Patents

Literature

161results about How to "Big free space" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

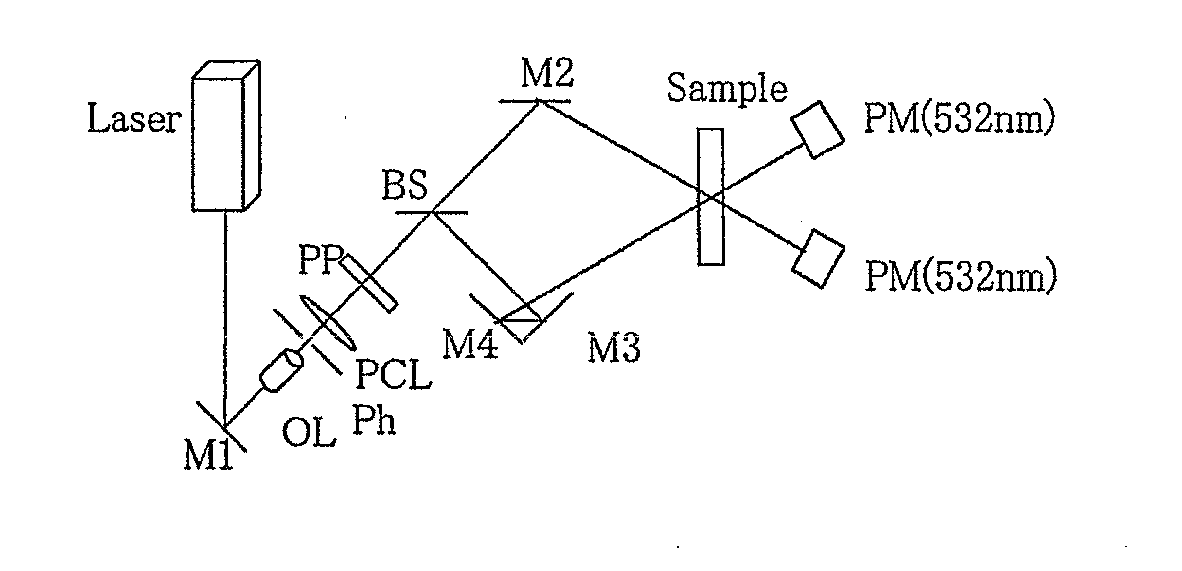

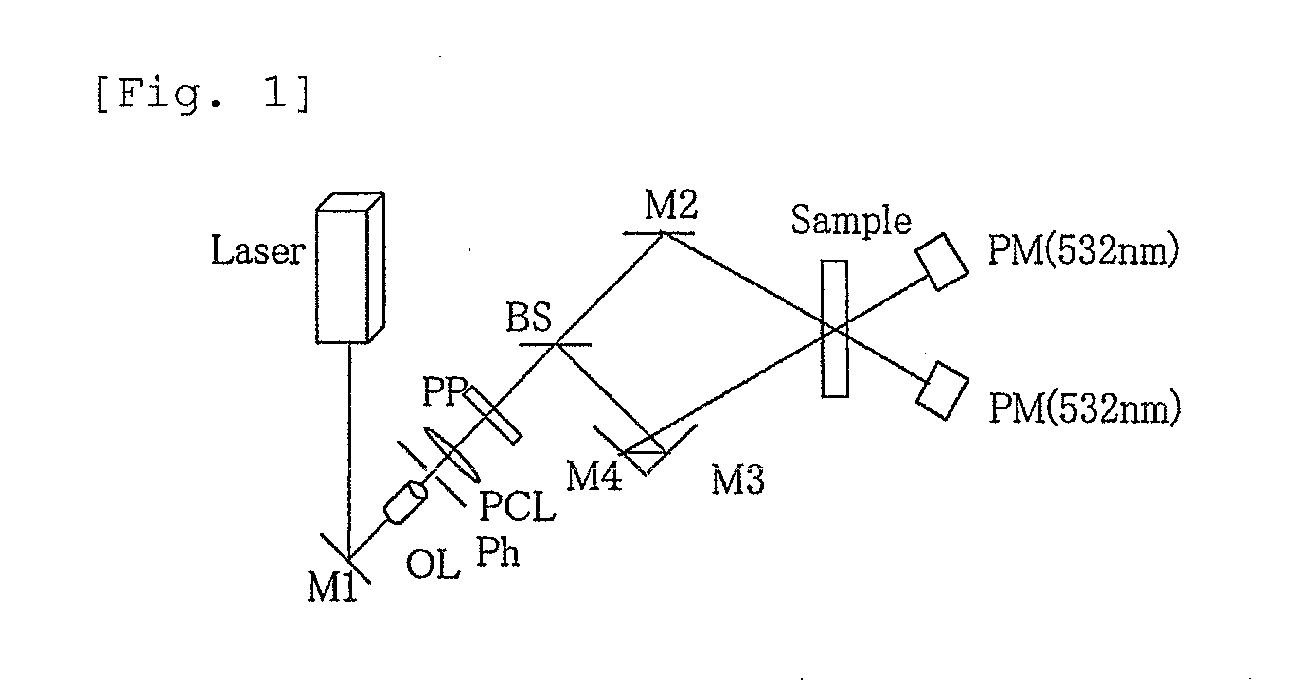

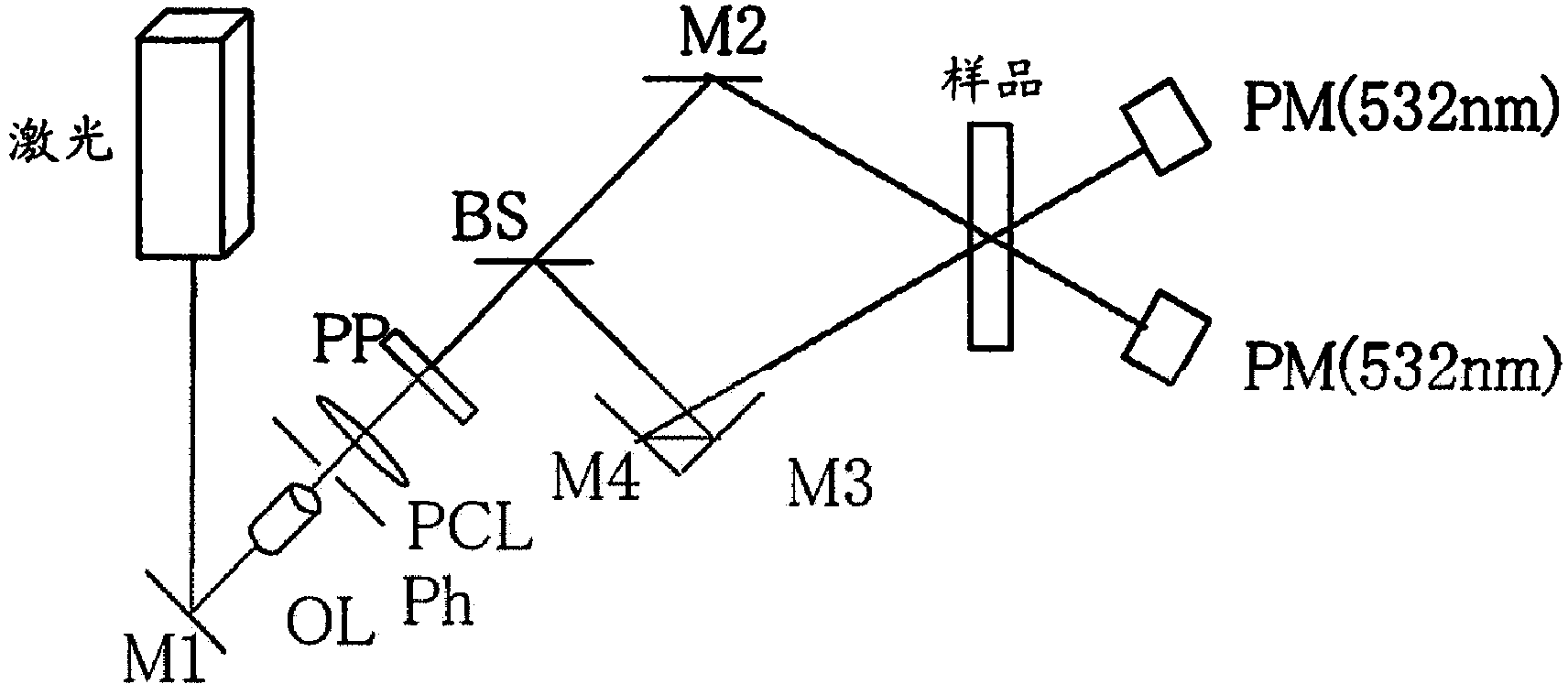

Photosensitive composition for volume hologram recording, volume hologram recording medium using same, method for manufacturing volume hologram recording medium, and hologram recording method

InactiveUS20150086907A1Stay rigidGood resistance stabilityPhotomechanical apparatusRecord information storagePolymerPhotochemistry

