Measuring instrument and method for determination of the properties of an item and its surface

A characteristic and detector technology, applied in the field of measuring instruments, can solve problems such as changes in reflected light intensity and distance angles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

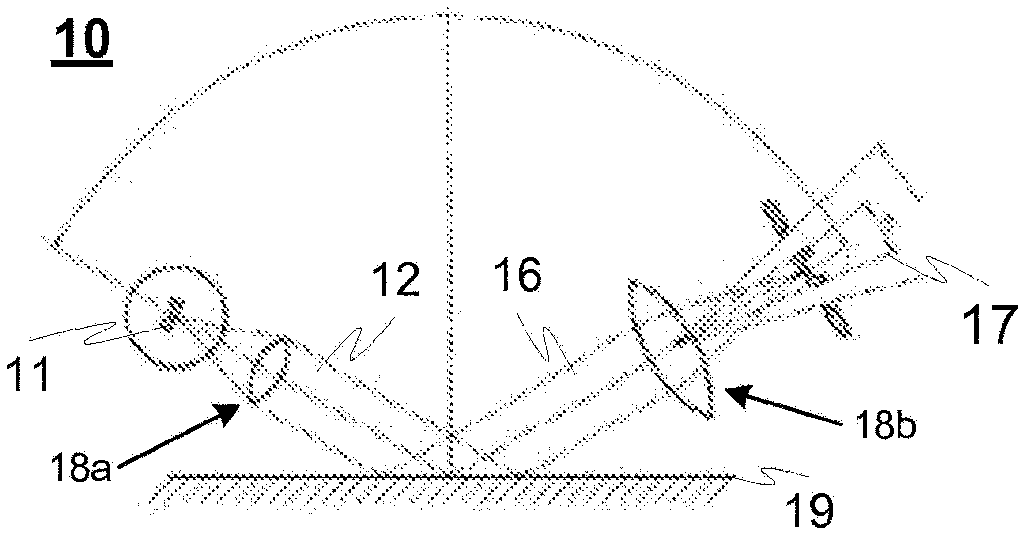

[0051] figure 1 A gloss measurement geometry 10 according to the gloss standard ISO 2813 is illustrated, wherein a light beam 12 generated by a light source 11 is directed by means of converging means 18a, such as a lens, to a surface 19 being measured. The light rays are reflected from the surface 19 in the direction of the mirror geometry 16 in which they are concentrated to the light radiation detector 17 by means of converging means 18b, eg lenses. The detector 17 measures the intensity of the reflected light ray 16 and determines the glossiness of the surface 19 being measured based on the intensity of the light ray 16 .

