Thickness Determination of Web Product by Mid-infrared Wavelength Scanning Interferometry

a technology of infrared wavelength and thickness determination, applied in the direction of instruments, caliper-like sensors, machines/engines, etc., can solve the problems of measurement drift and inaccuracy, prior art optical techniques are not suitable for all paper products, and achieve better than 1 micron accuracy a challeng

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

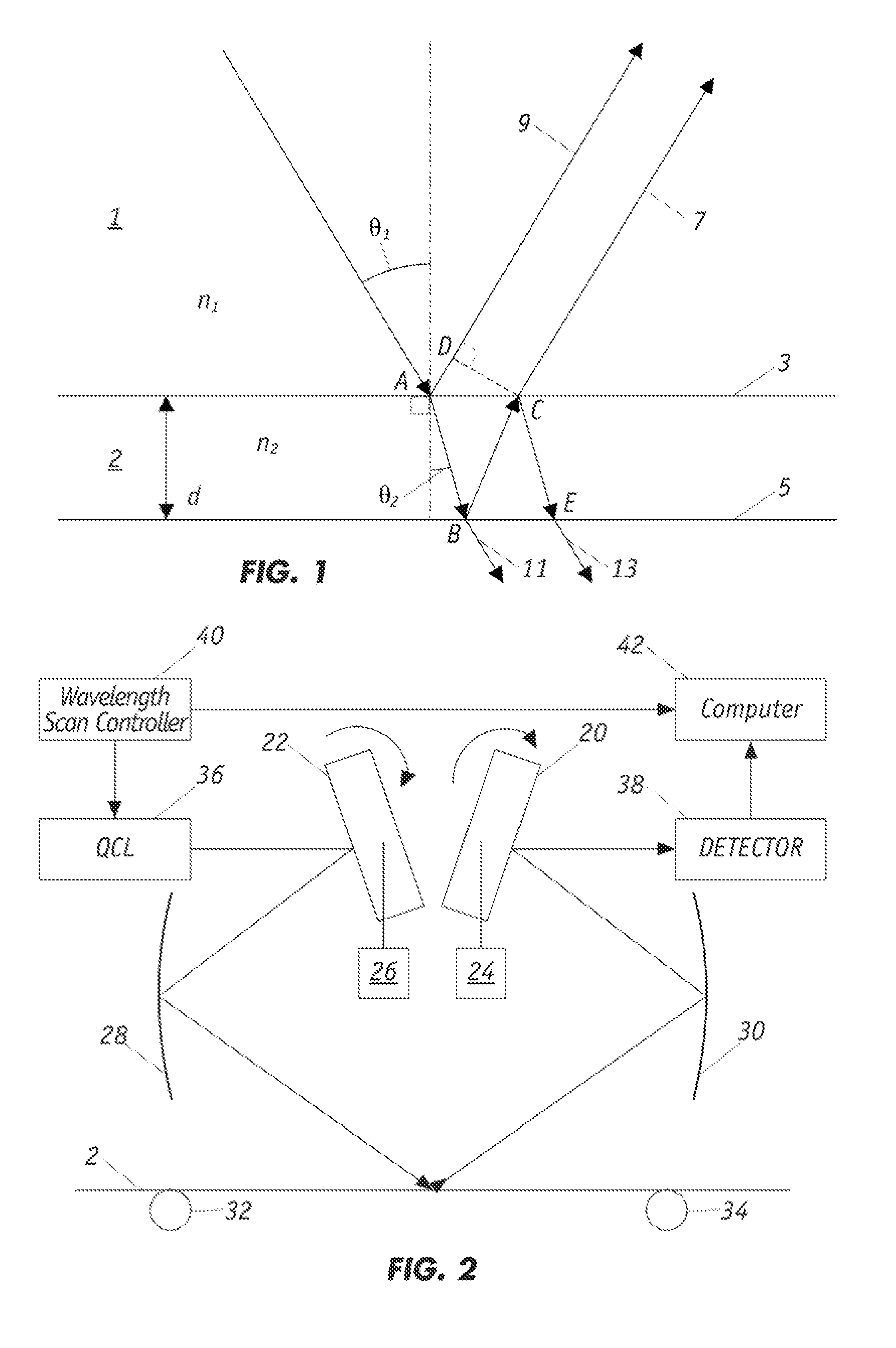

[0023]The present invention relates to non-contact sensor devices for measuring the thickness of a film, web or sheet. While the sensor will be illustrated in calculating the caliper of paper, it is understood that the sensor cart measure thickness of a variety of flat materials including, for example, coated materials, plastics, fabrics, and the like. The sensor is particularly suited for thickness detection of porous polymers (plastic) made of polyethylene, polypropylene, polyethylene terephthalate, polytetrafluoroethylene or polyvinyl chloride.

