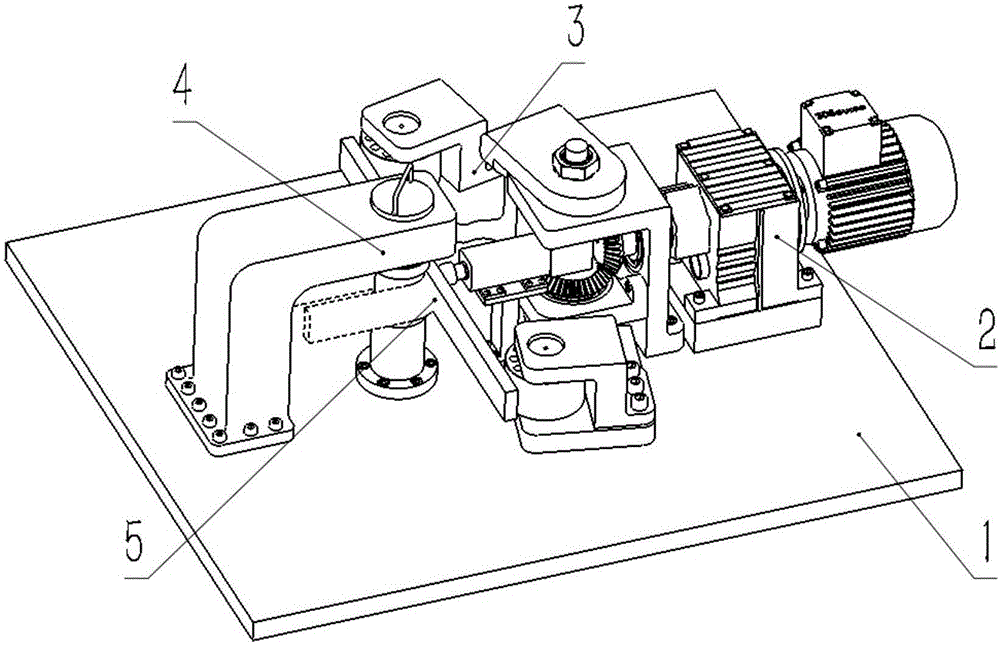

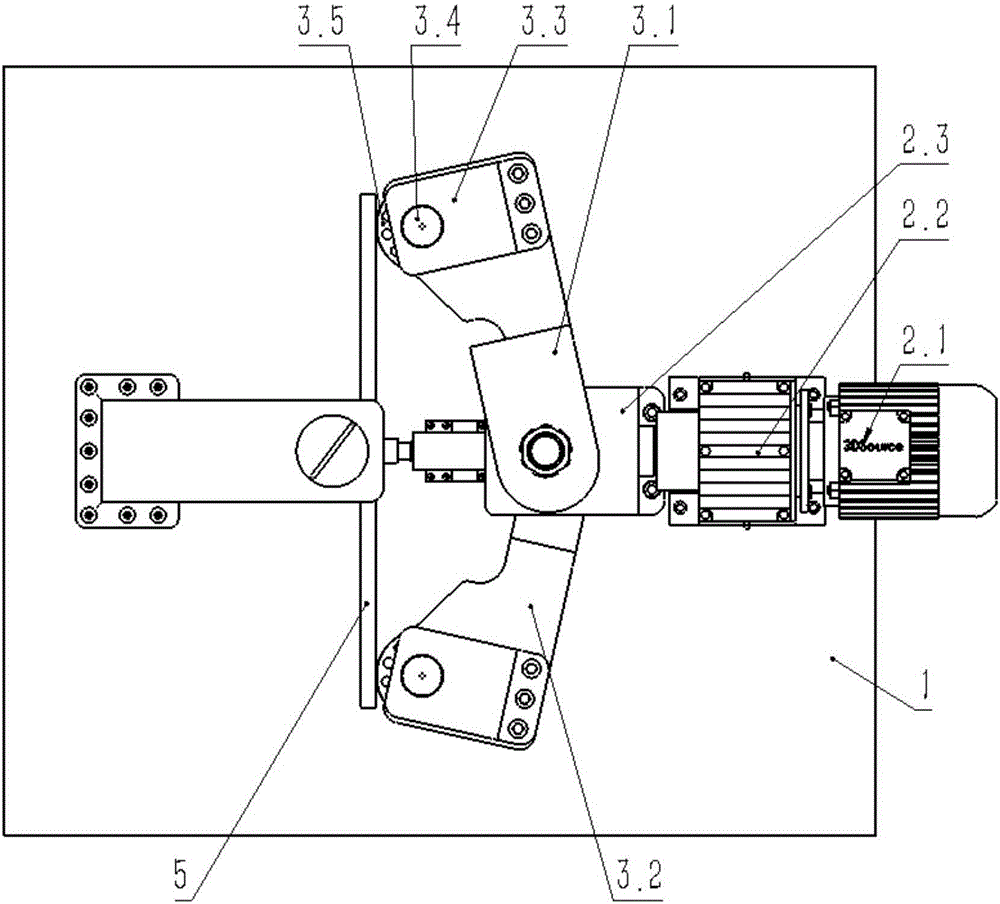

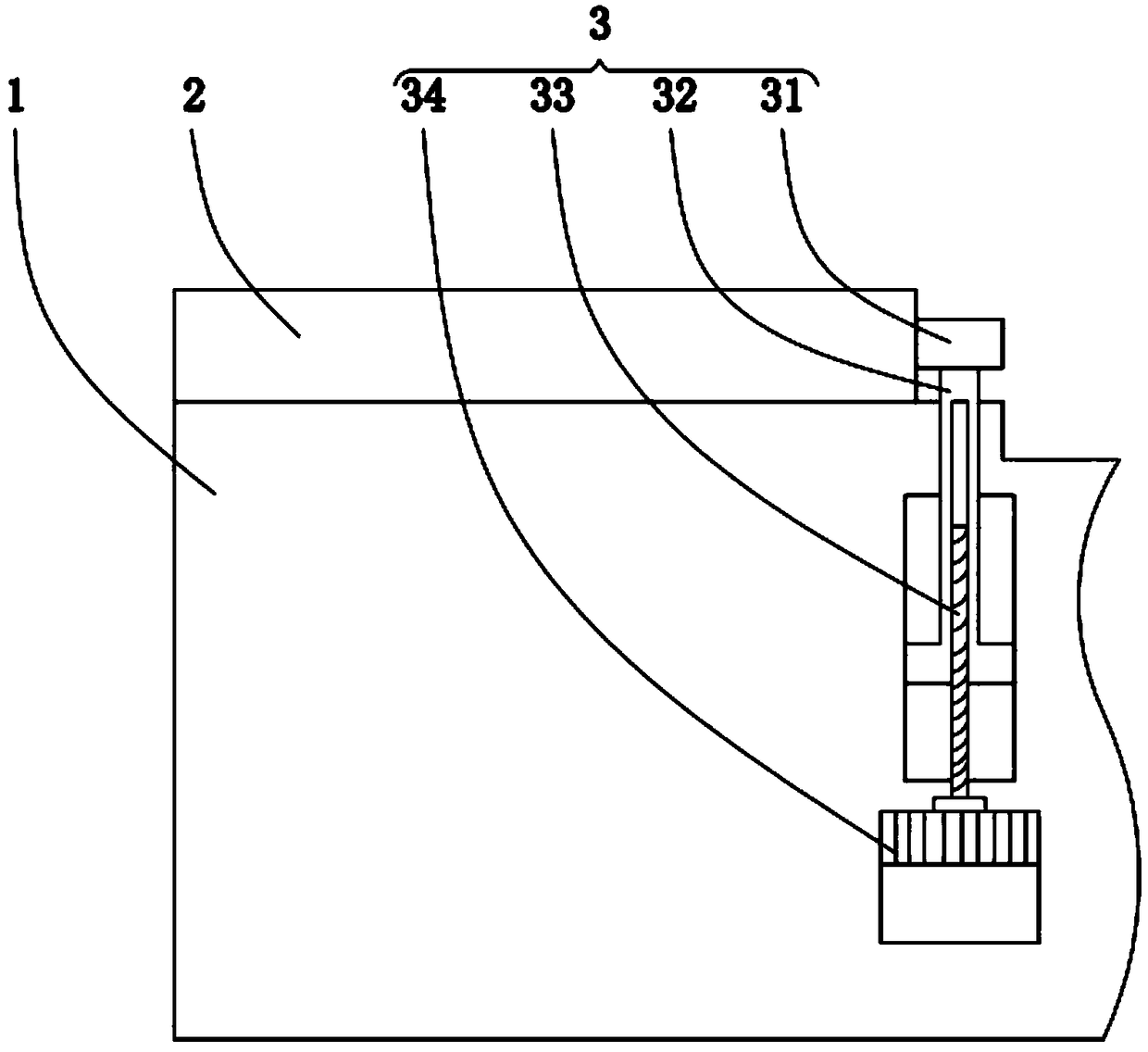

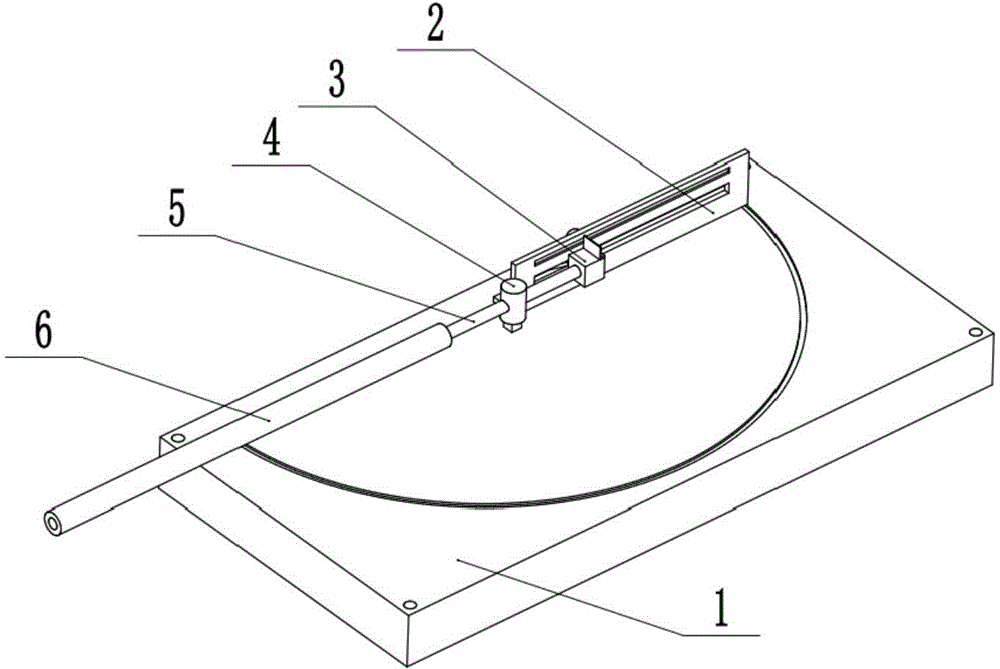

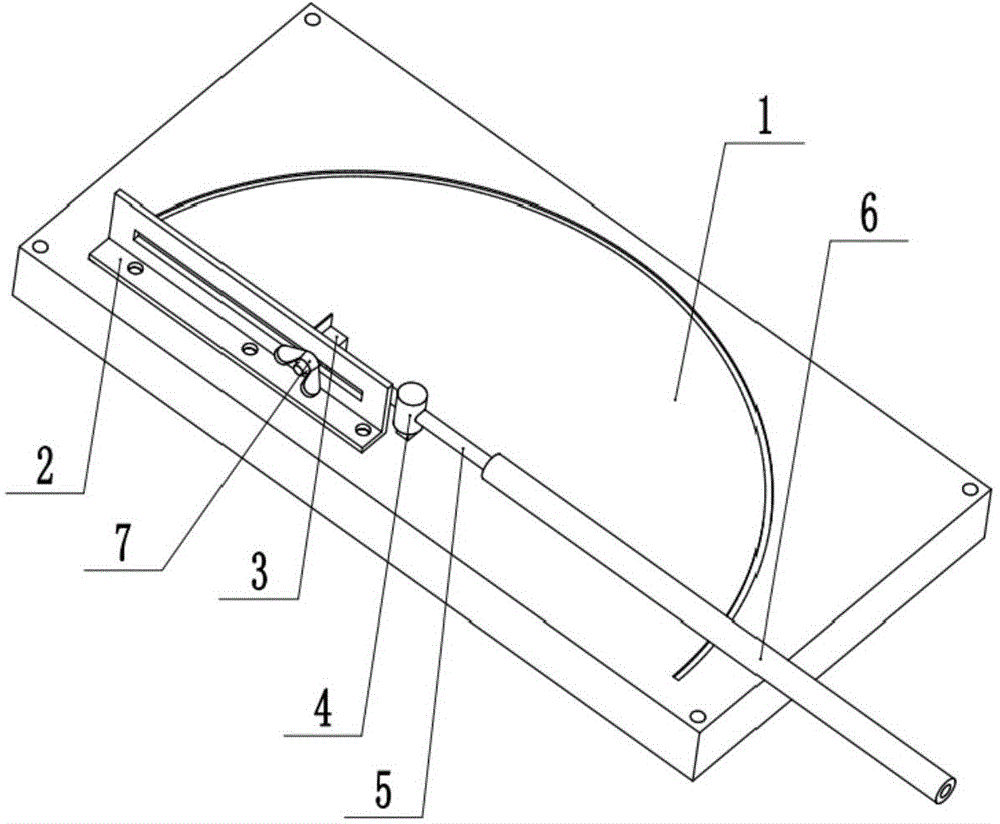

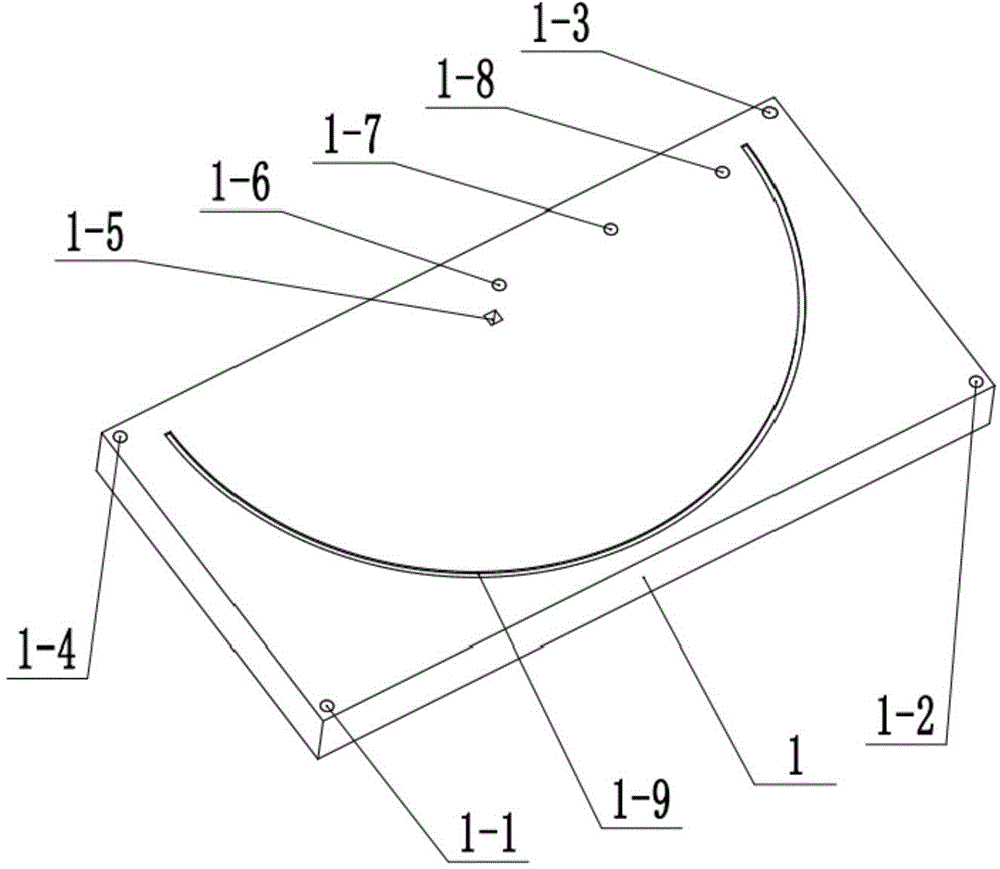

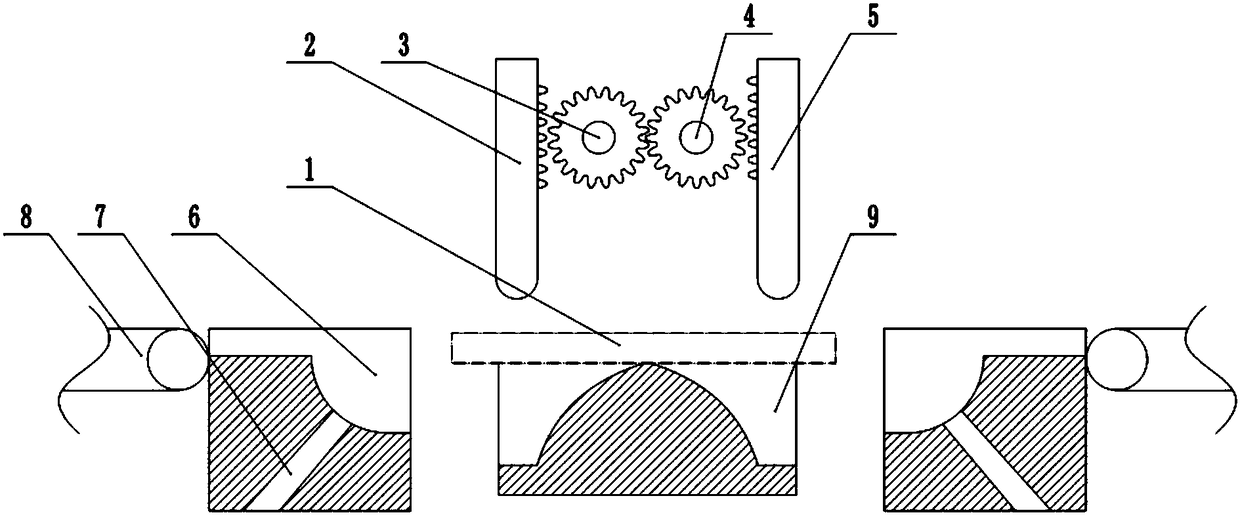

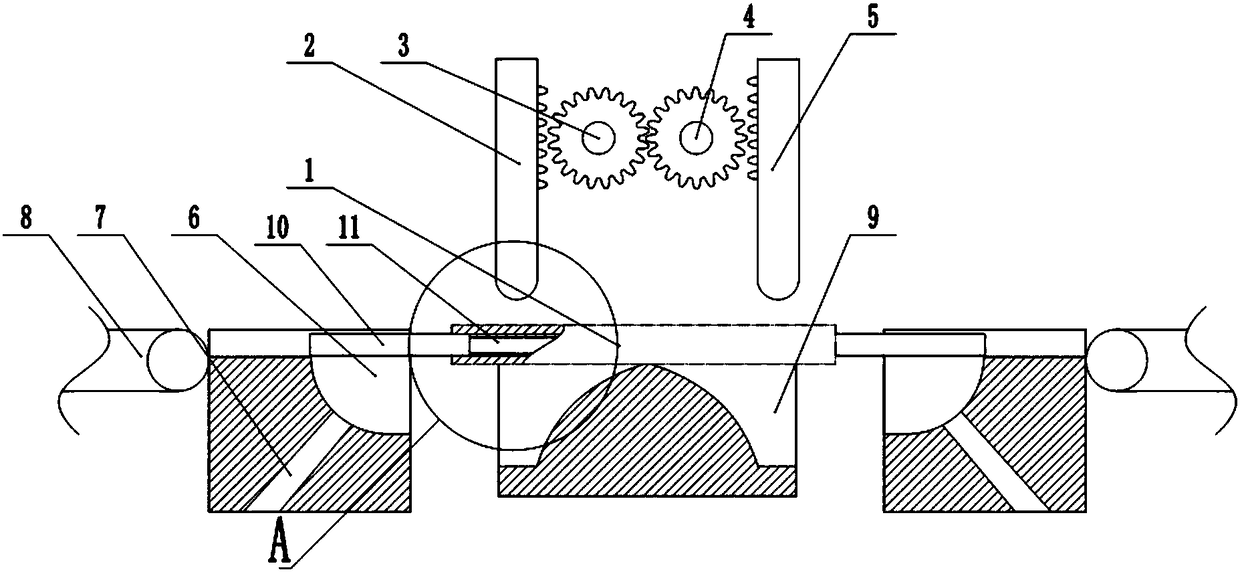

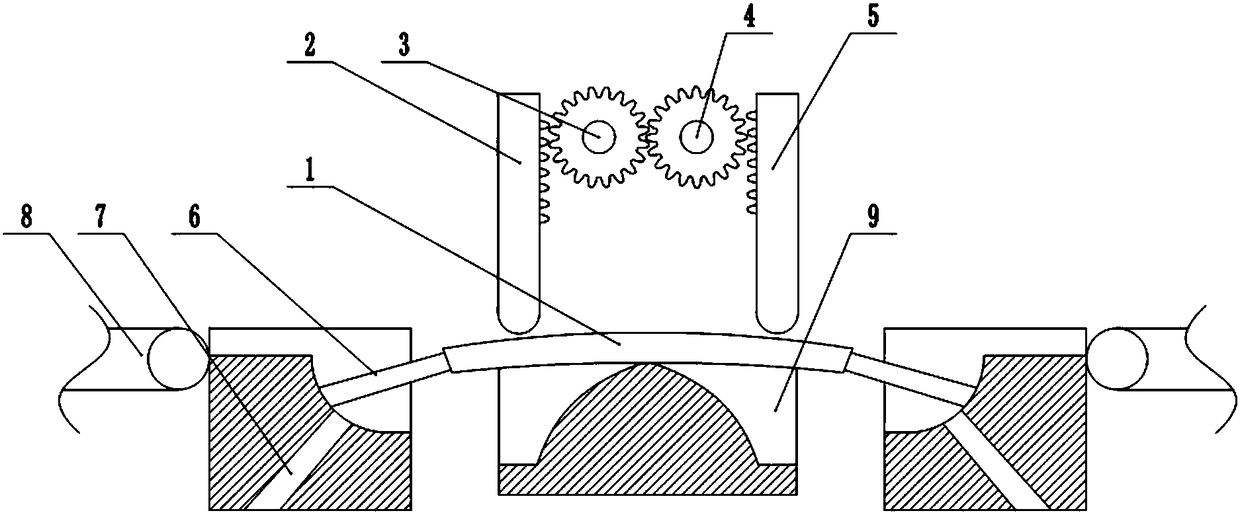

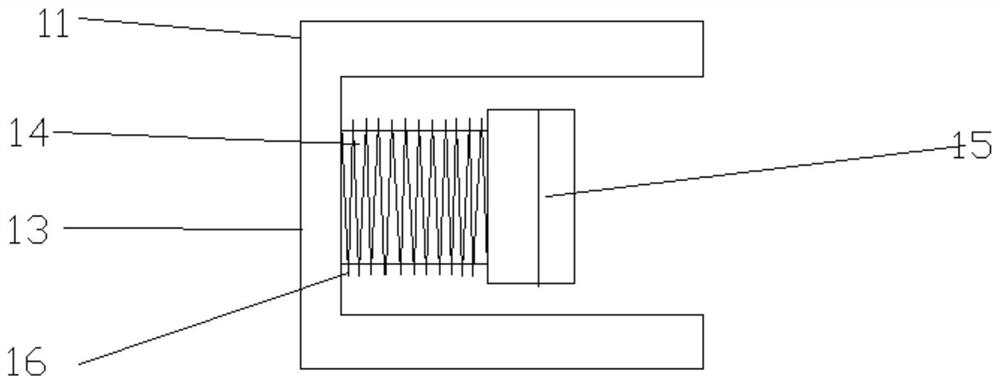

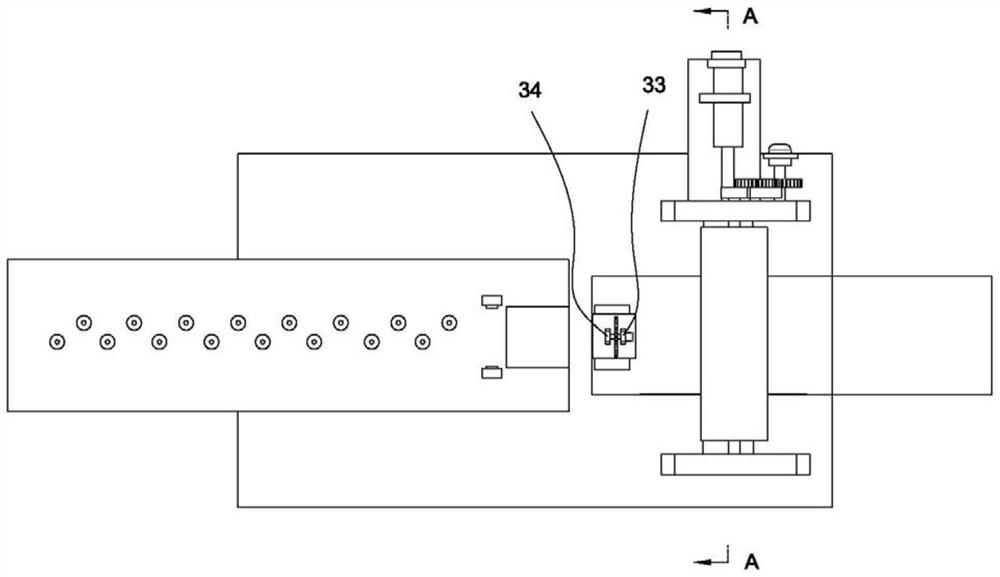

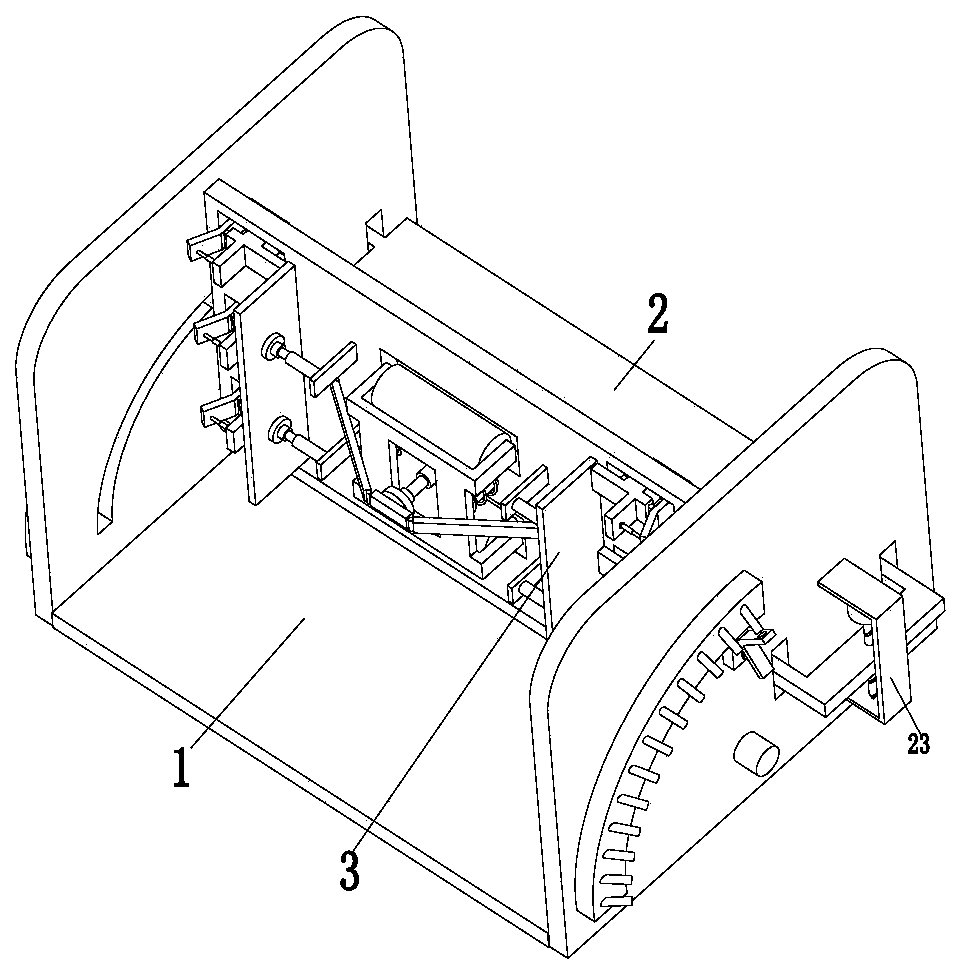

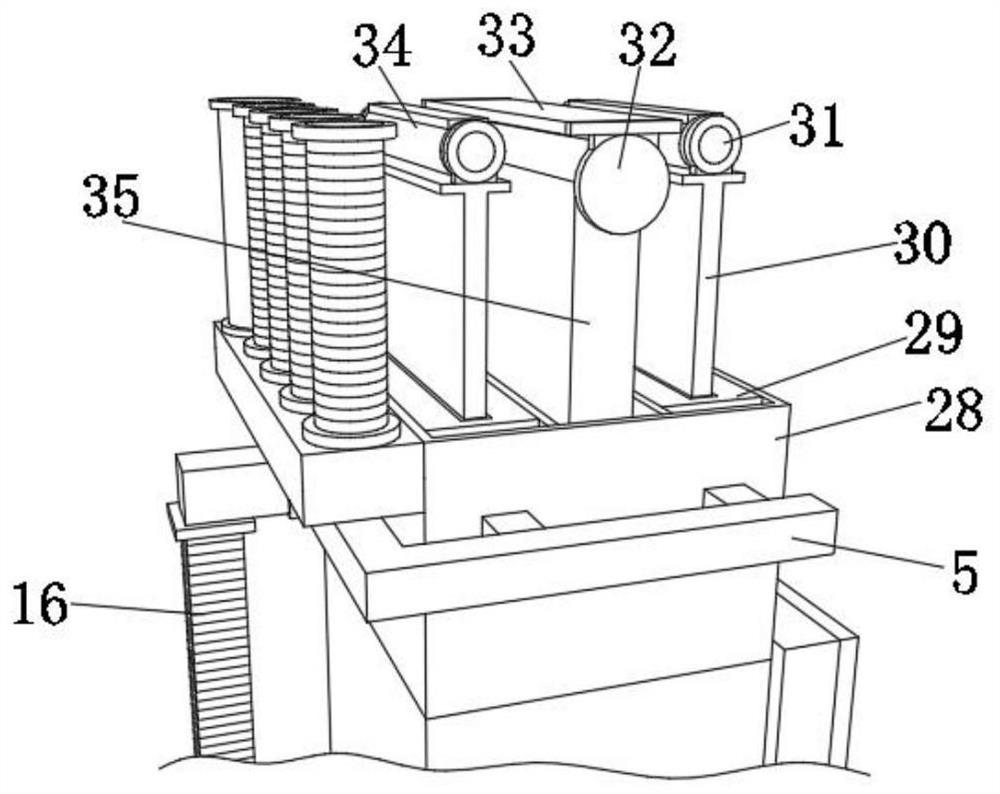

A three-roll bending test device with a detection plate weld performance

ActiveCN106053252BControl bend angleMaterial strength using steady bending forcesElectric machineEngineering

The invention discloses a three-roller bending test apparatus with capability of detecting a weld of a sheet material. The apparatus comprises a workbench, which is equipped with an electric machine. An output shaft of the electric machine is in fixed connection with a first bevel gear. The first bevel gear is engage with a second bevel gear and a third bevel gear, respectively, and is installed on a first bevel gear mounting base