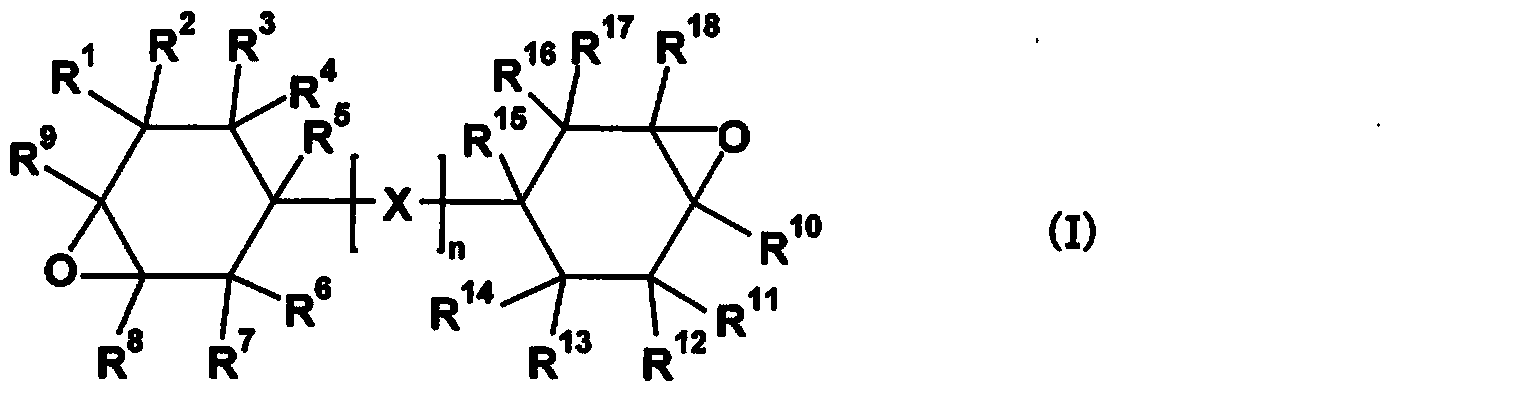

Provided is a photosensitive composition for volume hologram recording capable of forming a volume hologram recording medium that less shrinks upon curing in hologram recording (in hologram formation) and resists cracking. The photosensitive composition for volume hologram recording contains an alicyclic epoxy compound (A) represented by Formula (I); a thermal acid generator (B); a radically polymerizable compound (C); a radical polymerization initiator (D); and at least one epoxy compound (E) selected from the group consisting of compounds represented by Formula (1), epoxidized fatty acid esters, and epoxidized conjugated diene polymers.

