Patents

Literature

658 results about "Shadow effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

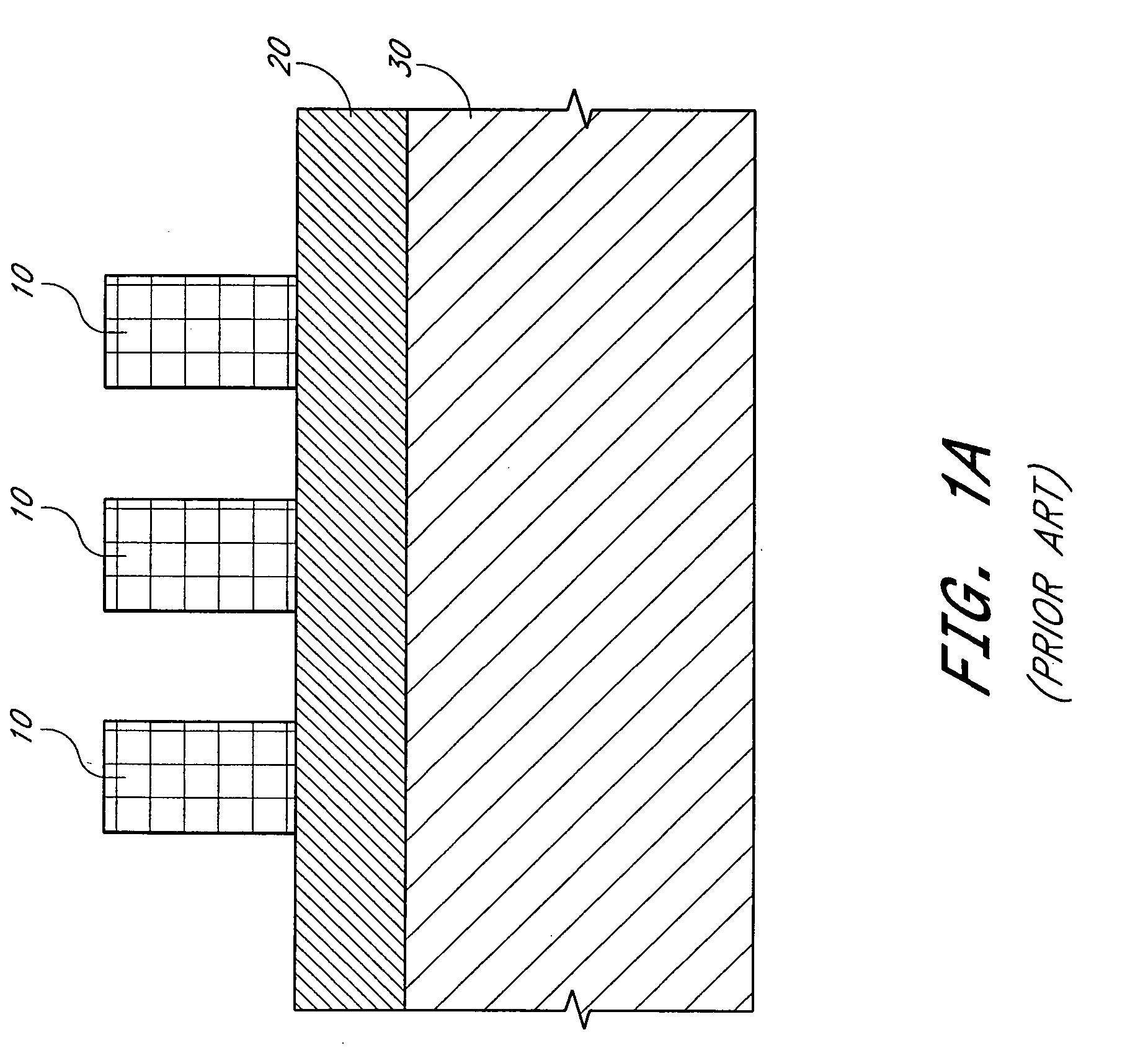

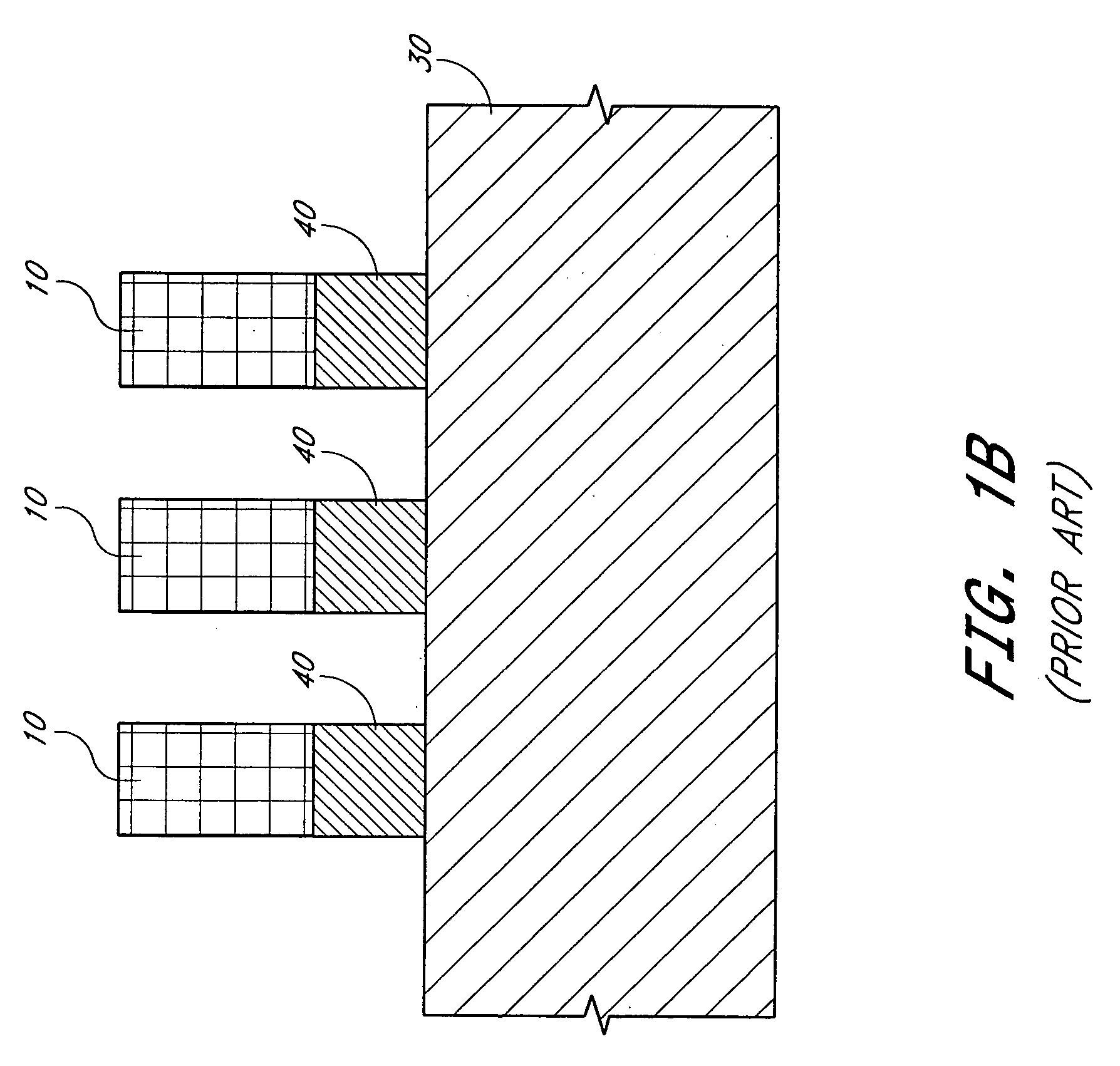

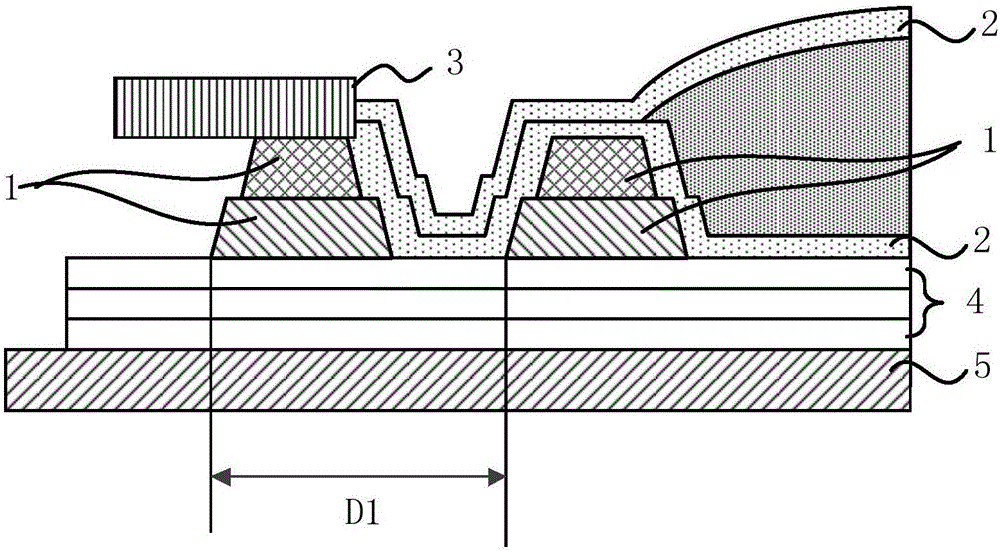

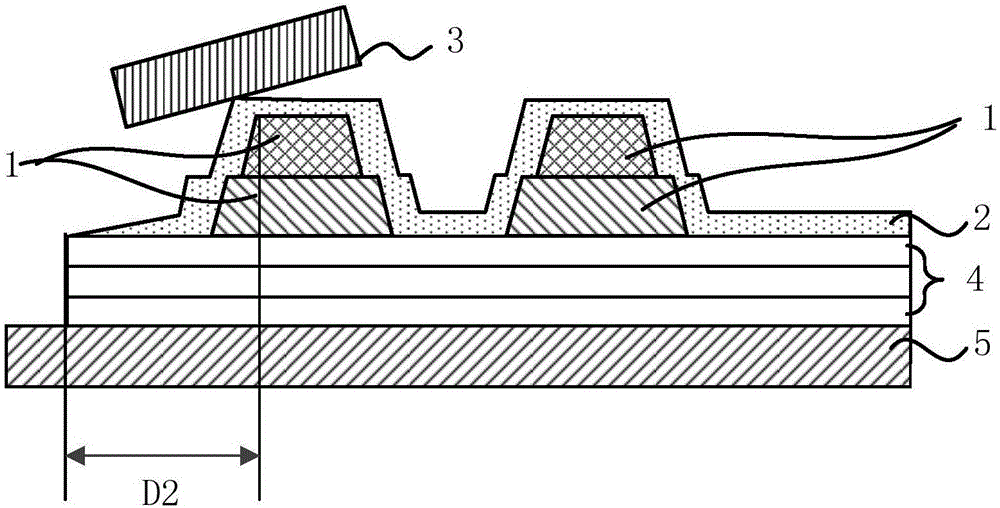

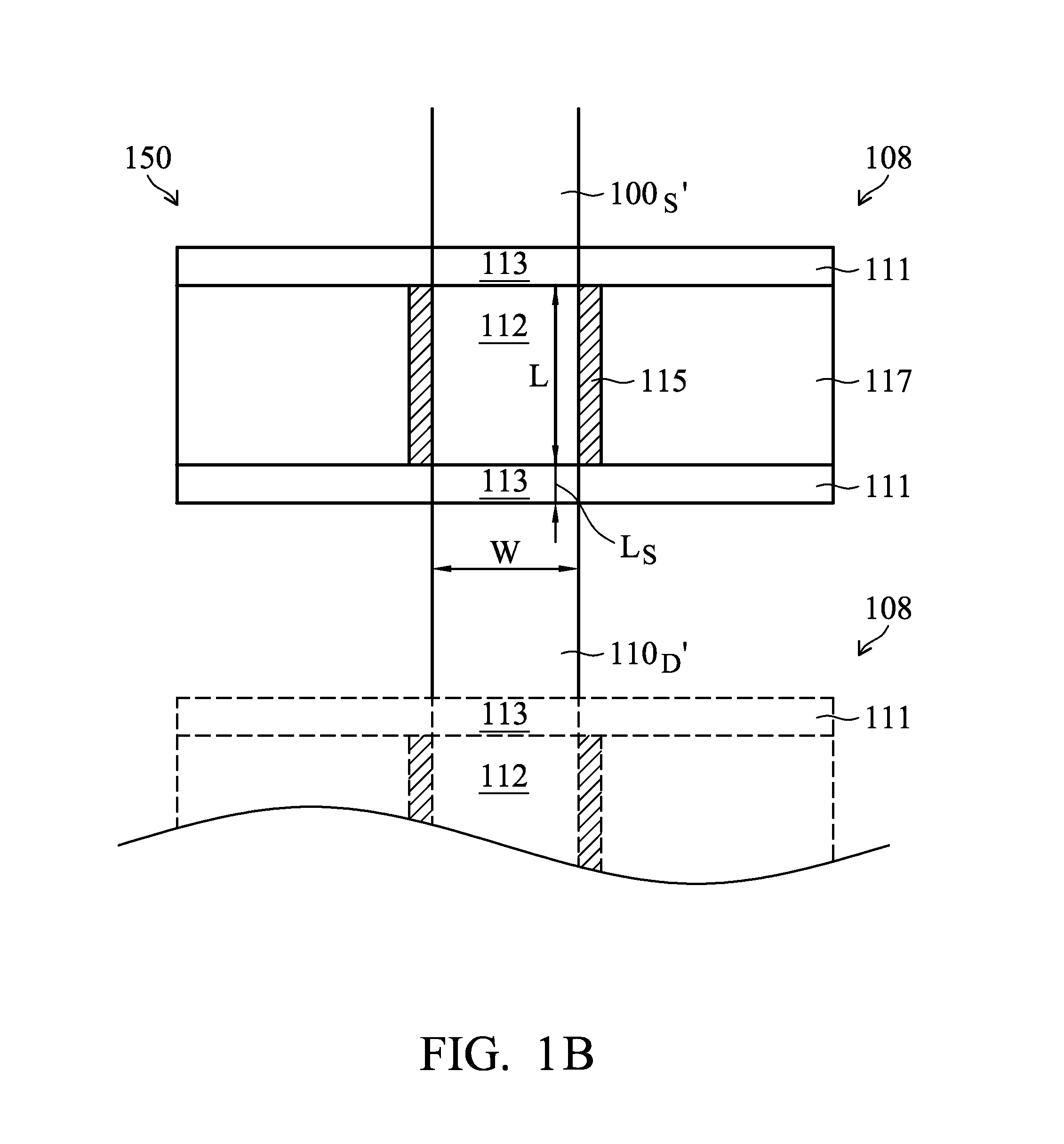

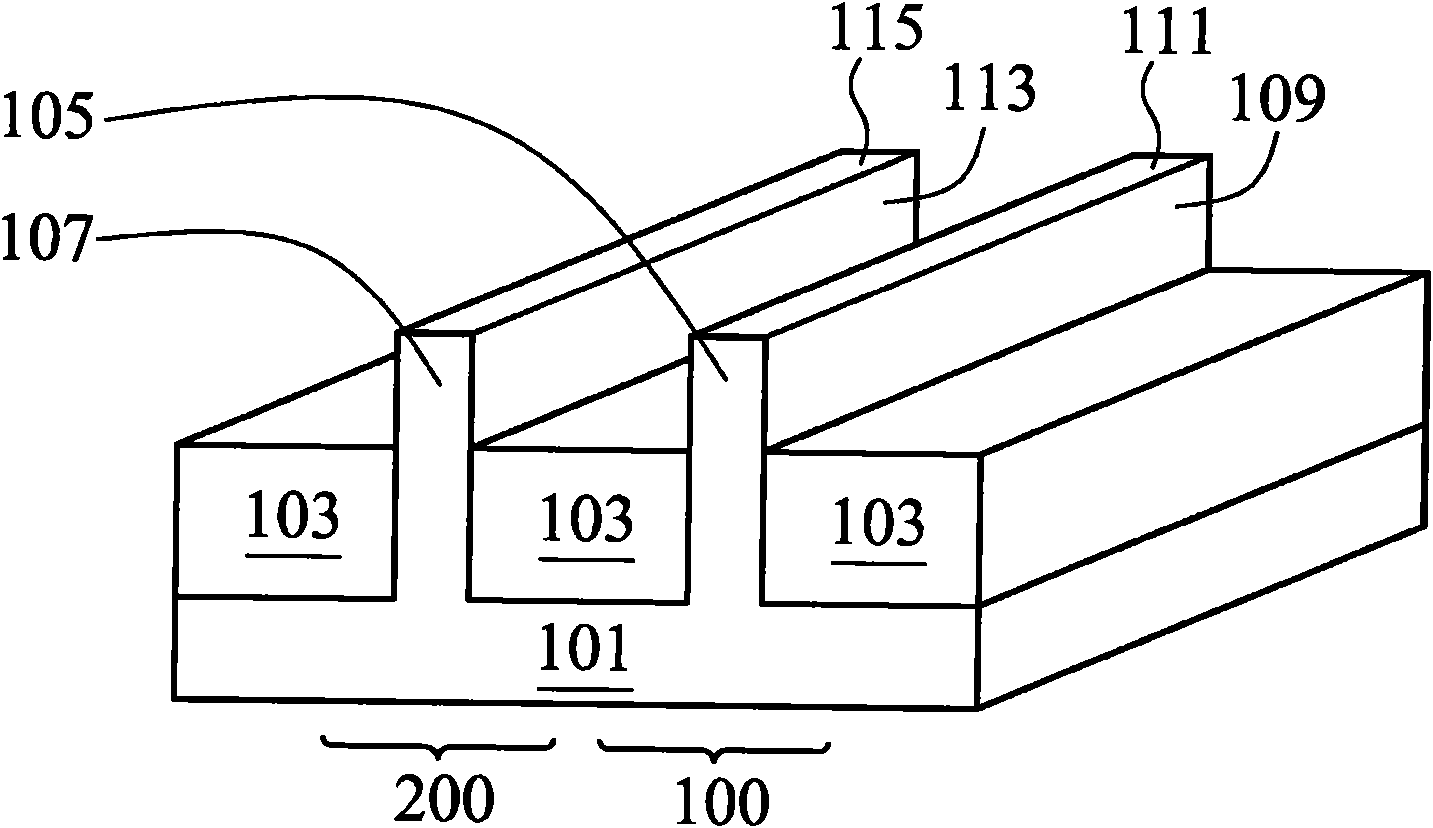

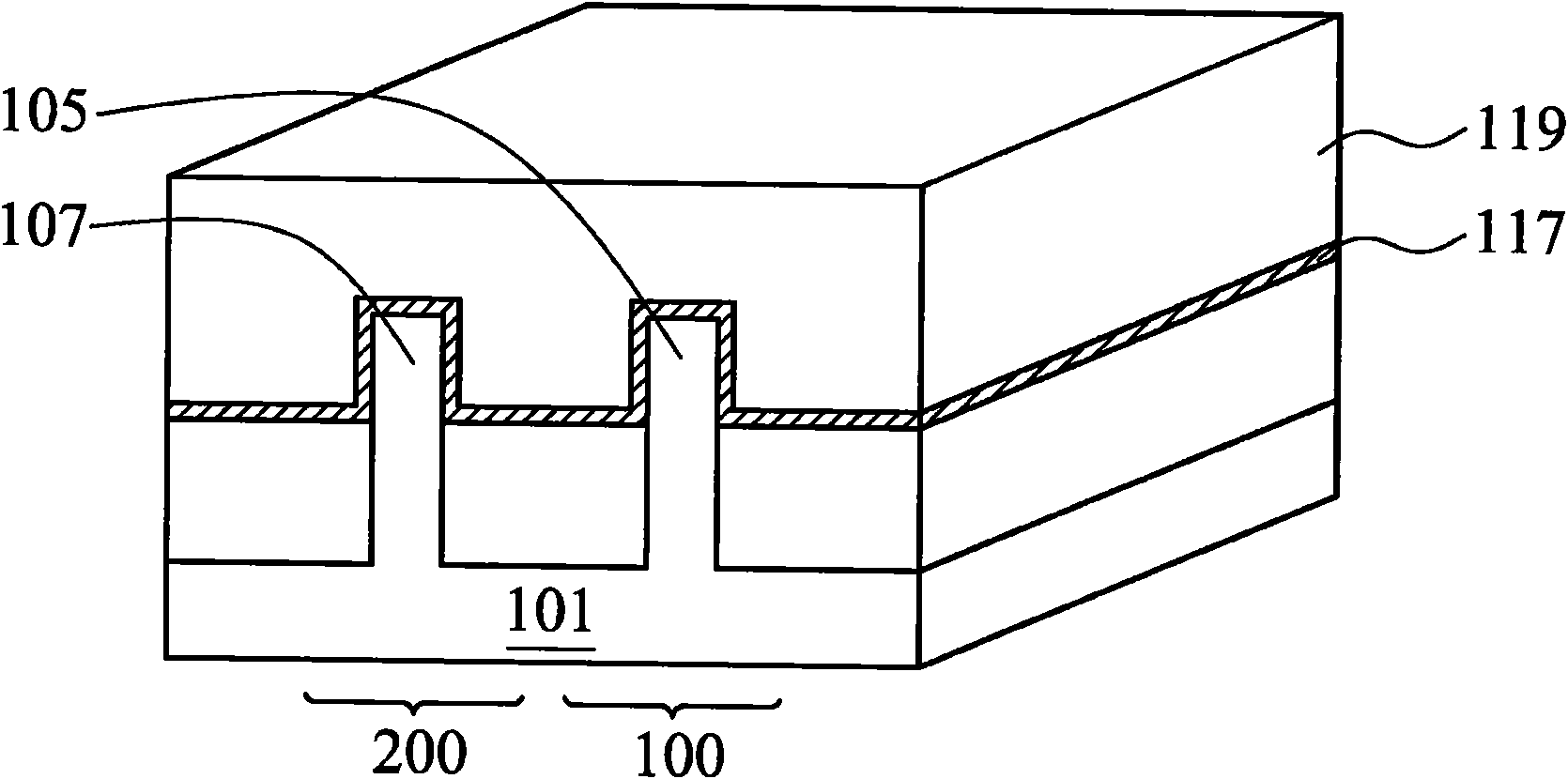

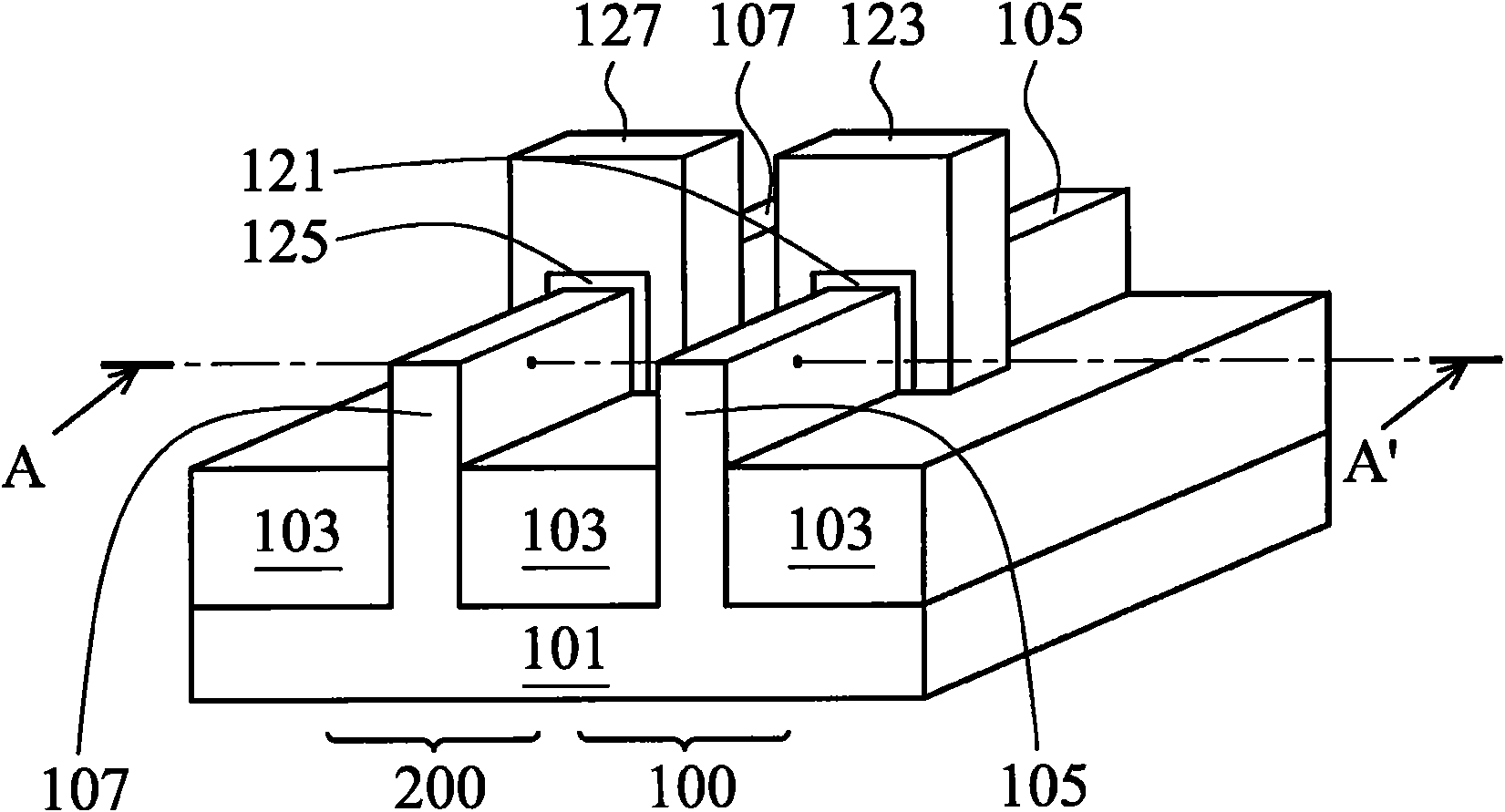

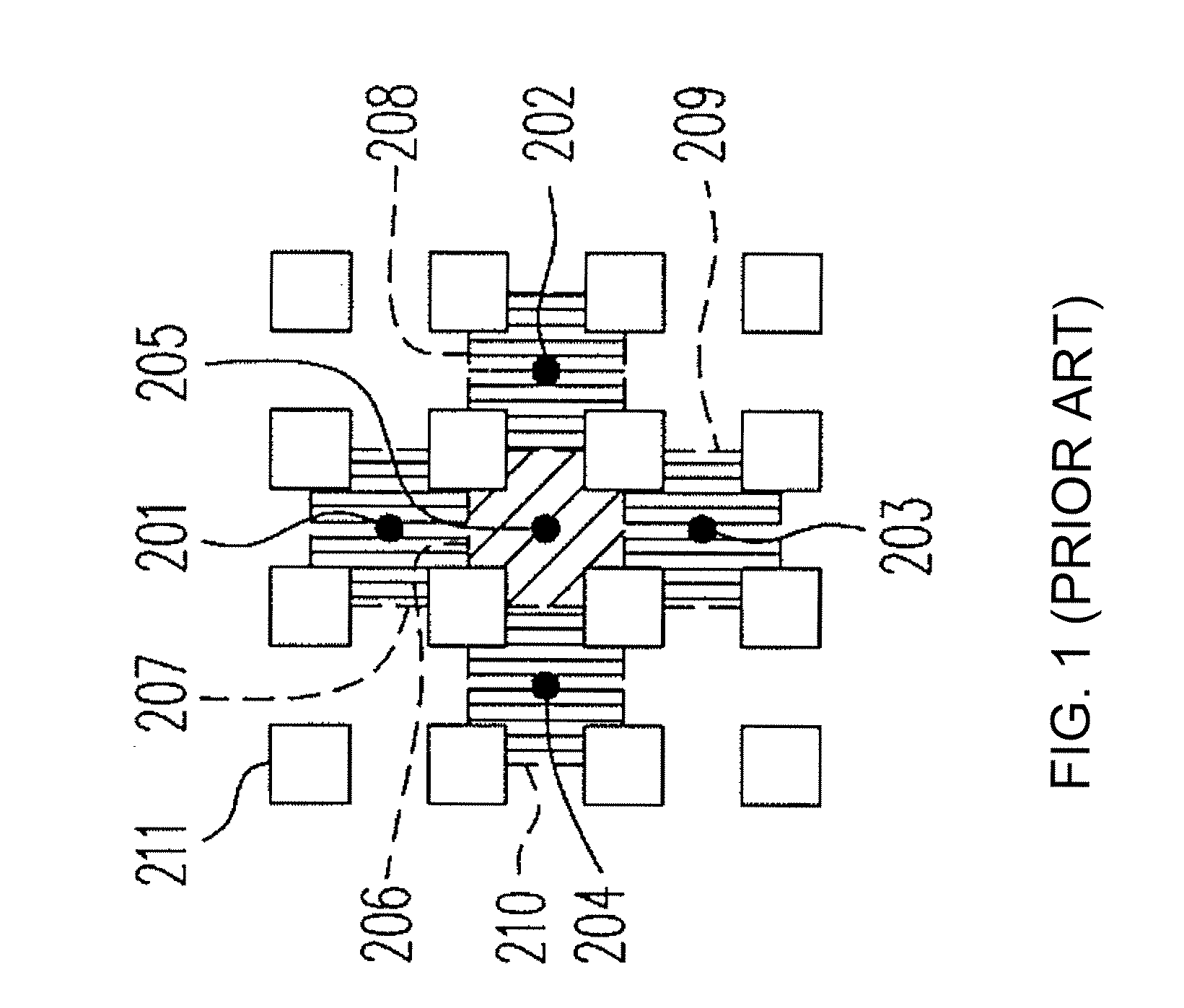

Method to align mask patterns

Alignment tolerances between narrow mask lines, for forming interconnects in the array region of an integrated circuit, and wider mask lines, for forming interconnects in the periphery of the integrated circuit, are increased. The narrow mask lines are formed by pitch multiplication and the wider mask lines are formed by photolithography. The wider mask lines and are aligned so that one side of those lines is flush with or inset from a corresponding side of the narrow lines. Being wider, the opposite sides of the wider mask lines protrude beyond the corresponding opposite sides of the narrow mask lines. The wider mask lines are formed in negative photoresist having a height less than the height of the narrow mask lines. Advantageously, the narrow mask lines can prevent expansion of the mask lines in one direction, thus increasing alignment tolerances in that direction. In the other direction, use of photolithography and a shadowing effect caused by the relative heights of the photoresist and the narrow mask lines causes the wider mask lines to be formed with a rounded corner, thus increasing alignment tolerances in that direction by increasing the distance to a neighboring narrow mask line.

Owner:MICRON TECH INC

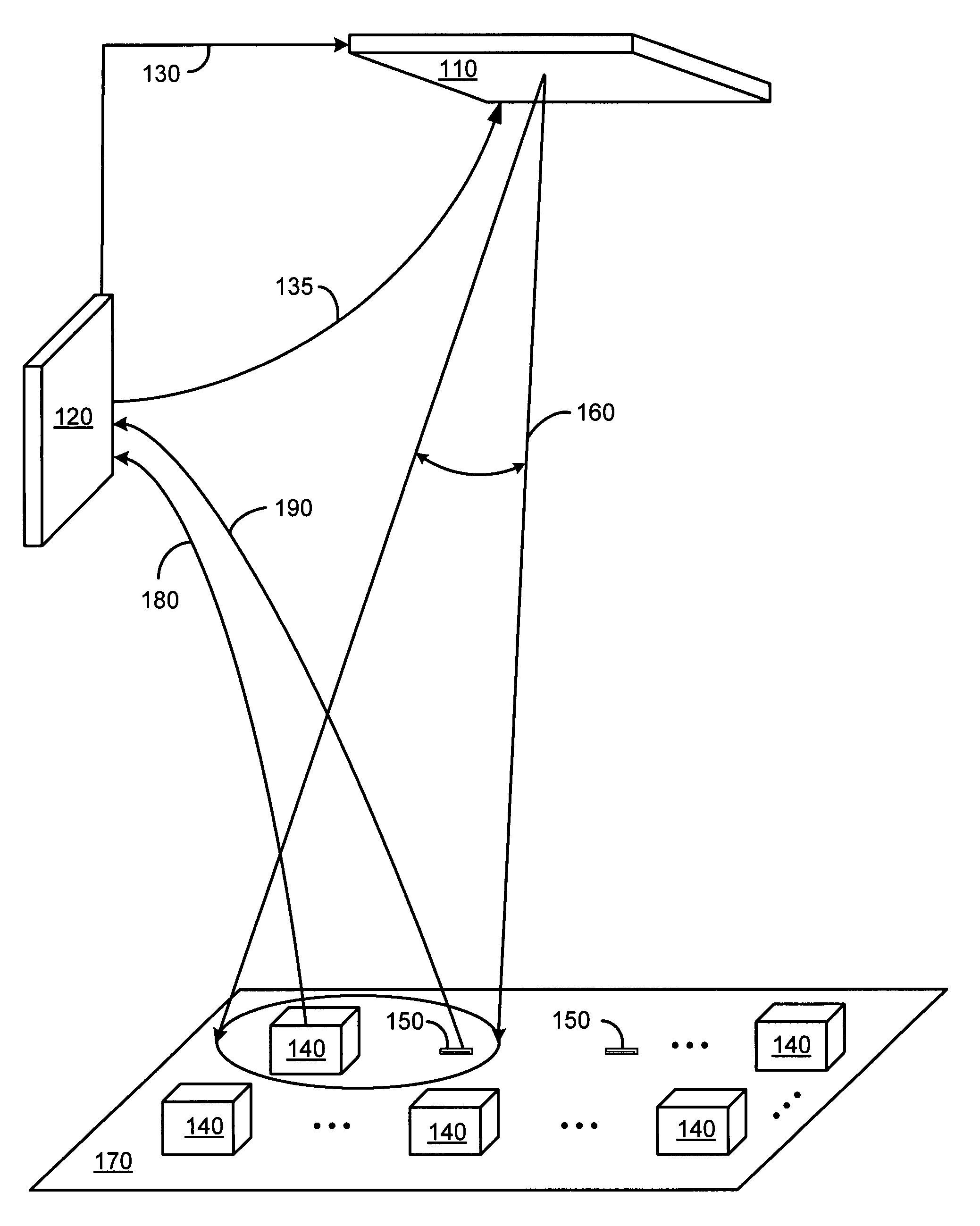

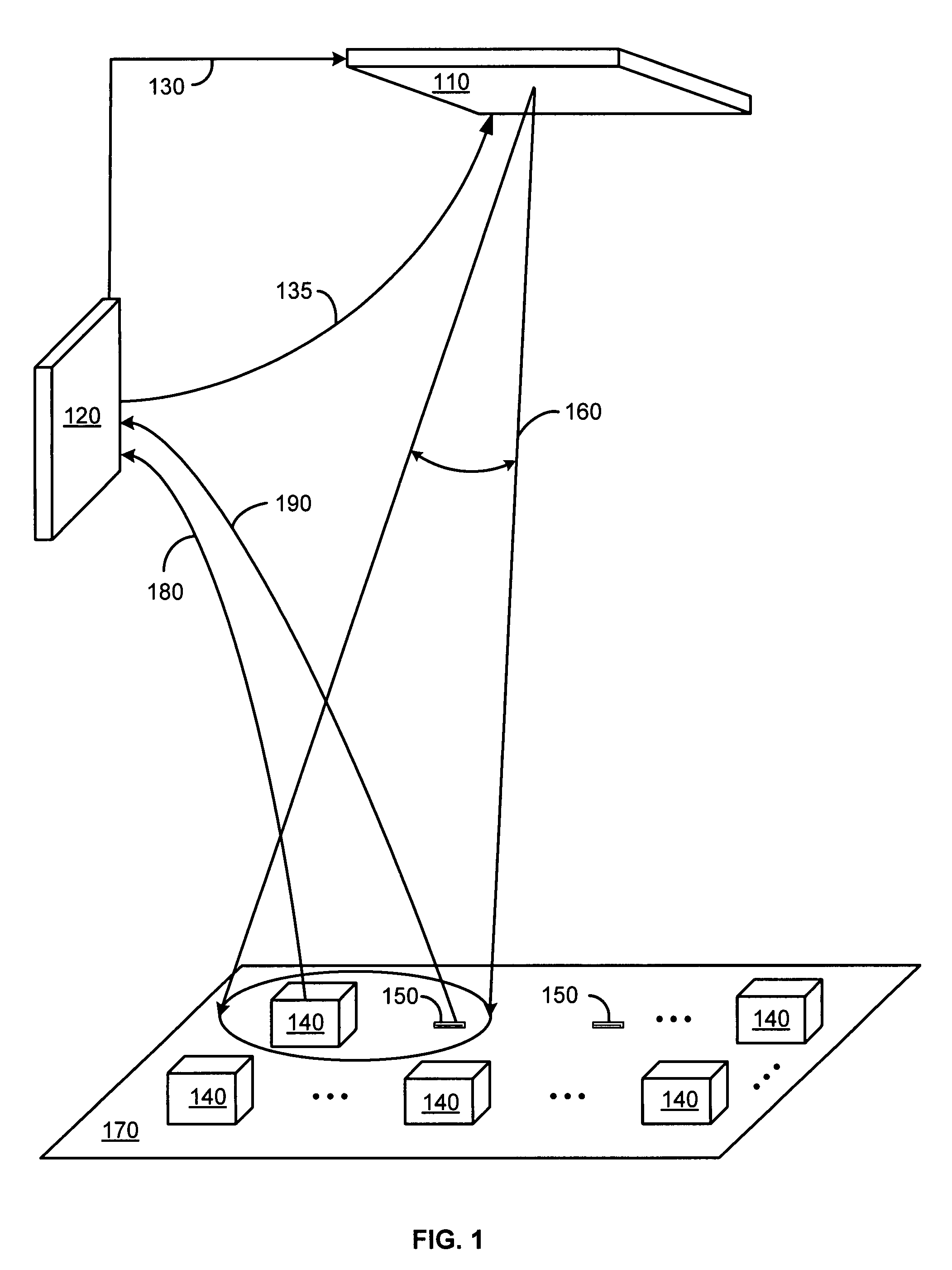

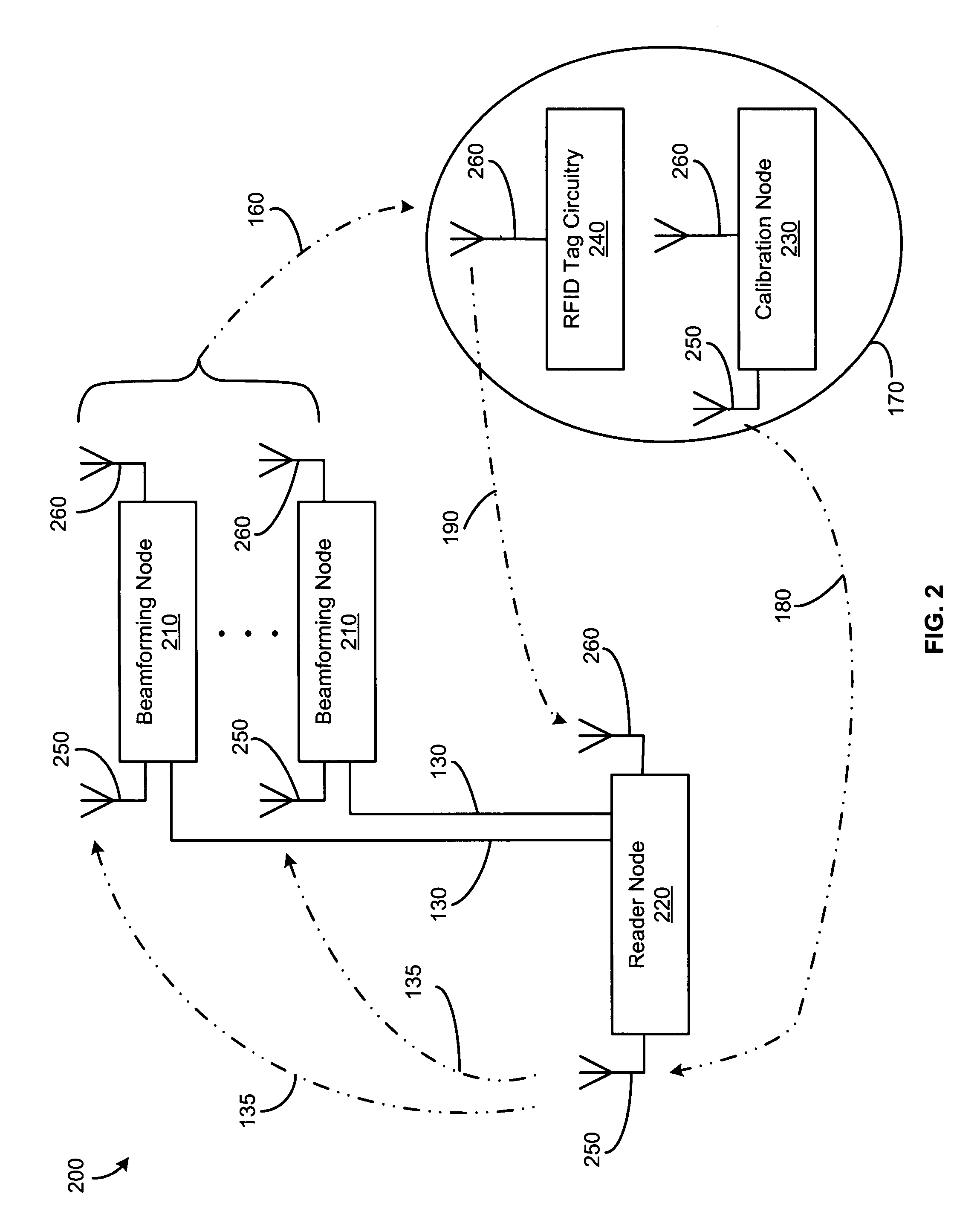

Systems and methods of beamforming in radio frequency identification applications

InactiveUS7652577B1Increased read rangeImprove reliabilitySensing record carriersBurglar alarm by hand-portable articles removalDistributed structureEngineering

Systems and methods for beamforming in radio frequency identification (RFID) applications are disclosed. A beamforming system uses a distributed architecture and techniques for antenna beamforming using a feedback control loop to direct radio frequency (RF) energy onto a specific region, referred to as an interrogation zone, which includes a calibration node where one or more RFID tags may be located. The distributed architecture of the beamforming system is resistant to fading and shadowing effects, providing accurate RFID reader operation even in environments with multi-path reflections or environmental changes, such as people moving around or changes in the location of equipment.

