Labor-saving steel bar bending tool capable of controlling bending angle and method

A technology for bending and bending of steel bars, applied in the fields of manufacturing tools, metal processing, metal processing equipment, etc., can solve the problems of hidden safety hazards, time-consuming and laborious, manual bending of steel bars, etc. Guaranteed quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to better understand the present invention, the technical solutions of the present invention will be further described below in conjunction with examples.

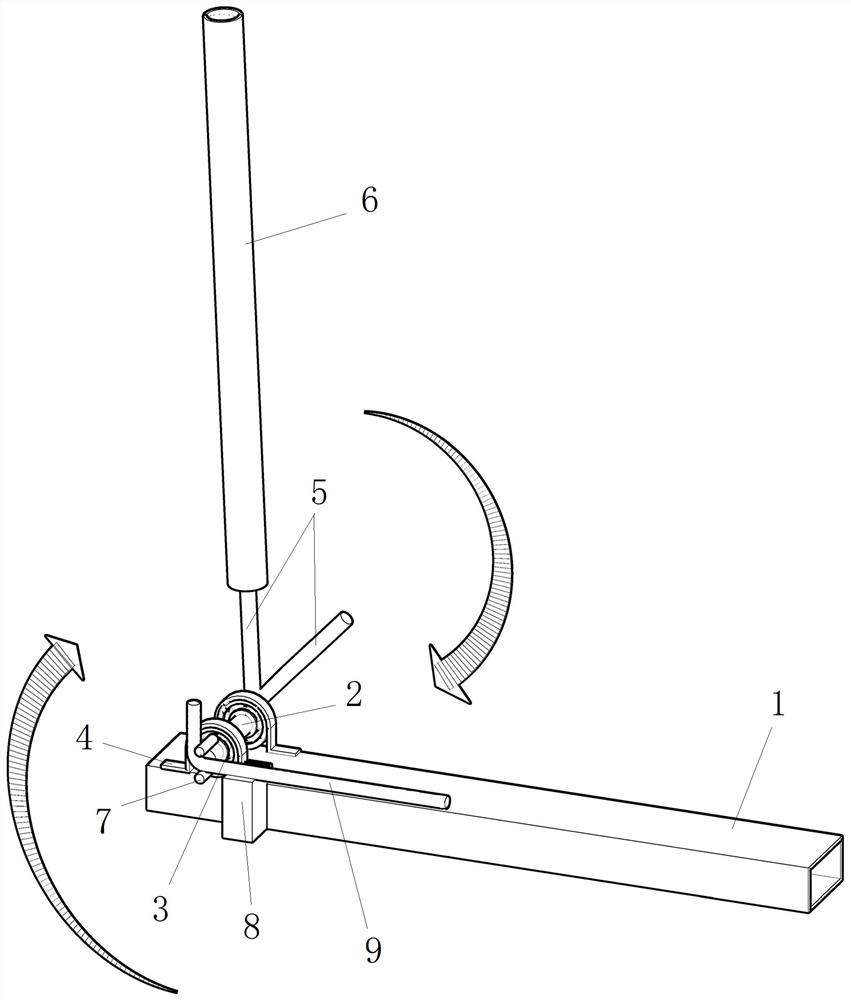

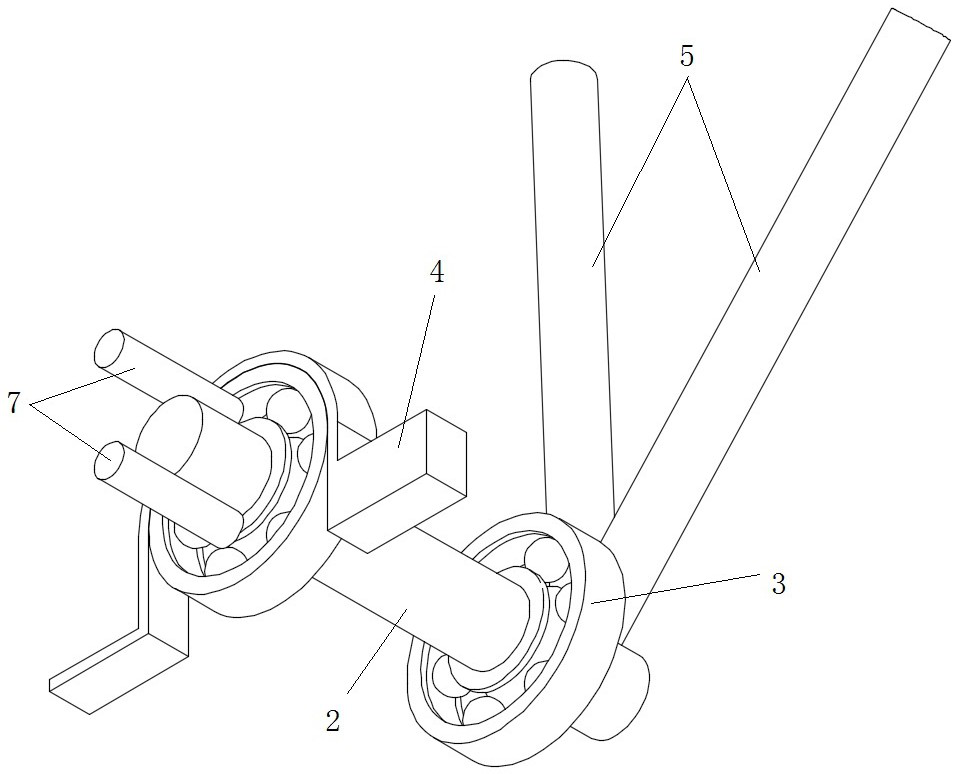

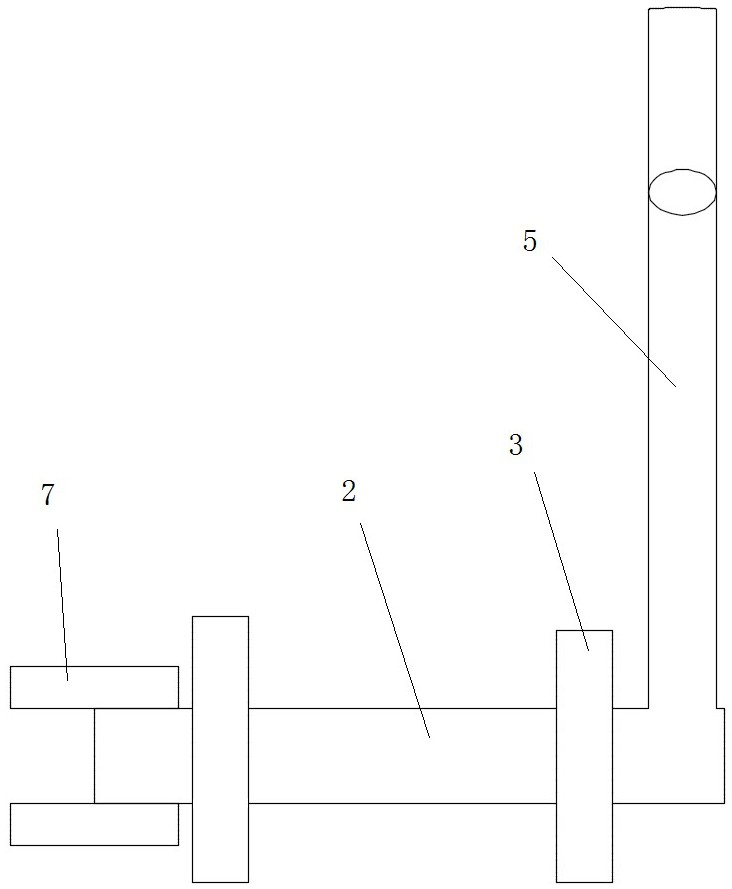

[0036] Such as figure 1 , 2 , 3, and 4, a labor-saving steel bar bending tool with controllable bending angle includes a rotating bending mechanism, and the rotating bending mechanism includes a rotating shaft 2; one end of the rotating shaft 2 is provided with a rotating rod 5, so The rotating rod 5 is perpendicular to the rotating shaft 2; the other end of the rotating shaft 2 is provided with two limit rods 7, which can adopt the waste and old steel bar heads of more than 20 mm on the construction site, and adopt welding. The two limit rods 7 are symmetrically arranged, welded At the two ends of the diameter of the rotating shaft 2, two limit rods 7 and the end face of the rotating shaft 2 jointly form a C-shaped notch for clamping the steel bar 9 to be bent; the rotating shaft 2 is provided with two be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com