through a first bearing. The top end of the first bevel gear mounting base is equipped with a second bevel gear through a second bearing. A second bevel gear mounting base is installed on the first bevel gear mounting base and supports the third bevel gear through a third bearing. In the apparatus, the electric machine drives the first bevel gear to rotate, so that the second and third bevel gears are driven to rotate, and then first and second active rollers are driven to move. Through cooperation of a fixed roller with the first and second active rollers, the sheet material is bent. Through an angle sensor arranged on the top part of the first bevel gear, the bending angle of the sheet material can be accurately controlled.

Owner:江苏华标检测研究院有限公司

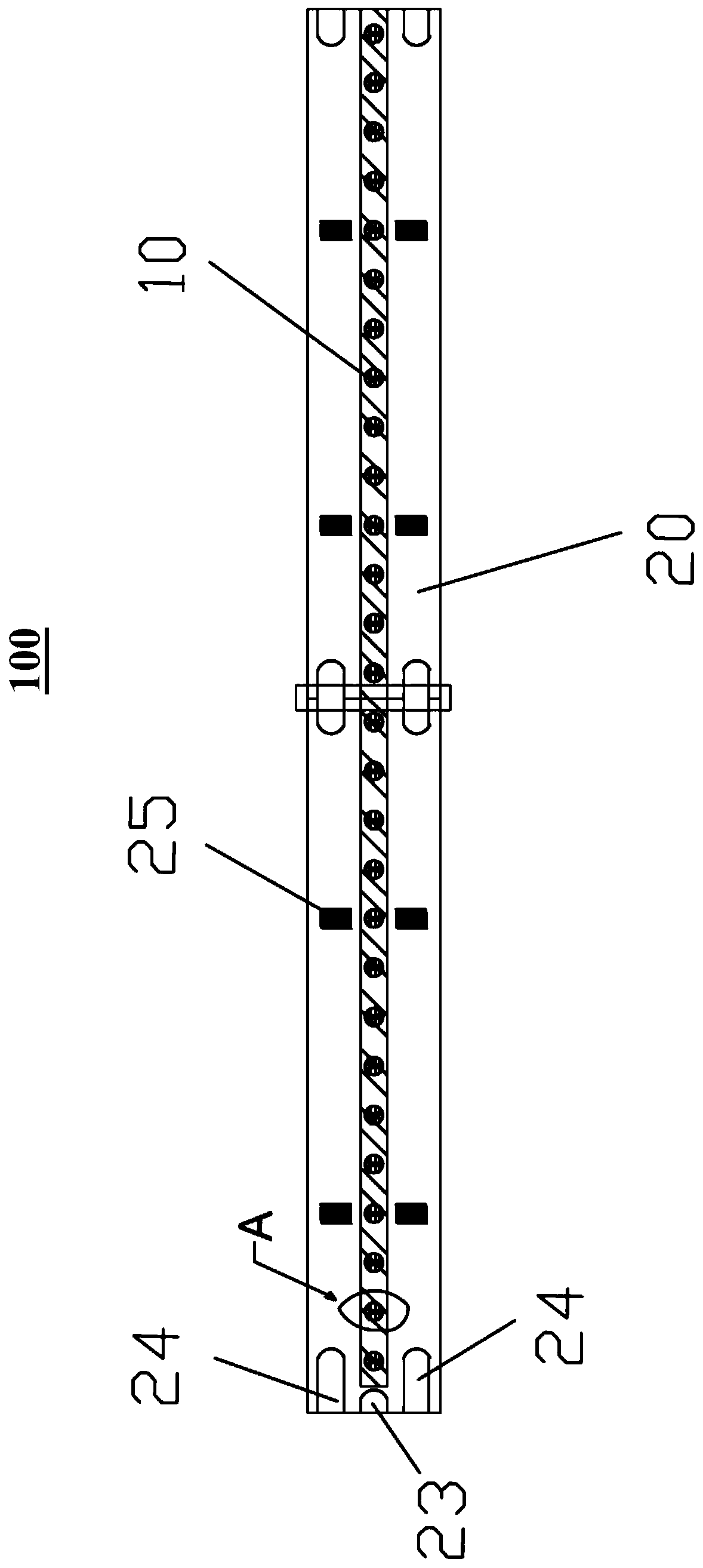

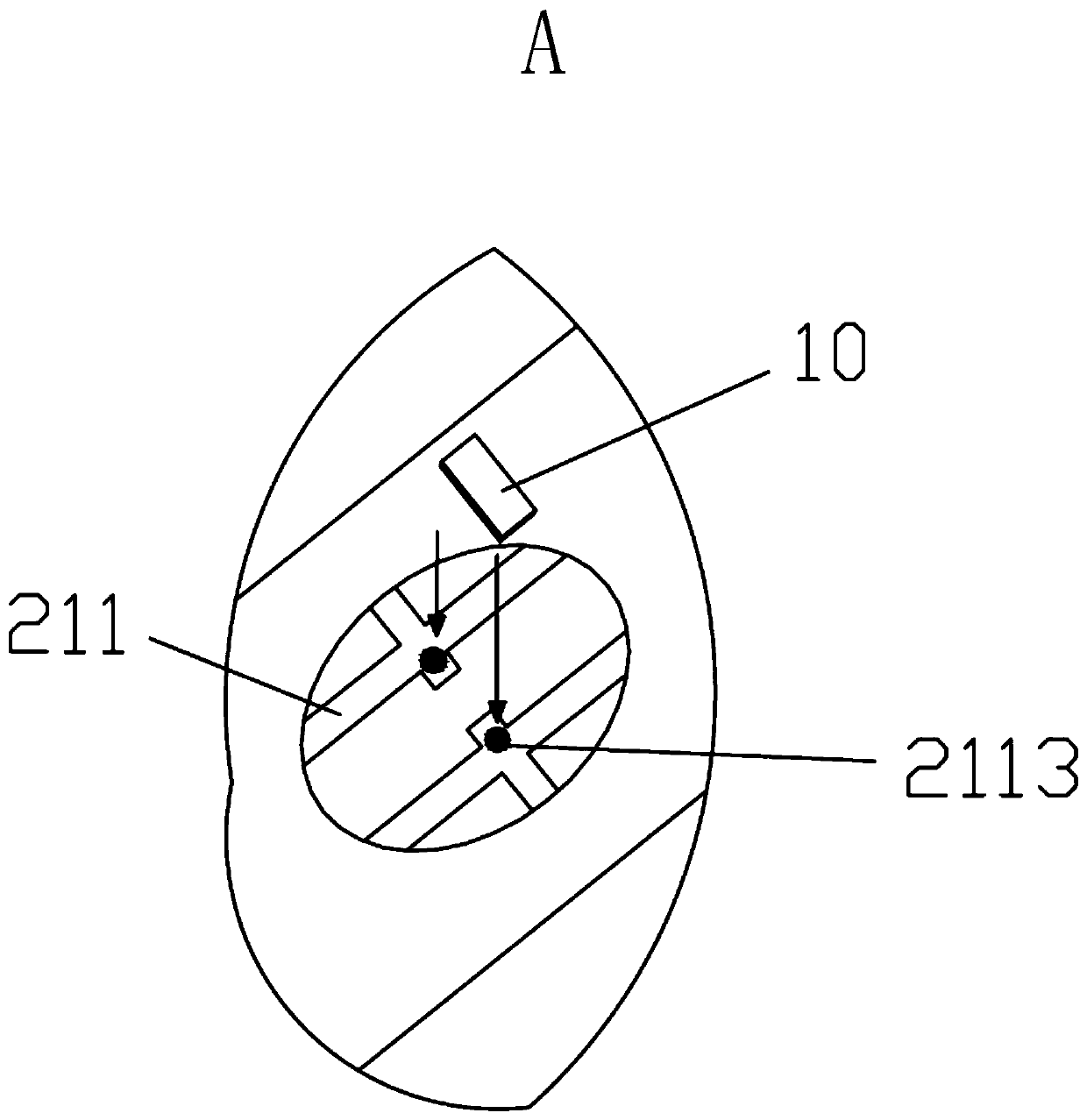

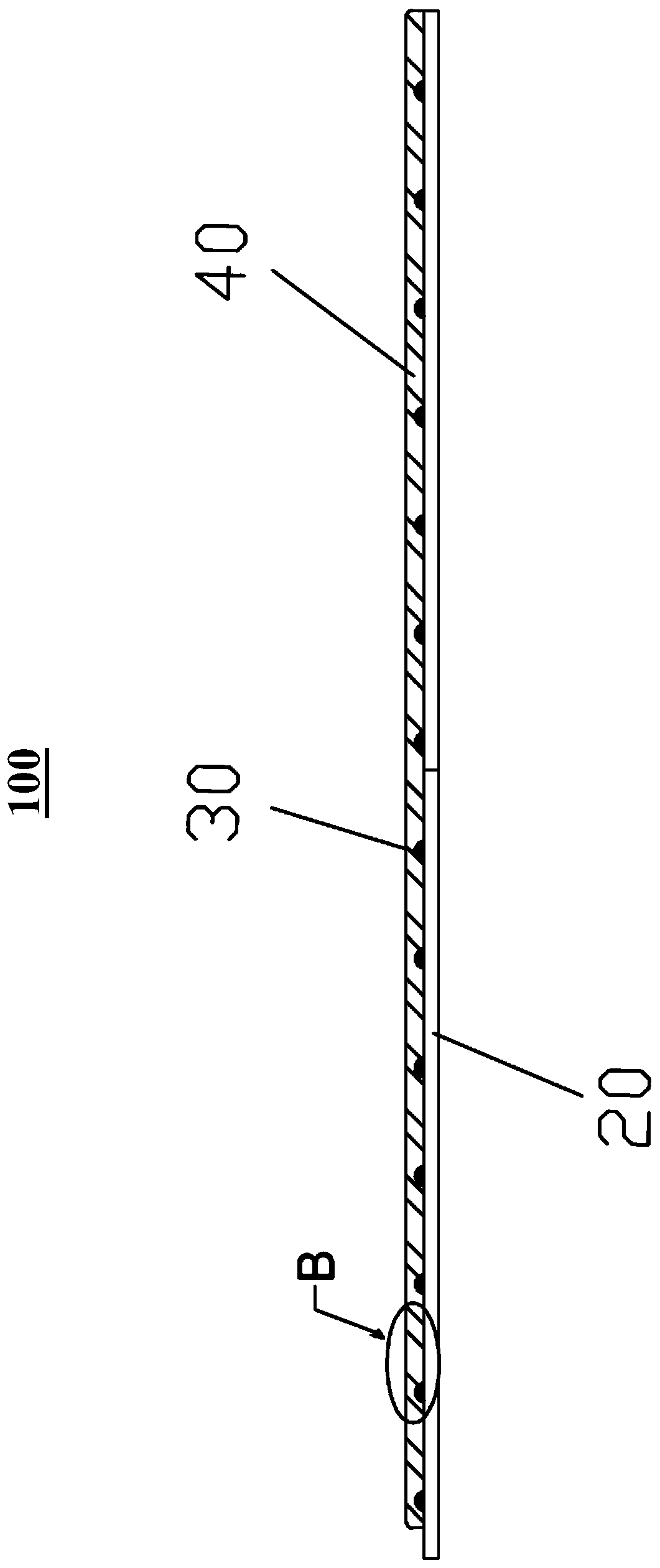

Color-temperature-variable flexible lamp strip with inverted LED chips

InactiveCN111076109APlay a supporting roleGood flexibilityElongate light sourcesElectric circuit arrangementsFlexible circuitsFluorescence

The invention discloses a color-temperature-variable flexible lamp strip with inverted LED chips. The flexible lamp strip comprises a plurality of flexible circuit board units and a plurality of LED light-emitting chips, the flexible circuit board units and the LED light-emitting chips extend in the length direction of the lamp strip, and the LED light-emitting chips are fixed to the flexible circuit board units in an inverted chip structure mode and covered with fluorescent glue with different color temperatures, so that the LED light-emitting chips have different color temperatures. The flexible circuit board unit comprises a circuit layer and a supporting layer, the circuit layer is provided with a plurality of wire structures, and the LED light-emitting chips are welded to the two oppositely-arranged wire structures so as to ensure reliable connection of the wire structures. The supporting layer is provided with a supporting structure so as to increase the flexibility of the flexible lamp strip when the flexible lamp strip is bent, so that the bending angle of the flexible circuit board unit is controlled, and the LED light-emitting chip cannot fall off due to excessive bendingof the flexible circuit board unit.