Owner:WIRAMA CORP +1

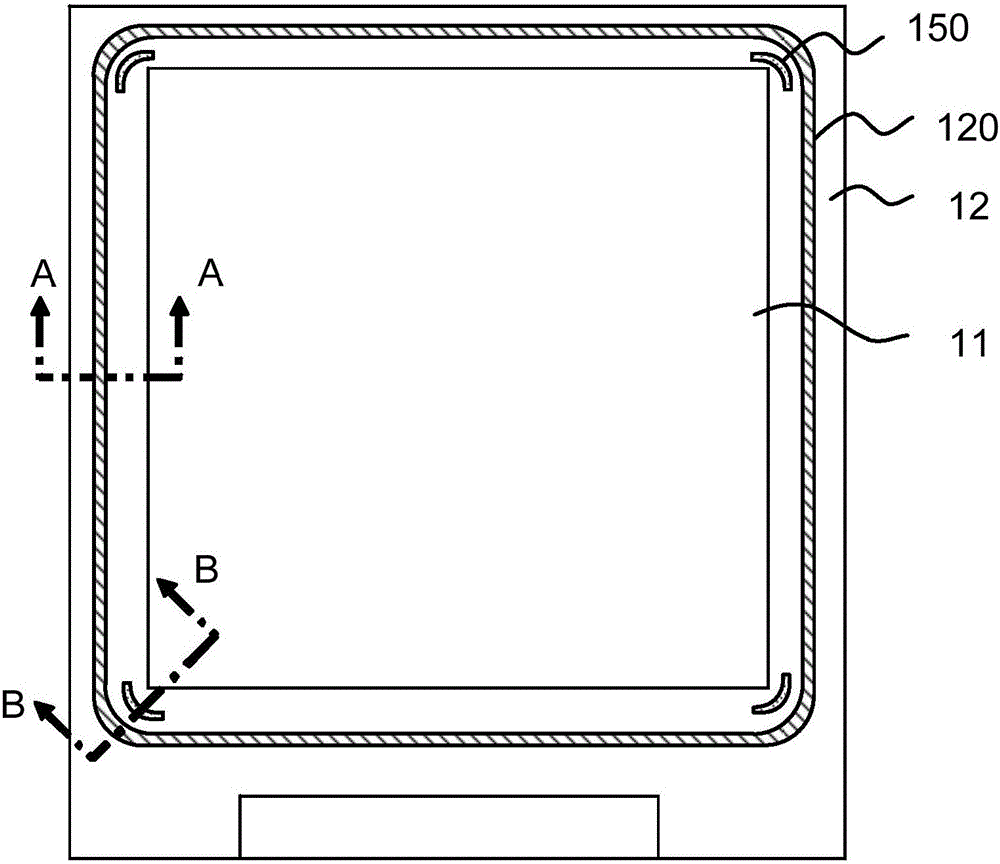

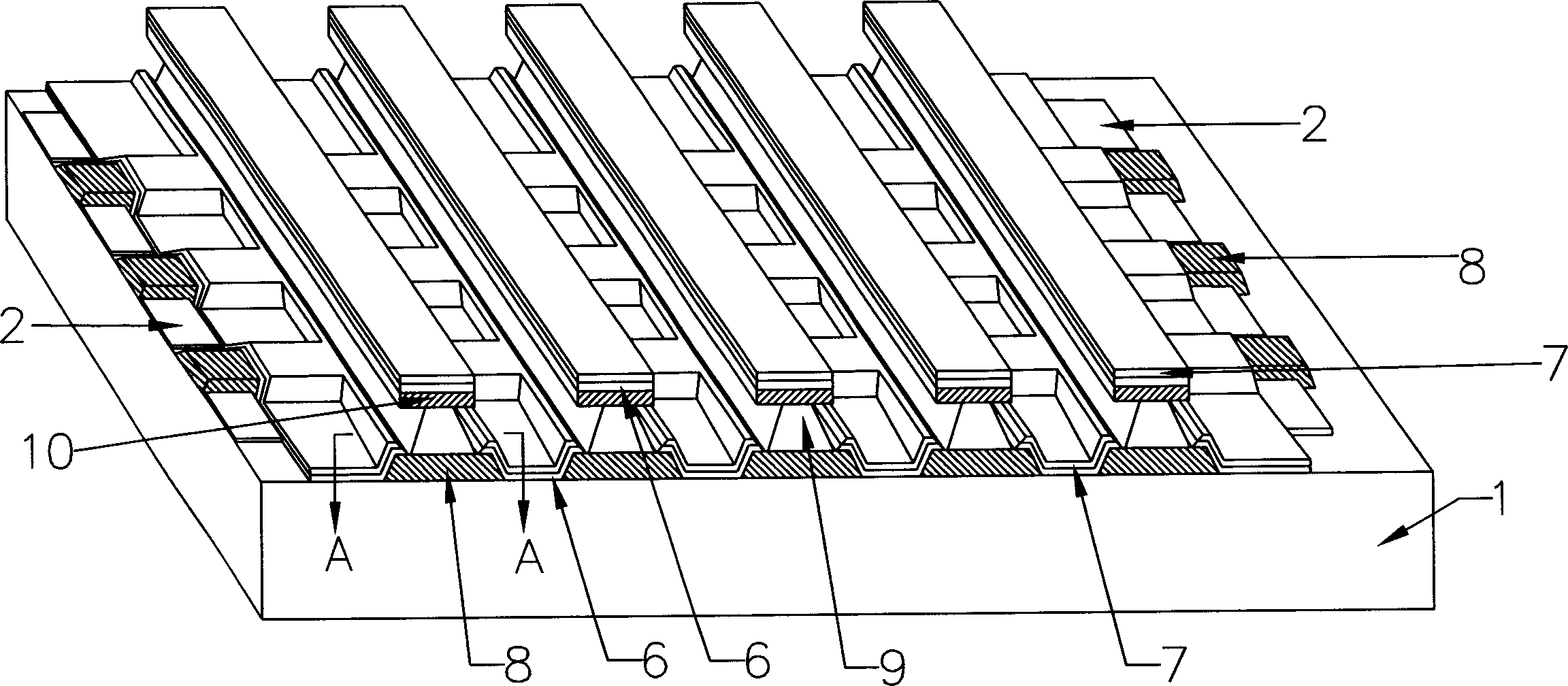

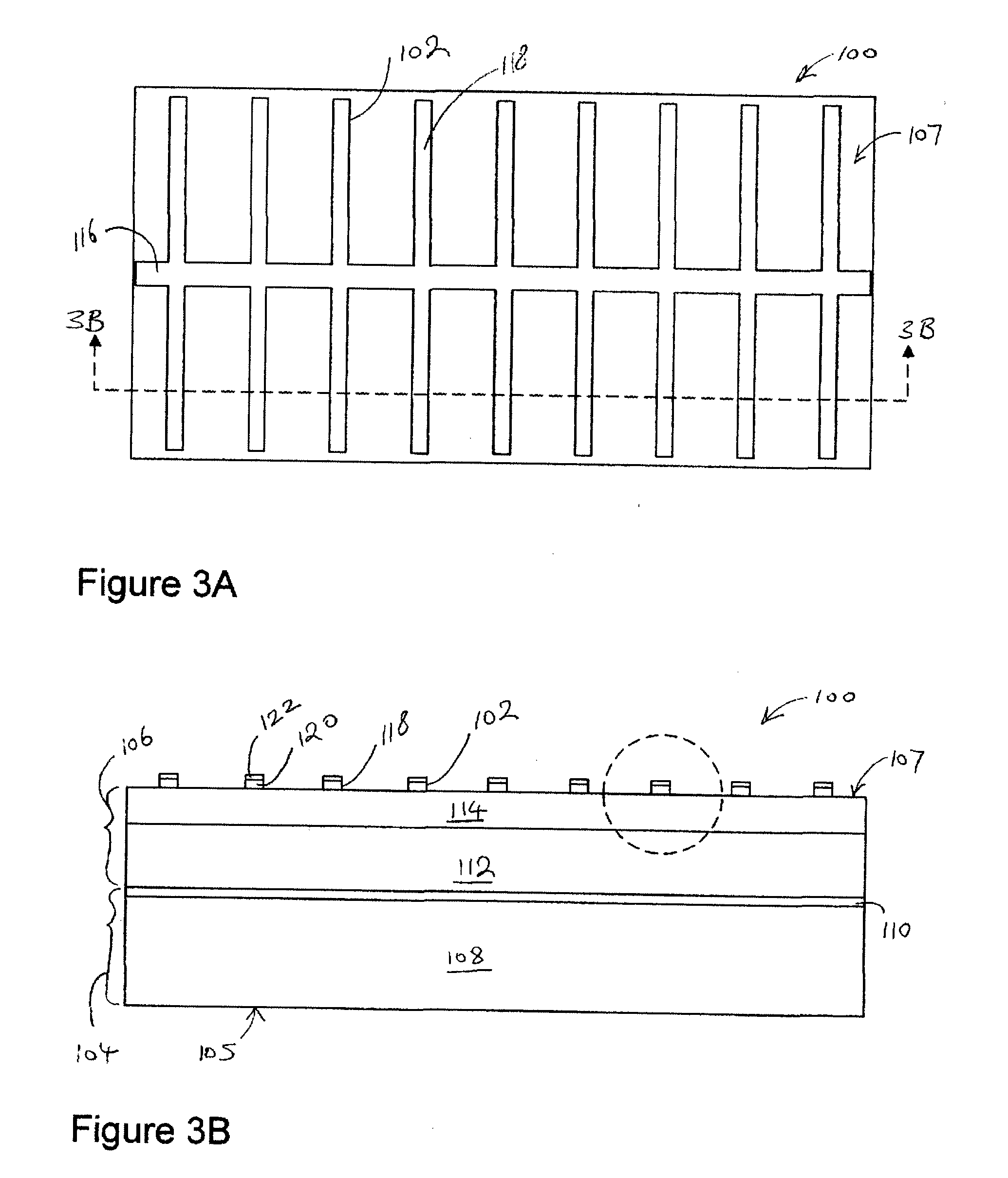

Organic light-emitting display panel and display apparatus

ActiveCN106601781AReduce border widthImprove the effect of blocking water vaporSolid-state devicesSemiconductor/solid-state device manufacturingEngineeringShadow effect

The invention discloses an organic light-emitting display panel and a display apparatus. The organic light-emitting display panel comprises a display area and a non-display area, wherein the display area comprises a substrate, a driving circuit layer and an light-emitting device layer disposed on the driving circuit layer; and the non-display area comprises a retaining wall arranged to encircle the display area, the retaining wall comprises at least one support layer, a barrier layer disposed on the support layer and multiple projections formed on the barrier layer, and the multiple projections are successively arranged along a direction away from the display area. The organic light-emitting display panel further comprises a packaging layer which covers the display area and the surfaces of a part of the projections. According to the invention, through designing the multiple projections at the top end of the retaining wall, the edge of the packaging layer can be sealed only by use of one retaining wall, the frame width of the display panel is reduced, the multiple projections generate deformation to make up for slits when being extruded by a mask, through the multiple projections, diffusion paths of reaction gas during deposition are also increased, diffusion can be ended in the multiple projections, and a shadow effect is eliminated.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

