Patents

Literature

172results about "Caliper-like sensors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

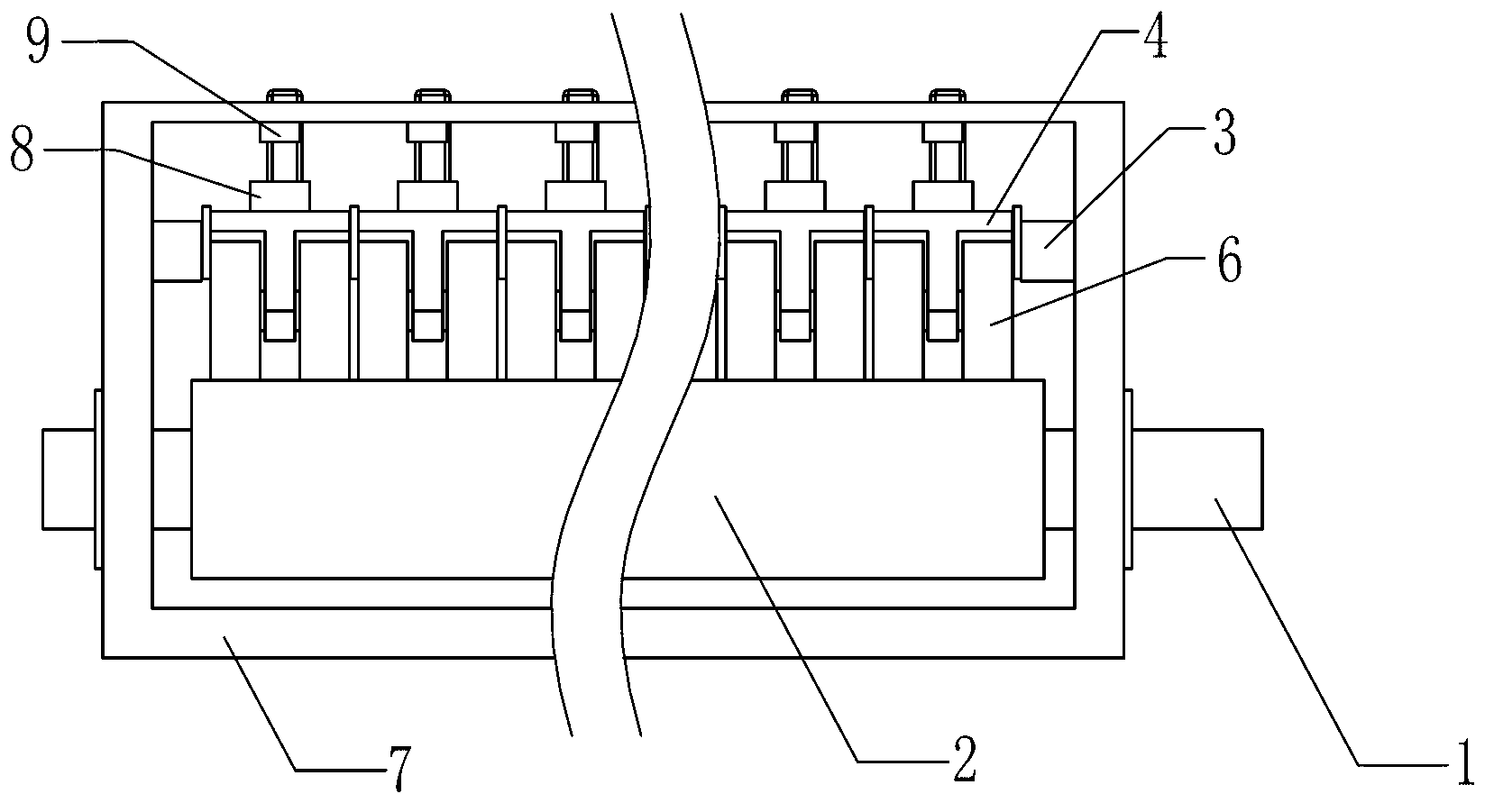

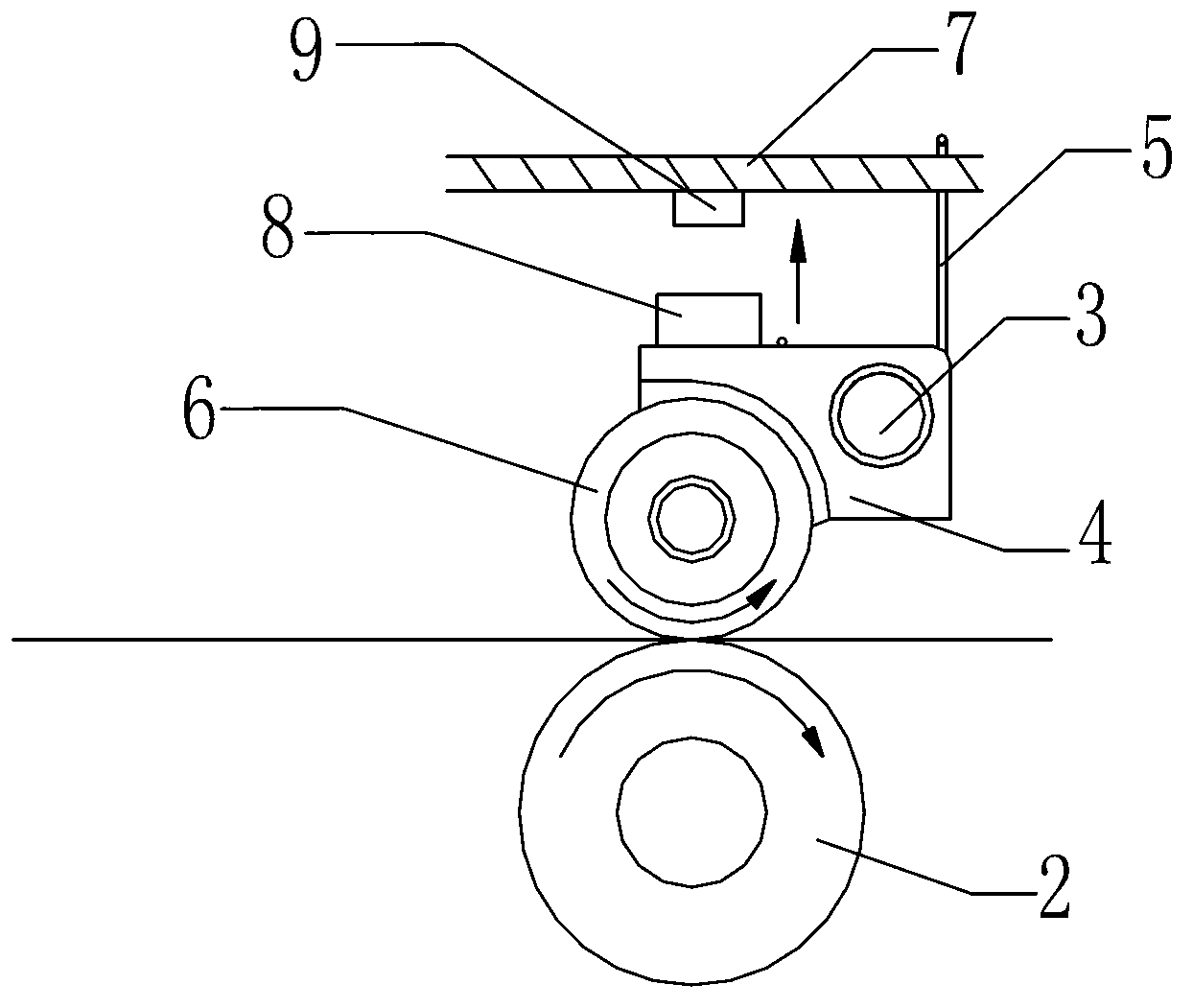

Testing device for thickness of slice medium

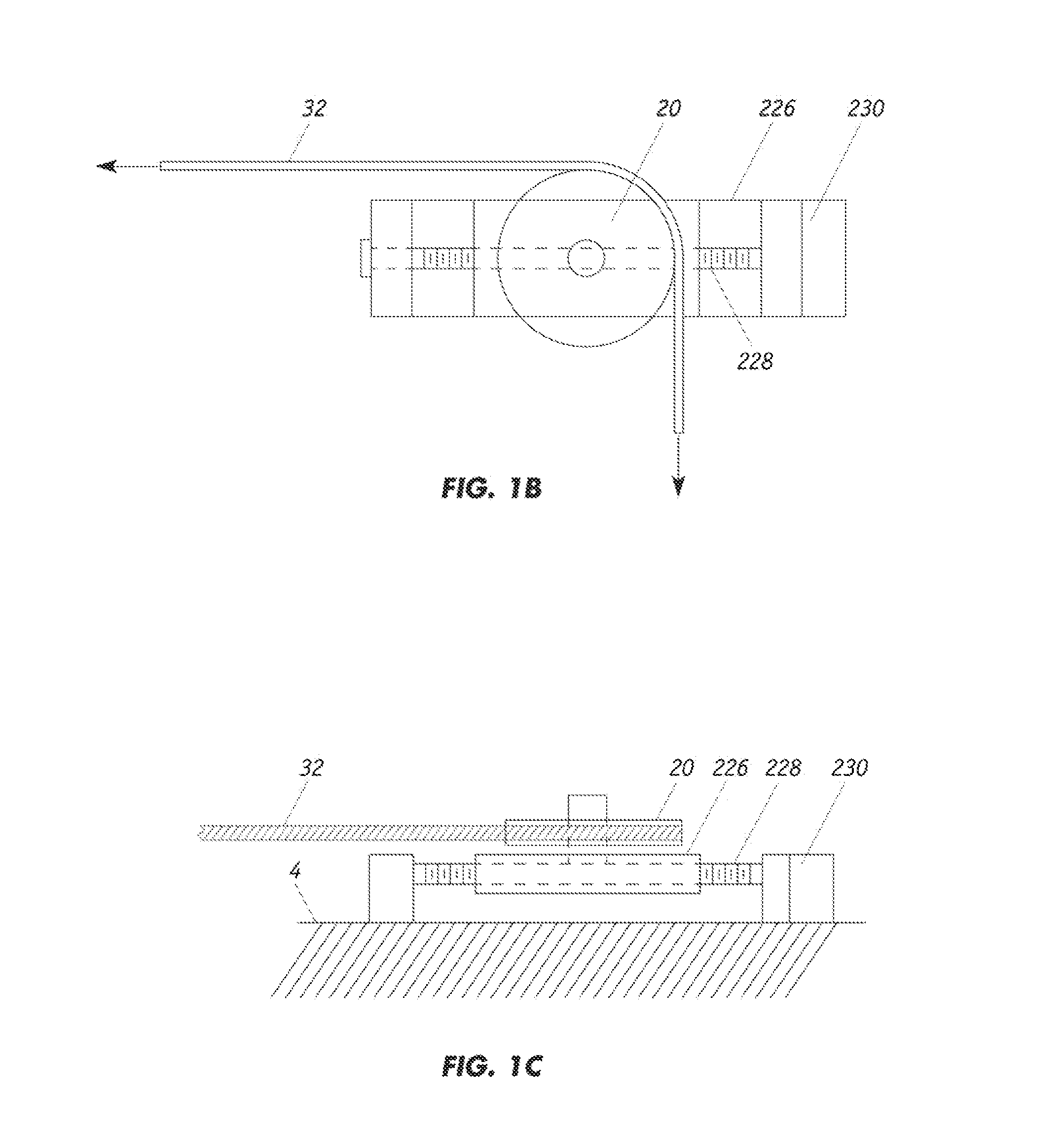

ActiveCN102842166AGuaranteed absolute oppositionGuaranteed accuracyCaliper-like sensorsPaper-money testing devicesContact modeEngineering

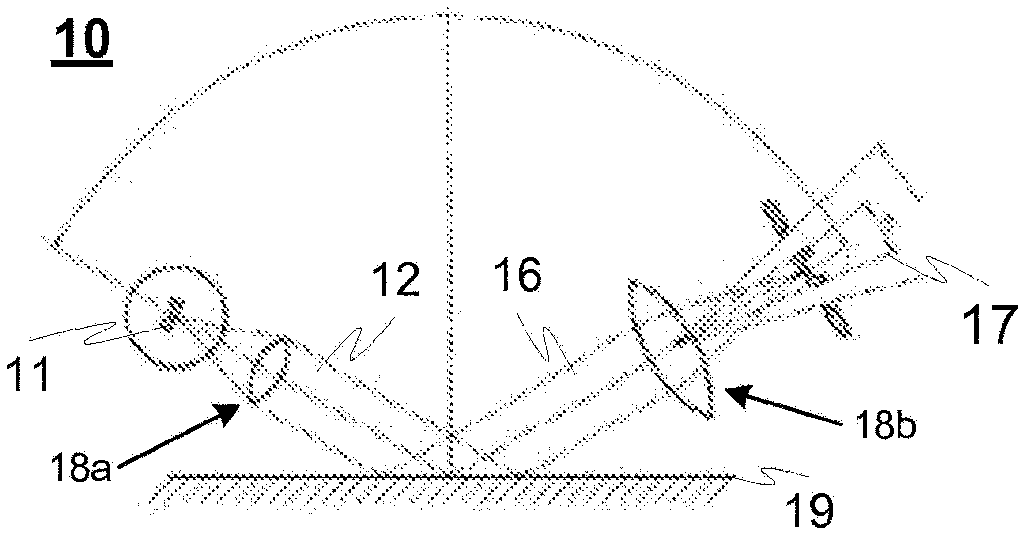

The invention relates to a device for measuring thickness, in particular to a testing device for thickness of a slice medium. The testing device comprises a fixed mount, a reference shaft, a testing shaft, an elastic press sheet, a magnet, and a Hall sensor, wherein two ends of the reference shaft are installed on the fixed mount by bearings, the reference shaft is fixedly sleeved with a reference roller; two ends of the testing shaft are fixedly installed on the fixed mount; the testing shaft is provided with at least one testing roller base of which one end is rotated freely around the testing shaft; a free end of the testing roller base is provided with a testing roller which can rotate freely; the testing roller and the reference roller are formed in elastic contact; the elastic press sheet is arranged correspondingly to the testing roller base; one end of the elastic press sheet is fixed on the fixed mount and the other end of the elastic press sheet forms a free end and applies a pressing force to the testing roller base at the reference roller; the free end of the elastic press sheet is fixedly provided with the magnet on the opposite side to the testing roller; and the Hall sensor for testing the displacement of the magnet in a non-contact mode is fixed on the fixed mount opposed to the magnet.

Owner:GRG BAKING EQUIP CO LTD

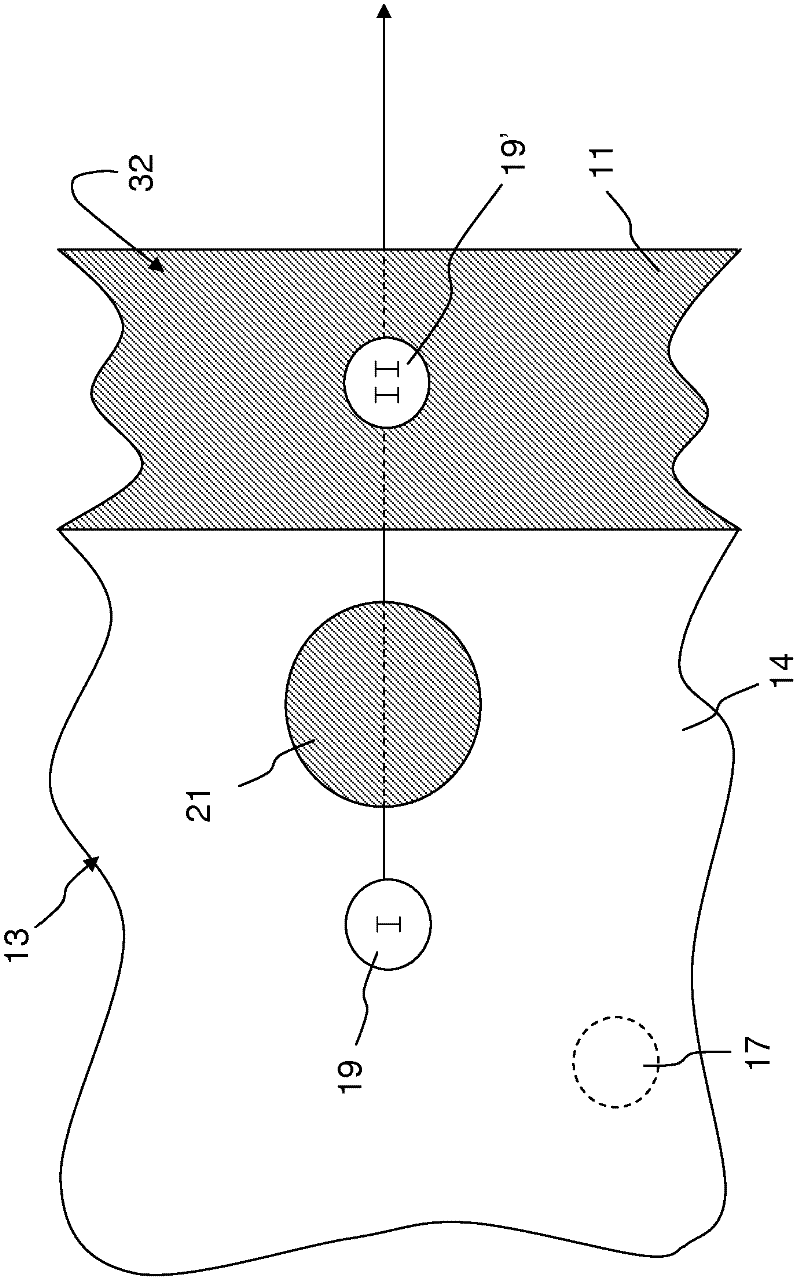

Web Measurement Device

ActiveUS20090056156A1Caliper-like sensorsInvestigating moving sheetsMeasurement deviceNetwork measurement

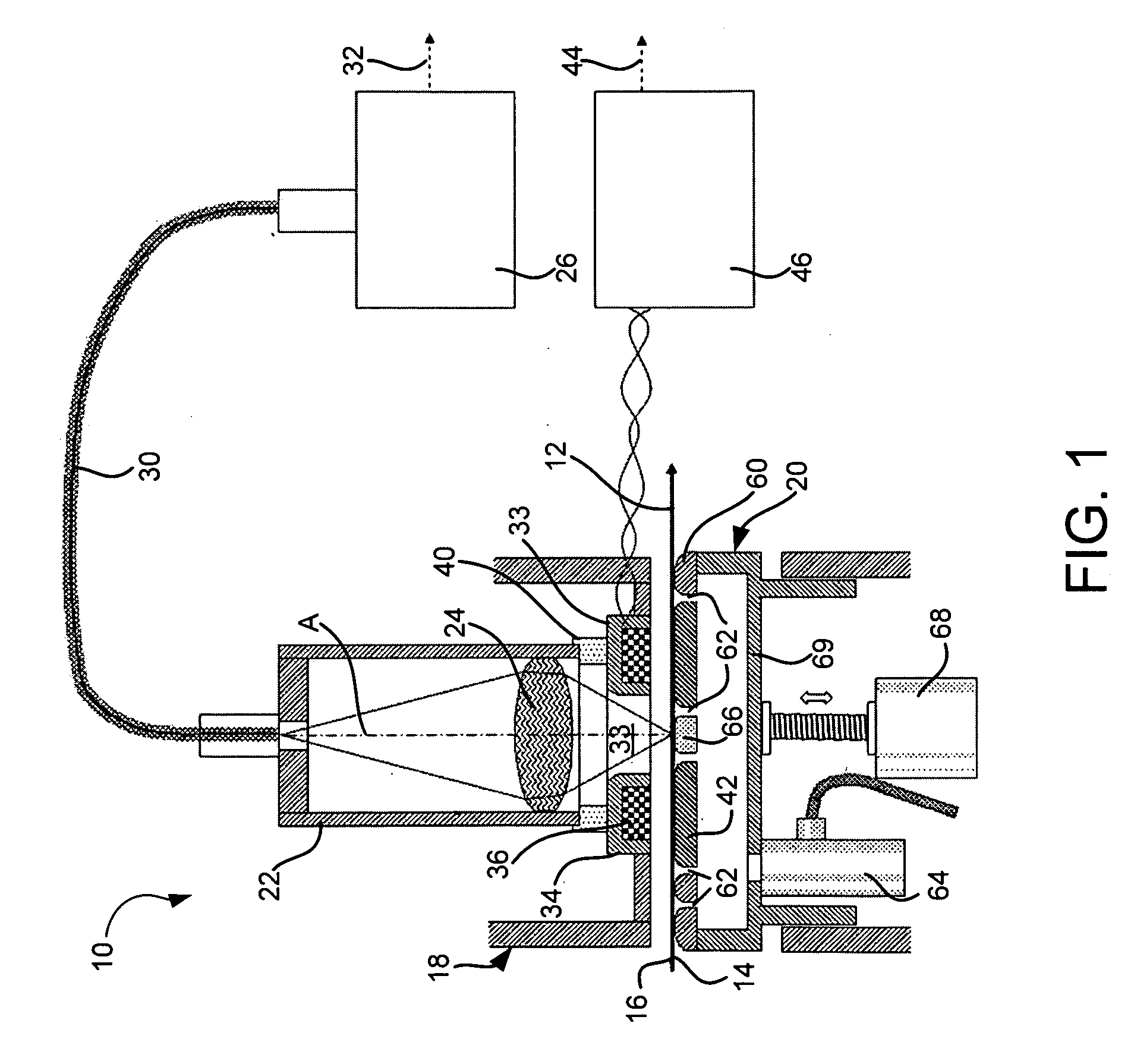

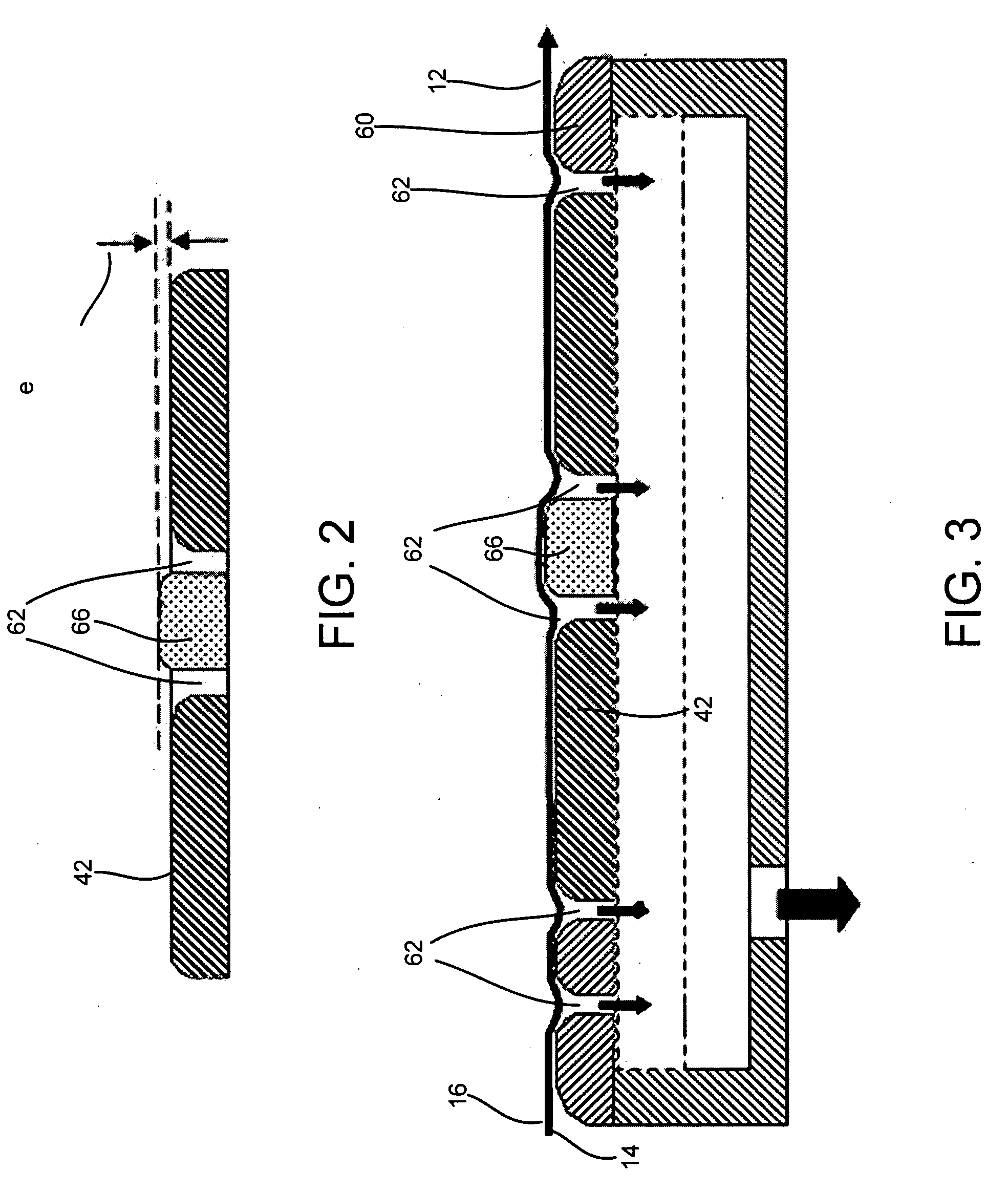

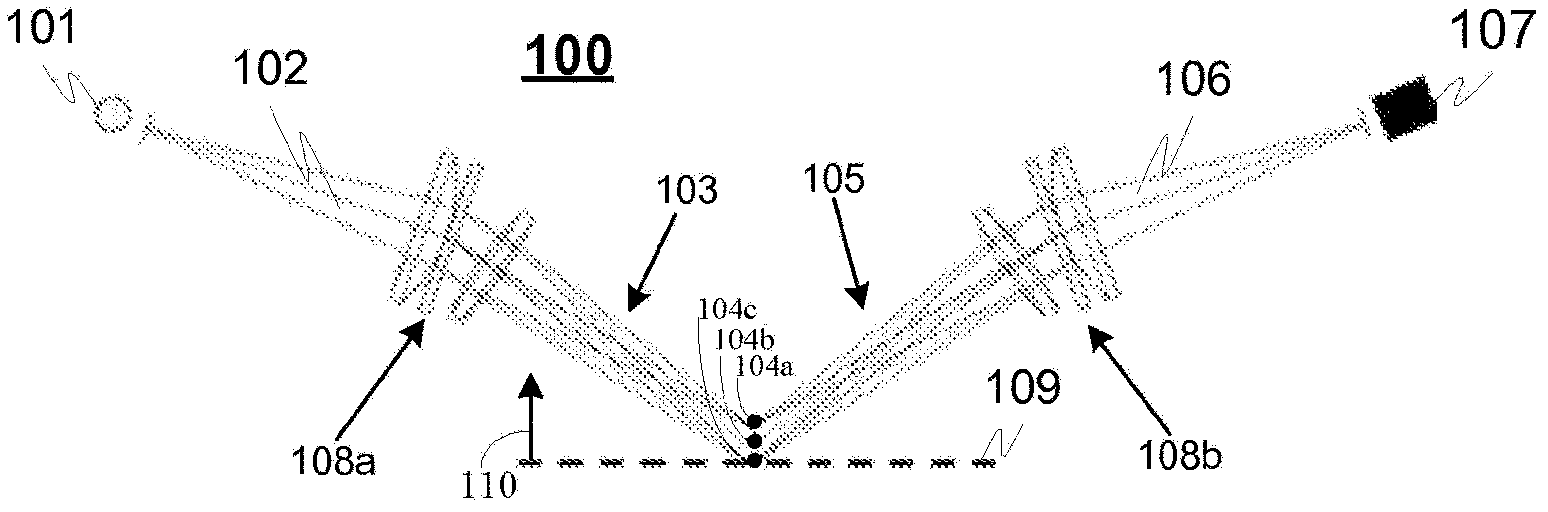

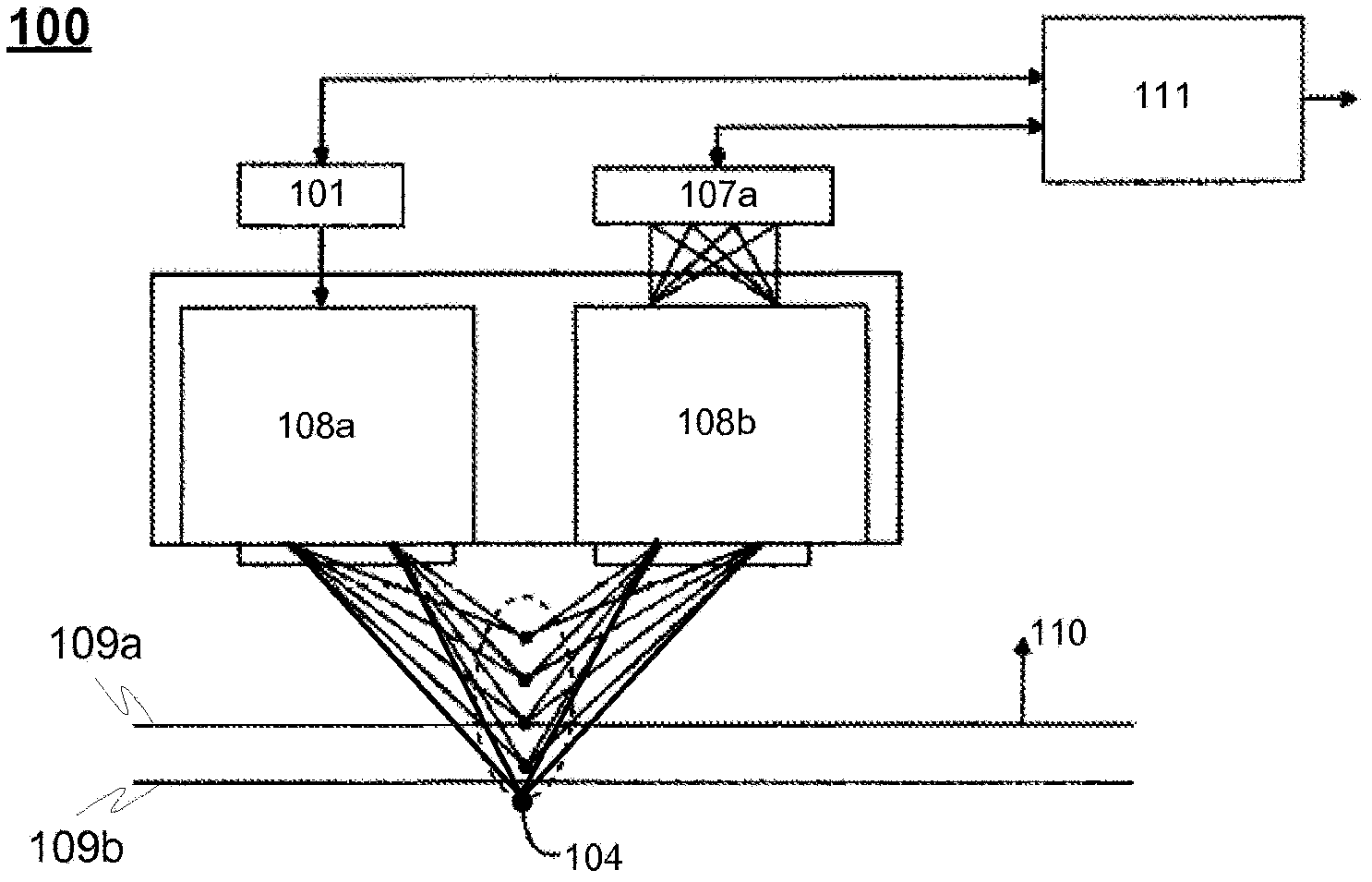

A sensor is provided that measures web caliper using optical and magnetic measuring devices. The optical measuring devices may employ a confocal chromatic aberration method to accurately determine the distance to the moving web and the magnetic devices may be ferrite core coil and target. Means of stabilizing a moving web are included for improving dynamic measurement accuracy.

Owner:ABB LTD

Measuring instrument and method for determination of the properties of an item and its surface

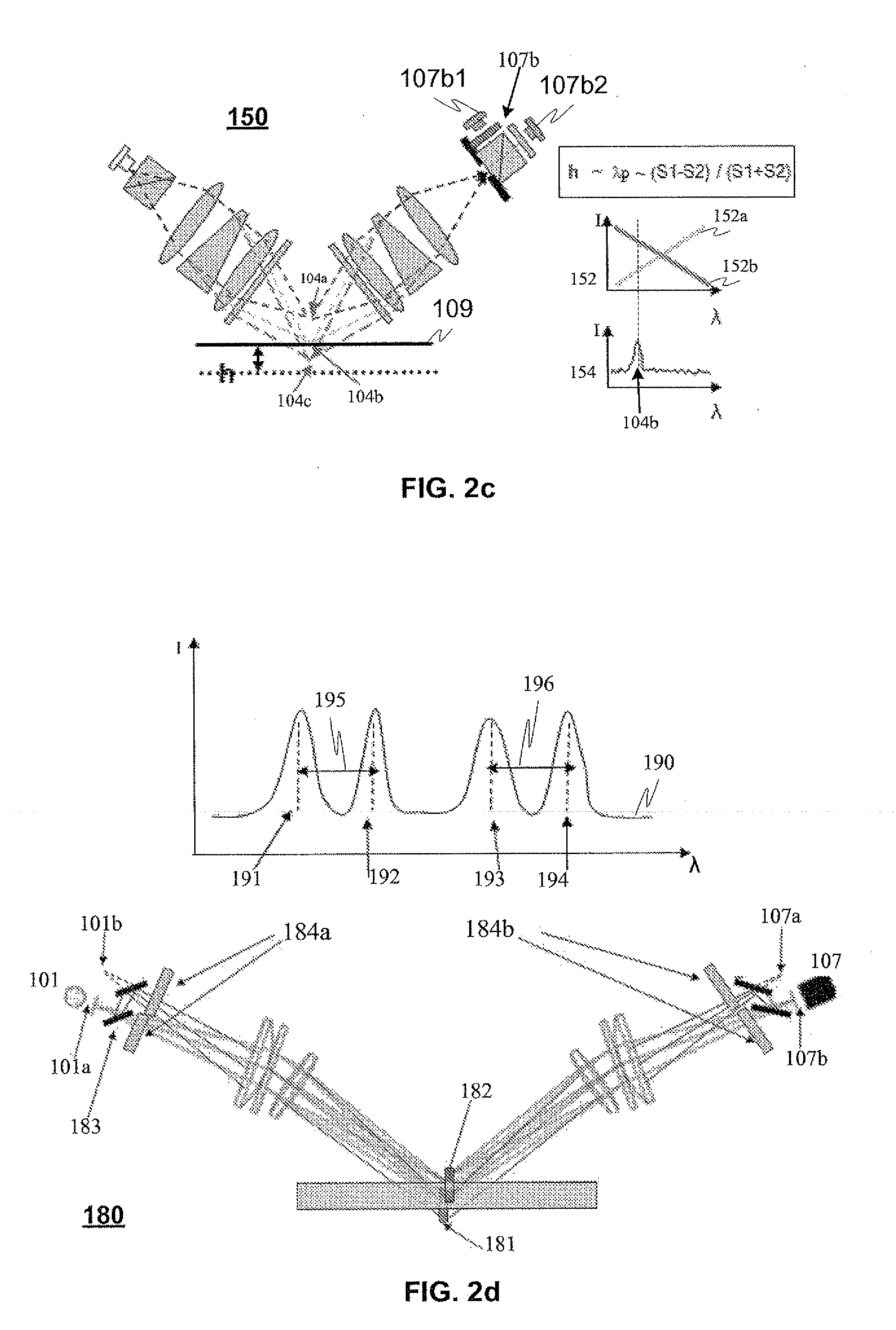

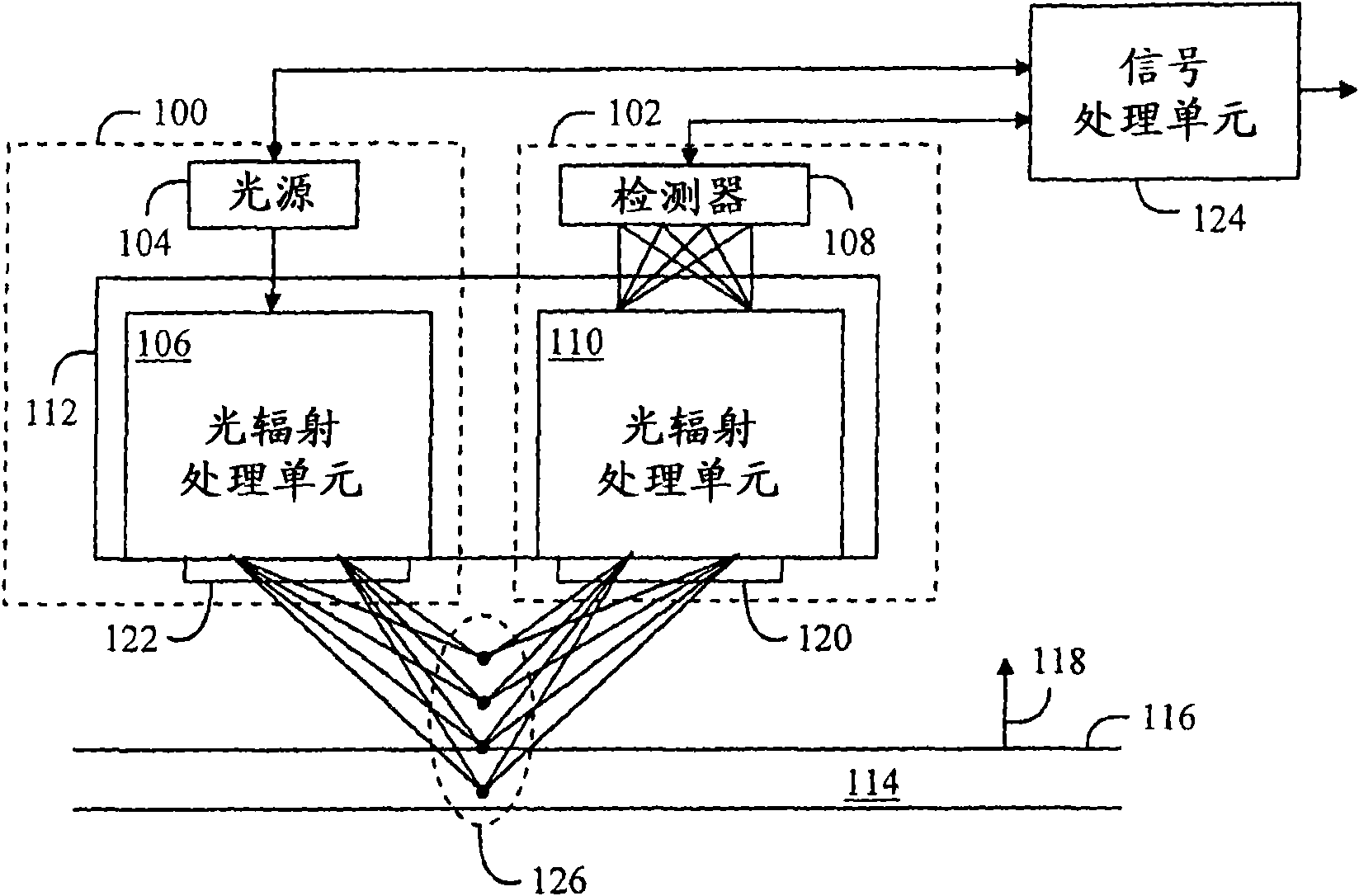

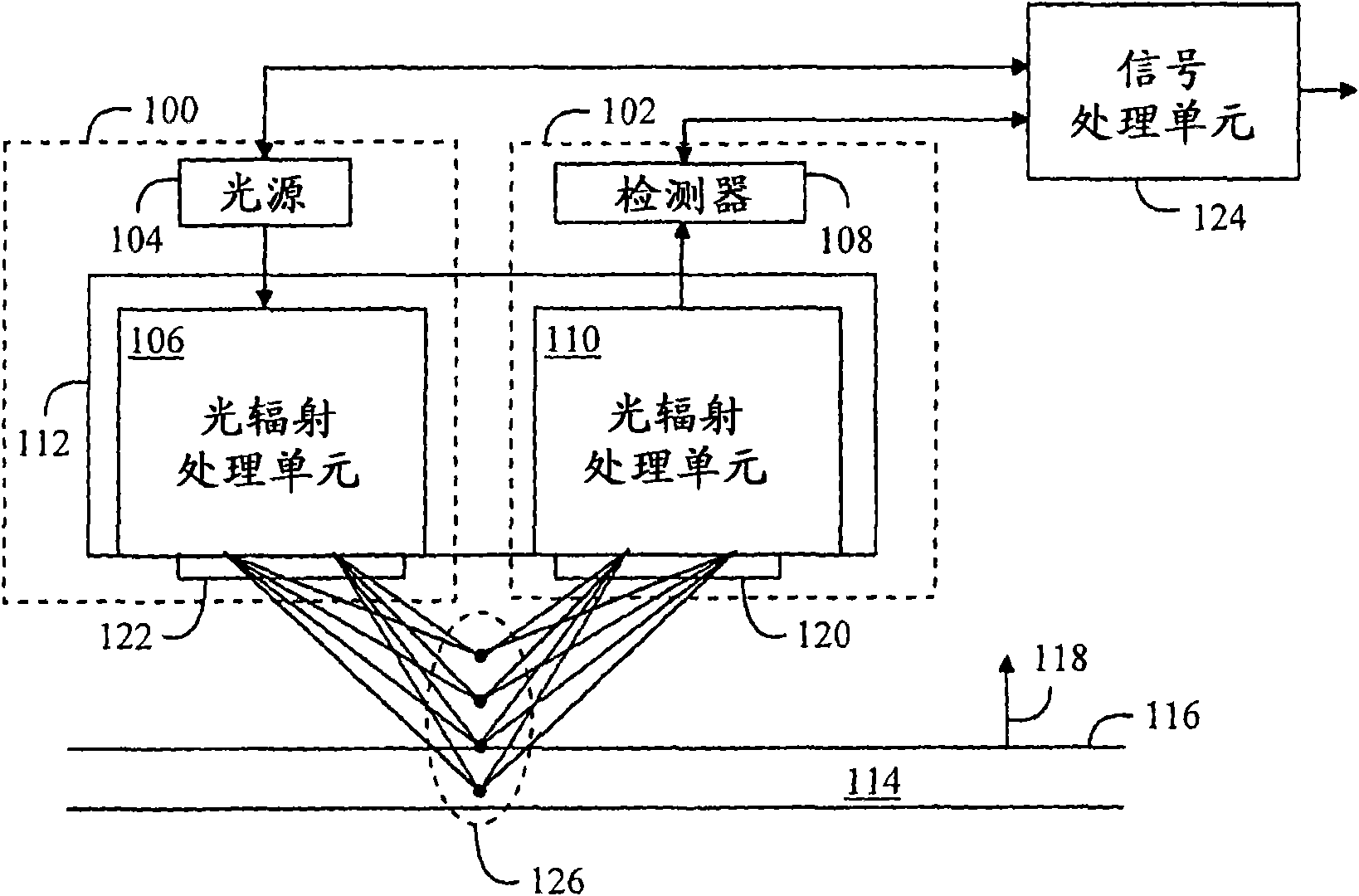

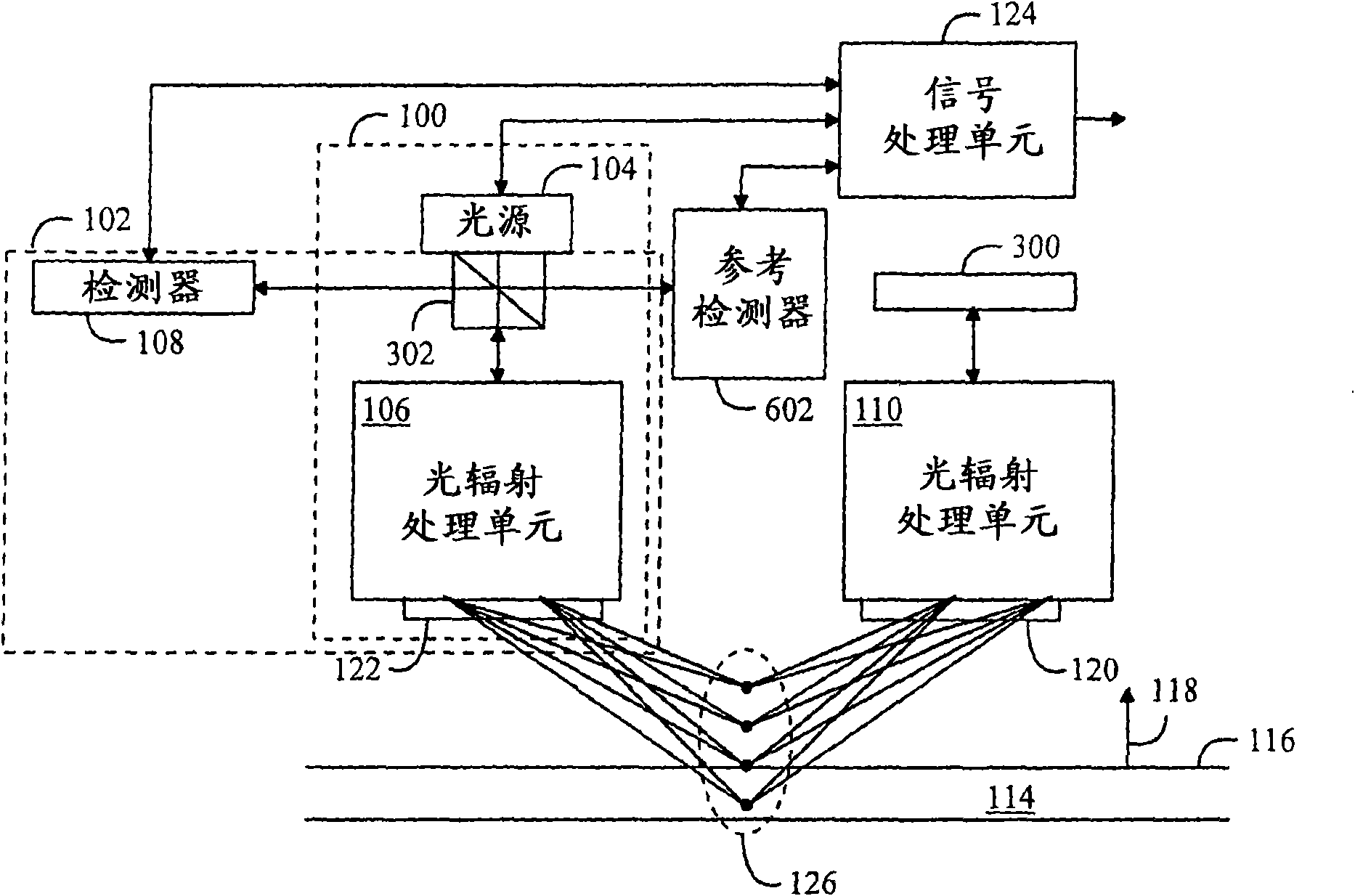

ActiveUS20120206710A1Affect qualityClear impact both on the production process quality assuranceCaliper-like sensorsOptical rangefindersOptical radiationMeasurement device