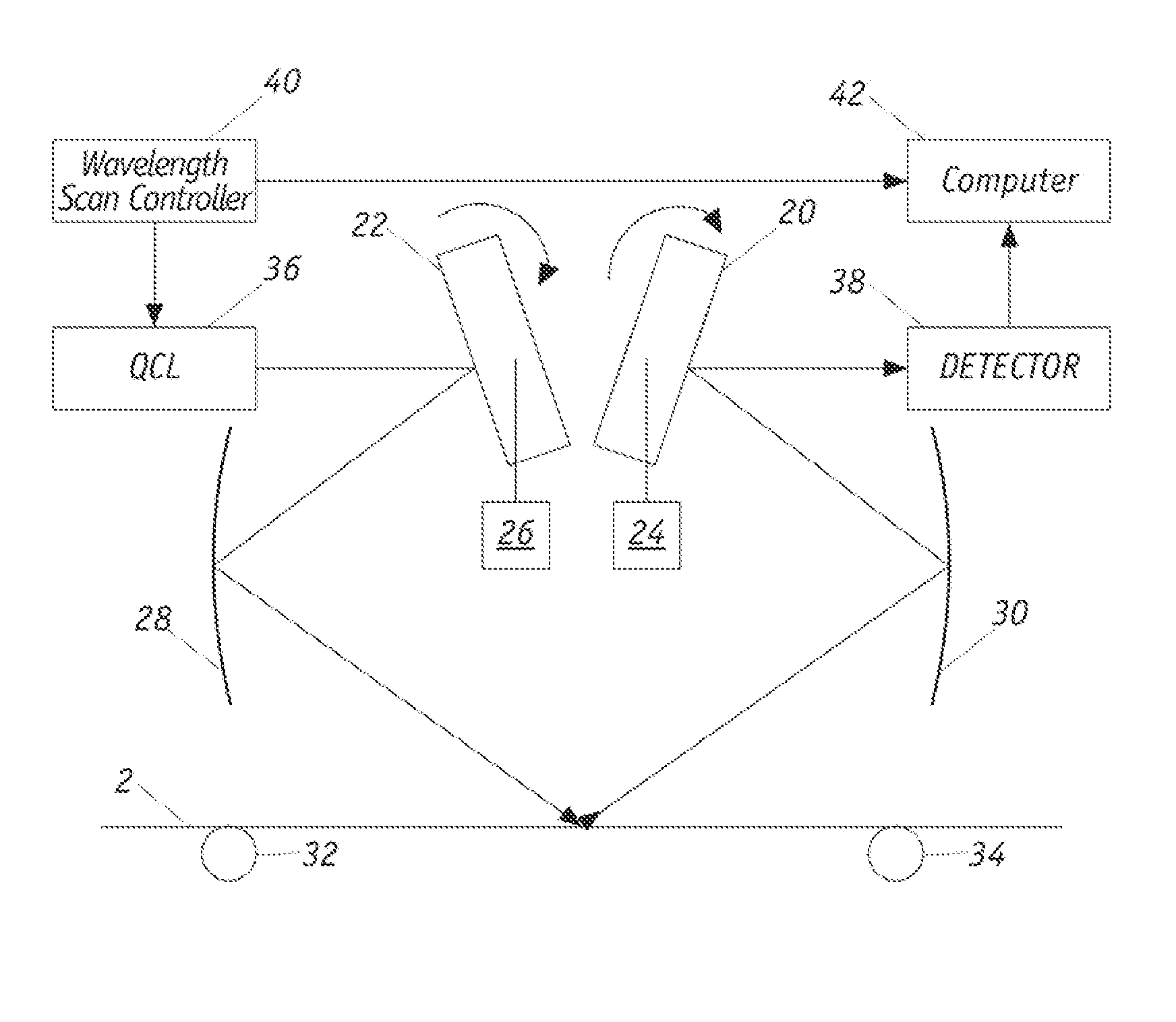

[0024]FIG. 1 illustrates the electromagnetic radiation beam geometry incident, reflected and refracted on a web product 2 of thickness d and having upper and lower sides or planes, plane 3 and plane 5, from which the incident electromagnetic radiation of vacuum wavelength λ0 is reflected (7, 9). In addition, the portion of the incident electromagnetic radiation propagating into the web is refracted since the index of refraction is different...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com