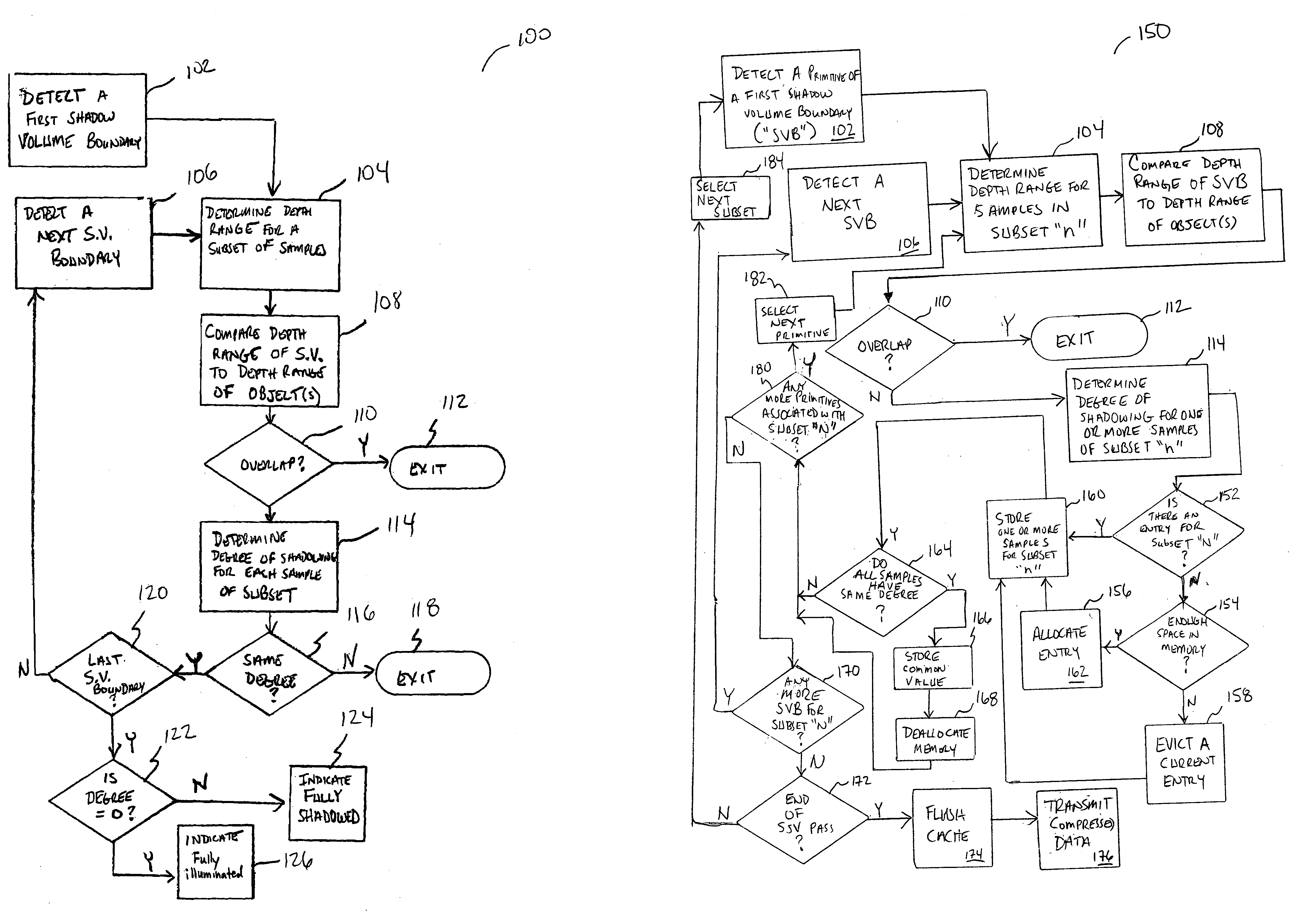

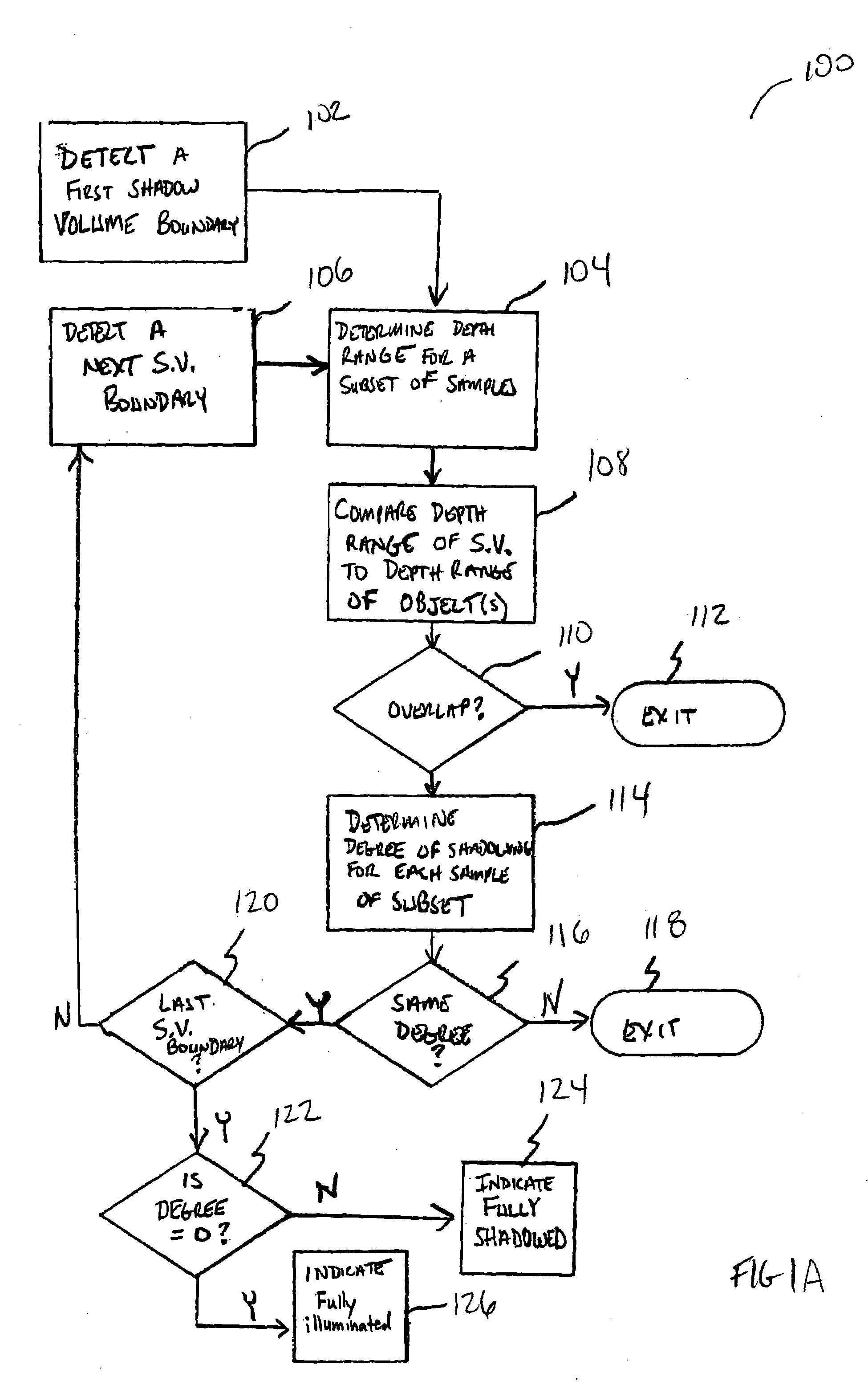

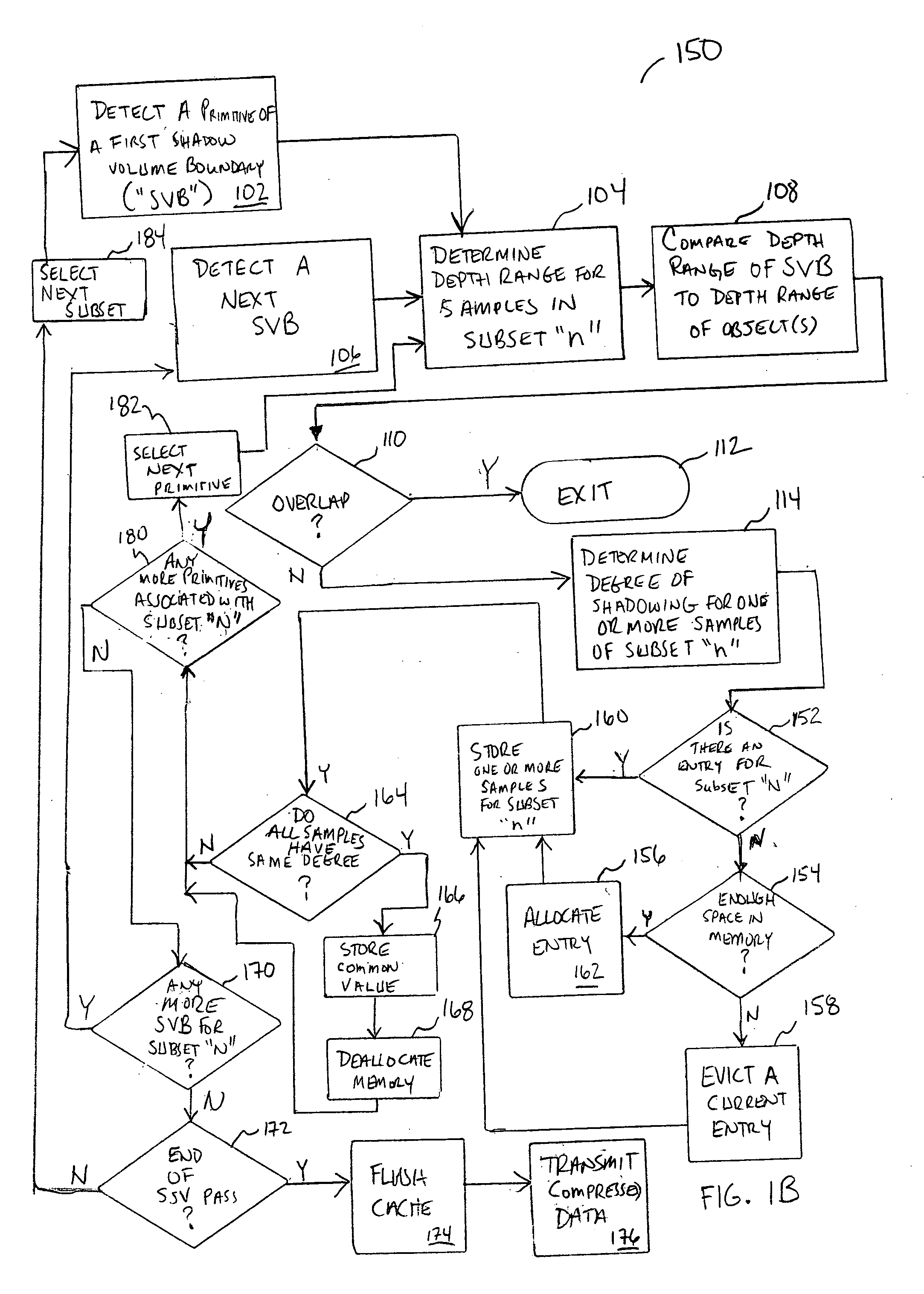

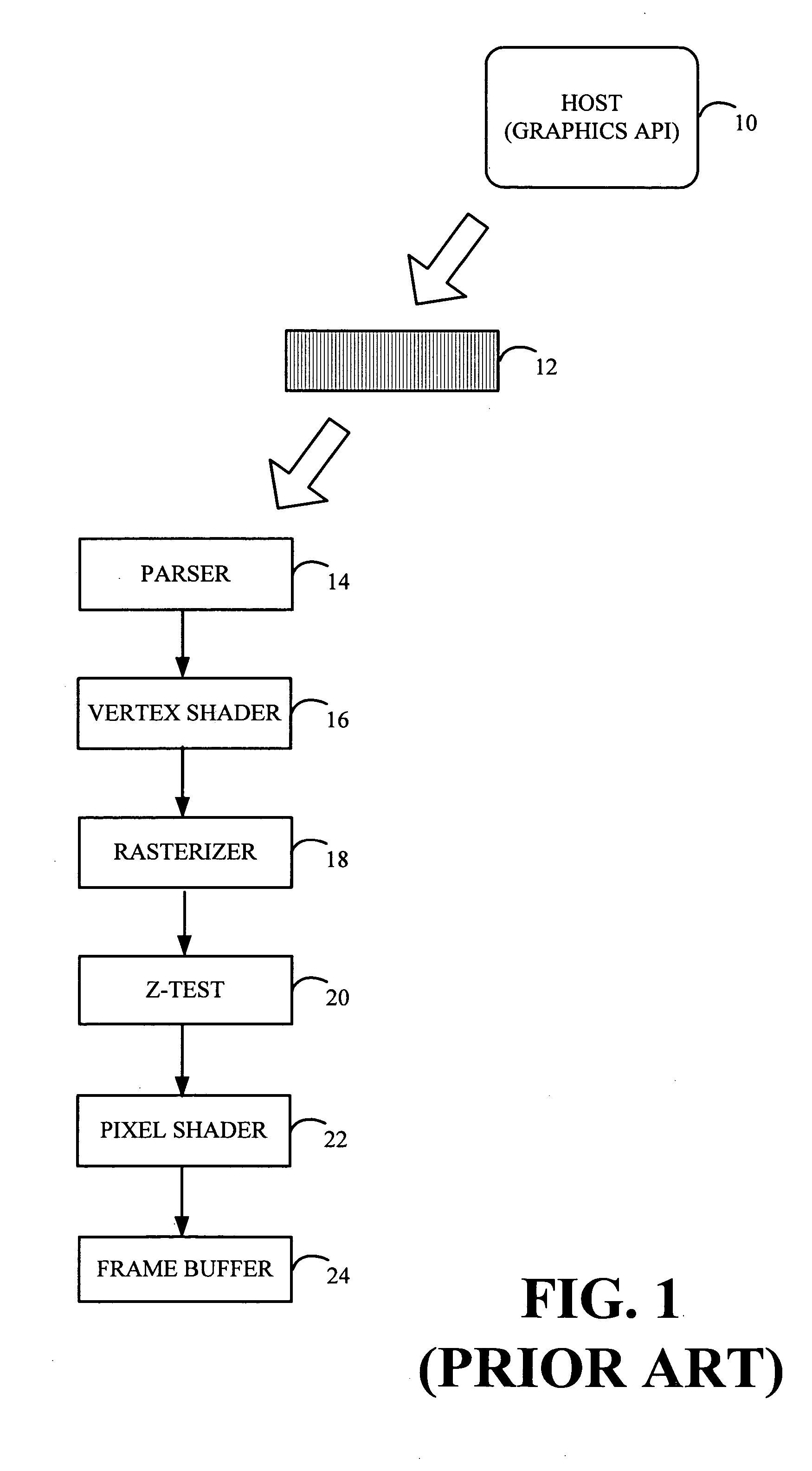

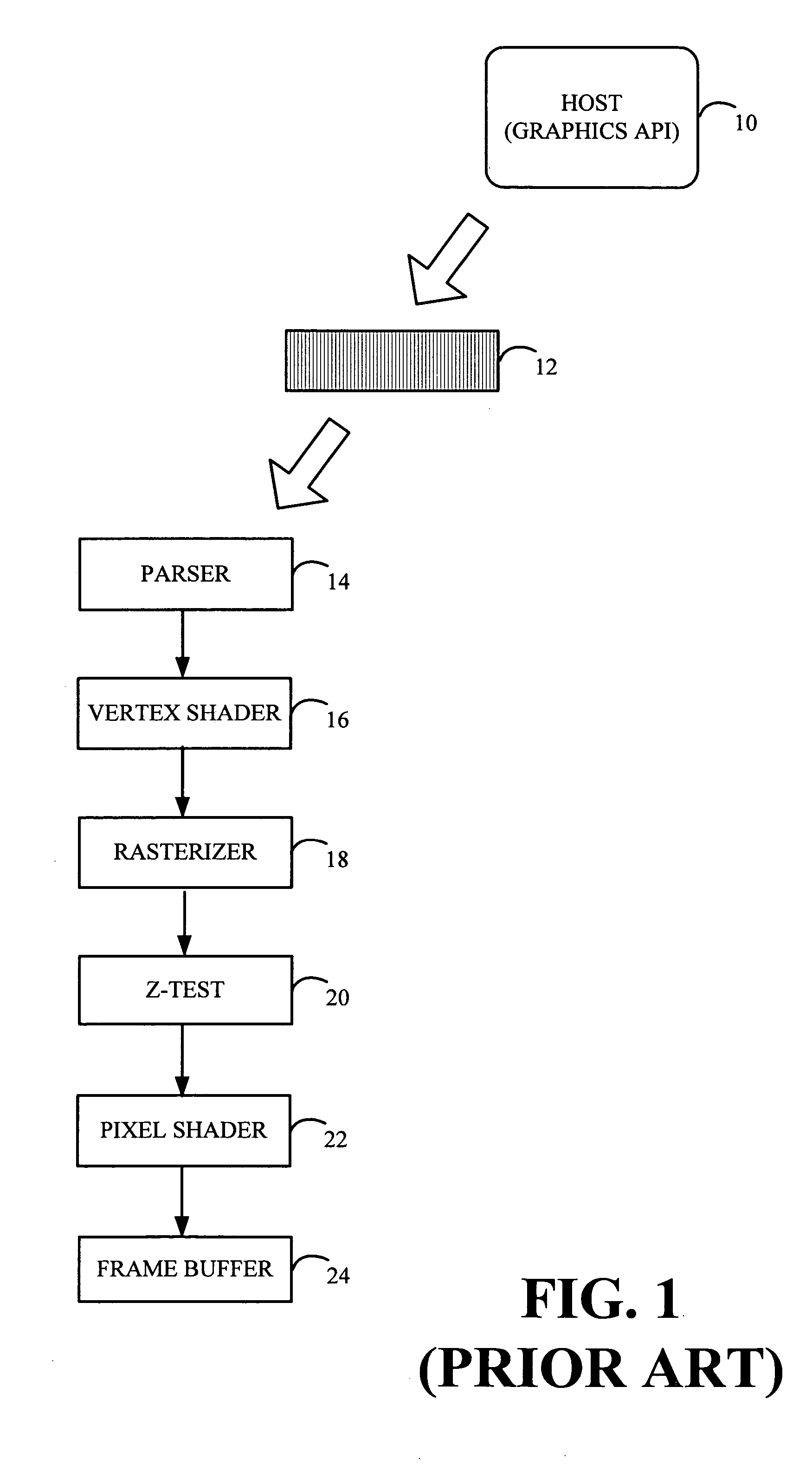

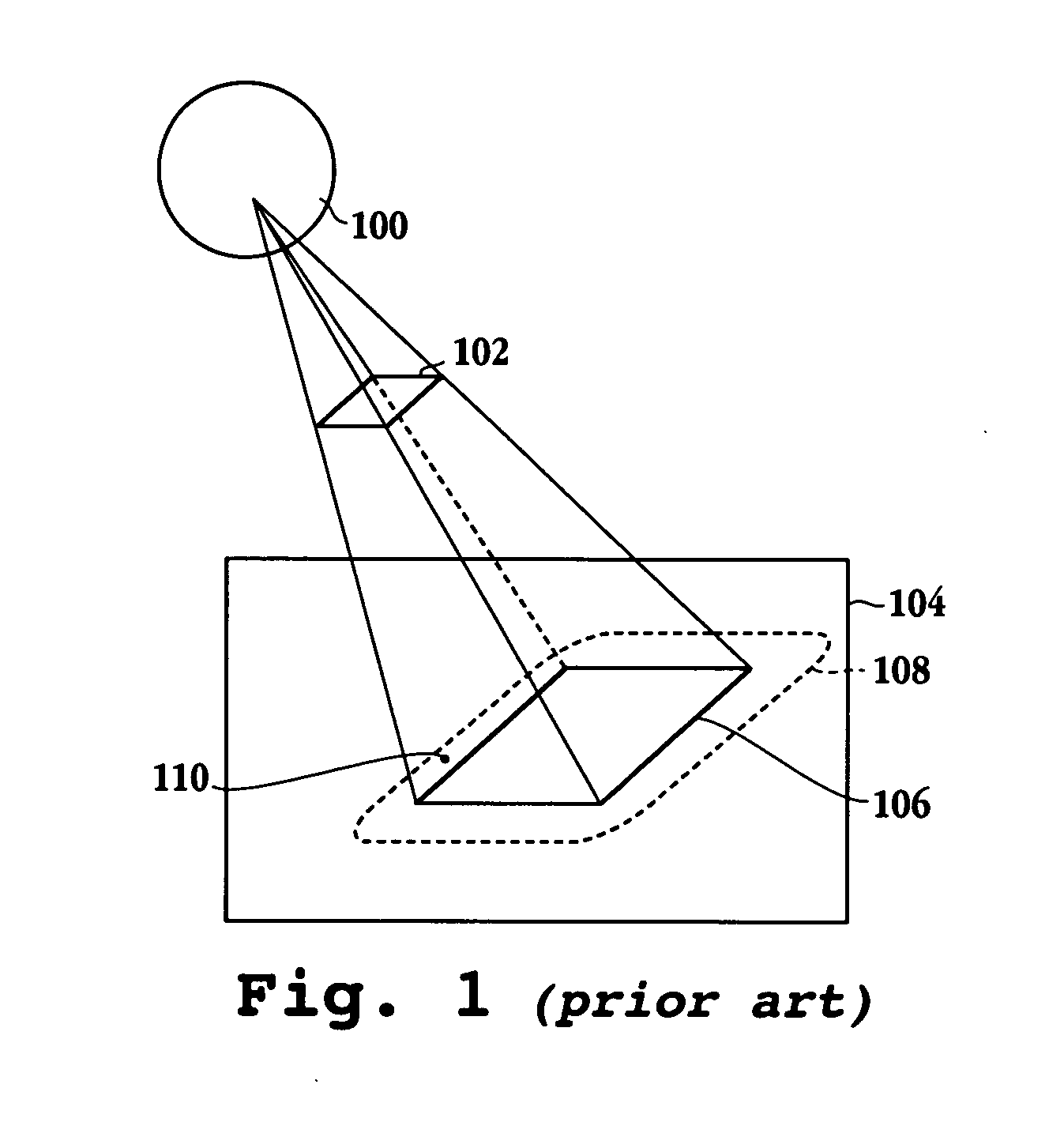

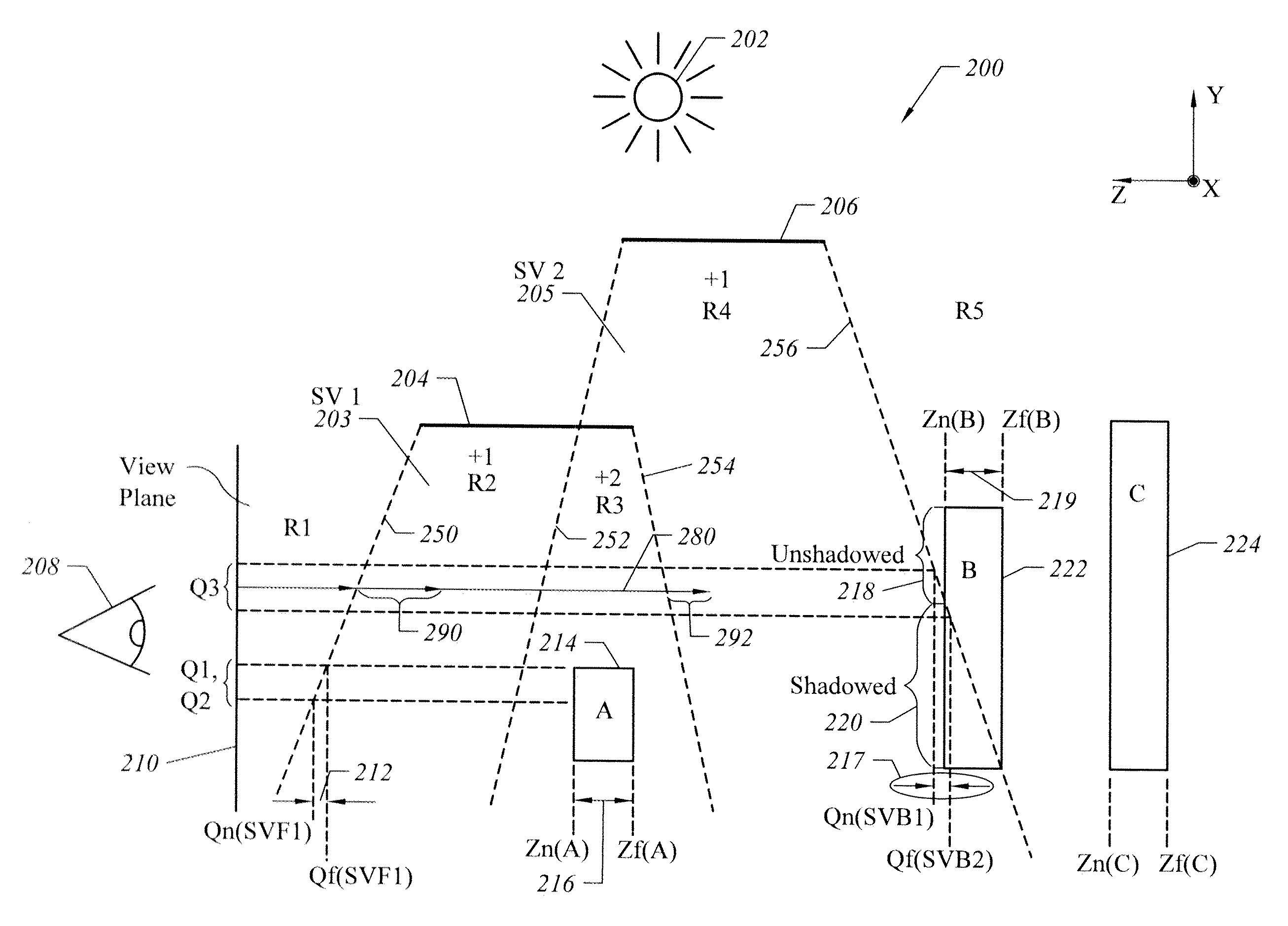

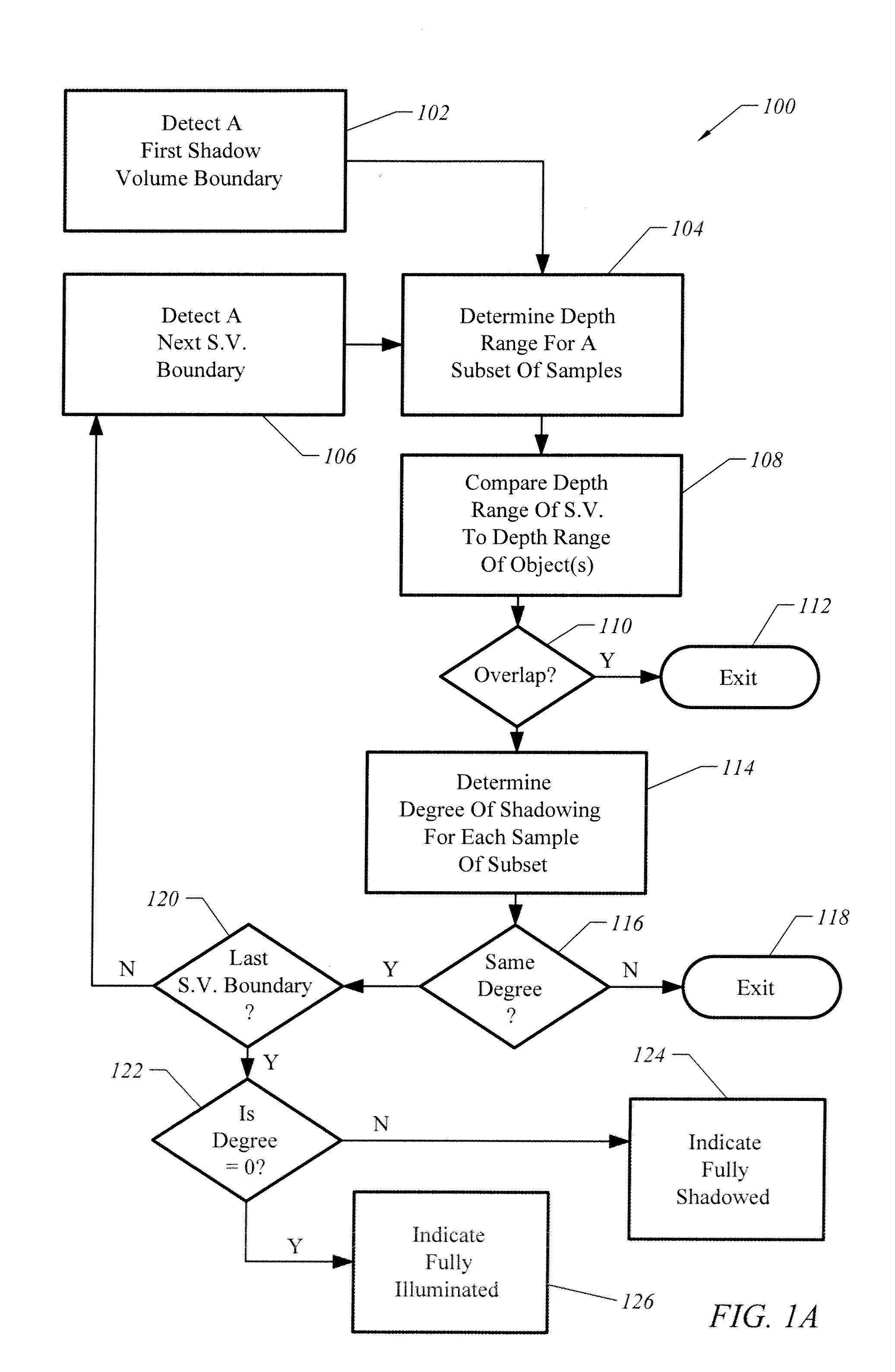

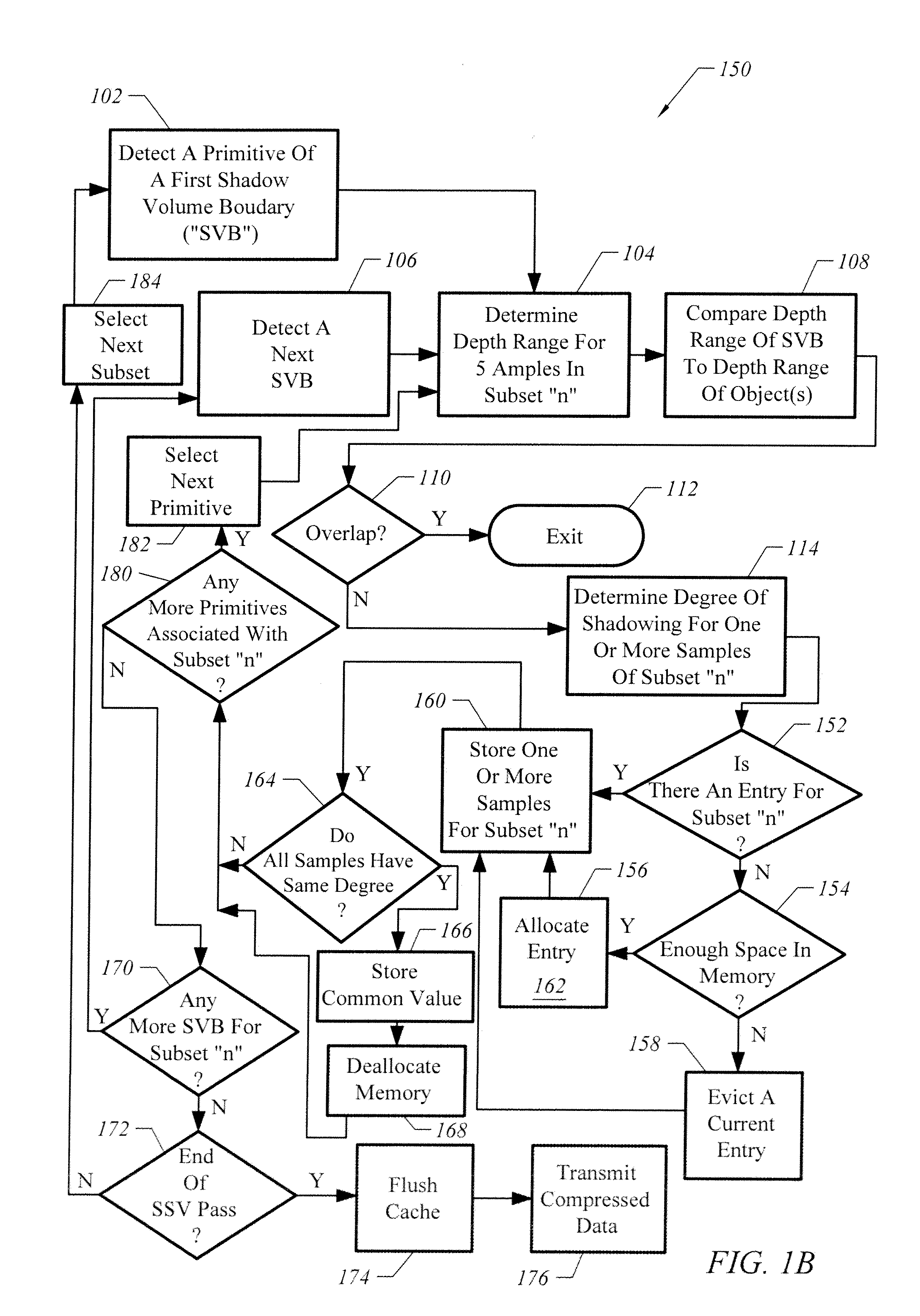

Method and apparatus to accelerate rendering of shadow effects for computer-generated images

The present invention provides for accelerating the generation of graphical images that include shadow effects by, for example, reducing the amount of data transmitted and / or stored necessary to render graphics based on stencil shadow volumes. In one embodiment, an exemplary apparatus is configured to render shadows using stencil shadow volumes. The apparatus includes a memory to store a degree of shadowing for each sample. A co-processor, which is coupled to the memory, is configured to generate an indicator that represents a common degree of shadowing associated with the subset of samples. In some cases, the apparatus includes a graphics processing unit (“GPU”), which is coupled to the co-processor, that is configured to render one or more shadows for a computer-generated image based on the indicator.

Owner:NVIDIA CORP

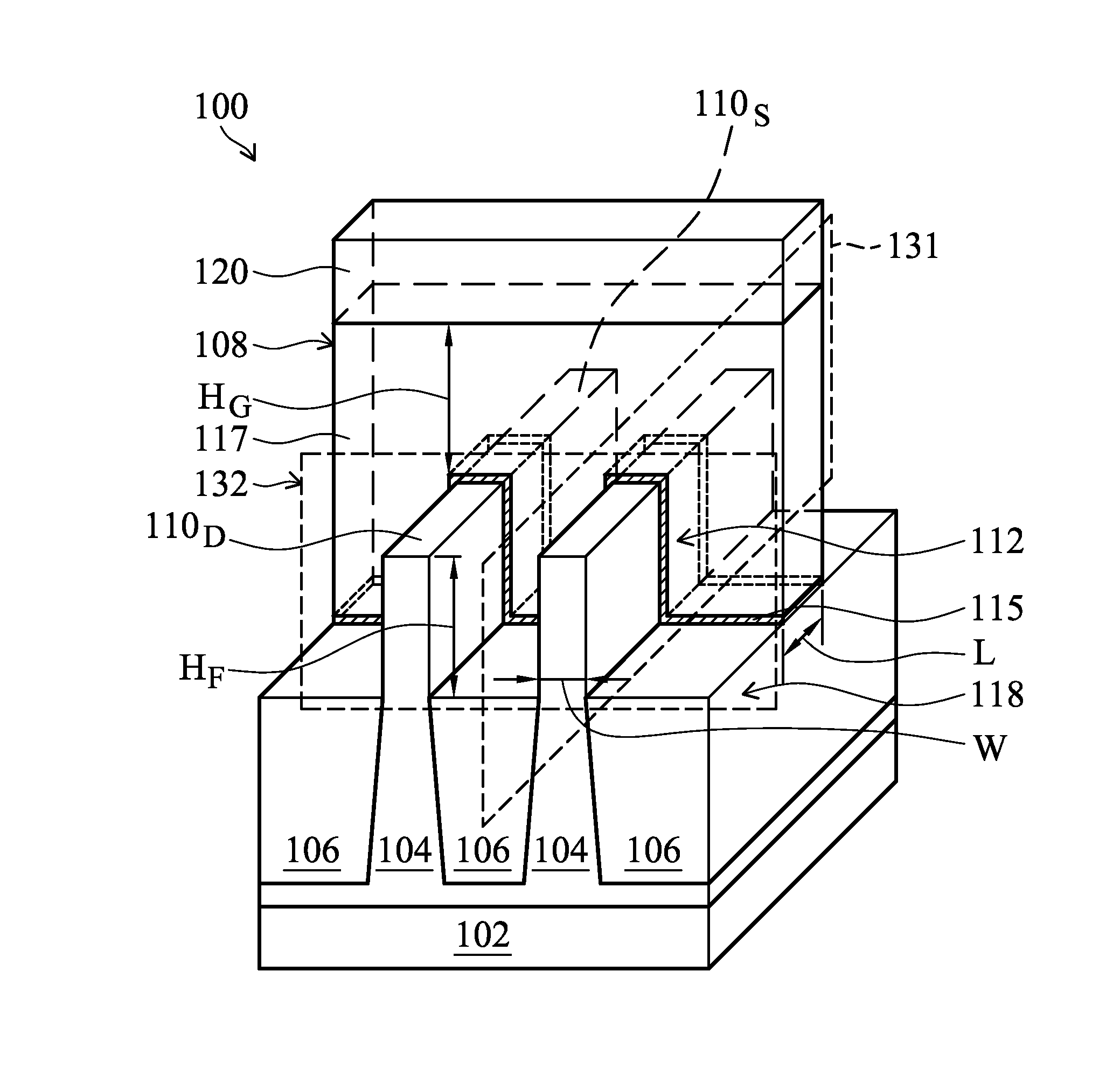

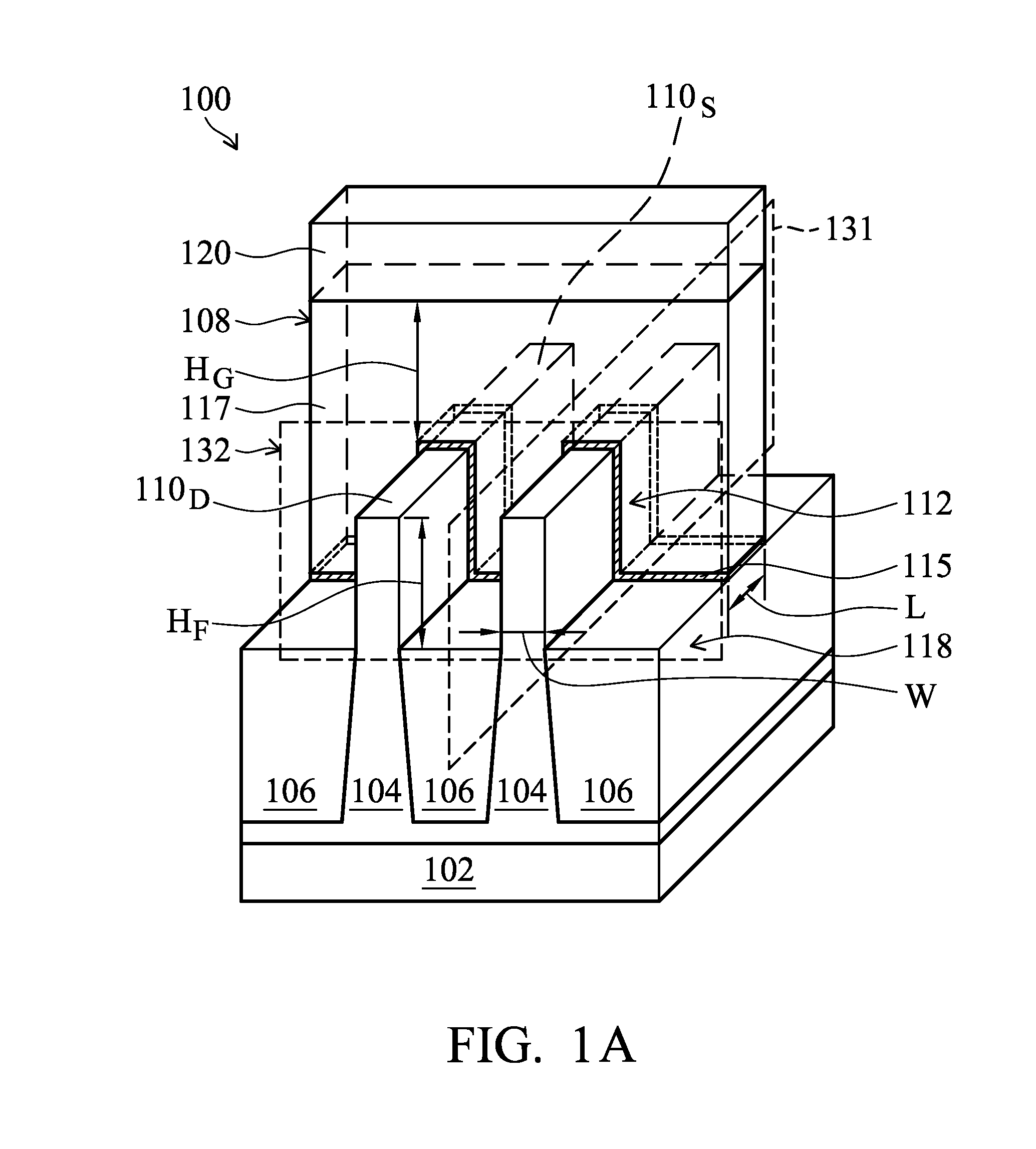

Mechanisms for doping lightly-doped-drain (LDD) regions of finfet devices

The embodiments of mechanisms for doping lightly doped drain (LDD) regions by driving dopants from highly doped source and drain regions by annealing for finFET devices are provided. The mechanisms overcome the limitation by shadowing effects of ion implantation for advanced finFET devices. The highly doped source and drain regions are formed by epitaxial growing one or more doped silicon-containing materials from recesses formed in the fins. The dopants are then driven into the LDD regions by advanced annealing process, which can achieve targeted dopant levels and profiles in the LDD regions.

Owner:TAIWAN SEMICON MFG CO LTD

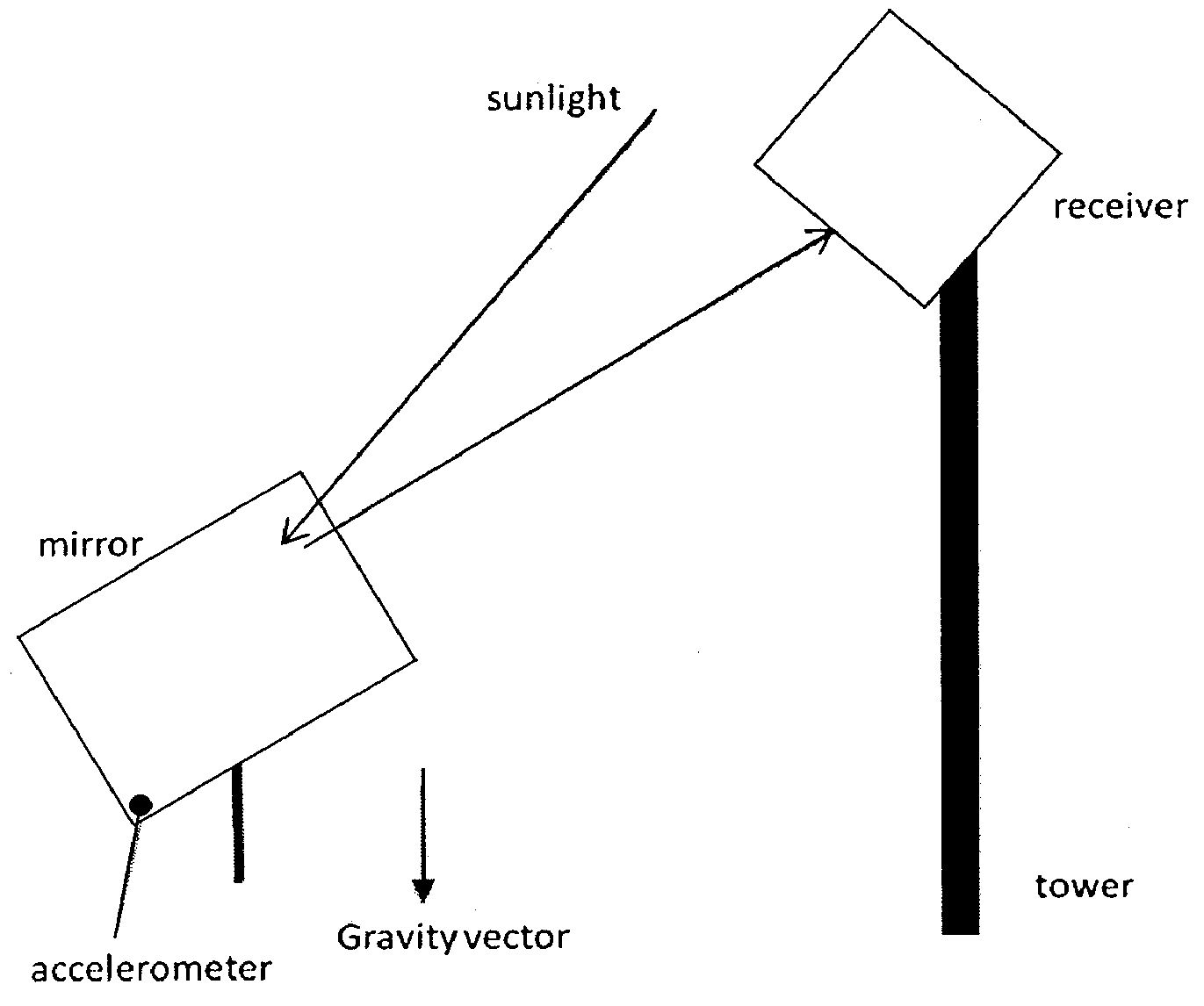

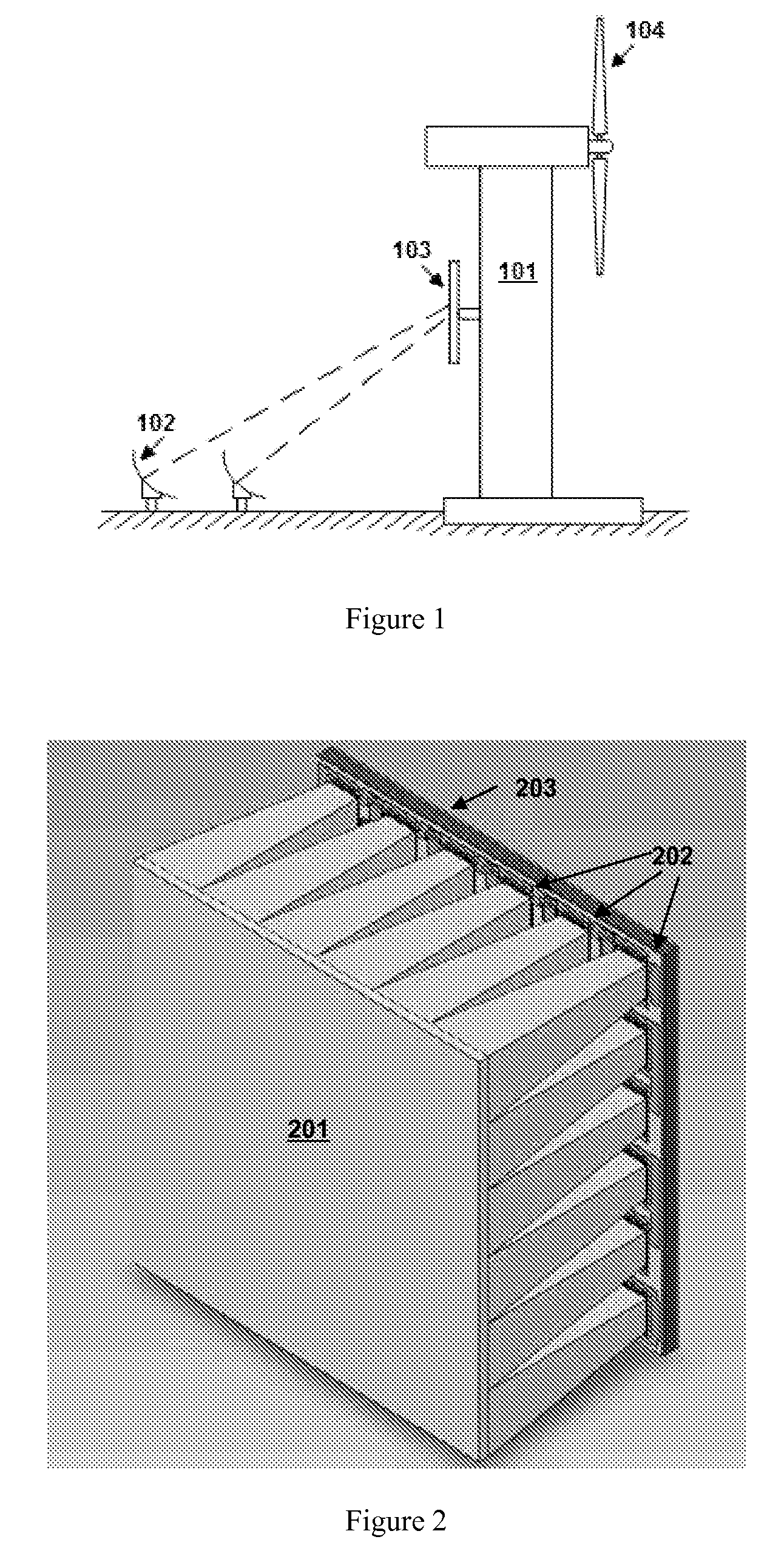

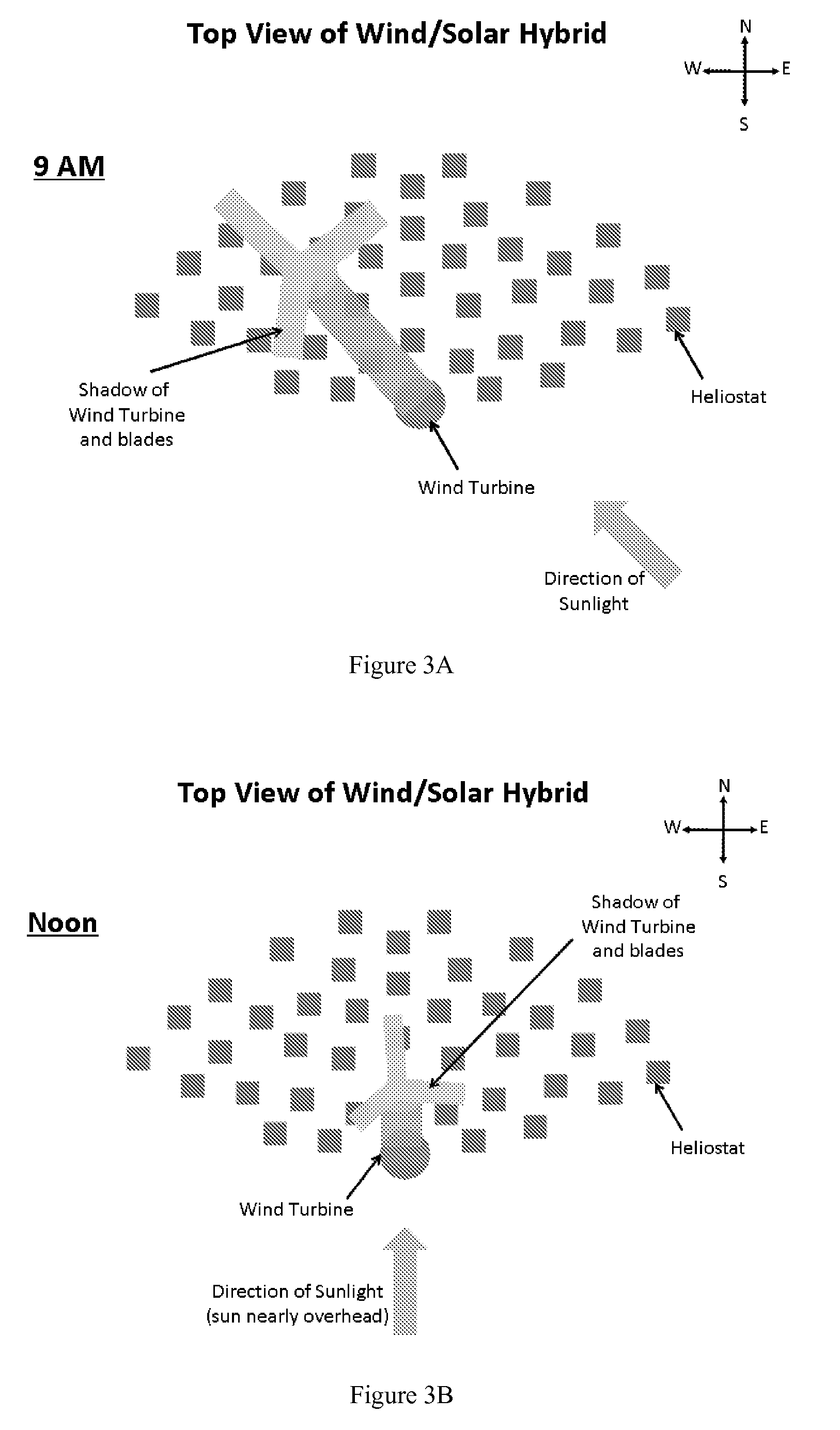

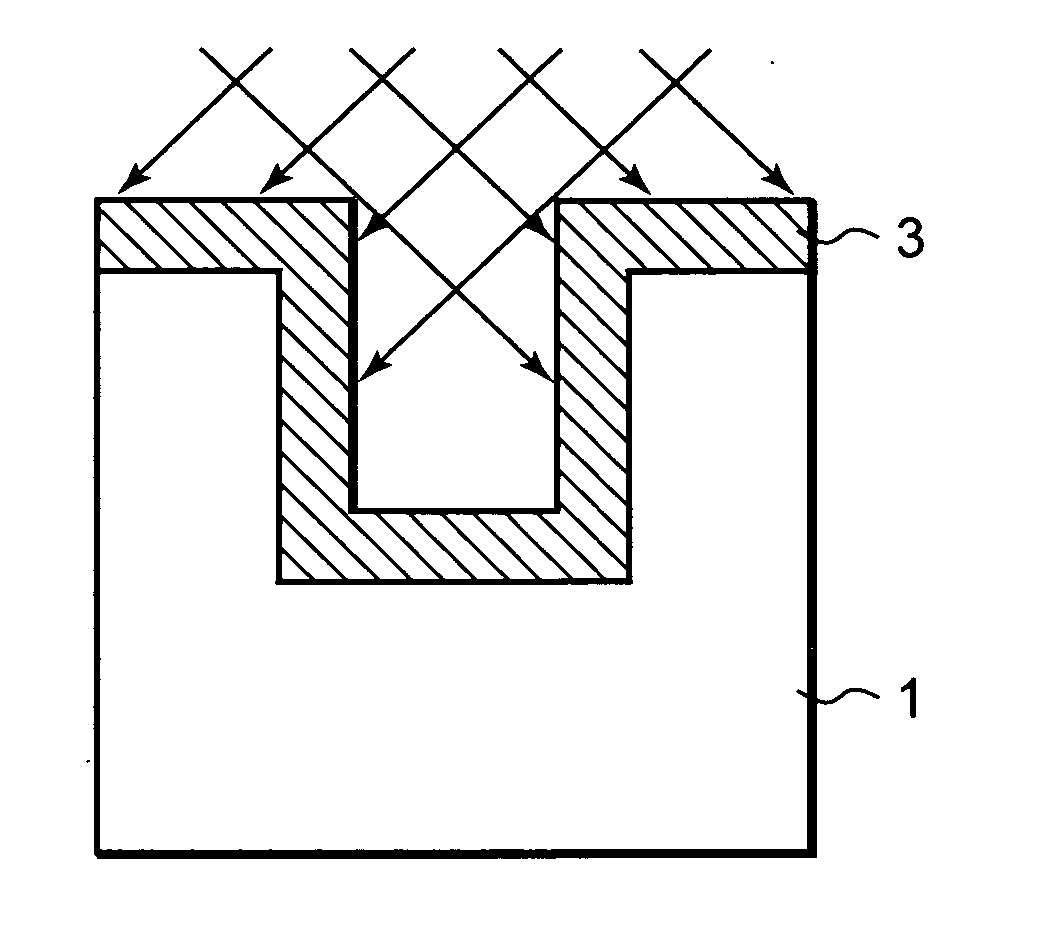

Central Receiver Solar Power Systems: Architecture And Controls Methods

InactiveUS20090178668A1Good flexibilityEasy to controlSolar heating energySolar heat devicesEngineeringShadow effect

The invention provides systems and methods for integrating central receiver solar power systems with existing infrastructure to form multi-purpose structures. The invention also provides arranging heliostats to accommodate shadowing effects. Additionally, improved systems and methods for solar tracking are provided. Such improved solar tracking may enable the heliostats to more accurately reflect sunlight to a central receiver.

Owner:CYANTO CORP

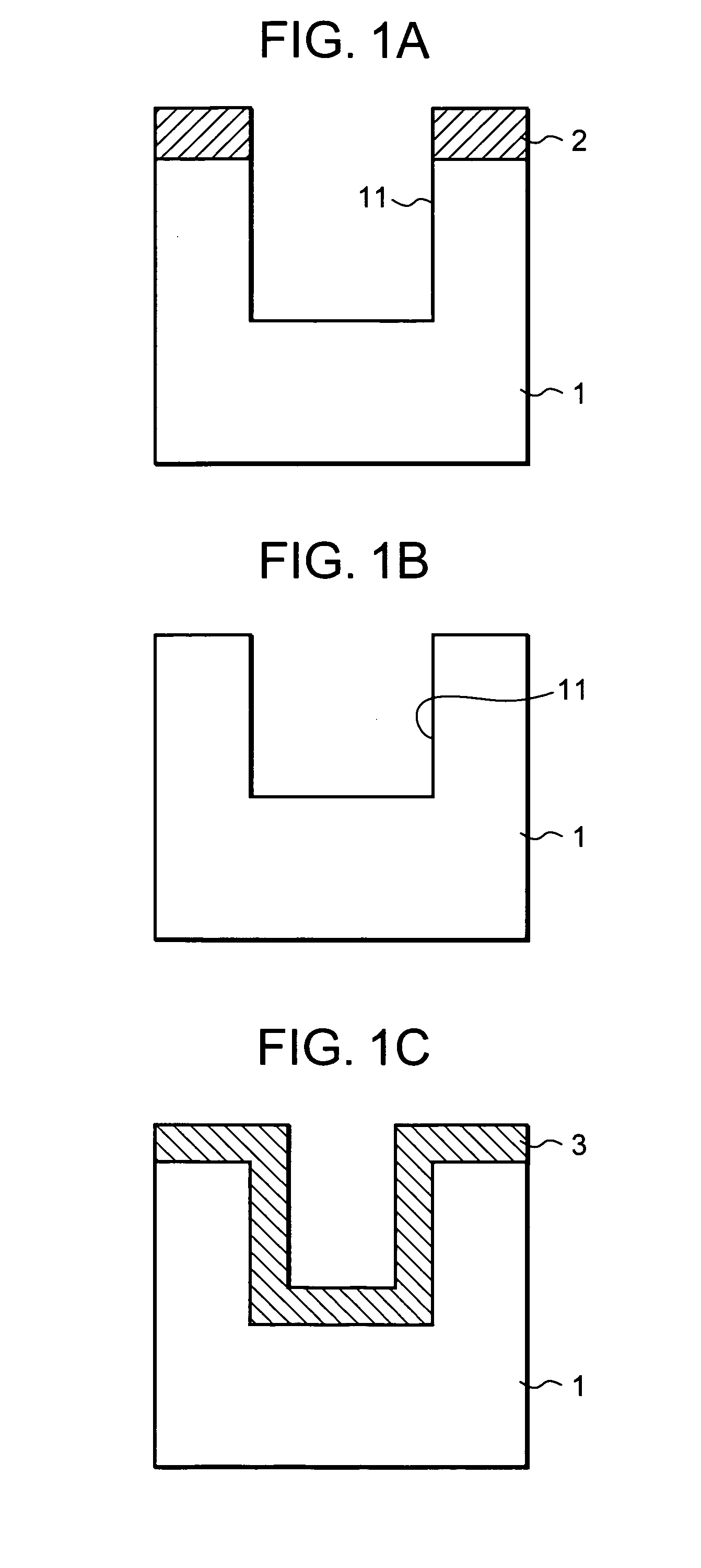

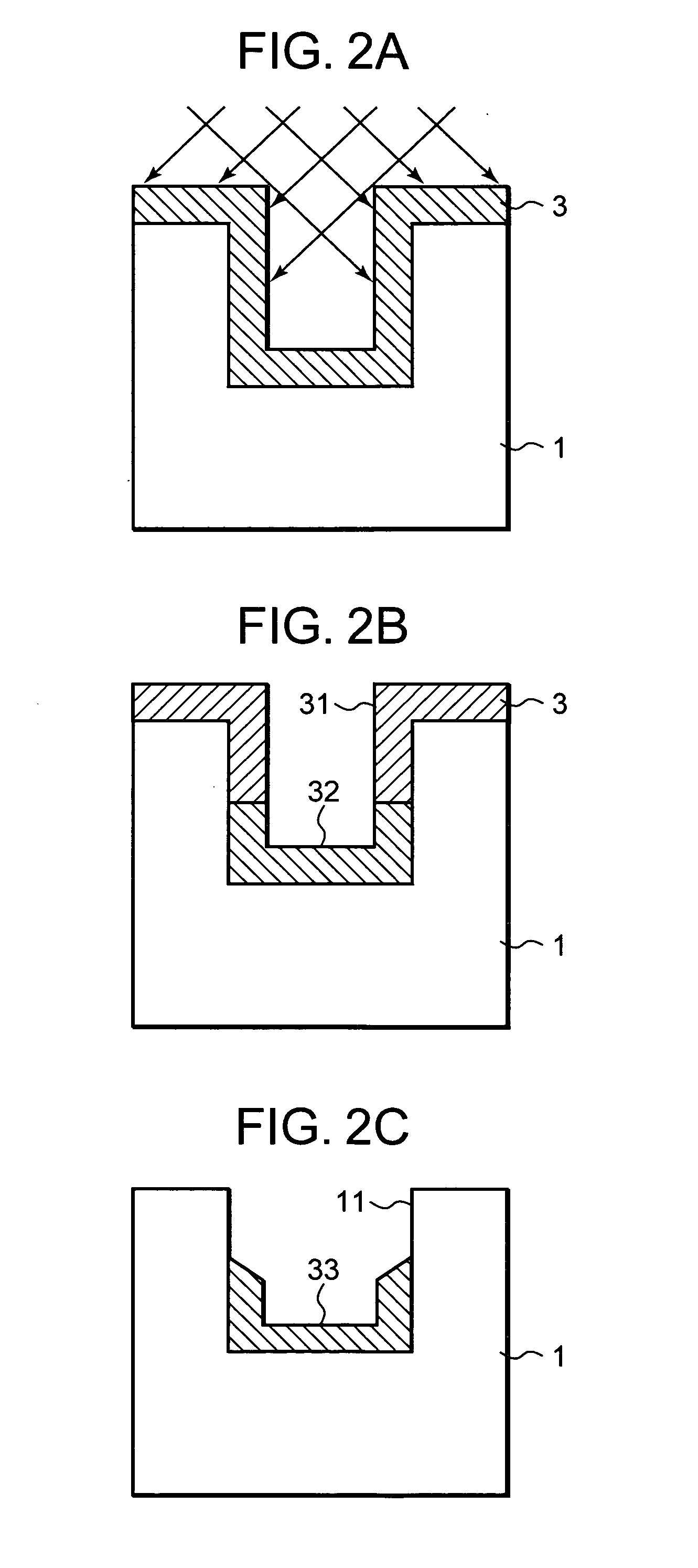

Method for manufacturing semiconductor device

InactiveUS20060166419A1Reduce thicknessWell formedSemiconductor/solid-state device manufacturingSemiconductor devicesDevice materialSilicon oxide

The method for manufacturing a semiconductor device according to the invention includes forming a thick silicon oxide film uniformly in a trench. Argon ions or the like implanted obliquely into the trench to form an ion implanted damaged region selectively in the portion of the silicon oxide film on the trench sidewall utilizing the shadowing effects of the oblique ion implantation. The silicon oxide film is wet etched to selectively remove the silicon oxide film in the ion implanted damaged region utilizing the etching rate difference, wherein the etching rate is faster in the damaged region than in the undamaged region. As a result, a thick residual oxide film is formed on the bottom and the lower sidewall portion of the trenchwithout causing any bird's beak.