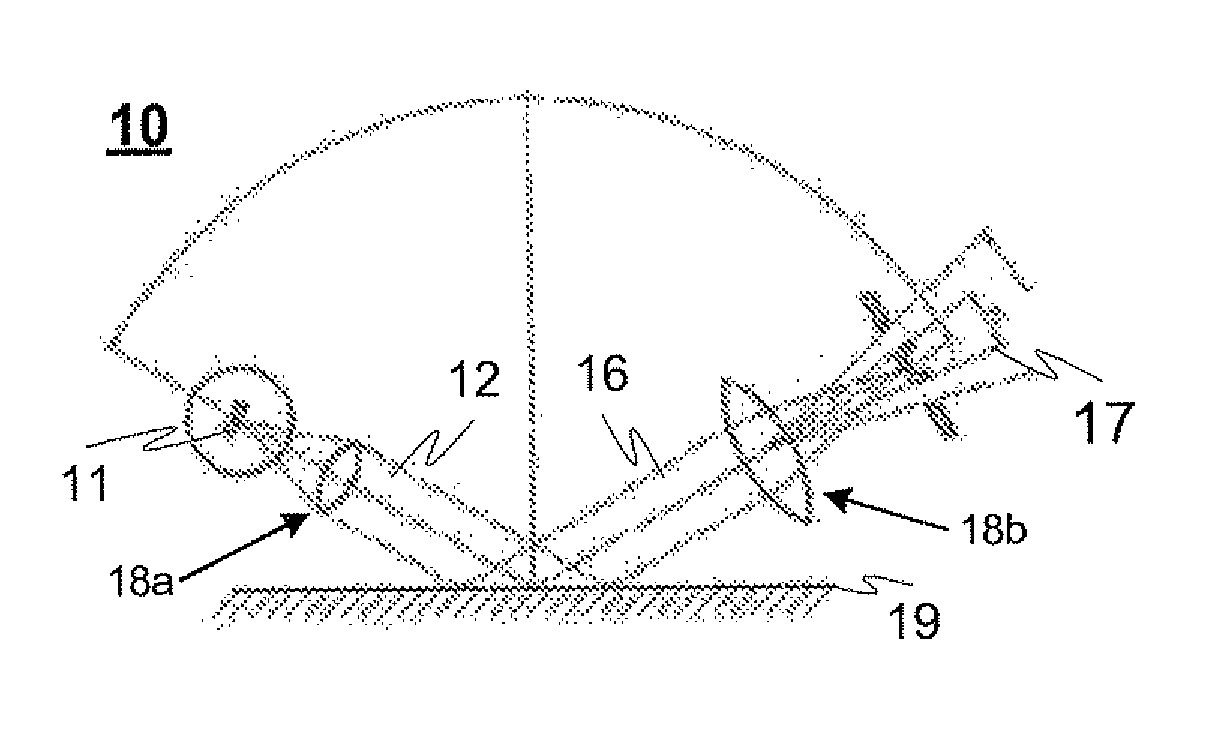

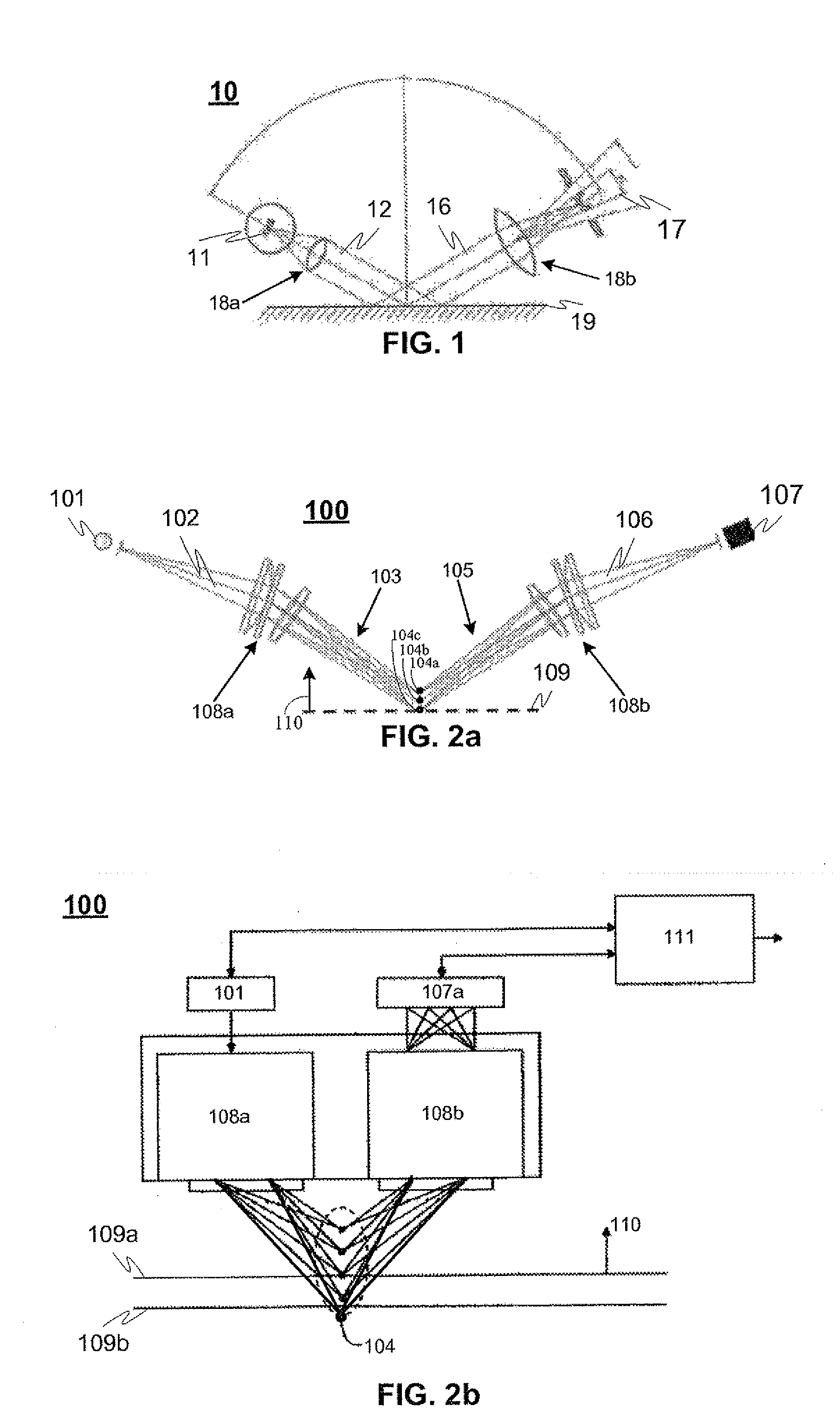

A measurement device for the determination of the characteristics of the object's surface by means of the optical radiation, wherein a measurement device comprises an optical radiation source and a detector to receive the radiation reflected from the surface being measured. In addition, a measurement device comprises an emitted optical radiation processing unit, which is adjusted to split optical radiation emitted by an optical source into separate wavelengths and to direct said separate wavelengths to the object being measured in a direction, that differs from the normal of the surface being measured so, that at least the shortest and the longest wavelengths of said wavelengths are focused on different halves and different heights of the measured object's surface, in the direction of the normal of the surface being measured. In addition, a measurement device comprises a reflected optical radiation processing unit, which is adjusted to receive an optical radiation reflected from the measured object at least in the direction of a specular reflection, which differs from the normal of the surface being measured, and to direct received optical radiation to said detector. Still further, the measurement device is adjusted to analyze an electric signal produced by the detector and proportional to the intensity of the radiation focused thereto, and to further determine a surface gloss (gloss degree) and / or thickness characteristic property of the measured object, based on the intensity of its wavelength, the focus point of which was located on the measured surface, and which wavelength was the strongest reflected from that point to the detector in the specular geometry.

Owner:FOCALSPEC

Measuring device

InactiveUS20050157314A1Improve accuracyAccurate measurementCaliper-like sensorsMaterial analysis by optical meansEngineeringElectrical and Electronics engineering

Owner:VOITH PATENT GMBH

Measuring instrument and method for determination of the properties of an item and its surface

InactiveCN102575985ARealize measurementCaliper-like sensorsPhase-affecting property measurementsOptical radiationMeasurement device

A measurement device for the determination of the characteristics of the object's surface by means of the optical radiation, wherein a measurement device comprises an optical radiation source and a detector to receive the radiation reflected from the surface being measured. In addition, a measurement device comprises an emitted optical radiation processing unit, which is adjusted to split optical radiation emitted by an optical source into separate wavelengths and to direct said separate wavelengths to the object being measured in a direction, that differs from the normal of the surface being measured so, that at least the shortest and the longest wavelengths of said wavelengths are focused on different halves and different heights of the measured object's surface, in the direction of the normal of the surface being measured. In addition, a measurement device comprises a reflected optical radiation processing unit, which is adjusted to receive an optical radiation reflected from the measured object at least in the direction of a specular reflection, which differs from the normal of the surface being measured, and to direct received optical radiation to said detector. Still further, the measurement device is adjusted to analyze an electric signal produced by the detector and proportional to the intensity of the radiation focused thereto, and to further determine a surface gloss (gloss degree) and / or thickness characteristic property of the measured object, based on the intensity of its wavelength, the focus point of which was located on the measured surface, and which wavelength was the strongest reflected from that point to the detector in the specular geometry.

Owner:LEMMAI TECH CO LTD

Wavelength selection method, film thickness measurement method, film thickness measurement apparatus, and system for producing thin film silicon device

InactiveUS20100033735A1Reducing film thickness measurement errorImprove power generation efficiencyCaliper-like sensorsLiquid surface applicatorsMeasurement deviceLength wave

An object is to reduce film thickness measurement error. Illumination light having different wavelengths is radiated onto a plurality of samples in which thin films having different film qualities and film thicknesses are provided on substrates, evaluation values related to the amounts of transmitted light when the illumination light of each wavelength is radiated are measured, film thickness characteristics, showing the relationship between the evaluation values and the film thicknesses for each film quality, are formed at each wavelength based on the measurement results, and among the film thickness characteristics, a wavelength at which a measurement difference between the evaluation values caused by the film qualities is in a predetermined range is selected.

