Three-roller bending test apparatus with capability of detecting weld of sheet material

A technology of bending test and sheet material, which is applied in the direction of measuring device, using stable bending force to test the strength of material, analyzing material, etc. It can solve the problems of raised welds, ineffective detection of weld performance, and poor guarantee of sheet position And other problems, to achieve the effect of precise bending angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

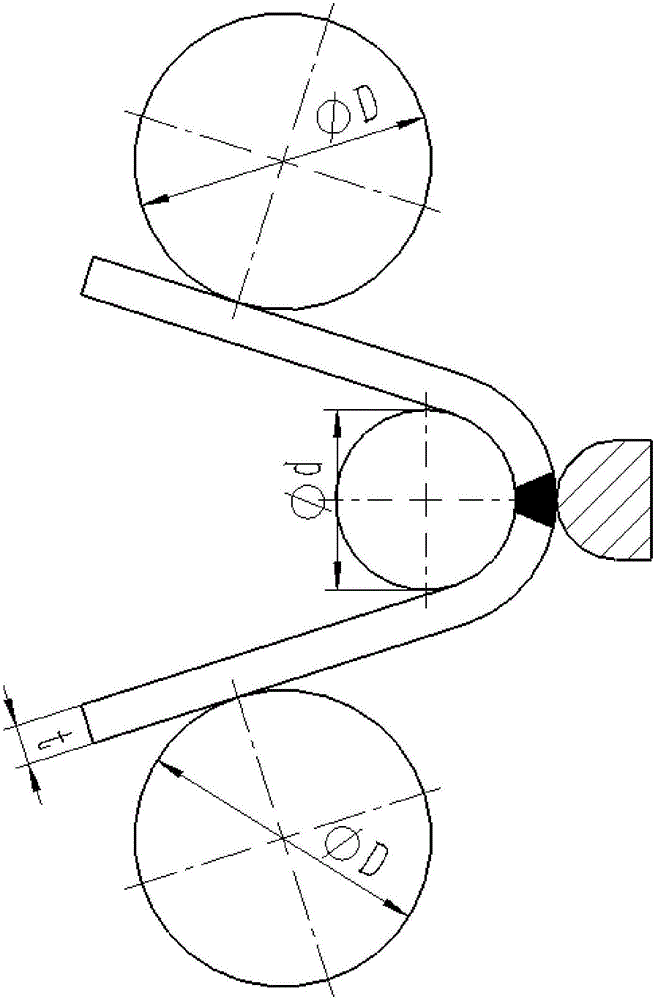

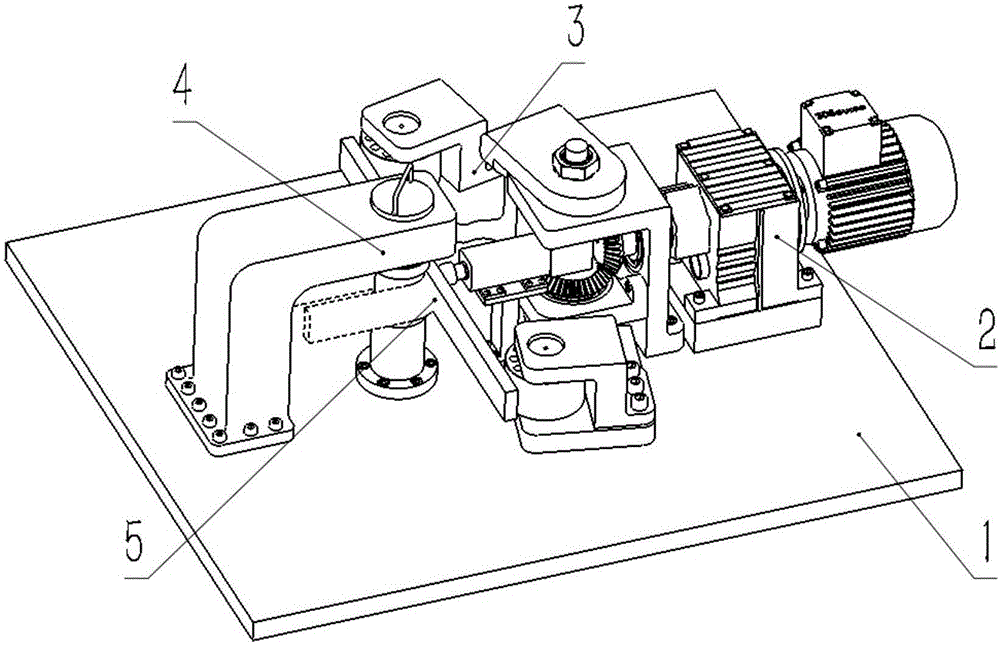

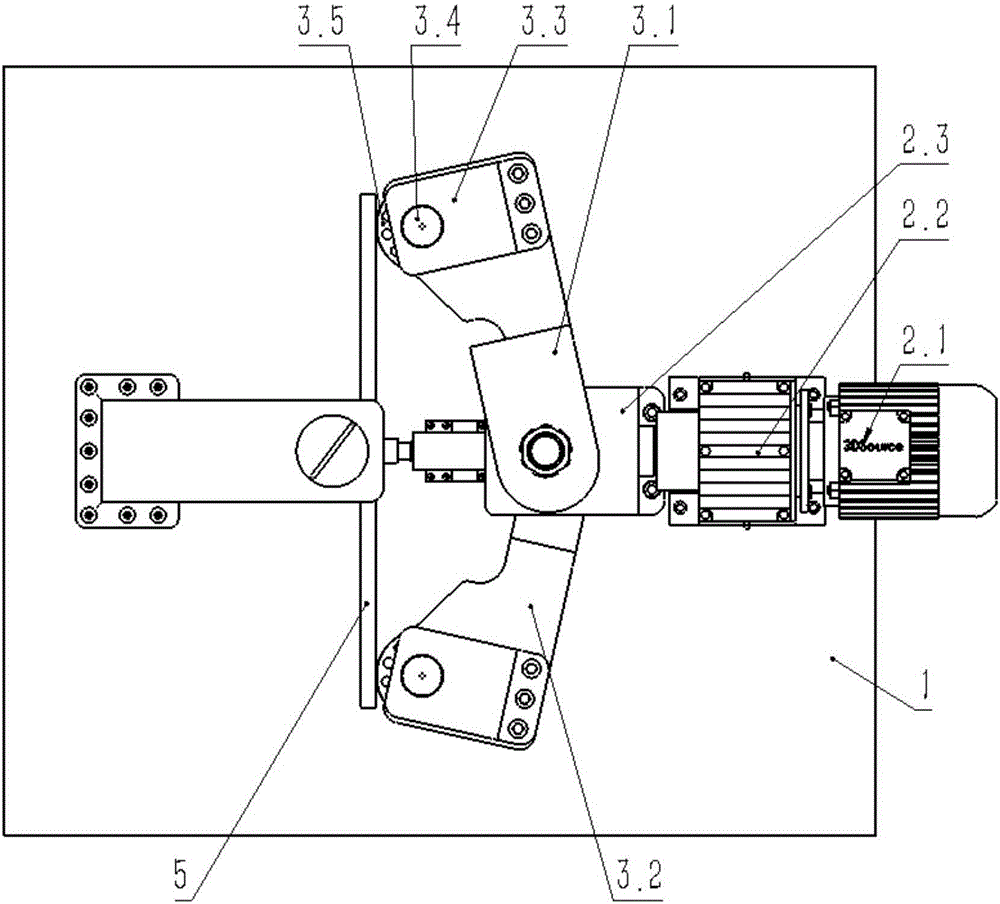

[0016] Such as Figure 1 to Figure 5 As shown, a three-roll bending test device with a detection plate weld performance, including a workbench 1, a power source and a transmission mechanism 2, a symmetrical bending device 3 on both sides, and a clamp and a fixing device 4 for fixed rolls. Workbench 1 is a rectangular steel plate on which mounting grooves and mounting holes are processed. The power source and transmission mechanism 2 and the fixture and fixed roller fixing device 4 are all fixed on the workbench 1 by bolts, and the bilateral symmetrical bending device 3 is connected with the power source and transmission mechanism 2 through spline fit.

[0017] The power source and the transmission mechanism 2 are fixed on the workbench 1 by bolts, including the motor 2.1, the reducer 2.2, the first bevel gear 2.5, the second bevel gear 2.6 and the third bevel gear 2.7, the first bevel gear mounting seat 2.3 and The second bevel gear mount 2.8, the first bearing 2.4, the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com