Owner:FUJI ELECTRIC CO LTD

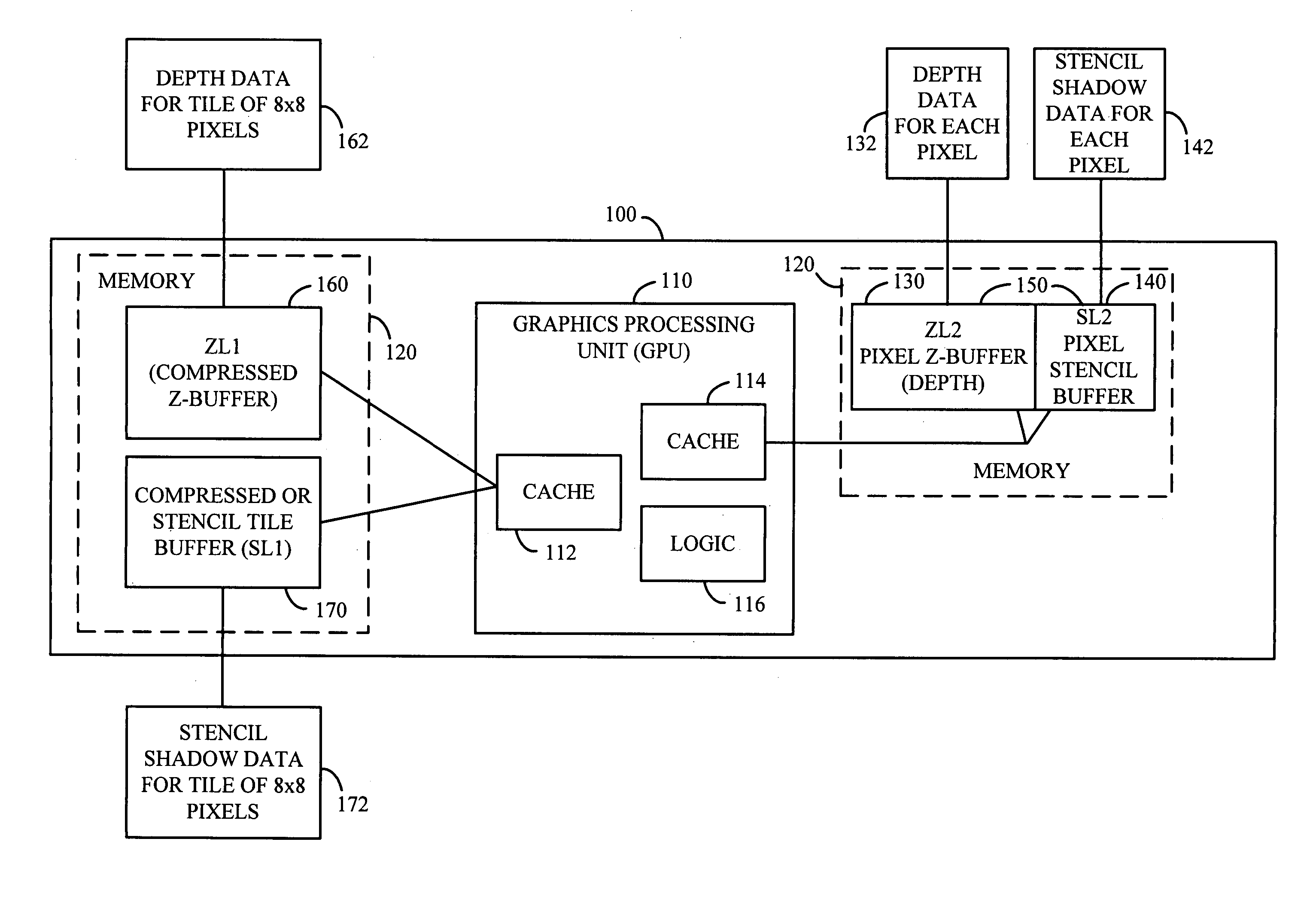

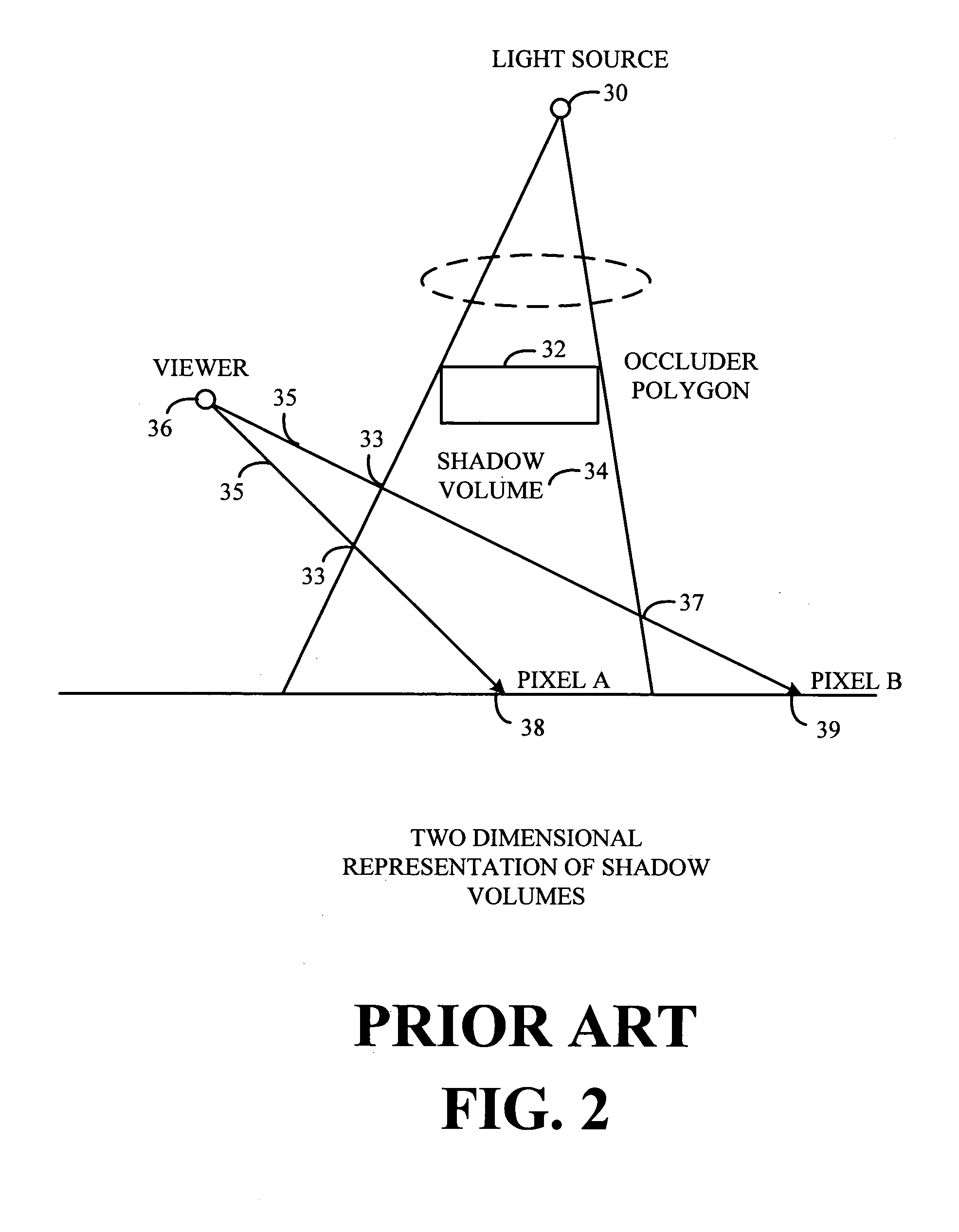

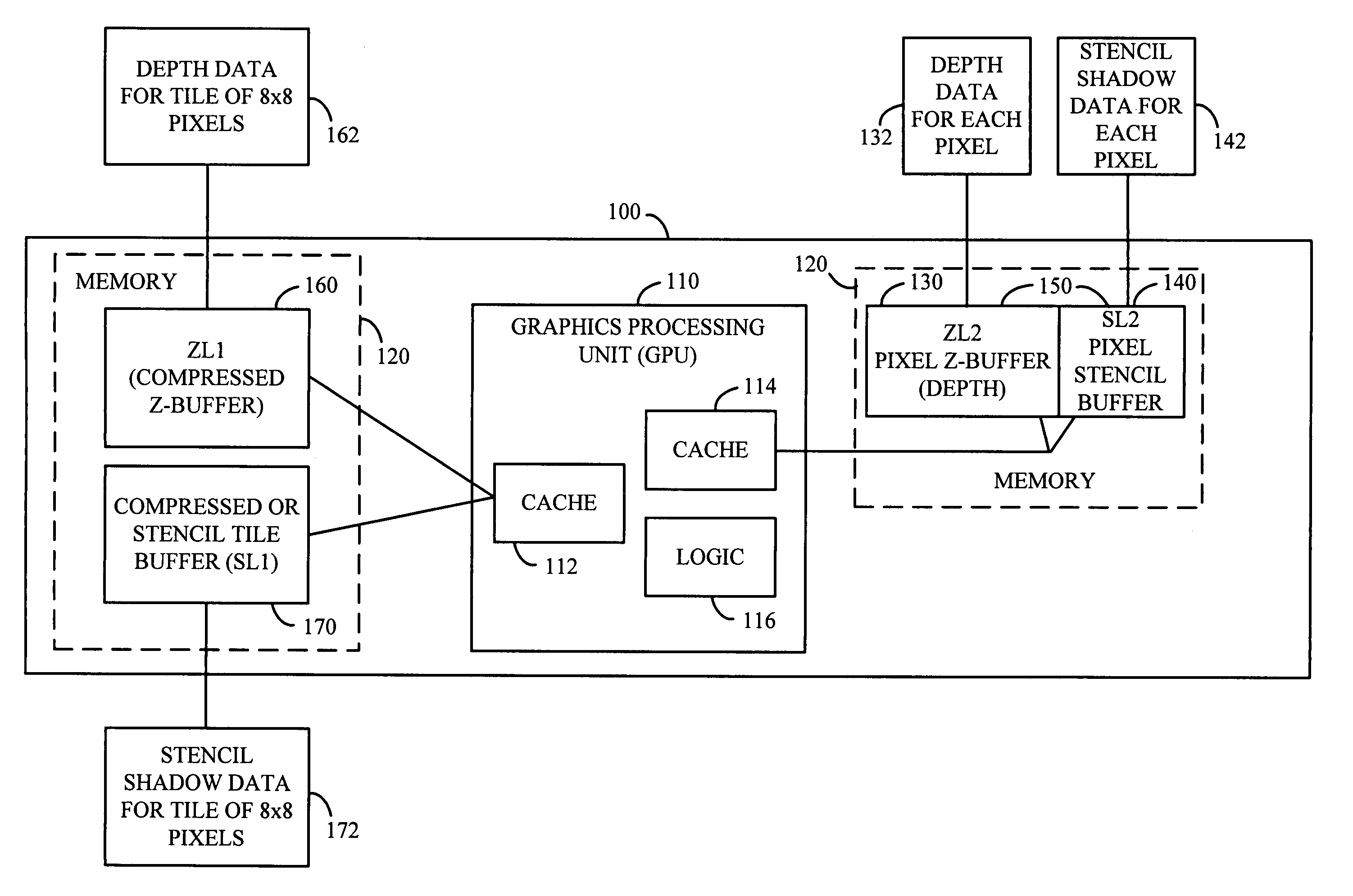

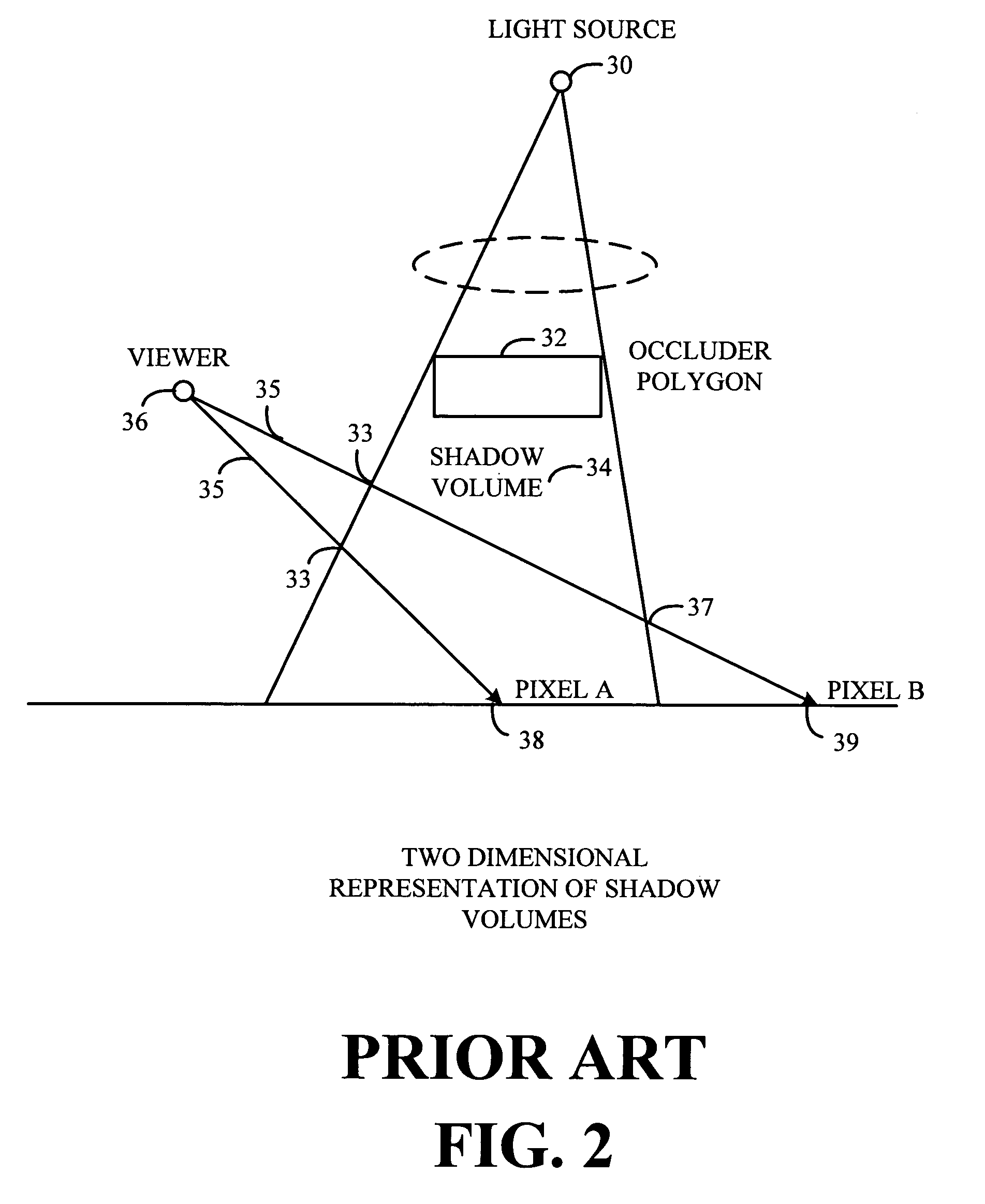

Method and apparatus for generating a shadow effect using shadow volumes

The computer graphics system is configured to generate a shadow effect with a stencil shadow volume method using a combination of compressed and uncompressed stencil buffers in coordination with compressed and uncompressed depth data buffers. An uncompressed stencil buffer is capable of storing stencil shadow volume data for each pixel and a compressed stencil buffer is capable of storing stencil shadow volume data for a group of pixels.

Owner:VIA TECH INC

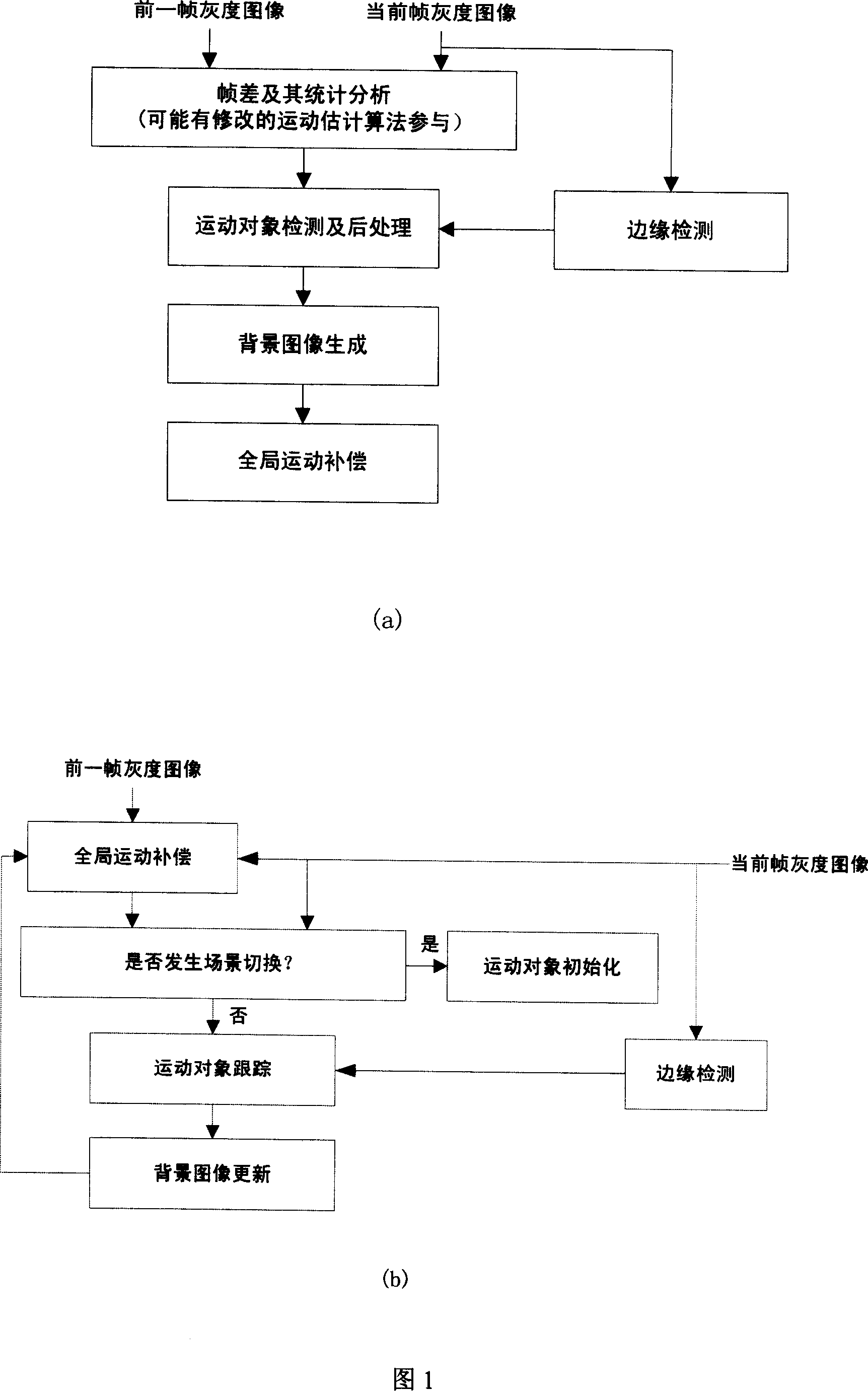

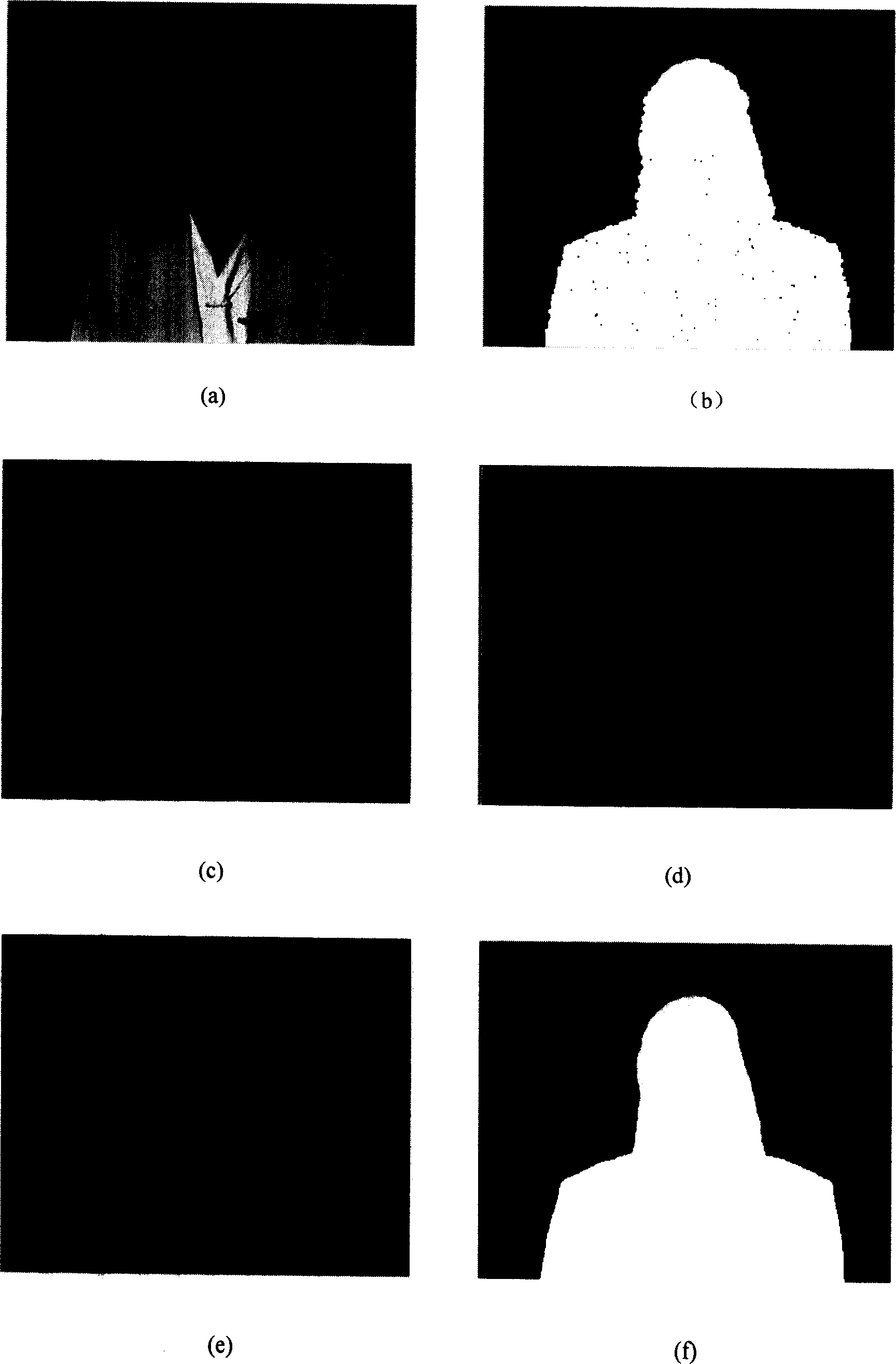

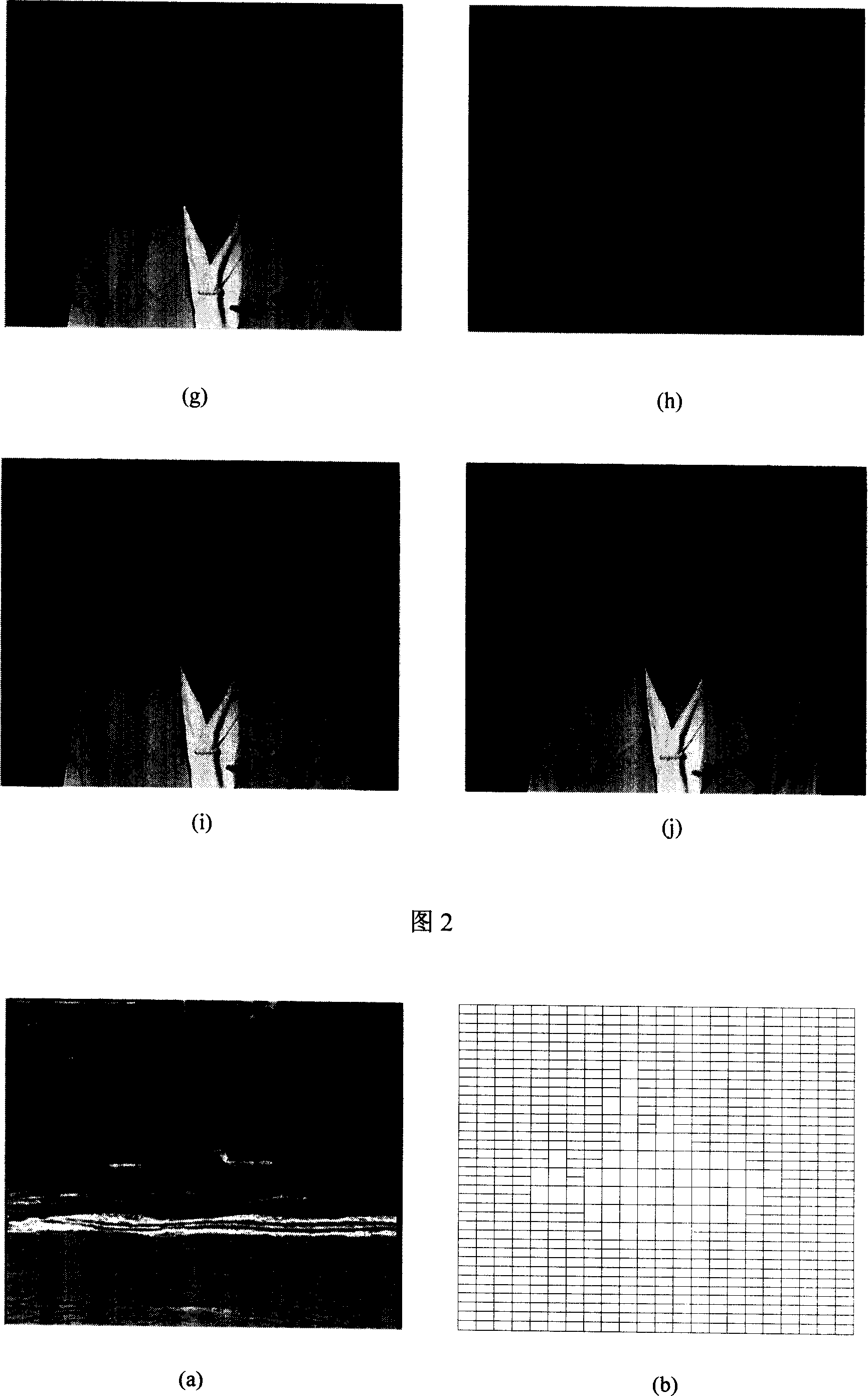

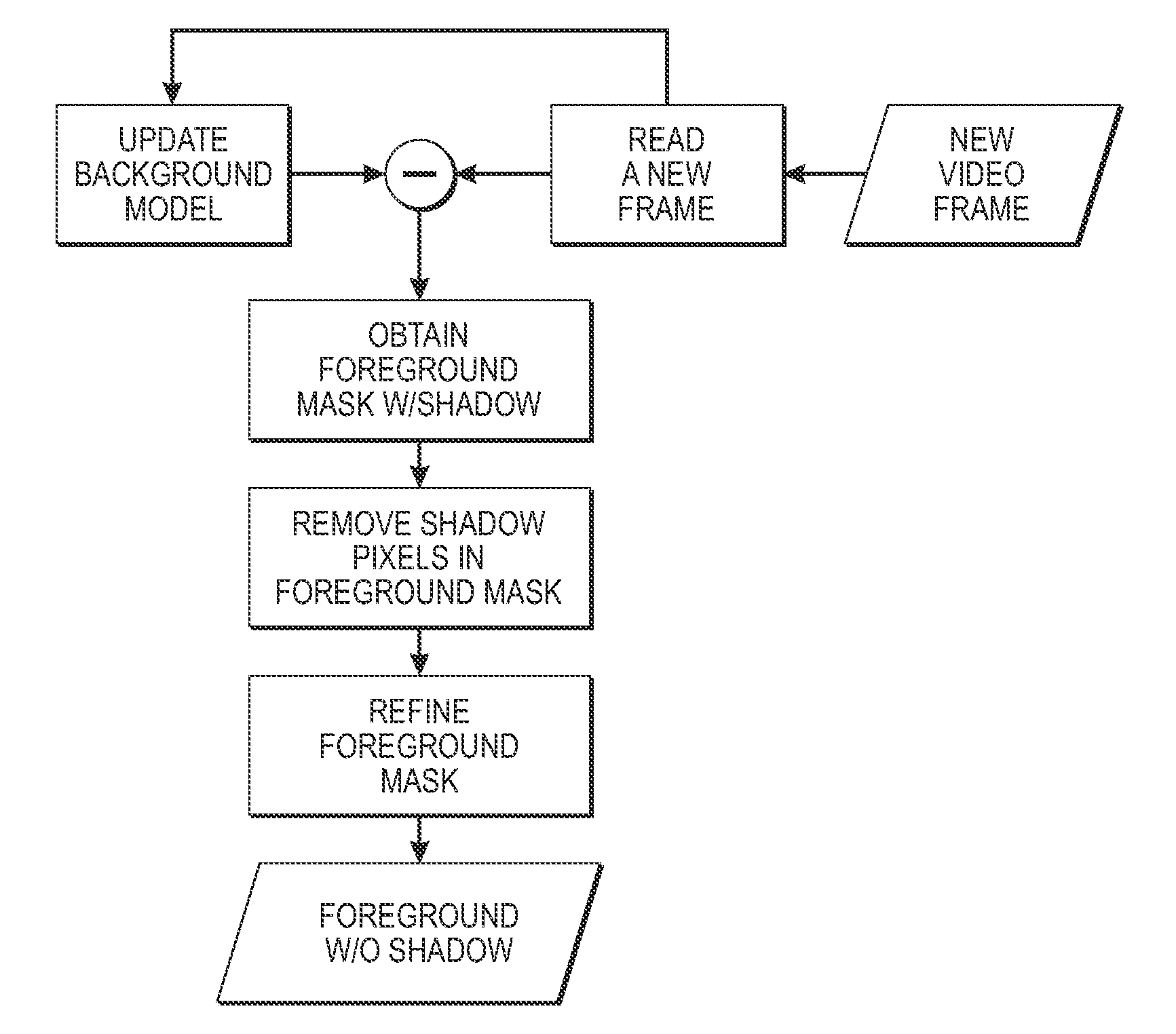

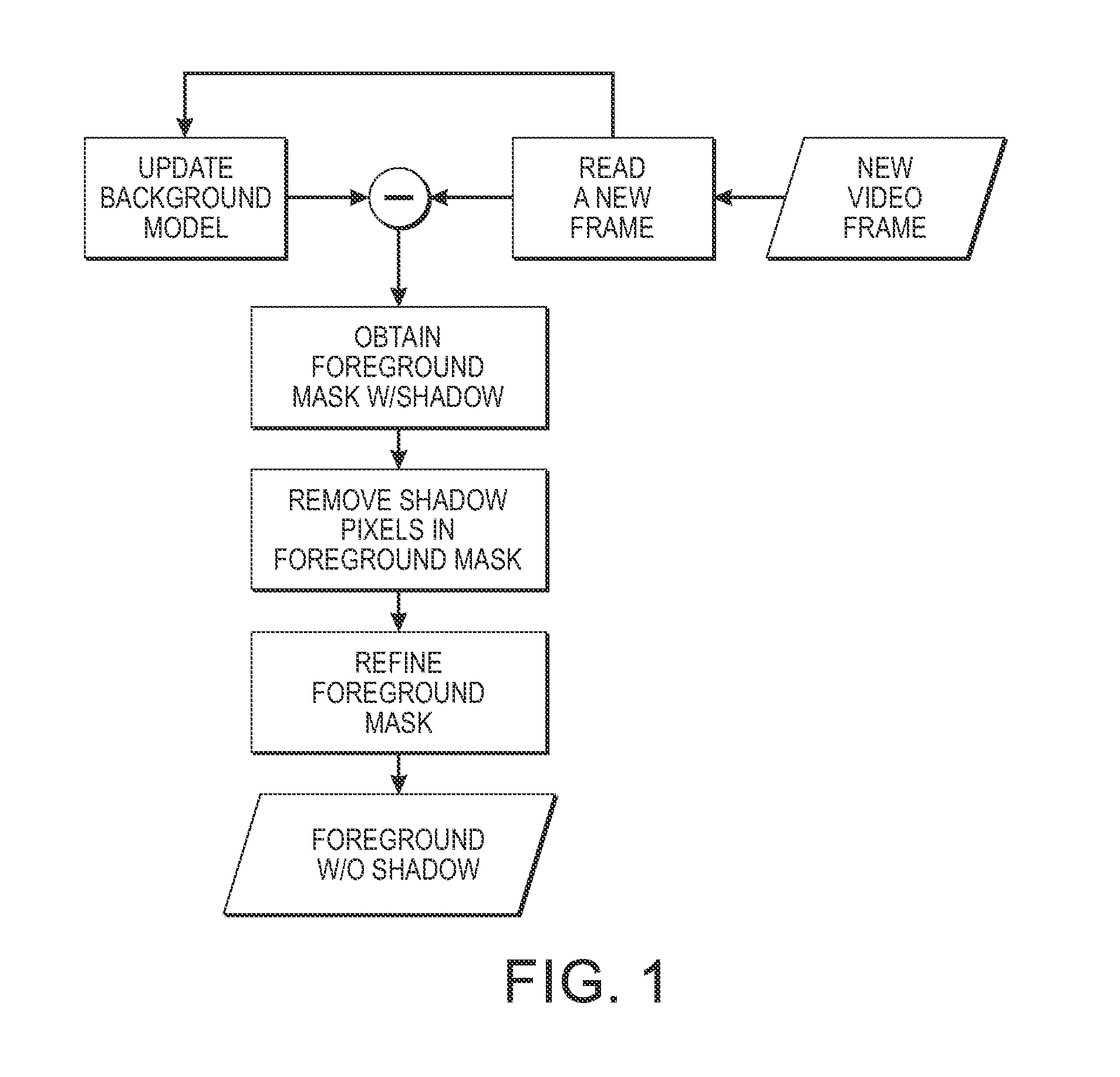

Division method of motive object in video sequence

The invention discloses a dividing method of moving object in video sequence. Aiming at resolving problem of current technique is affected by speed of object, shadow effect, background miscarriage of justice. The dividing method of moving object in video sequence is analyzing current frame gray image and former frame gray image, global movement estimation, modality filter, edge examination, movement object examination and post treatment, background image generation, global movement compensation, commutation scene examination, movement object track, background image renewal, by adopting said method, lesser calculation quality can overcome disadvantageous factors of shadow effect, background miscarriage of justice, better result can be obtained.

Owner:ZTE CORP

Method and apparatus for generating a shadow effect using shadow volumes

The computer graphics system is configured to generate a shadow effect with a stencil shadow volume method using a combination of compressed and uncompressed stencil buffers in coordination with compressed and uncompressed depth data buffers. An uncompressed stencil buffer is capable of storing stencil shadow volume data for each pixel and a compressed stencil buffer is capable of storing stencil shadow volume data for a group of pixels.