Owner:MITSUBISHI HEAVY IND LTD

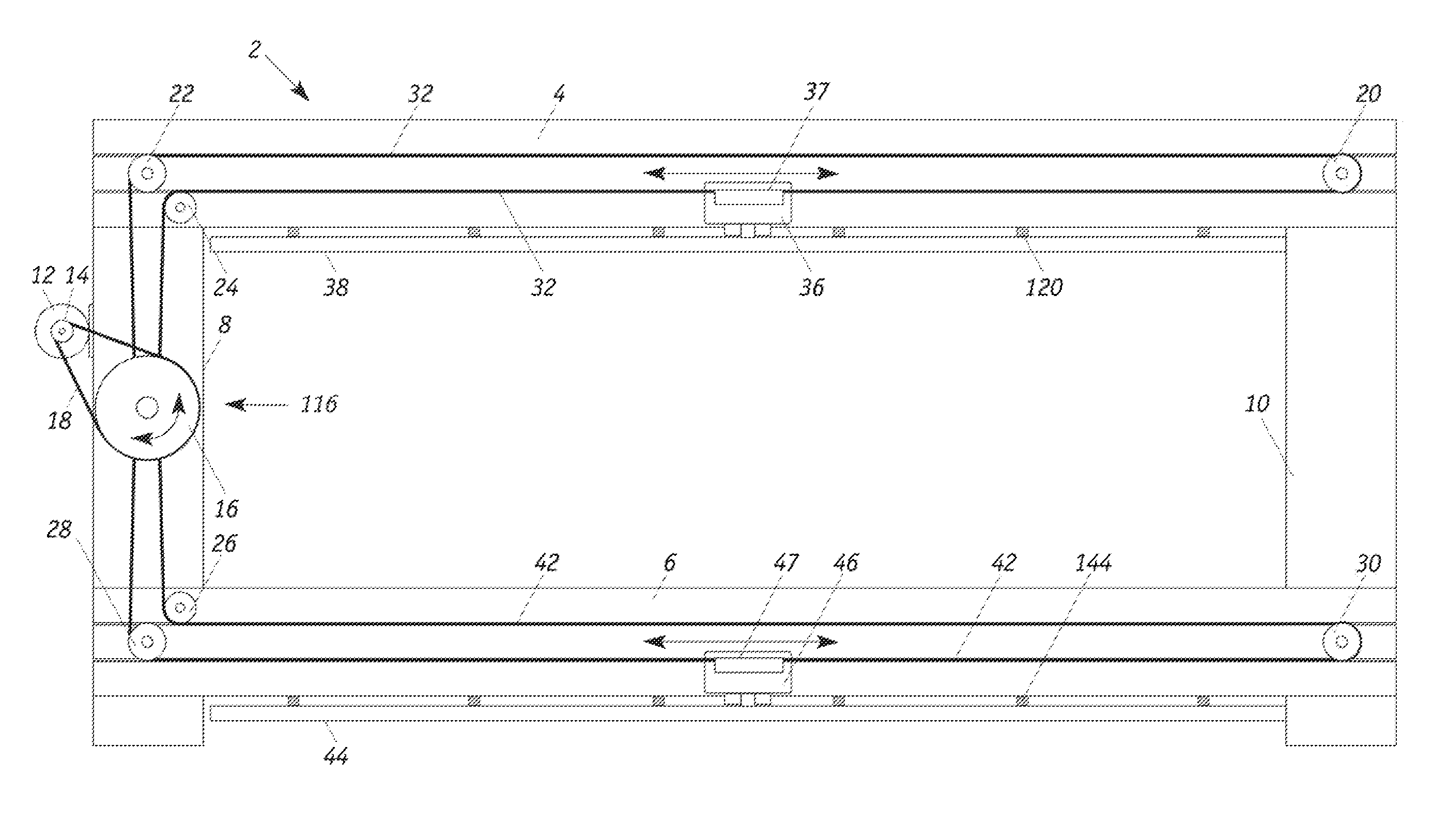

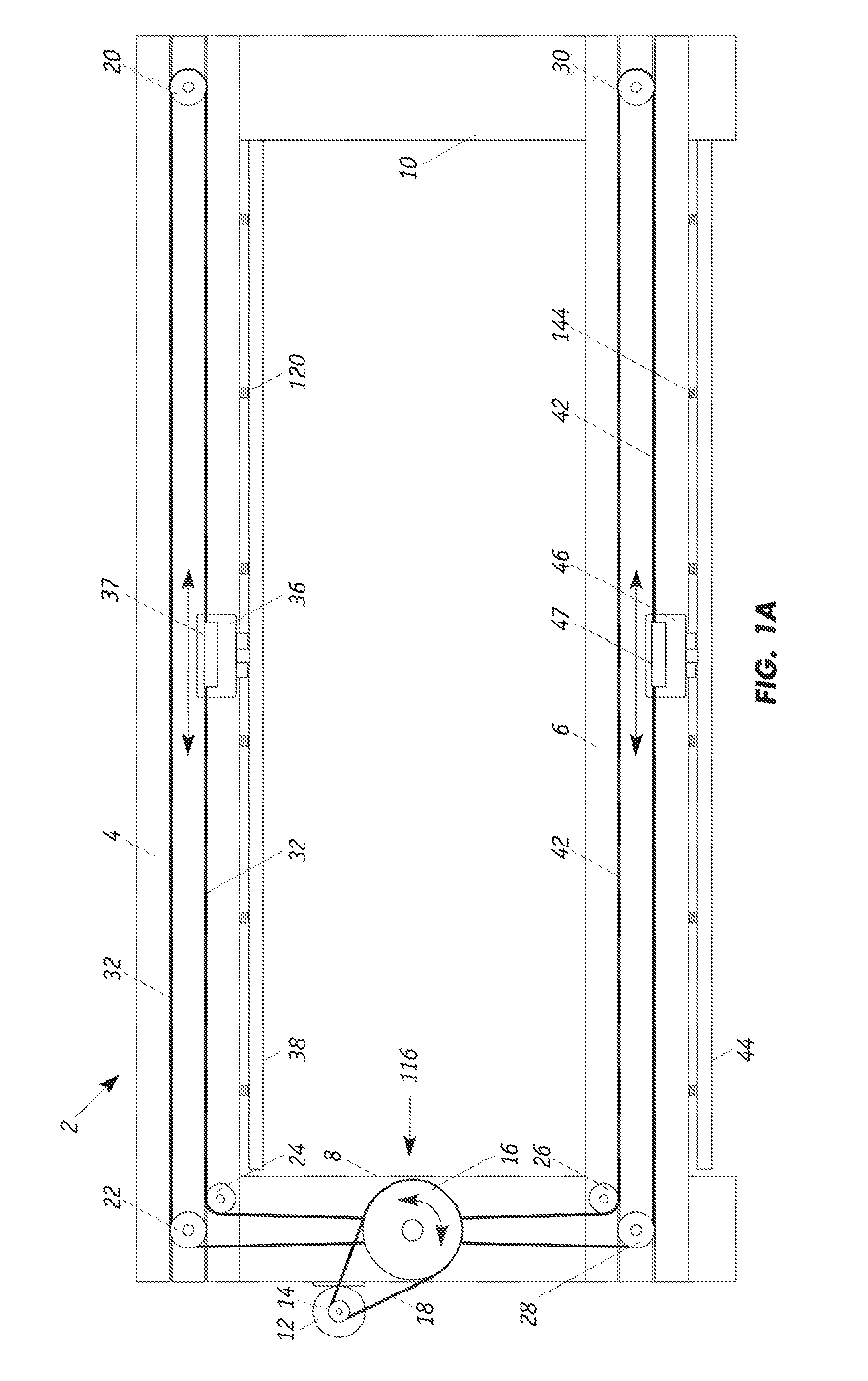

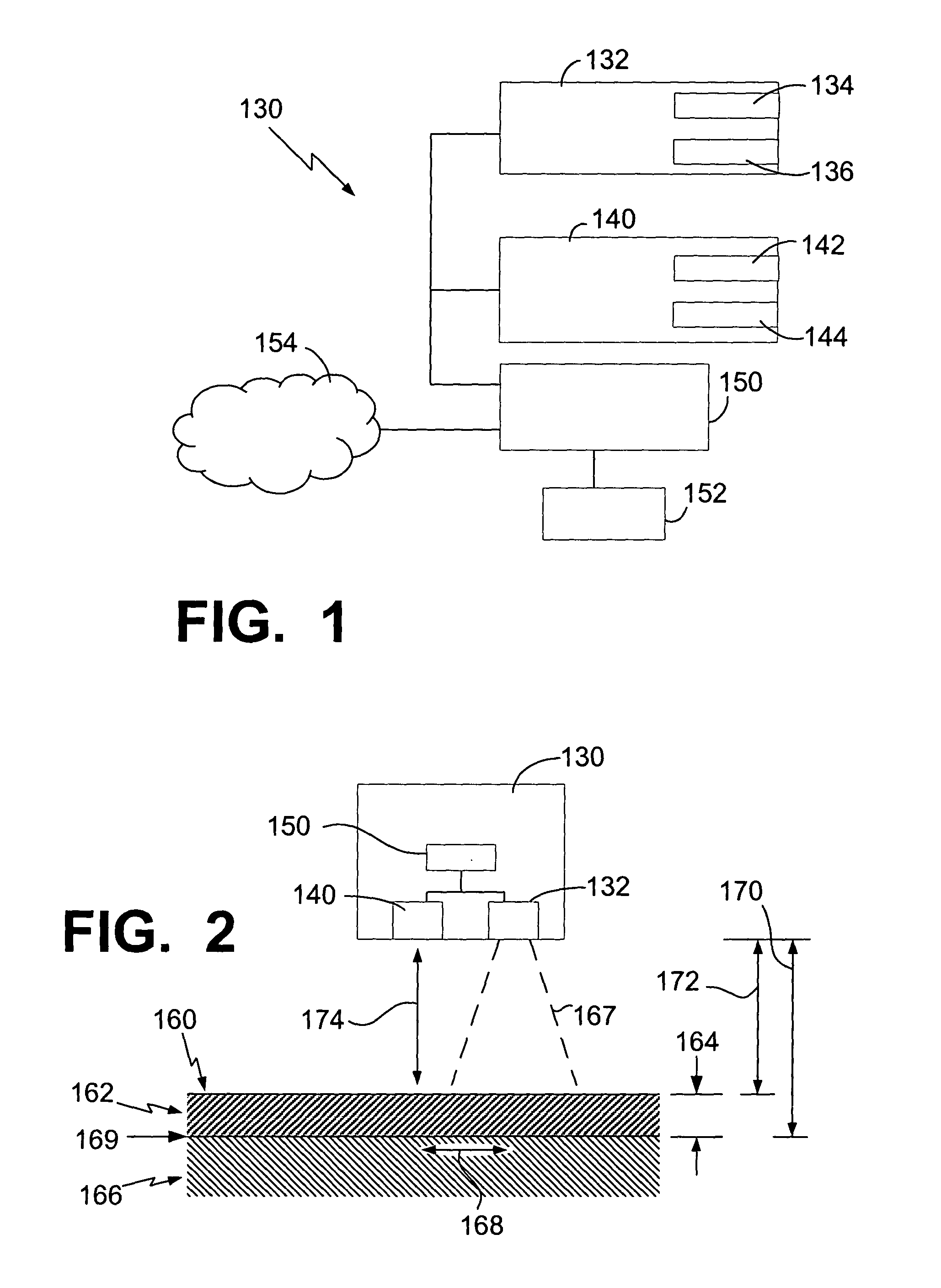

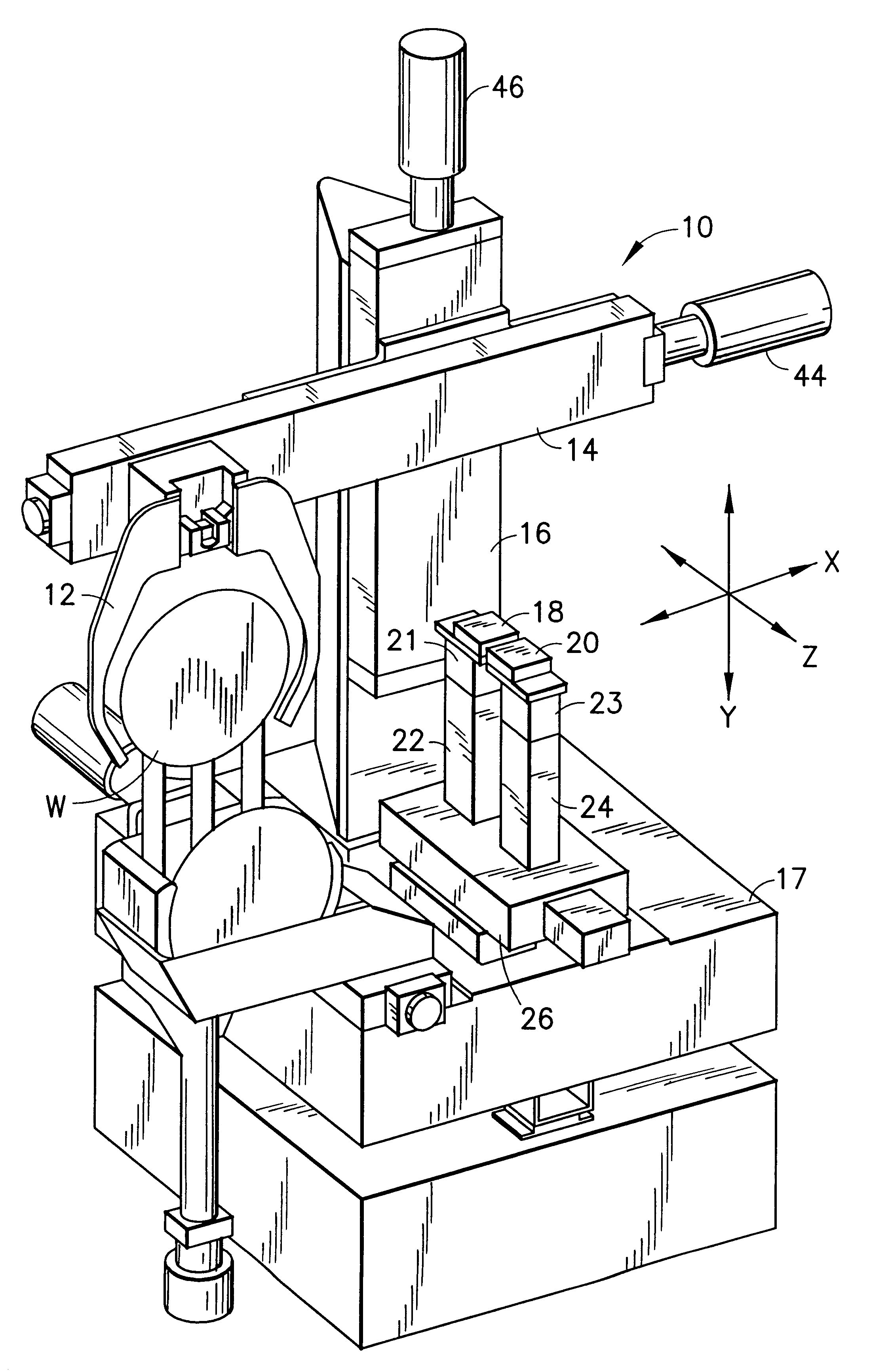

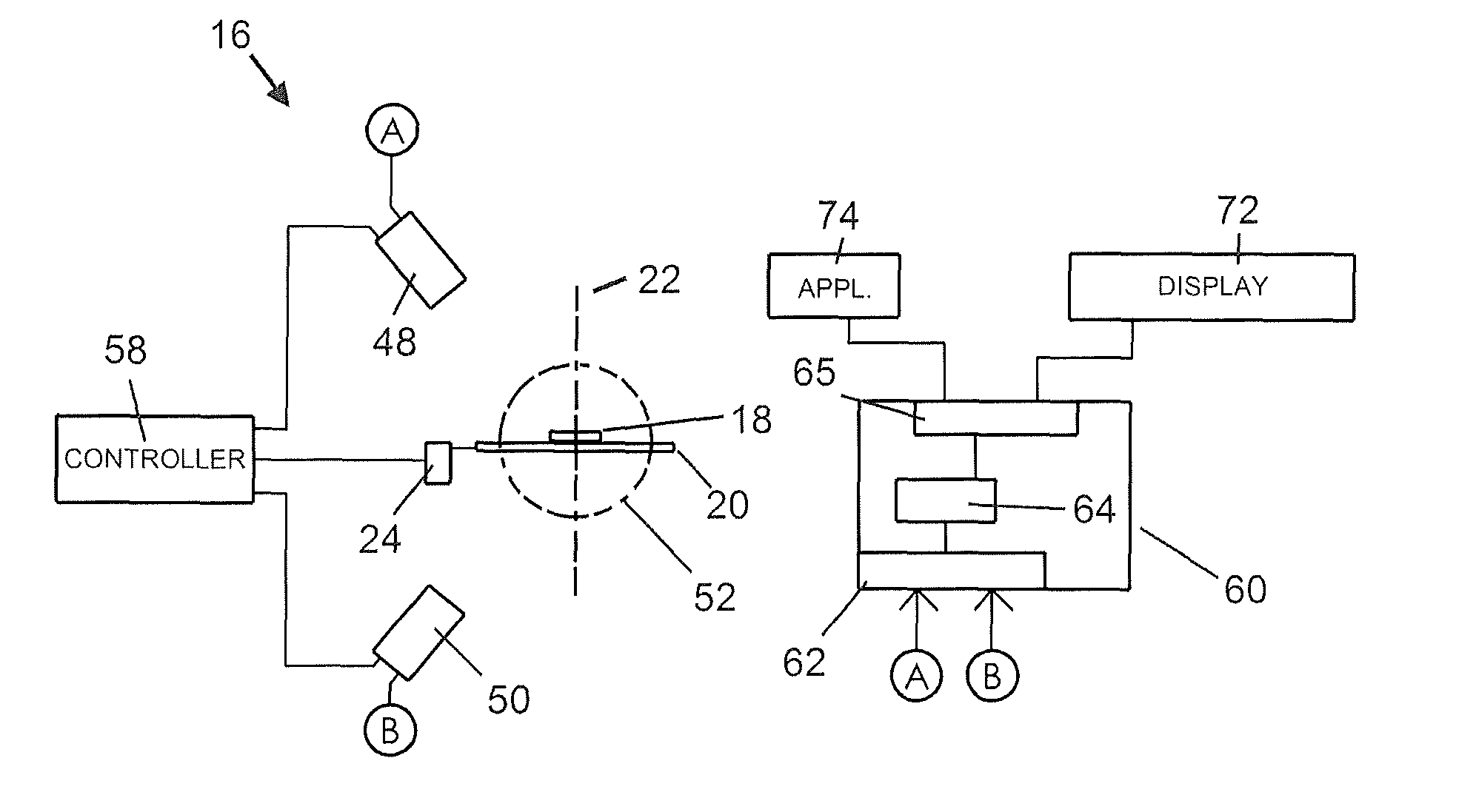

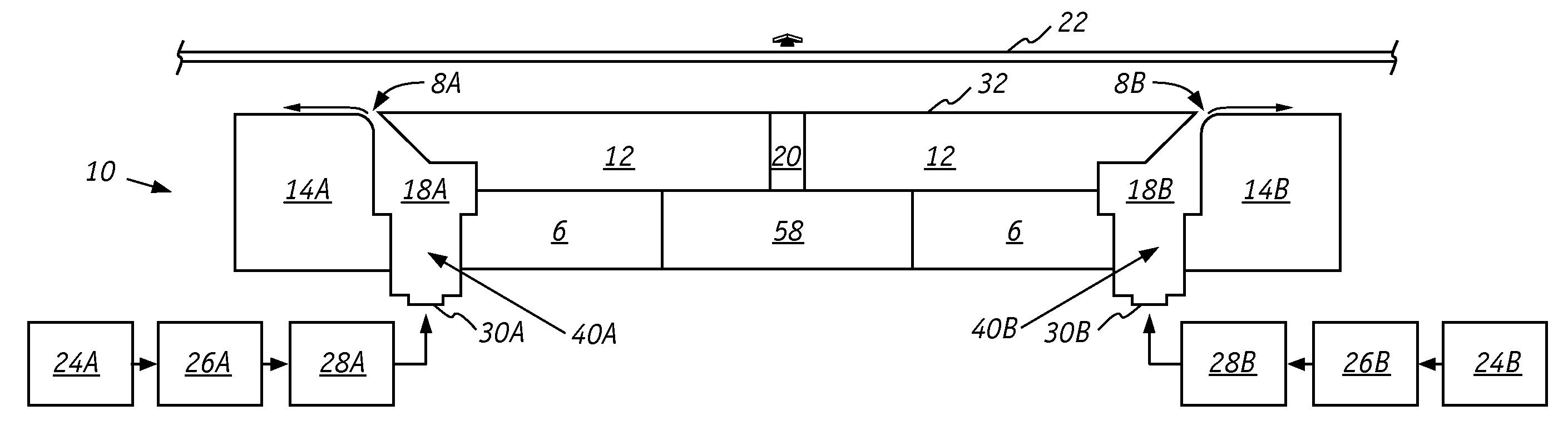

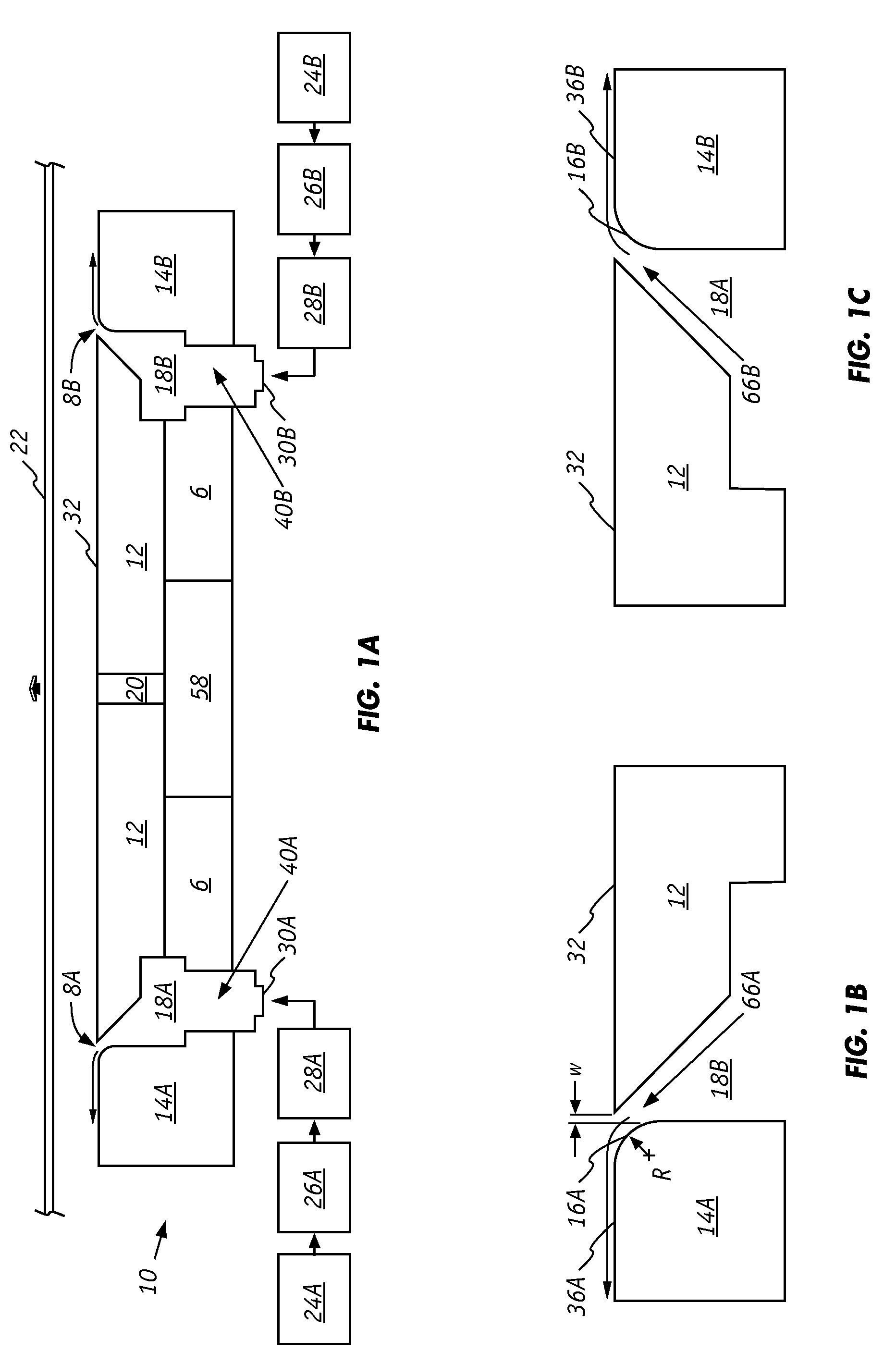

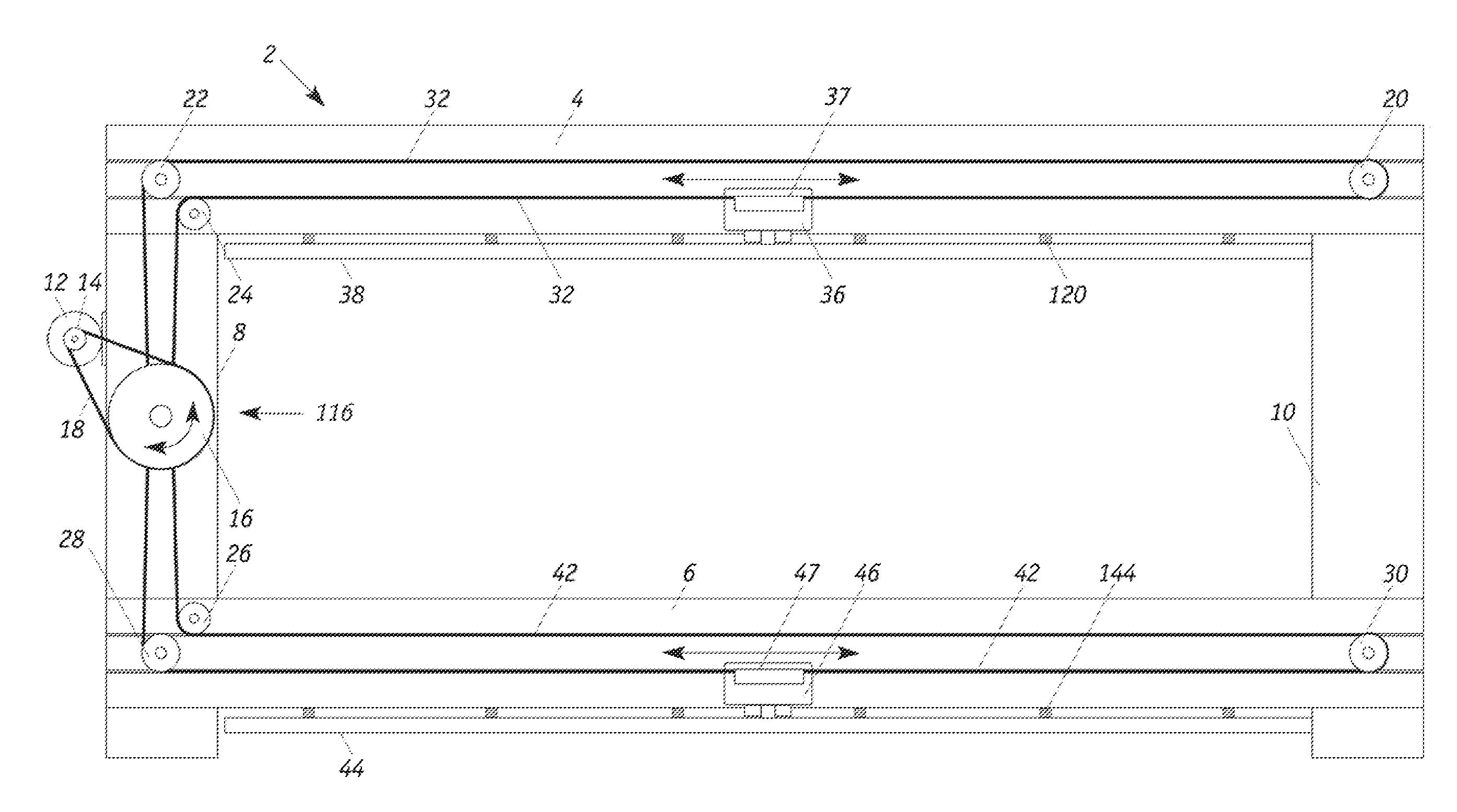

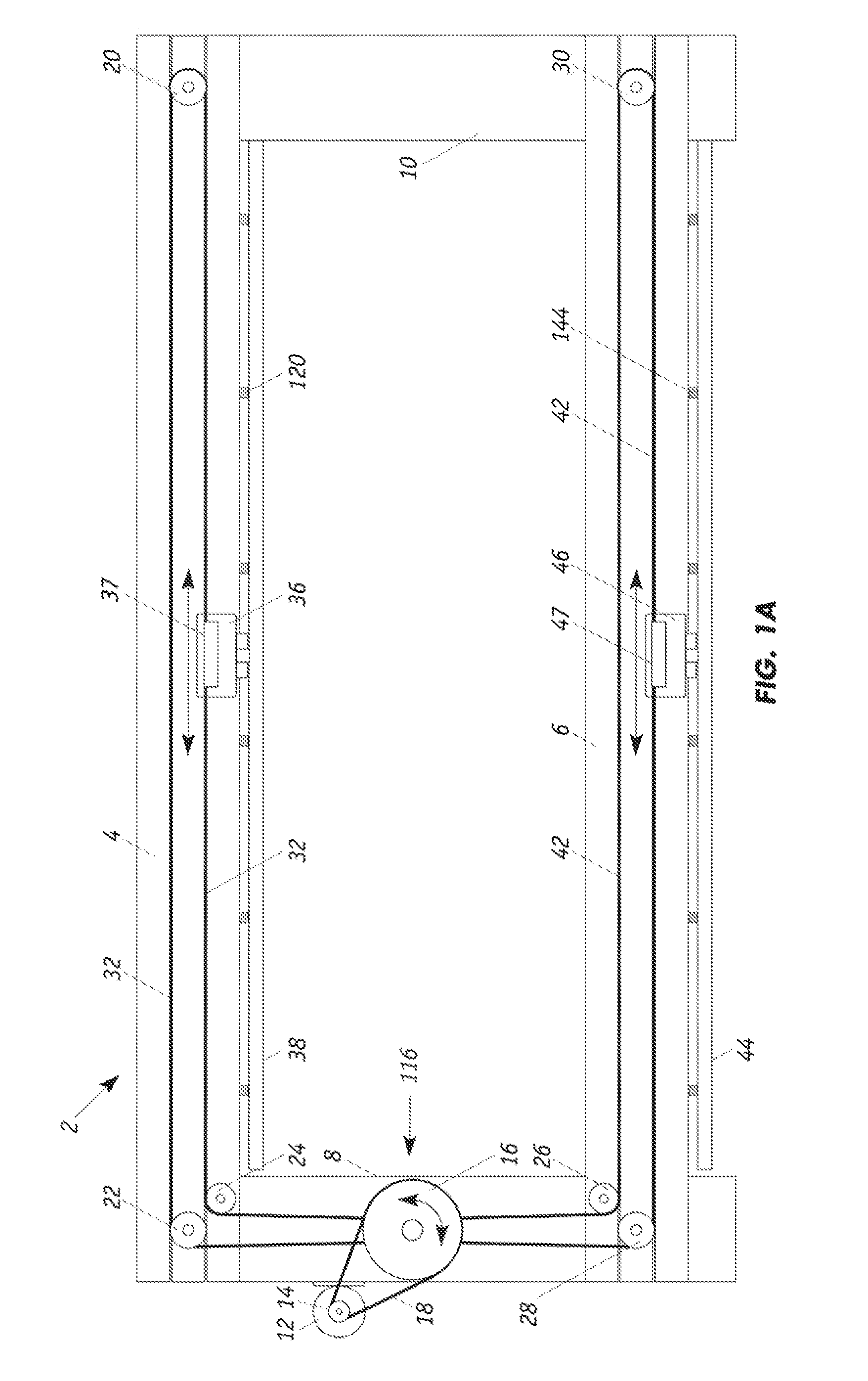

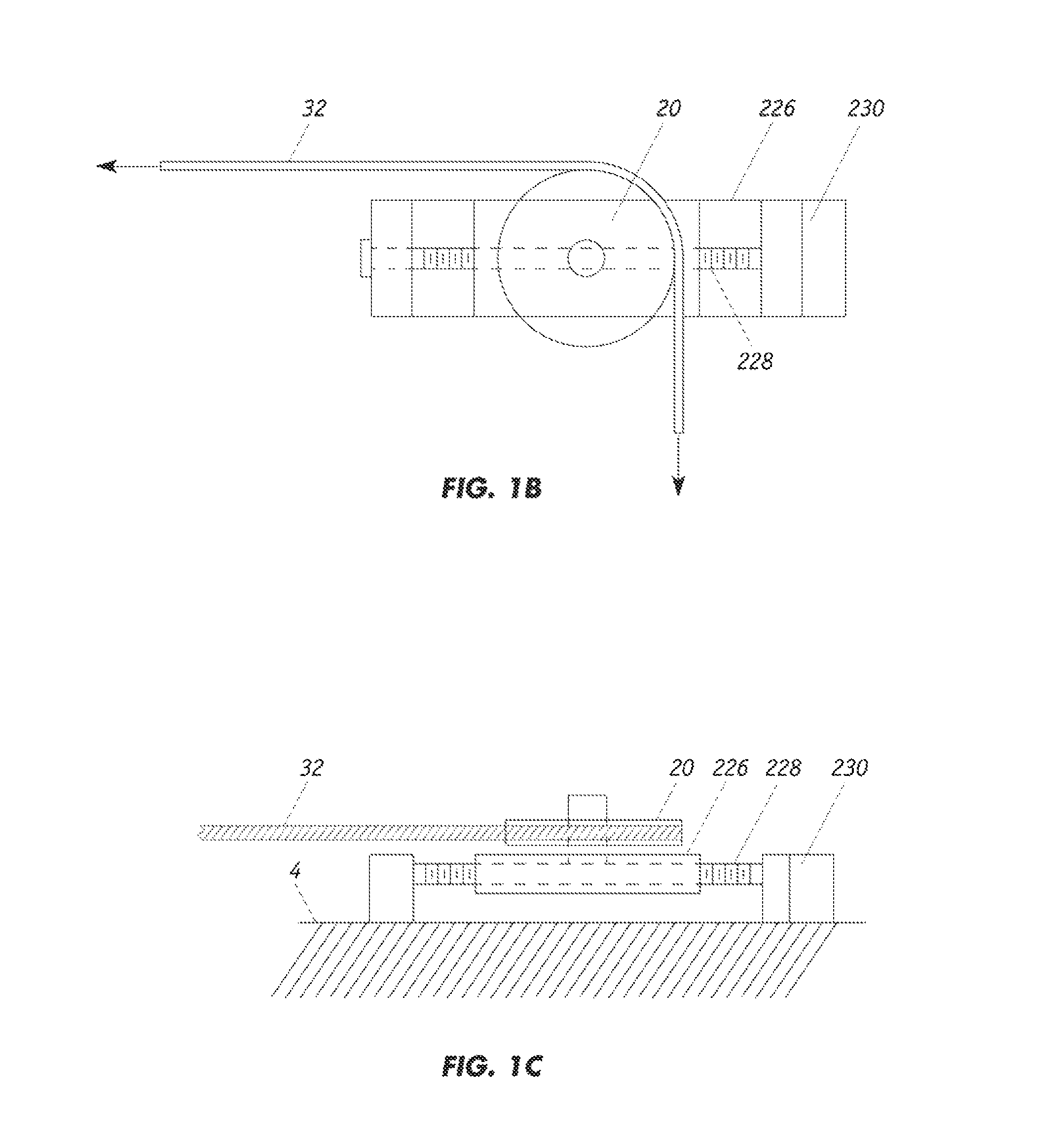

Scanner Belt Load and Stretch Compensation Control System

ActiveUS20130100503A1Evenly loadedReduce errorsCaliper-like sensorsRadiation pyrometryControl systemActuator

Upper to lower assembly analog position sensors in a dual scanning system measure alignment offsets. A controller uses error signals from the position sensors to calculate actuator error profiles that are used in the next scan in the same direction, with different error profiles being used for forward and reverse scans. Since the alignment error profiles are repeatable for a given set of scanner conditions, the actuator controller anticipates what the error signal will be before each scanning assembly reaches a given position. An optimized error correction can be calculated based on the error profiles and actuator bandwidth without concerns regarding feedback loop speed, overshoot, and unstable control oscillations. An actuation system driven from error profiles can correct for alignment offsets by actively changing belt tensions at the offsetting drive pulleys and / or changing the position of sensor assemblies relative to the drive belt systems.

Owner:HONEYWELL ASCA INC

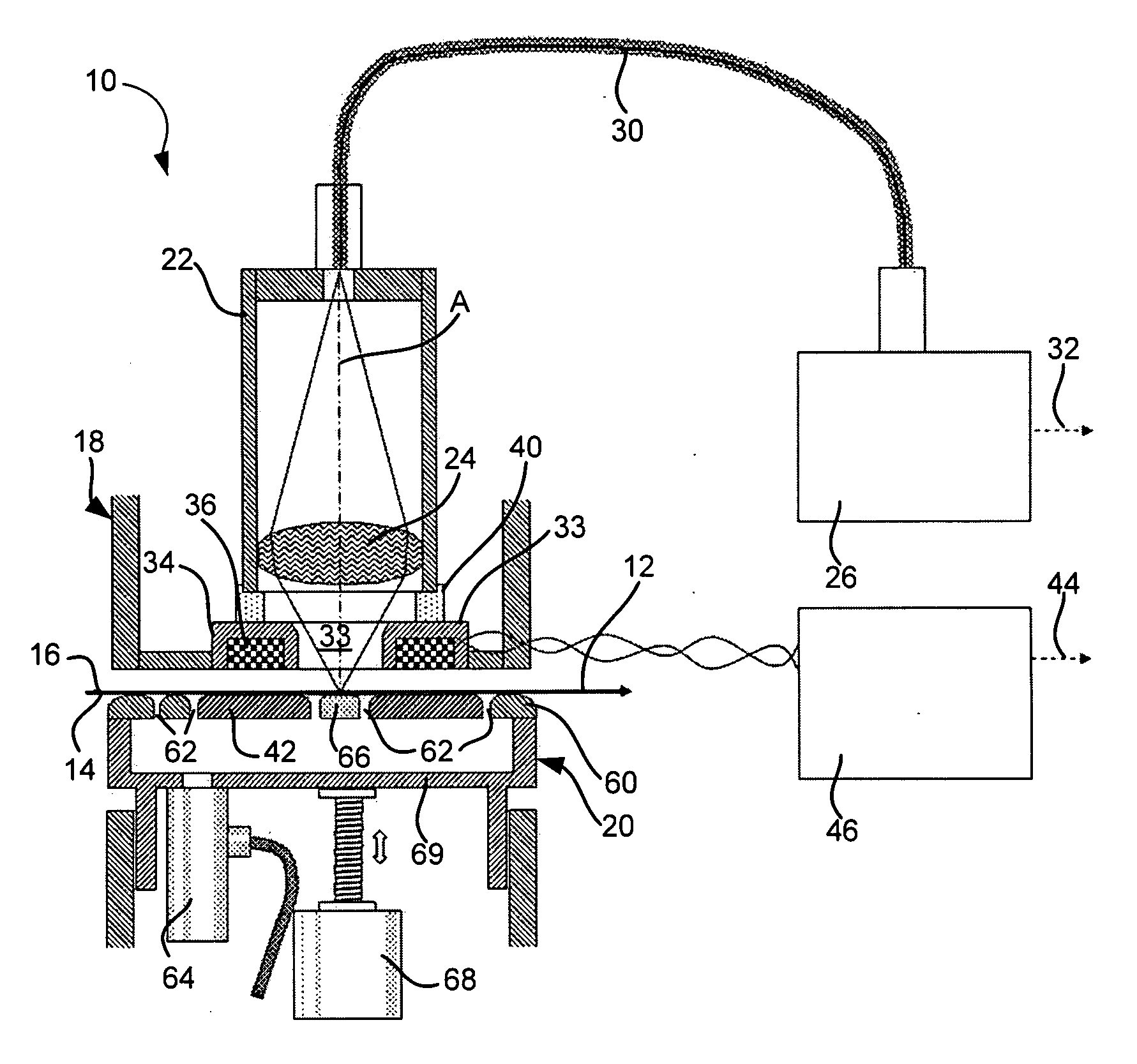

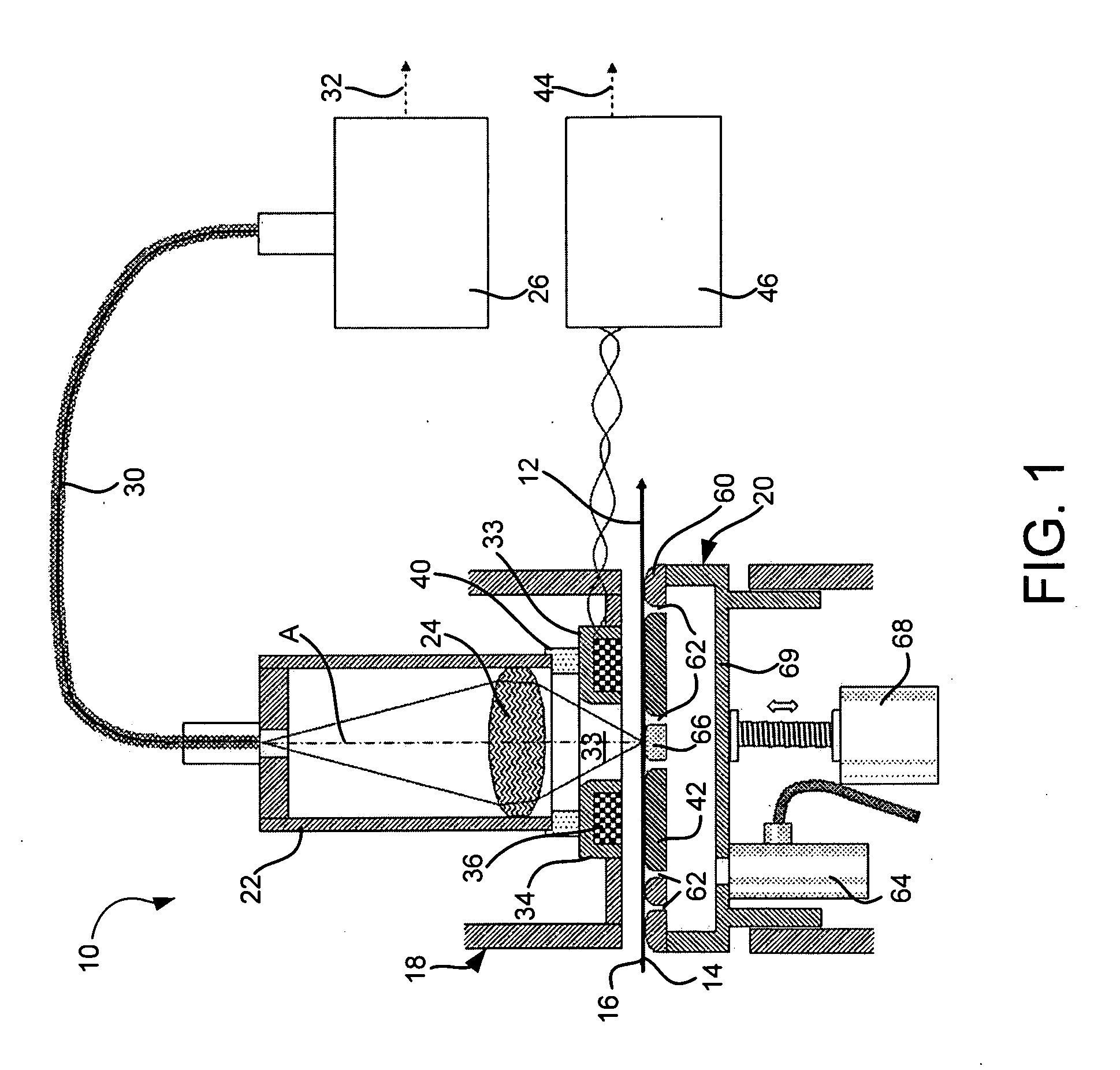

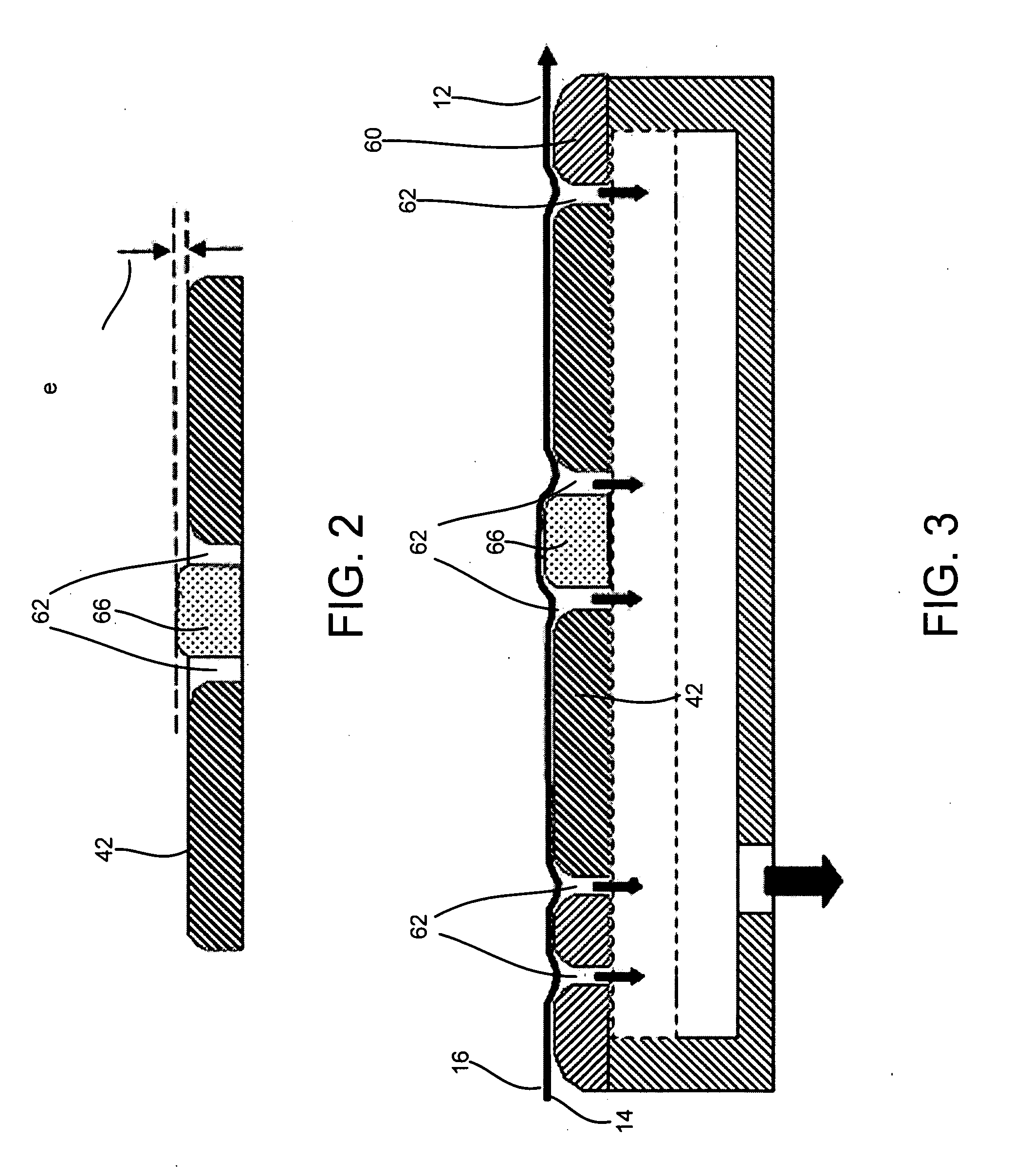

Web Measurement Device

InactiveUS20090059244A1Accurate measurementCaliper-like sensorsInvestigating moving sheetsMeasurement deviceNetwork measurement

A sensor is provided that measures web caliper using optical and magnetic measuring devices. The optical measuring devices may employ a confocal chromatic aberration method to accurately determine the distance to the moving web and the magnetic devices may be ferrite core coil and target. Means of stabilizing a moving web are included for improving dynamic measurement accuracy.

Owner:ABB LTD

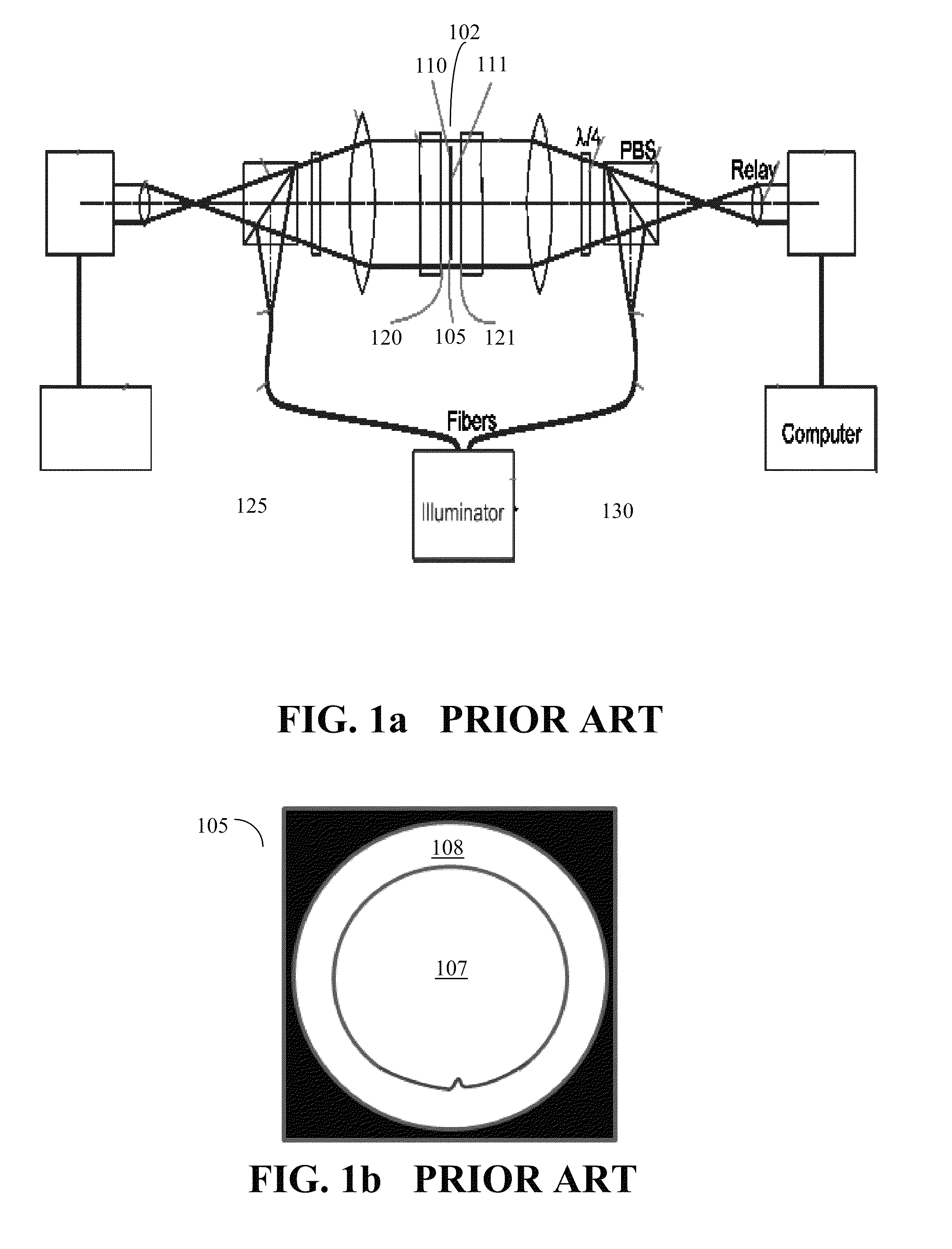

Determining surface and thickness

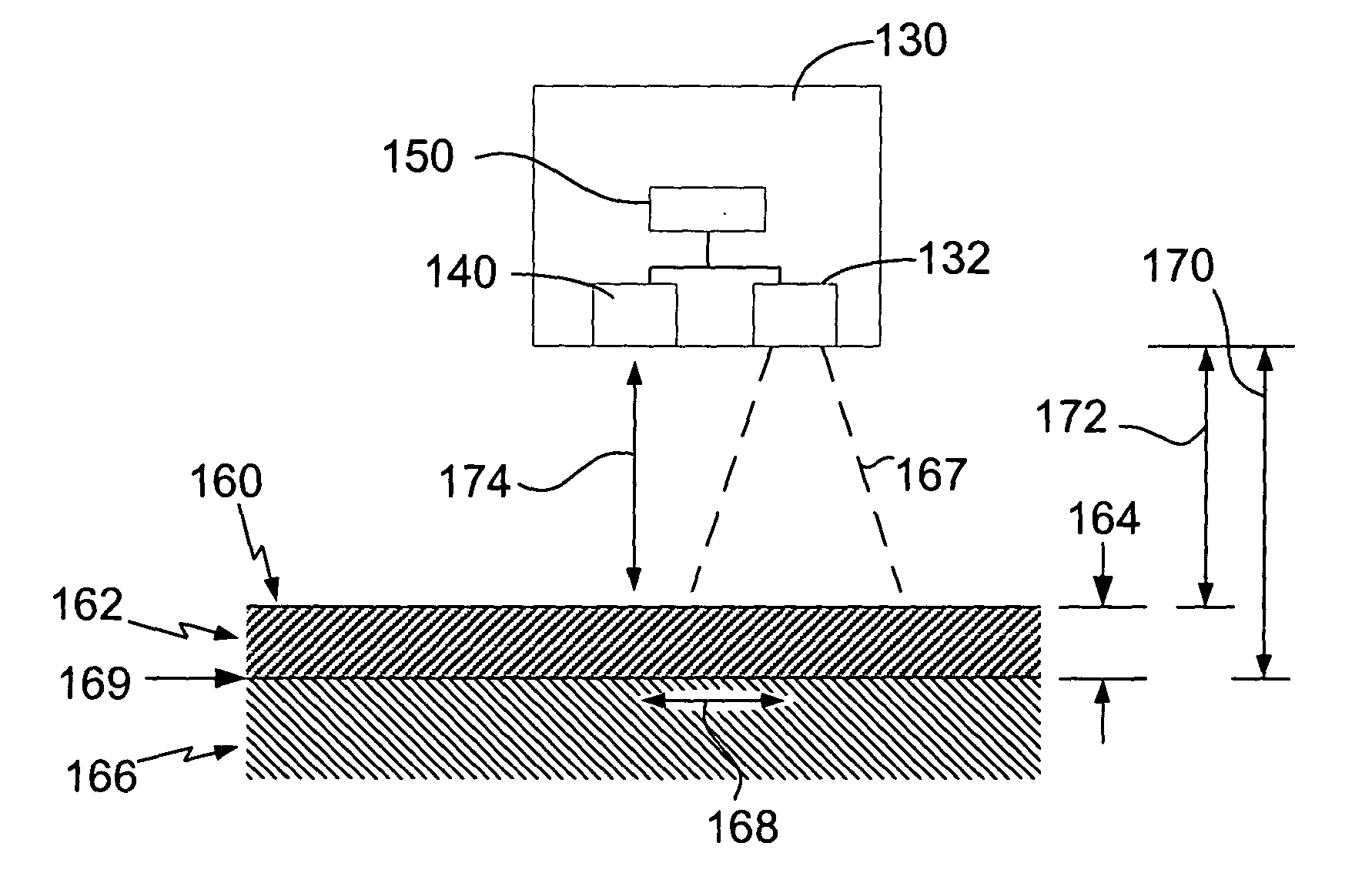

ActiveCN101529200AAccurate measurementReduce diffuseCaliper-like sensorsPolarisation-affecting propertiesOptical radiationPolarizer

An optical radiation processing unit (112) directs different wavelengths of the optical radiation emitted by an optical source (104) to an object (114) being measured from a direction that differs from the normal (118) of a surface (116) being measured in such a manner that the different wavelengths focus on different heights in the direction of the normal (118) of the surface (116) being measured. A possible polarizer (120, 122) polarizes the reflected radiation in a direction perpendicular to the normal (118) of the surface (116). The optical radiation processing unit (112) directs to a detector (108) polarized optical radiation that it receives from the object (114) being measured. The signal processing unit (124) determines on the basis of a signal provided by the detector (112) from the detected radiation the wavelength on which the intensity of the radiation is the highest, and determines the location of the surface (116) by means of the determined wavelength. When measuring an object (114) from both sides, the thickness of the object (114) being measured is determinable using the locations of the surfaces.

Owner:LEMMAI TECH CO LTD

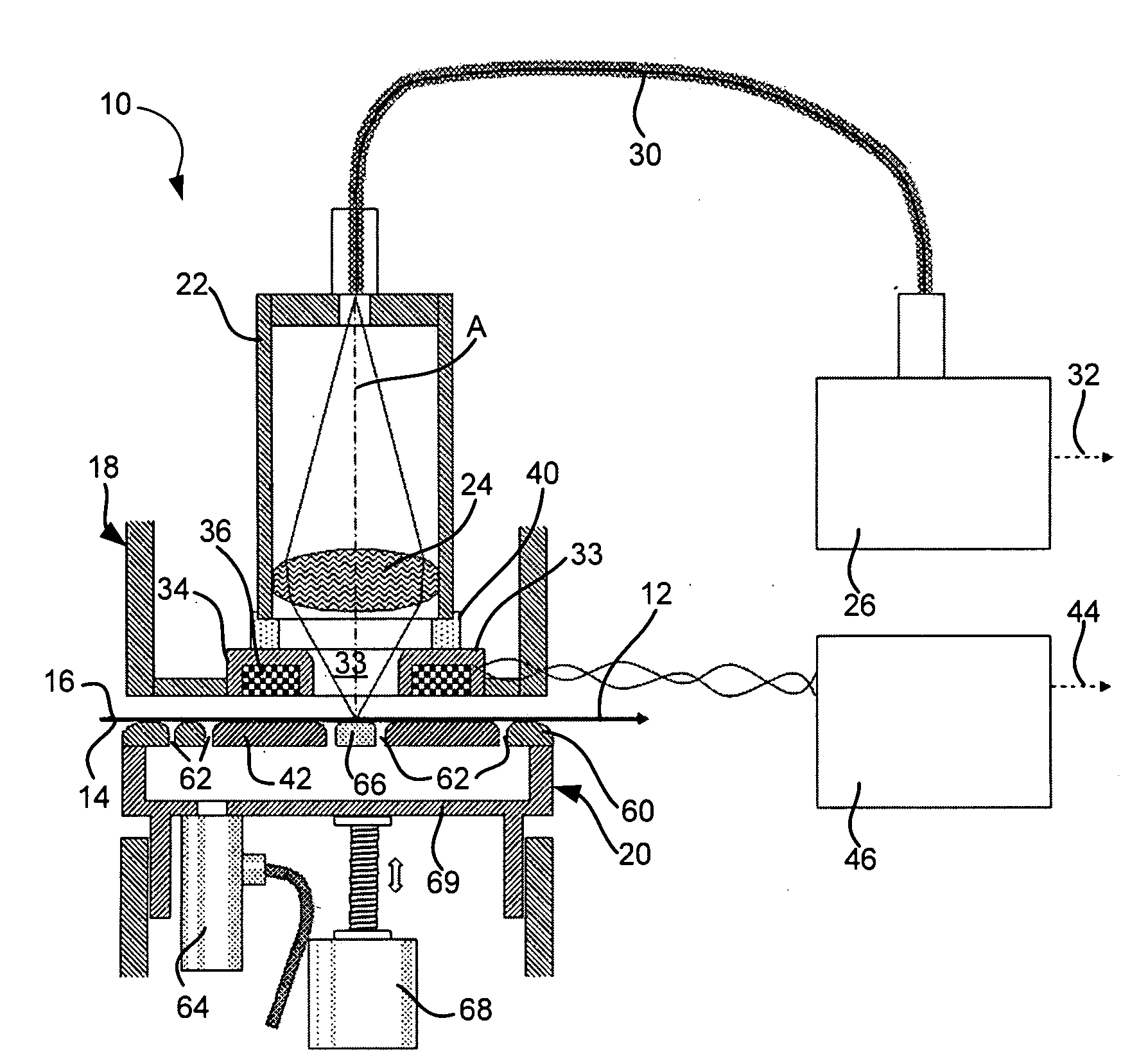

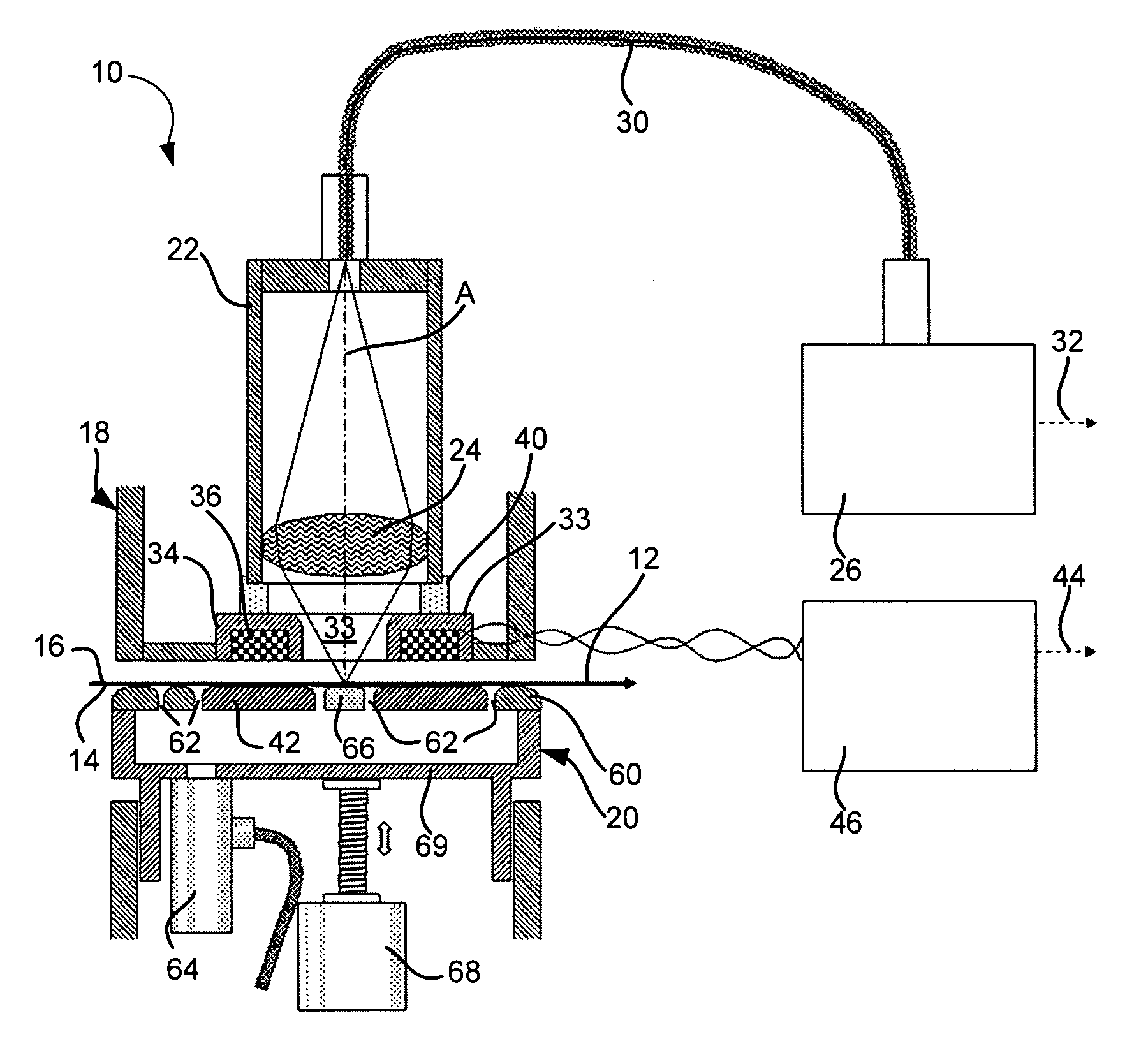

Method and apparatus for non-contact thickness measurement

ActiveUS20050046874A1Caliper-like sensorsMaterial analysis by optical meansLight beamLayer thickness

The present invention provides a method and apparatus for use in measuring a thickness of a layer and / or variations in layer thickness for layers that are flat, curved or have curves. The apparatus comprises a light source to generate a light beam, a light beam detector to detect at least a portion of the light beam reflected, an eddy current field generator that induces an eddy current, an eddy current detector to detect the induced eddy current and a processor coupled with the light source, light detector, eddy current field generator and eddy current detector, wherein the processor controls the light detector, eddy current field generator and eddy current detector. A radial characteristic of a region of the surface can be determined, a scaling factor can be determined based on the radial characteristic and a measured distance can be scaled based on the scaling factor in determining a thickness.