Owner:DAICEL CHEM IND LTD

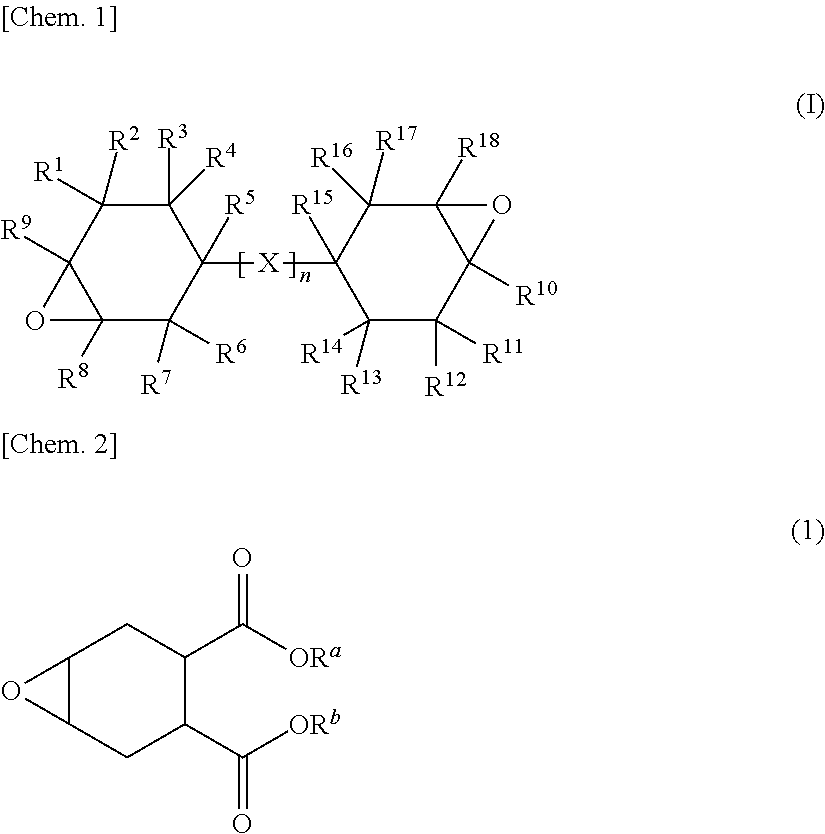

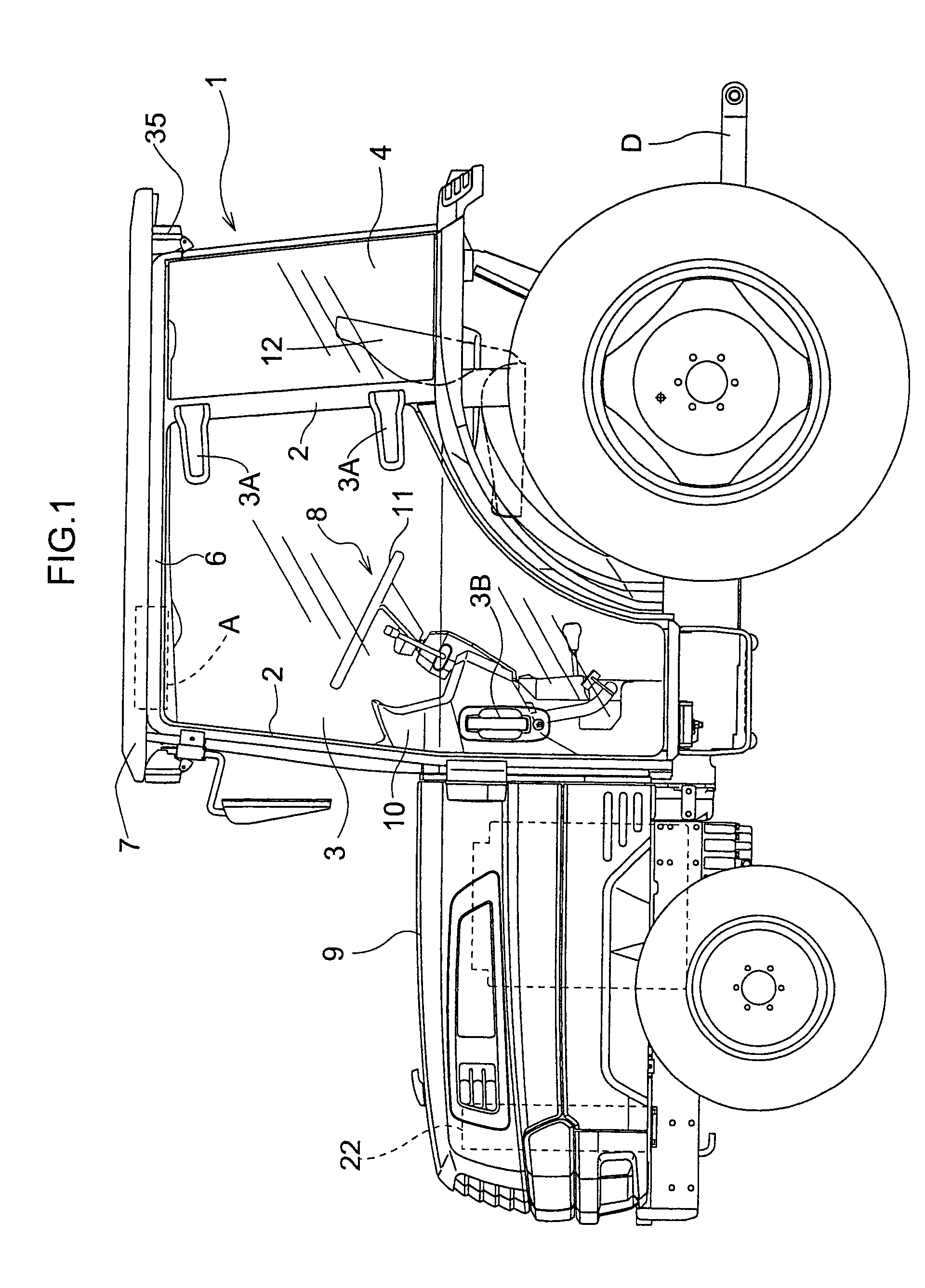

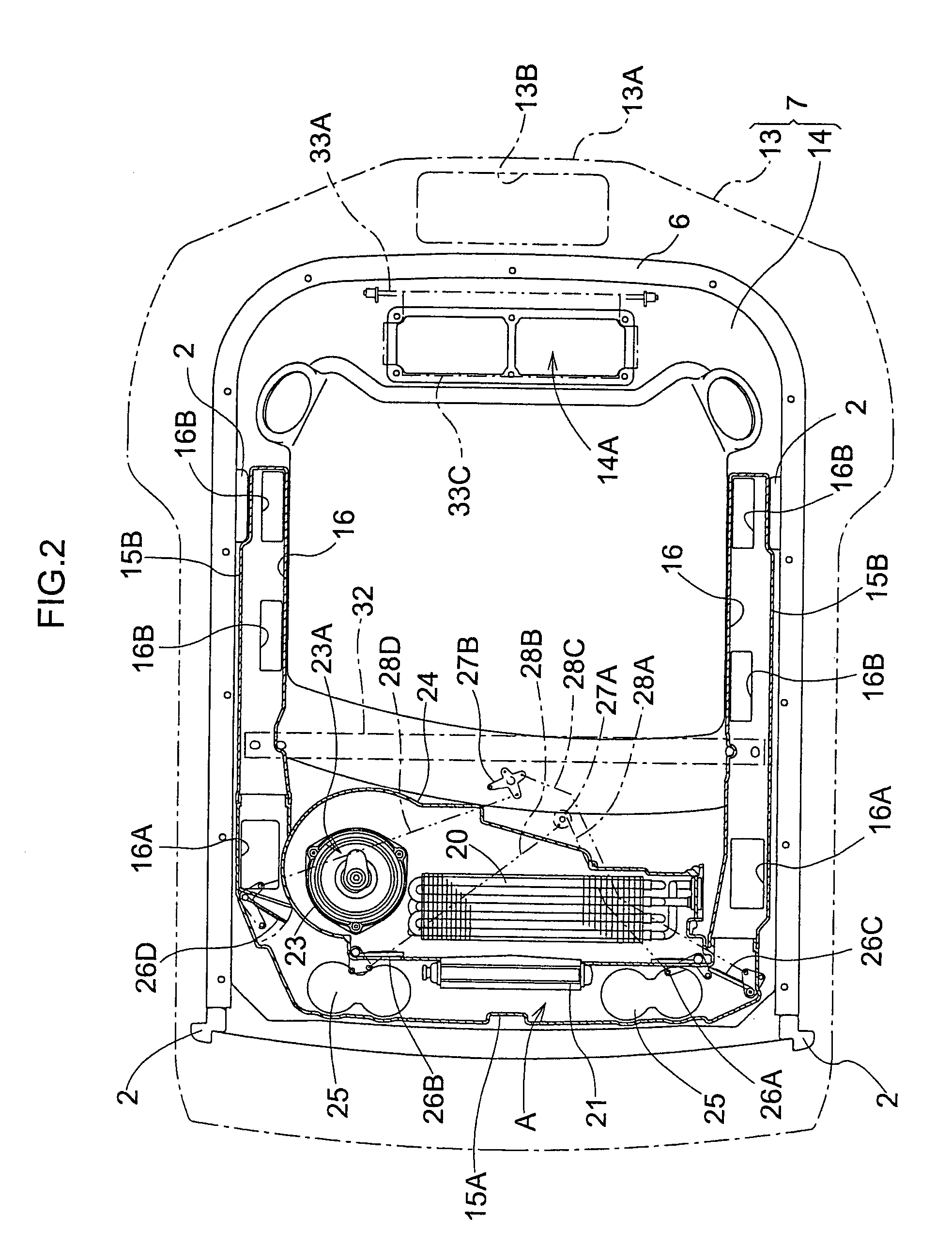

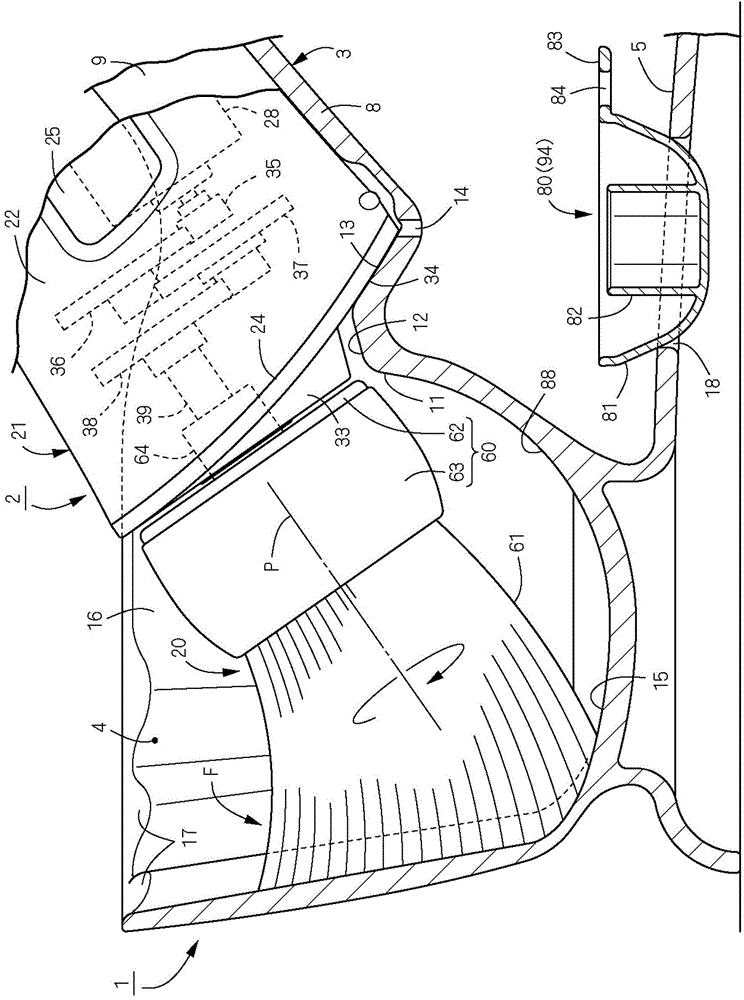

Work-vehicle cabin having air-conditioning unit

ActiveUS7252585B2Reduce riskEnlargement can be preventedAir-treating devicesRailway heating/coolingNacelleEngineering

A work-vehicle cabin having an air-conditioning unit is disclosed. The cabin includes a roof unit, a downwardly bulging ceiling portion constituting a part of the roof unit, a heater provided in the ceiling portion, an evaporator provided in the ceiling portion and arranged adjacently rearwardly of the heater, and a pair of forward air-supply openings provided in the ceiling portion and respectively disposed laterally of the heater for feeding conditioned air to the inside of the cabin.