Owner:VIA TECH INC

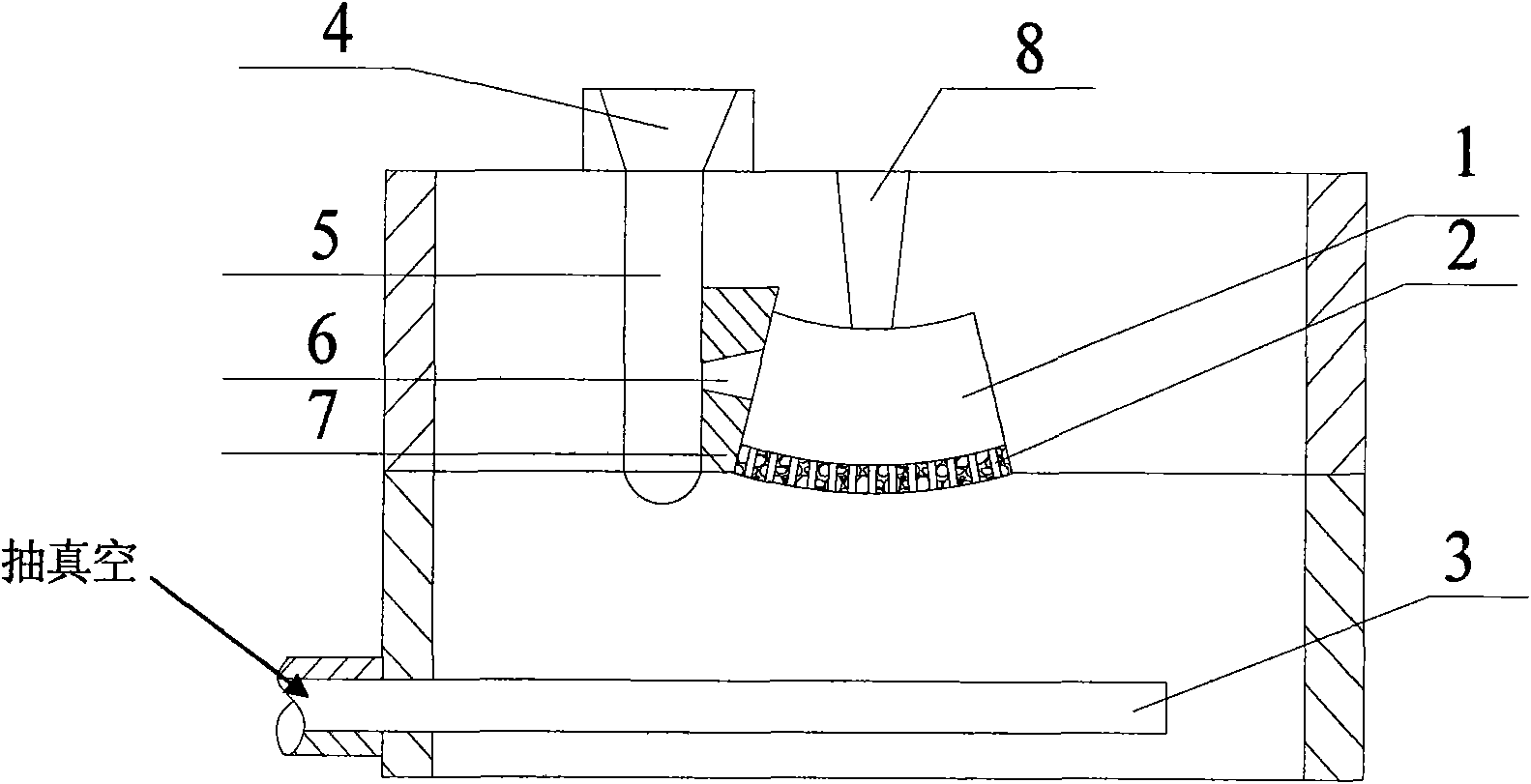

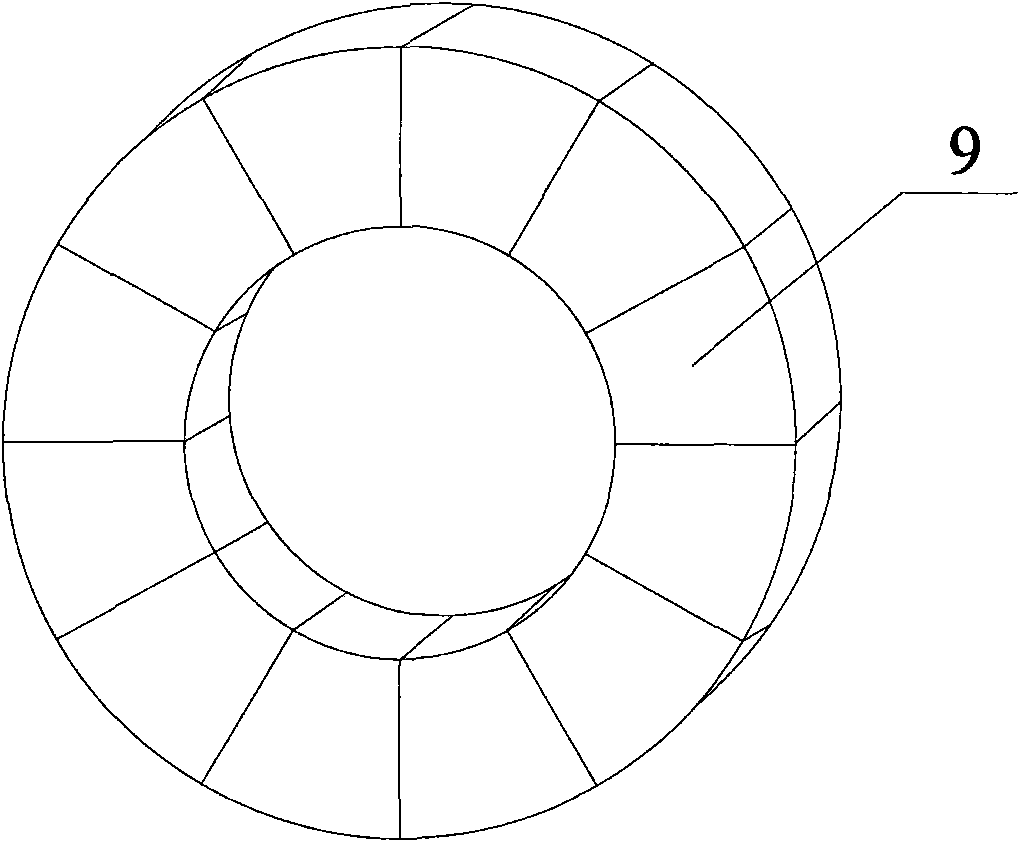

Composite-material grinding roller, grinding disc, and negative-pressure casting method thereof

InactiveCN101585081AQuality improvementHelps prevent scourGrain treatmentsShadow effectPressure casting

The invention provides a composite-material grinding roller, a grinding disc, and a negative-pressure casting method thereof. The method comprises: preparing WC particles and binder into paste; filling a mold with the paste to form a honeycomb-like prefabricated body; placing the prefabricated body on the side of the end face of a casting mold cavity; melting metal parent material to form molten metal; allowing the molten metal to enter the bottom of the casting mold cavity from a straight pouring channel and an inner pouring channel of a pouring cup; and forming the composite-material grinding roller and the grinding disc after the molten metal solidifies. As a reinforcement body of the invention adopts a honeycomb-like structure, on the one hand, the reinforcement body is favorable for blocking the scouring effect of the molten metal, benefiting the stable production of castings and reducing reject rate, and on the other hand, the honeycomb-like reinforcement body can realize macro-shadow effect during the service of the composite-material grinding roller, helps to improve the wear resistance of materials, and can also avoid the phenomena that the purely block-shaped reinforcement body peels off or falls.

Owner:XI AN JIAOTONG UNIV +1

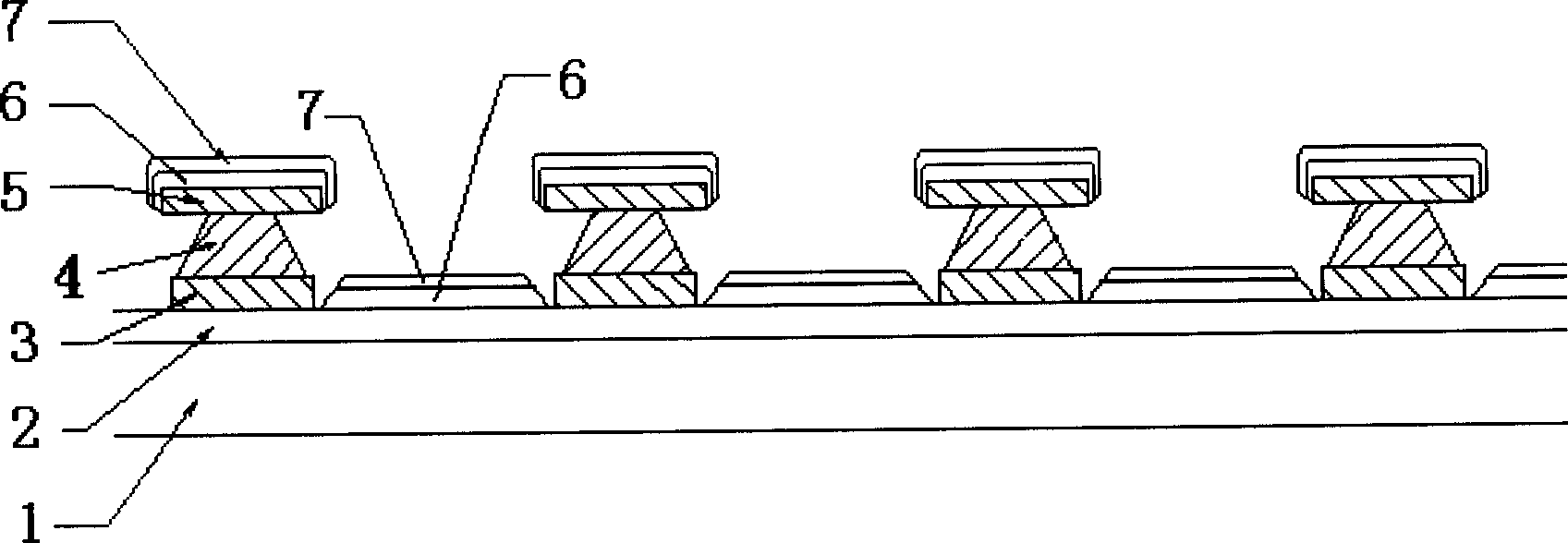

Orgnic electroluminescence device and its preparation device

InactiveCN1416300ALight evenlyIncrease contrastElectroluminescent light sourcesSolid-state devicesShadow effectOrganic electroluminescence

The invention belongs to the technique area of the semiconductor elements and devices. Three layers of the isolation pole are prepared on the graphics of the first electrode. The graphics of the first layer of the isolation pole is the mesh texture with the cross section being as trapezoid shape. The cross section of the lines on the second layer and the third layer of the isolation pole possess the shape with big at the upper and small at the lower. Then, the organic function layer and the second electrode are deposited in sequence. The shadow effect caused by the shape with big at the upper of the second layer and the third layer makes the second electrode possible to be partitioned. The first layer of the isolation pole being equivalent to 'insulating base' prevents the short circuit between the electrodes.

Owner:BEIJING VISIONOX TECH

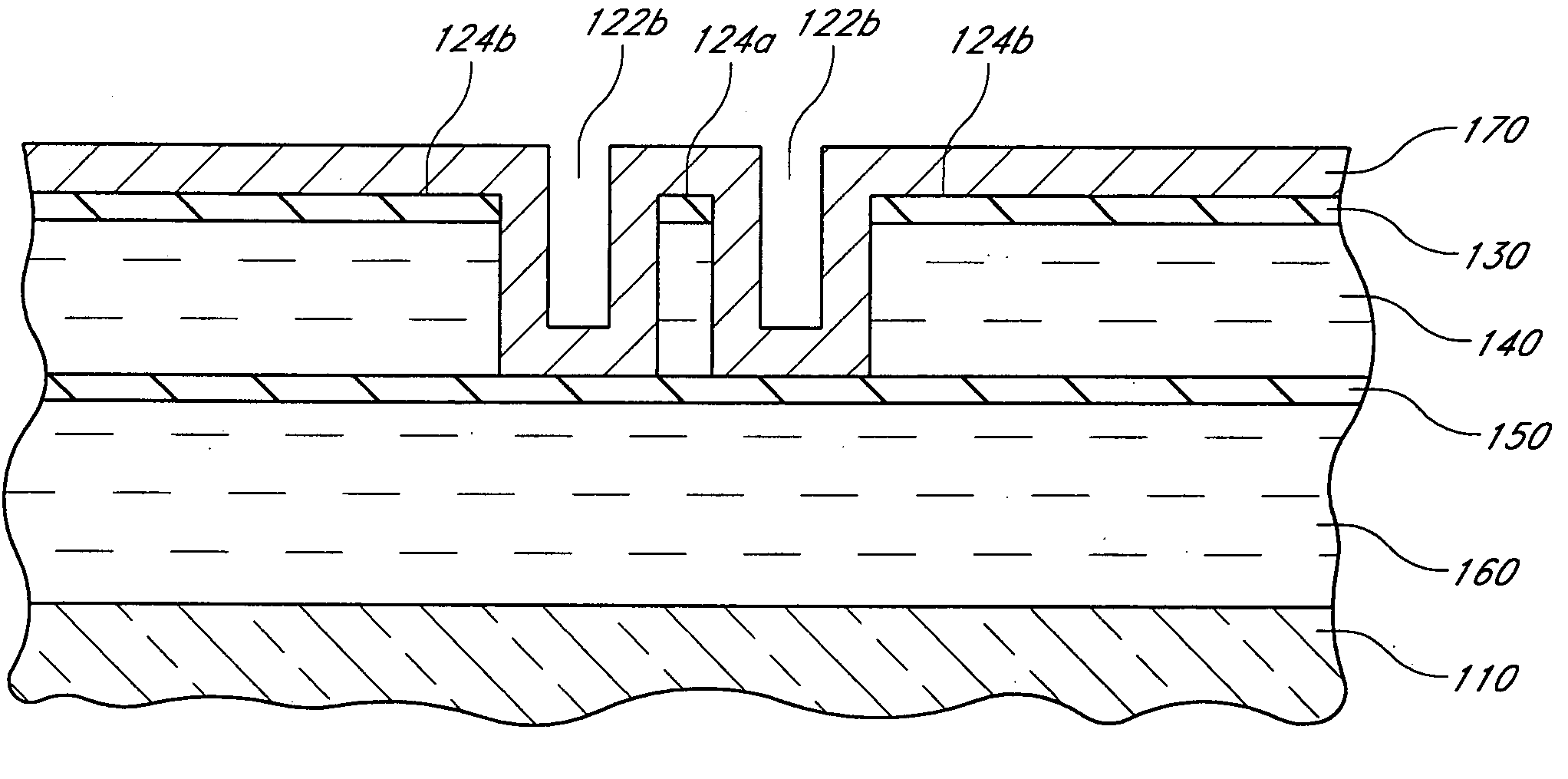

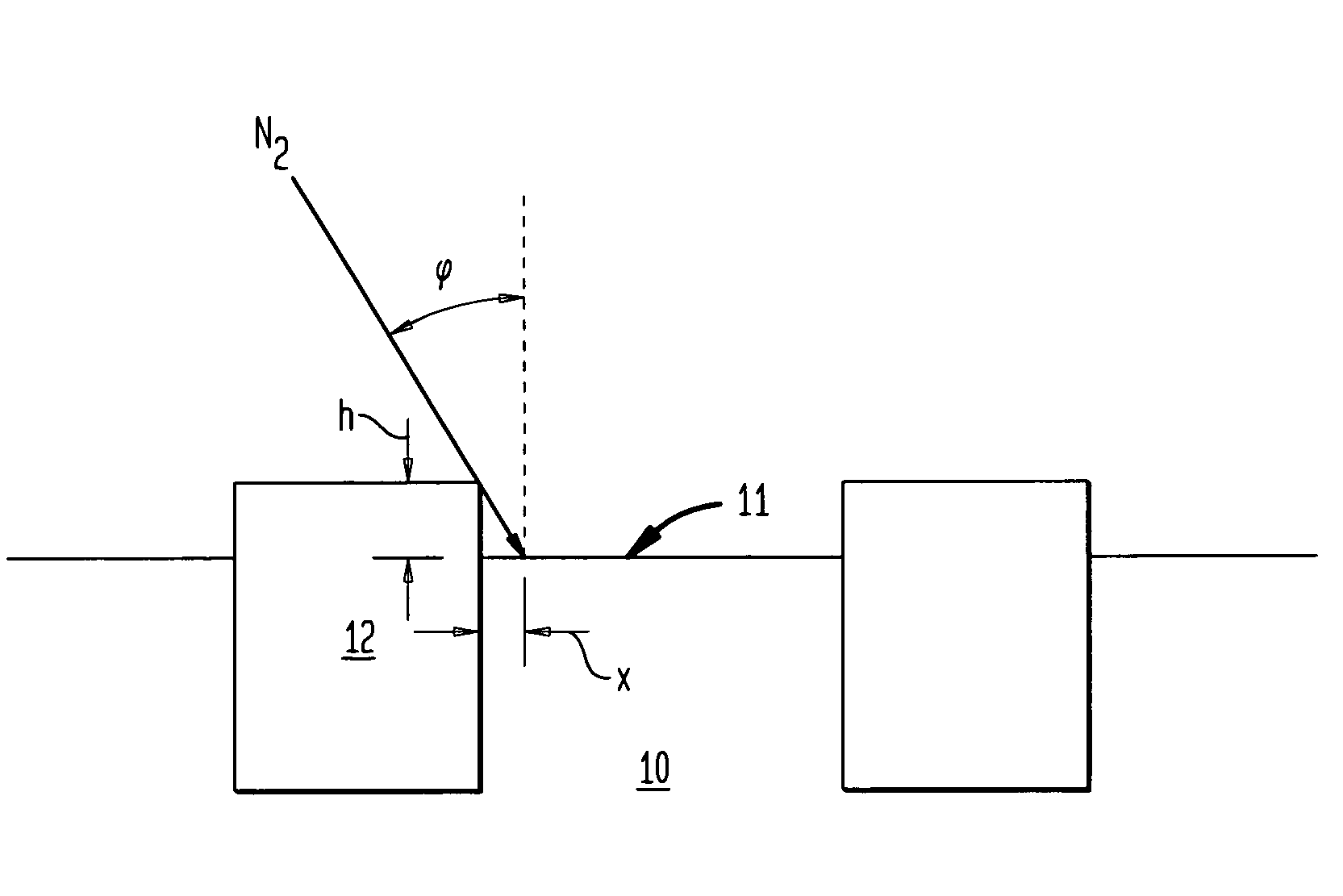

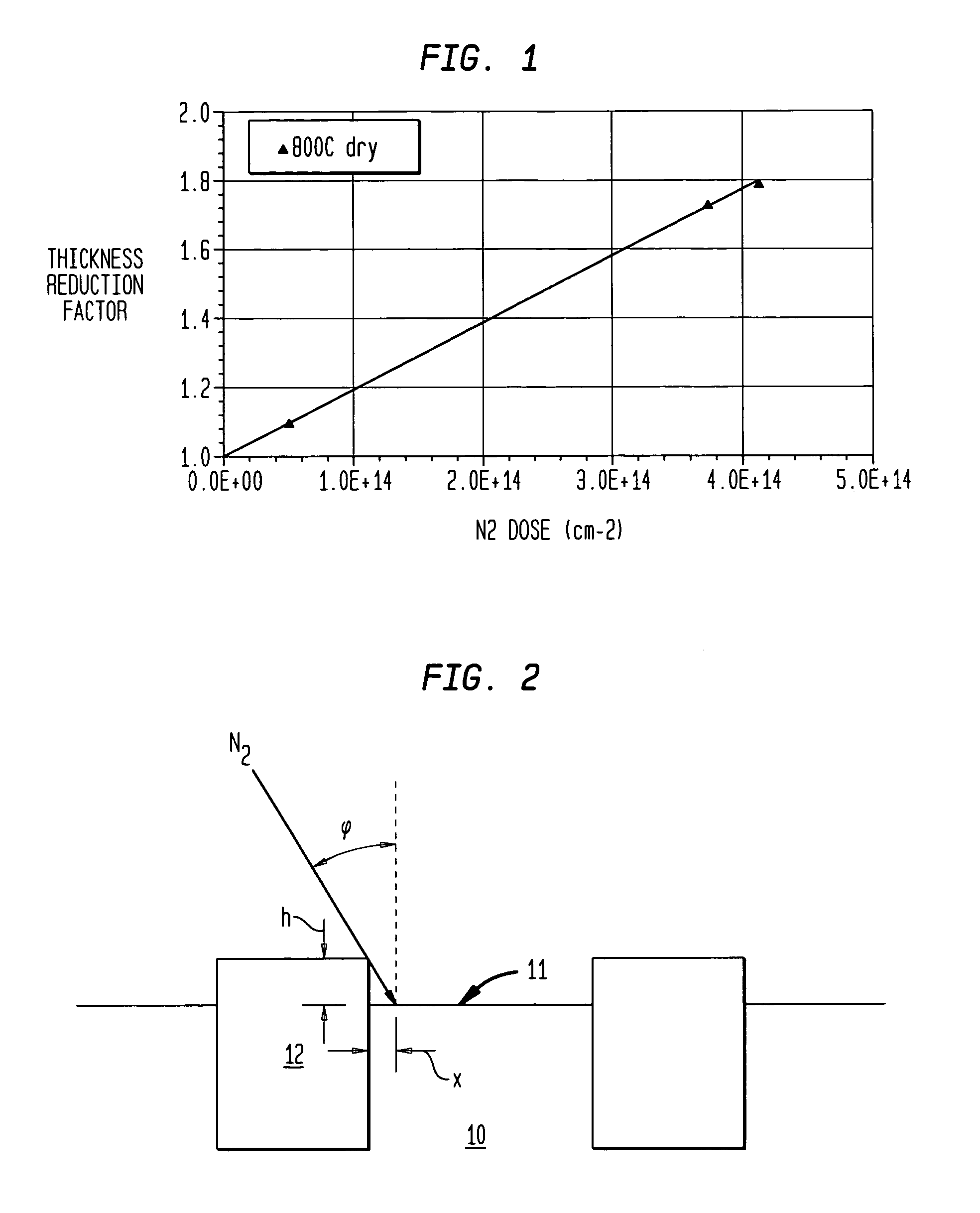

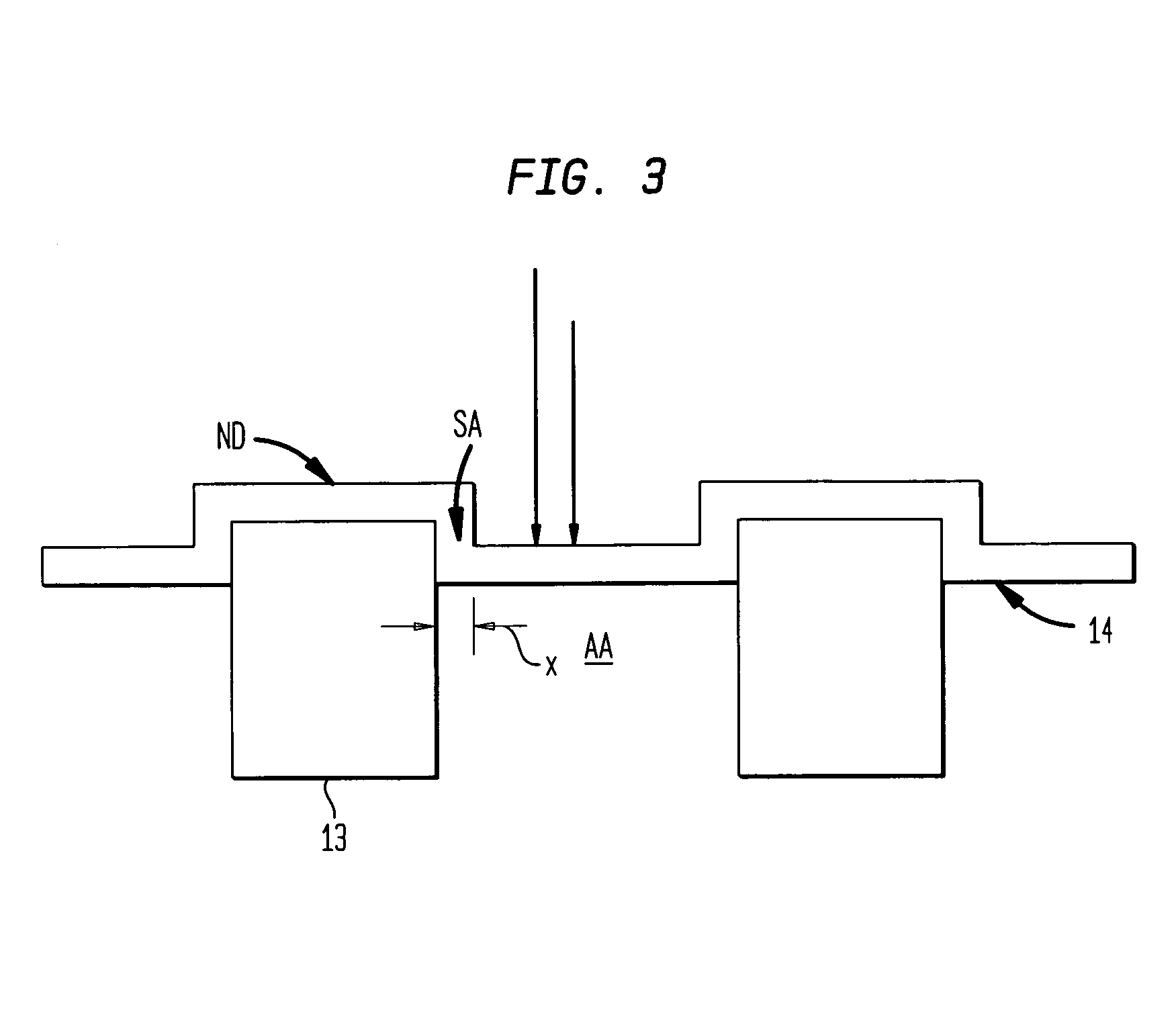

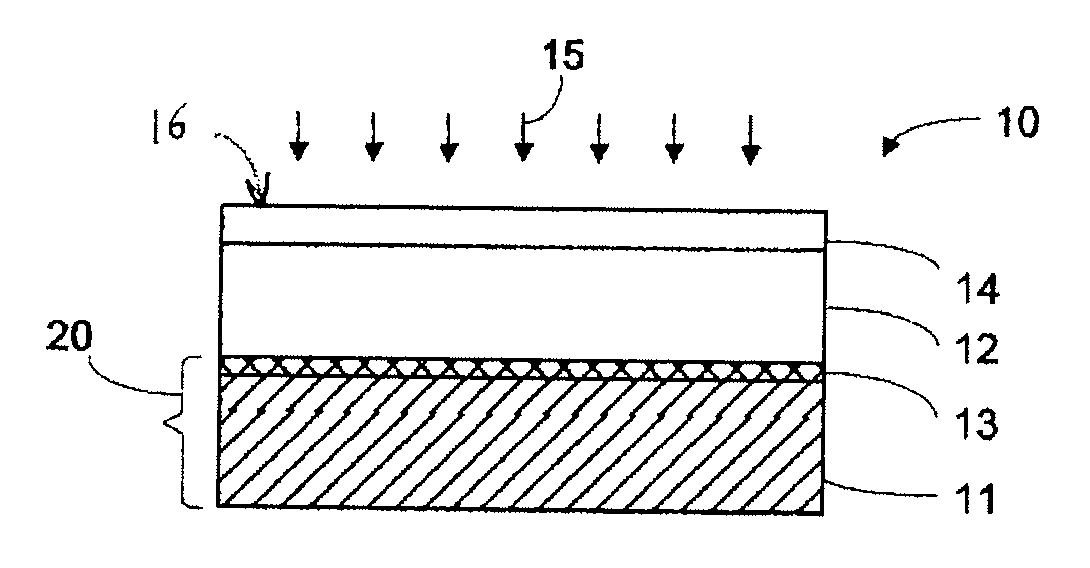

Nitrogen implantation using a shadow effect to control gate oxide thickness in DRAM semiconductor

Process for forming dual gate oxides for DRAMS by incorporating different thicknesses of gate oxides by using nitrogen implantation. Either angled nitrogen implantation or nitride spacers is used to create a “shadow effect” or area, which limits the nitrogen dose close to the edges of the active area. The reduction of nitrogen dose leads to an increased gate oxide thickness at the active area (AA) adjacent to the shallow trench, increases the threshold of the parasitic corner device and reduces sub Vt (threshold voltage) and junction leakage.

Owner:POLARIS INNOVATIONS LTD

Method for doping fin field-effect transistors

InactiveCN102237278AImprove shortcomingsImprove electrical performanceSemiconductor/solid-state device manufacturingSemiconductor devicesElectricityDopant

Owner:TAIWAN SEMICON MFG CO LTD

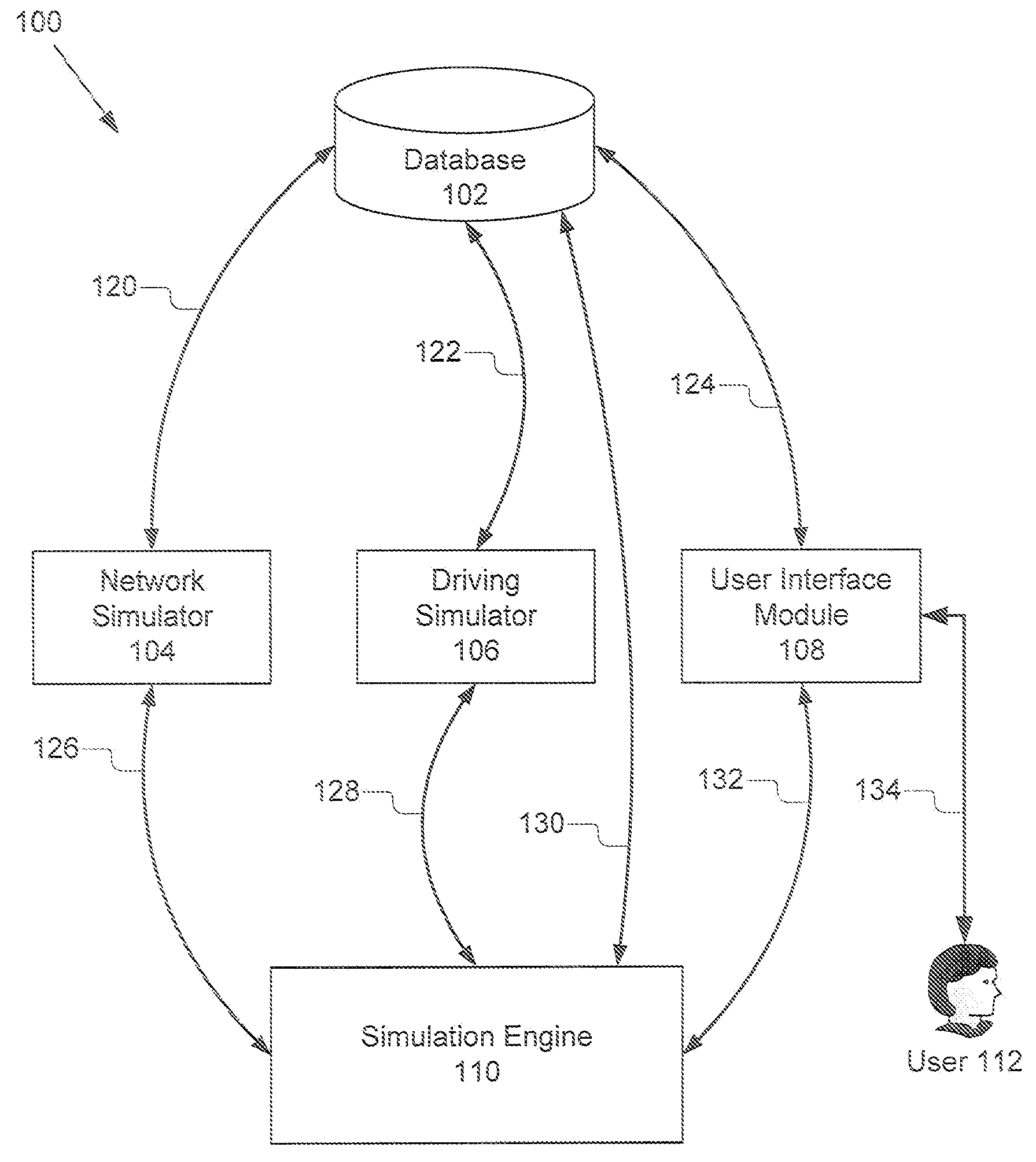

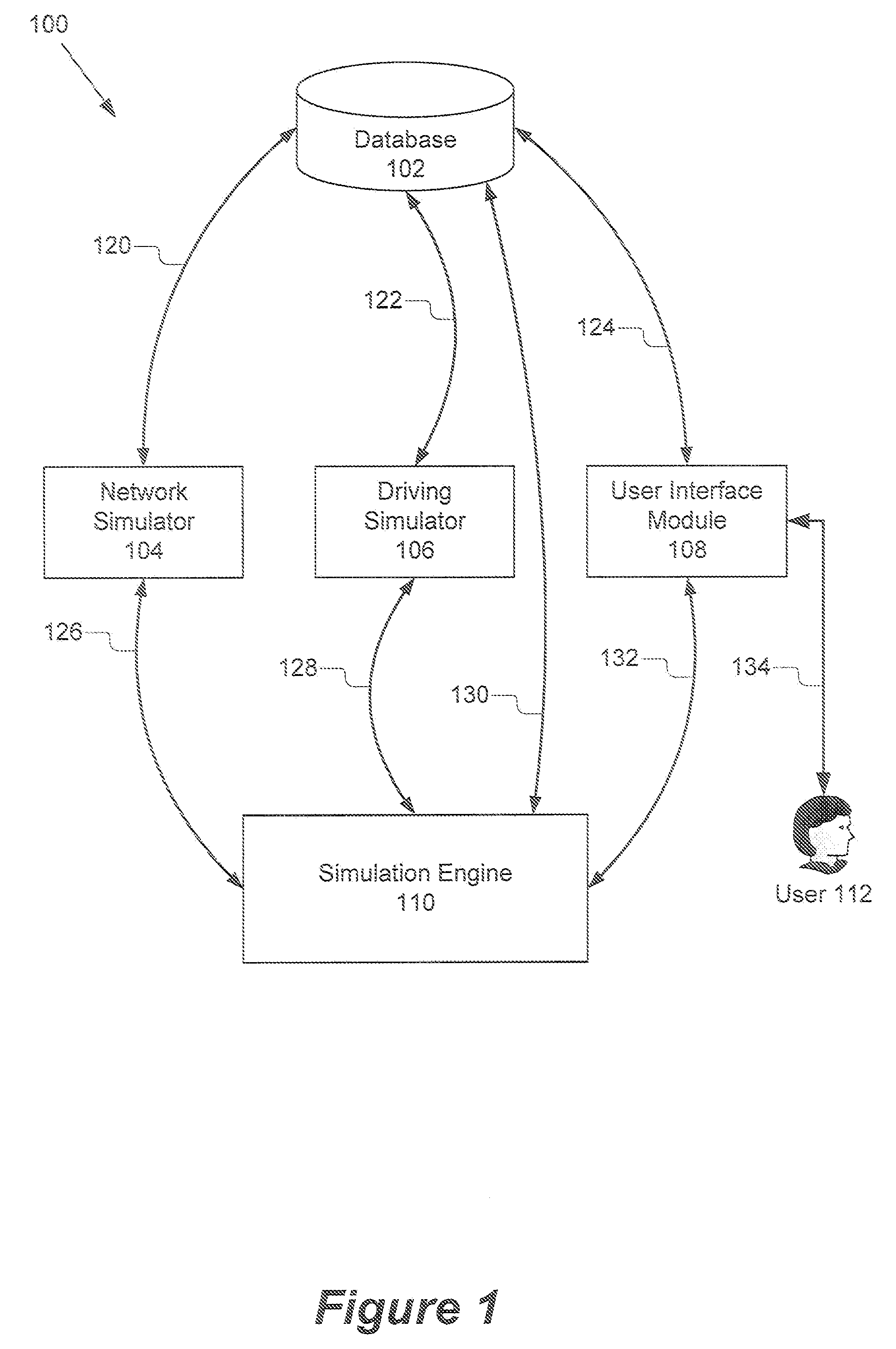

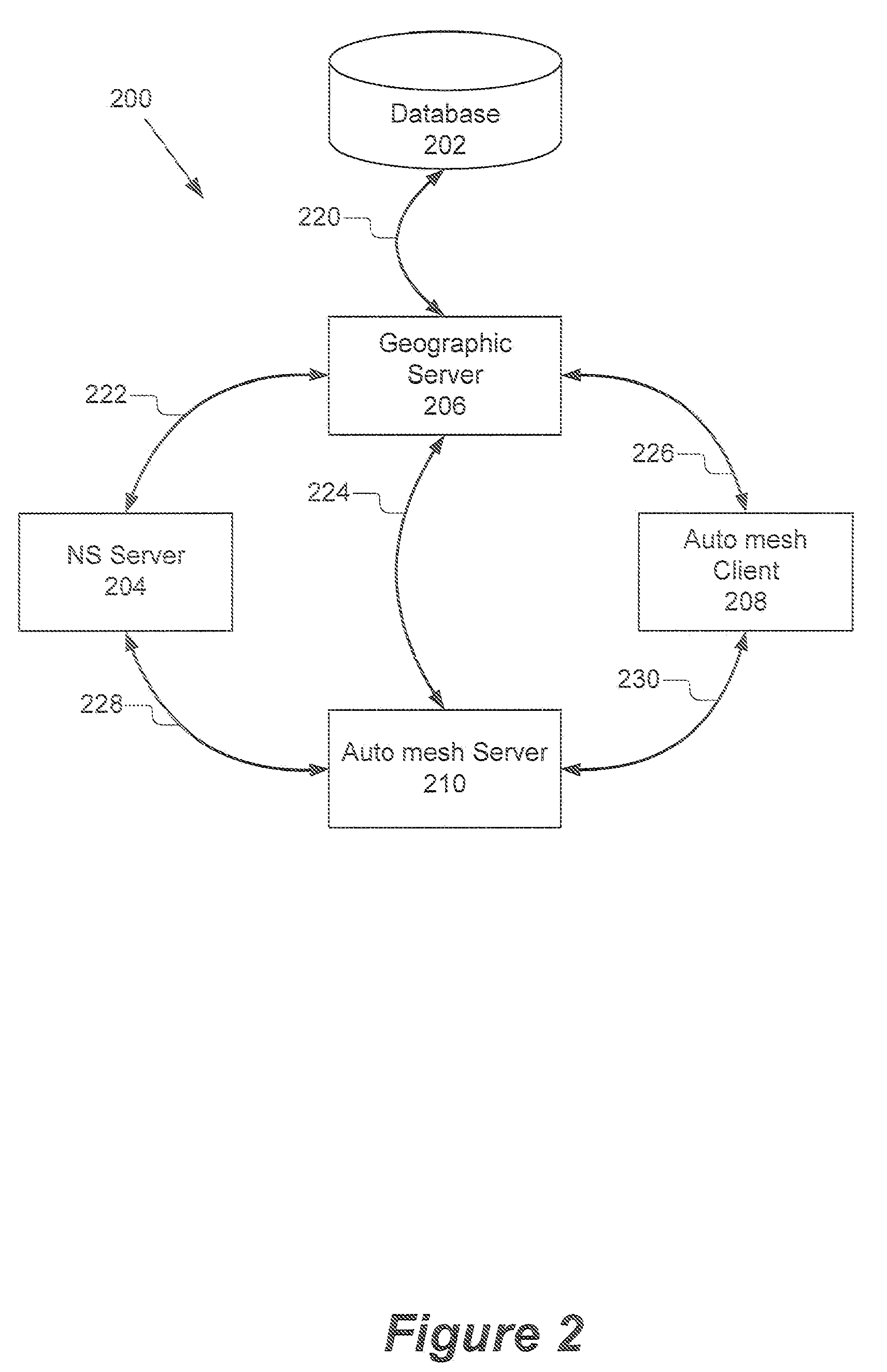

Simulator for Vehicle Radio Propagation Including Shadowing Effects

InactiveUS20070271079A1Transmission monitoringAnalogue processes for specific applicationsShadowingsTerrain

A simulator for inter-vehicle radio communication includes terrain and building data and can simulate the effects of buildings in terrain on radio propagation. The simulator also models other vehicles and the shadow effects of their presence. The system comprises a simulation engine, a network simulator, a driving simulator, a database and a user interface module adapted for communication. The simulation engine simulates the propagation of communication signals between vehicles including the effects of shadowing, and also receives data from the network simulator, the driving simulator and database to generate the propagation simulation. The simulation engine outputs the results of the propagation simulation to the user interface module which translates the information into various displays. The present invention is particularly advantageous because it provides a variety of different user interfaces to show the effective range / propagation of communication signals for different conditions including vehicle locations, terrain, vehicle movements, data traffic and networks configuration.