Owner:THE BOEING CO

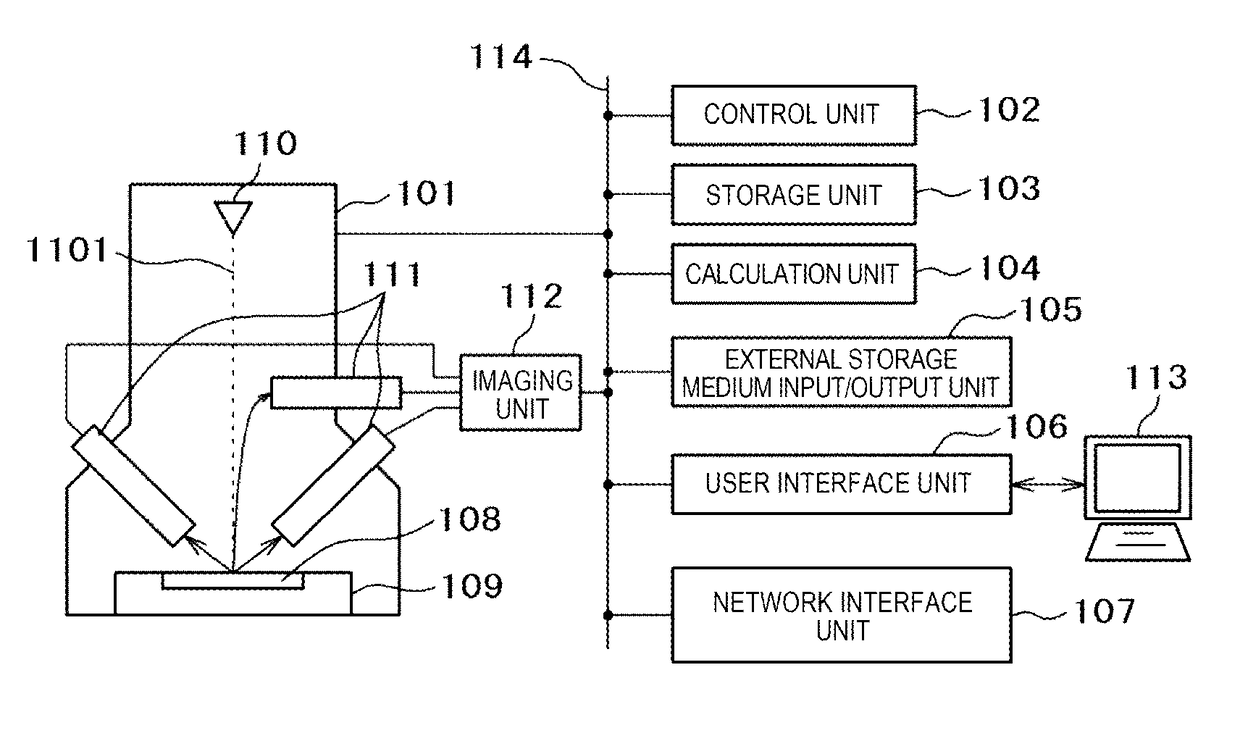

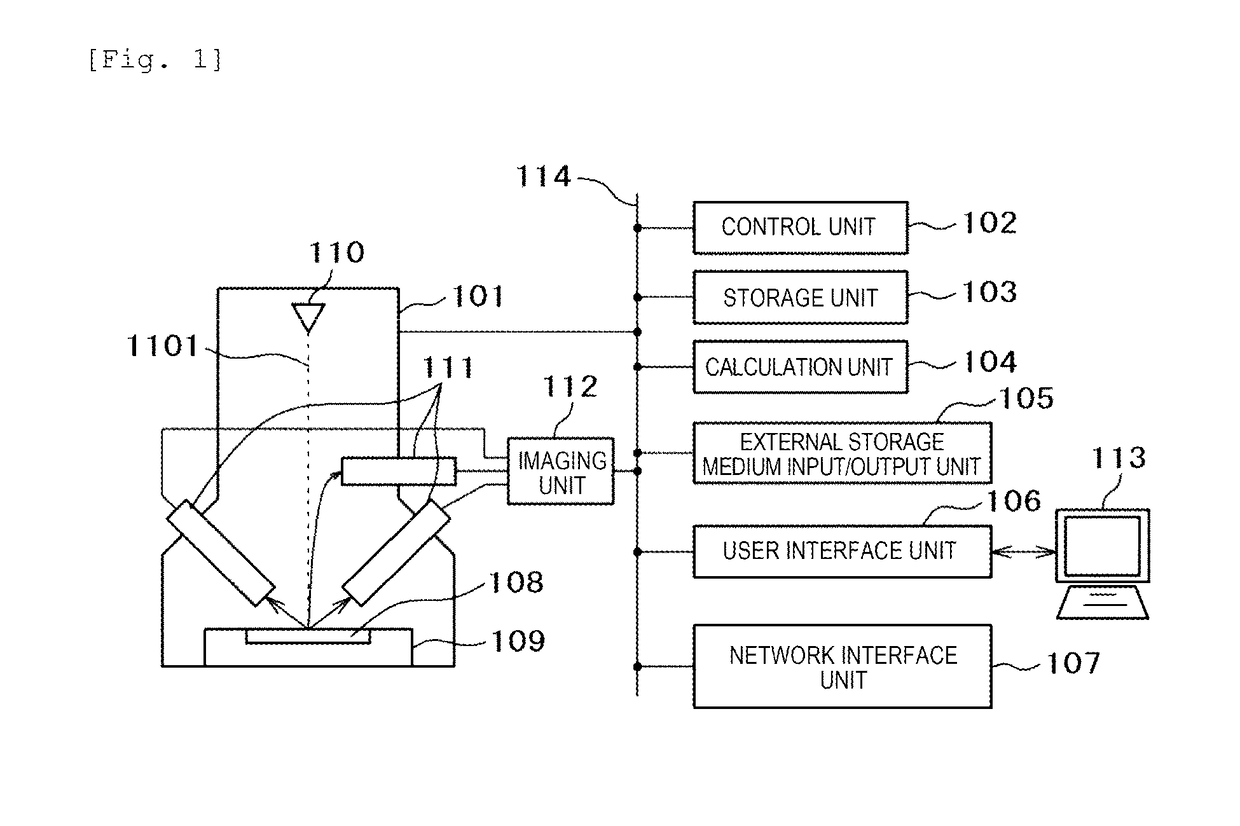

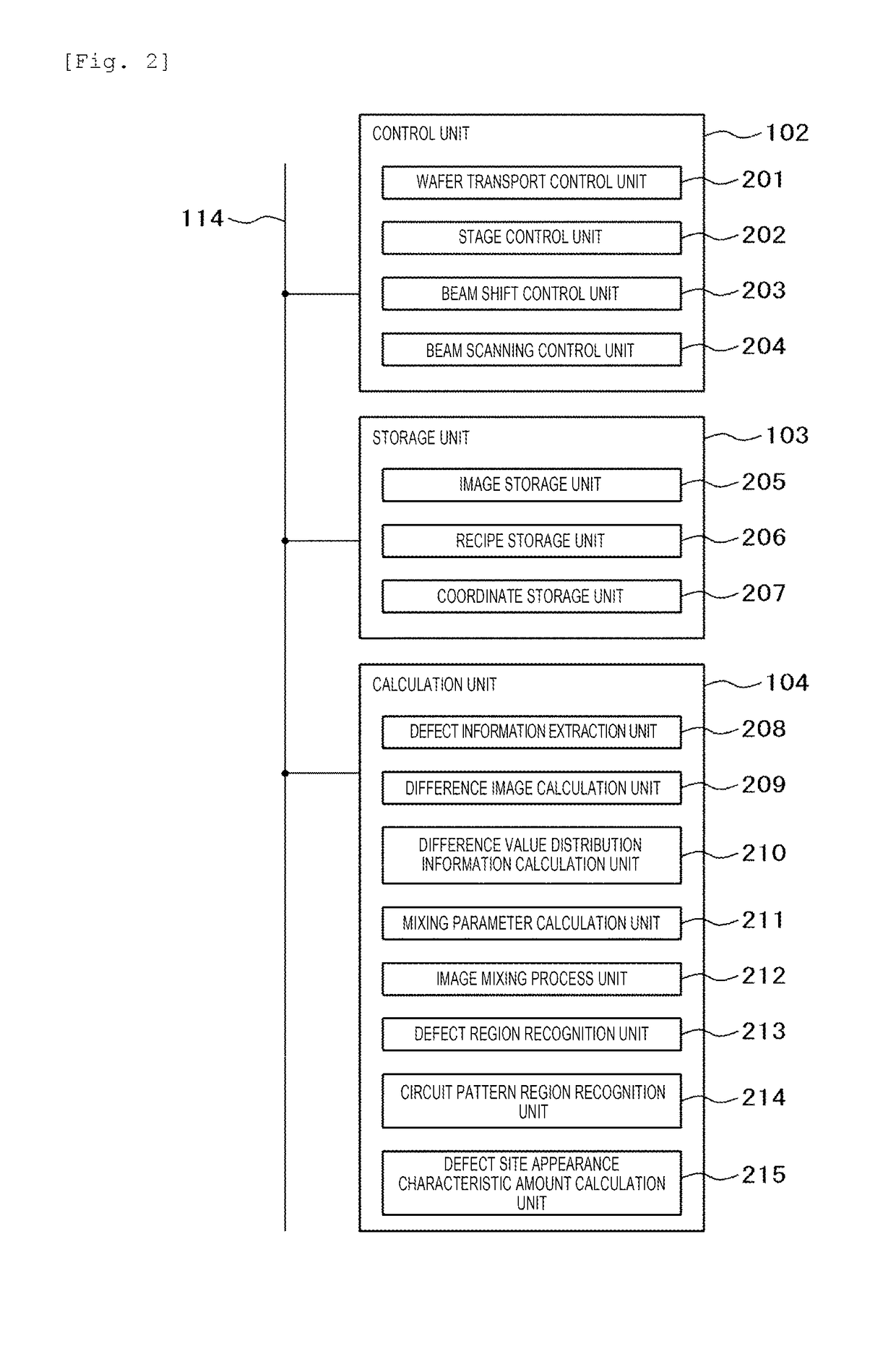

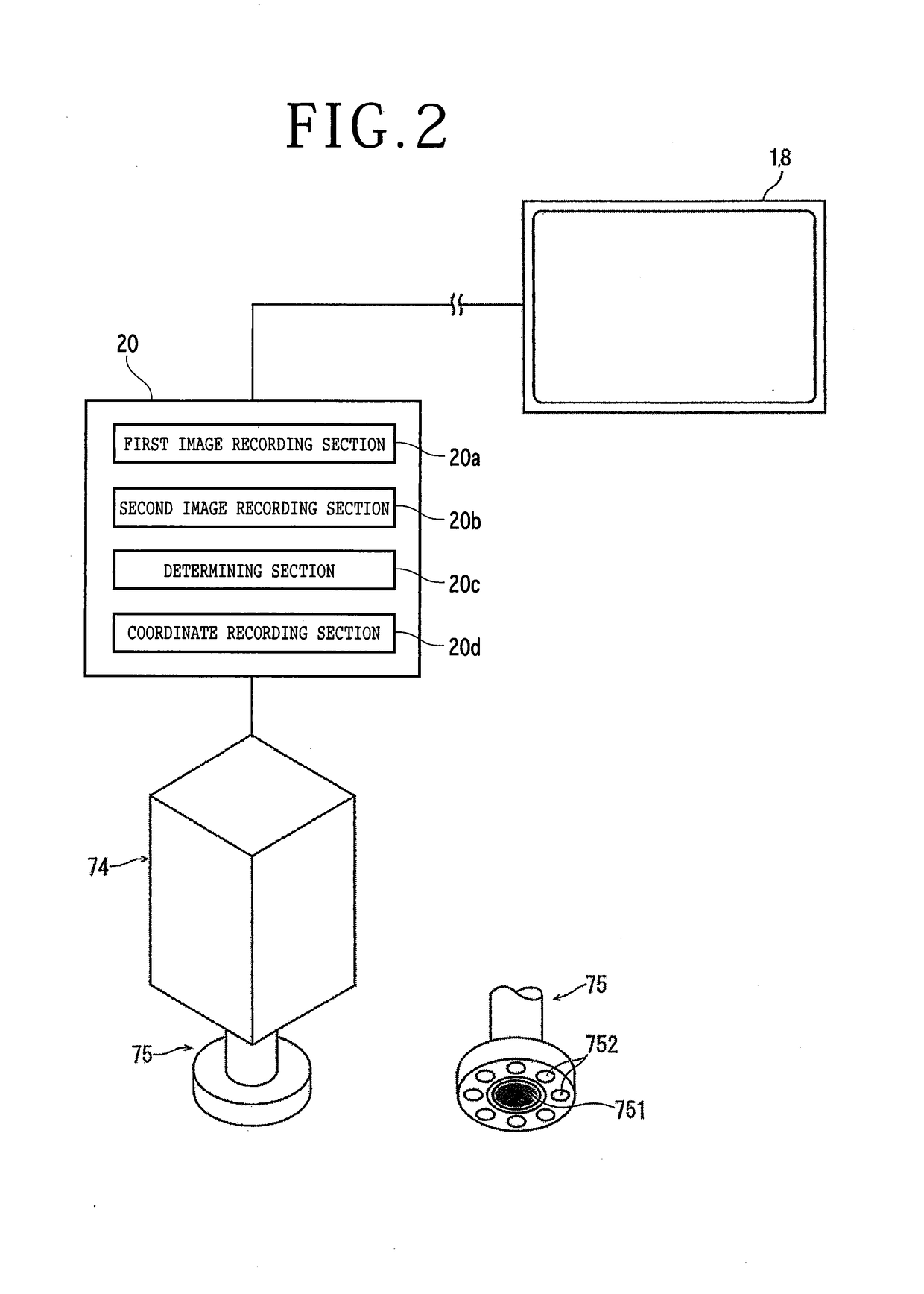

Sample observation method and sample observation device

ActiveUS20180019097A1Reduce the burden onCaliper-like sensorsImage enhancementSecondary electronsObservation method

An inspection method uses a charged particle microscope to observe a sample and view a defect site or a circuit pattern. A plurality of images is detected by a plurality of detectors and a mixed image is generated by automatically adjusting and mixing weighting factors required when the plurality of images are synthesized with each other. The sample is irradiated and scanned with a charged particle beam so that the plurality of detectors arranged at different positions from the sample detects a secondary electron or a reflected electron generated from the sample. The mixed image is generated by mixing the plurality of images of the sample with each other for each of the plurality of detectors, which are obtained by causing each of the plurality of detectors arranged at the different positions to detect the secondary electron or the reflected electron. The generated mixed image is displayed on a screen.

Owner:HITACHI HIGH-TECH CORP

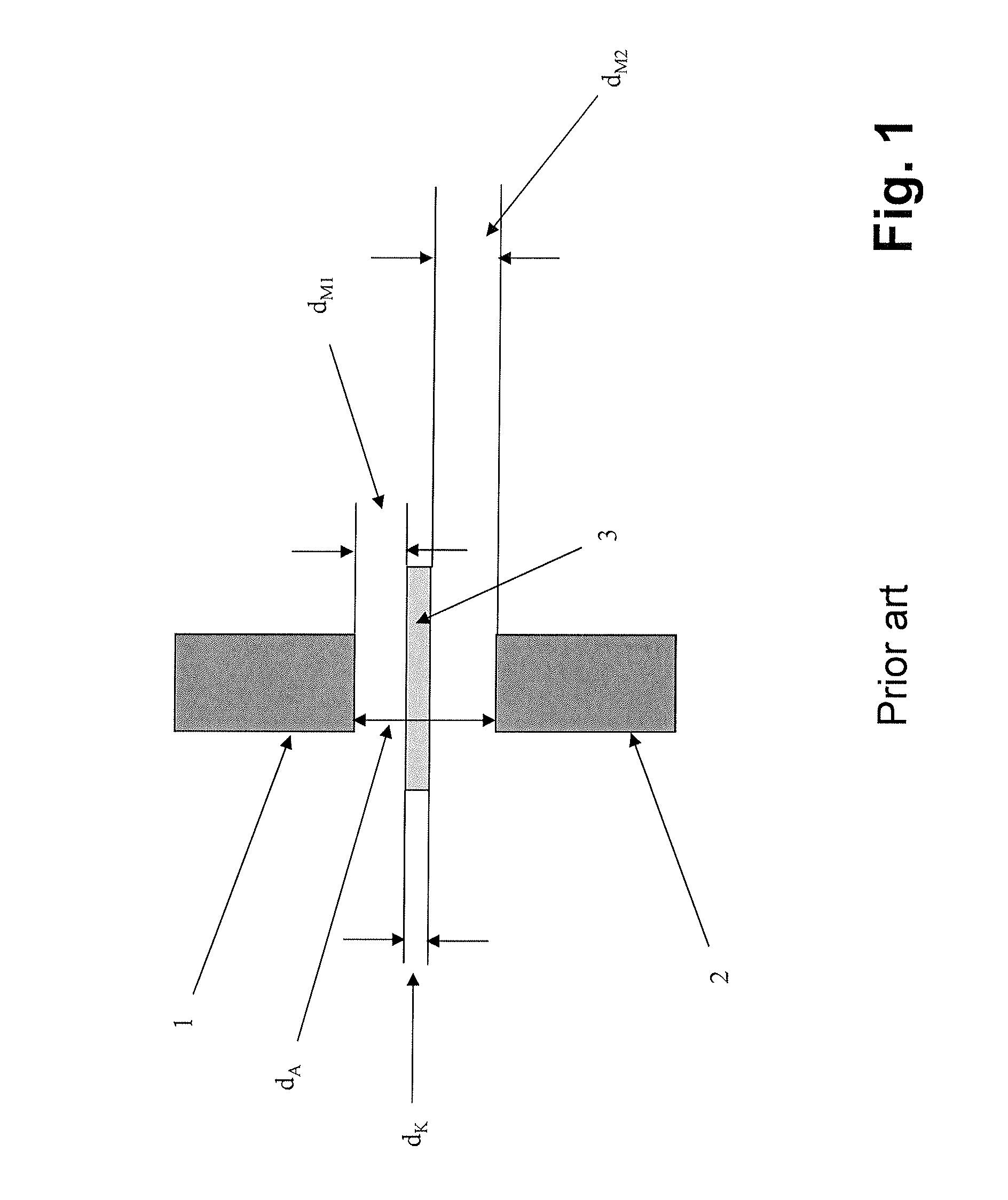

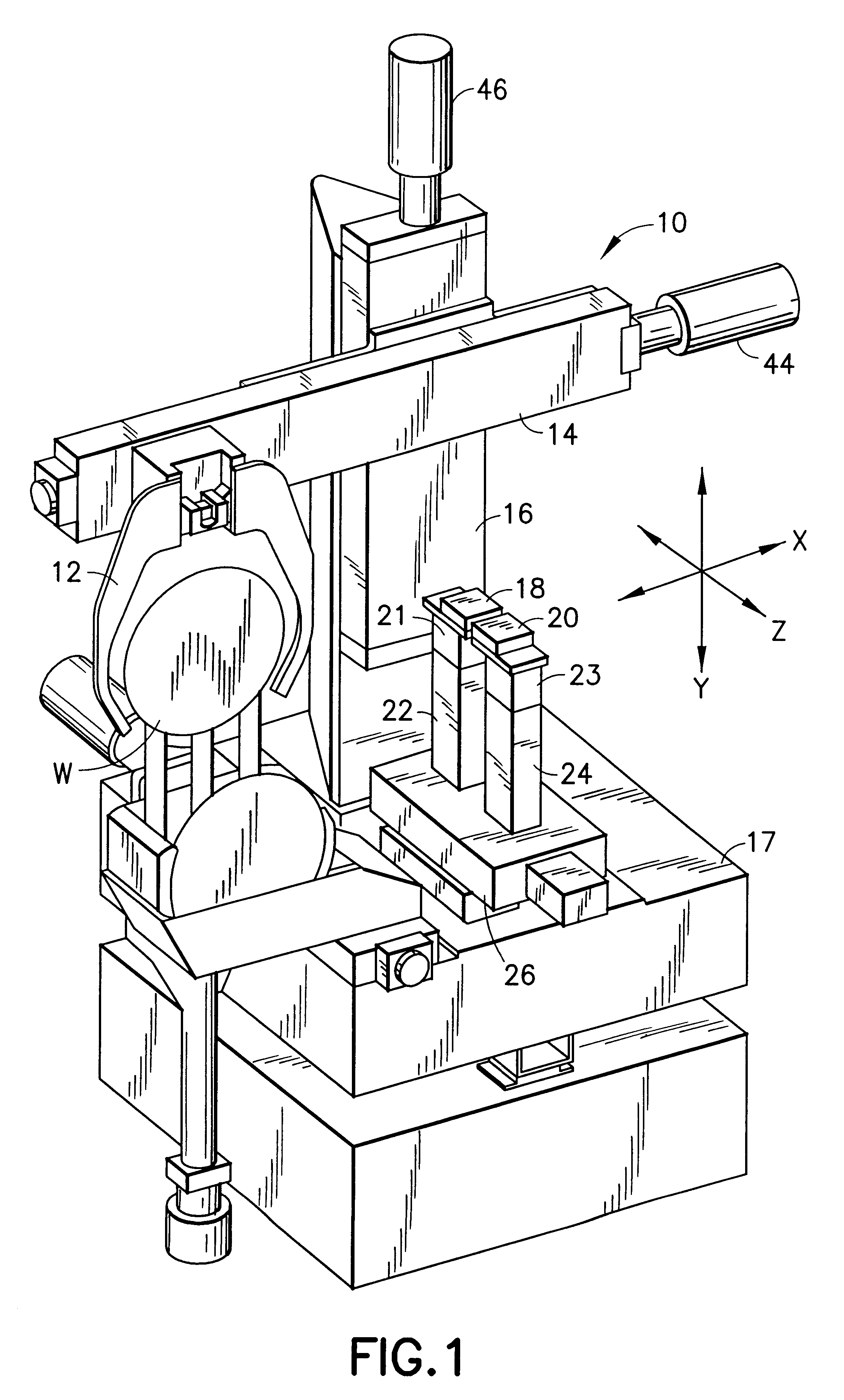

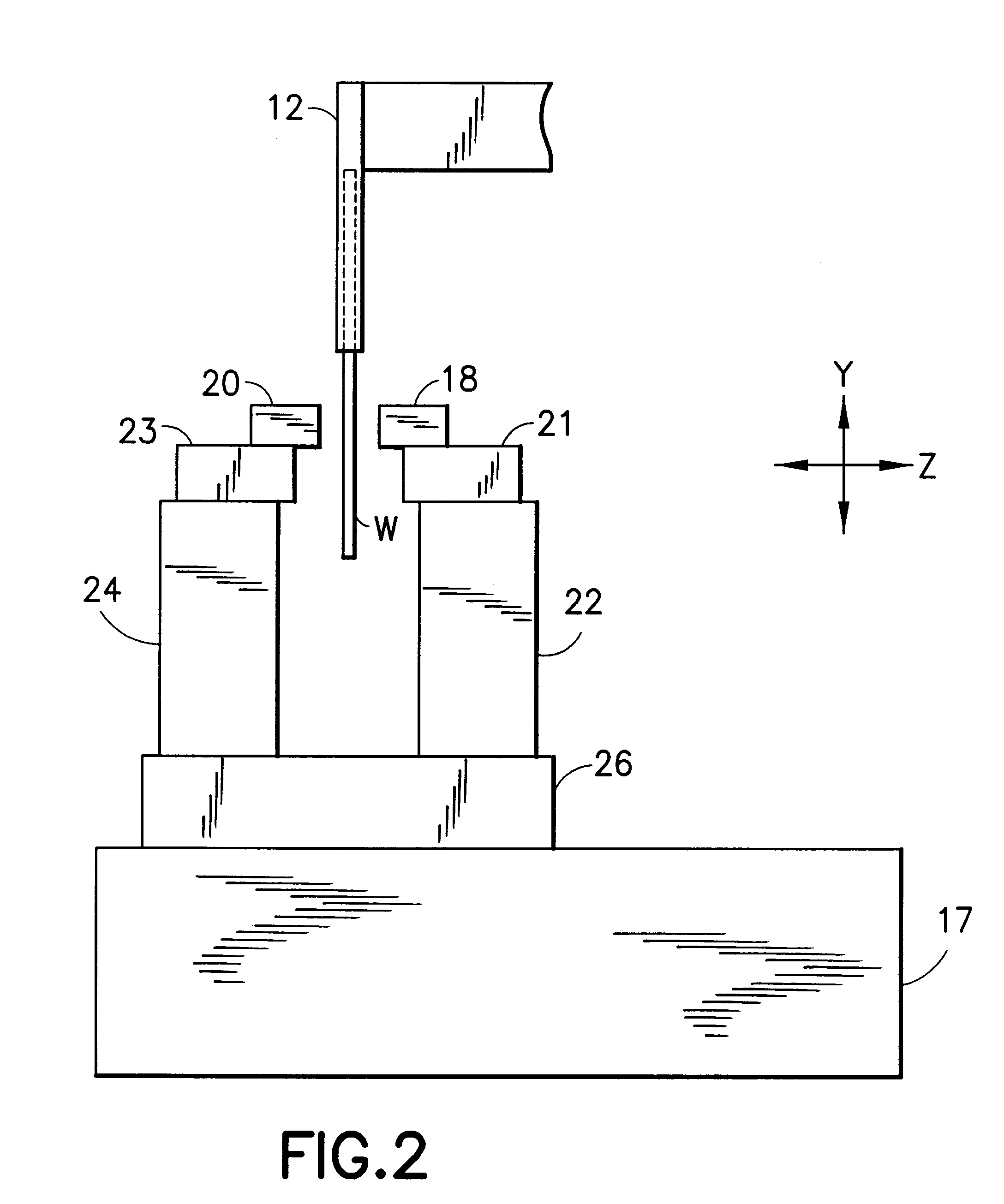

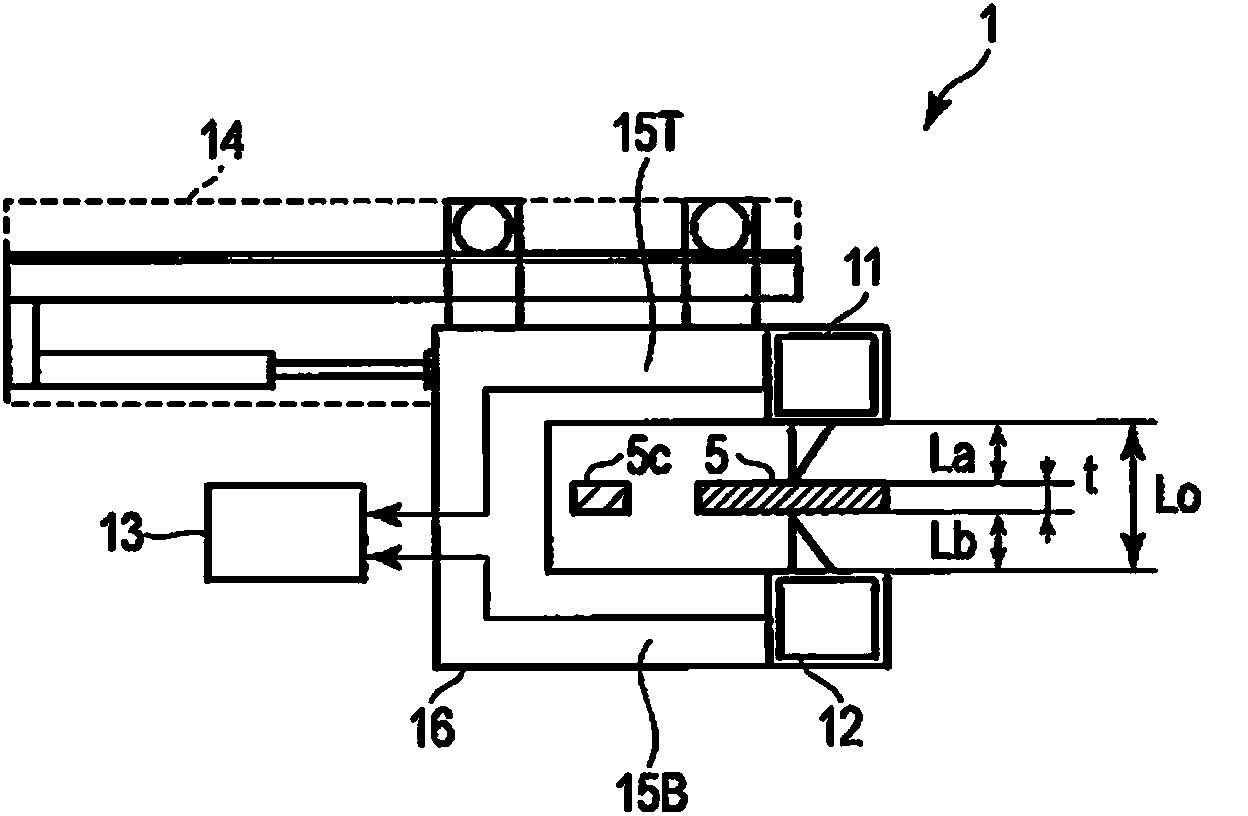

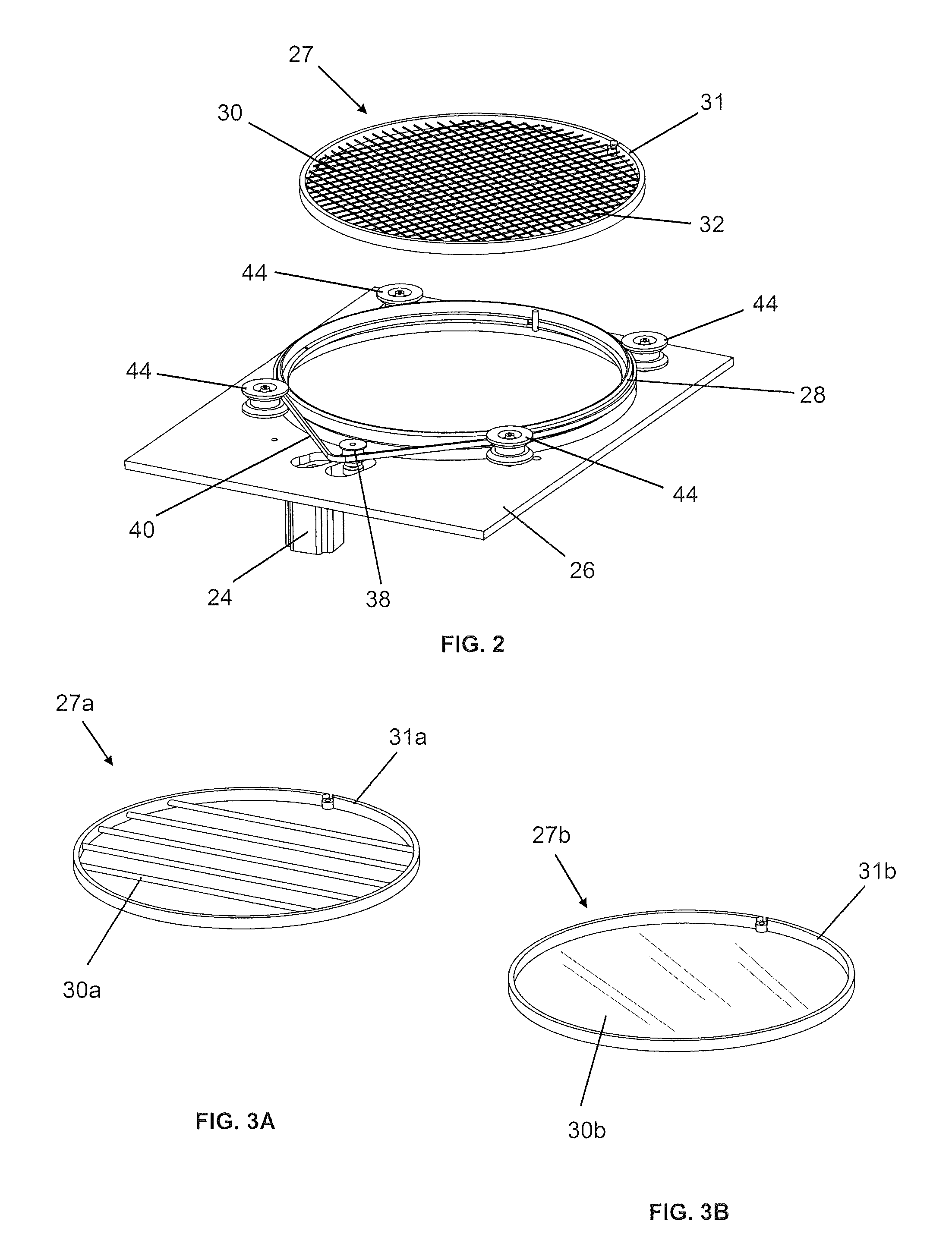

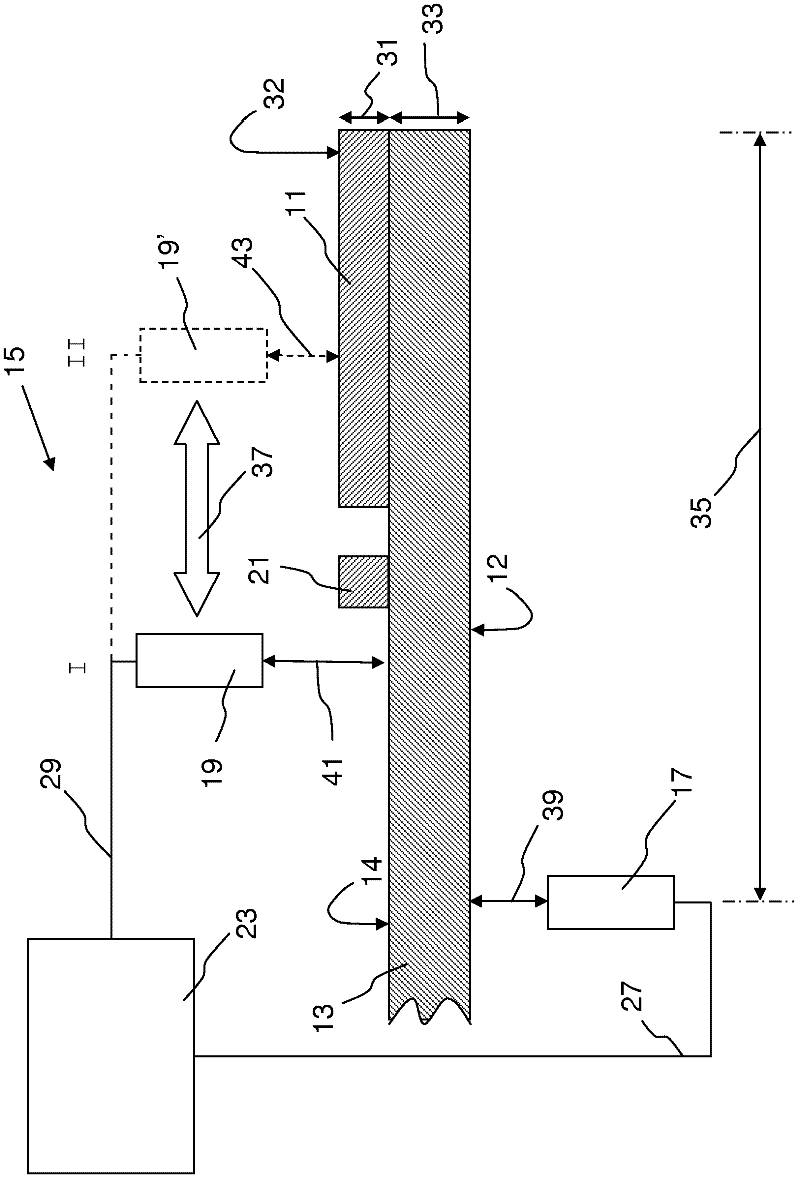

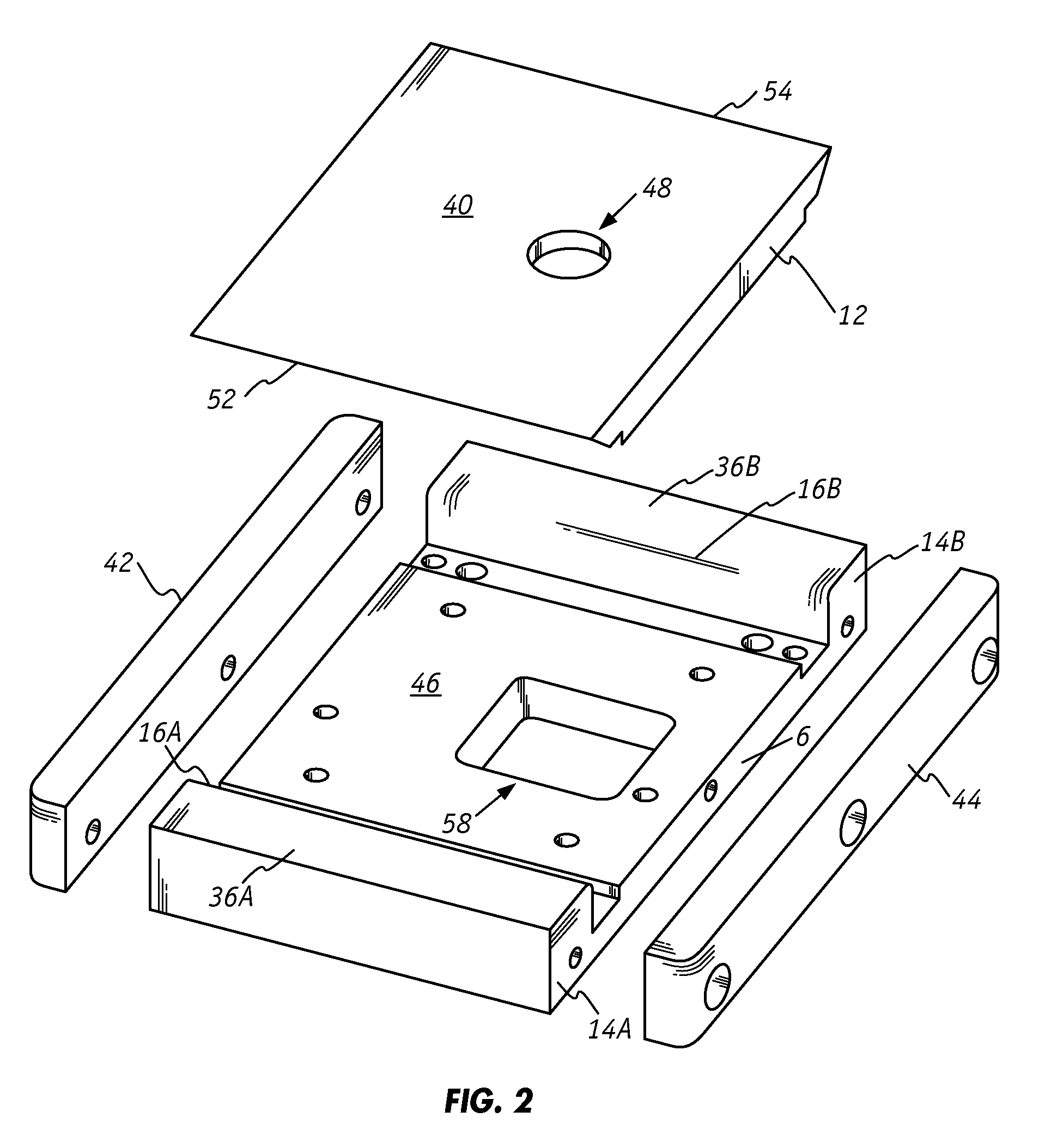

Apparatus and Method for Measuring the Thickness of a Measurement Object

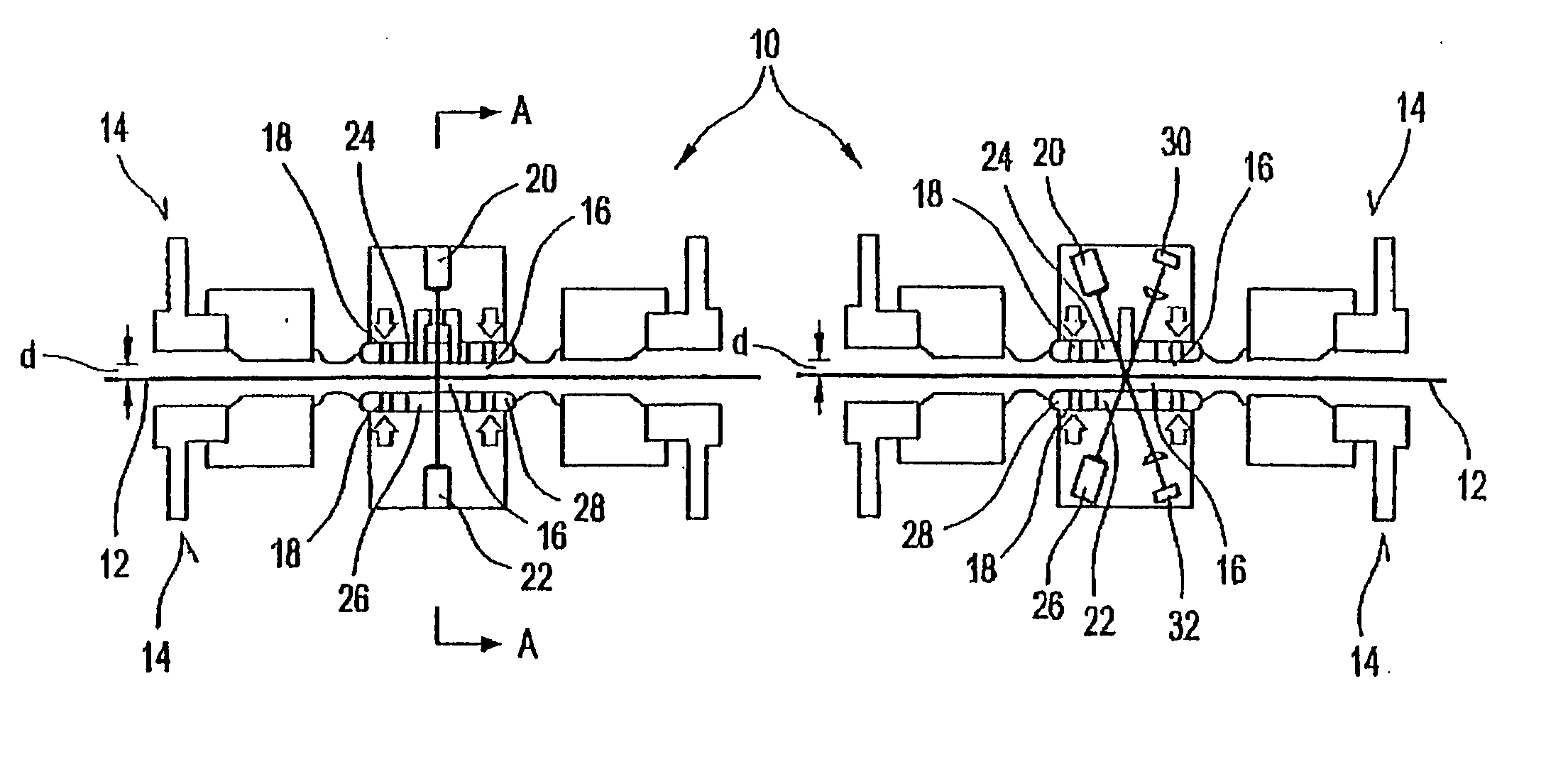

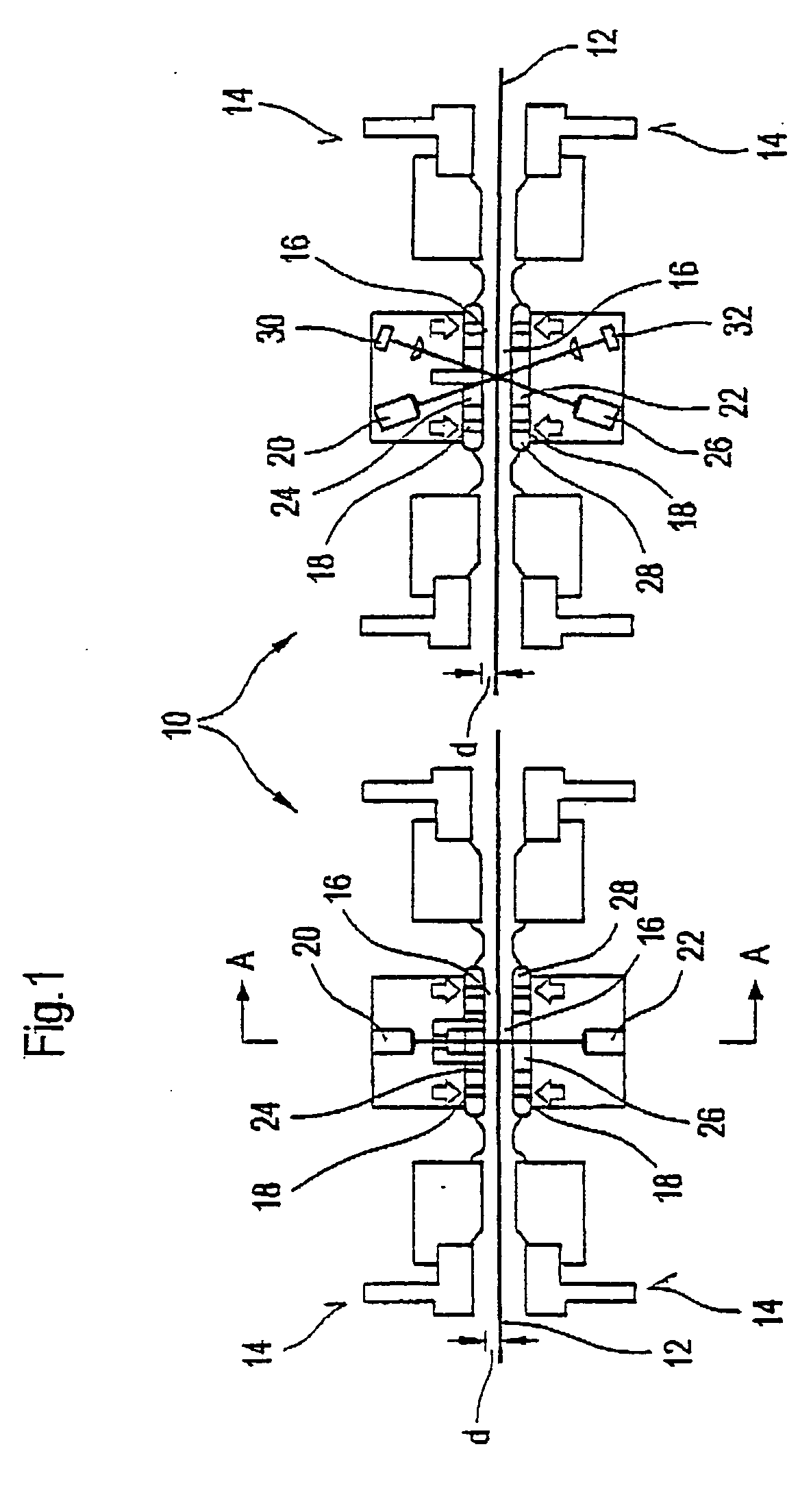

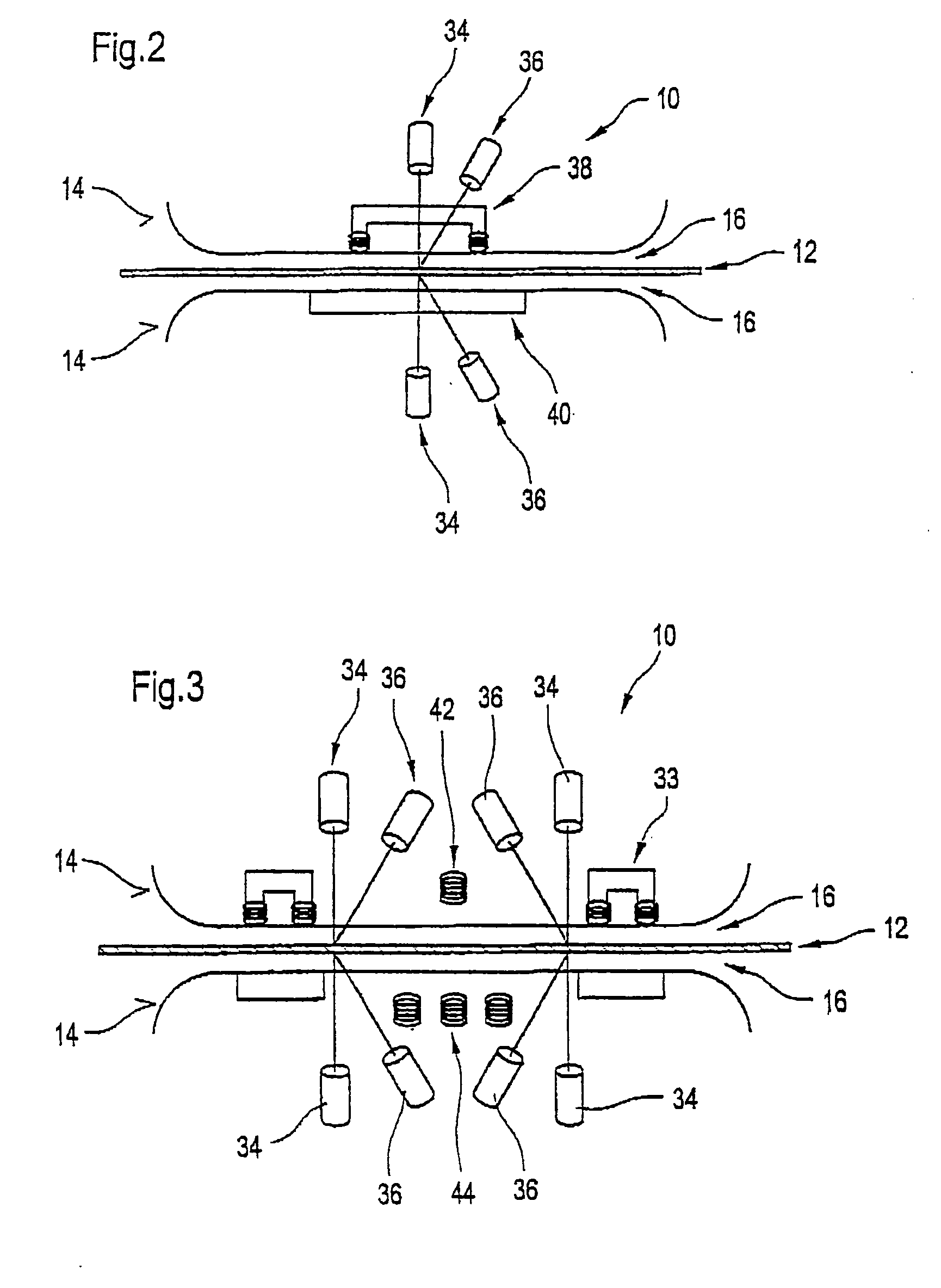

ActiveUS20140101954A1Easy to measureSimple and cost-effectiveCaliper-like sensorsUsing electrical meansReference devicePhysics

An apparatus for measuring the thickness of a measurement object, preferably a measurement object in the form of a web or piece goods, in a measuring gap, with a measuring mechanism which is fitted to a machine frame, wherein the measuring mechanism for measuring the thickness comprises one or more travel measurement sensor(s) aimed at the measurement object, is characterized in that a compensation sensor which is coupled to a travel measurement sensor measures the distance to a reference rule in order to detect and compensate for a change in the measuring gap, in that the reference rule is in the form of a side of a frame-shaped reference device integrated in the measuring mechanism, and in that the reference device is configured in such a manner that the distance between the reference rule and that side of the reference device which is opposite the reference rule is known during the thickness measurement. A corresponding method for measuring the thickness is also stated.