Owner:KUBOTA LTD

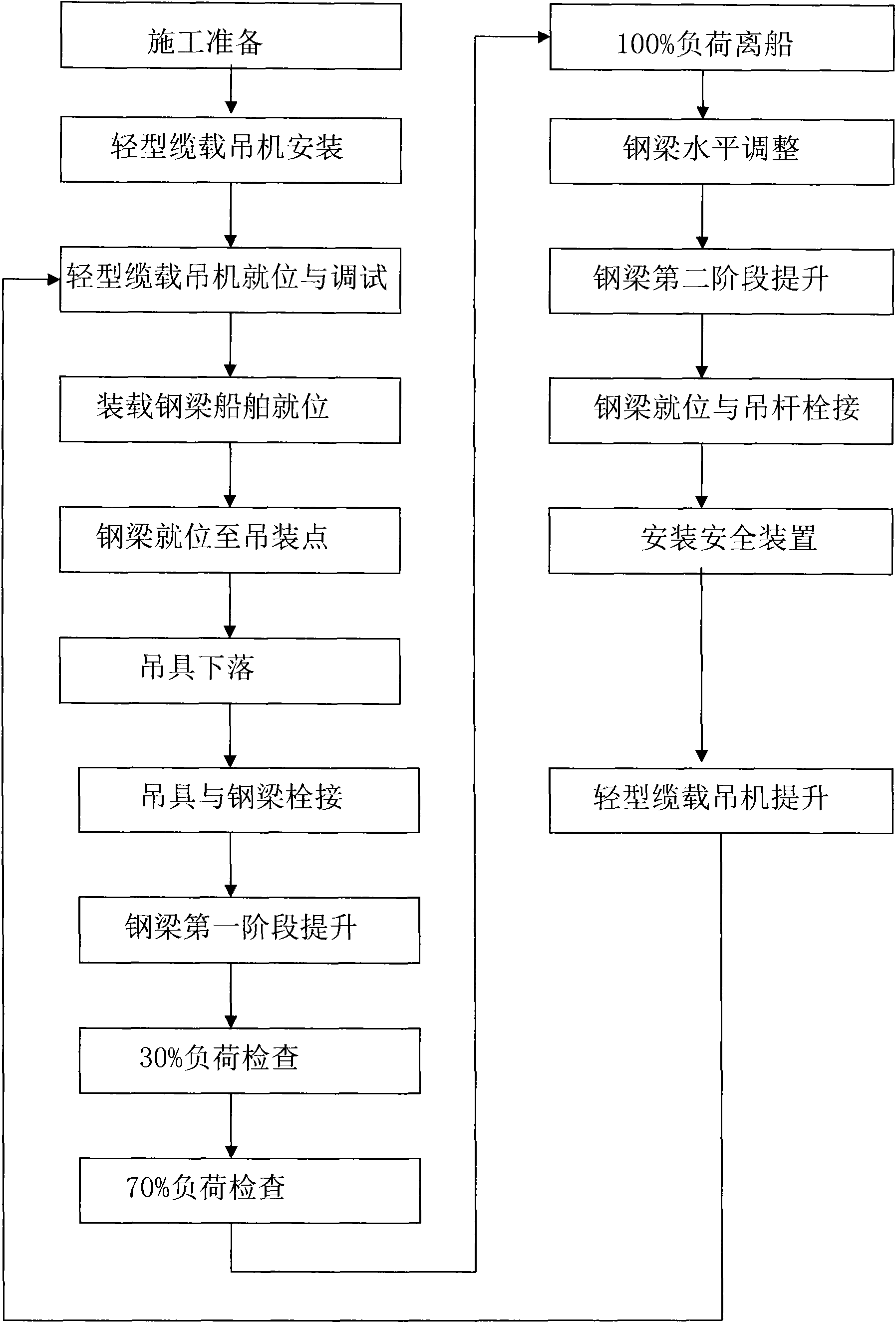

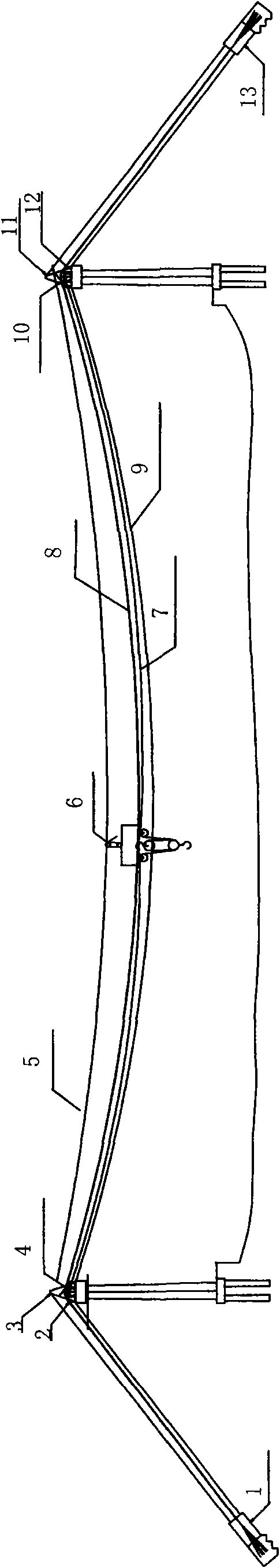

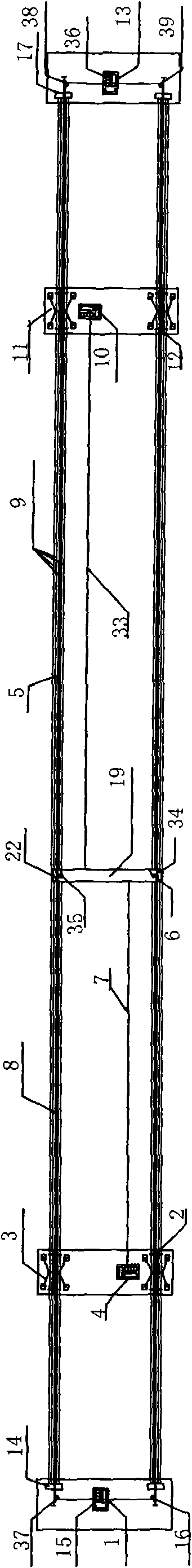

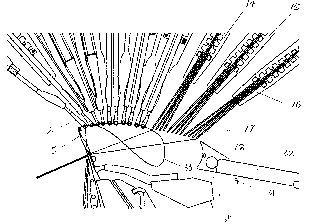

Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

InactiveCN101684639AReduce weightSimple structureSuspension bridgeBridge erection/assemblyStructural engineeringLightering

The invention provides a process method for the construction of a steel-structured suspension bridge and a light type cable carrying crane specially used in the same, wherein the process flow comprises the steps of construction preparation, assembly of the light type cable carrying crane, the positioning and debugging of the light type cable carrying crane, the positioning of a ship carrying steelbeams, the lifting of the steel beams up to the hoisting point, the descent of a lifting device, the bolting connection of the lifting device and the steel beams, the first stage lifting of the steelbeams, the 30-percent load detection, the 70-percent load detection, the 100-percent load detection, the horizontal adjustment of the steel beams, the second stage lifting of the steel beams, the positioning of the steel beams and boiling connection of a lifting rod, the assembly of a security device, the lifting of the light type cable carrying crane, the movement positioning of the light type cable carrying crane; and the special light type cable carrying crane consists of a load-bearing mechanism, a load-lifting mechanism, a traveling mechanism, an anchoring mechanism and a weight-balancing beam. The process method and the special light type cable carrying crane have the advantages of light weight, simple structure, easy processing, convenient assembly and disassembly, no waterway occupation, big free space brought to transport barges and waterway traffic, high flexibility and maneuverability, high lifting speed, low construction cost, low labor intensity of workers and the suitability for the construction of the suspension bridge.

