Improved film thickness measurement

A film thickness and thin film technology, applied in the direction of measuring devices, instruments, caliper sensors, etc., can solve time-consuming problems and achieve the effect of improving the measurement speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

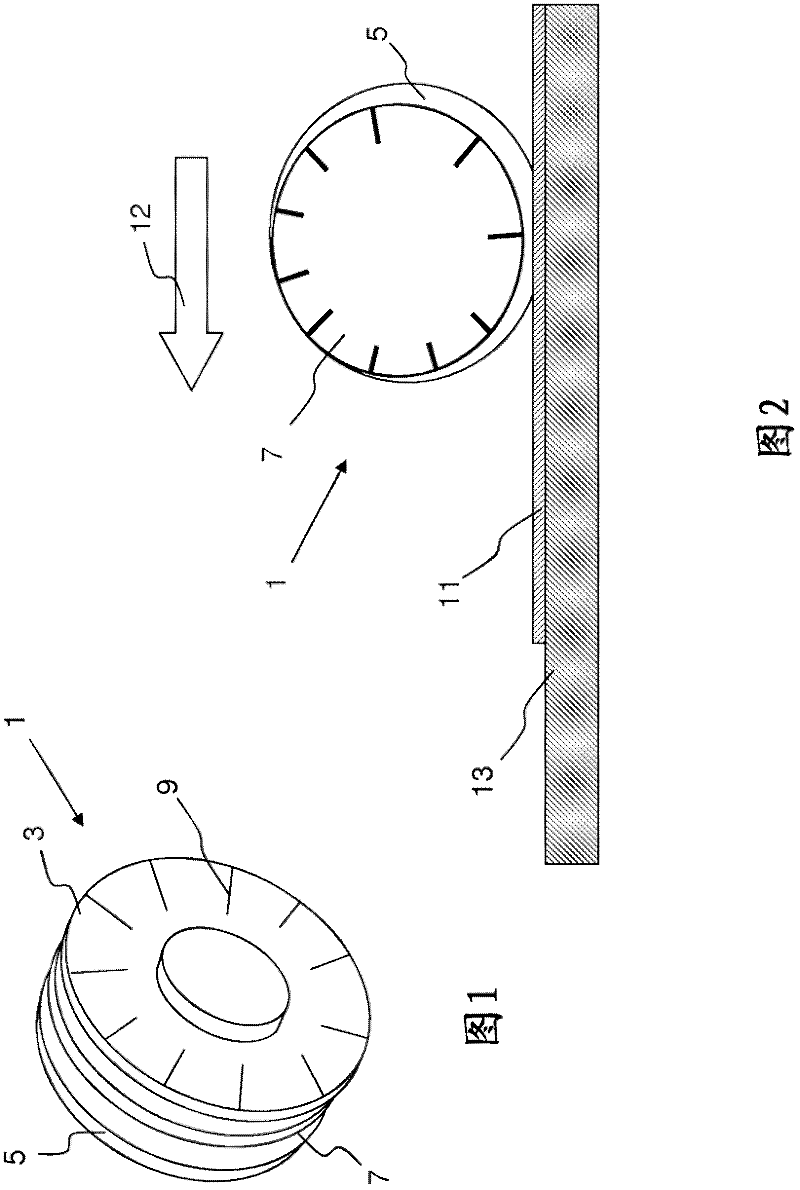

[0047] figure 1 A perspective view of a wheel for measuring wet ink thickness on a flat glass substrate in a manner known to those skilled in the art is shown. The wheel 1 comprises three metal discs, two outer discs 3 , 5 and one inner disc 7 . The outer discs 3, 5 are concentric and have the same outer diameter. The inner discs are smaller than the outer discs 3, 5 and are arranged concentrically with respect to the outer discs. The outer diameter of the inner disc 7 coincides at one point with the outer diameters of the two outer discs. On the outer disc 3 there is a calibration scale 9 .