Owner:MICRO EPSILON MESSTECHNIK GMBH & CO KG

Method for calibrating a thickness gauge

InactiveCN102066872AGuaranteed measurementCaliper-like sensorsMeasurement devicesMeasurement deviceClassical mechanics

Owner:MICRO EPSILON MESSTECHNIK GMBH & CO KG

Web measurement device

ActiveUS7847943B2Caliper-like sensorsInvestigating moving sheetsMeasurement deviceNetwork measurement

A sensor is provided that measures web caliper using optical and magnetic measuring devices. The optical measuring devices may employ a confocal chromatic aberration method to accurately determine the distance to the moving web and the magnetic devices may be ferrite core coil and target. Means of stabilizing a moving web are included for improving dynamic measurement accuracy.

Owner:ABB LTD

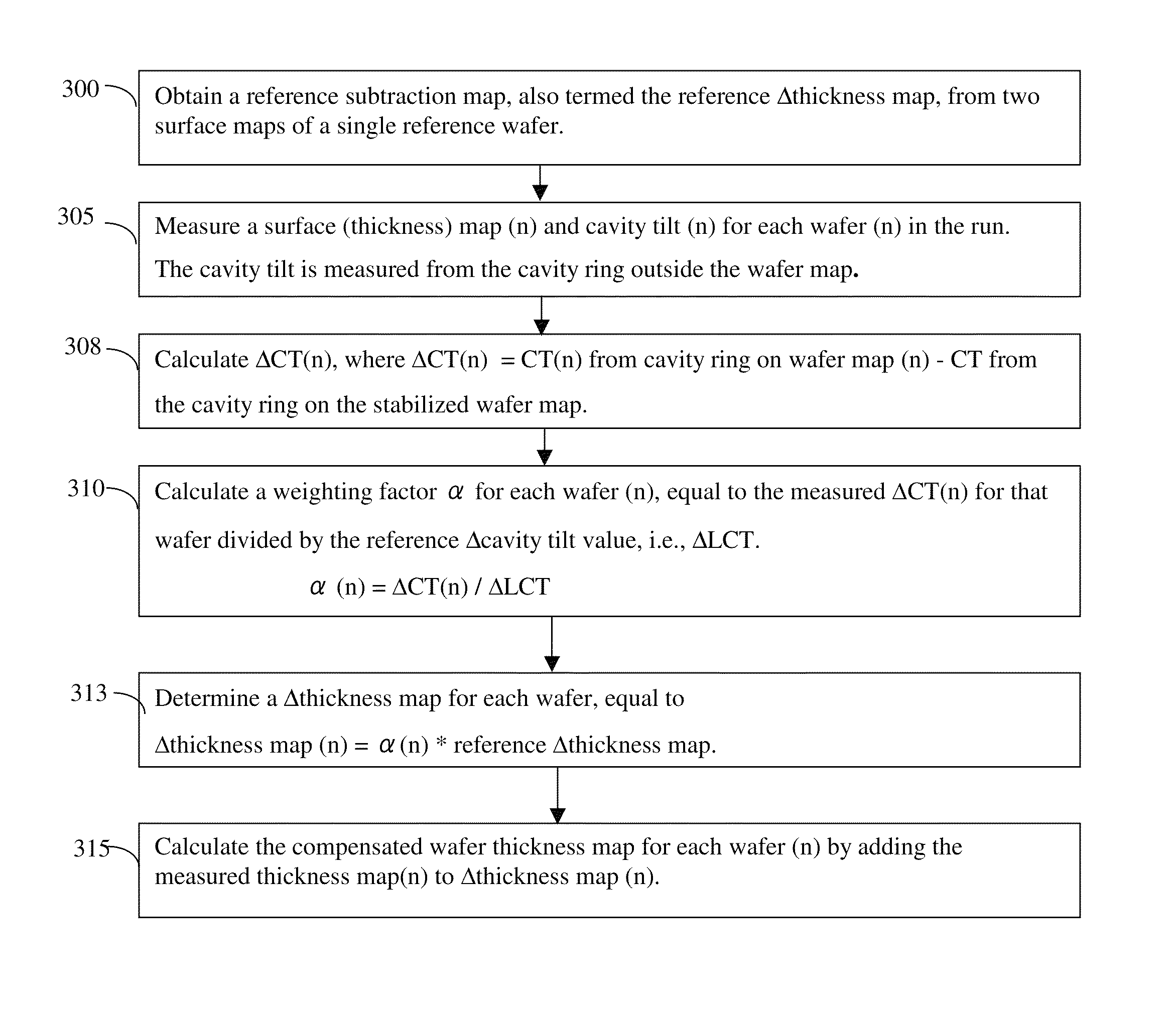

Method for compensating for wafer shape measurement variation due to variation of environment temperature

ActiveUS8949057B1Reduce measurement errorCaliper-like sensorsThermometer testing/calibrationObservational errorComputational physics

Disclosed herein is a method and apparatus for reducing measurement error resulting from temperature variations across a wafer, without measuring the wafer temperature, the temperature gradient in the surrounding air, or the distribution of the index of refraction of the air.

Owner:KLA TENCOR TECH CORP

Method and apparatus for moving an article relative to and between a pair of thickness measuring probes to develop a thickness map for the article

InactiveUS6242926B1Reduce errorsCaliper-like sensorsResistance/reactance/impedenceMeasurement devicePhysics

Owner:ADE CORPORATION

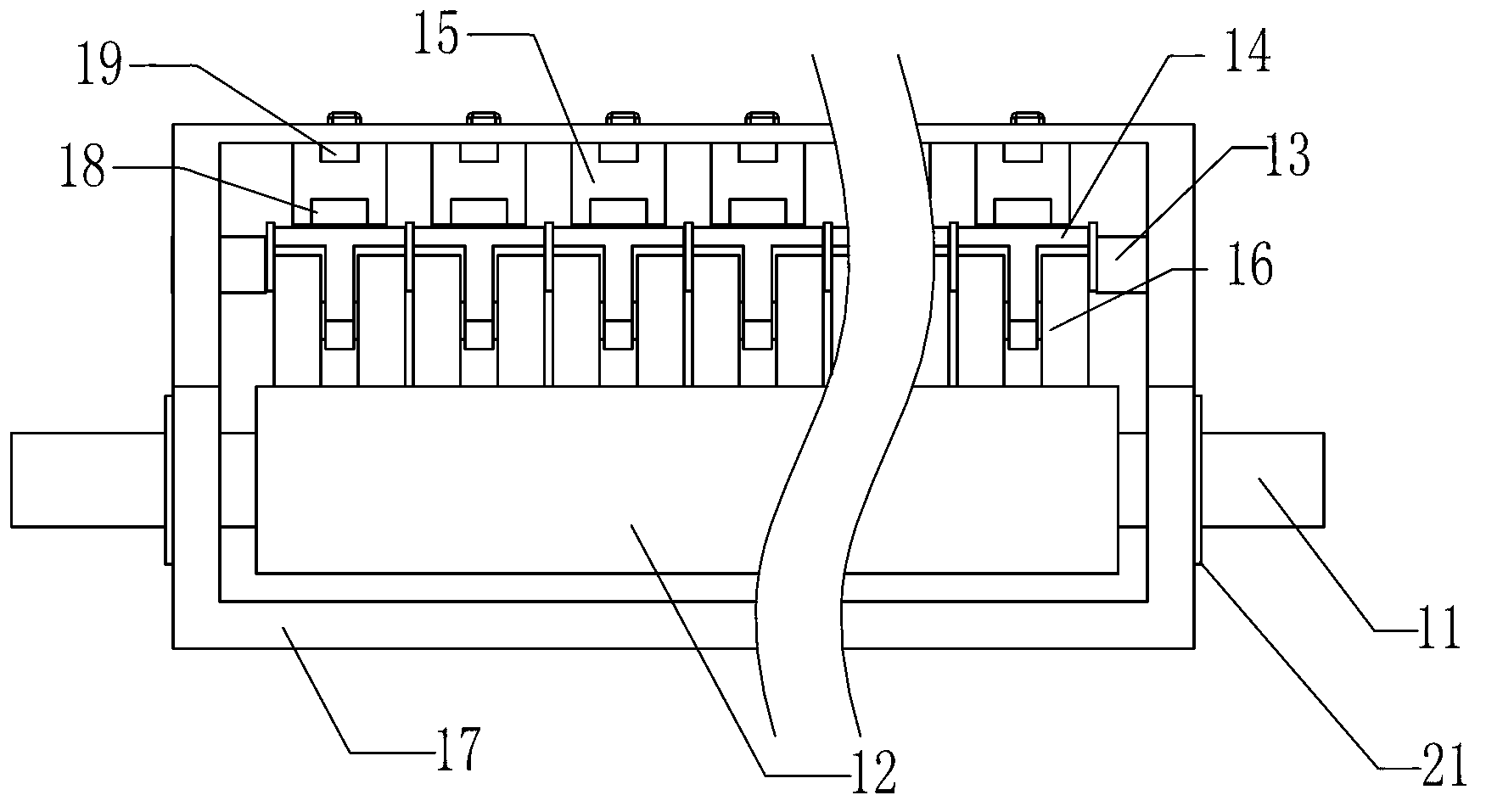

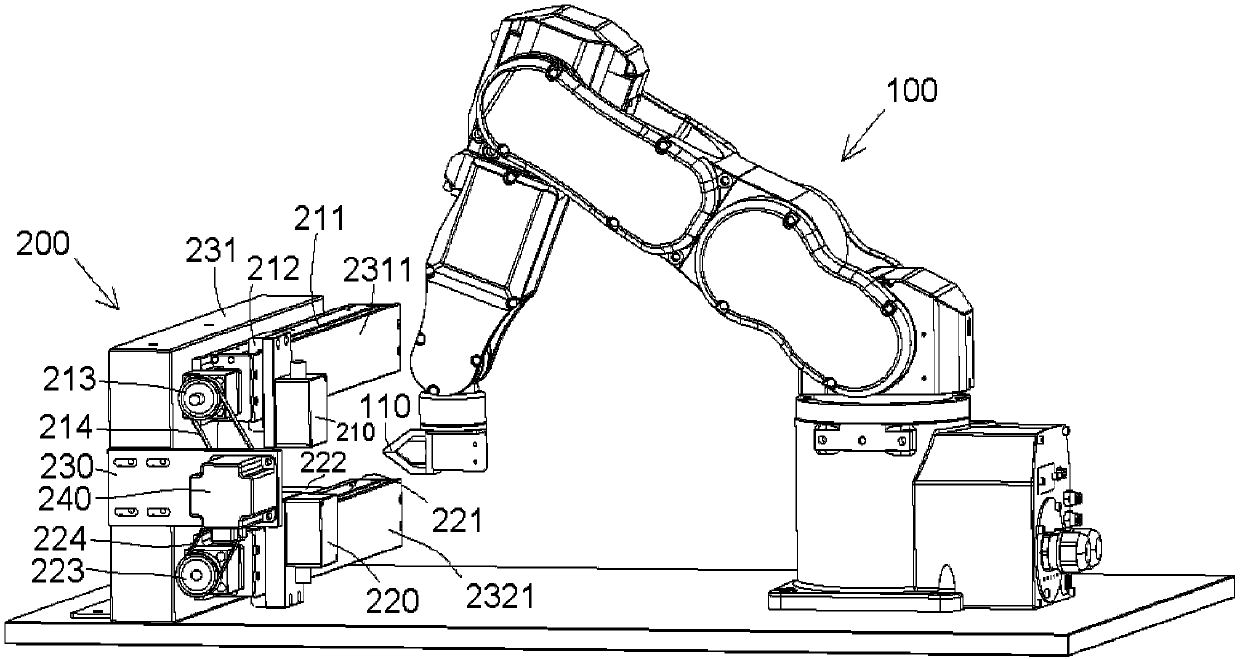

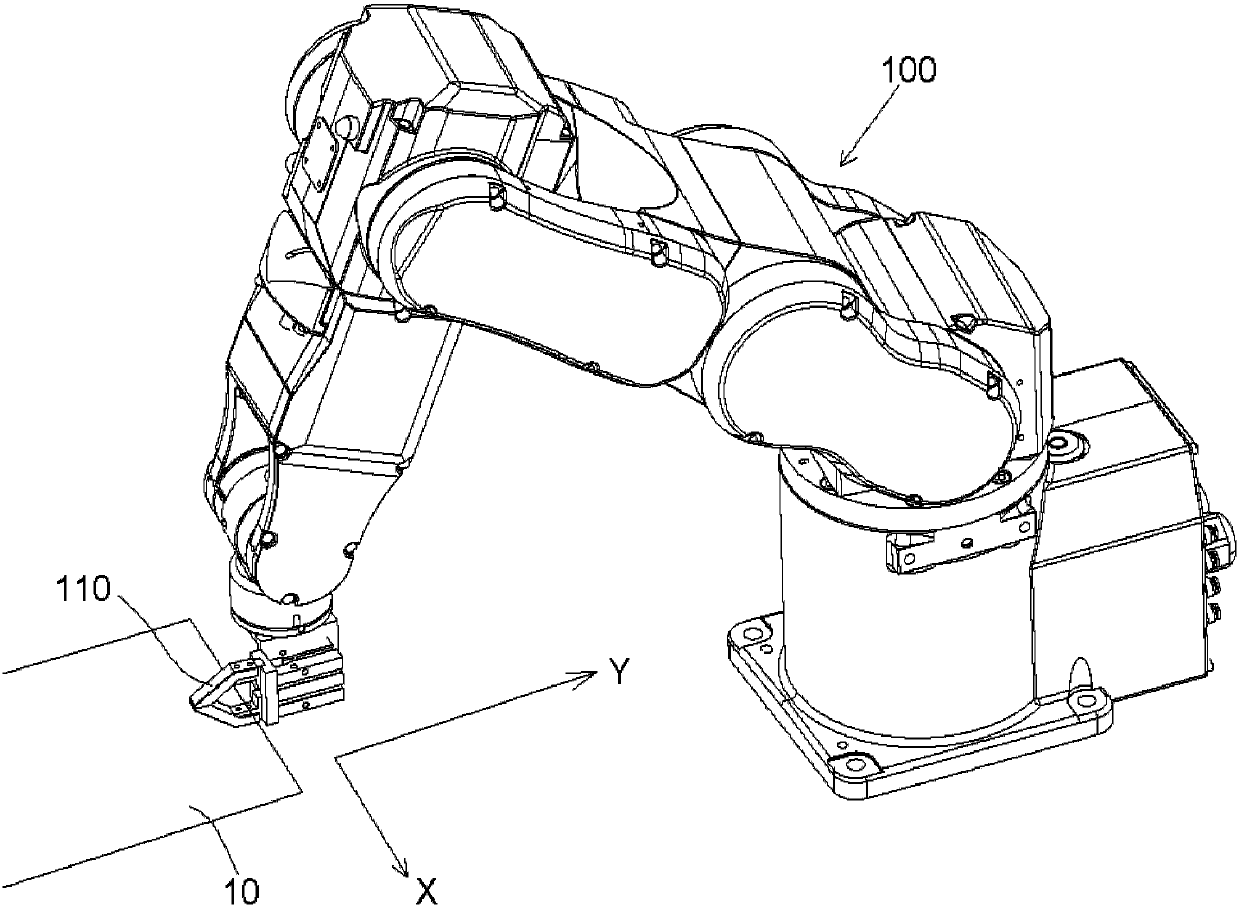

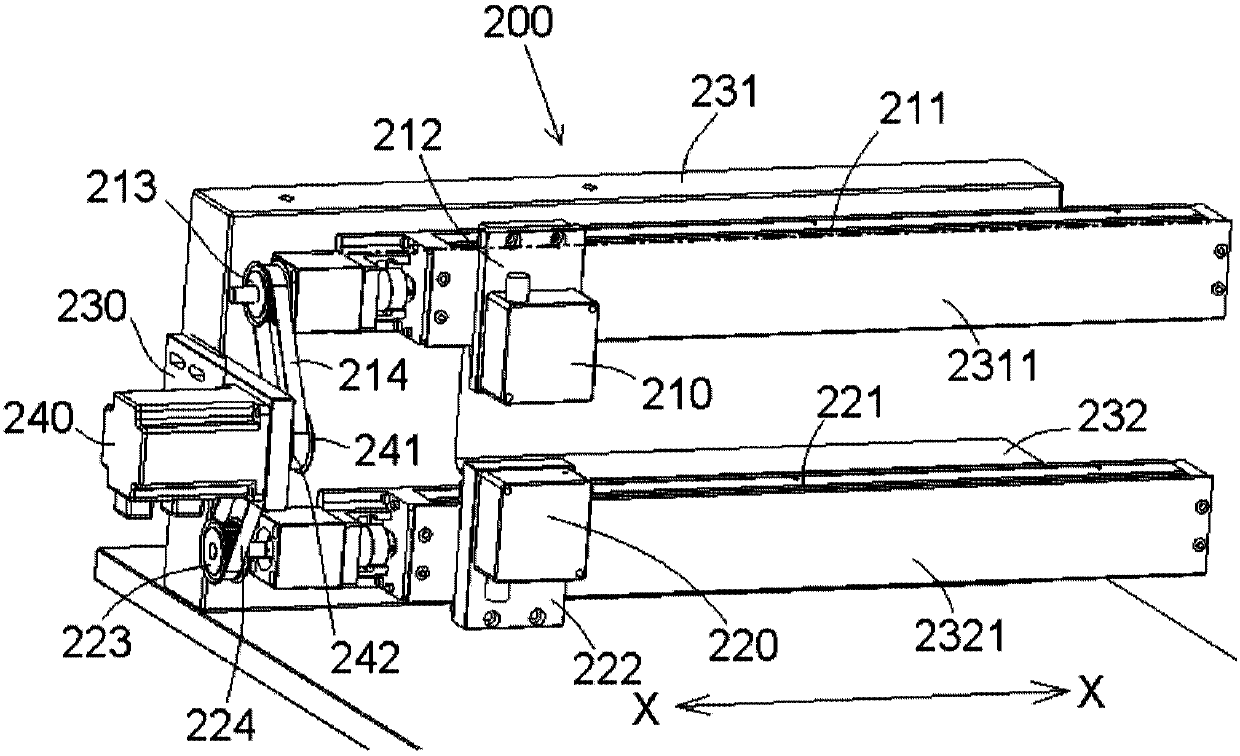

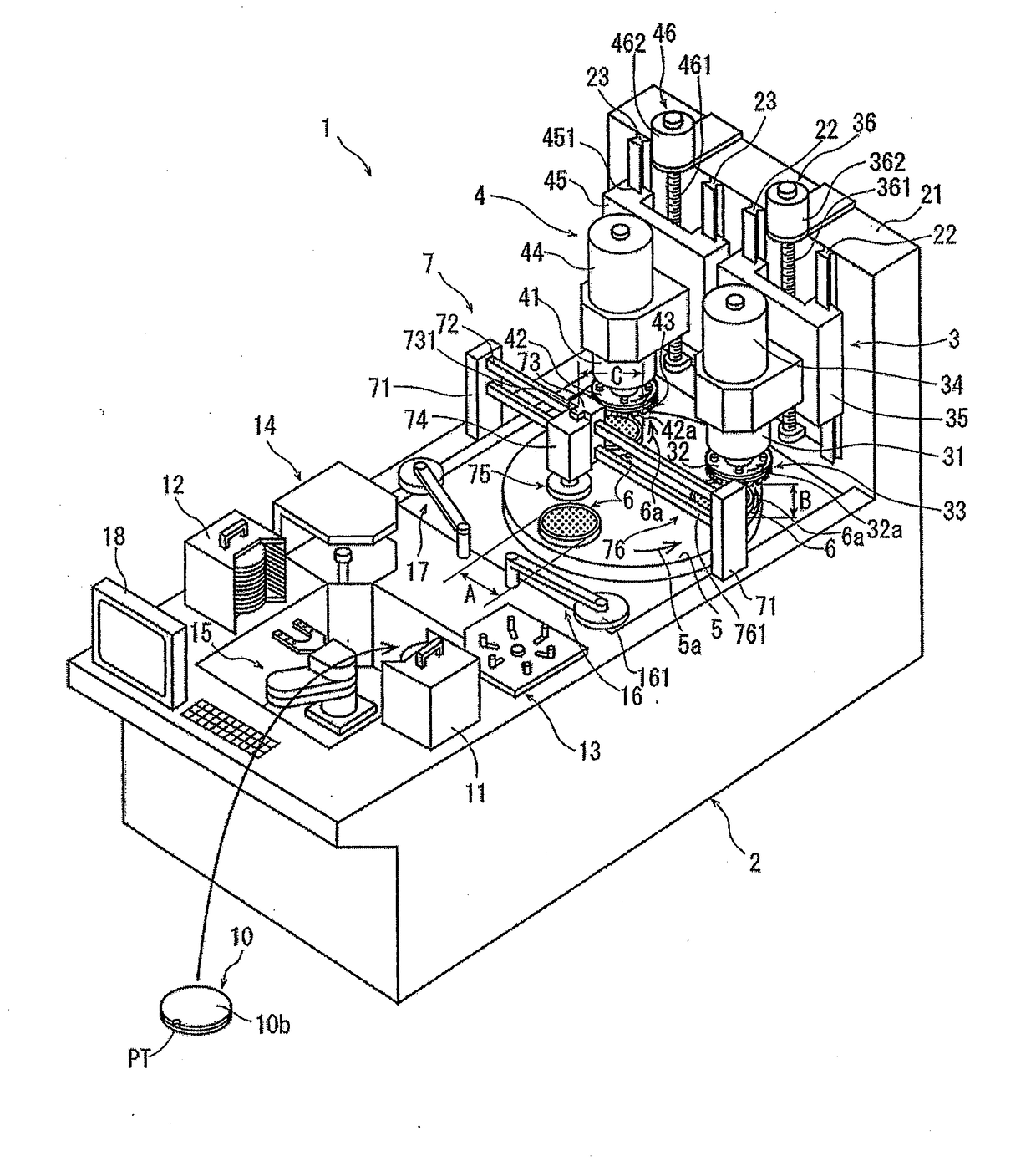

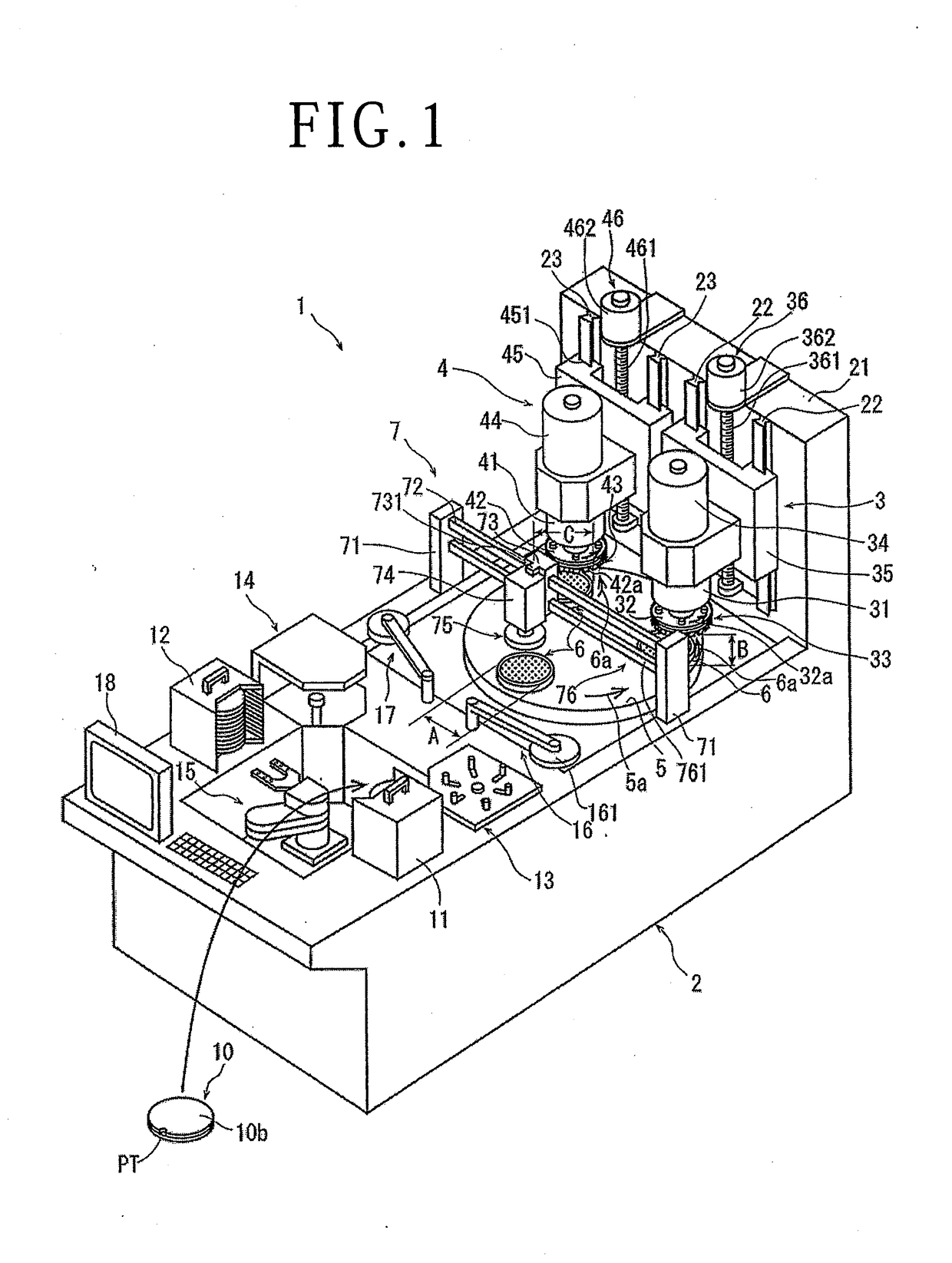

Thickness detecting experimental platform

ActiveCN108020164AWill not affect normal productionDebugging is inconvenientProgramme controlCaliper-like sensorsProduction lineComputer module

The invention discloses a thickness detecting experimental platform. The platform comprises a motion simulation module and a thickness detection module, the motion simulation module drives a to-be-detected product to execute predetermined simulation motions which are used to simulate different motions of the production in a practical production line, and the thickness detection module is used to detect the thickness of the to-be-detected product driven by the motion simulation module. According to the platform, the motion simulation module drives the to-be-detected product to simulate the different motions in the practical production line, the condition of the product in the practical production line can be reproduced in a lab, and thus, thickness detection equipment can be debugged offline in the lab, online debugging is not needed, normal production of the production line is not influenced, and debugging is convenient.