Owner:TOYOTA INFOTECHNOLOGY CENT CO LTD

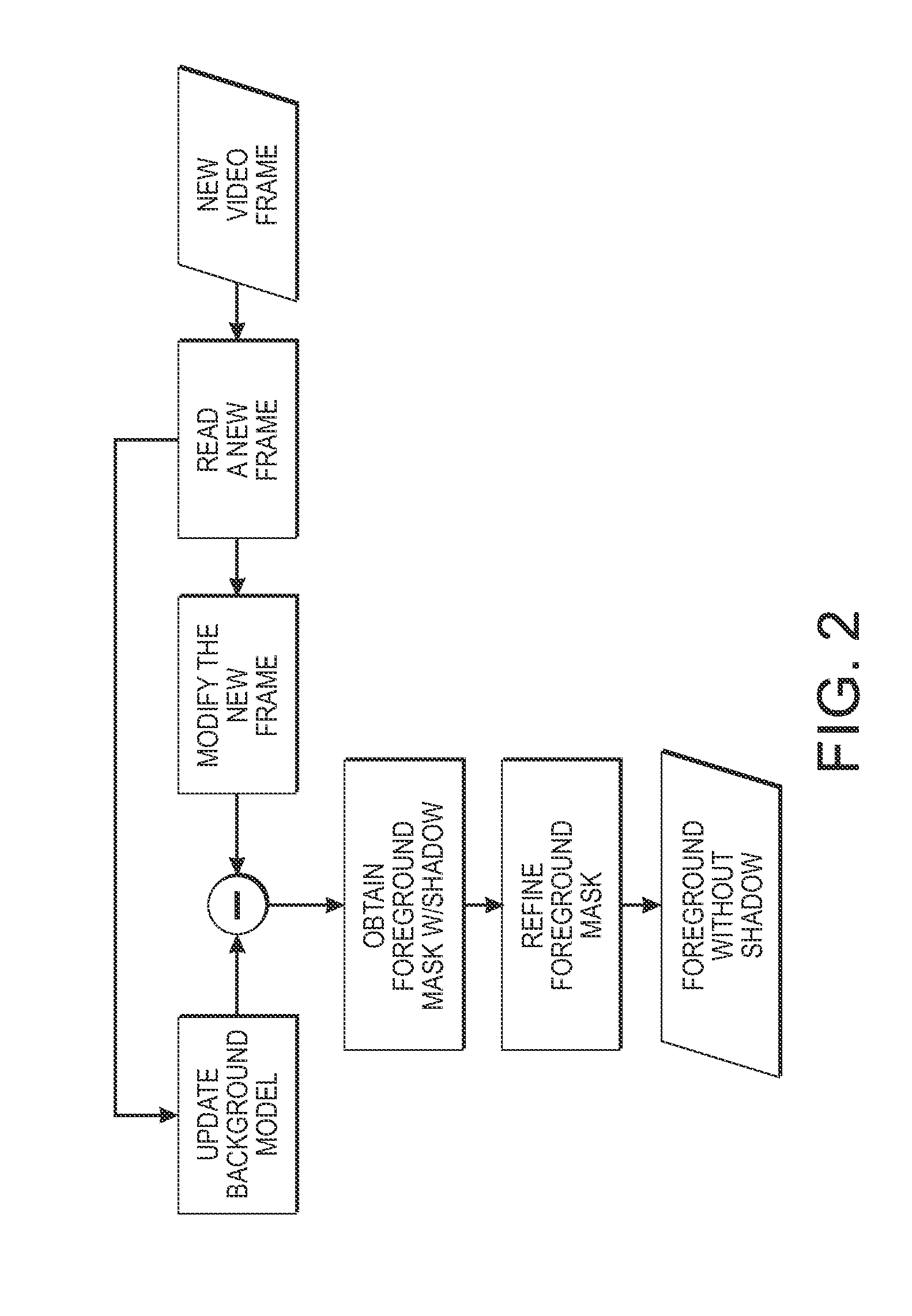

Method and apparatus for processing image of scene of interest

A method for processing an image of a scene of interest includes receiving an original target image of a scene of interest at an image processing device from an image source device, the original target image exhibiting shadowing effects associated with the scene of interest when the original target image was captured, the original target image comprising a plurality of elements and representing an instantaneous state for the scene of interest, pre-processing the original target image using a modification identification algorithm to identify elements of the original target image to be modified, and generating a copy mask with a mask region representing the elements to be modified and a non-mask region representing other elements of the original target image. An image processing device for processing an image of a scene of interest and a non-transitory computer-readable medium are also provided.

Owner:CONDUENT BUSINESS SERVICES LLC

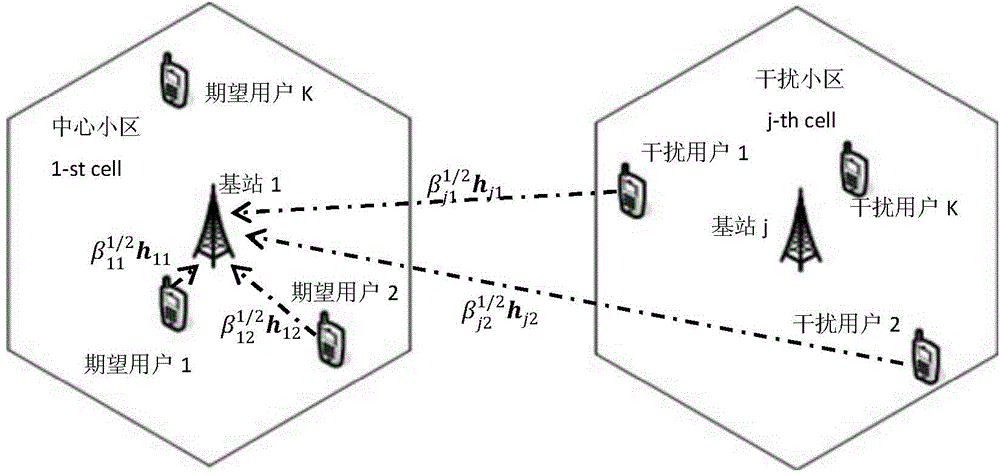

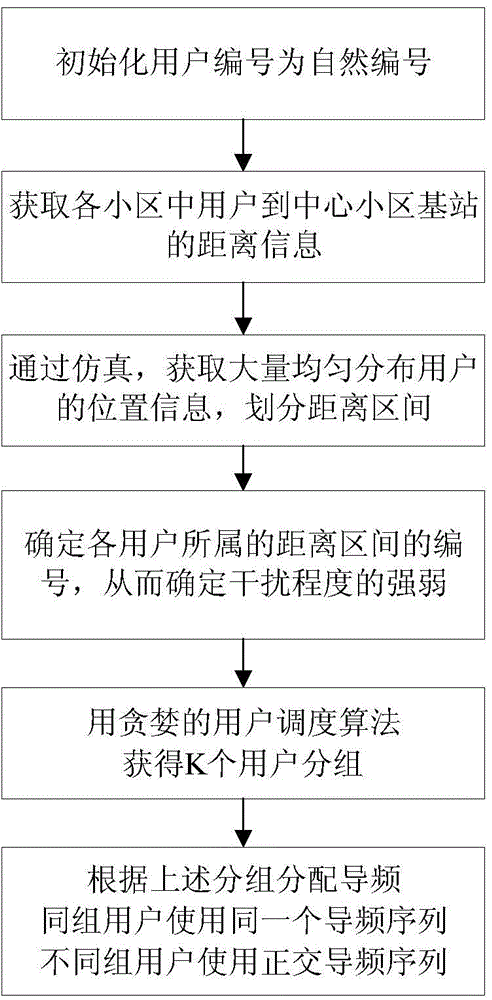

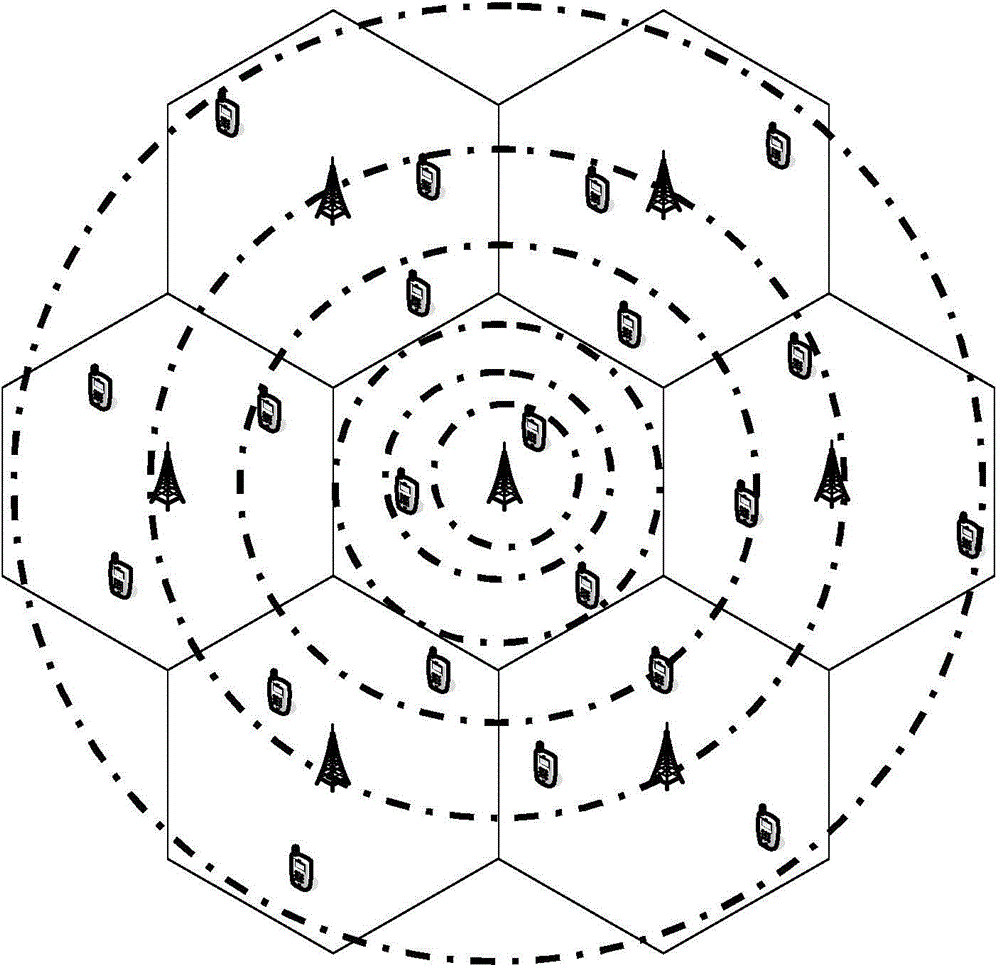

User location information based large-scale MIMO system pilot frequency distribution method

ActiveCN104393972APracticalImprove fairnessCriteria allocationPilot signal allocationDistribution methodShadow effect

A user location information based large-scale MIMO system pilot frequency distribution method comprises initializing user numbers to be natural numbers; obtaining information of distances from users in all communities to a base station in a central community; dividing distance sections through Monte-Carlo simulation; determining section numbers of the distances of all users, and determining the interfered degree of expectation users and the interfering degree of interfering users; performing user scheduling and obtaining user groups with SINR maximization as the criterion and using a greedy user scheduling algorithm; the base station performs pilot frequency distribution on all the groups. By the aid of the method, pilot frequency distribution is performed on user location information changing slowly along with time, and accordingly, the influence of pilot frequency pollution effect is reduced; by the method of user equivalence class division through the distance, the influence of shadow effect uncertainty on the interference degree is reduced effectively, and the pilot frequency distribution result robustness is improved.

Owner:SHANDONG UNIV

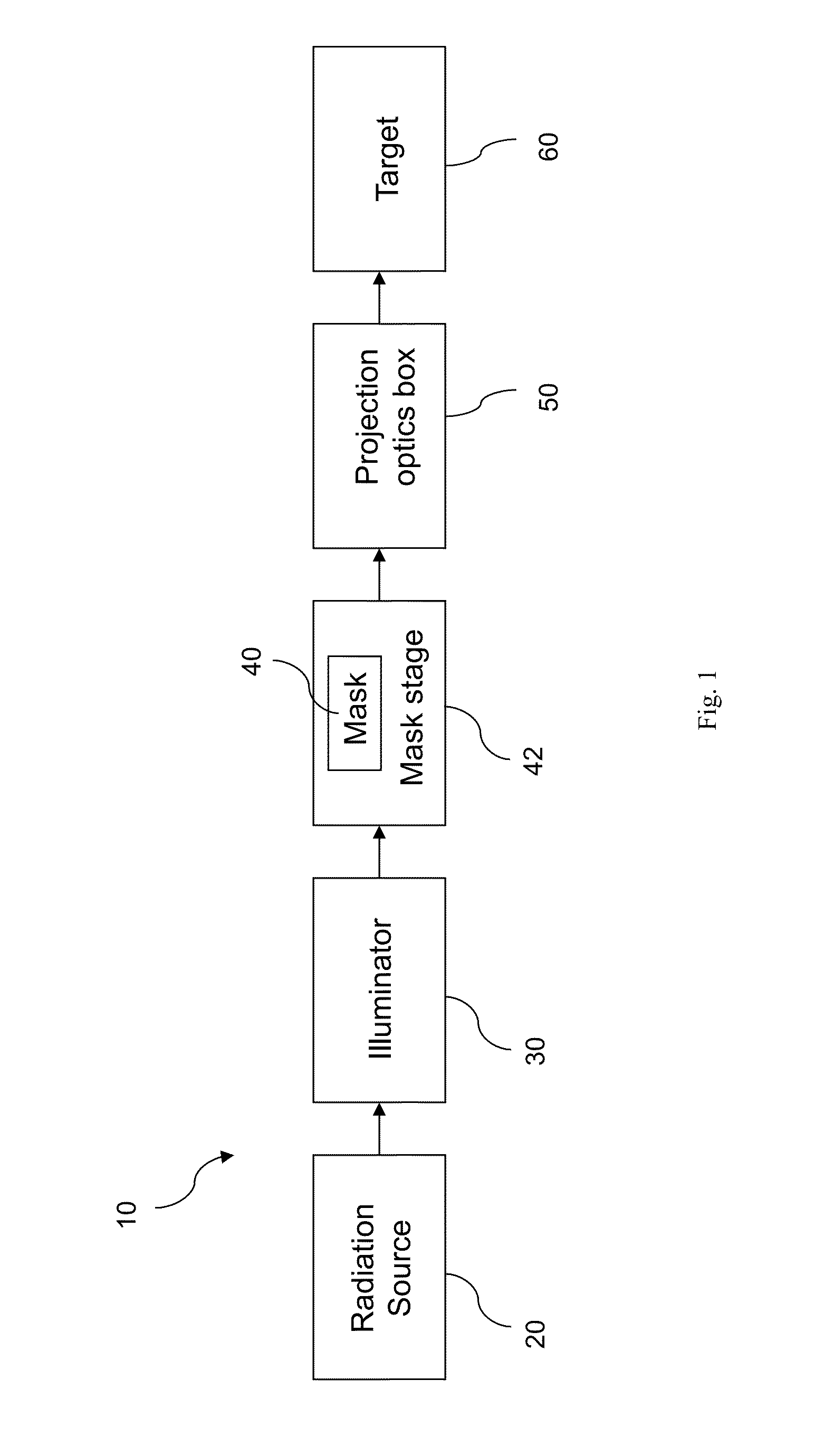

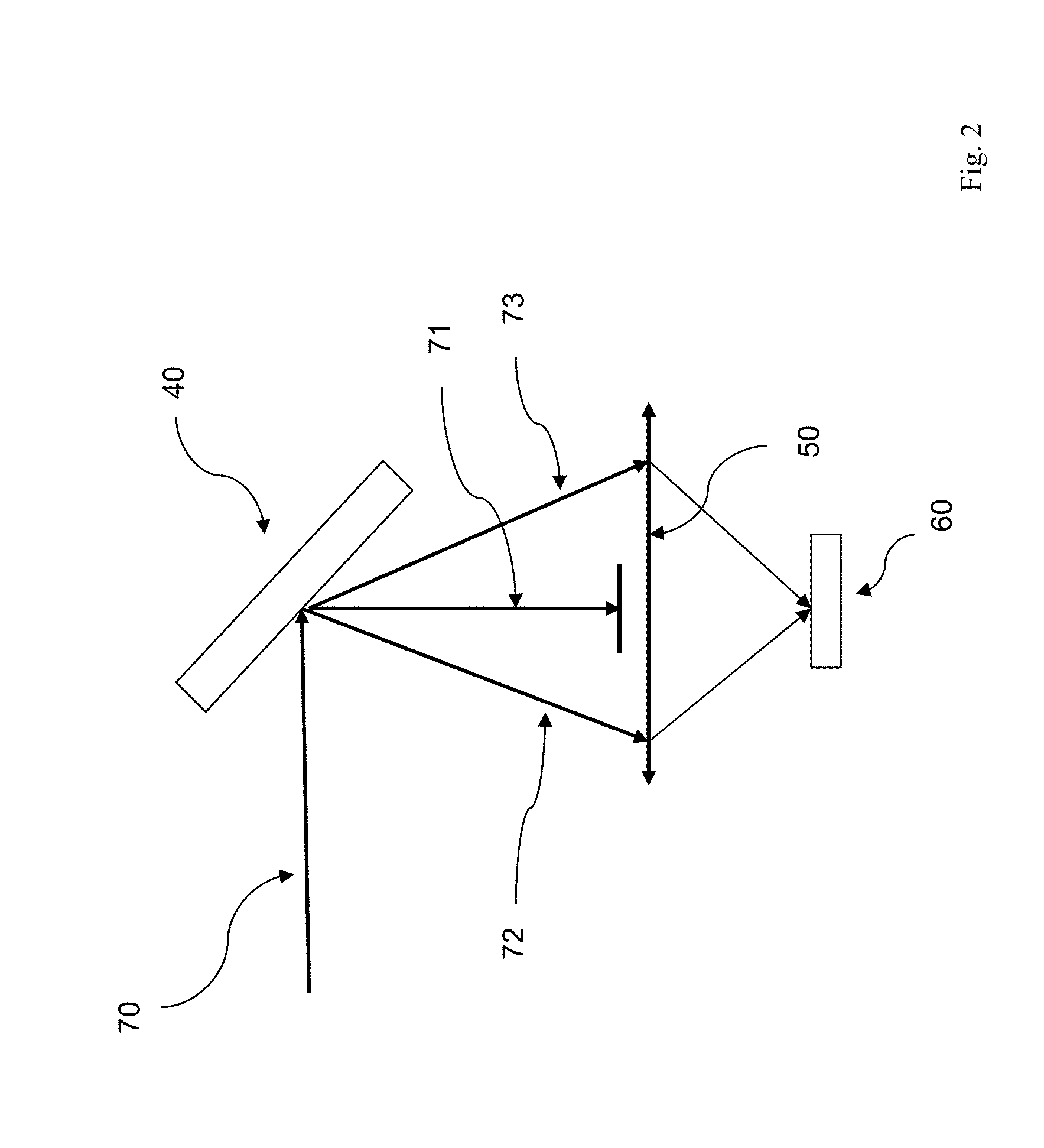

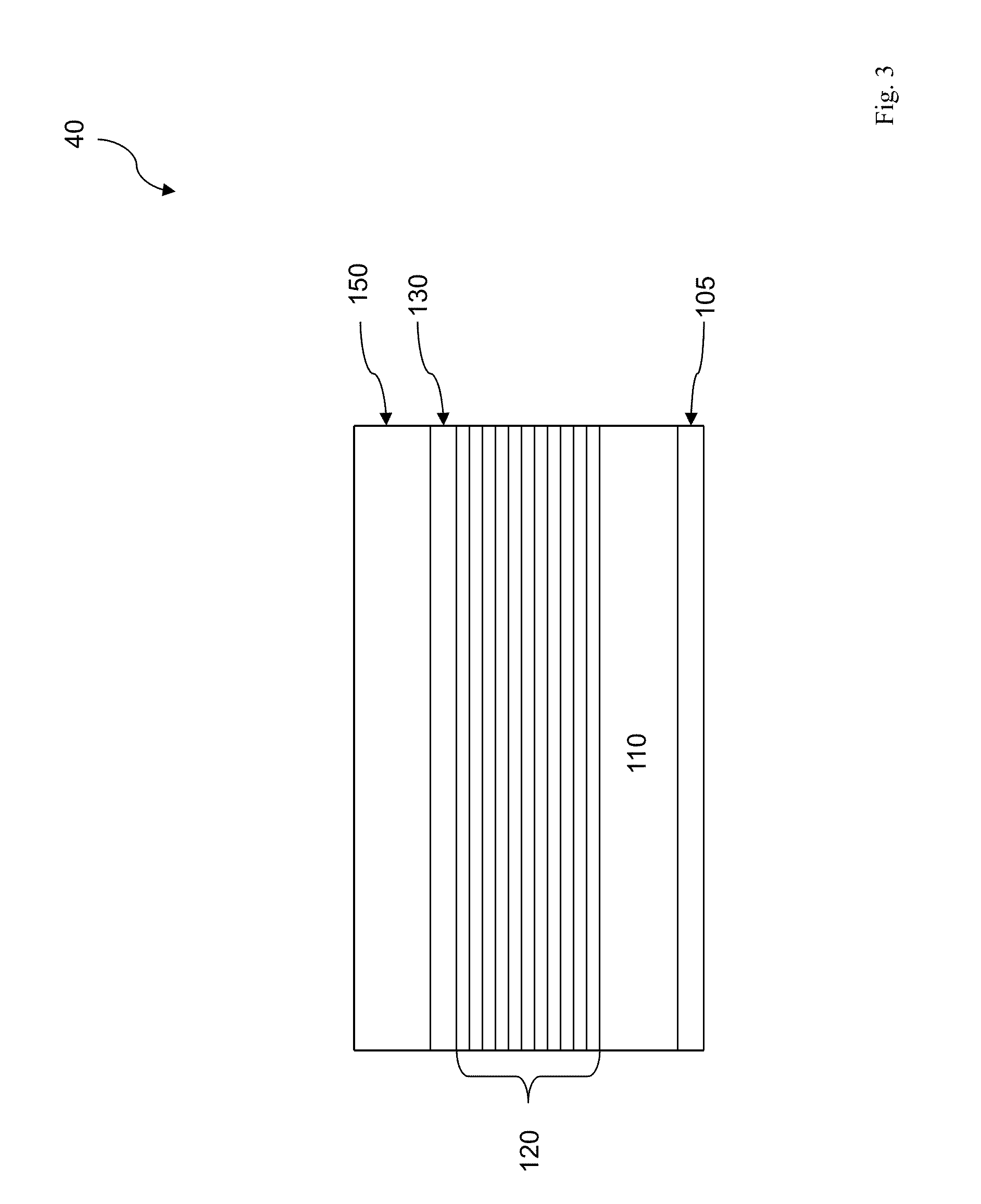

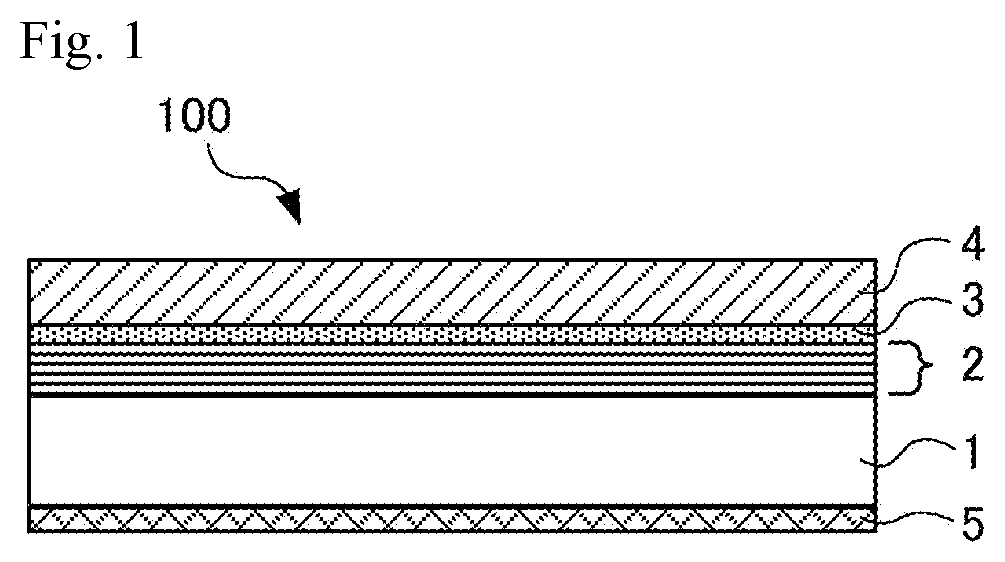

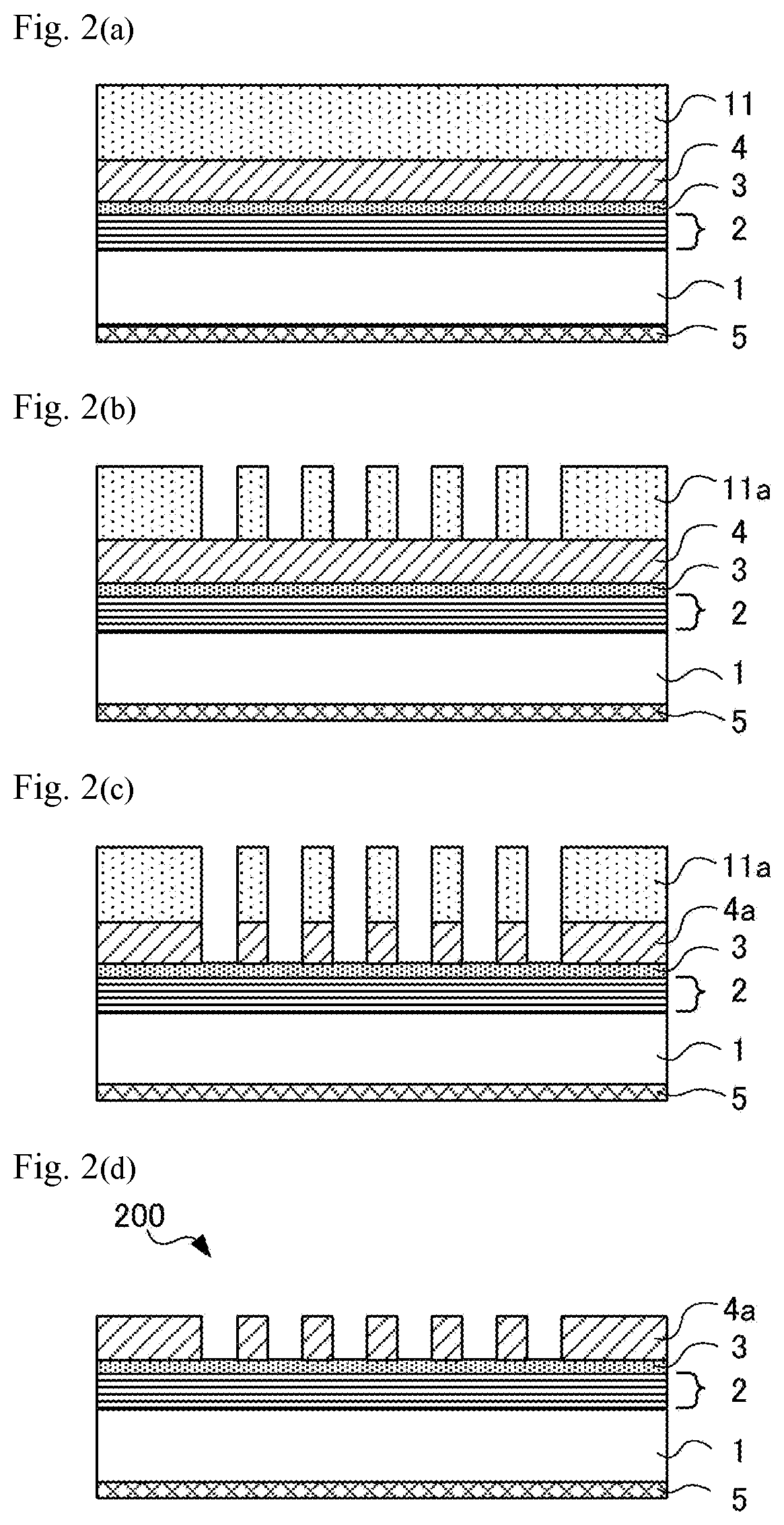

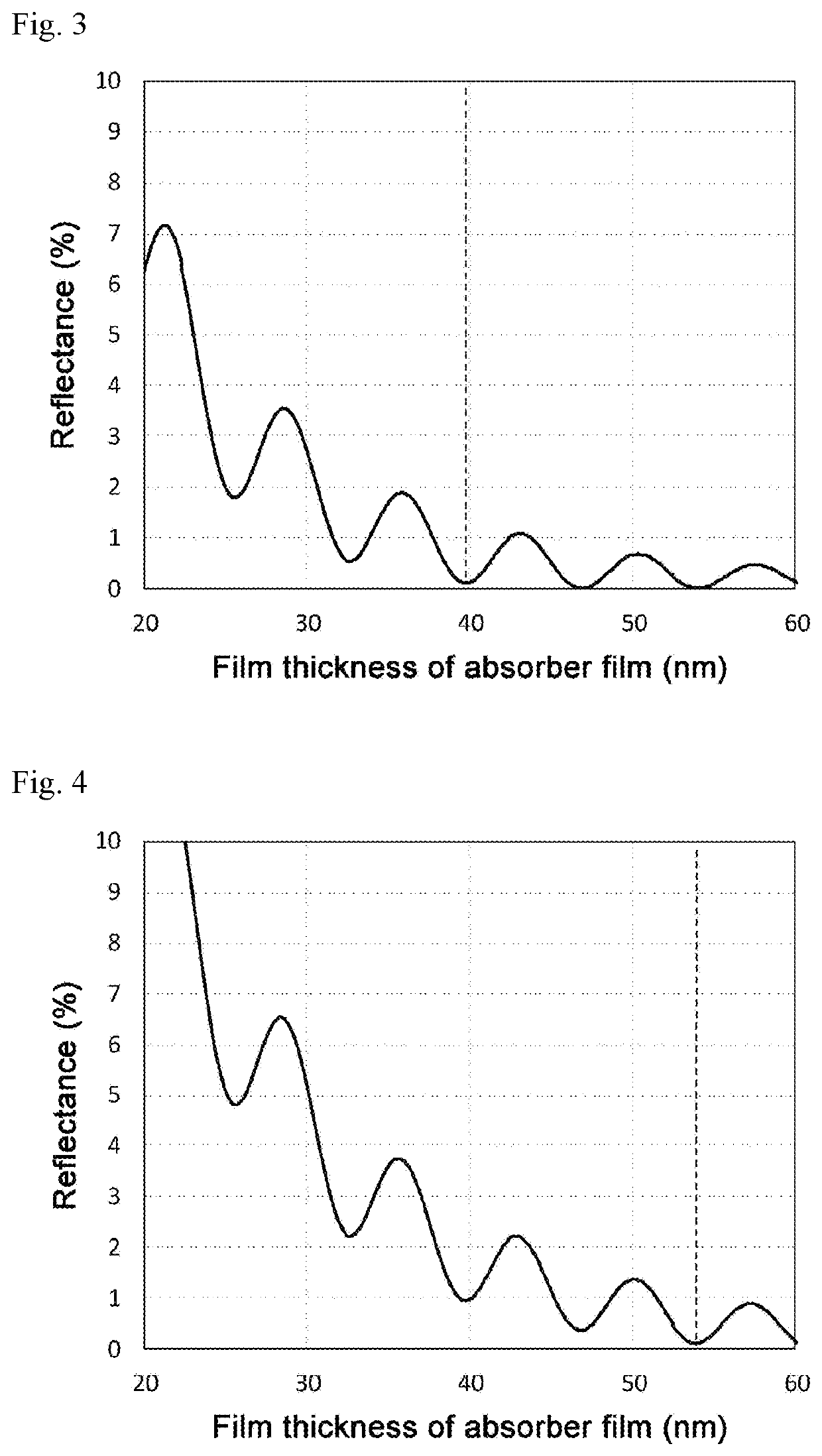

Extreme Ultraviolet Lithography Process and Mask with Reduced Shadow Effect and Enhanced Intensity

ActiveUS20160161839A1Semiconductor/solid-state device manufacturingPhotomechanical exposure apparatusPhase differenceReflective layer

A method of forming a mask for semiconductor fabrication is disclosed. The method includes providing a substrate and forming a first reflective layer over the substrate, wherein the first reflective layer comprises pairs of alternating materials. The method further includes forming a buffer layer over the first reflective layer and forming a second reflective layer over the buffer layer. The second reflective layer has a total thickness less than 90 nanometer (nm). The method further includes patterning the second reflective layer to form a first state and a second state of the mask. A first reflection coefficient of the first state and a second reflection coefficient of the second state have a phase difference of about 180 degrees.

