Two-dimensional microscale measuring device and method based on twin-core fiber bragg grating

A dual-core fiber grating and micro-scale technology, applied in the direction of measurement devices, optical devices, instruments, etc., can solve the problems of inability to apply, complicated measurement steps, low primary amplification, etc., to eliminate the impact on measurement, probe Effect of long service life and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

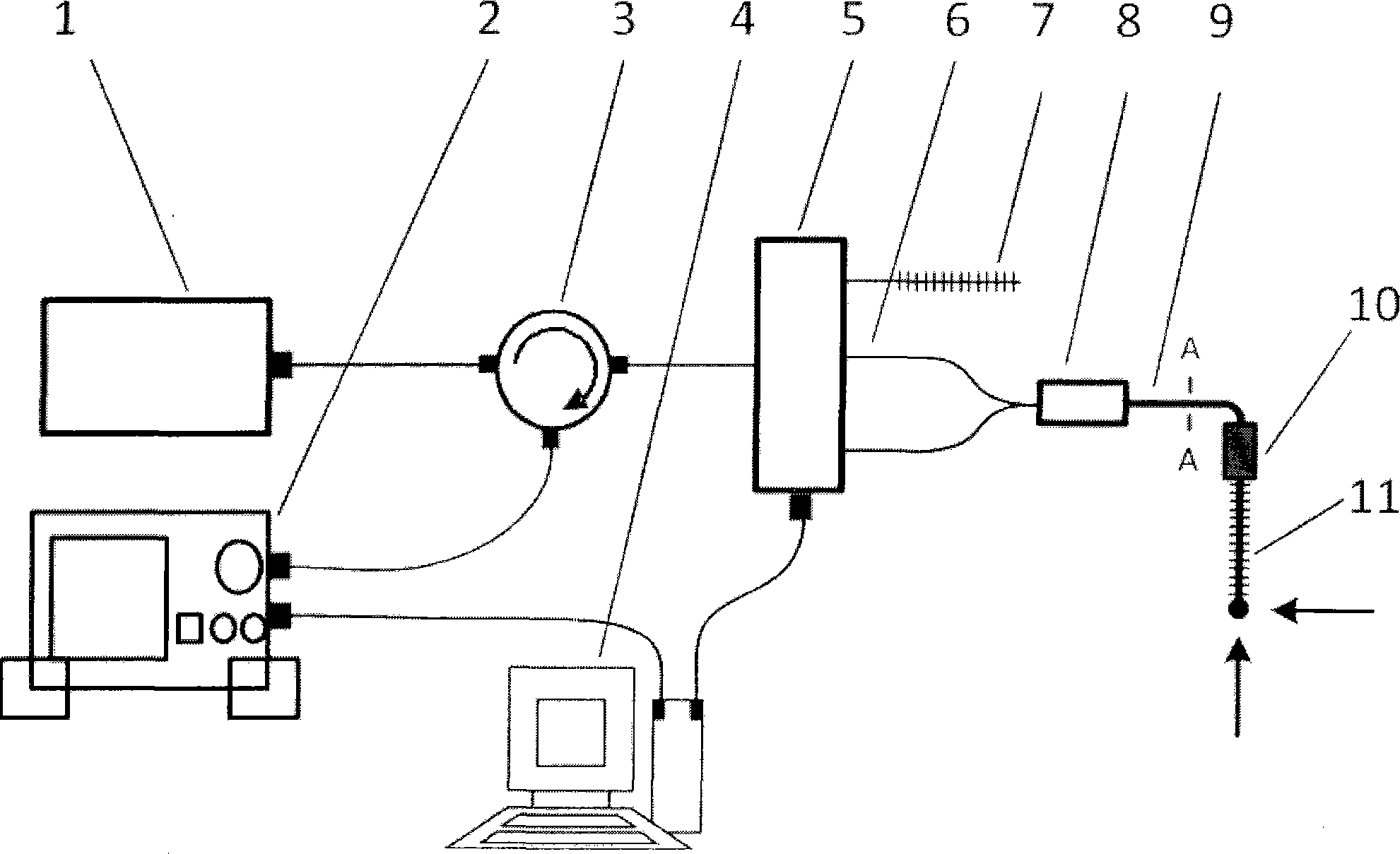

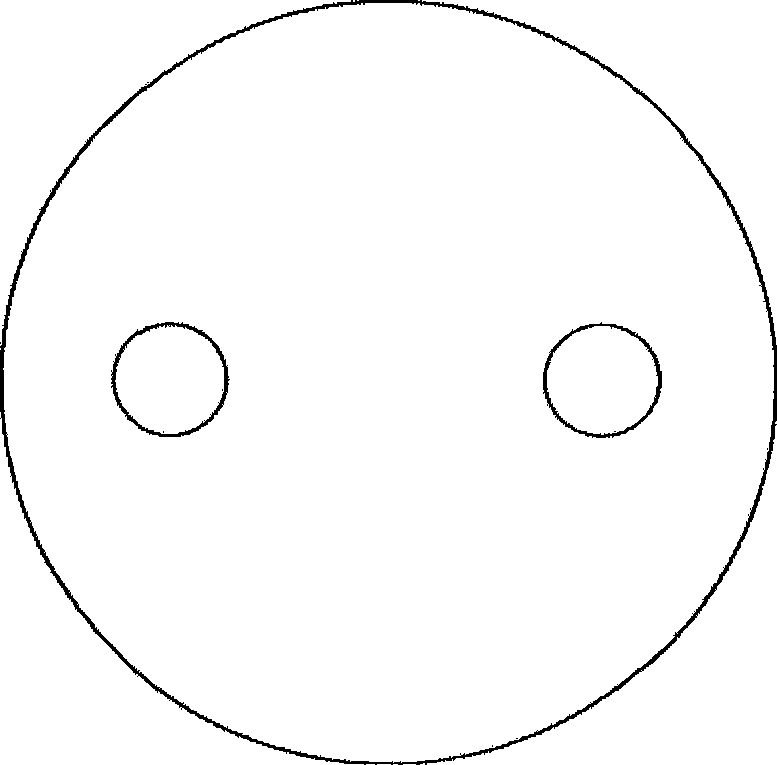

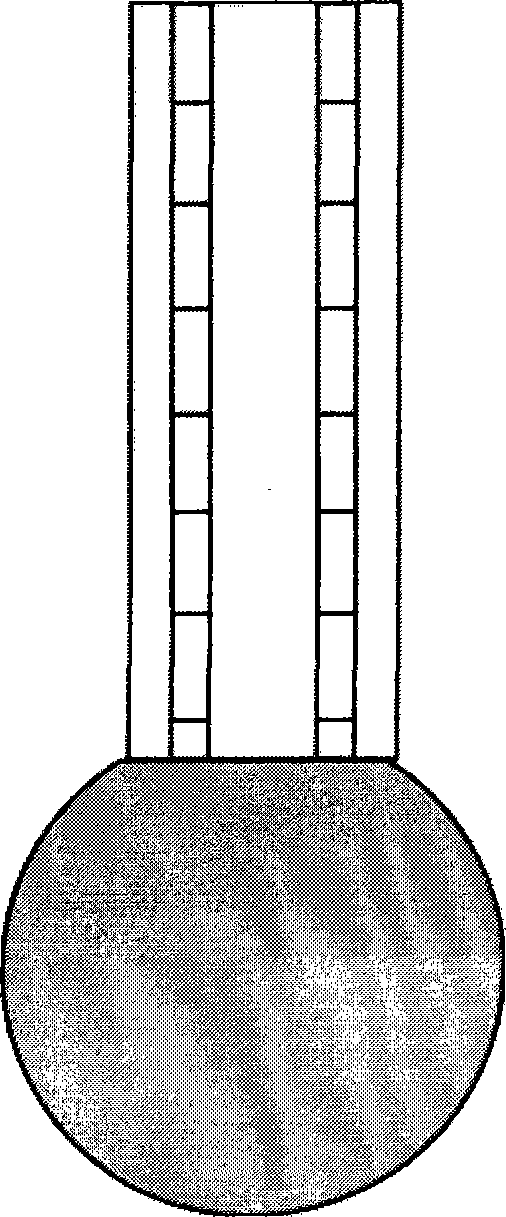

[0026] A two-dimensional micro-scale measurement device based on a dual-core fiber grating, including a broadband light source 1, a spectrum analyzer 2, an optical ring device 3, a control computer 4, a multi-channel optical switch 5 and an external reference grating 7, the broadband light source 1 The optical circulator 3 is connected to the multi-channel optical switch 5, the multi-channel optical switch 5 is connected to the control computer 4, the control computer 4 is connected to the spectrum analyzer 2, and the multi-channel optical switch 5 is connected to the external The reference grating 7 is connected to form a path, and two single-mode optical fibers 6 respectively connect the multi-channel optical switch 5 with the dual-core optical fiber fan-out device 8, and one end of the dual-core optical fiber 9 is connected to the dual-core op...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com