Owner:TYCO ELECTRONICS (SHANGHAI) CO LTD +2

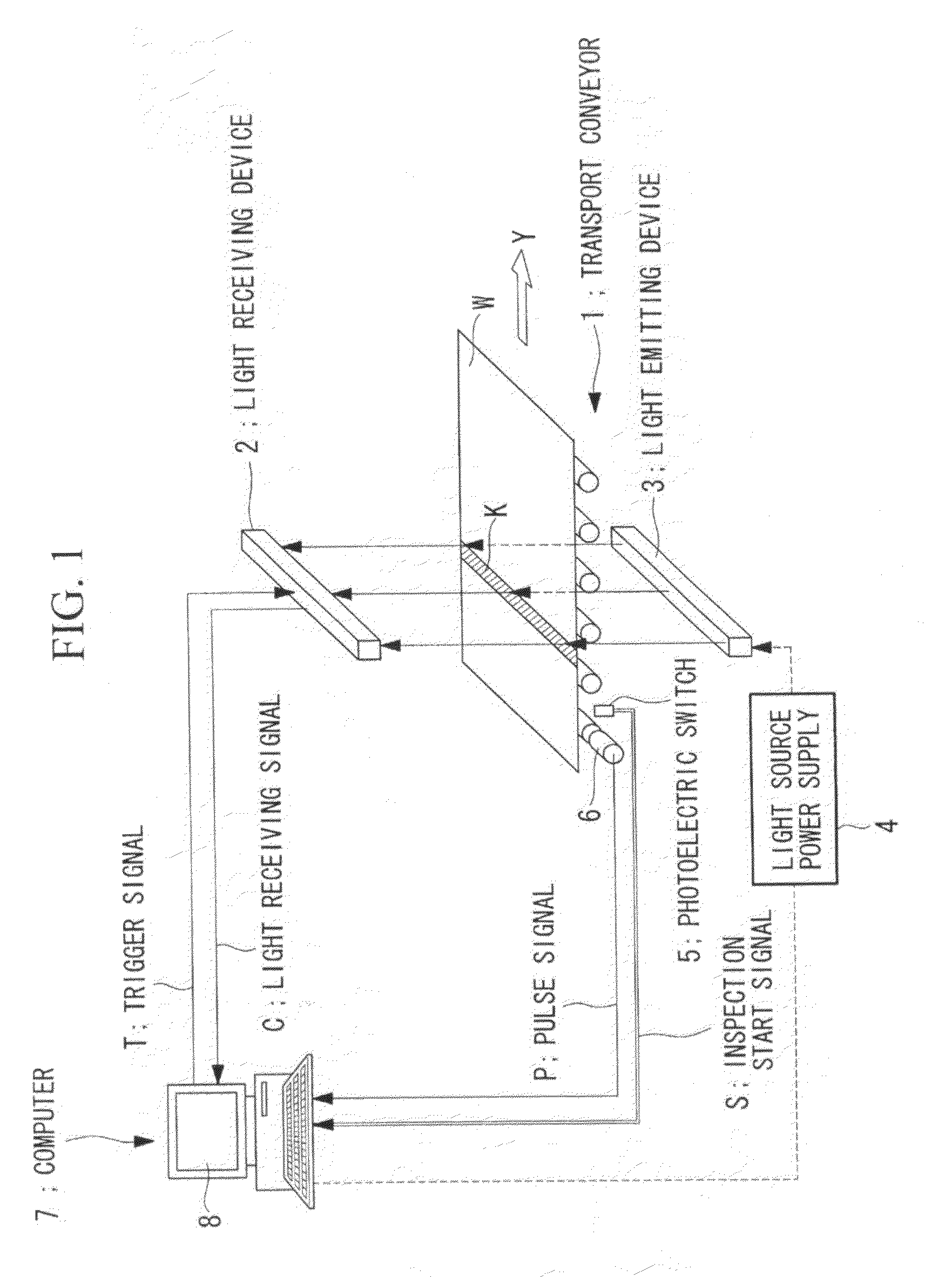

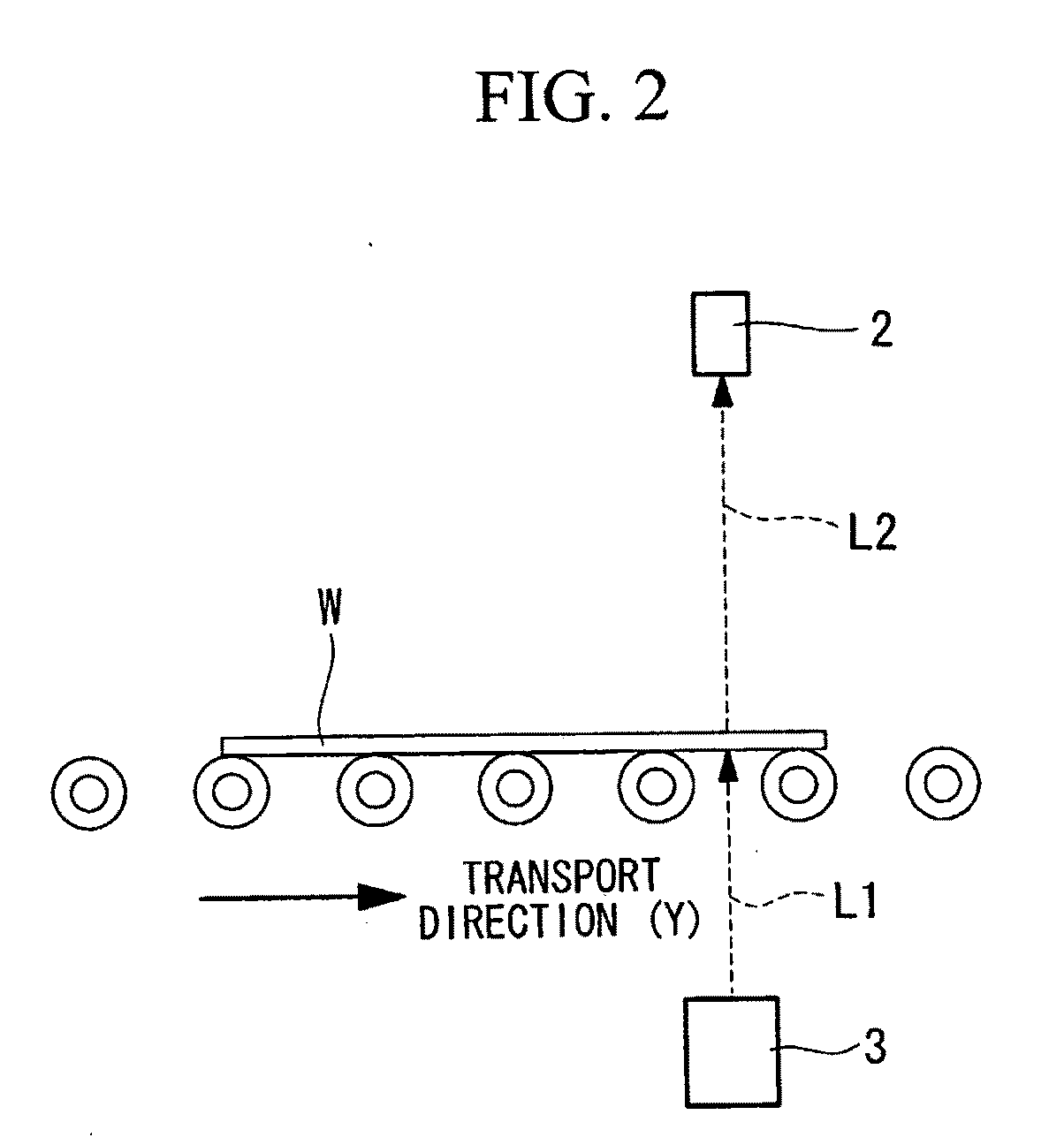

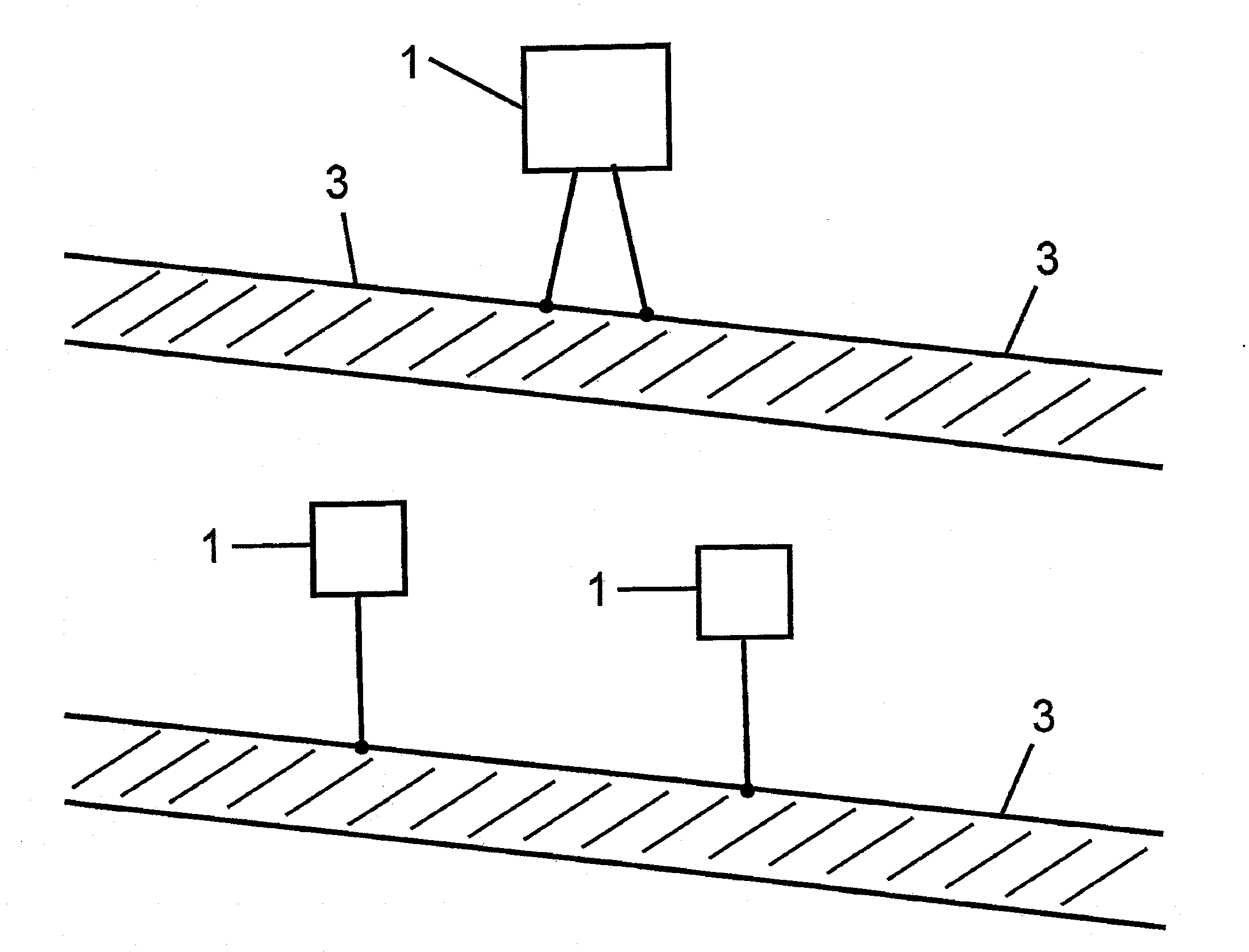

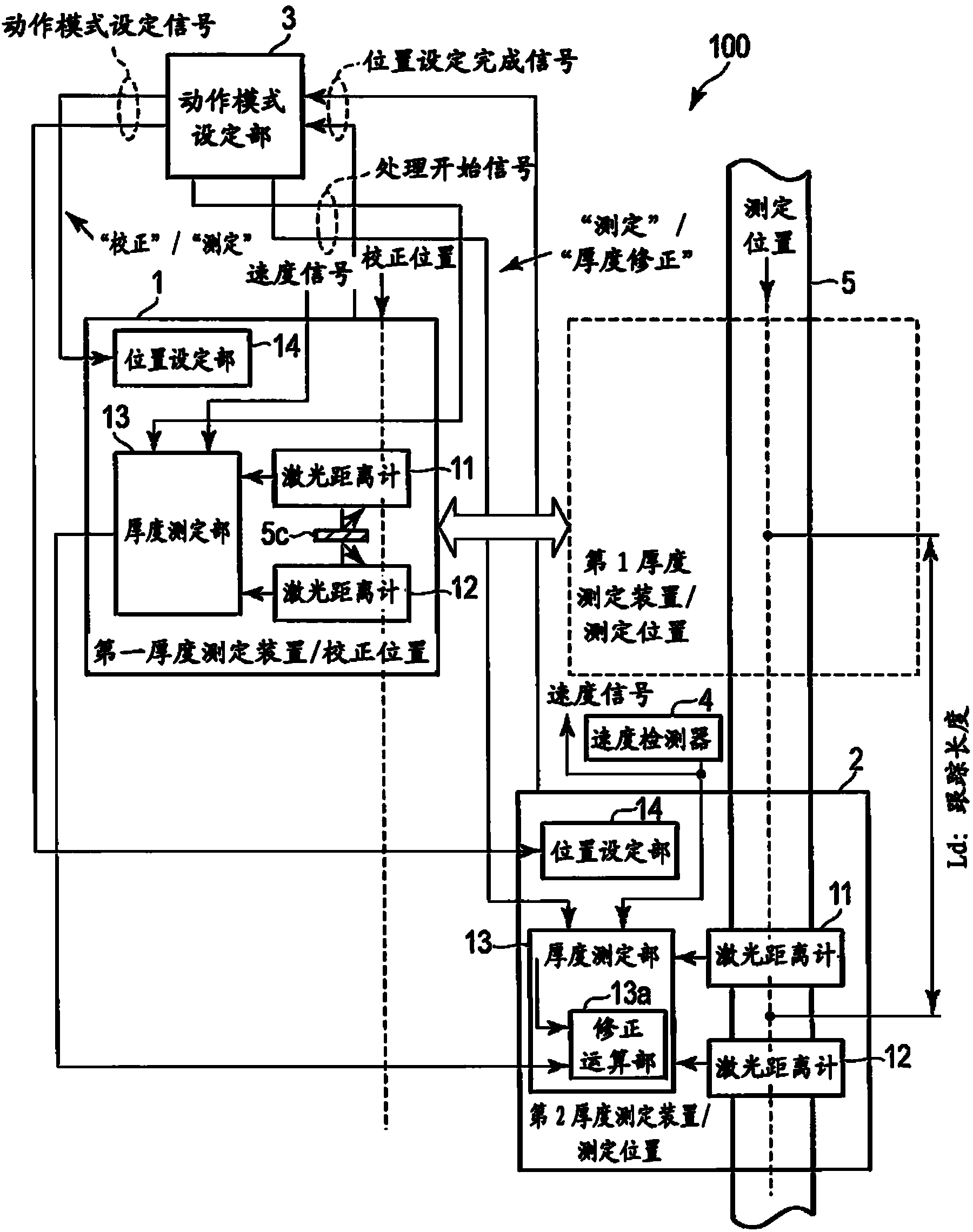

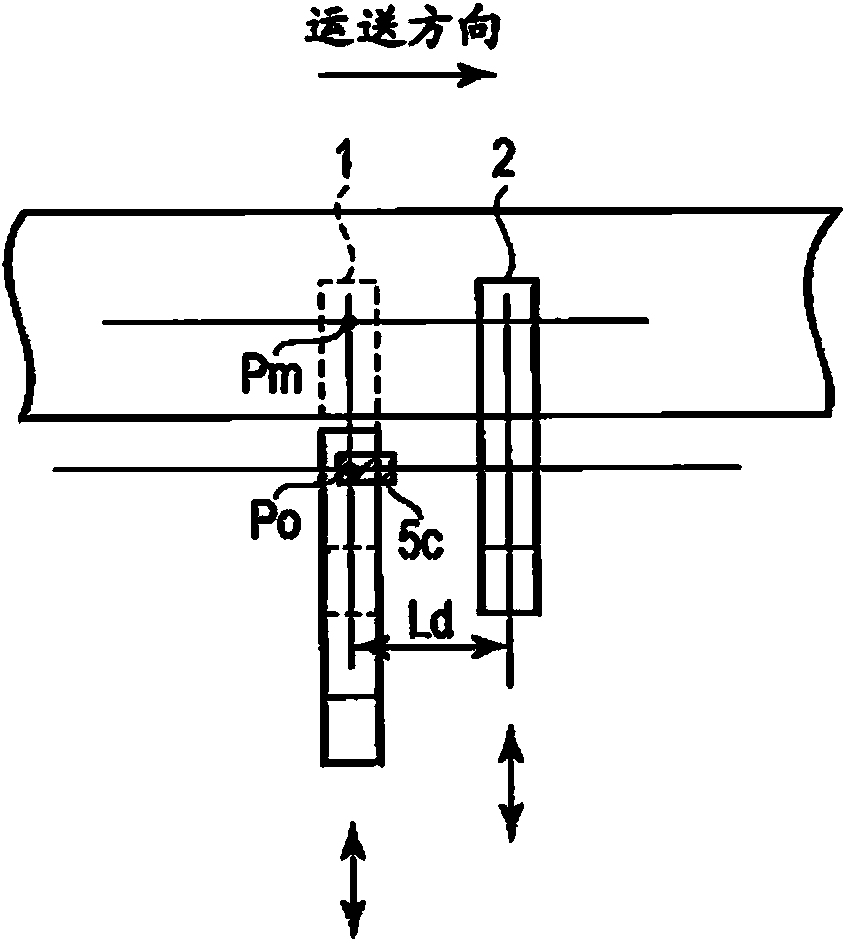

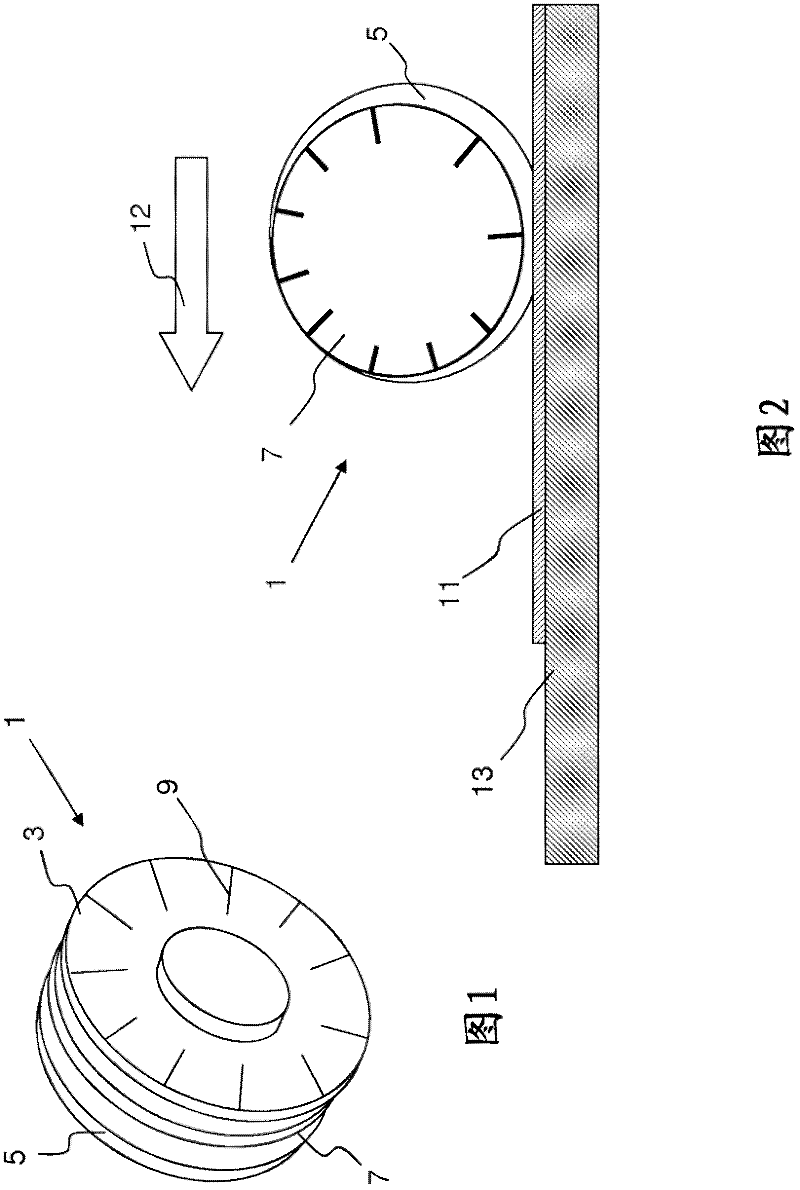

Thickness measurement system and thickness measurement method

InactiveCN103890540AContinuous measurementCaliper-like sensorsUsing optical meansMeasurement deviceEngineering

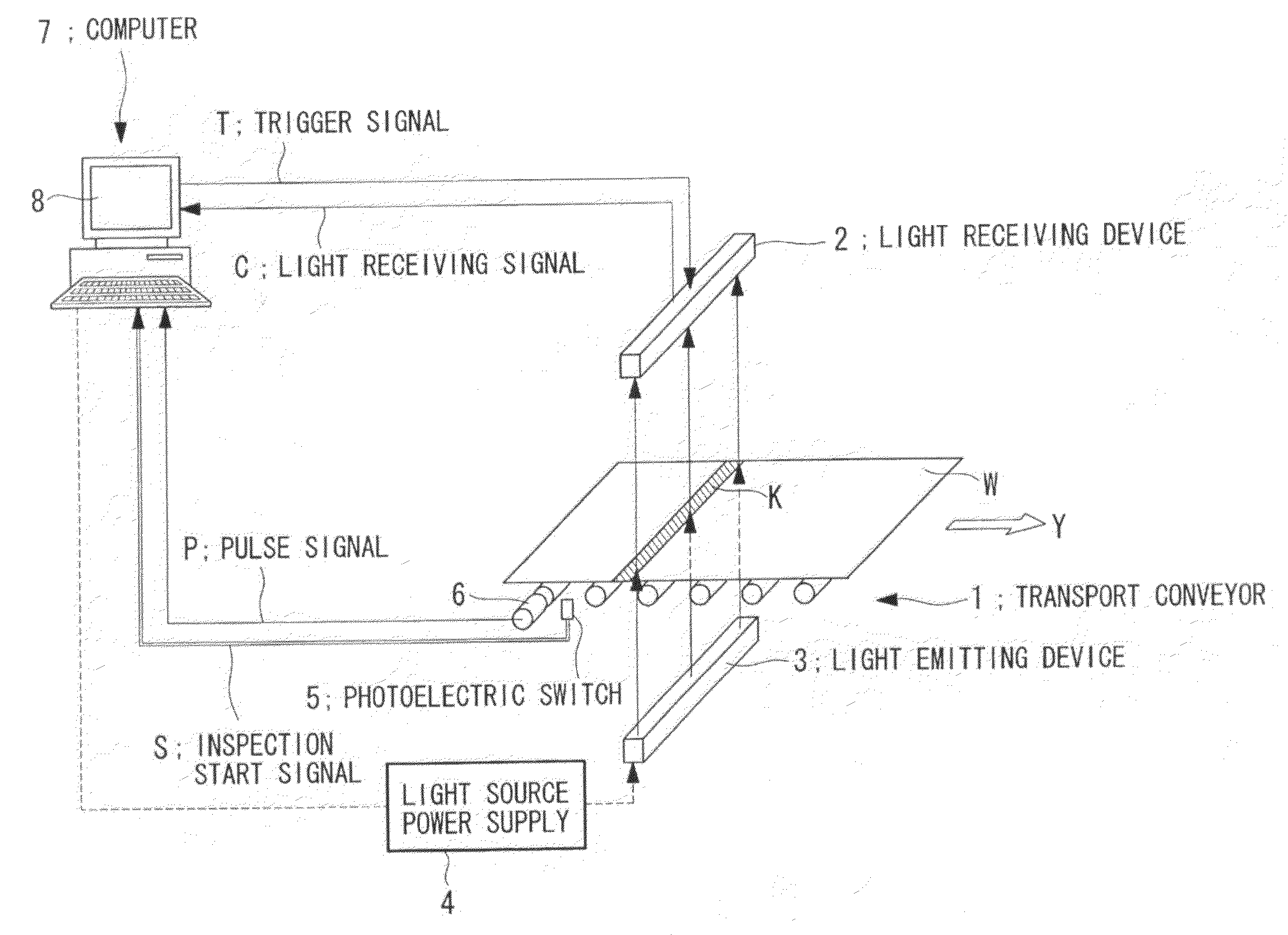

An objective of the present invention is to allow removing the effect of measurement error caused when the distance between support points of a pair of laser rangefinders of a thickness measurement device fluctuates due to temperature changes, and to allow contiguous measurement without special measures being required for safety management. Thickness measurement devices (1, 2) are set with a predetermined gap (Ld), while the first thickness measurement device (1) executes a thickness correction process with a thickness reference plate (5c), and while the second measurement device (2) which is placed on the downstream side of a movement direction executes a measurement process, an operation mode setting unit (3) sets the first thickness measurement device (1) to "measurement", instructs the second thickness measurement device (2) to commence a "thickness correction" process, delays a first thickness measurement value (1) to a location corresponding to a gap in the movement direction, derives the difference between the first thickness measurement value (1) and a second thickness measurement value (2) thereof as a correction value, and executes a thickness correction without interrupting the measurement by the second thickness measurement device (2).

Owner:KK TOSHIBA

Internal crack detecting method and internal crack detecting apparatus

A method for detecting an internal crack in a wafer includes a first image recording step of applying near infrared light having a transmission wavelength to a reference wafer having the same configuration as a target wafer to be subjected to the detection of the internal crack, thereby obtaining a first image of the reference wafer having no internal crack and then recording the first image, a processing step of processing the target wafer, a second image recording step of applying the near infrared light to the target wafer, thereby obtaining a second image of the processed target wafer and then recording the second image, and an internal crack detecting step of removing the same image information between the first image and the second image from the second image to obtain a residual image, thereby detecting the residual image as the internal crack in the target wafer.

Owner:DISCO CORP

Method for thickness measurement on measurement objects and device for applying the method

ActiveUS20160252343A1Eliminate measurement errorsCaliper-like sensorsUsing optical meansObservational errorClassical mechanics

Owner:MICRO EPSILON MESSTECHNIK GMBH & CO KG

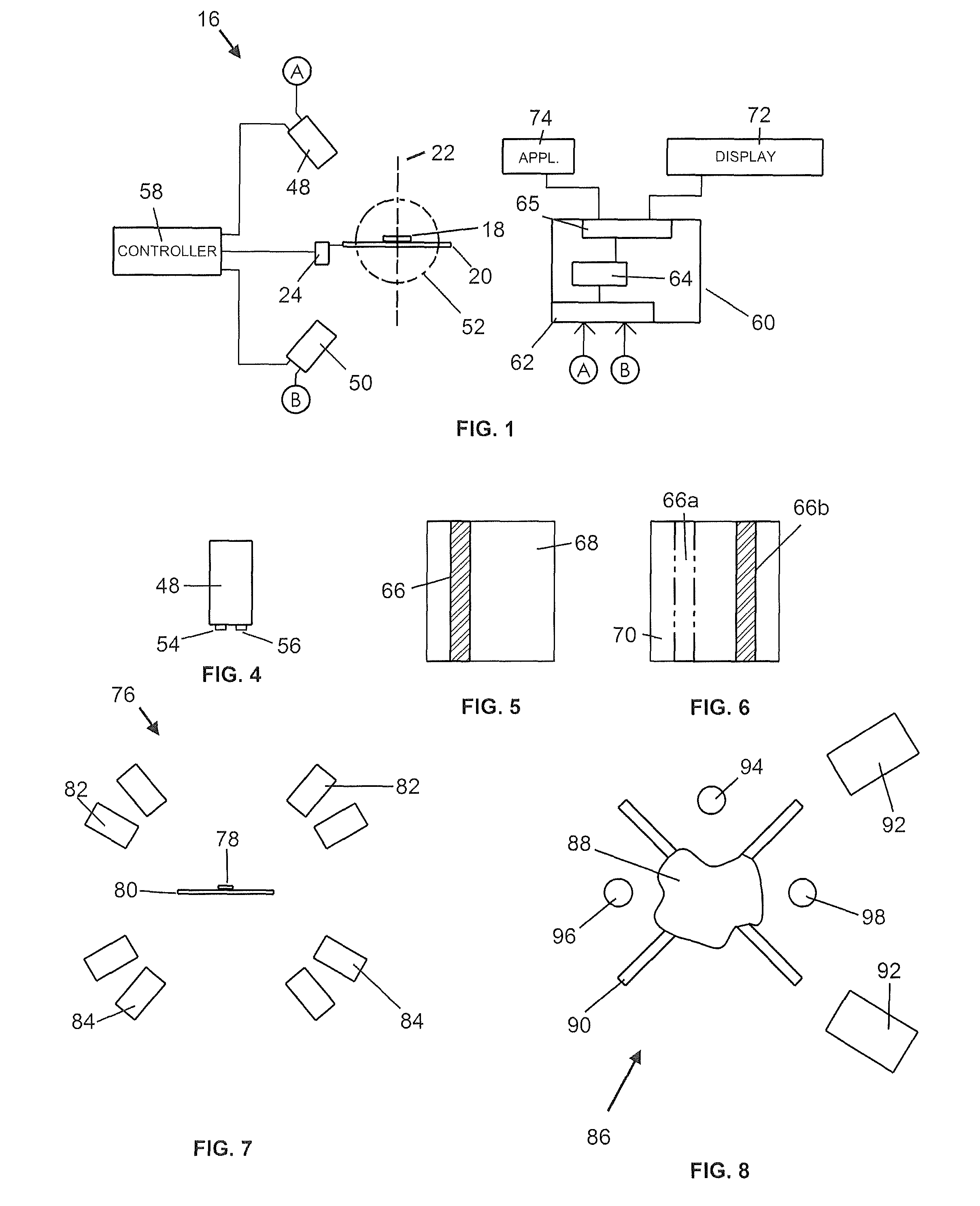

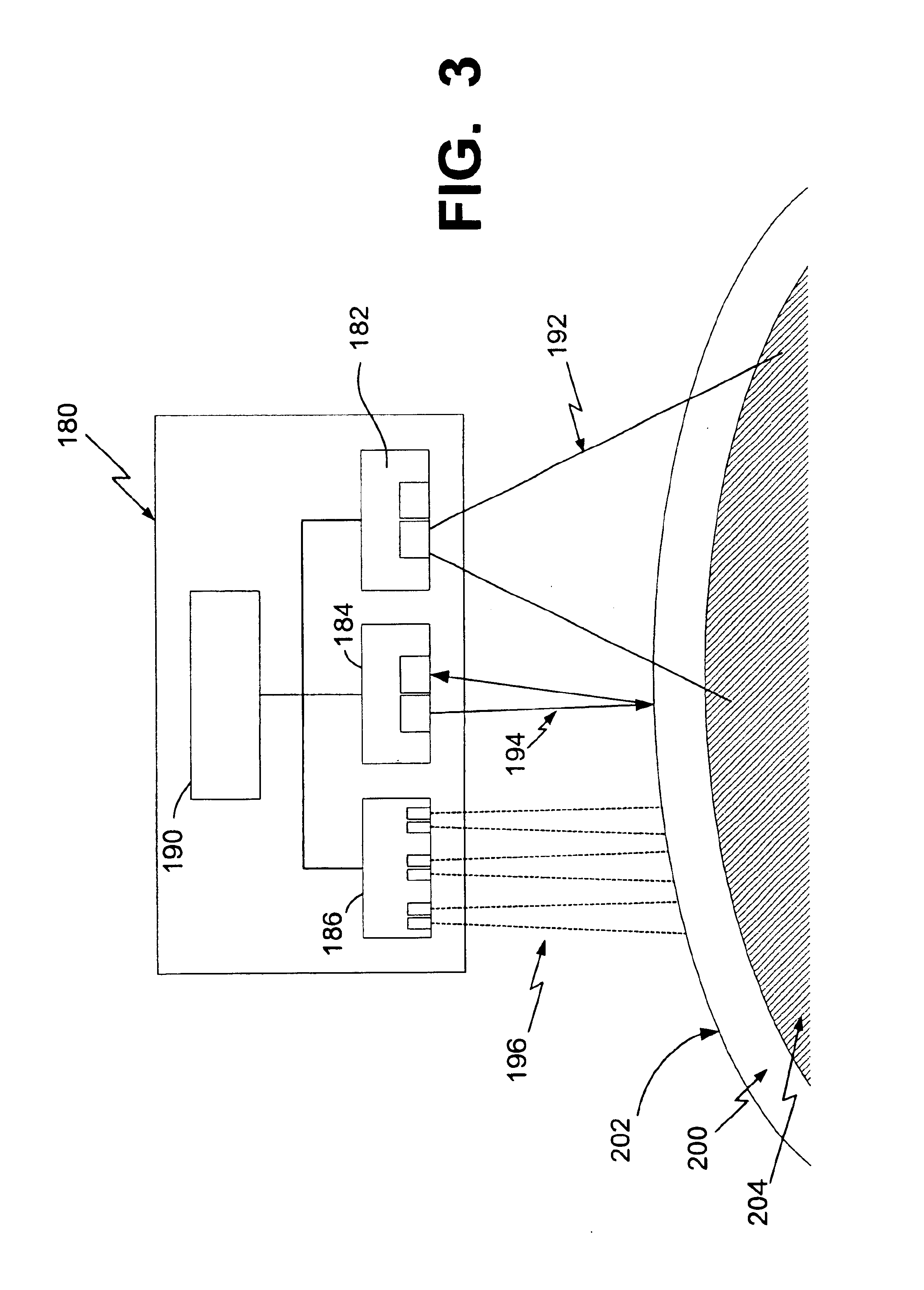

Noncontact scanning system

ActiveUS8526012B1Promote useHigh precisionCaliper-like sensorsUsing optical meansComputer graphics (images)Shadow effect

A noncontact object scanning system includes a horizontal table rotatable on a vertical axis, one or more scanners above the table and one or more scanners below the table. The table allows passage of radiant energy therethrough due to its transparency or construction as a nonreflective grid. A controller automatically steps the scanners through a scanning sequence, each scan associated with a segment of the object's exterior surface. Surface segments scanned from above the table and from below the table combine to provide a comprehensive scan of the entire exterior surface. Adjacent surface segments overlap one another to provide redundant data used to overcome shadowing effects from the grid and to accurately align and merge the segments into a three dimensional representation of the complete exterior shape of the object. The scanners can incorporate color responsive light detectors whereby the three dimensional representation portrays color and shape.

Owner:CYBEROPTICS

Improved film thickness measurement

InactiveCN102458681ANot easy to vibrateFast measurementCaliper-like sensorsSpraying apparatusOptoelectronicsControl parameters

A method for determining the thickness of a film on a substrate is described. The substrate has a first major surface opposite a second major surface, and the film covers a portion of the first major surface. During a first measurement step, a first measuring beam is used to determine the distance from a first reference point to a portion of the first major surface of the substrate that is not covered with the film,and a second measuring beam is used to determine the distance from a second reference point to a portion of the second major surface of the substrate that is not covered with film. During a second measurement step the first measuring beam is used to determine the distance from the first reference point to the film, and the second measuring beam is used to determine the distance from the second reference point to a portion of the second major surface of the substrate that is not covered with film. The thickness of the film so determined may be used as a control parameter in a method of applying an ink to an automotive glazing pane.

Owner:PILKINGTON GROUP LTD

Method and apparatus for non-contact thickness measurement

The present invention provides a method and apparatus for use in measuring a thickness of a layer and / or variations in layer thickness for layers that are flat, curved or have curves. The apparatus comprises a light source to generate a light beam, a light beam detector to detect at least a portion of the light beam reflected, an eddy current field generator that induces an eddy current, an eddy current detector to detect the induced eddy current and a processor coupled with the light source, light detector, eddy current field generator and eddy current detector, wherein the processor controls the light detector, eddy current field generator and eddy current detector. A radial characteristic of a region of the surface can be determined, a scaling factor can be determined based on the radial characteristic and a measured distance can be scaled based on the scaling factor in determining a thickness.

Owner:THE BOEING CO

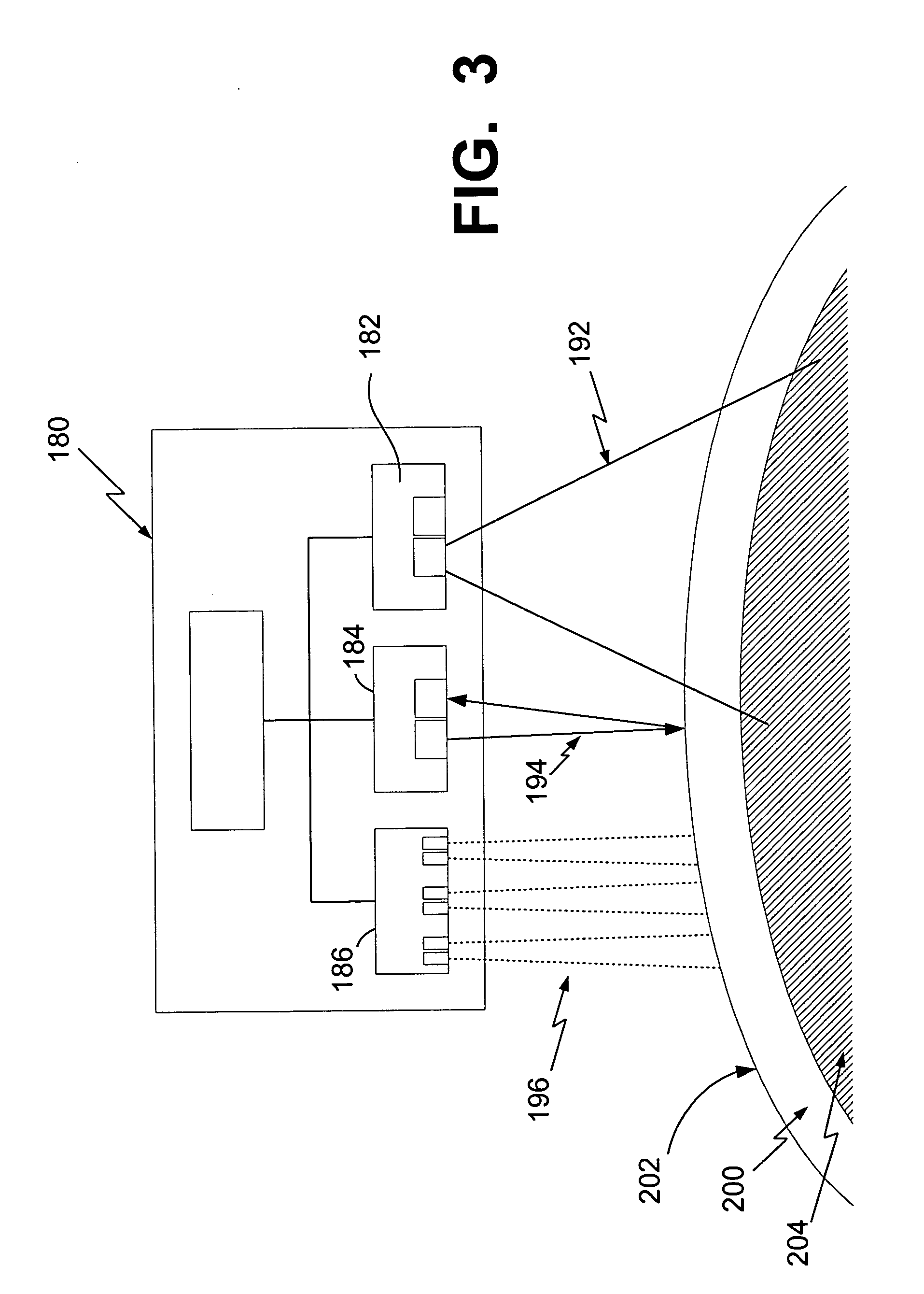

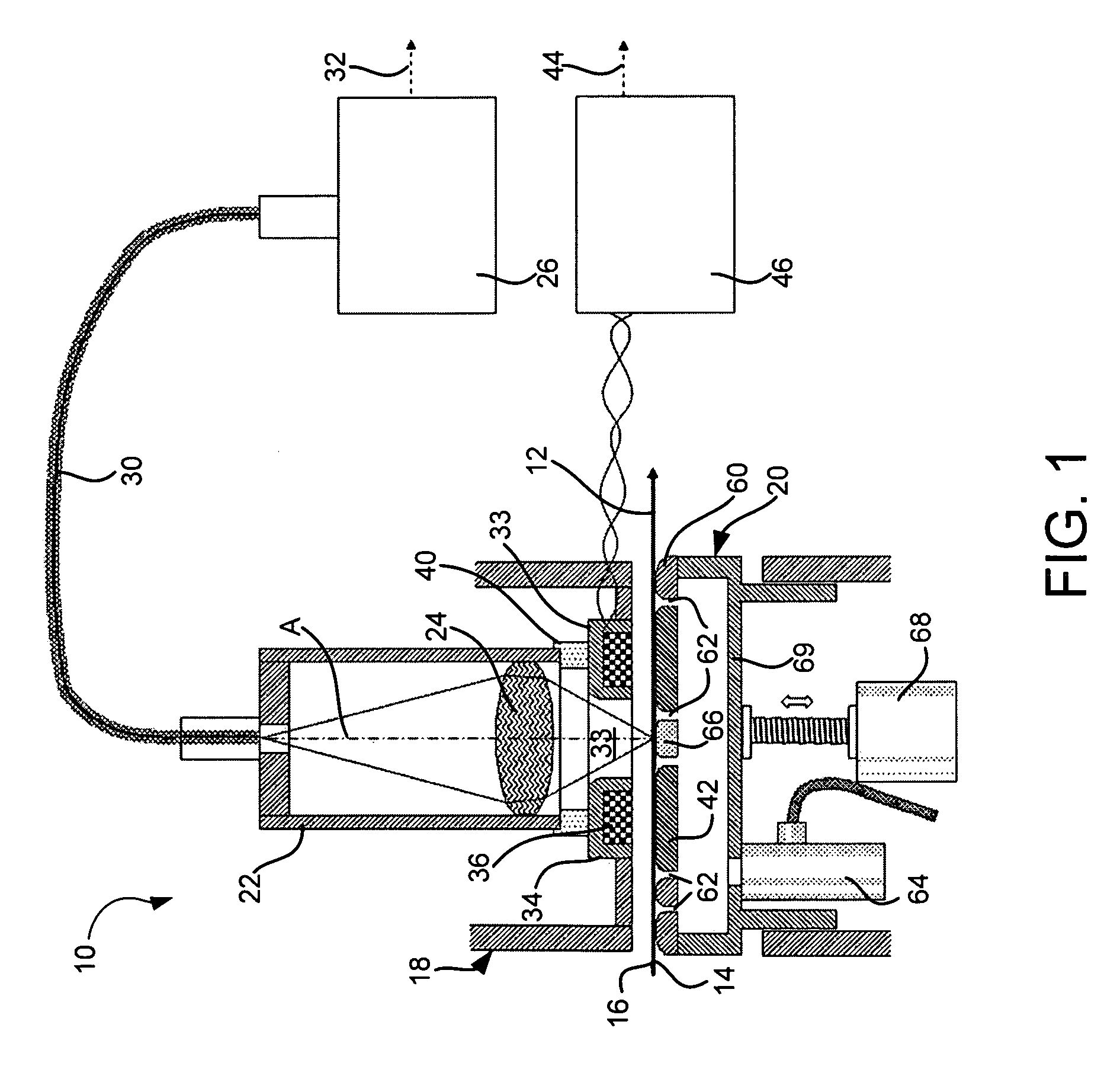

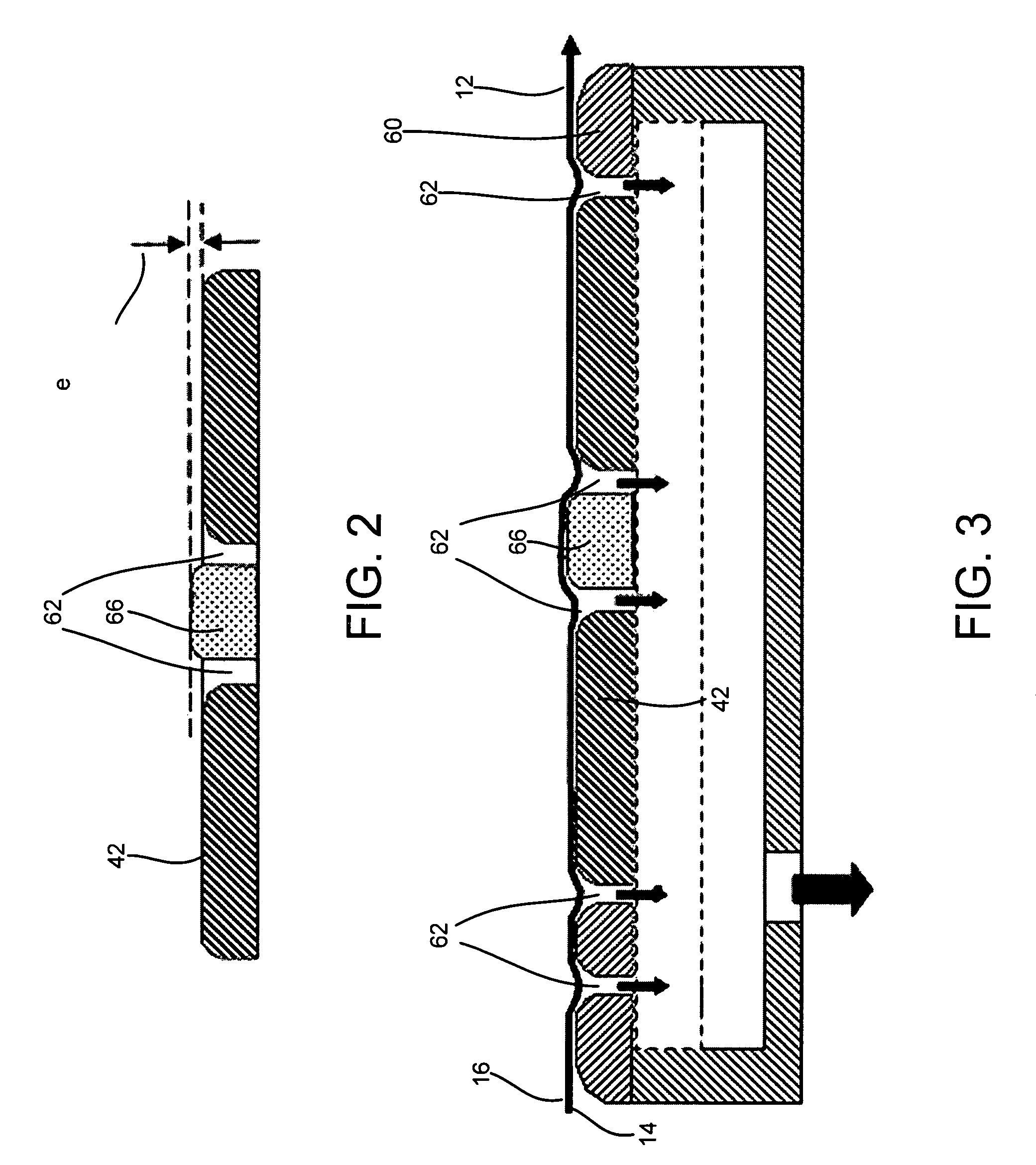

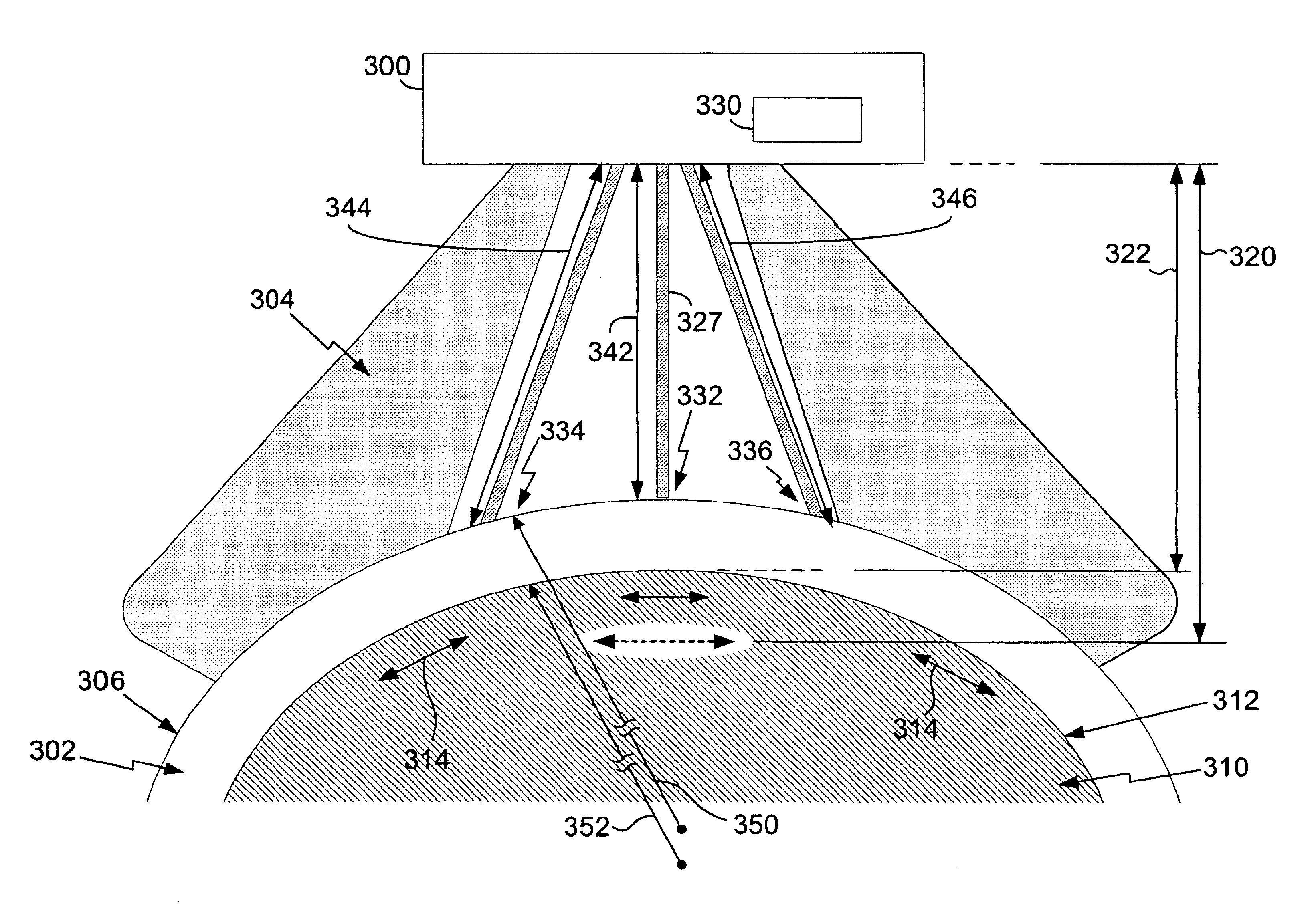

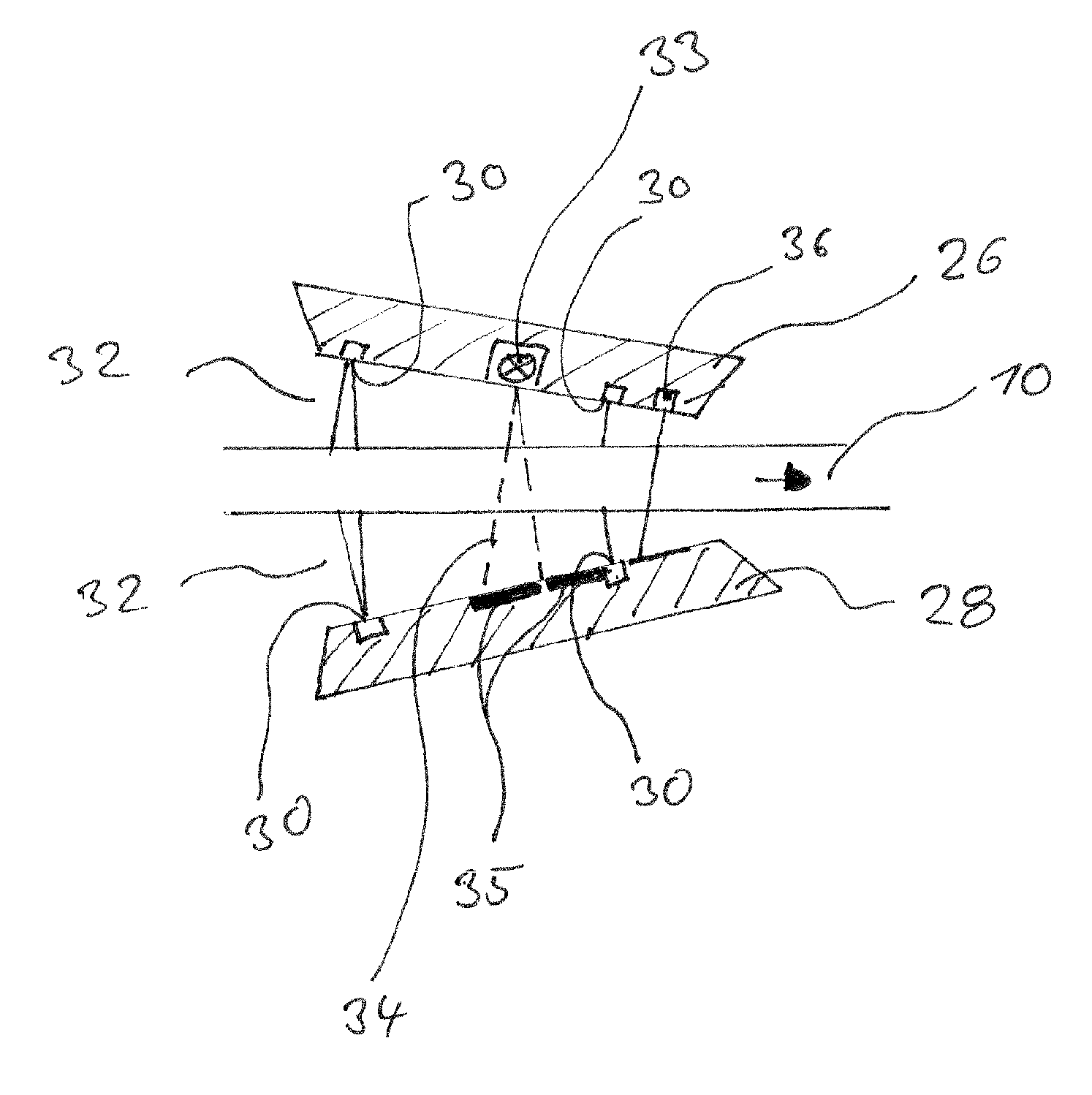

Sheet Stabilization With Dual Opposing Cross Direction Air Clamps

ActiveUS20090260772A1Accurate thicknessAccurate other measurementCaliper-like sensorsDryer sectionEngineeringCalipers

An air stabilization system employing two parallel, opposite facing Coanda nozzles, that are positioned adjacent a flexible moving web, with each nozzle exhausting gas at opposite directions, subjects the moving web to opposing forces effective to stabilize the web. Each nozzle includes an elongated slot that is parallel to the path of the moving web. The two Coanda nozzles serve as separate points along the machine direction for controlling the height of the moving web. By modulating the flow, pressure and other parameters of gases exiting the Coanda nozzles, the shape of the moving web between the nozzles can be manipulated to present a planar contour for measurements. The air stabilization system can be incorporated into a scanner head to measure the caliper of paper, plastic, and other flexible web products.