Owner:TAIWAN SEMICON MFG CO LTD

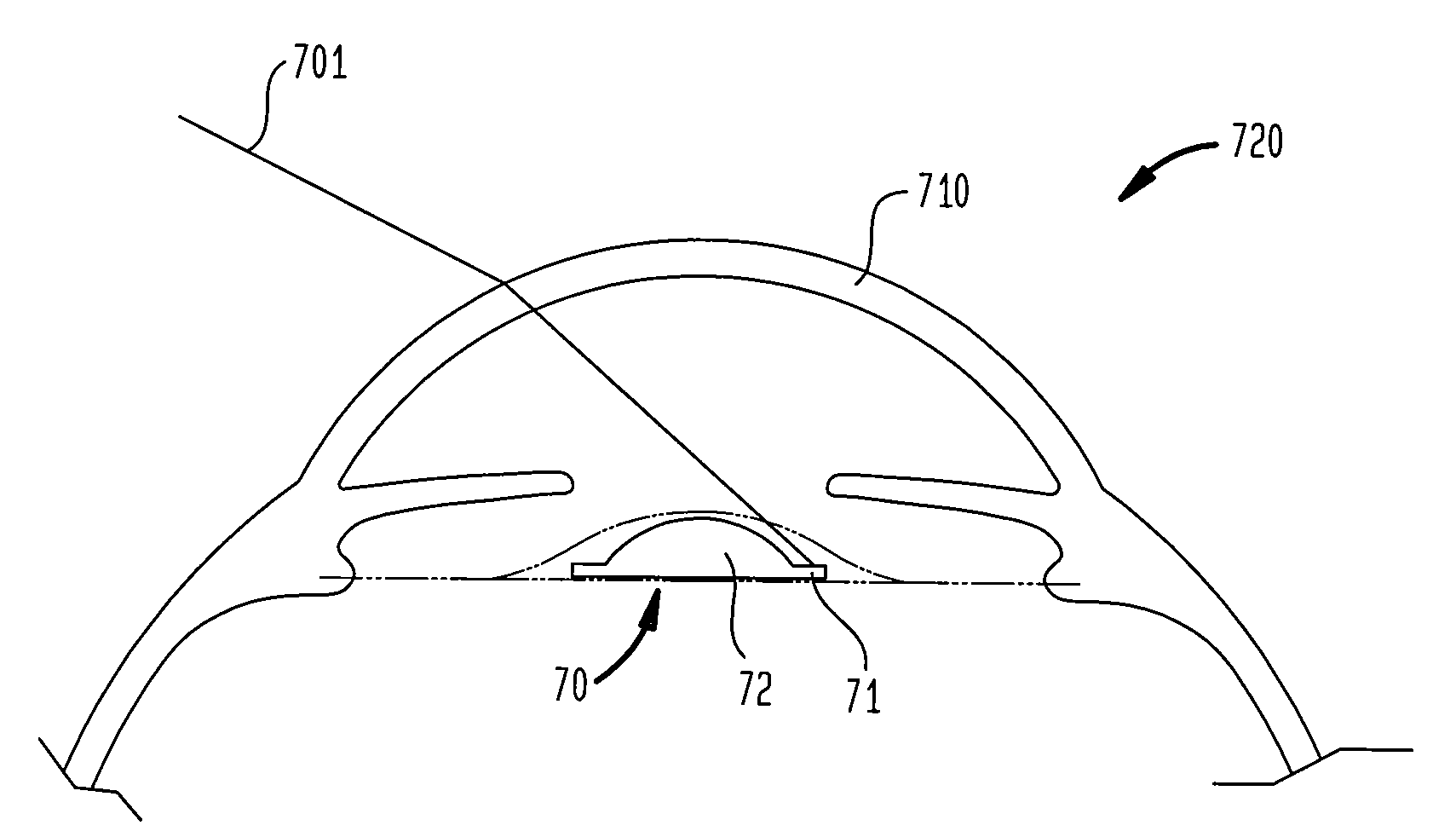

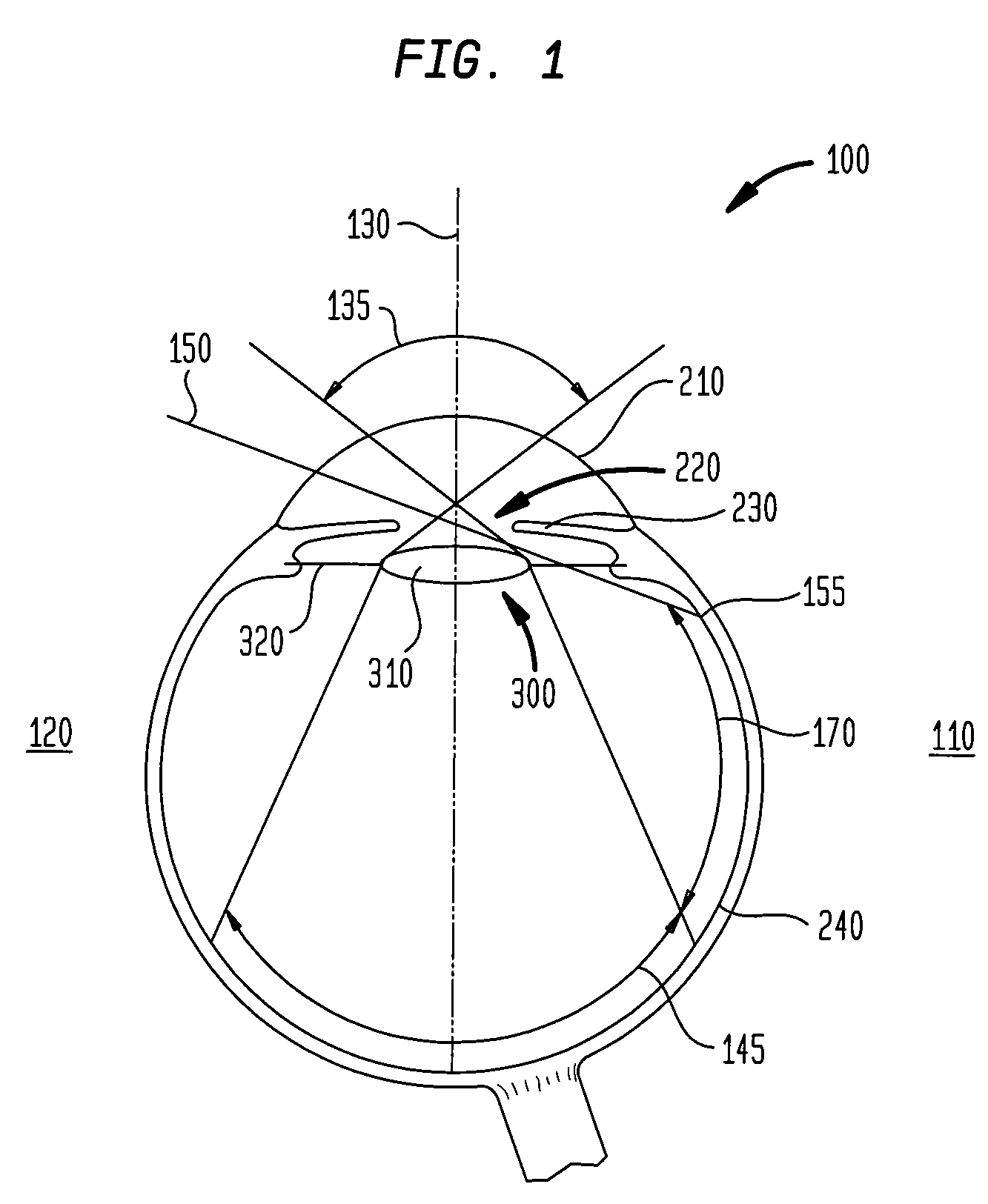

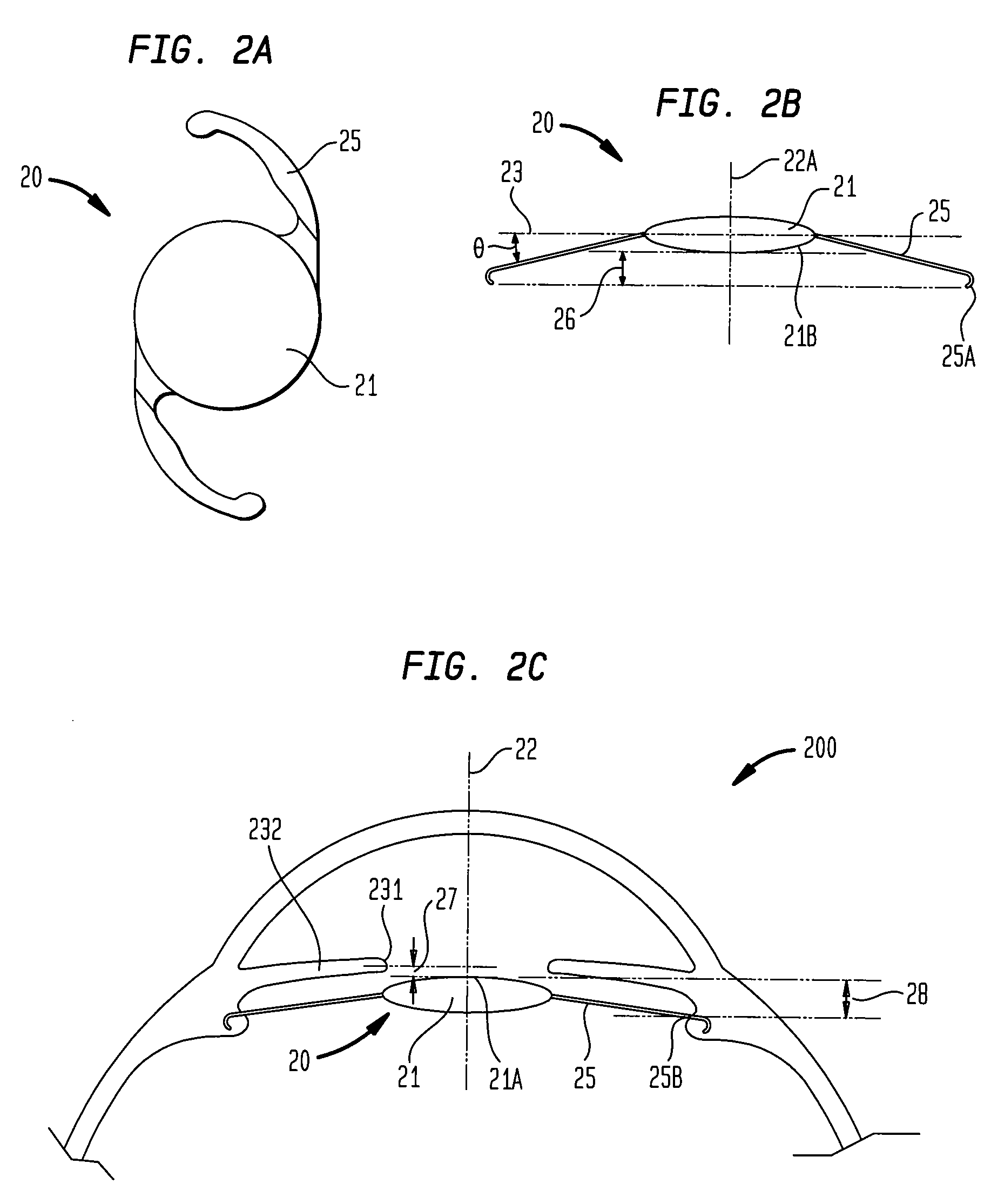

Ocular implant to correct dysphotopsia, glare, halos and dark shadow type phenomena

InactiveUS20080269883A1Reduce complicationsReduce the overall diameterIntraocular lensOphthalmologyVisual Disorders

Methods and devices for inhibiting the dark shadow effect, known as dysphotopsia, perceived by some subjects having implanted intraocular lenses (IOLs) are presented. In one aspect, an IOL can include an optic and one or more fixation members for facilitating placement of the IOL. The fixation member can be adapted to position the optic sufficiently close to the iris to inhibit dysphotopsia. As some examples, a fixation member can position an optic to within some distance of the tip of the iris, or the fixation member can be adapted to contact a portion of an eye posterior to an optic's posterior surface; or the fixation member can have an end that is posterior to a posterior surface of the optic. Various techniques for achieving these improvements among others are discussed, both in terms of the structures of improved IOLs, and methods for alleviating dysphotopsia.

Owner:NOVARTIS AG

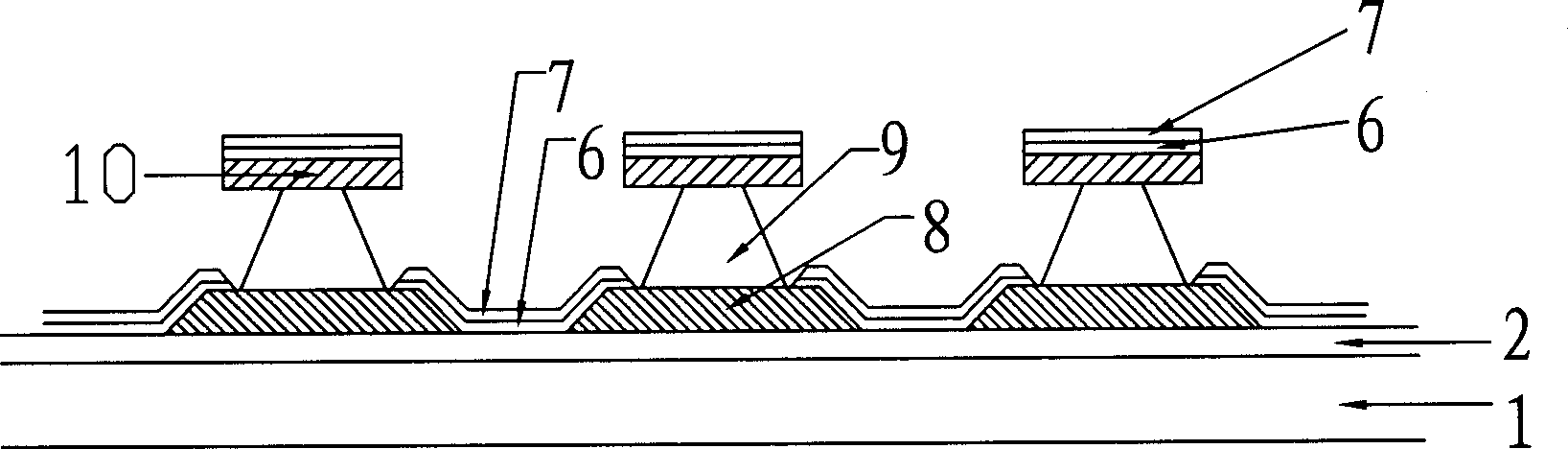

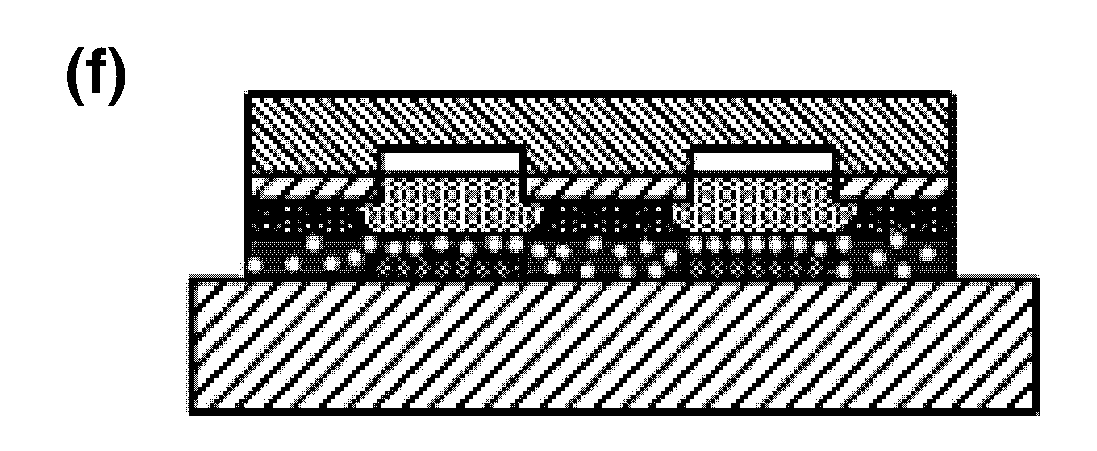

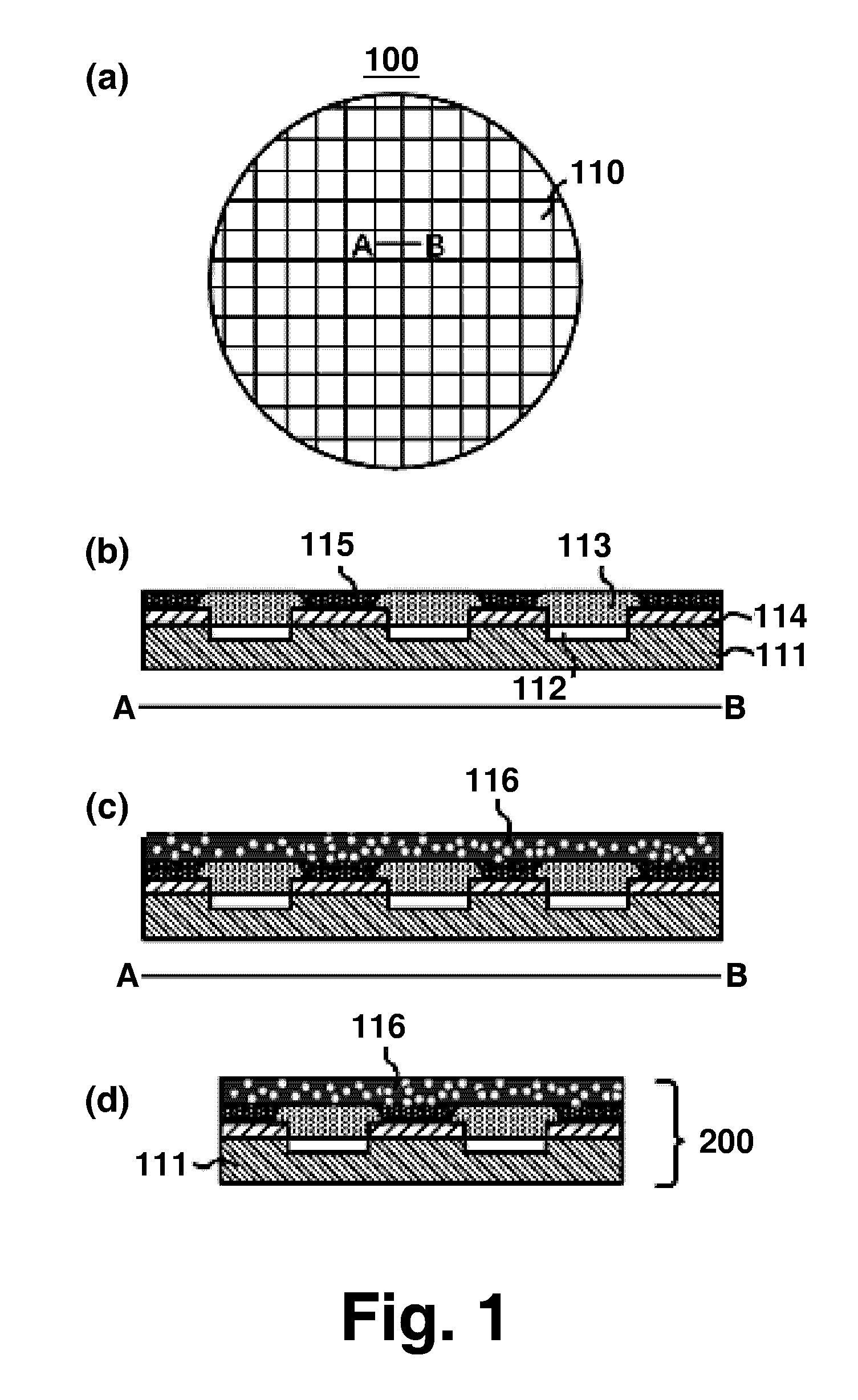

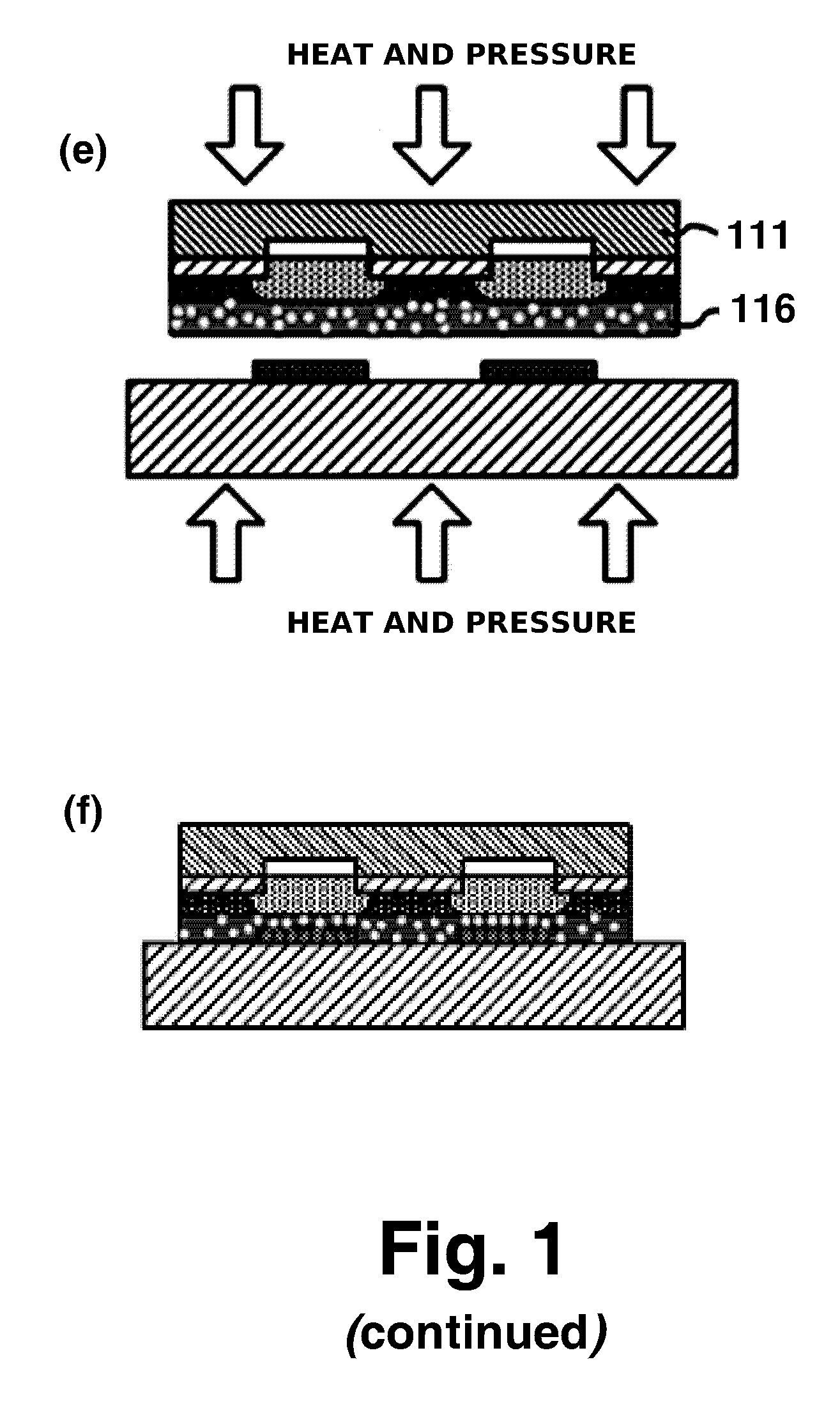

Wafer-level aca flip chip package using double-layered aca/nca

InactiveUS20090029504A1Reduce shadowing effectHigh selectivitySolid-state devicesSemiconductor/solid-state device manufacturingAnisotropic conductive adhesiveEngineering

A method of manufacturing a wafer-level flip chip package is capable of being used to produce a flip chip package by directly coating a flip chip package using anisotropic conductive adhesives (ACA) and non conductive adhesives (NCA) in a solution state as a double layer on a wafer. The method can be used to manufacture a non-conductive mixed solution and a conductive mixed solution and directly coat them on a substrate, such that it is possible to: increase productivity; simplify a manufacturing process; suppress a shadow effect; easily perform thickness control that is difficult with the anisotropic conductive adhesive paste or the non-conductive adhesive paste; and obtain the non-conductive layer and the anisotropic conductive layer in an initial state of a B-stage with a level not losing latent of hardening through a simple drying process to volatilize an organic solvent. Above all, the non-conductive layer and the anisotropic conductive layer is sequentially stacked on the substrate formed with the non-solder bump, making it possible to make the selectivity of electrical conduction and the stability of a connection process excellent, shorten process time and costs, and dramatically reduce consumption of the conductive particles which account for a large portion of total production costs.

Owner:KOREA ADVANCED INST OF SCI & TECH

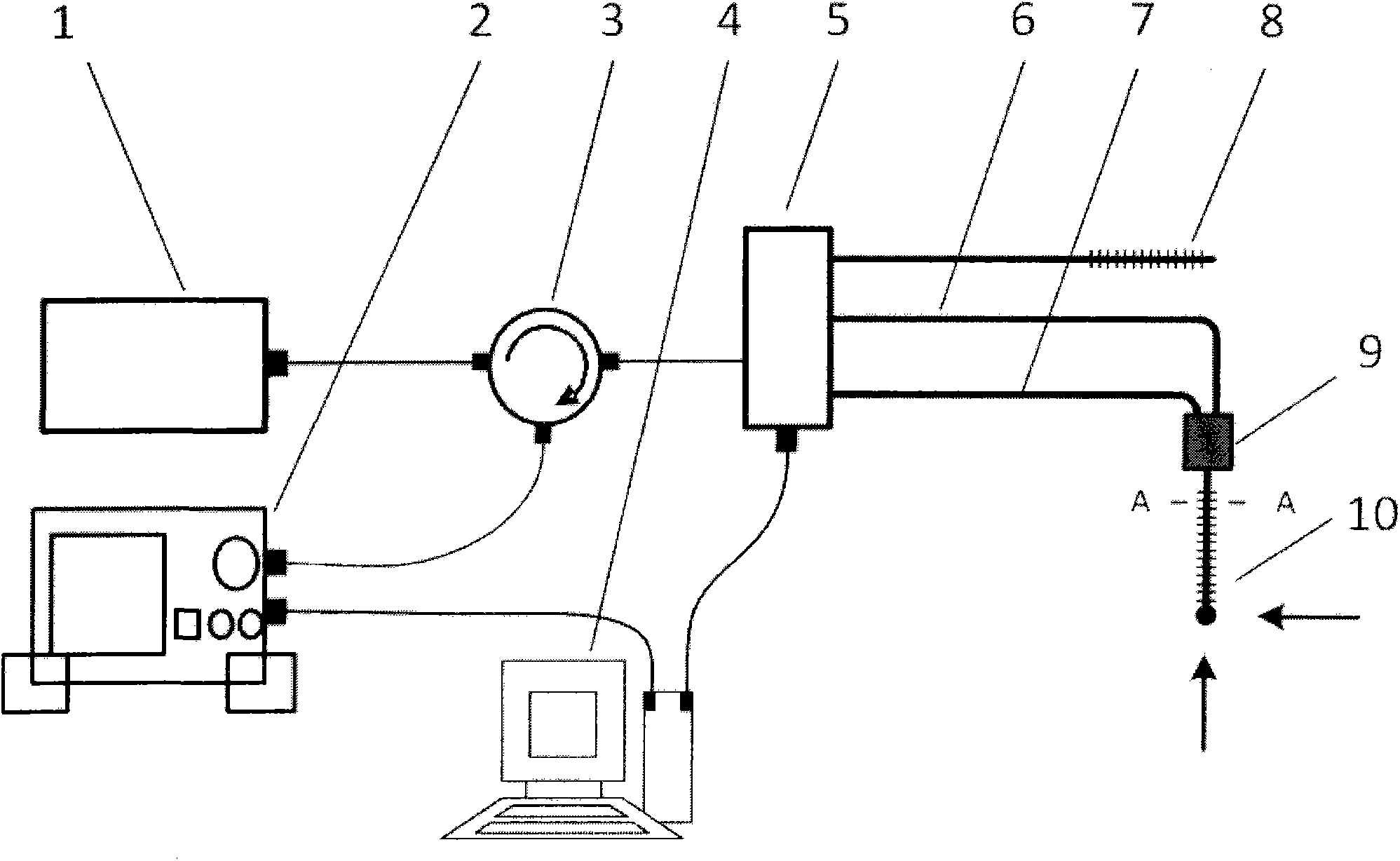

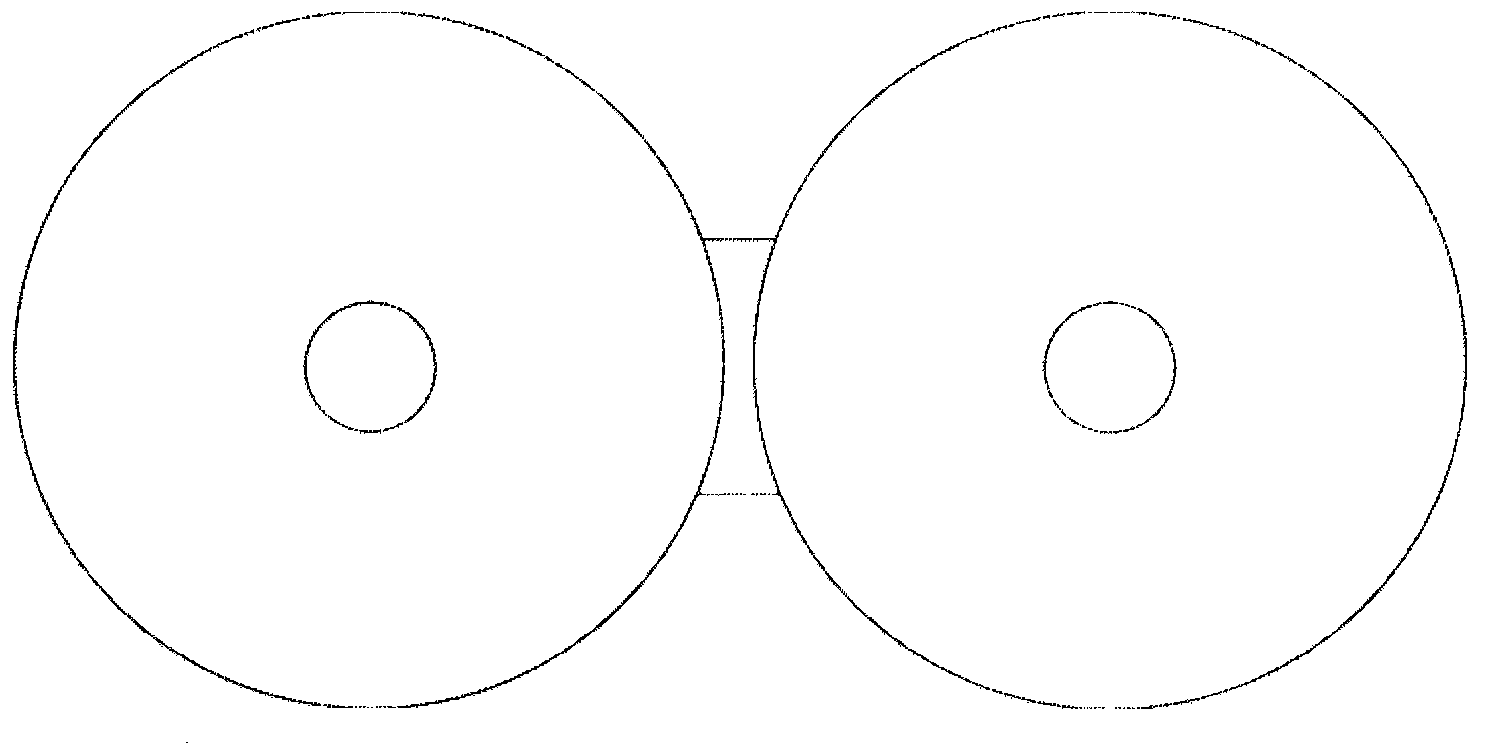

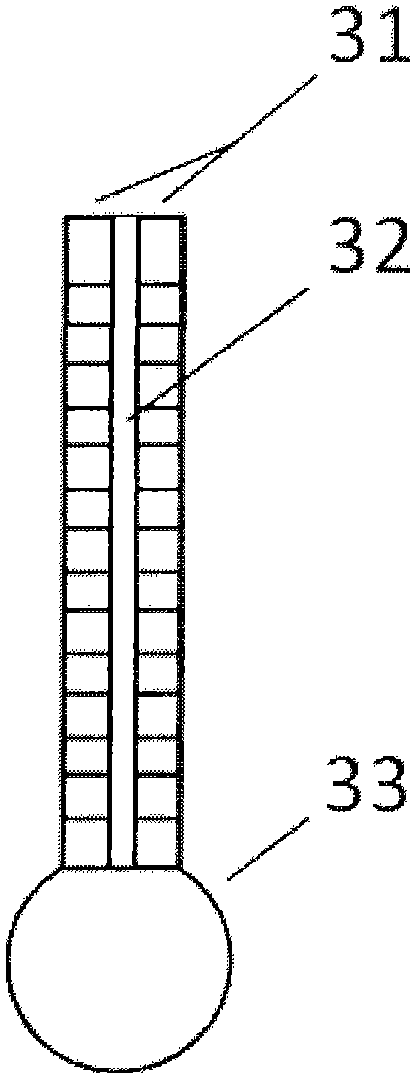

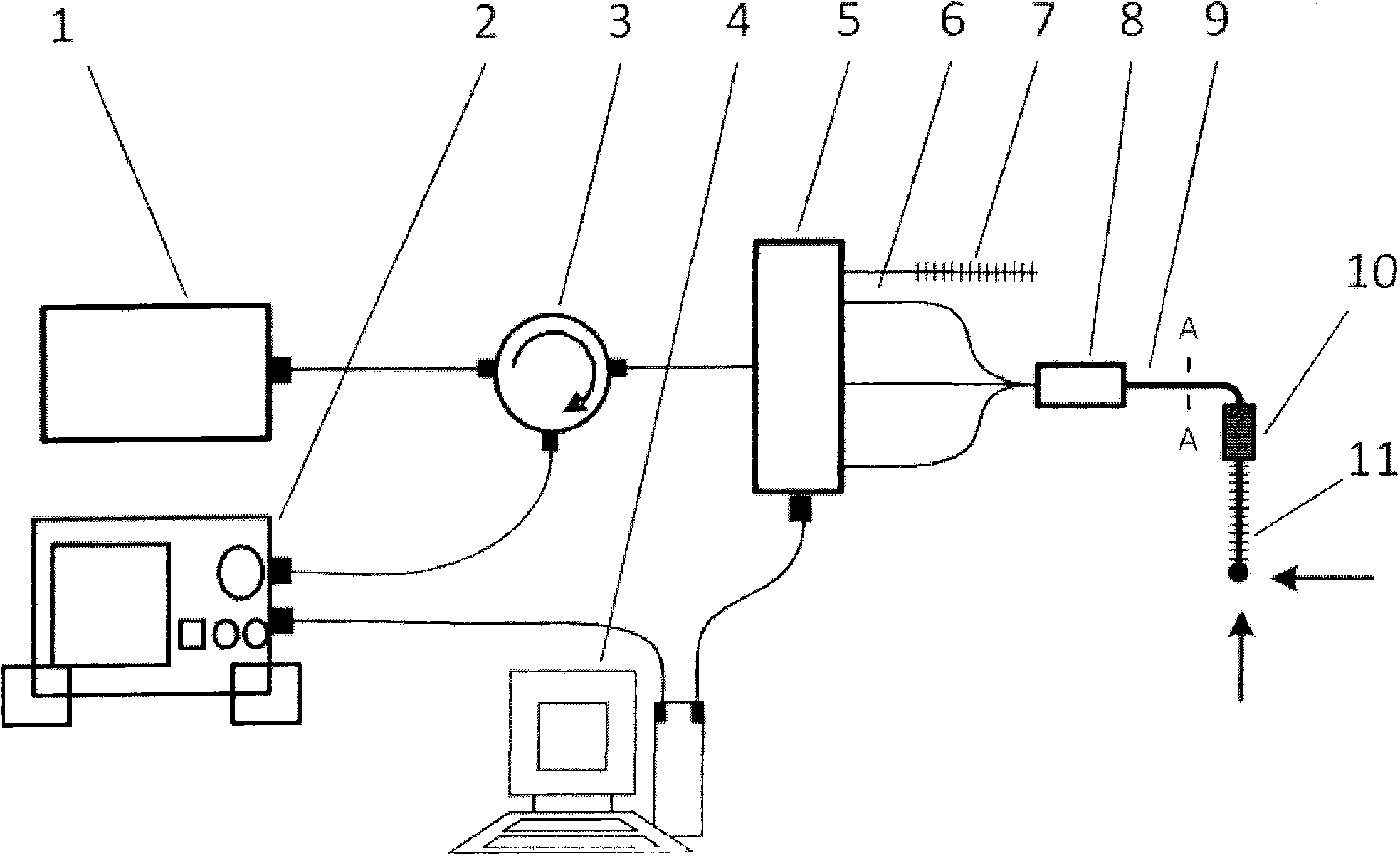

Two-dimensional microscale measuring device and method based on double fiber bragg gratings

Owner:HARBIN INST OF TECH

Reflective mask blank, reflective mask and manufacturing method thereof, and semiconductor device manufacturing method

ActiveUS20190384157A1Fine and highly accurate absorber patternStable cross-sectional shapePhotomechanical apparatusSemiconductor/solid-state device manufacturingLithographic artistShadow effect

Provided are a reflective mask blank and a reflective mask, which are able to reduce the shadowing effects of EUV lithography and form a fine pattern. As a result, a semiconductor device can be stably manufactured with high transfer accuracy. The reflective mask blank comprises a multilayer reflective film and an absorber film in that order on a substrate, and the absorber film comprises a material comprising an amorphous metal comprising at least one or more elements among cobalt (Co) and nickel (Ni).