Owner:SHENZHEN WEIERSHENG PHOTOELECTRIC CO LTD

Three-roller bending test apparatus with capability of detecting weld of sheet material

ActiveCN106053252AAccurate bending angleControl bend angleMaterial strength using steady bending forcesEngineeringWorkbench

The invention discloses a three-roller bending test apparatus with capability of detecting a weld of a sheet material. The apparatus comprises a workbench, which is equipped with an electric machine. An output shaft of the electric machine is in fixed connection with a first bevel gear. The first bevel gear is engage with a second bevel gear and a third bevel gear, respectively, and is installed on a first bevel gear mounting base through a first bearing. The top end of the first bevel gear mounting base is equipped with a second bevel gear through a second bearing. A second bevel gear mounting base is installed on the first bevel gear mounting base and supports the third bevel gear through a third bearing. In the apparatus, the electric machine drives the first bevel gear to rotate, so that the second and third bevel gears are driven to rotate, and then first and second active rollers are driven to move. Through cooperation of a fixed roller with the first and second active rollers, the sheet material is bent. Through an angle sensor arranged on the top part of the first bevel gear, the bending angle of the sheet material can be accurately controlled.

Owner:江苏华标检测研究院有限公司

Plastic board heating bending mechanism

Owner:安徽万安塑料制品有限公司

Electric portable bar connector bending hook bending device

The invention relates to an electric portable bar connector bending hook bending device. The electric portable bar connector bending hook bending device comprises an electric push rod and a pulling hook, wherein the pulling hook comprises a first pulling hook body and a second pulling hook body, one end of the first pulling hook body is connected to one end of the second pulling hook body, and thefirst pulling hook body is further connected to the electric push rod through a connecting plate and reciprocates in the radial direction of the electric push rod. According to the electric portablebar connector bending hook bending device, when the maximum stroke of the electric push rod is reached, the relative distance between the pulling hook and the top end of the push rod is adjusted to control the bending angle of a bar connector bending hook, and the molding quality is effectively ensured.

Owner:CHINA FIRST METALLURGICAL GROUP

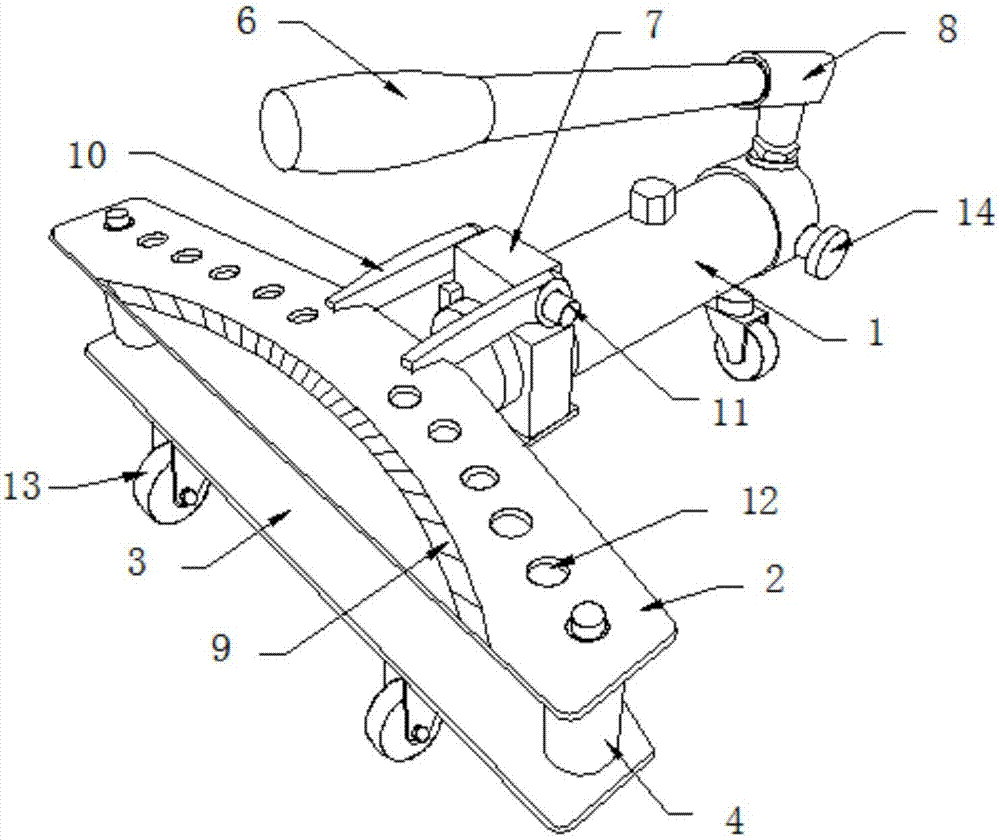

Hand-hydraulic pipe bender

InactiveCN107363131AReasonable structural designFlexible bending angleShaping toolsGoniometerEngineering

The invention discloses a manual hydraulic pipe bending machine, which comprises a hydraulic oil cylinder, an upper clamp, a lower clamp, a movable limiter, a pipe bending mold and a handle. One end of the hydraulic cylinder is provided with an upper clamp mounting seat, The other end of the hydraulic cylinder is provided with a handle mounting seat, and the lower clamping plate is connected to the underside of one end of the hydraulic cylinder located at the mounting seat of the upper clamping plate through bolts, and the upper surface of the upper clamping plate is provided with An angle ruler, a pair of connecting arms is provided on one side of the upper clamp, and a connecting shaft is provided on the connecting arm, and the connecting arm is connected with the mounting seat of the upper clamp through the connecting shaft, and the movable limiter is set The structure design of the present invention is reasonable, and the bending angle of the pipe can be controlled more flexibly by adopting the manual operation mode to bend the pipe, and the operation is simple and convenient. At the same time, the added angle ruler design can adjust the angle of the pipe Processing is more precise.

Owner:WUXI WELL ELECTRO HYDRAULIC EQUIP CO LTD

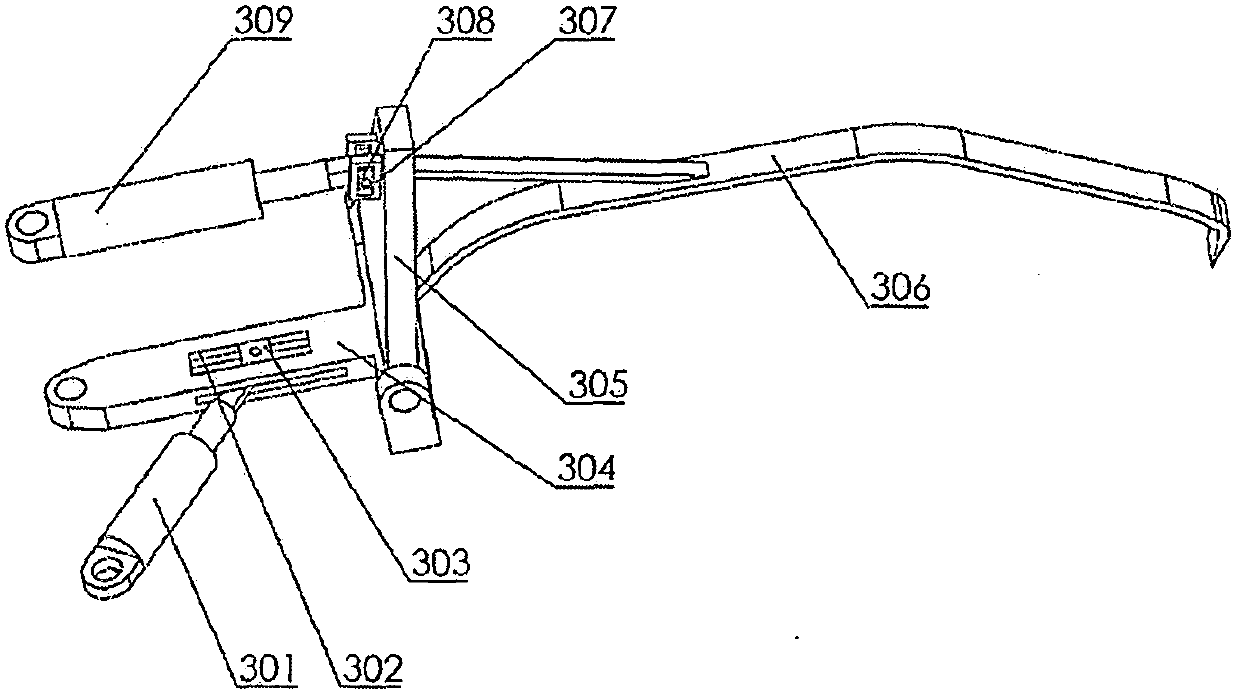

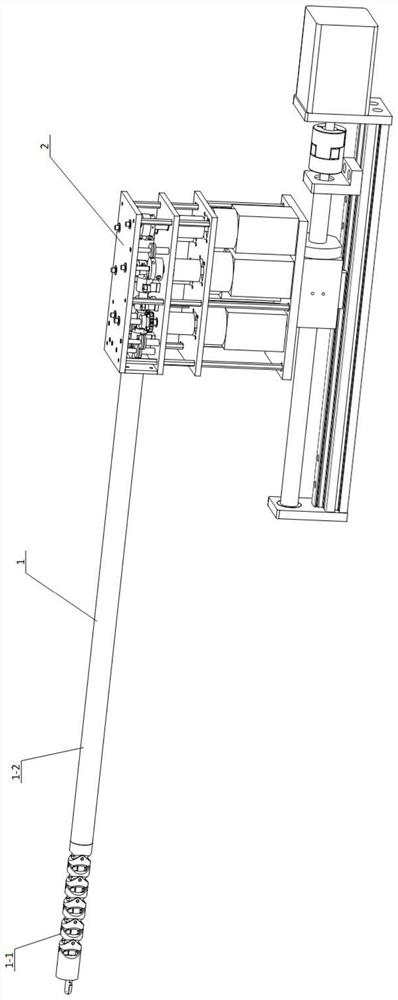

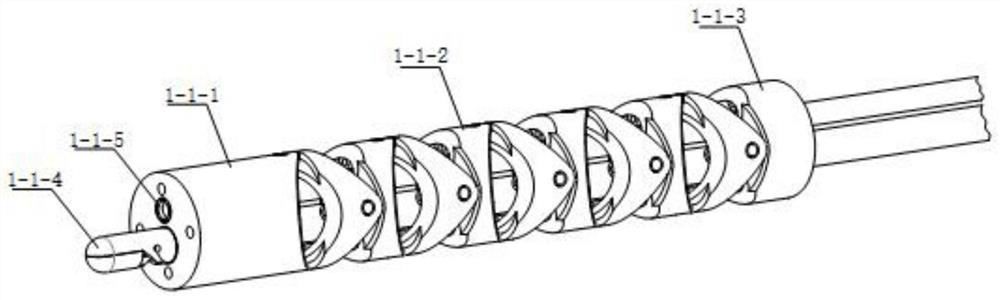

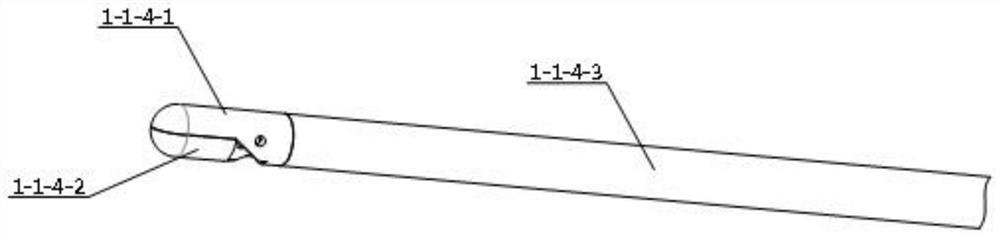

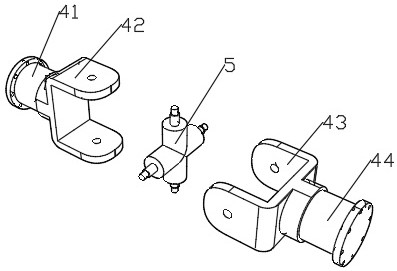

Flexible surgical robot

PendingCN114631891AControl bend angleSurgical manipulatorsSurgical robotsSurgical ManipulationSurgical operation

The invention discloses a flexible surgical robot. The flexible surgical robot comprises a flexible execution device and a transmission device. The flexible execution device comprises a snakelike joint string and an execution instrument. The snakelike joint string comprises at least three joints which are sequentially hinged end to end, and the rotating axis of the hinged position comprises a first axis and a second axis perpendicular to the first axis. The joints comprise the head joint, the tail joint and a plurality of middle joints located between the head joint and the tail joint, and the execution instrument is connected with the head joint. The transmission device comprises a first transmission assembly and a second transmission assembly. Compared with the prior art, the flexible robot disclosed by the invention can adapt to complex unstructured environments such as narrow and crowded body of a patient so as to help a doctor to better perform related surgical operations.

Owner:JILIN UNIV

Steel element bending device

The invention relates to a steel element bending device which comprises a base, a length scale plate, a slippage block, a bending column, a push rod and a butterfly nut. The length scale plate is fixed to the base, one end of the slippage block is a threaded column, a blind hole for fixing the end of a steel element is formed in the other end of the slippage block, and the threaded column is fixed to the length scale plate through the butterfly nut. The base portion of the bending column is fixed to the base, and a through hole for the steel element to penetrate through is formed in the head portion. The push rod is a hollow rod, one end of the steel element penetrates through the bending column and is fixed in the blind hole formed in the slippage block, the other end of the steel element is sleeved with the push rod, and the steel element is bent by turning the push rod under the effect of the bending column. The steel element bending device can adjust the length of the portion required to be bent of the steel element, can control the bending angle of the steel element and is convenient and practical to use.

Owner:GUANGXI UNIV

Anti-dislocation angle-adjustable bending device for steel plate production

ActiveCN111167904AInhibition biasImprove practicalityMetal-working feeding devicesPositioning devicesButt jointClassical mechanics

The invention discloses an-dislocation angle-adjustable bending device for steel plate production. The anti-dislocation angle-adjustable bending device comprises a base body, a hydraulic rod, a butt joint pressing head and an electric cutter, the hydraulic rod is installed at the middle end of the base body in a penetrating mode, the output end of the hydraulic rod is rotationally connected with the butt joint pressing head, the outer end of the butt joint pressing head is fixedly connected with a traction rope, the traction rope is connected with the inner surface of the base body, a connecting shaft is rotationally connected to the outer surface of the base body, a lower limiting block is fixedly connected to the outer surface of the connecting shaft, a first sliding groove is formed inthe outer surface of the base body, and a reset spring is fixedly connected to the inner surface of the first sliding groove. According to the anti-dislocation angle-adjustable bending device for steel plate production, a butt joint catch wheel is driven by a handheld threaded rod to perform adjustment and control on up and down positions along the upper end of the base body, so that changing theheight position of the butt joint catch wheel is carried out, and the ejection height of a butt joint pressing head is controlled; and therefore, conveniently changing the bending angle of a contact workpiece can be carried out.

