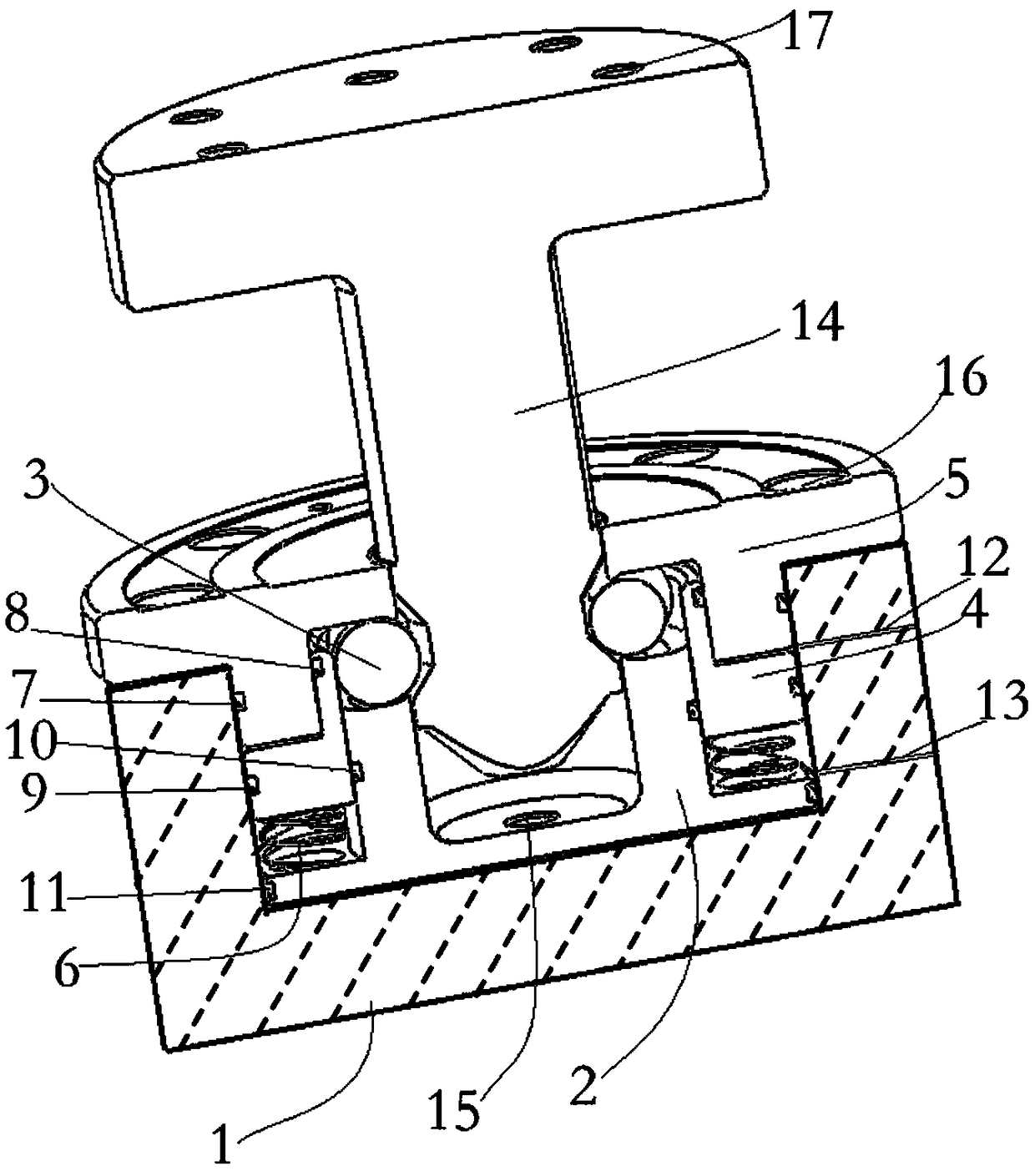

Quick clamping system

A fast, clamping technology, applied in the direction of clamping, positioning device, support, etc., can solve problems such as piston stuck clamping function, piston wear and loss, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The specific implementation manner of the present invention will be described in more detail below with reference to schematic diagrams. Advantages and features of the present invention will be apparent from the following description and claims. It should be noted that all the drawings are in a very simplified form and use imprecise scales, and are only used to facilitate and clearly assist the purpose of illustrating the embodiments of the present invention.

[0022] After the inventor studied the existing pneumatic tooling fixtures, he found that:

[0023] (1) Most of the current pneumatic fixtures adopt mechanical locking methods, such as general piston gravity locking or spring mechanical locking. The locking process does not require or only needs short-term pneumatic pressure, mainly relying on the force of the piston. The gravity and the thrust of the compression spring work together to squeeze and push the steel ball and then lock it. During the locking process,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com