Owner:HOYA CORP

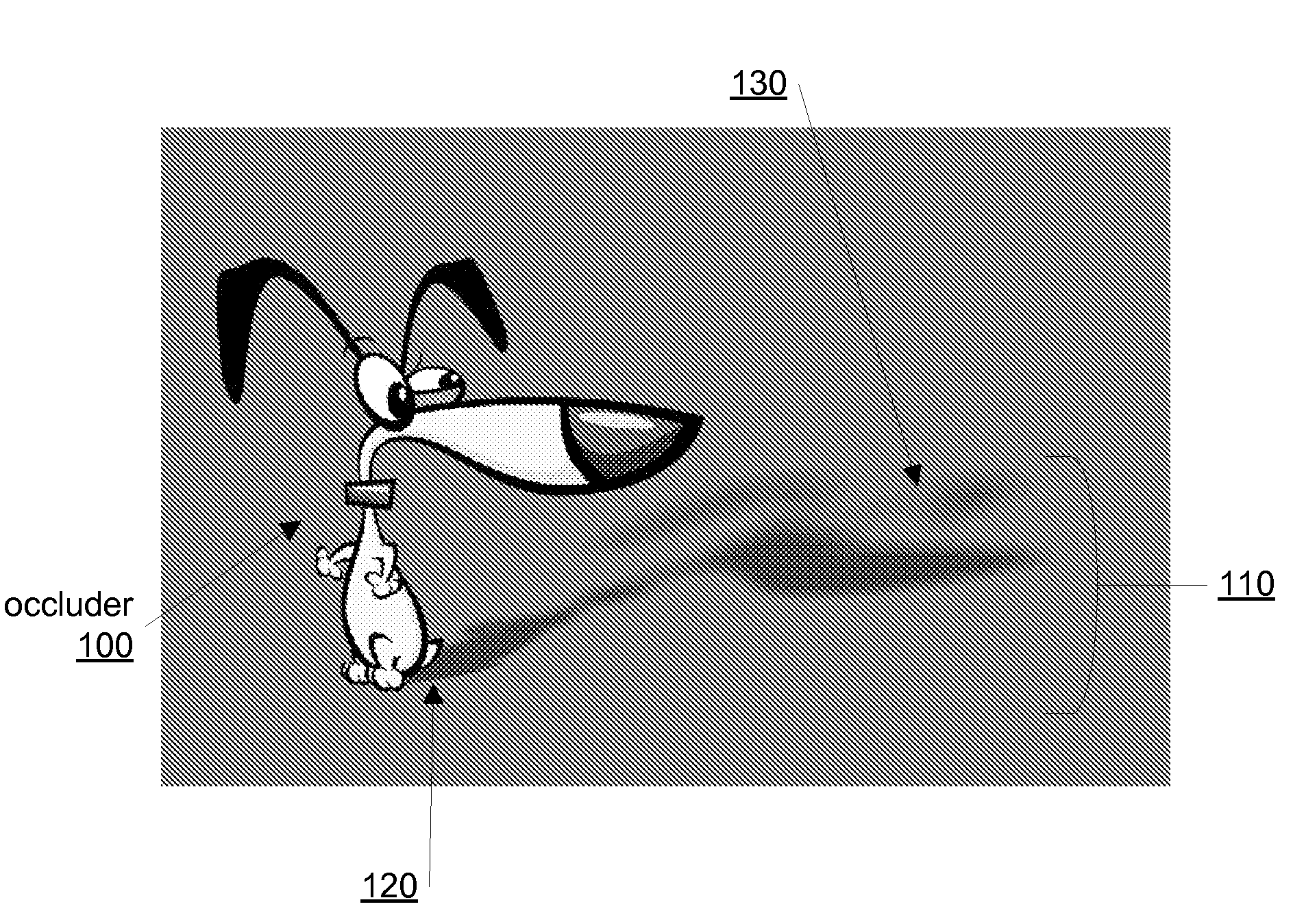

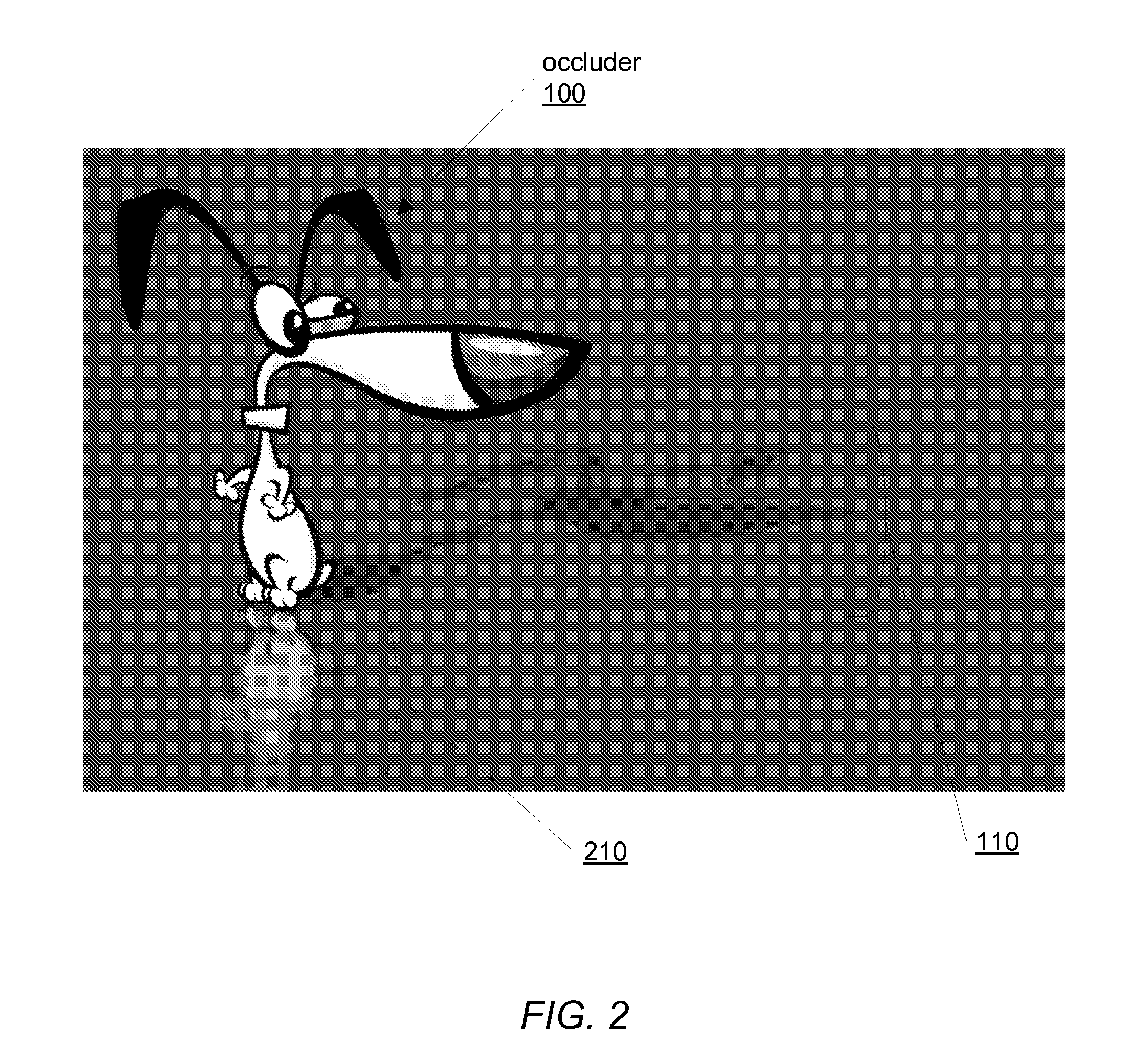

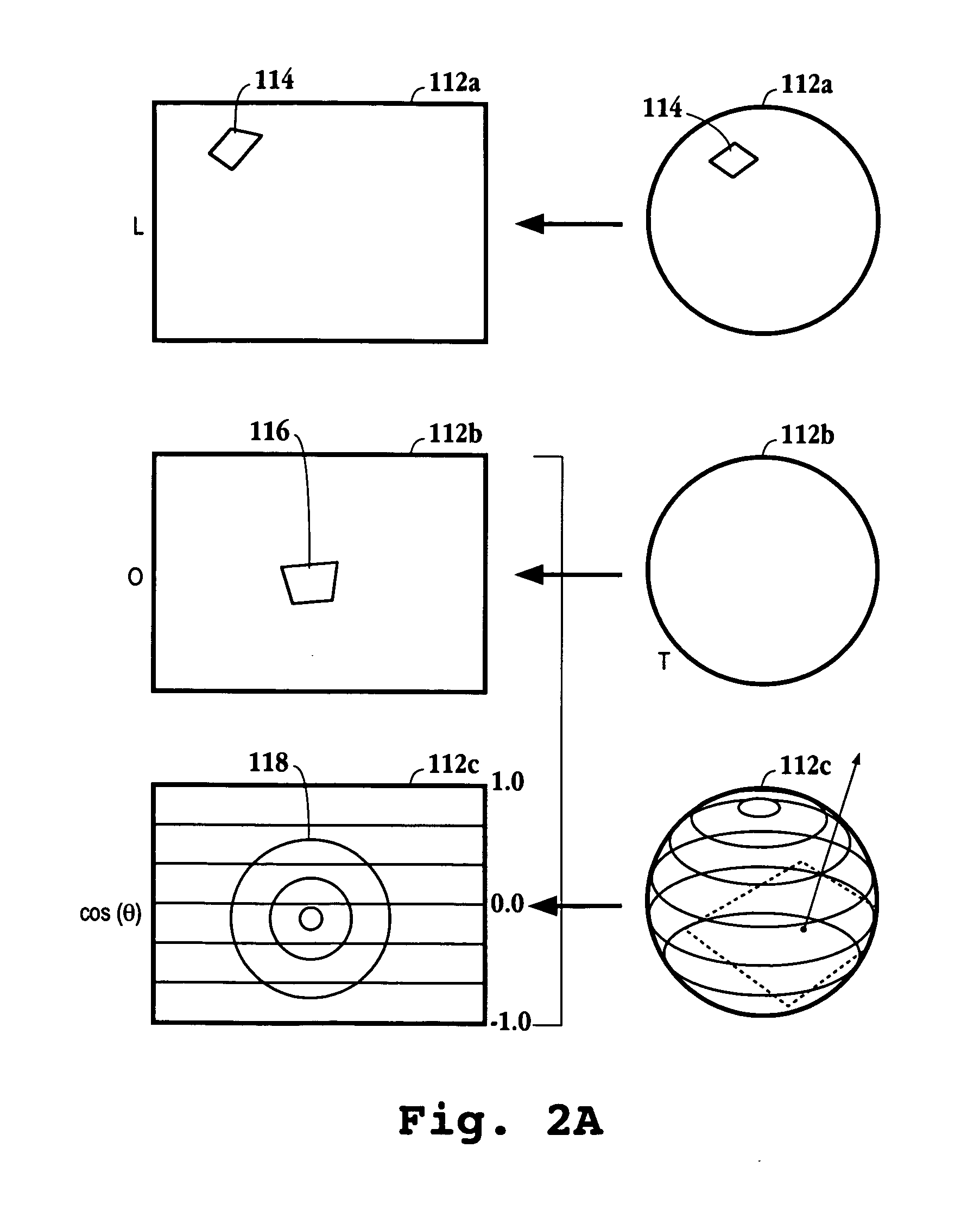

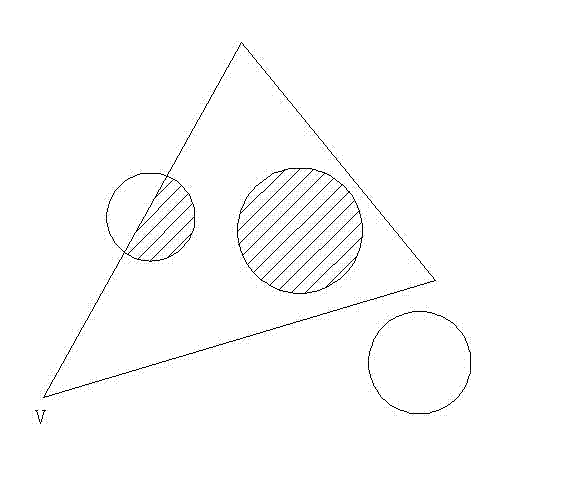

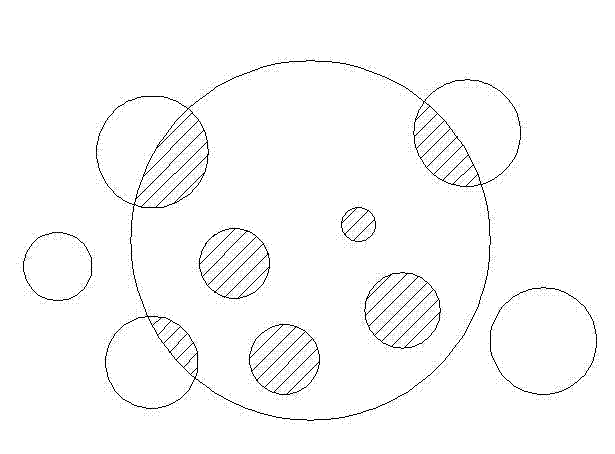

Spatially-Varying Convolutions for Rendering Soft Shadow Effects

ActiveUS20090033661A1Enhance interestImprove usabilityCathode-ray tube indicators3D-image renderingConvolution filterLinear filter

Soft shadows may include areas that are less clear (more blurry) than other regions. For instance, an area of shadow that is closer to the shadow caster may be clearer than a region that is farther from the shadow caster. When generating a soft shadow, the total amount of light reaching each point on the shadow receiving surface is calculated according to a spatially-varying convolution kernel of the occluder's transparency information. Ray-tracing, traditionally used to determine a spatially varying convolution, can be very CPU intensive. Instead of using ray-tracing, data structures, such as MIP-maps and summed-area tables, or separable linear filters may be used to compute the spatially-varying convolution. For example, a two-dimensional convolution may be computed as two spatially-varying, separable, linear convolution filters—one computing a horizontal component and the other a vertical component of the final 2D convolution.

Owner:ADOBE SYST INC

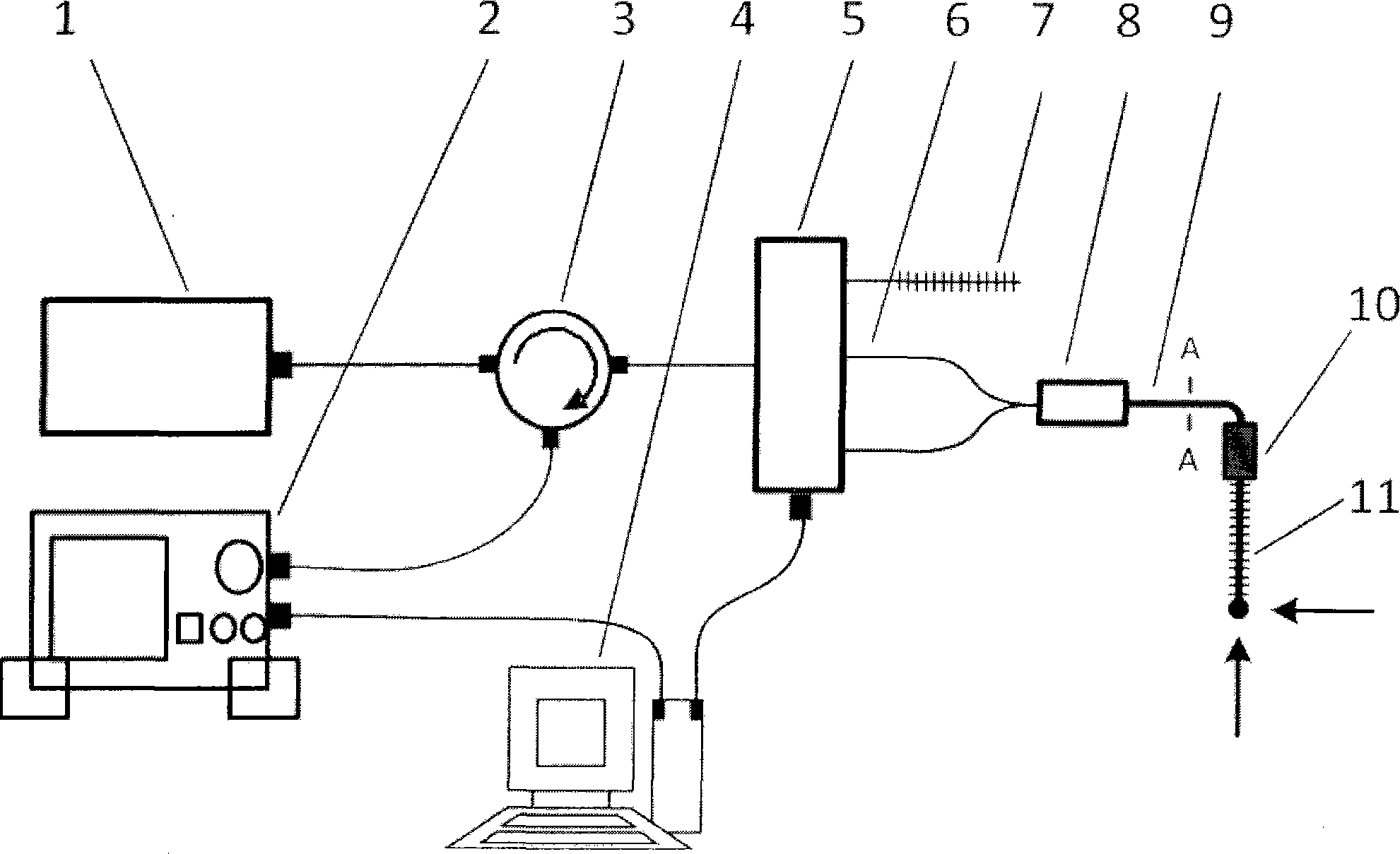

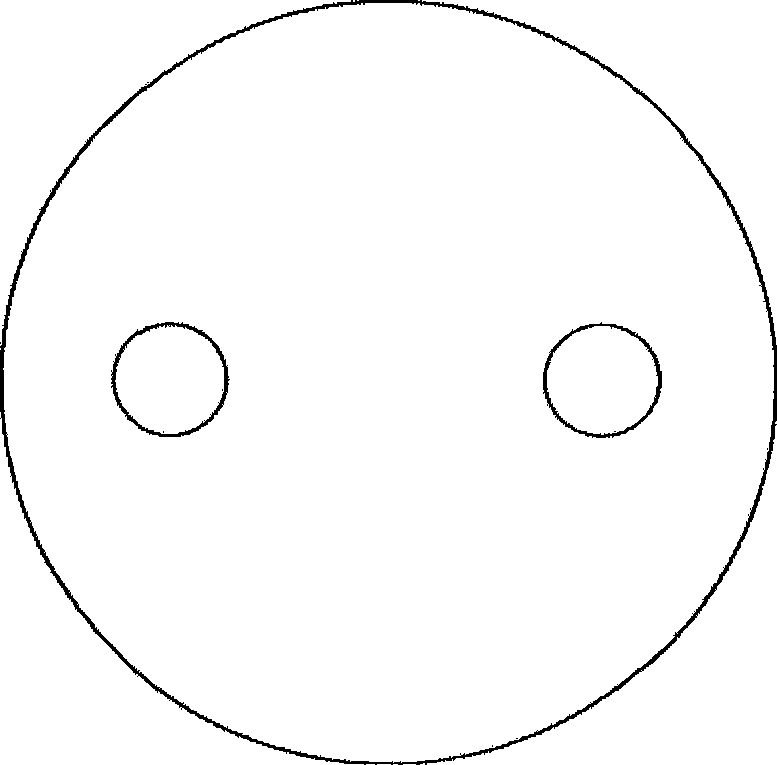

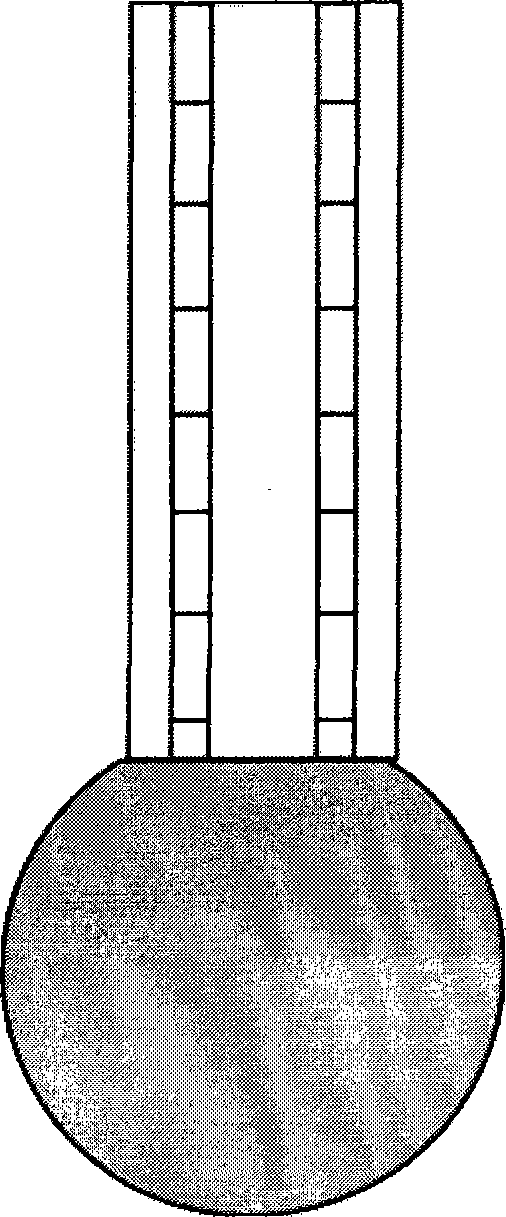

Two-dimensional microscale measuring device and method based on three-core fiber bragg grating

The invention belongs to the technical field of precision instrument manufacture and measurement and provides a two-dimensional microscale measuring device and method based on a three-core fiber bragg grating. The device comprises a wideband light source, a spectrum analyzer, an optical circulator, a control computer, a multiplex photoswitch and an external reference grating. The multiplex photoswitch is communicated with a three-core optical fiber fan-out device through three single mode optical fibers respectively. One end of the three-core optical fiber is connected to the three-core optical fiber fan-out device, a three-core fiber bragg grating probe is fixedly arranged at the other end of a three-core fiber through a probe clamping device, and the three-core fiber and the three-core fiber bragg grating probe are connected to form a channel. The method comprises the following steps that the control computer controls the multipath photoswitch to switch optical paths, the spectrum analyzer is utilized to respectively measure reflectance spectrums of the fiber bragg grating, and two-dimensional microscale measurement of non-temperature coupling is achieved by utilizing the differential data processing algorithm. The two-dimensional microscale measuring device has the advantages of being high in precision, small in contact force and not influenced by the shadowing effect. In addition, the service life of the probe is long.

Owner:HARBIN INST OF TECH

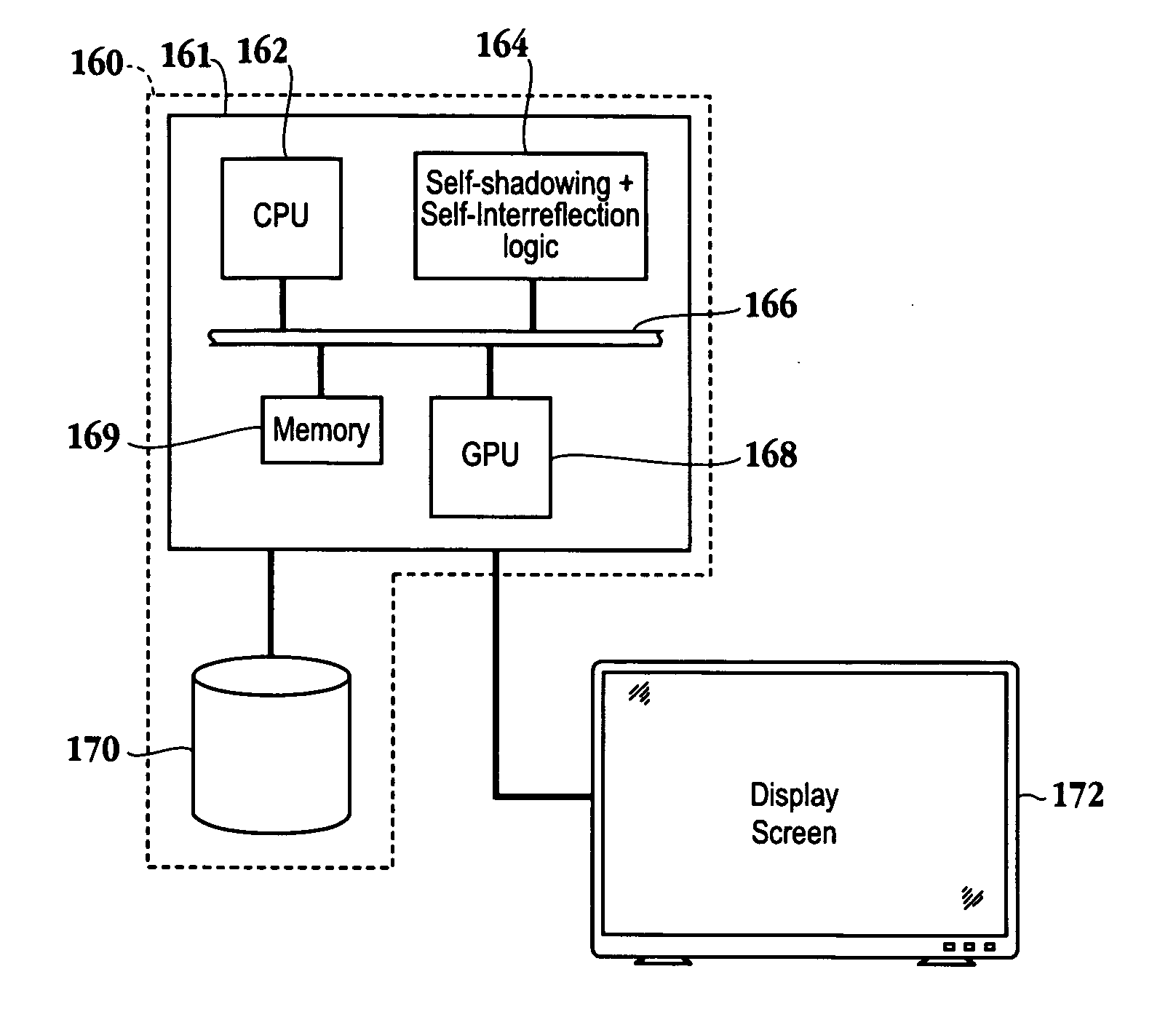

Method and apparatus for self shadowing and self interreflection light capture

ActiveUS20050041023A1Simplifies lighting functionMinimal computationCathode-ray tube indicators3D-image renderingSpatial correlationComputer graphics (images)

A method for rendering an image with high resolution lighting characteristics is provided. The method initiates with generating a texture map associated with the image. The texture map is defined by texels. Then, a value representing a lighting characteristic for each of the texels is calculated. Next, the value is stored. Then, a coordinate space of the texture map is associated with a display screen coordinate space. Next, the image is rendered on a display screen using the stored value. A method for incorporating the lighting characteristics of an image into a texture map is also provided. A computing device and integrated circuit both configured to present real time shadowing effects are also provided.

Owner:SONY COMPUTER ENTERTAINMENT INC

Real-time soft shadow rendering method for point light sources

InactiveCN102768765ASoften edge detailsSave computing resources3D-image renderingShadowingsPoint light

The invention discloses a method based on cubic texture shadow mapping in order to overcome the shortcomings that shadow edges are ubiquitously too hard in shadow mapping at present, and real soft shadows cannot be achieved. The shadow edges are softened in a special optimization mode, jags are eliminated, and satisfactory soft shadow effects of point light sources are achieved. The method includes the steps: judging whether the point light sources in a scene are visual point light sources or not by calculating whether a visual angle cone and a point light source illumination sphere are intersected or not to obtain a visual point light source list; judging whether each visual point light source is a potential projector or not by calculating whether the point light source illumination sphere and a spherical bounding box in the scene are intersected or not to obtain a potential projector list; rendering the potential projector into a cubic texture for each visual point light source; and performing scene illumination rendering for each visual point light source and optimizing shadow edge quality by a percentage approach filtering algorithm during shadow processing.

Owner:南京安讯网络服务有限公司

Two-dimensional microscale measuring device and method based on twin-core fiber bragg grating

The invention belongs to the technical field of precision instrument manufacture and measurement and provides a two-dimensional microscale measuring device and method based on twin-core fiber bragg grating. The device comprises a wideband light source, a spectrum analyzer, an optical circulator, a control computer, a multiplex photoswitch and an external reference grating. Two single mode fibers respectively enable the multiplex photoswitch to be communicated with a double-core fiber fan-out device. One end of a double-core fiber is connected to the double-core fiber fan-out device, the other end of the double-core fiber is fixedly provided with a double-core fiber bragg grating probe through a probe clamping device, and the double-core fiber and the double-core fiber bragg grating probe are connected to form a channel. The method comprises the following steps that the control computer controls the multiplex photoswitch to switch light paths, the spectrum analyzer is utilized to respectively measure reflectance spectrums of the fiber bragg grating, and two-dimensional microscale measurement of non-temperature coupling by utilizing the differential data processing algorithm is achieved. The two-dimensional microscale measuring device and method based on the twin-core fiber bragg grating have the advantages of being high in precision and small in contact force. In addition, the two-dimensional microscale measuring device is not influenced by the shadowing effect, and the service life of the probe is long.

Owner:HARBIN INST OF TECH

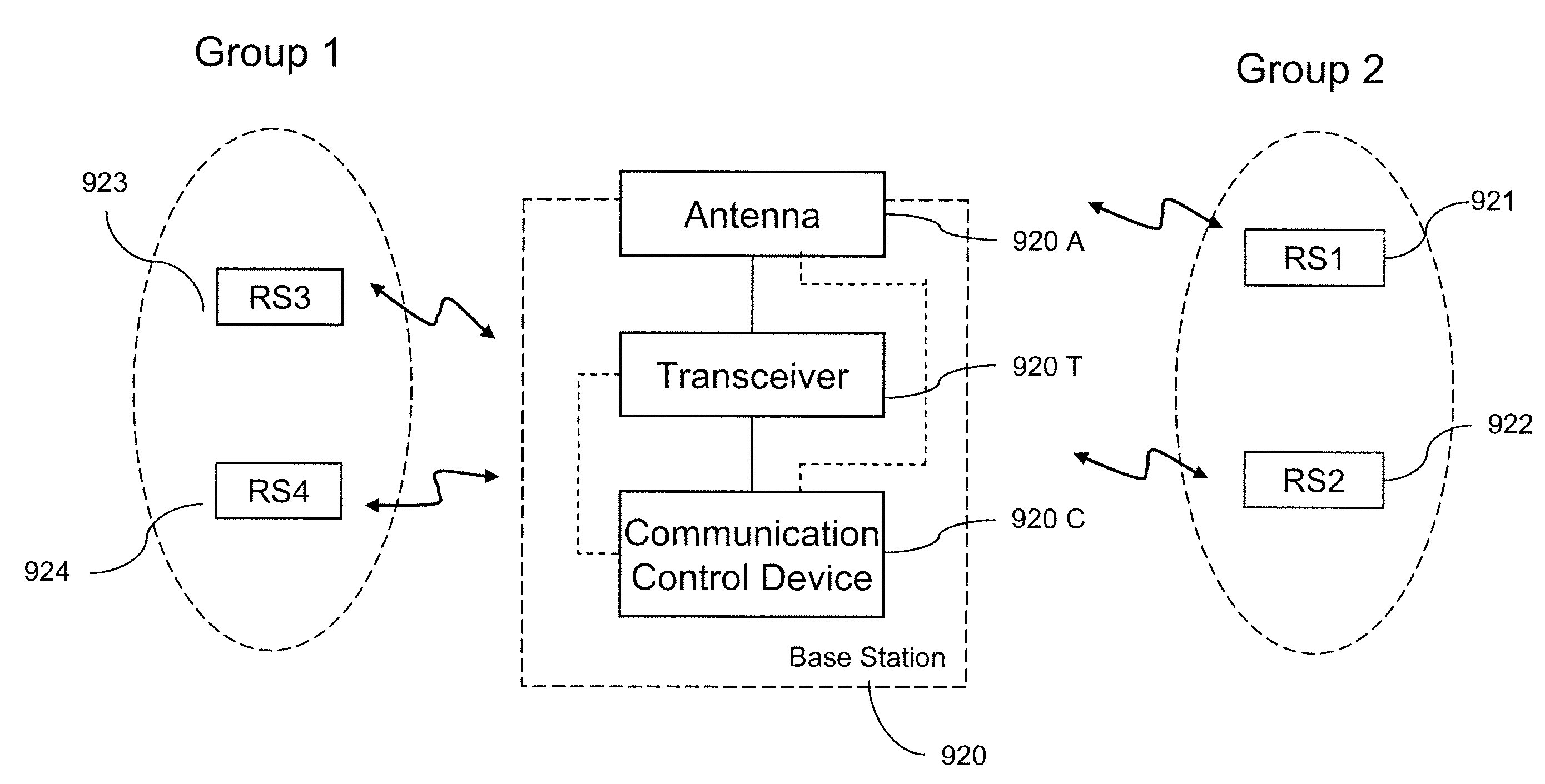

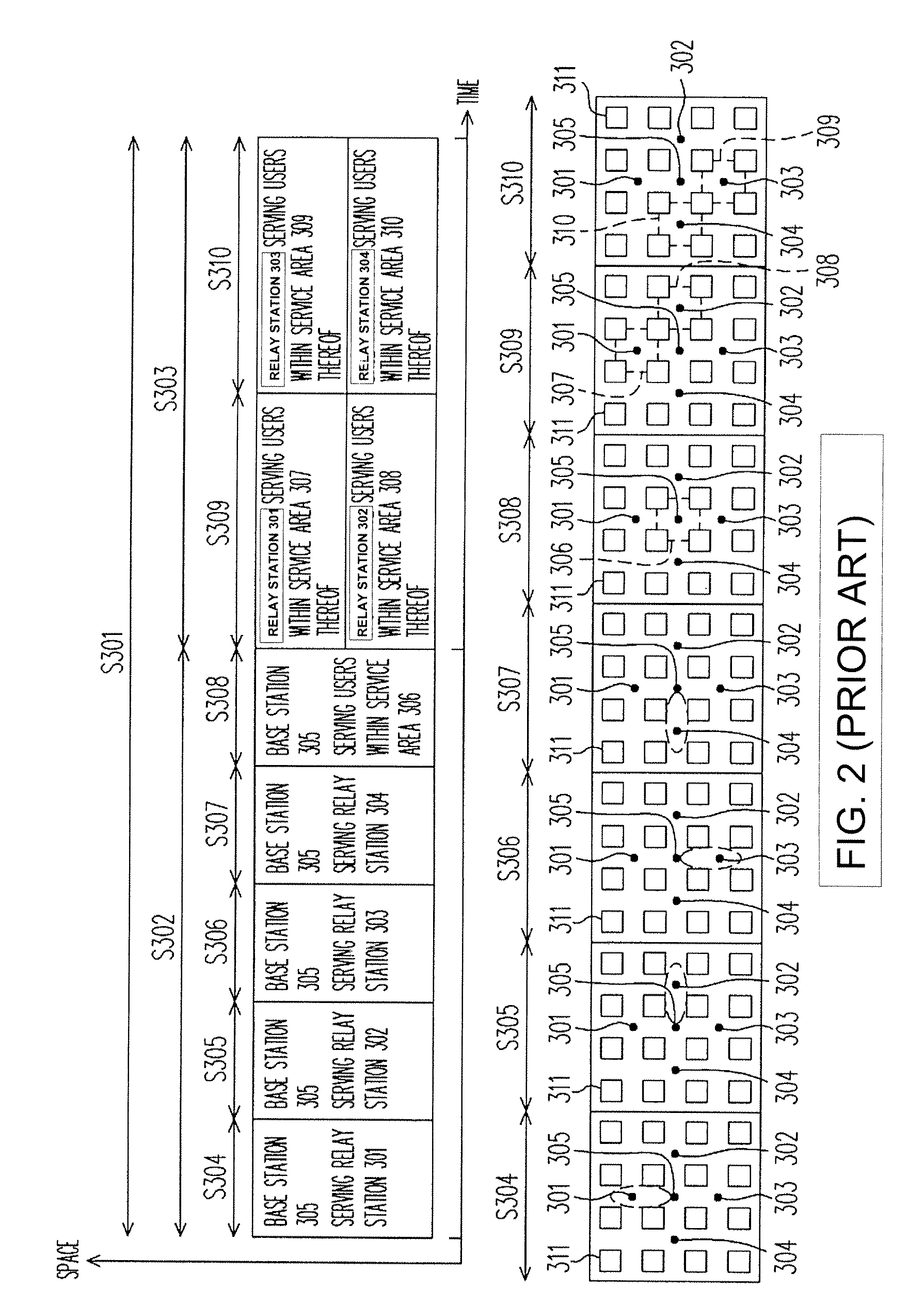

Scheduling methods and systems for multi-hop relay in wireless communications

ActiveUS20090286465A1Increase system capacityBad link qualityError preventionFrequency-division multiplex detailsShadow effectPower control

A scheduling technique for wireless multihop relay communication systems is provided. With spatial separation caused by the shadowing effect of surrounding buildings, a base station and its relay stations in a single cell are divided into several groups by following the rule that stations with severe potential interference are separated into different groups. The base station arranges the scheduling of these groups and serves these groups sequentially in the time domain. To take advantage of shadow effect, the same radio resources can be scheduled for relay stations within the same group due to the isolation of interfering signals. In the present invention, base stations and relay stations are equipped with directional antennas or sector antennas to further exploit the advantage of spatial separations. Different relay groups can also reuse the radio resource through appropriate power control. The cell capacity can be enhanced substantially because of aggressive radio resource reuse.

Owner:ACER INC

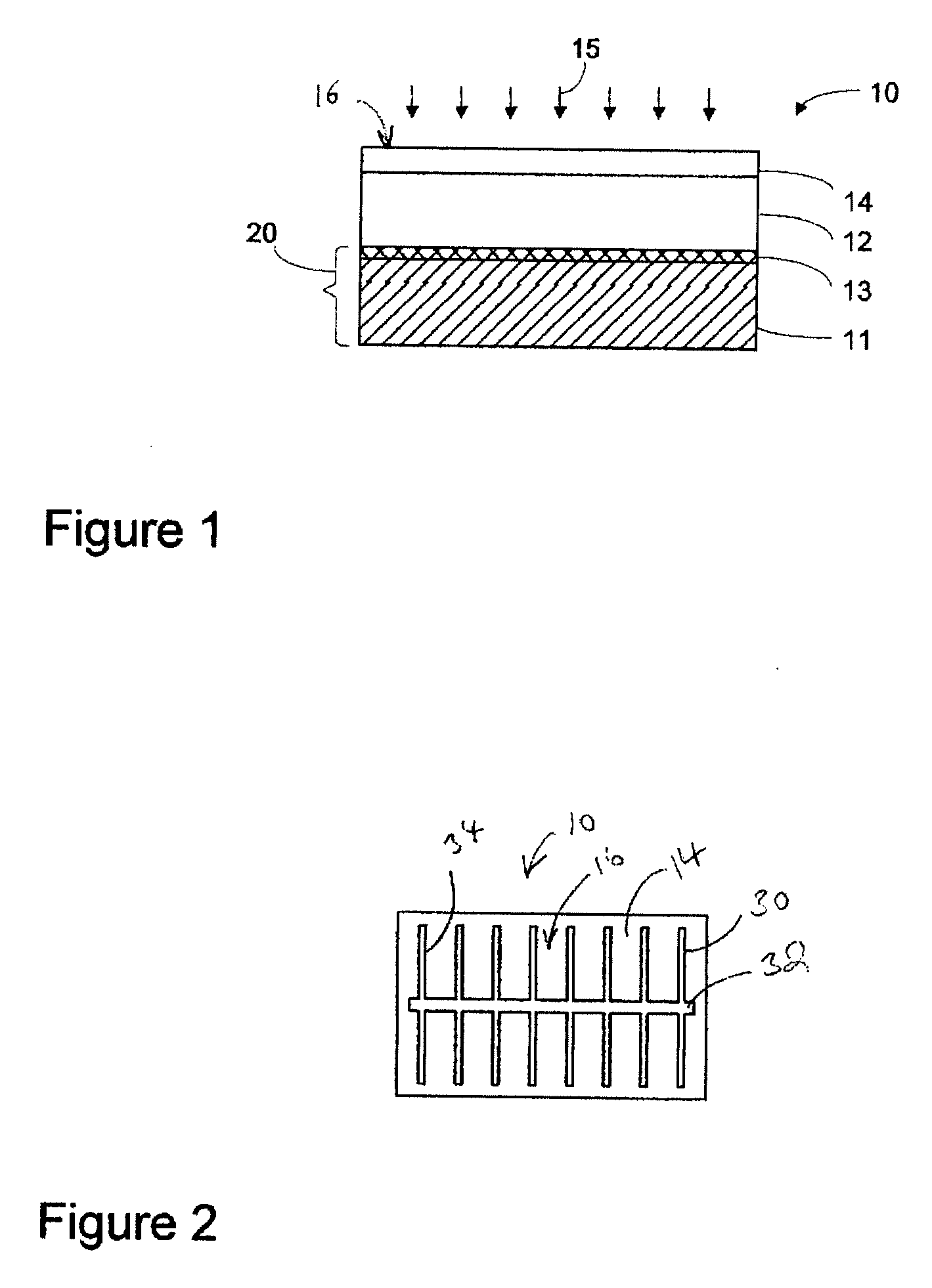

Conductive grids for solar cells

InactiveUS20100089447A1Minimum shadowing effectImprove conductivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationGrid patternBusbar

Embodiments of the present inventions provide structures and methods for manufacturing high electrical conductivity grid patterns having minimum shadowing effect on the illuminated side of the solar cells. To manufacture a conductive grid for a solar cell, a first conductive layer is initially formed over a transparent conductive oxide layer of a solar cell. The first conductive layer has a pattern including a busbar and fingers connected to the busbar. Next, a second conductive layer is formed on the first conductive layer. In one embodiment, the first conductive layer includes silver and the second conductive layer includes carbon nano tube material, or the first conductive layer includes carbon nano tube material and the second conductive layer includes silver.

Owner:SOLOPOWER

Method and apparatus to accelerate rendering of shadows

The present invention provides for accelerating the generation of graphical images that include shadow effects by, for example, reducing the amount of data transmitted and / or stored necessary to render graphics based on stencil shadow volumes. In one embodiment, an exemplary apparatus is configured to render shadows using stencil shadow volumes. The apparatus includes a memory to store a degree of shadowing for each sample. A co-processor, which is coupled to the memory, is configured to generate an indicator that represents a common degree of shadowing associated with the subset of samples. In some cases, the apparatus includes a graphics processing unit (“GPU”), which is coupled to the co-processor, that is configured to render one or more shadows for a computer-generated image based on the indicator.

Owner:NVIDIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com