Owner:绍兴市卓诚新材料有限公司

Exhaust pipe machining device

The invention belongs to the field of automobile part machining, and particularly discloses an exhaust pipe machining device. The device comprises a machine frame, wherein a workbench is arranged on the machine frame, a placing groove is formed in the upper surface of the workbench, and the bottom of the containing groove is arc-shaped; bent parts are symmetrically arranged on the two sides of thecontaining groove in the machine frame, the bending parts comprise sliding grooves arranged on the machine frame, the sliding grooves comprise horizontal sections and arc sections, and through holesare formed in the arc section; bending rods are slidably connected in the sliding grooves, the bending rods comprise flexible sections and rigid sections, storage cavities are formed in the flexible sections, and hydrochloric acid and sodium carbonate are correspondingly arranged in the storage cavities of the two flexible sections; discharging openings are formed in the flexible section; the lower pressing unit comprises a first gear and a second gear, the first gear is rotationally connected to the machine frame, and the second gear is meshed with the first gear; and the lower pressing unitfurther comprises a first rack and a second rack which are connected to the machine frame in a sliding mode, and stamping heads are arranged at the lower ends of the first rack and the second rack. Bythe adoption of the scheme of the exhaust pipe machining device, the problem that cross section shape distortion is easily caused when the exhaust pipe is bent is solved.

Owner:宁波高新区新柯保汽车科技有限公司

Intelligent bending equipment for hardware machining and manufacturing

PendingCN114523011AControl Bend AngleEasy to adjustMetal-working feeding devicesPositioning devicesStructural engineeringMechanical engineering

The invention relates to the technical field of hardware machining production, in particular to intelligent bending equipment for hardware machining and manufacturing, the intelligent bending equipment comprises a rack and a bending mechanism, the bending mechanism comprises a clamping arm, a driving assembly, a supporting wheel, a positioning assembly, a clamping assembly and an adjusting assembly, and hardware is placed on the rack; the hardware is positioned through the positioning assembly, the hardware is pushed to move on the positioning assembly so that the hardware can move to the position between the supporting wheel and the clamping arm, the hardware on the supporting wheel is clamped through the clamping assembly, and after clamping is completed, the clamping arm is driven by the driving assembly to rotate along the arc-shaped sliding rail; according to the hardware bending device, the clamping assembly is arranged on the supporting wheel, the hardware moves along the outer edge of the supporting wheel along with movement of the clamping arm, so that the hardware is bent through clamping of the clamping assembly and the supporting wheel, the swing angle of the clamping arm driven by the driving assembly is conveniently adjusted through the adjusting assembly, the bending angle of the hardware is accurately controlled, and the product quality is improved.

Owner:吴剑

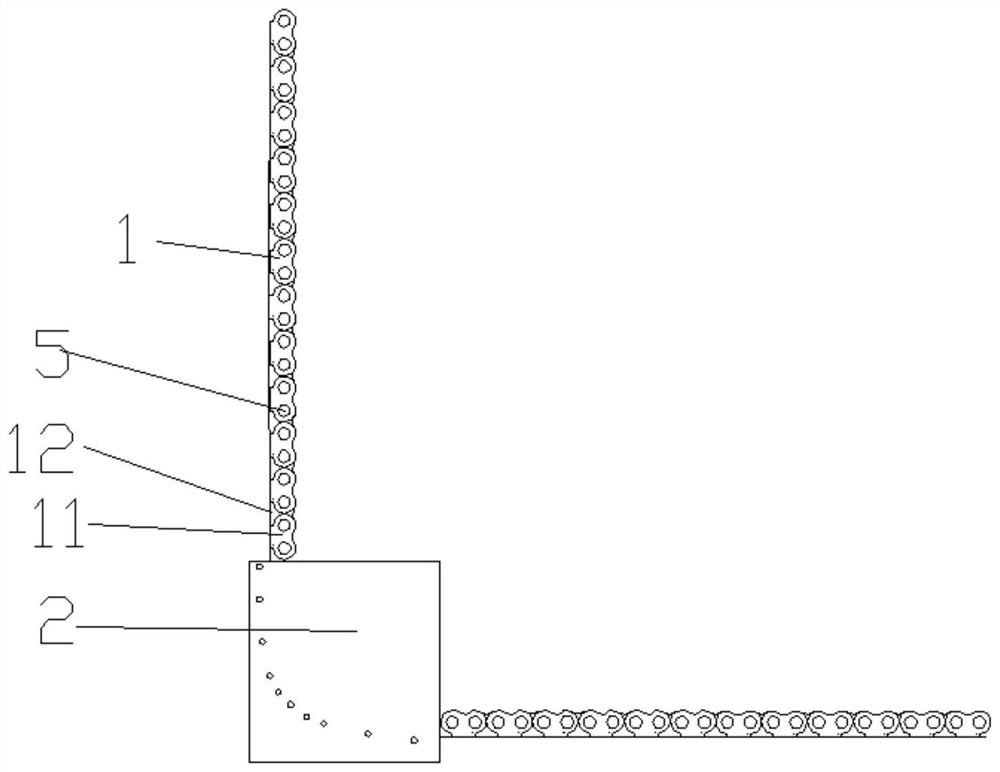

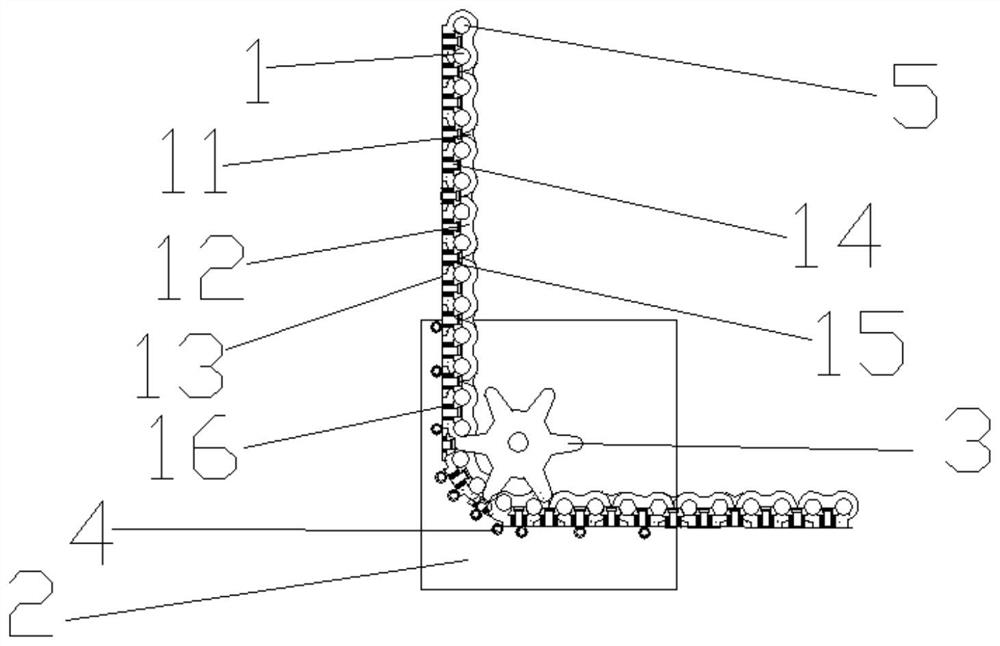

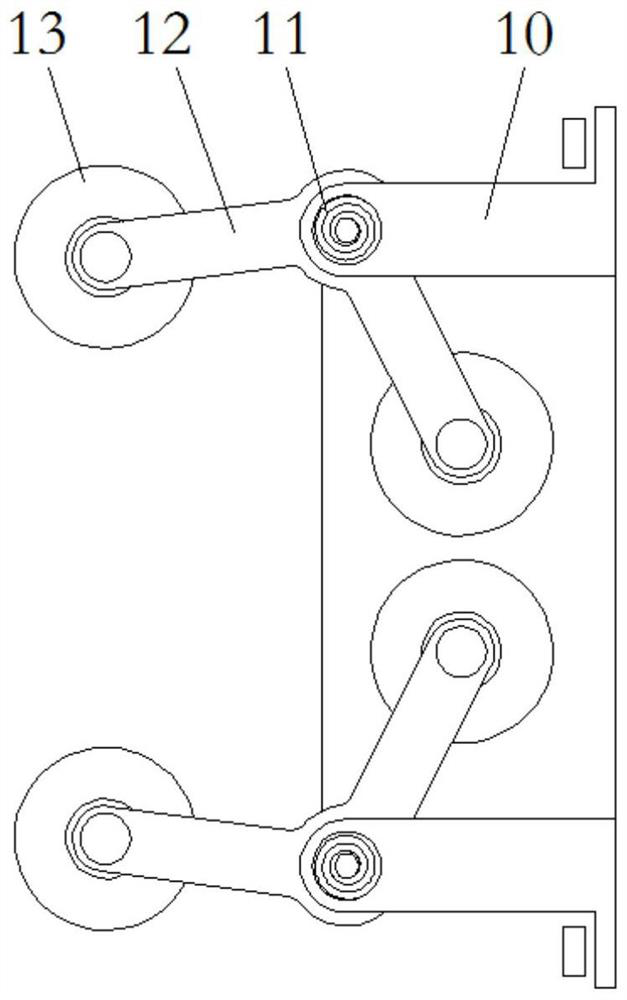

Transmission device of self-locking straight chain

The invention discloses a transmission device of a self-locking straight chain. The transmission device comprises the straight chain, a chain wheel and a machine case. The chain wheel is arranged in the machine case, the straight chain penetrates through the machine case, the straight chain comprises an outer chain plate and an inner chain plate, the outer chain plate and the inner chain plate are each provided with a flat plate, guide columns are arranged on the flat plates, one ends of the guide columns are connected with spring sleeves, the guide columns are sleeved with springs, and the spring sleeves are matched with pin shafts. According to the transmission device of the self-locking straight chain, the two-way anti-bending function is achieved on the straight chain through the flat plates and the guide columns, the springs and the spring sleeves arranged on the flat plates, bending and transmission of the straight chain are achieved through a chain wheel and guide wheels, the bending direction and the bending angle of the straight chain can be controlled, the anti-bending chain can conduct linear transmission or steering transmission, the structure is simple, mounting is convenient, and the application range and the transmission stability of the chain are greatly improved.

Owner:江苏省光华科技发展有限公司

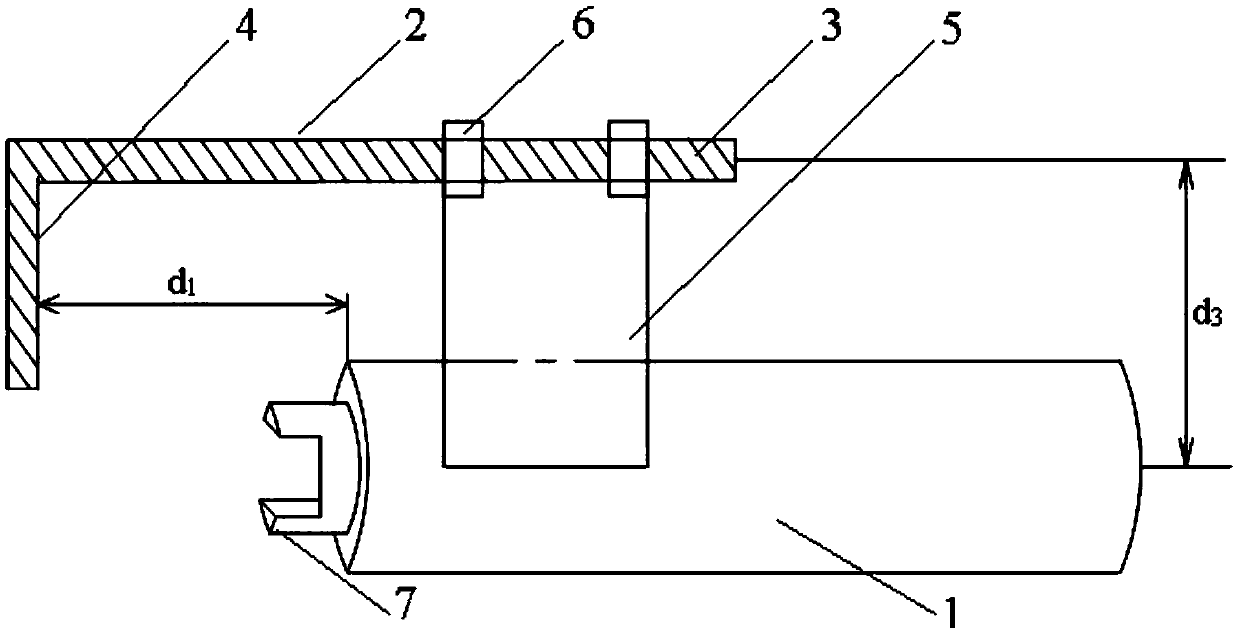

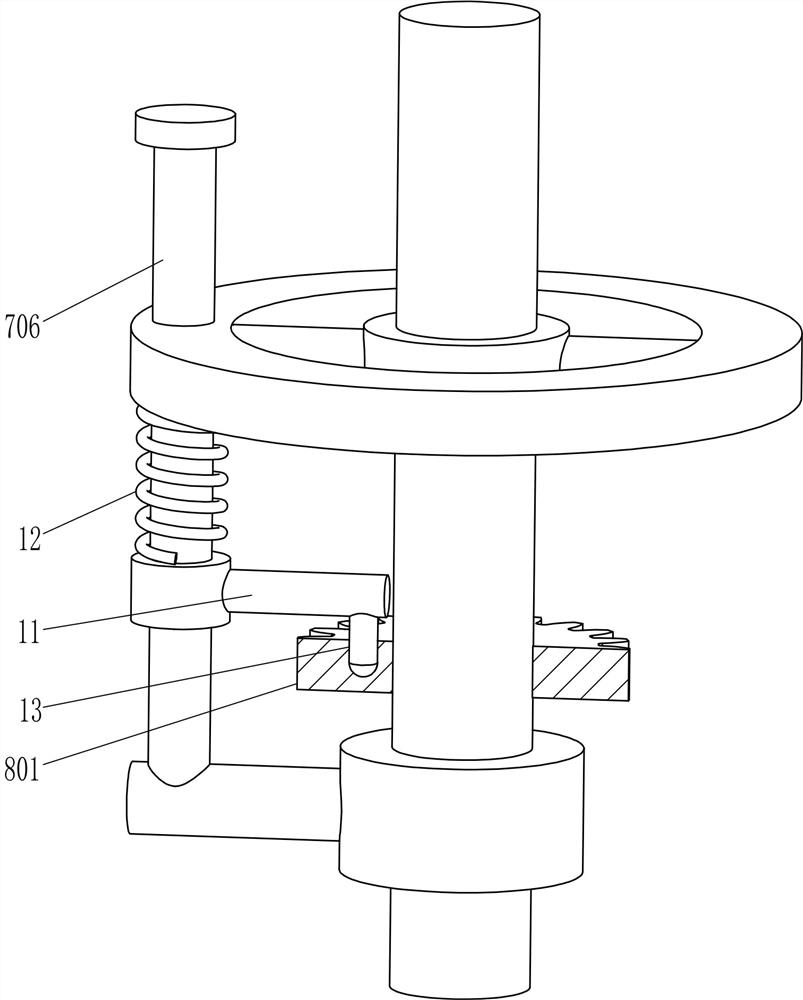

A kind of pipe bending die and bending pipe pressing method

The invention provides a pipe bending die. The pipe bending die includes an upper die and a lower die, wherein the upper die comprises an upper template, an elastic limiting push rod, an upper die oscillating rod and an upper die bending block, and the lower die comprises a lower template, a lower die seat, a pipe bending wheel and a lower die oscillating arm. The invention further provides a bent pipe pressing method. Through the pipe bending die and the bent pipe pressing method, a bent pipe with small deformation can be efficiently obtained by bending; a pipe of which the bending angles at the two ends have the requirements of obverse bending and then reverse bending can be compressed by two working procedures by means of cooperation of up-and-down swing of the lower die oscillating arm with the upper die bending block.