Owner:HONEYWELL ASCA INC

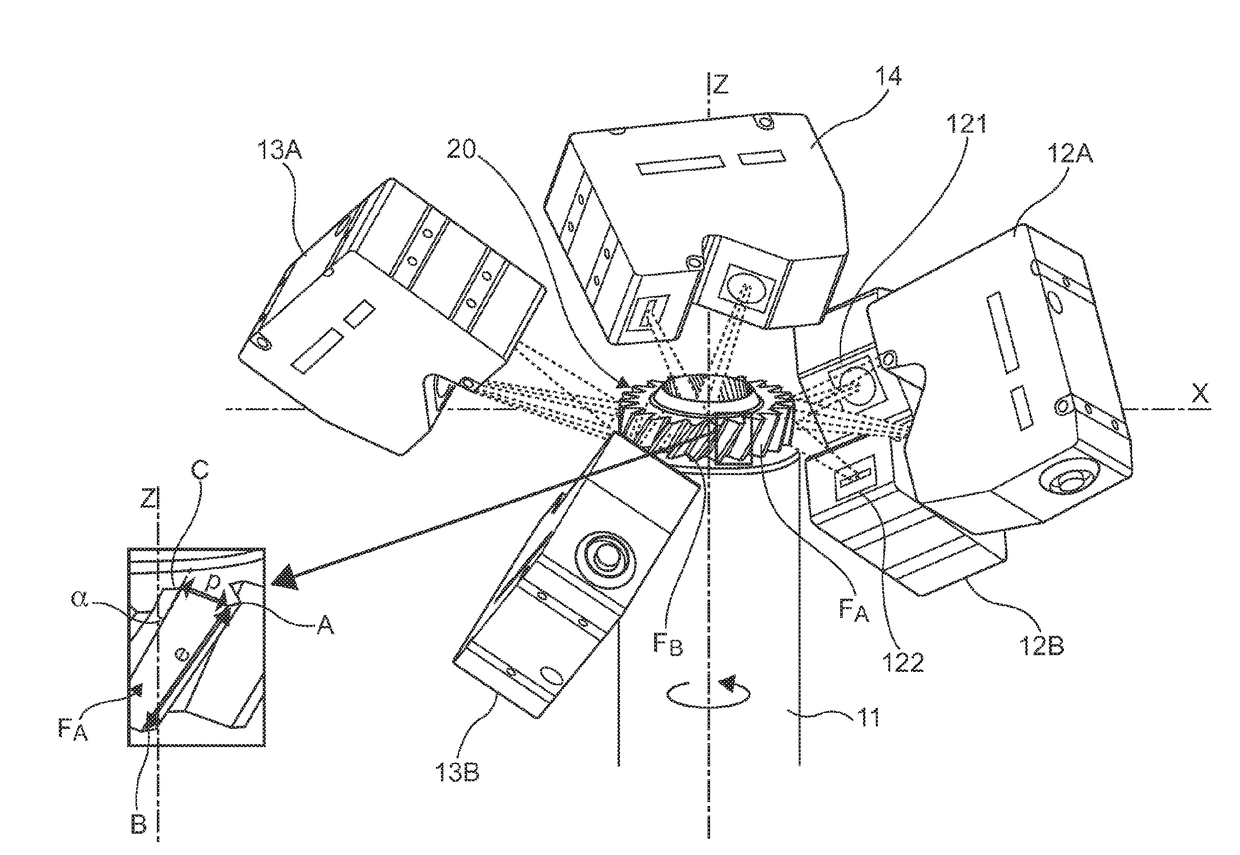

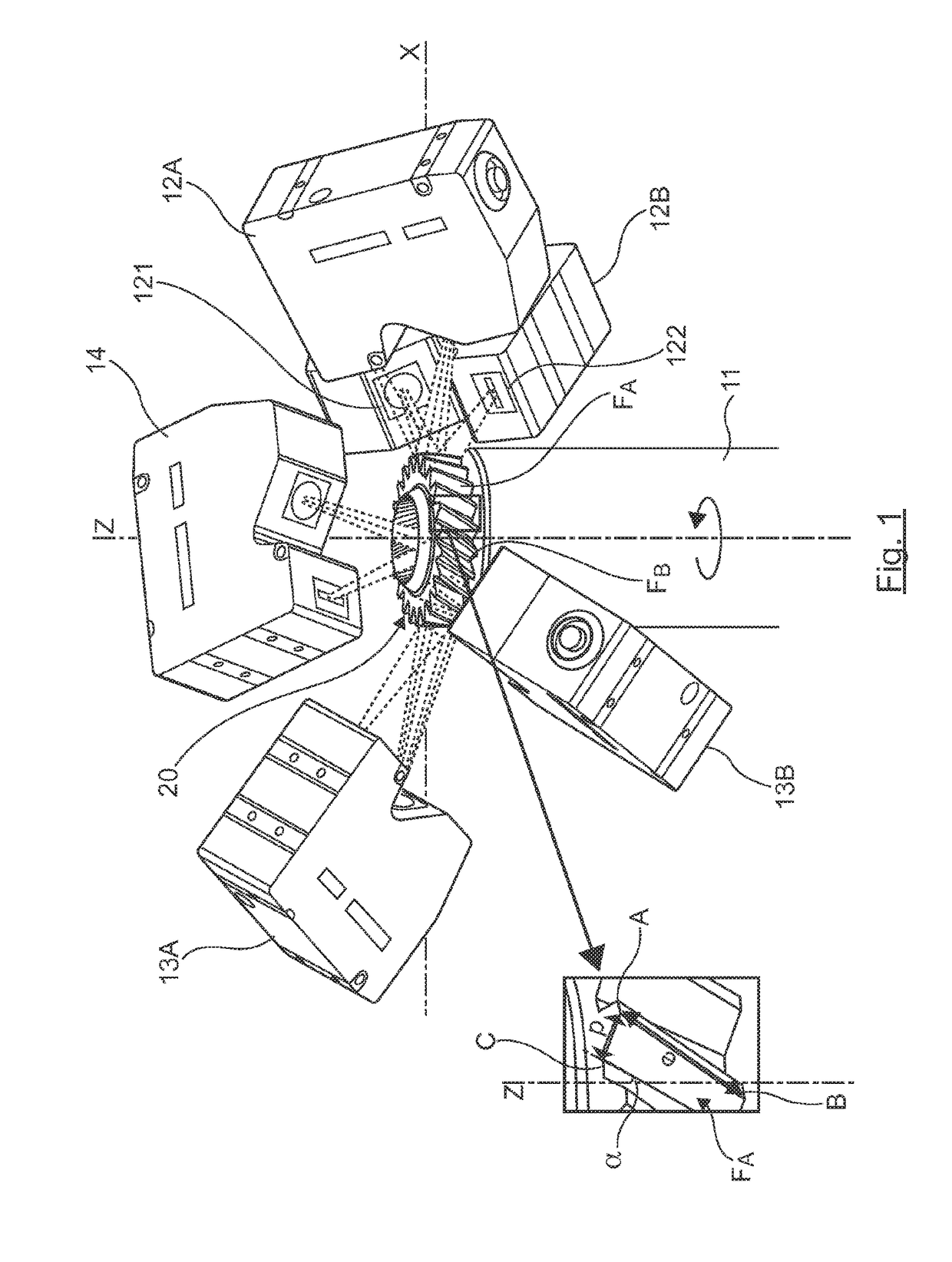

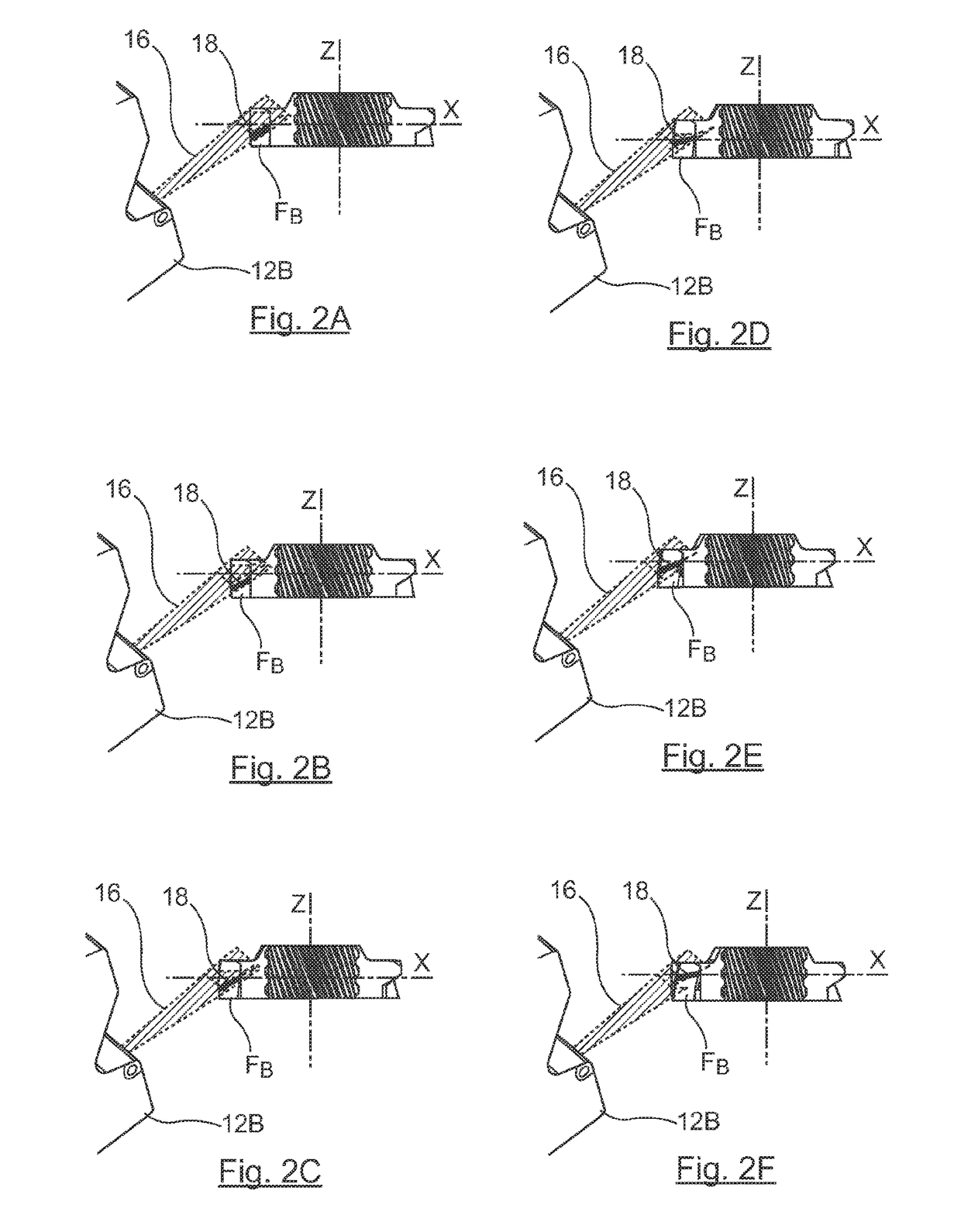

Device for the contactless three-dimensional inspection of a mechanical component with toothing

ActiveUS20180252517A1Enable performanceShorten the timeCaliper-like sensorsUsing optical meansMechanical componentsEngineering

An inspection device for contactless three-dimensional inspection of a circular, mechanical component with toothing having a main axis of rotation. The device is configured to scan the teeth by at least one first pair of laser measurement modules and rotationally drive the component about the main axis relative to the laser measurement modules. The device then rebuilds a virtual three-dimensional representation of the component using data coming from said scanning and performs a dimensional inspection using the three-dimensional representation. Each pair of modules includes a first module oriented towards a first face of a tooth and a second module oriented towards a second face of a tooth. The modules are oriented relative to the component so that during a rotation of the component, the laser measurement modules scan the first and second faces of each tooth throughout their thickness and depth.

Owner:DWFRITZ AUTOMATION INC

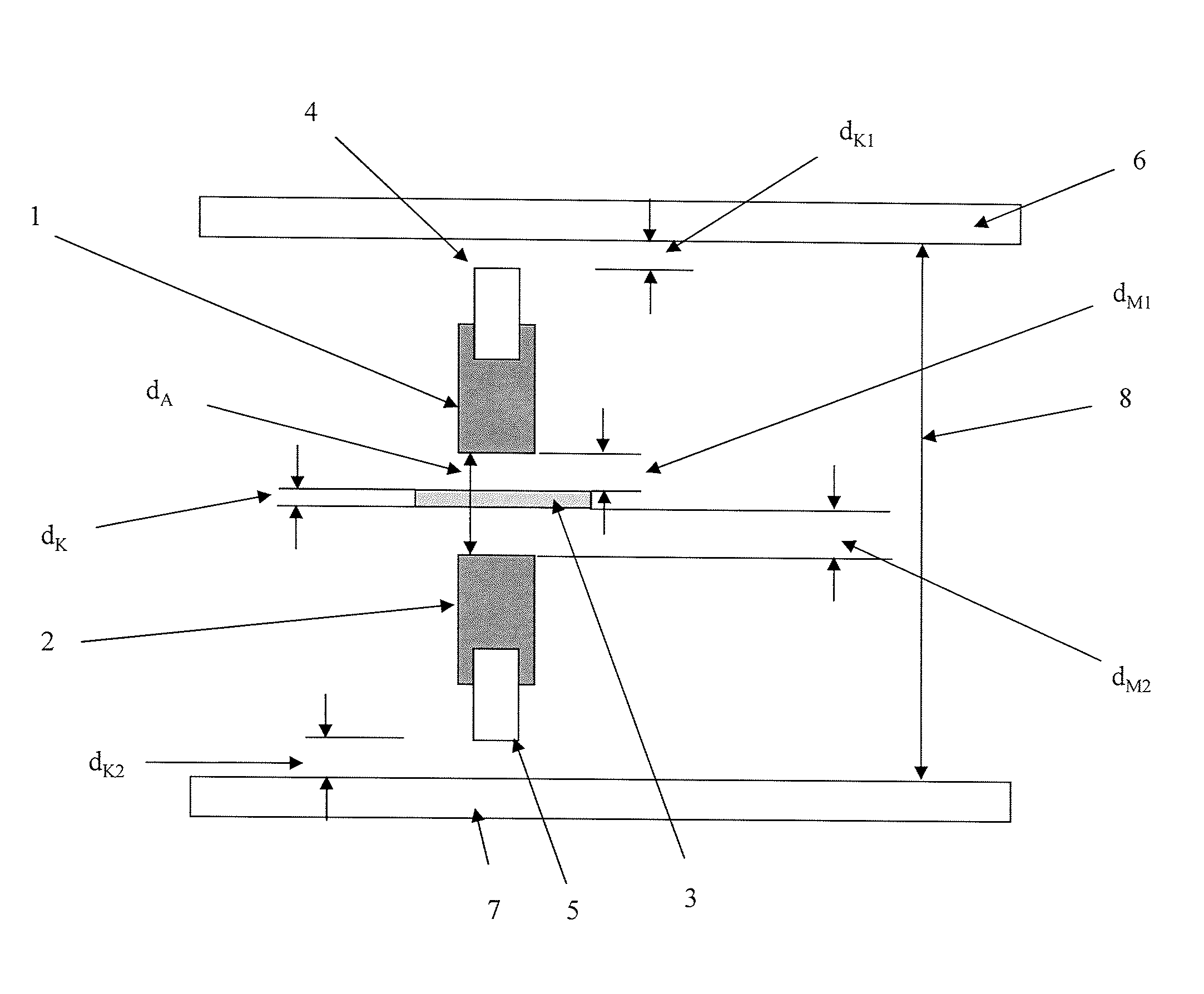

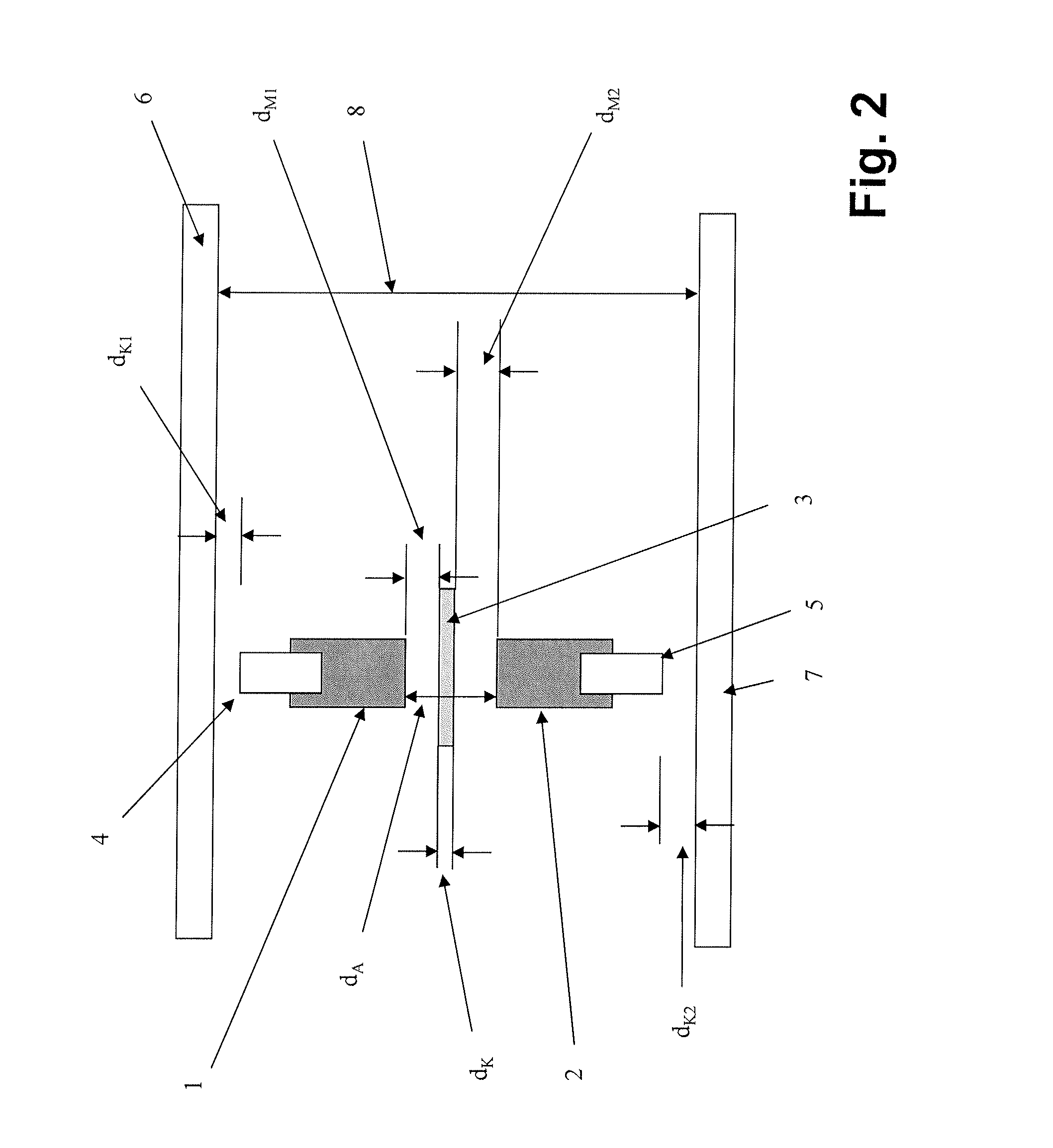

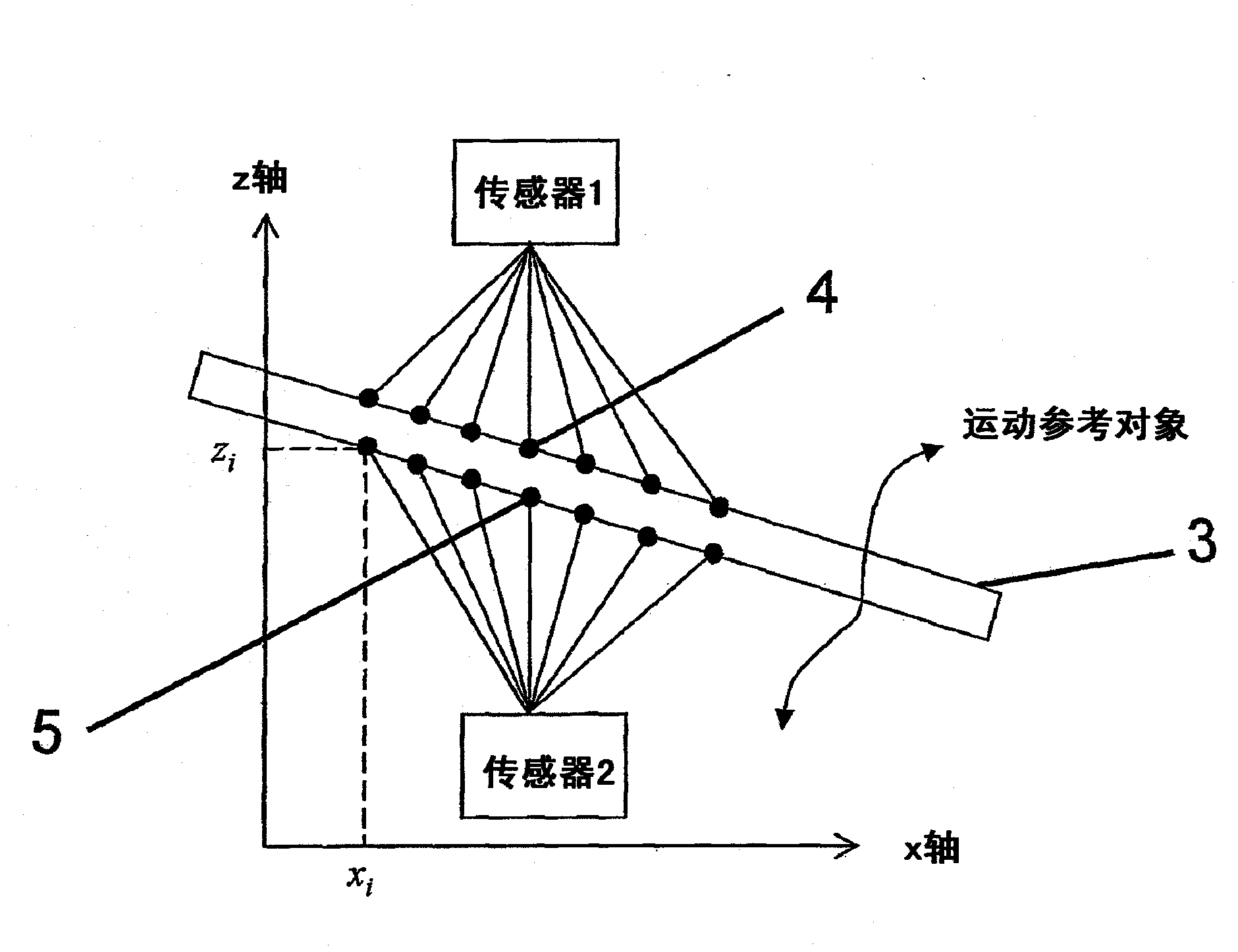

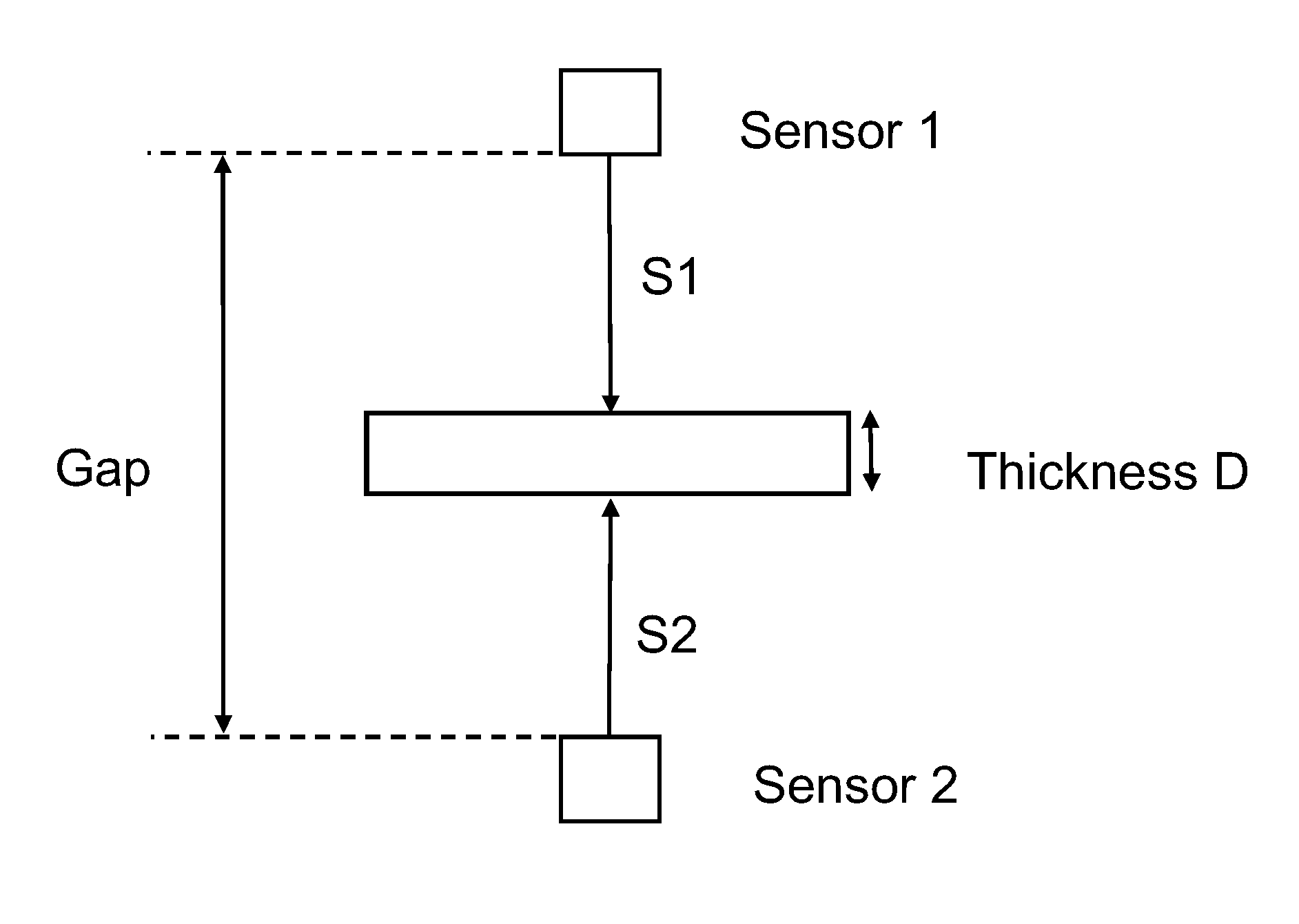

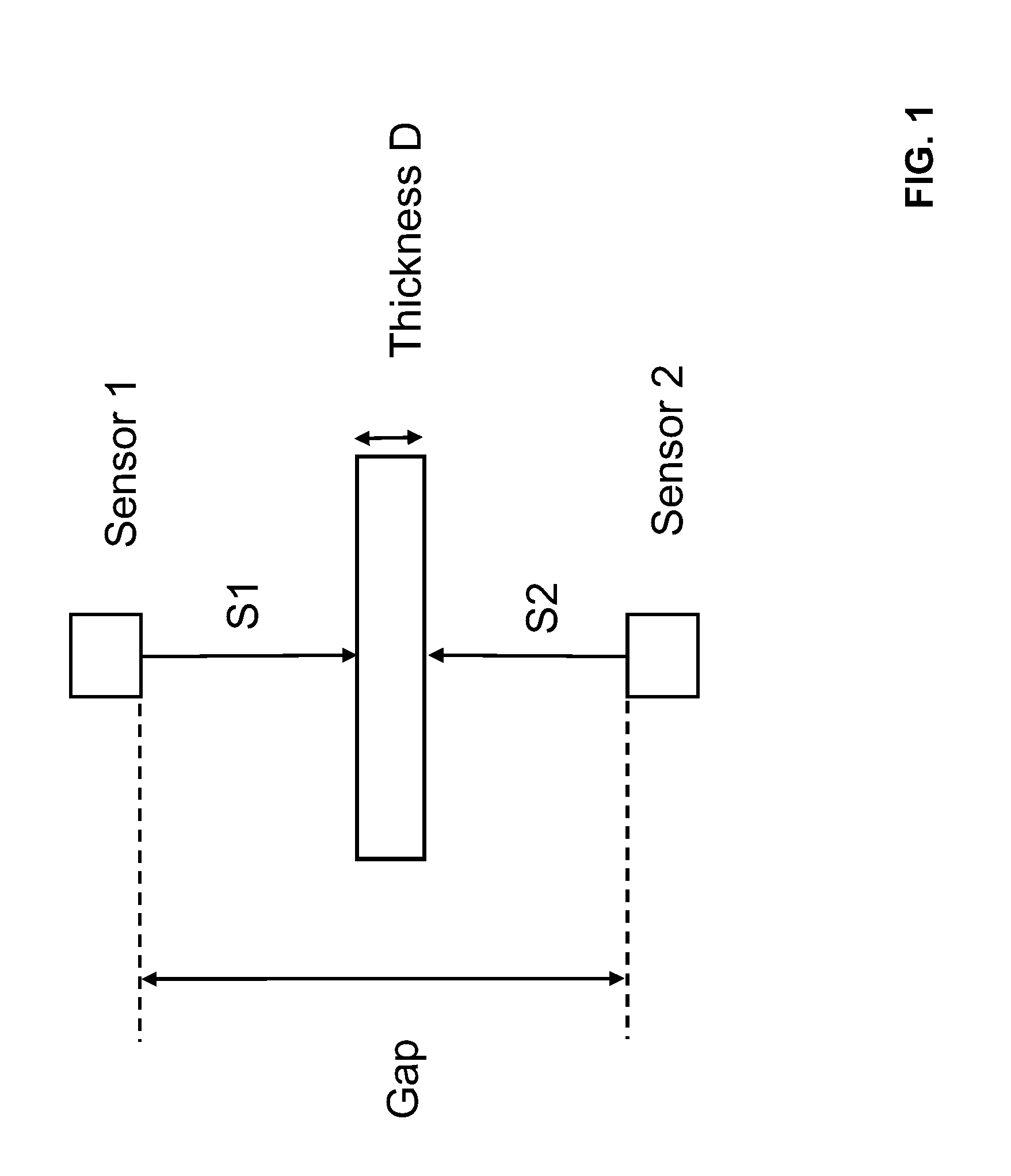

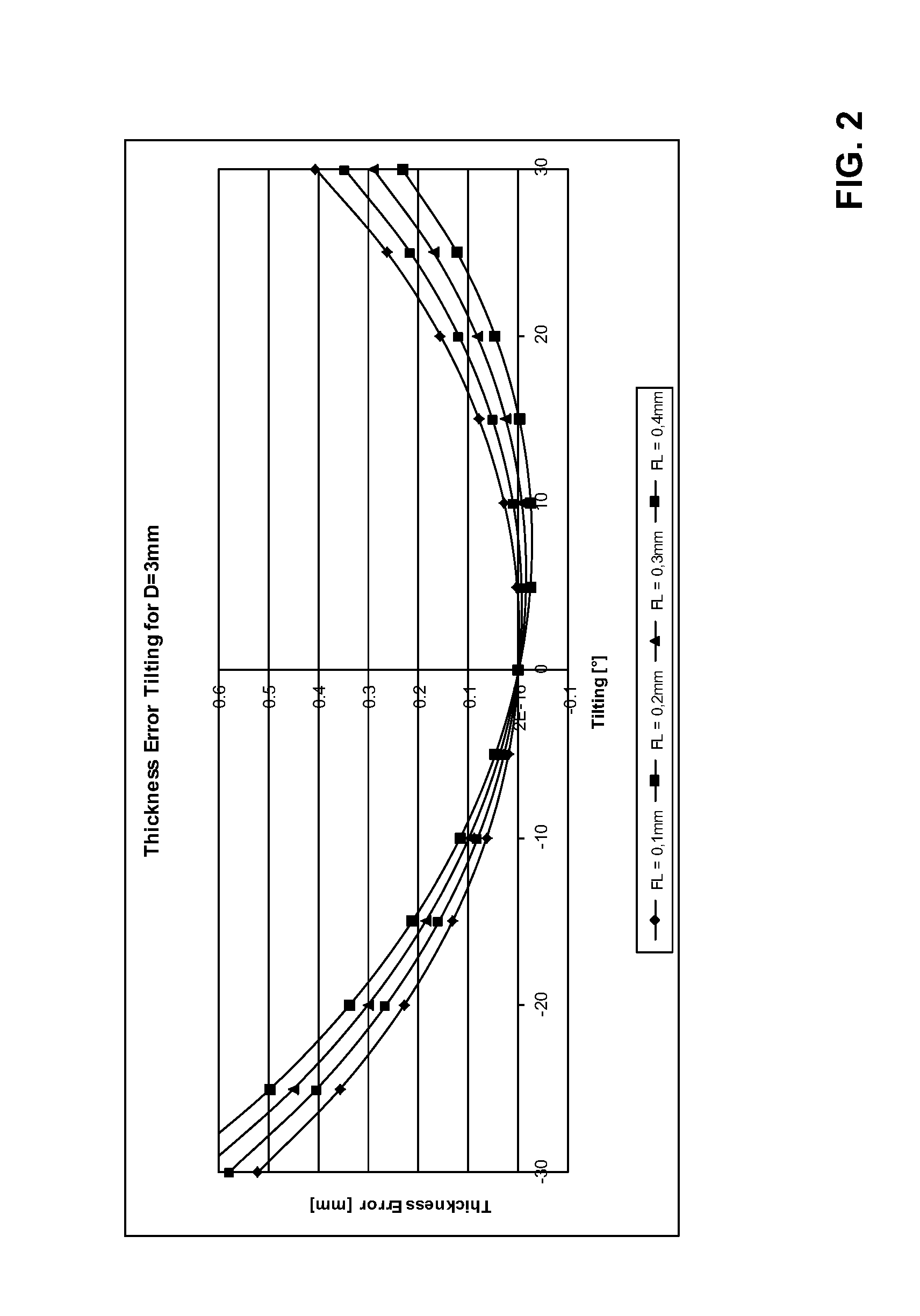

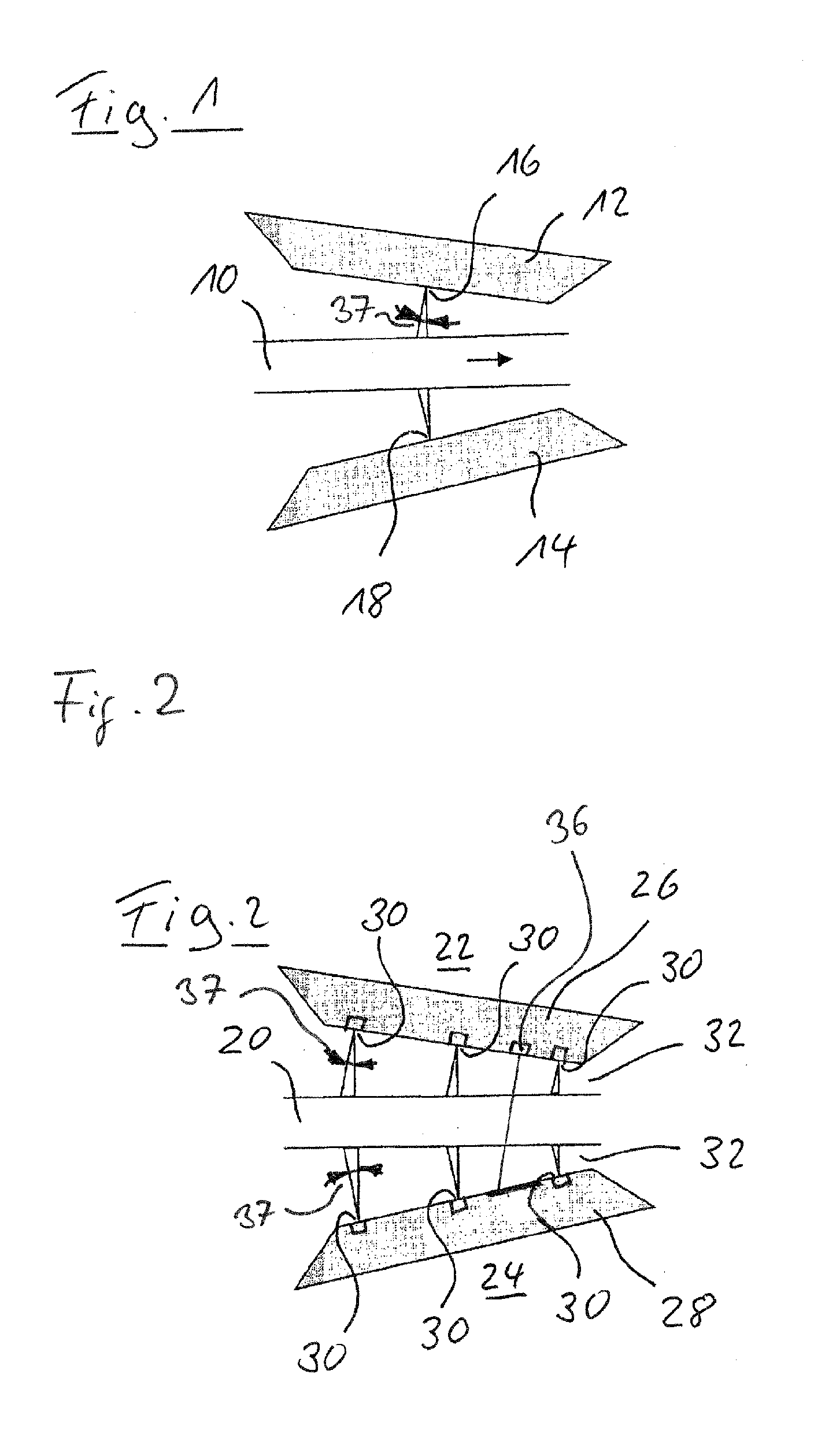

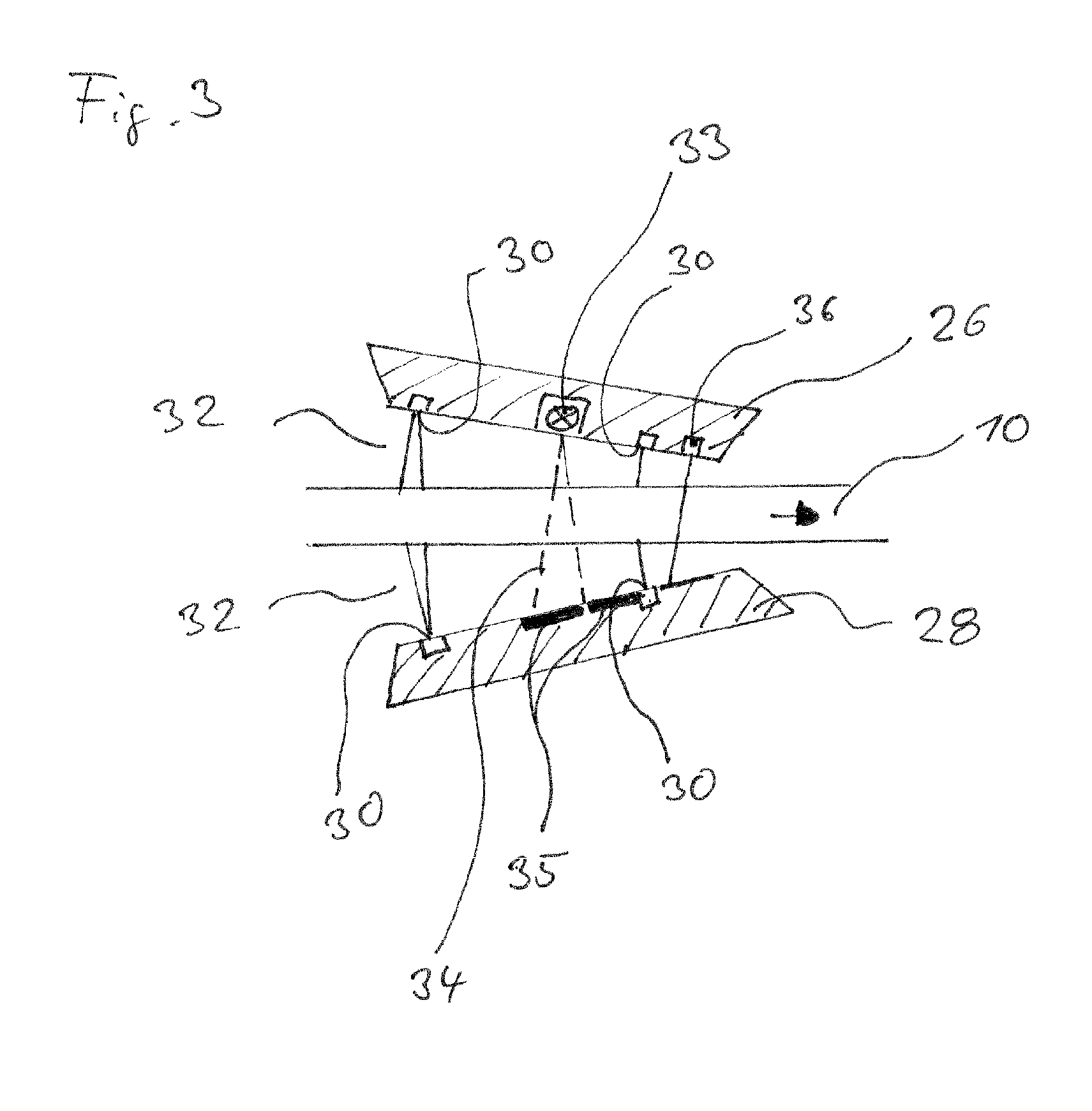

Method and device for contactless determination of the thickness of a web of material, including correction of the alignment error

InactiveUS20120170059A1Increased level of precisionHigh measurement accuracyCaliper-like sensorsUsing electrical meansSensor arrayEngineering

A method for the contactless determination of the thickness of a web of material, for example a web of fibrous material using a sensor array including at least two optical measurement units between which the web can be guided. Each of the optical measurement units includes a measurement plate on the side facing the web. The optical measurement units, which are arranged on opposite sides of the web, are used to measure the distance of the measurement units from the web, and an evaluation unit is used to determine the thickness of the web from the determined distances between the optical measurement units and the web and the distance between the optical measurement units arranged on opposite sides of the web. Multiple optical sensors which are disposed at a distance from each other are associated with the optical measurement units arranged on opposite sides of the web and the evaluation unit is used to determine the angle of inclination of the measurement plates relative to the web and / or an offset between the optical measurement units arranged on opposite sides of the web or between the measurement plates of said units on the basis of the measured values obtained from the optical sensors.