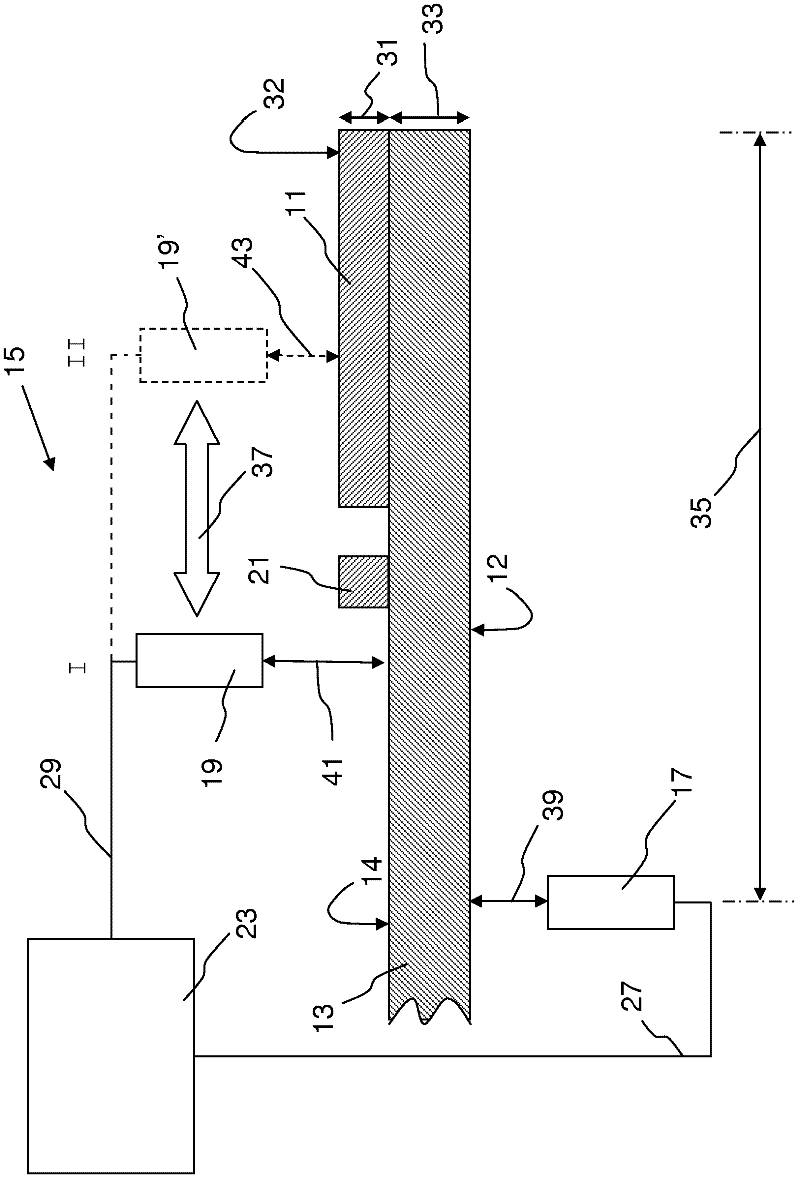

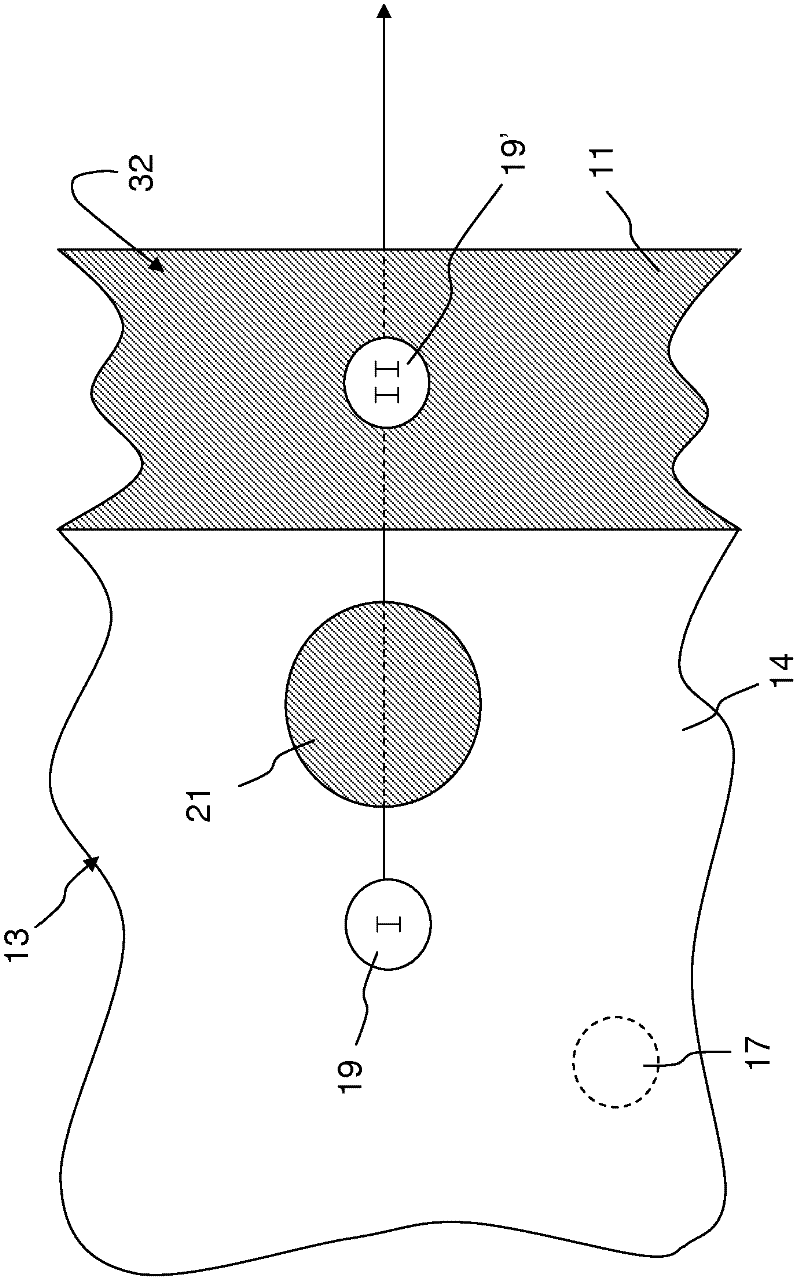

[0048] refer to figure 2 , the thickness of the wet ink film 11 on the flat glass plate 13 is determined using the wheel 2 in the following manner. First, the wheel is placed on the glass plate 13 so that the wheel 1 contacts the wet ink film 11 . The wheel then rolls in the direction of arrow 12 . As the wheel rolls past the wet ink film, the inner disc 7 will eventually contact...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com