Owner:柳州市楷都汽车零部件有限公司

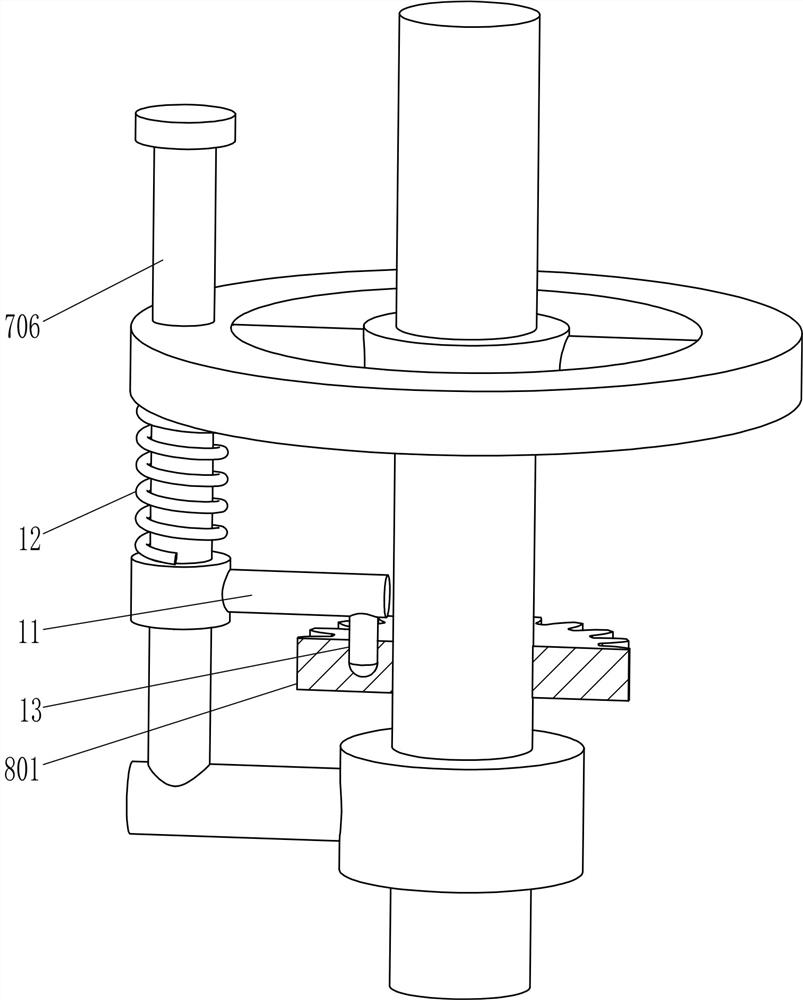

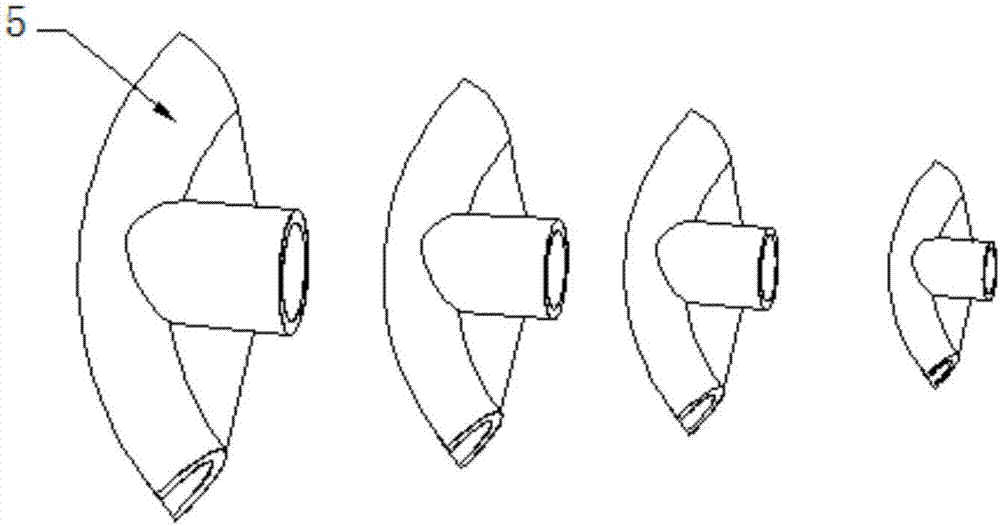

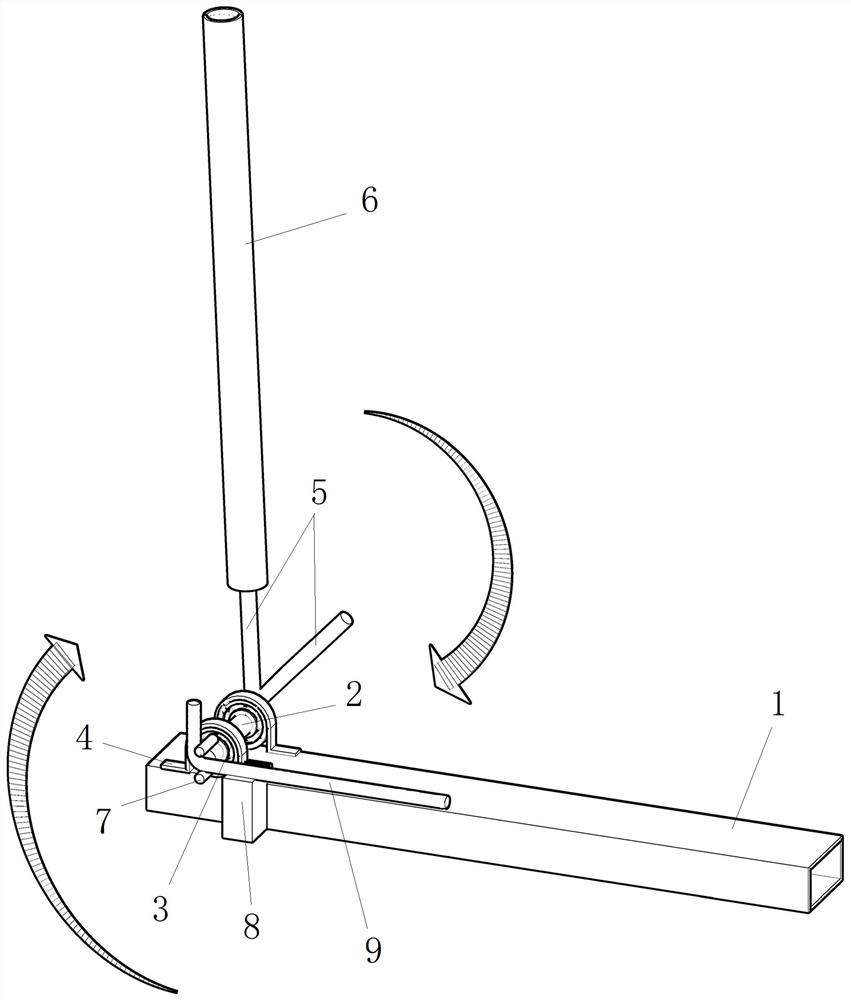

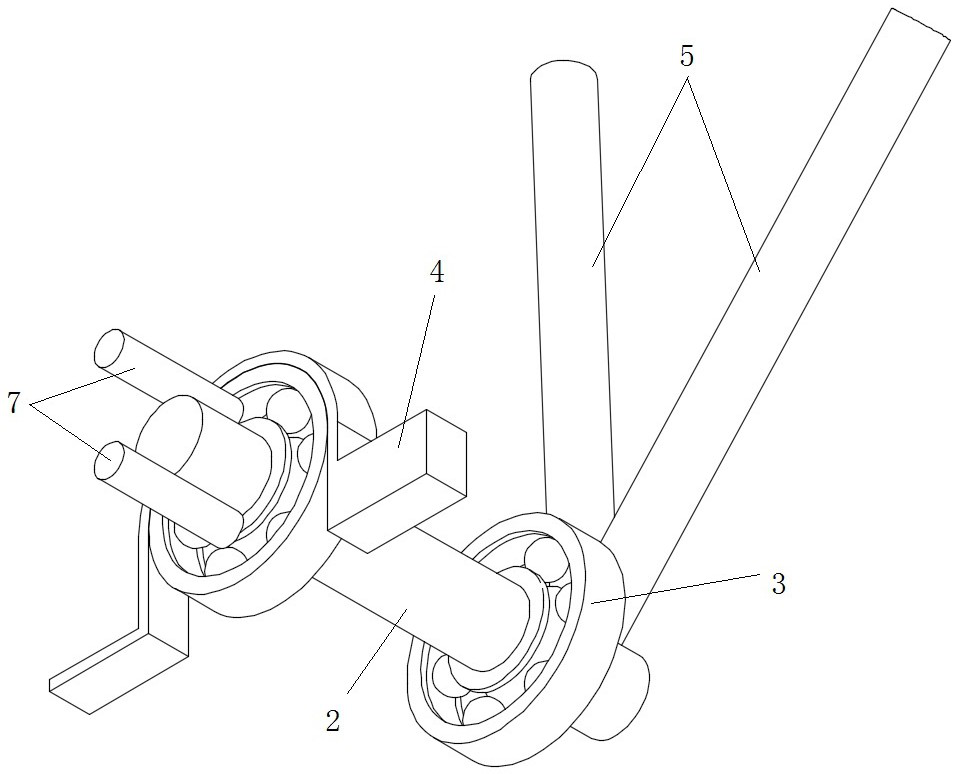

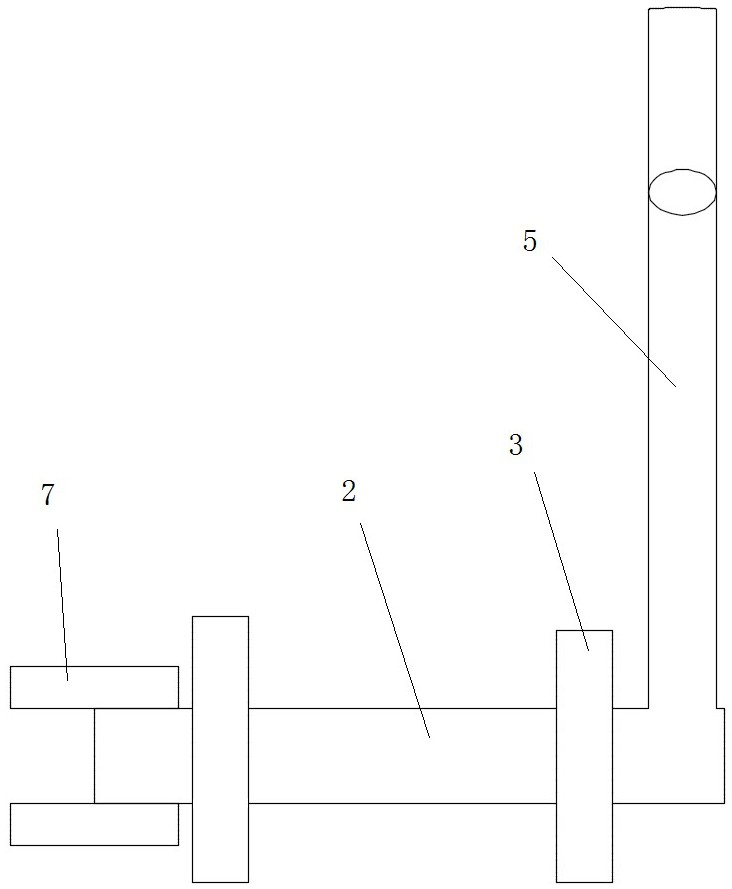

Labor-saving steel bar bending tool capable of controlling bending angle and method

PendingCN111974901ASimple organizationEasy to make on siteMetal working apparatusRebarManufacturing engineering

The invention belongs to the field of steel bar bending equipment and tools, and specifically relates to a labor-saving steel bar bending tool capable of controlling a bending angle and a method. Thelabor-saving steel bar bending tool capable of controlling the bending angle comprises a rotary bending mechanism, wherein the rotary bending mechanism comprises a rotating shaft, a rotating rod is arranged on one end of the rotating shaft, the rotating rod is perpendicular to the rotating shaft, two limiting rods are arranged on the other end of the rotating shaft, the two limiting rods are symmetrically arranged, the two limiting rods and the end surface of the rotating shaft form a C-shaped notch which is used for clamping a to-be-bent steel bar, two bearings are arranged on the rotating shaft, and the two bearings are fixedly installed on a base by virtue of bearing seats. The labor-saving steel bar bending tool has the advantages of the simple structure, convenience in field fabrication and low cost, and the problems of time consumption, labor consumption and potential safety hazards when temporary and scattered steel bars are manually bent due to no condition of a steel bar processing plant or due to the limitation to the distance to the steel bar processing plant on site are specifically solved.