Owner:VOITH PATENT GMBH

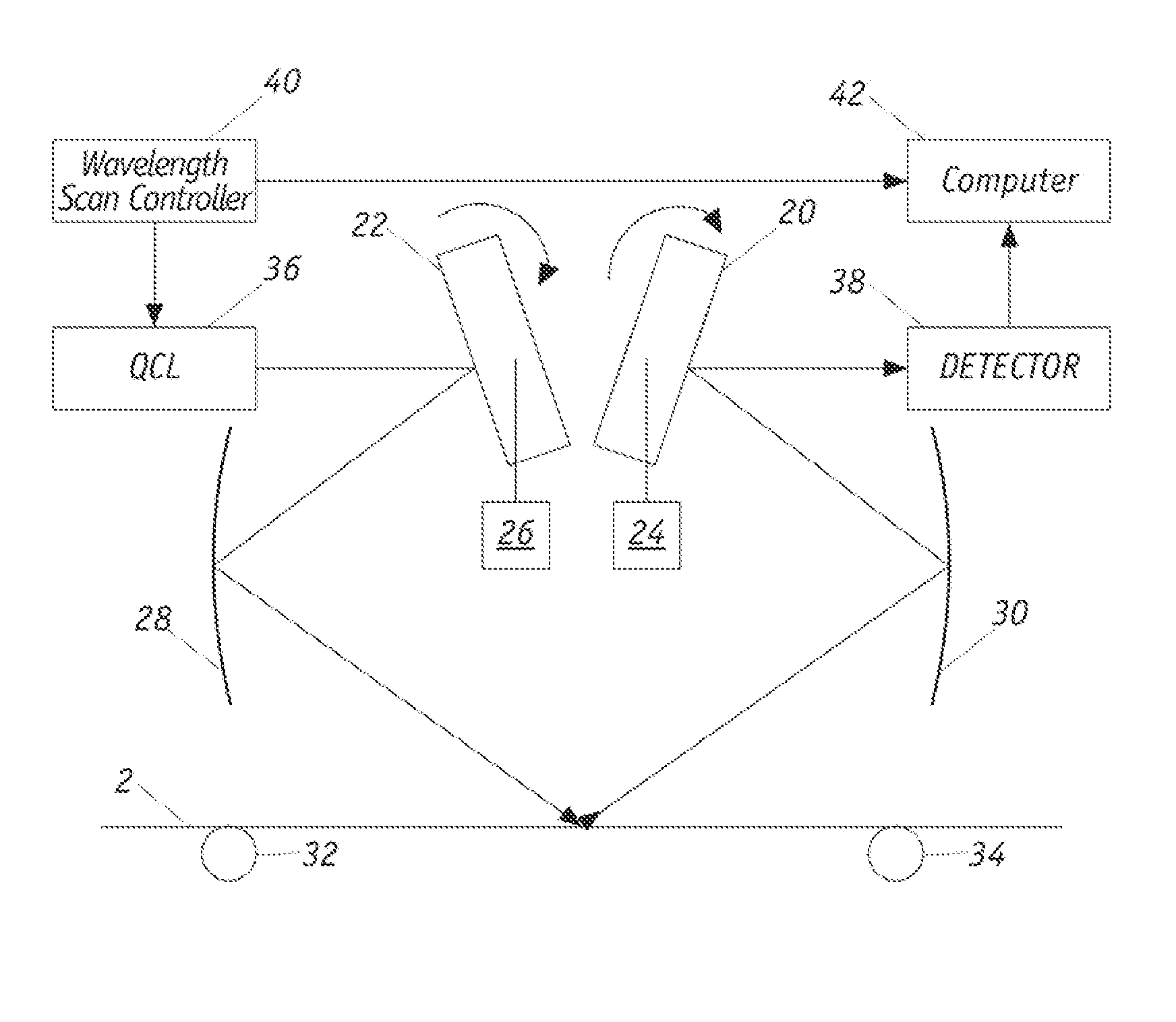

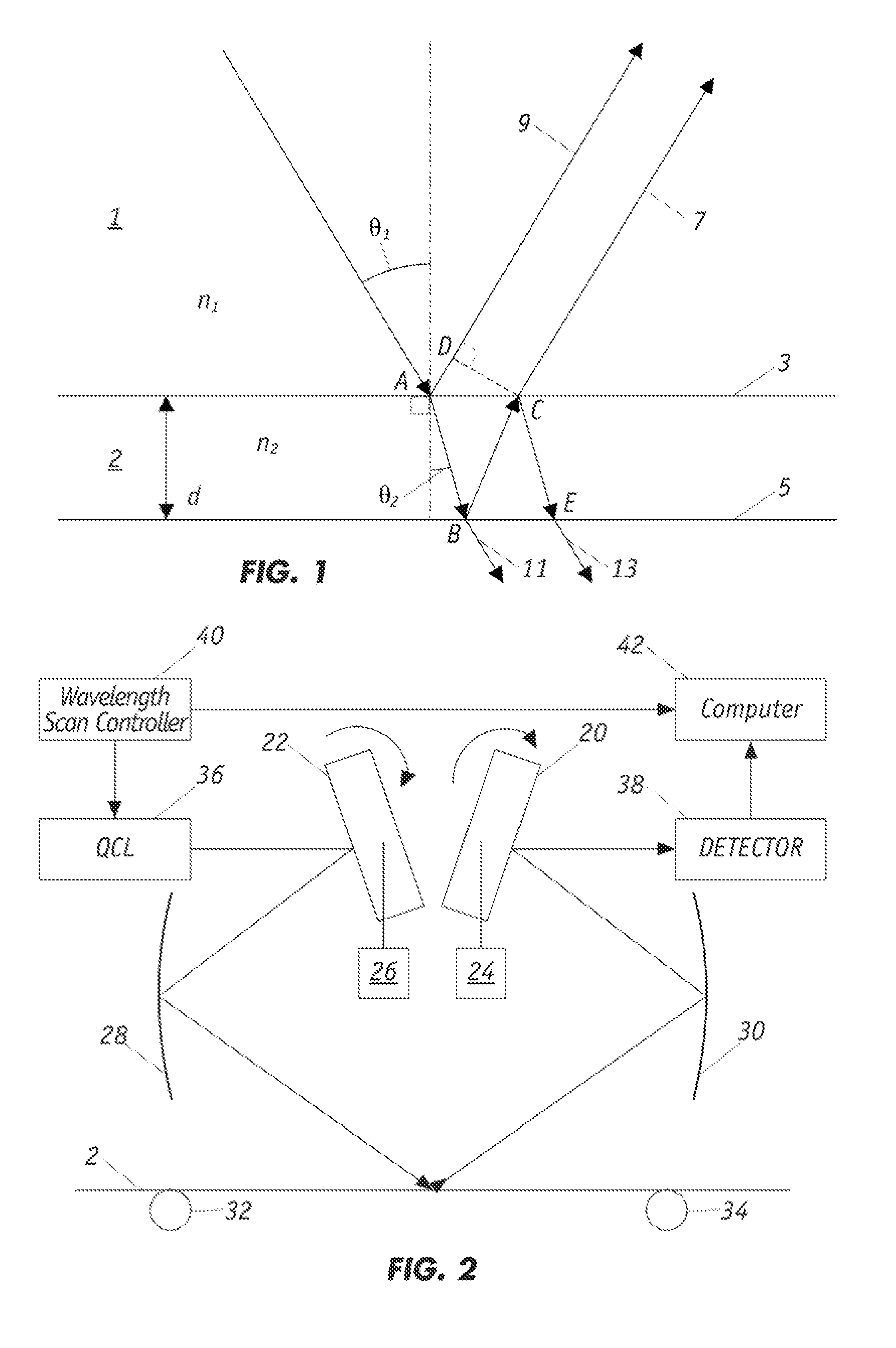

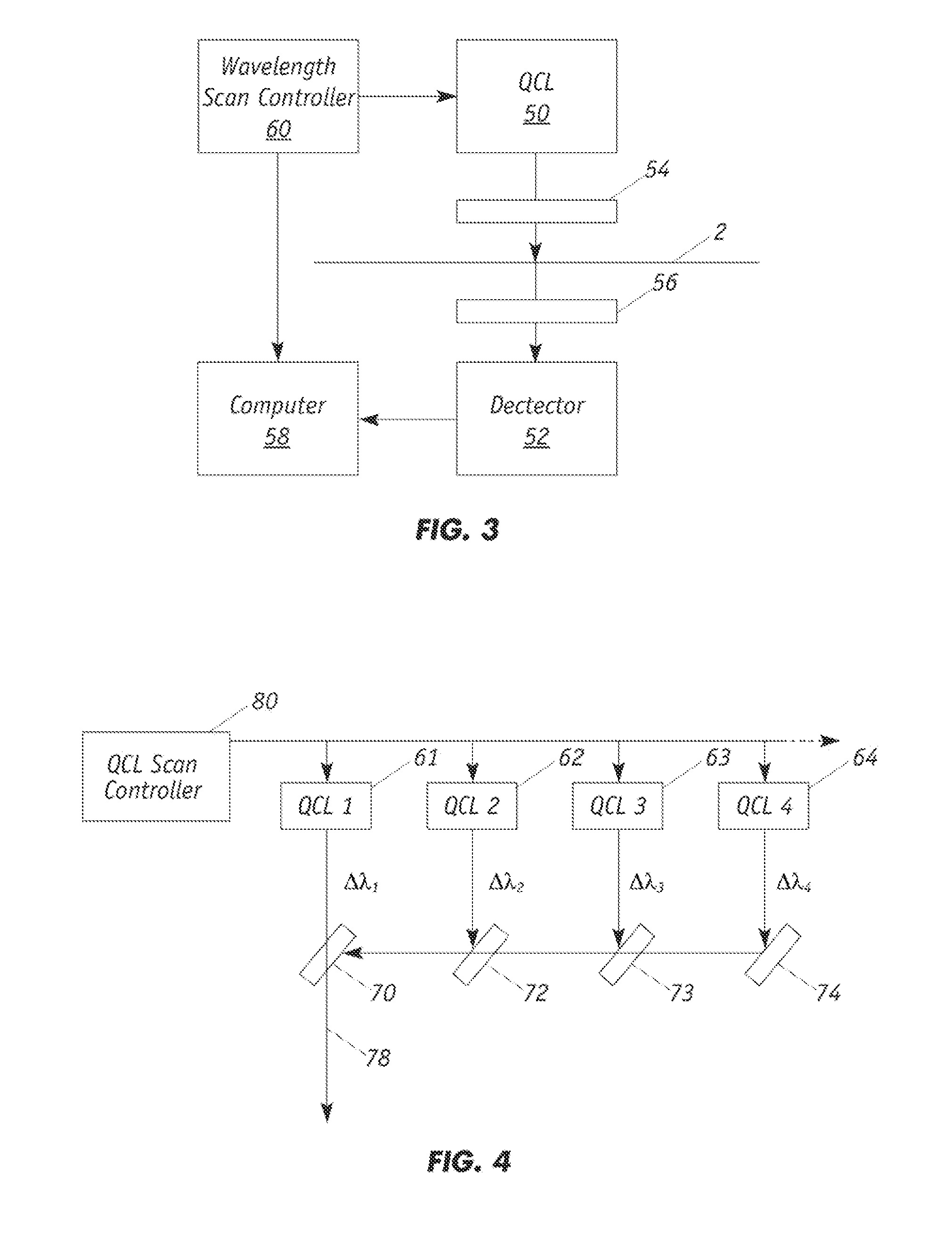

Thickness Determination of Web Product by Mid-infrared Wavelength Scanning Interferometry

InactiveUS20150253127A1Suitable for applicationCaliper-like sensorsMaterial analysis by optical meansAngle of incidenceLight reflection

Non-contacting caliper measurements of free-standing sheets detect mid-IR interferometric fringes created by the reflection of light from the top and bottom surfaces of the sheet. The technique includes directing a laser beam at a selected angle of incidence onto a single spot on the exposed outer surface and scanning the laser beam through a selected wavelength range as the laser beam is directed onto the exposed outer surface and measuring the intensity of an interference pattern that forms from the superposition of radiation that is reflected from the exposed outer surface and from the inner surface. Alternatively, the intensity of an interference pattern formed from the superposition of radiation that is directly transmitted through the web and radiation that is transmitted through the web after internal reflections from the internal surfaces of the web. Thickness can be extracted from the fringe separation in the interference pattern.

Owner:HONEYWELL ASCA INC

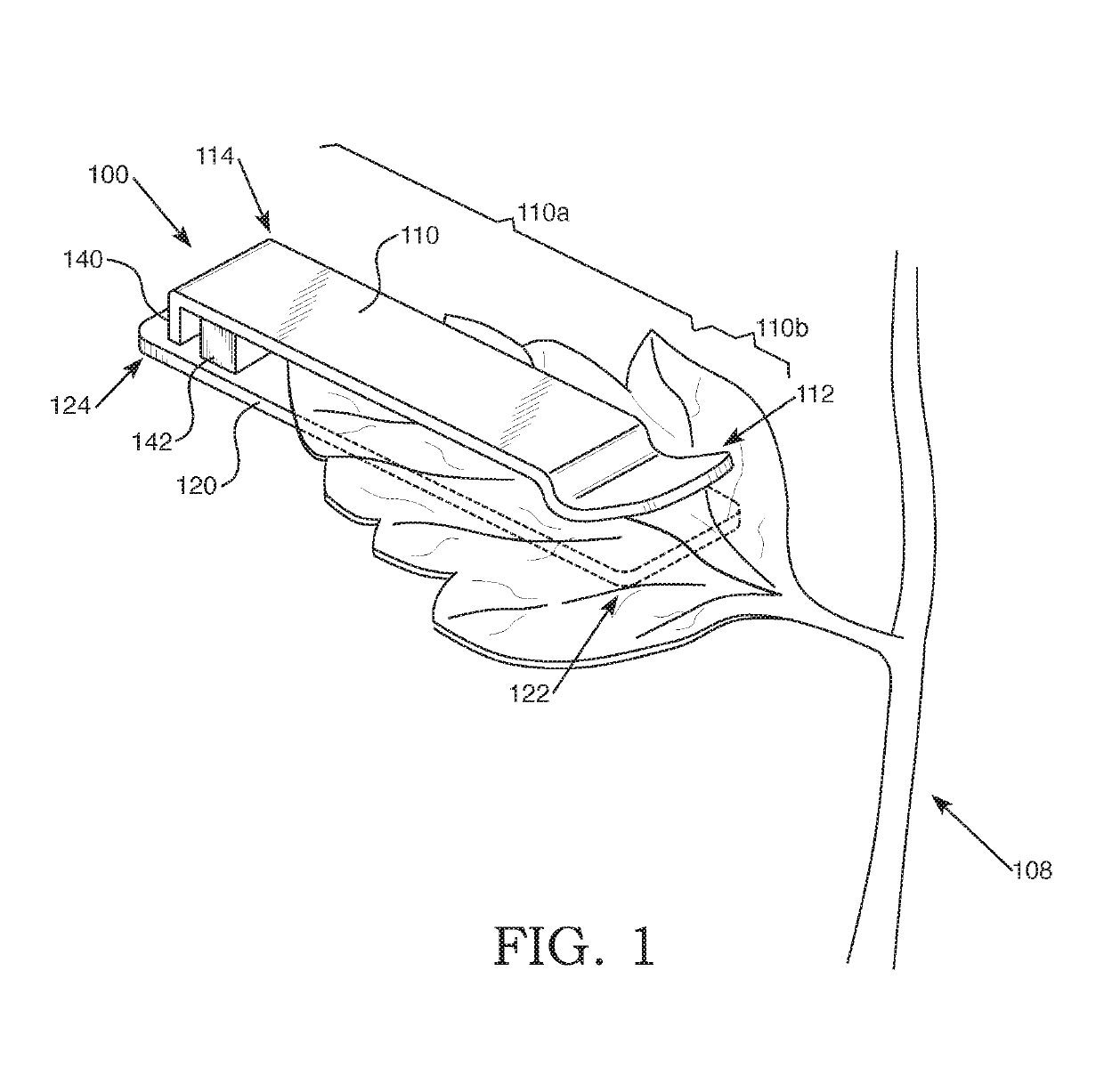

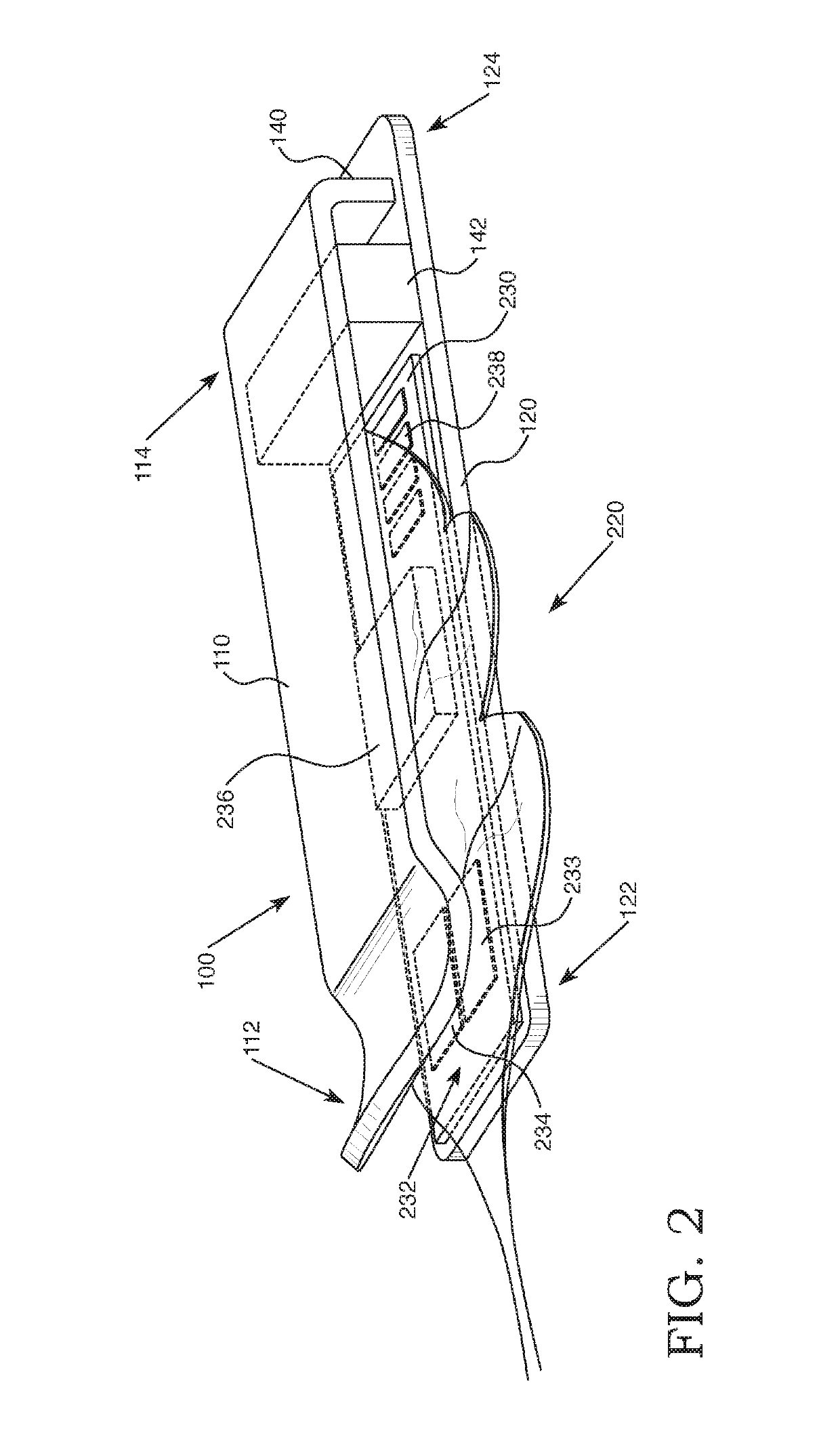

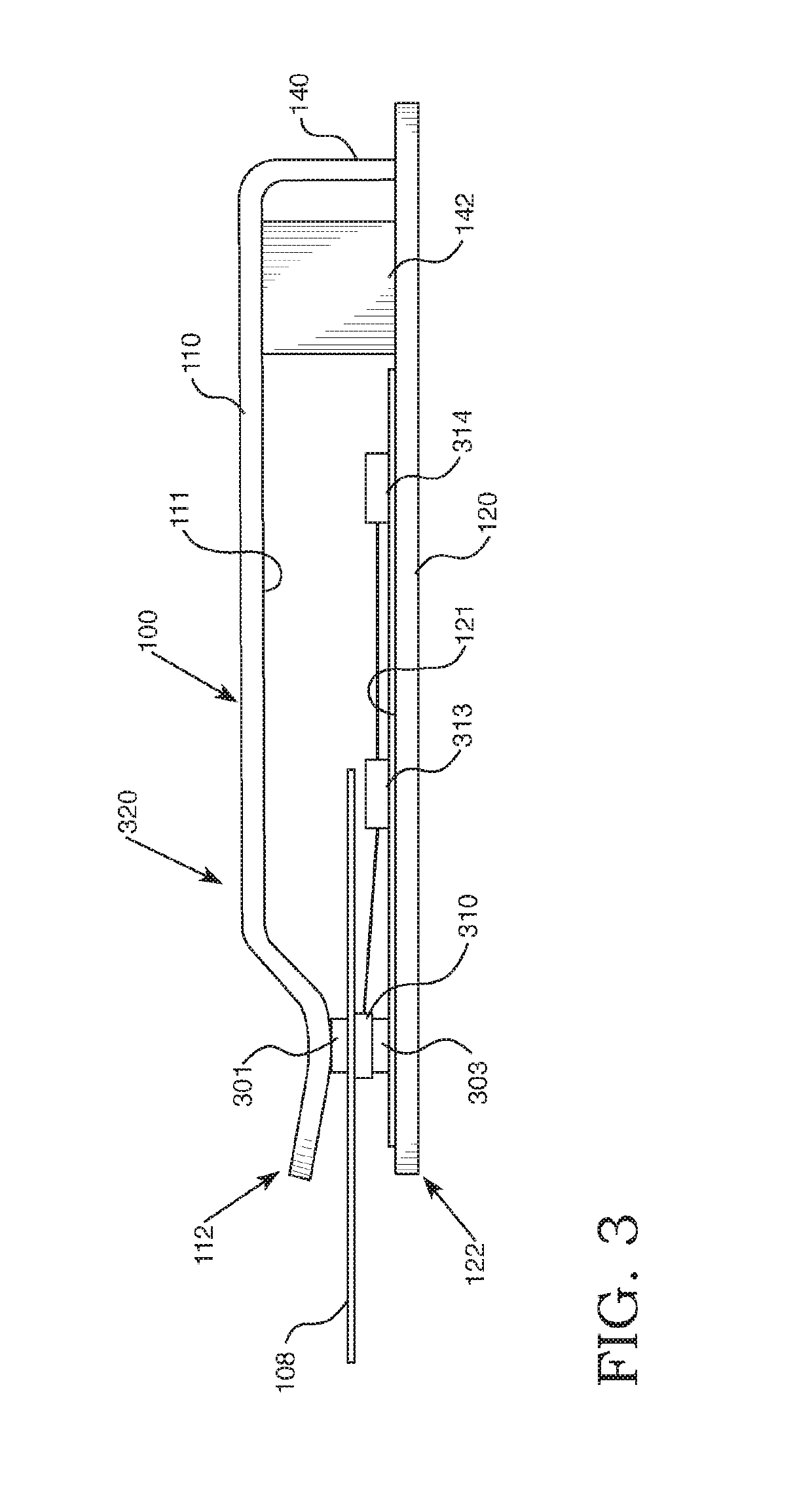

Sensors for measuring water/solute content and thickness of plant tissue

ActiveUS20190101516A1Caliper-like sensorsMagnetic field measurement using galvano-magnetic devicesGrip forcePlant tissue

Systems and methods for non-invasively determining a water content, a solute content, and a thickness of plant tissue are disclosed. A system includes a sensing device having a first piece and a second piece, where the first piece and the second piece are coupled together to form a clip. The system further includes a capacitive tissue sensor including a capacitor. The capacitor includes a plurality of coplanar conductive plates. The first piece and the second piece are biased in a closed position to provide a gripping force around the plant tissue such that at least a portion of the plant tissue contacts the plurality of coplanar conductive plates.

Owner:PENN STATE RES FOUND

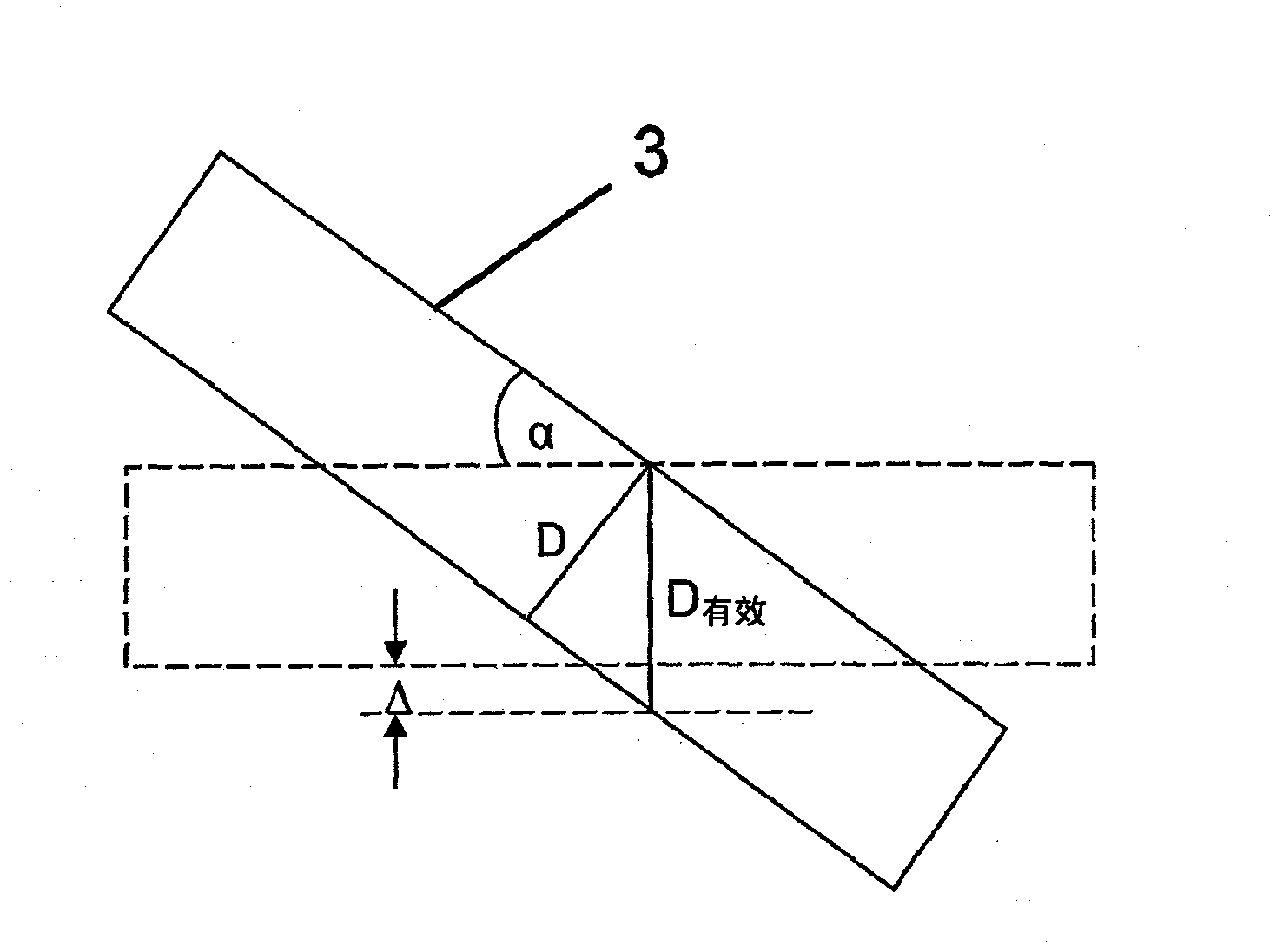

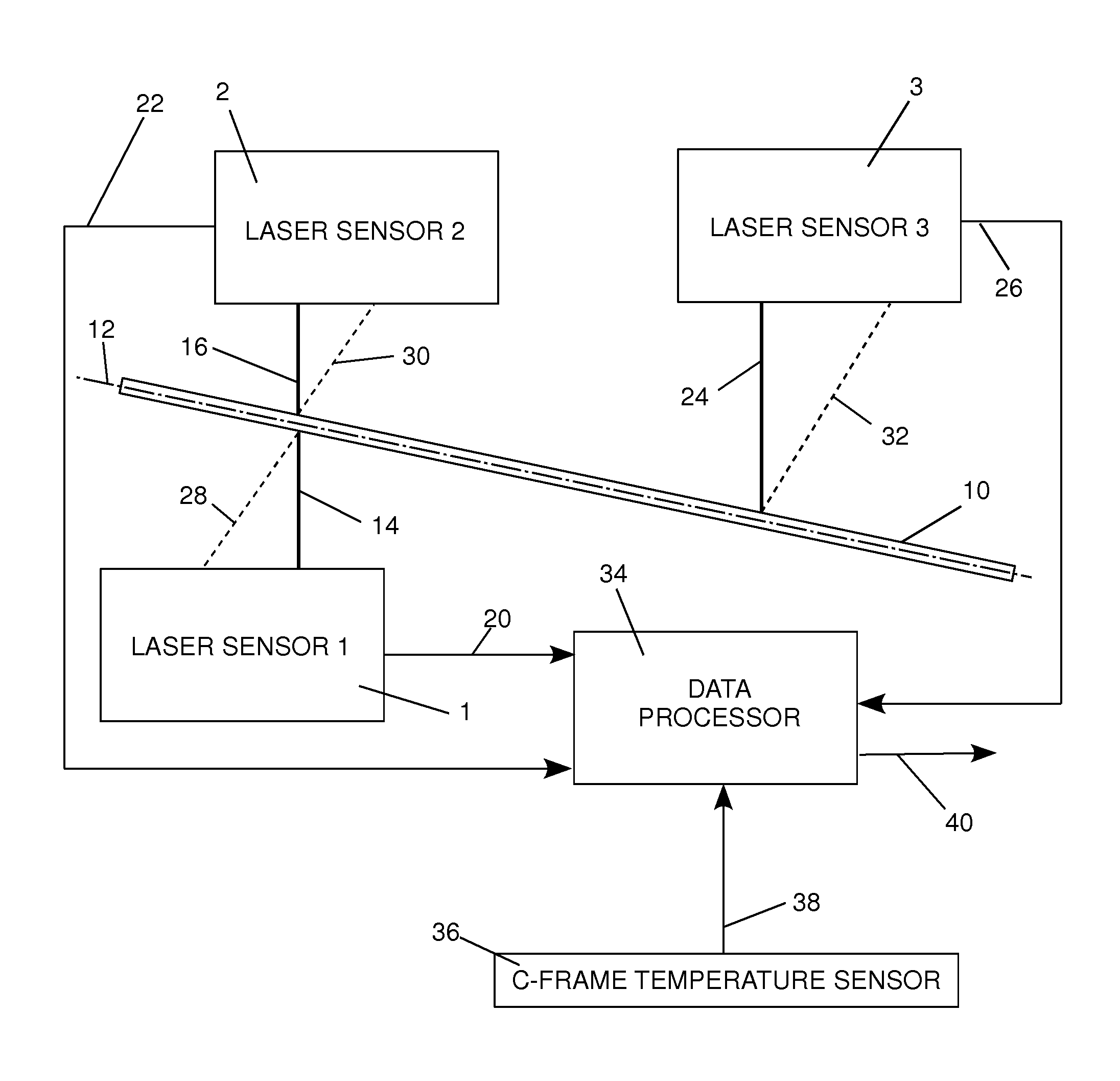

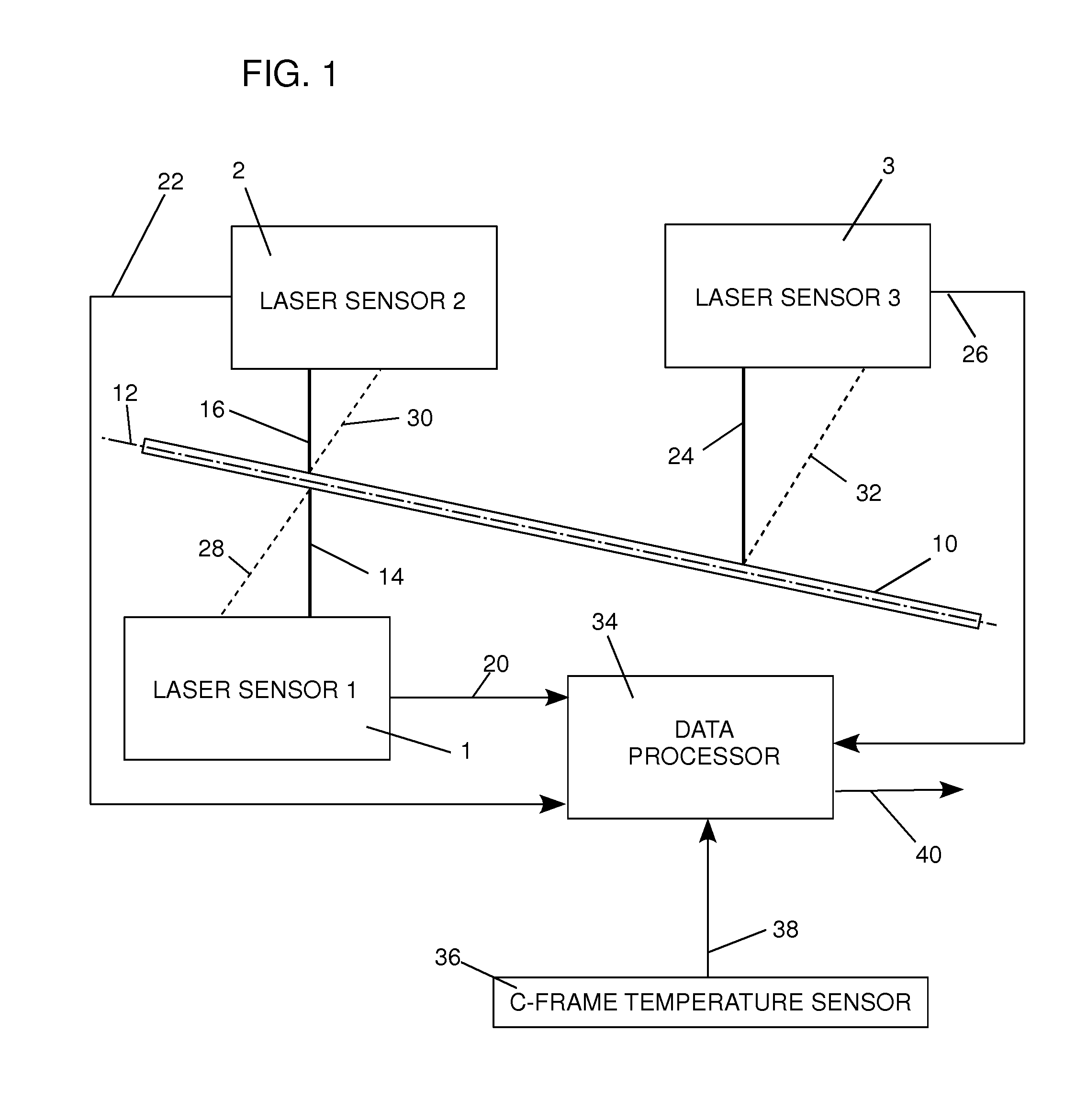

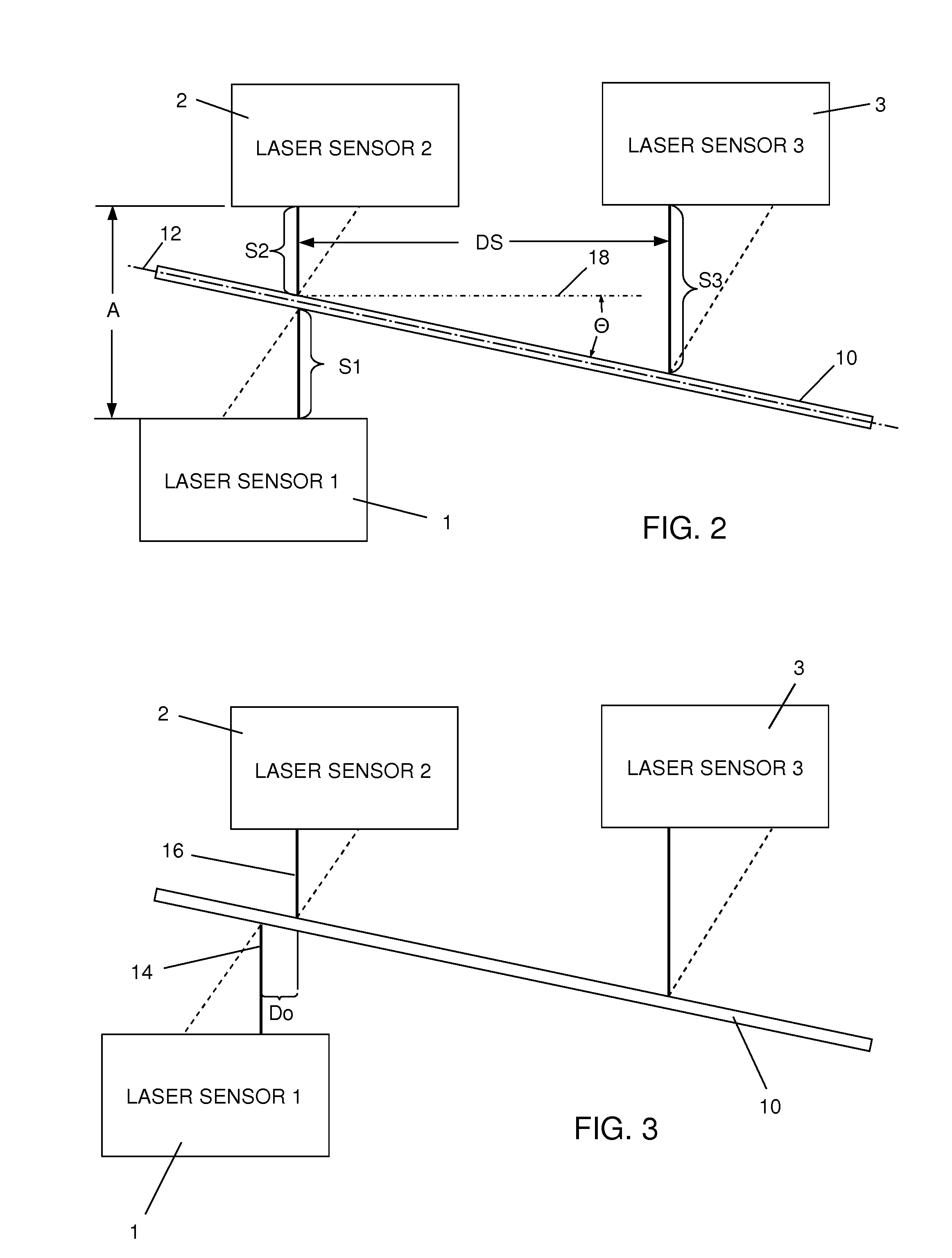

Laser thickness gauge and method including passline angle correction

A laser thickness gauge has three laser displacement sensors each transmitting a laser beam onto a target web. Two sensors are spaced along the web and face one surface of the web and the third sensor faces the opposite surface. The thickness of a web that is positioned along a passline plane between the sensor is measured even when the passline plane is not perpendicular to the beams of the sensors. A data processor computes the passline angle from the distance measurements communicated from the three sensors. During setup and calibration, data representing physical characteristics of the gauge are measured and stored and during operation are processed with currently measured data to generate correction factors that are used to correct thickness measurements determined from the three laser sensors.

Owner:ADVANCED GAUGING TECH

Scanner belt load and stretch compensation control system

ActiveUS8564851B2Evenly loadedReduce errorsCaliper-like sensorsRadiation pyrometryControl systemActuator

Owner:HONEYWELL ASCA INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com