Owner:CHINA FIRST METALLURGICAL GROUP

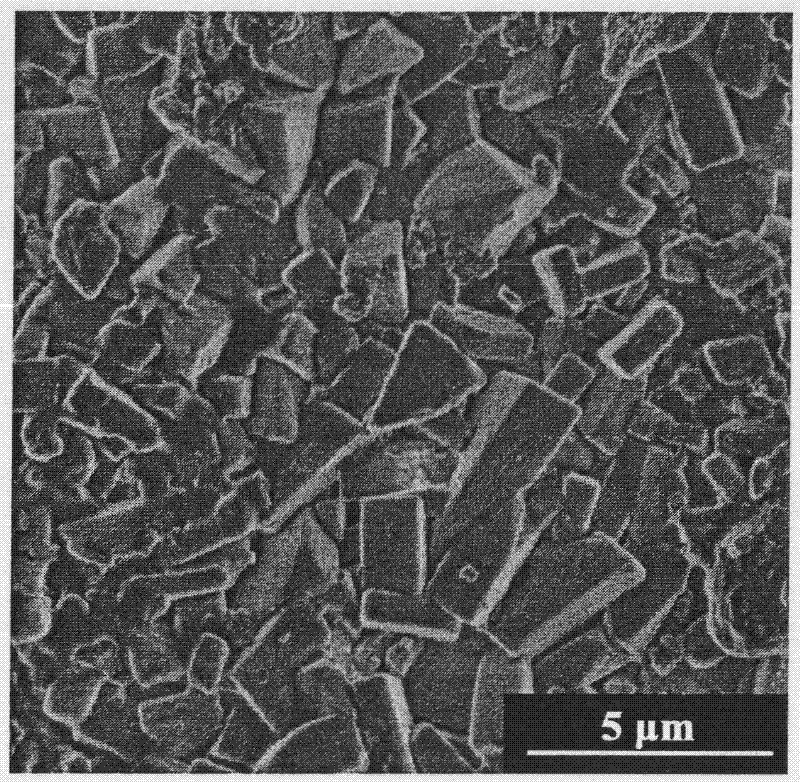

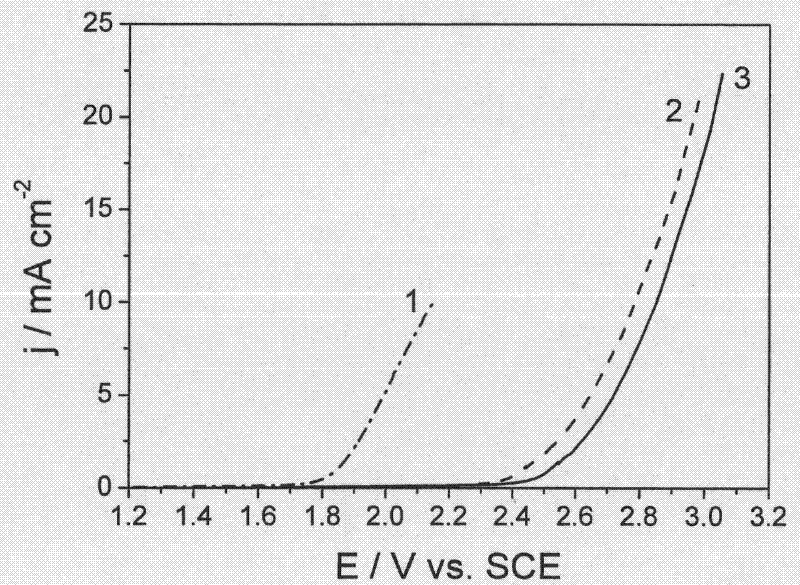

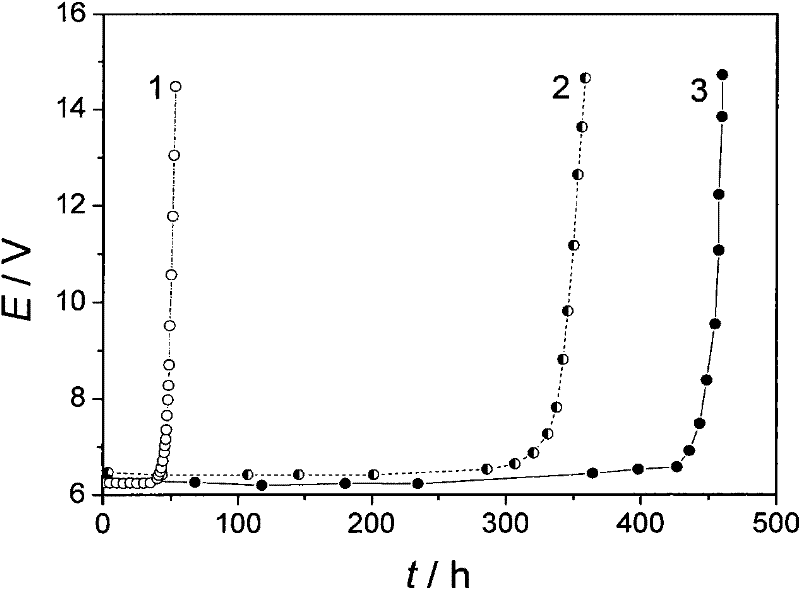

Electrode Ce doped PbO2 used for treating waste water and its preparation method

InactiveCN102190351AImprove stabilityImprove oxidation capacityWater/sewage treatment by electrochemical methodsElectricitySocial benefits