Owner:CHINA FIRST METALLURGICAL GROUP

A rectangular steel pipe bending equipment

ActiveCN111644496BPrecise control of bending anglesAutomatic and efficient bendingMetal-working feeding devicesPositioning devicesGear wheelClassical mechanics

The invention relates to a bending device, in particular to a rectangular steel pipe bending device. The technical problem to be solved by the present invention is to provide a rectangular steel pipe bending equipment that can precisely control the bending angle and can automatically and efficiently bend the steel pipe. A rectangular steel pipe bending equipment, comprising: a bottom plate, the shape of the bottom plate is a cuboid; a worktable, the workbench is arranged on the top of the bottom plate; a fixed block, the fixed block is arranged on the top of the workbench Side; guide plate, the guide plate is arranged on the side of the top of the workbench away from the fixed block. The present invention achieves the effect that the bending angle can be precisely controlled, and the steel pipe can be bent automatically and efficiently. Since the tooth on the tooth-missing gear is a quarter turn, the first gear and the rotating shaft can only rotate 90 degrees. The support block and the pressing bar can only bend the rectangular steel pipe by 90 degrees, so that the bending angle of the steel pipe can be effectively controlled.

Owner:郓城鸿源专用车有限公司

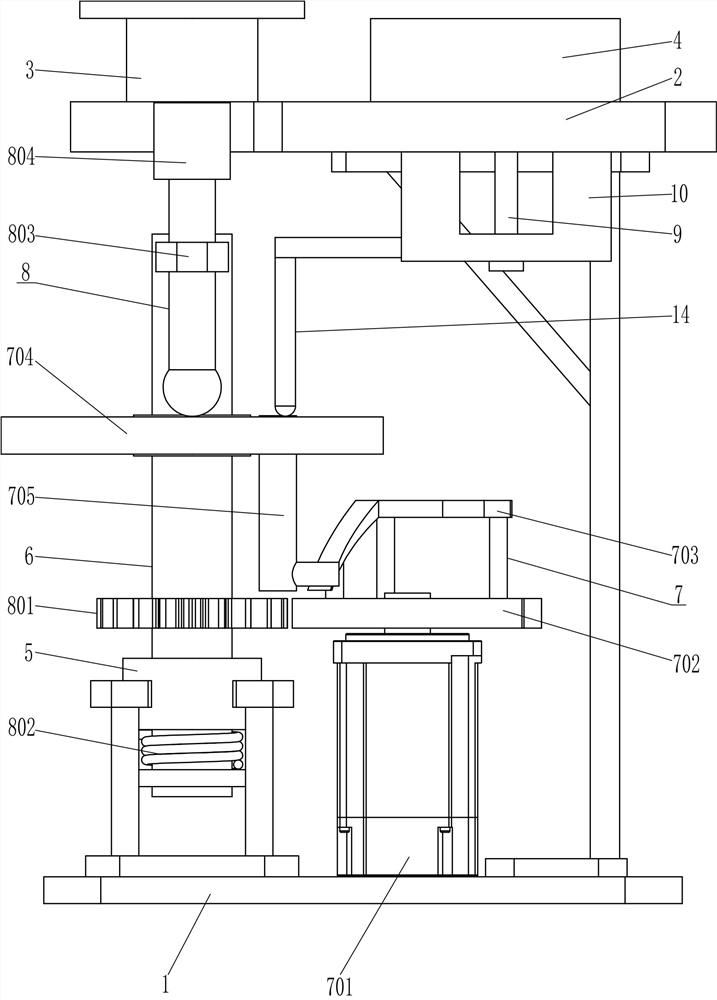

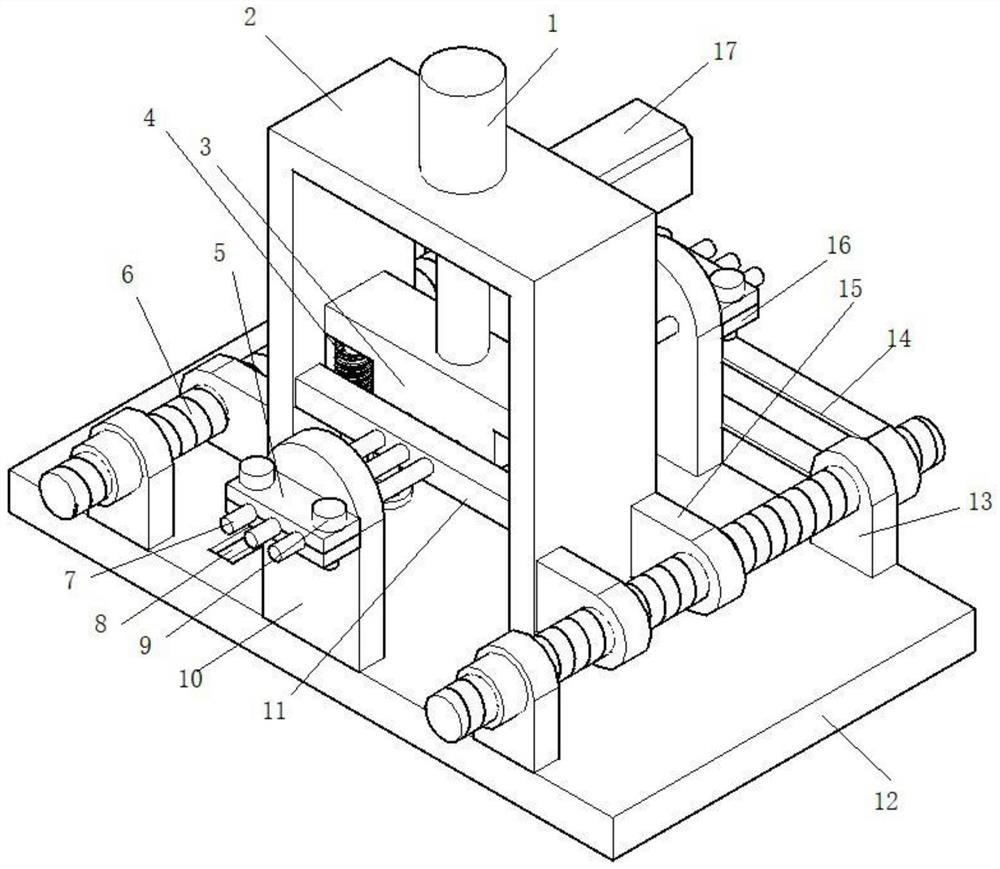

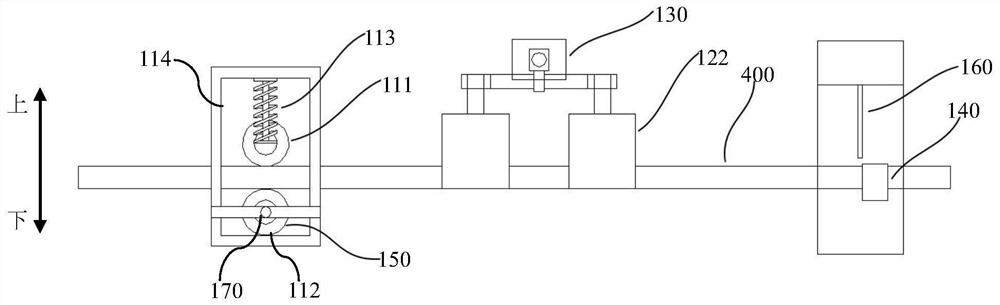

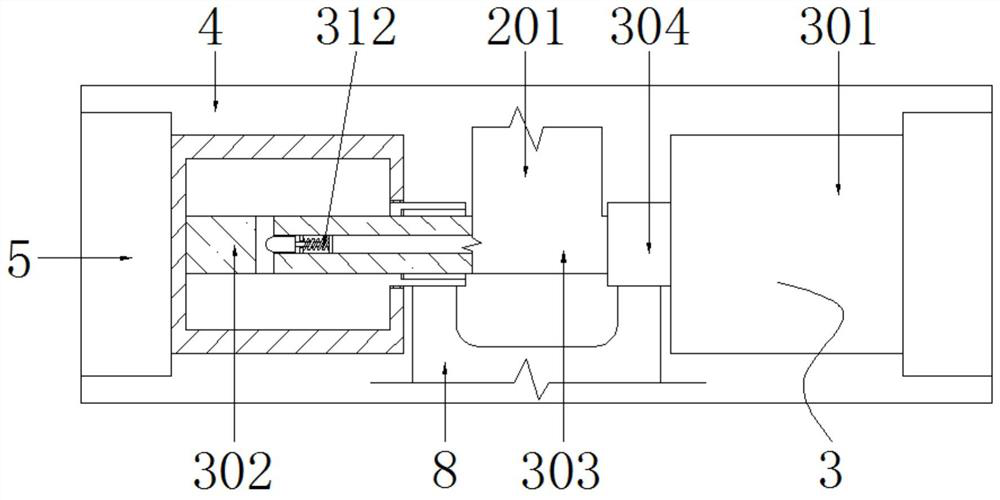

Copper bar processing system and processing method

ActiveCN113579742BUnhindered movementNo skewingOther manufacturing equipments/toolsPunchingStructural engineering

The invention discloses a copper bar processing system and a processing method. The present invention includes a shearing system, a punching system and a bending system; the shearing system includes a first clamping mechanism for clamping copper bars up and down, a second clamping mechanism for clamping copper bars left and right mechanism, the first control mechanism for controlling the clamping state of the second clamping mechanism, the first identification mechanism for identifying the origin position of the copper bar, the first driving mechanism for driving the copper bar to move, and the first driving mechanism for copper bar shearing A shearing mechanism and a second identification mechanism for detecting the rotation angle of the second clamping mechanism; the punching system includes a positioning device for copper bar alignment and punching equipment for copper bar punching; The bending system includes a bending mold and bending equipment for bending copper bars. The invention can realize precise cutting, punching and bending of copper bars.

Owner:南京恒标斯瑞冷冻机械制造有限公司

Method for controlling electronic equipment and electronic equipment

ActiveCN105138076BControl bend anglePrecise bending angleInput/output for user-computer interactionDetails for portable computersStructural engineeringBending force

Owner:LENOVO (BEIJING) LTD

A kind of automatic processing equipment for steel

ActiveCN113523808BNo manual operationImprove processing efficiencyOther manufacturing equipments/toolsStructural engineeringManual handling

The invention provides an automatic processing equipment for steel, including an operation table, a backing plate is fixed on the operating table, a feeding module is arranged on the backing plate, and an avoidance groove is arranged on the operation table, and the avoidance groove is arranged on the operation table. A cutting module is arranged in the groove, the cutting module is disposed close to one side of the feeding module, and a bending module is also arranged on the upper side of the avoidance groove. The automatic processing equipment of the invention has a simple structure, can perform automatic bending and automatic cutting of the steel, and also has the function of automatic unloading without manual operation, thereby improving the processing efficiency.

Owner:GUANGDONG GRAND GREENBUILT TECH CO LTD

Steel bar bending device

The invention discloses a steel bar bending device. The steel bar bending device comprises a bottom plate, wherein two supporting plates are fixedly arranged at the center of the bottom plate; a sliding frame movably arranged on the bottom plate is arranged between the two supporting plates; drivers fixedly arranged on the bottom plate are arranged on two sides of the sliding frame; a bending plate movably arranged on the sliding frame and driven by a cylinder is arranged in the sliding frame; and the bottom of the bending plate is provided with a supporting structure fixed on the bottom plate. In use, a steel bar is arranged on the supporting plates, and is clamped through screws, an upper clamping plate and a lower clamping plate, a motor drives a screw rod to rotate, the sliding frame is driven to move along a sliding groove, consequently, the purpose of adjusting the bending position is achieved, after the position is adjusted, the cylinder drives a plate body to move downwards tobend the steel bar, and the bending angle of the steel bar is controlled through controlling the downward movement distance of the plate body according to requirements.

Owner:六安长城钢结构有限公司

Steel plate bending machine for steel structure building

ActiveCN109590354BCause some damagesGuaranteed accuracyMetal-working feeding devicesPositioning devicesClassical mechanicsEngineering

The invention relates to a steel plate bending machine for a steel structure building. The steel plate bending machine comprises a bending table. An extruding device is arranged in the middle of the bending table, an executing device is arranged at the front end of the bending table, the extruding device comprises an extruding supporting plate mounted between the inner walls of the bending table,adjusting grooves are symmetrically formed in the side wall of the bending table, the adjusting grooves are formed in two sides of the extruding supporting plate, and an extruding plate is connected in a sliding fit manner between the adjusting grooves. The steel plate bending machine can solve the following problems in an existing steel plate bending process that follow-up mounting of a steel plate is affected as the manual steel plate bending precision is poor and a worker is likely to be hurt as the steel plate rebounds if being bended and the steel plate cannot be fixed effectively if being bended. The steel plate bending machine can achieve a function of bending the steel plate precisely and safely.

Owner:合肥巍华钢结构有限公司

Copper bar processing system and processing method

ActiveCN113579742AUnhindered movementNo skewingOther manufacturing equipments/toolsPunchingStructural engineering

The invention discloses a copper bar processing system and a copper bar processing method. The copper bar processing system comprises a shearing system, a punching system and a bending system, wherein the shearing system comprises a first clamping mechanism used for clamping a copper bar up and down, a second clamping mechanism used for clamping the copper bar left and right, a first control mechanism used for controlling the clamping state of the second clamping mechanism, a first recognition mechanism used for recognizing the original position of the copper bar, a first driving mechanism used for driving the copper bar to move, a shearing mechanism used for shearing the copper bar, and a second recognition mechanism used for detecting the rotation angle of the second clamping mechanism; the punching system comprises a positioning device used for copper bar centering and punching equipment used for copper bar punching. The bending system comprises a bending die and bending equipment used for bending the copper bar. Precise shearing, punching and bending of the copper bar can be achieved.