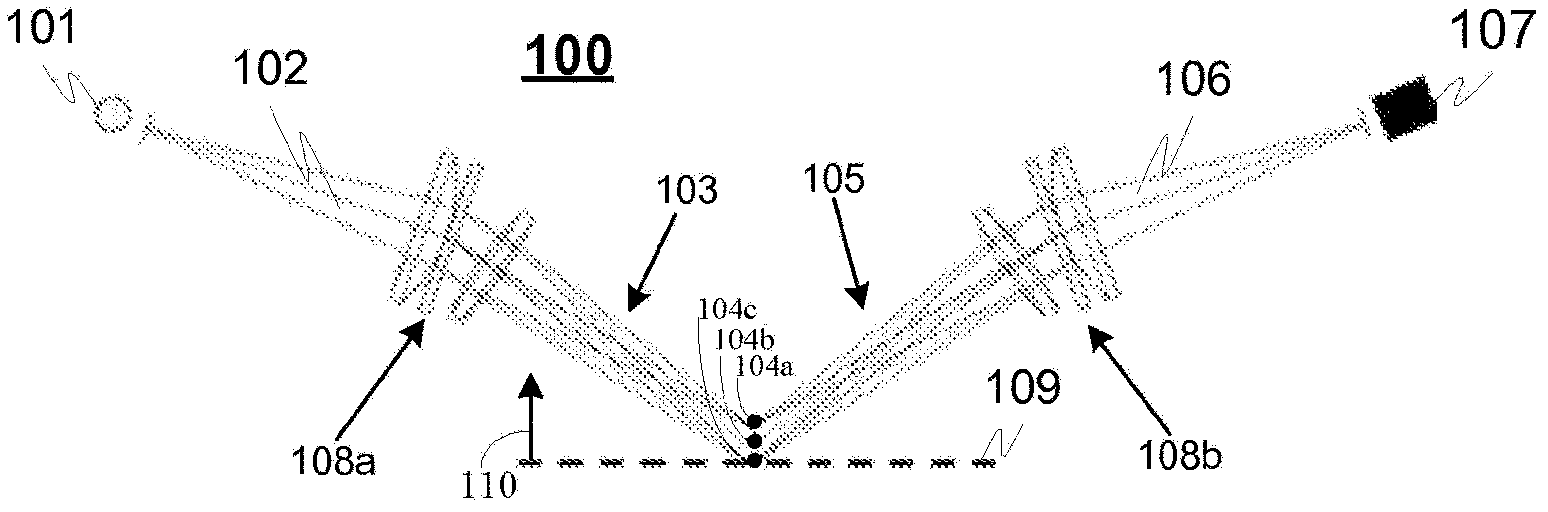

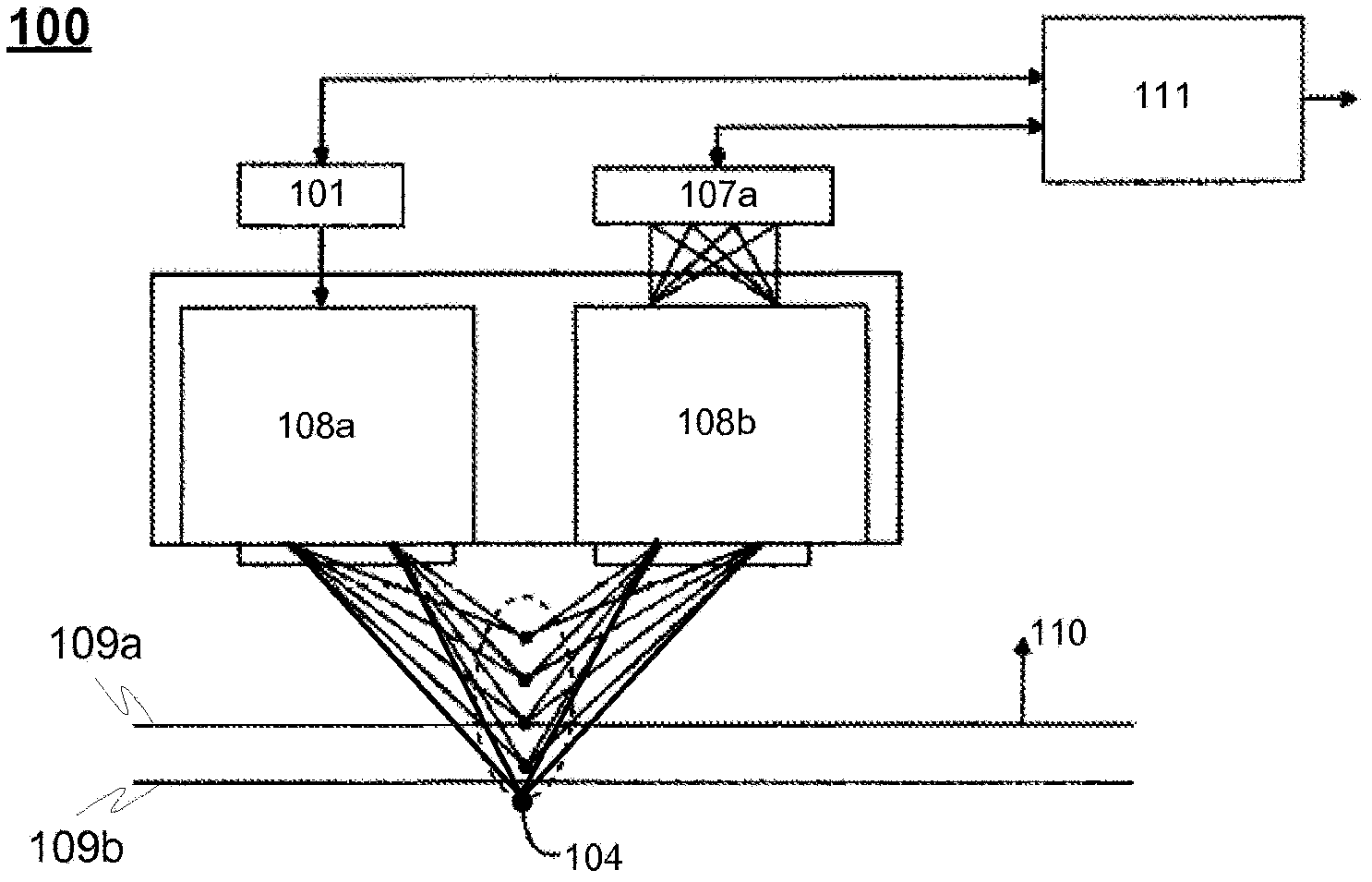

[0052] Figure 2a An exemplary measuring device 100 according to an embodiment of the invention is illustrated, wherein the system comprises an optical radiation source 101 for emitting optical radiation 102 (eg white light or other moderately continuous spectral light) towards an optical radiation processing unit 108a . The optical radiation process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com