Owner:南京恒标斯瑞冷冻机械制造有限公司

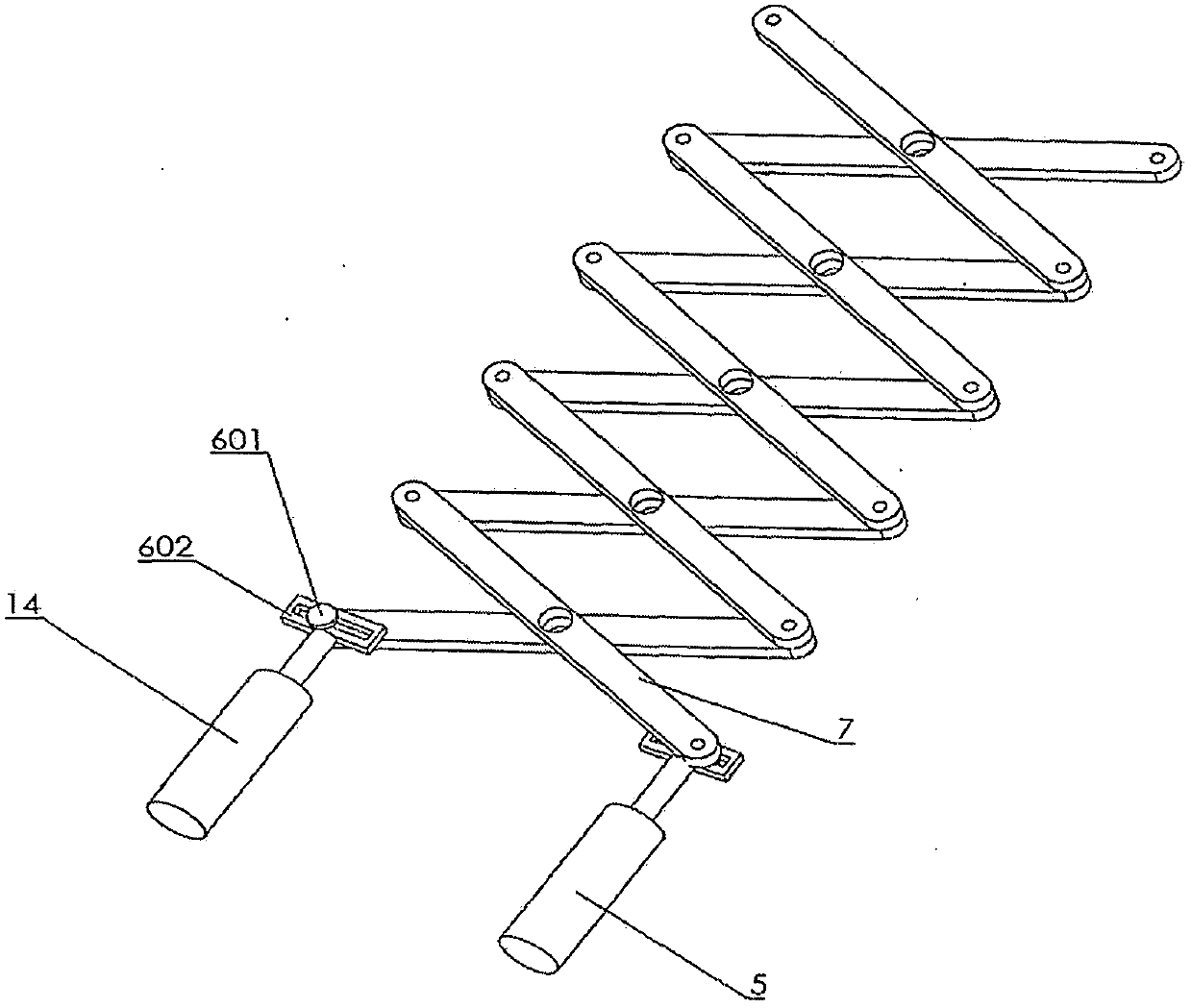

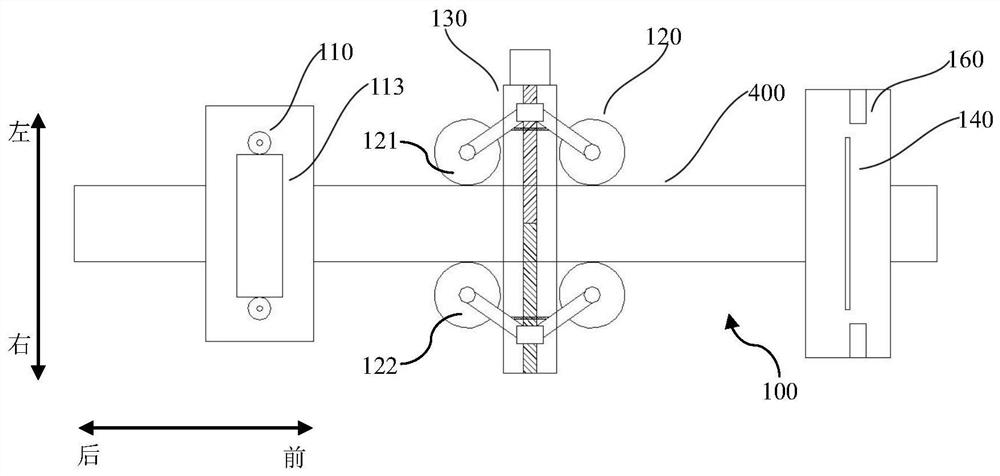

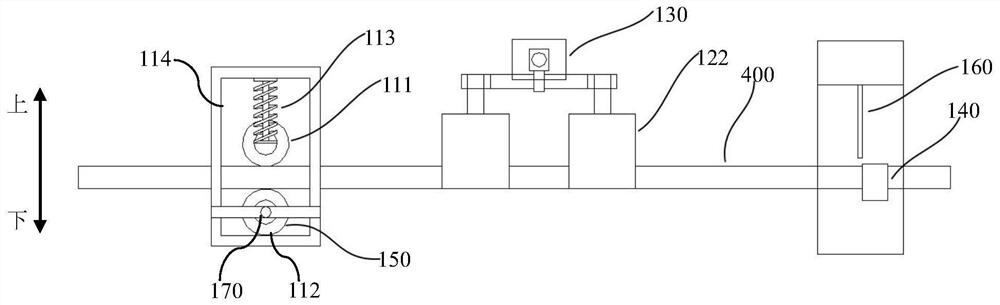

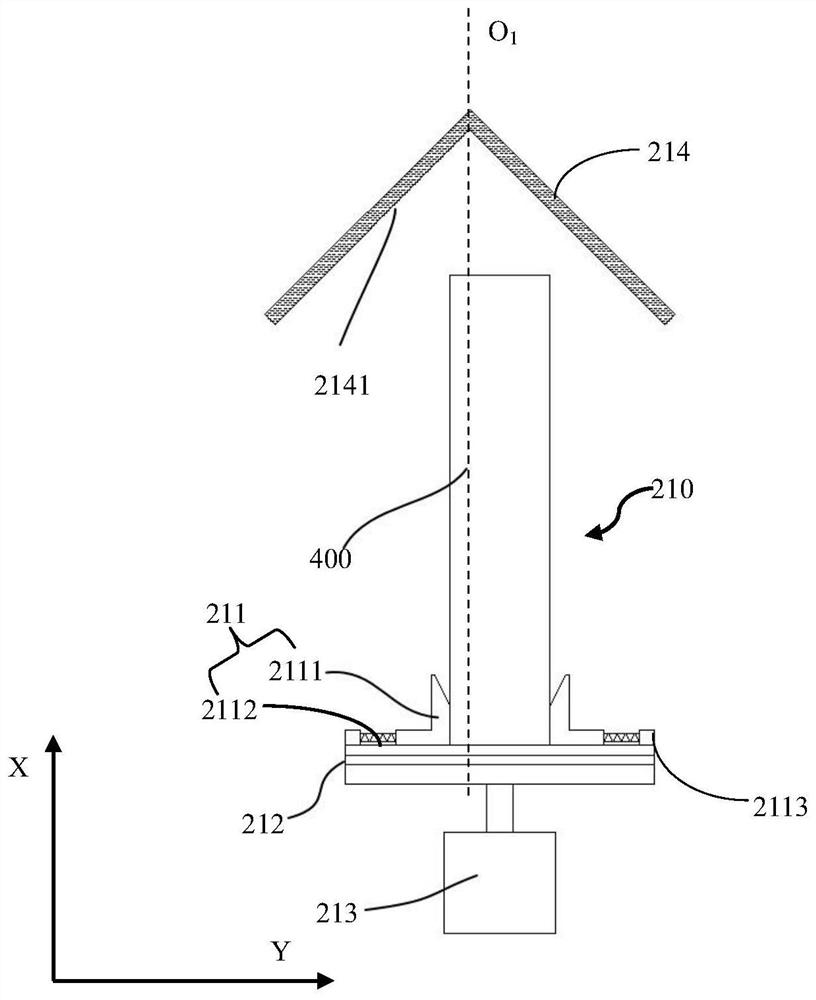

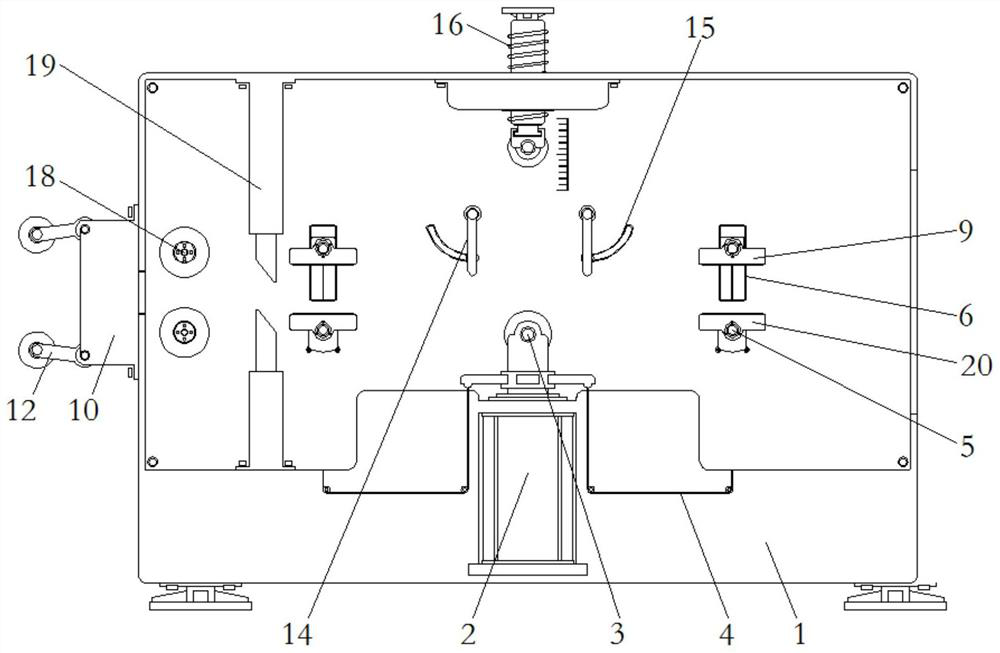

Wearable rigid-flexible hybrid driving finger joint rehabilitation training robot

ActiveCN114452159AAchieving Angle BendsReduce the impact of damageChiropractic devicesReduction driveGear wheel

The invention relates to the technical field of finger rehabilitation training, in particular to a wearable rigid-flexible hybrid driving finger joint rehabilitation training robot. Comprising a first finger section and a second finger section. The first finger section comprises an upper end cover and a first finger section base, the upper end cover is fixedly connected with the first finger section base, a cavity is formed between the upper end cover and the first finger section base, a driving motor and a speed reducer are arranged in the cavity, and an output shaft of the driving motor is connected with the input end of the speed reducer. The output end of the speed reducer is connected with the transmission system, and two gear systems are further arranged at the bottoms of the first finger section and the second finger section. The robot and the fingers are fixed through the binding bands, the acting force borne by the finger joints in the finger direction can be reduced through sliding of the connecting rods and the stiffness springs in the rectangular grooves, and the influence factors of joint damage are reduced; the two rotating blocks can act in sequence through the inclined plane inclination angles of the first rotating telescopic structure and the second rotating telescopic structure, and the bending angle of the fingers can be controlled to a certain degree by controlling the rotating angle of the motor.

Owner:CHONGQING UNIV OF TECH

An anti-misalignment angle adjustable bending device for steel plate production

ActiveCN111167904BInhibition biasImprove practicalityMetal-working feeding devicesPositioning devicesClassical mechanicsStructural engineering

The invention discloses a misalignment-proof angle-adjustable bending device for steel plate production, which includes a base body, a hydraulic rod, a butt joint pressure head and an electric cutter. A hydraulic rod is installed through the middle end of the base body, and the hydraulic pressure The output end of the rod is rotatably connected with a butt press head, the outer end of the butt press head is fixedly connected with a traction rope, and the traction rope is connected with the inner surface of the base body, the outer surface of the base body is rotatably connected with a connecting shaft, and connected The outer surface of the shaft is fixedly connected with a lower limit block, the outer surface of the base body is provided with a first chute, and the inner surface of the first chute is fixedly connected with a return spring. The anti-misalignment angle-adjustable bending device for steel-shaped plate production uses a hand-held threaded rod to drive the docking retaining wheel to adjust and control the upper and lower positions along the upper end of the base body, thereby changing the height and position of the docking retaining wheel so that the butt joint pressure The ejection height of the head is controlled, so that the bending angle at which it contacts the workpiece can be easily changed.

Owner:绍兴市卓诚新材料有限公司

Pneumatic-control rigidity-variable two-finger manipulator

The invention discloses a pneumatic-control rigidity-variable two-finger manipulator and relates to the technical field of manipulators. By means of the pneumatic-control rigidity-variable two-finger manipulator, the problem that the finger bending angle of the manipulator cannot be accurately controlled is solved. The pneumatic-control rigidity-variable two-finger manipulator specifically comprises a mounting plate, a connecting plate is fixed to the outer wall of the bottom of the mounting plate, two connecting valves are fixed to the outer walls of the two sides of the connecting plate, a first finger section and a third finger section are arranged on the outer wall of the top of the mounting plate, and a second air supply pipe and a third air supply pipe are fixed to the outer wall of the top of the connecting plate. According to the pneumatic-control rigidity-variable two-finger manipulator, by means of the arrangements of air cylinders, push plates, a connecting circular ring, a rotating column, a connecting disc and a fixing block, when a second finger section needs to be bent, a worker can control the corresponding air cylinder to push one push plate to move upwards and control the other air cylinder to drive the corresponding push plate to move downwards by the same distance at the same time, and at the moment, the rotating column and the fixed block are driven by the two push plates to rotate through the connecting circular ring, so that the second finger section connected with the top of the rotating column and the top of the fixed block is inclined.

Owner:ANHUI UNIVERSITY

Bending angle adjusting mechanism for hydraulic plate bending machine

The invention relates to the technical field of hydraulic bending machines, and discloses a bending angle adjusting mechanism for a hydraulic plate bending machine. The bending angle adjusting mechanism comprises a mechanical frame, a clamping mechanism and a locking mechanism. A supporting seat is fixedly mounted at the top end of the mechanical frame, a center column is fixedly mounted at the top end of the supporting seat, a pressing rod is movably mounted on the front face of the center column, a hydraulic column is movably mounted in the supporting seat, a rotating plate is fixedly mounted at the top end of the hydraulic column, a pedestal is fixedly mounted at the bottom end of the rotating plate, the clamping mechanism is fixedly mounted at the top end of the supporting seat, and the locking mechanism is fixedly mounted on the front face of the center column. Before a plate material is bent, the equipment is adjusted according to a required angle, after the plate material is bent, when the plate material is bent to the required angle, the rotating device can be automatically locked, the rotating device stops rotating, and the plate material is bent, so that the purpose of adjusting the bending angle according to requirements is achieved.

Owner:青岛宇航钢结构有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com