The invention relates to an electrode Ce doped PbO2 used for treating waste water and its preparation method. The electrode is a F-PbO2-CeO2 / TiO2-NTs / Ti electrode. The method for producing the electrode comprises that: obtaining a titania nano-tubes array (TiO2-NTs / Ti) matrix prepared by an anodization processing, doping rare earth Ce, preparing a doped-type F-PbO2-CeO2 / TiO2-NTs / Ti electrode by using an electrodeposition method. Compared with the prior art, the PbO2 electrode by the present invention has the advantages of high oxygen evolution potential, strong catalytic activity, stable electrode electrochemical performance and long service life. Compared with the traditional PbO2 electrode, the oxygen evolution potential of the electrode is higher than 2.4 V, and accelerated and strengthen life is more than 400 hours, the service life can reach about 40 years. The electrode has the advantages of simple preparation technology and low manufacturing cost, and can be effectively used for an electrochemical oxidation treatment of organic waste water which has high density and is difficult to degrade, the electrode also has a wide economic and social benefit.

Owner:TONGJI UNIV

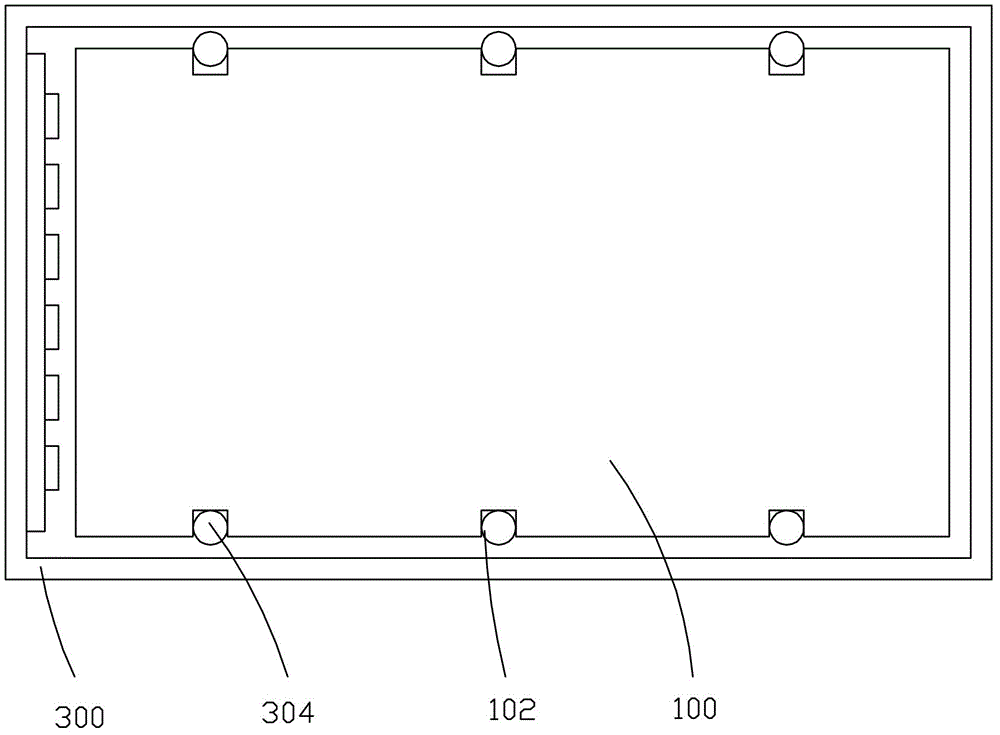

Side-in type backlight module

ActiveCN102748668AEffective positioningBig free spacePlanar/plate-like light guidesNon-linear opticsLight guideRight trapezoid

The invention provides a side-in type backlight module which comprises a light guide plate. The light guide plate is provided with a first mounting side and a second mounting side opposite to each other; a first positioning hole, a first positioning slot and a second positioning slot are formed on the first mounting side; a second positioning hole, a third positioning slot and a fourth positioning slot are correspondingly formed on the second mounting side; six rivet columns are arranged on a back plate and are contained in the first and second positioning holes and the first, second, third and fourth positioning slots respectively; the first and second positioning slots are in a right-trapezoid shape, wherein the straight edge of the trapezoid is open, and the bevel edge of the trapezoid inclines downward toward the first positioning hole; the third and fourth positioning slots are in a right-trapezoid shape, wherein the straight edge of the trapezoid is open, and the bevel edge of the trapezoid inclines downward toward the second positioning hole; and the rivet columns in the first, second, third and fourth positioning slots lean on the bevel edge of the trapezoid respectively.

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

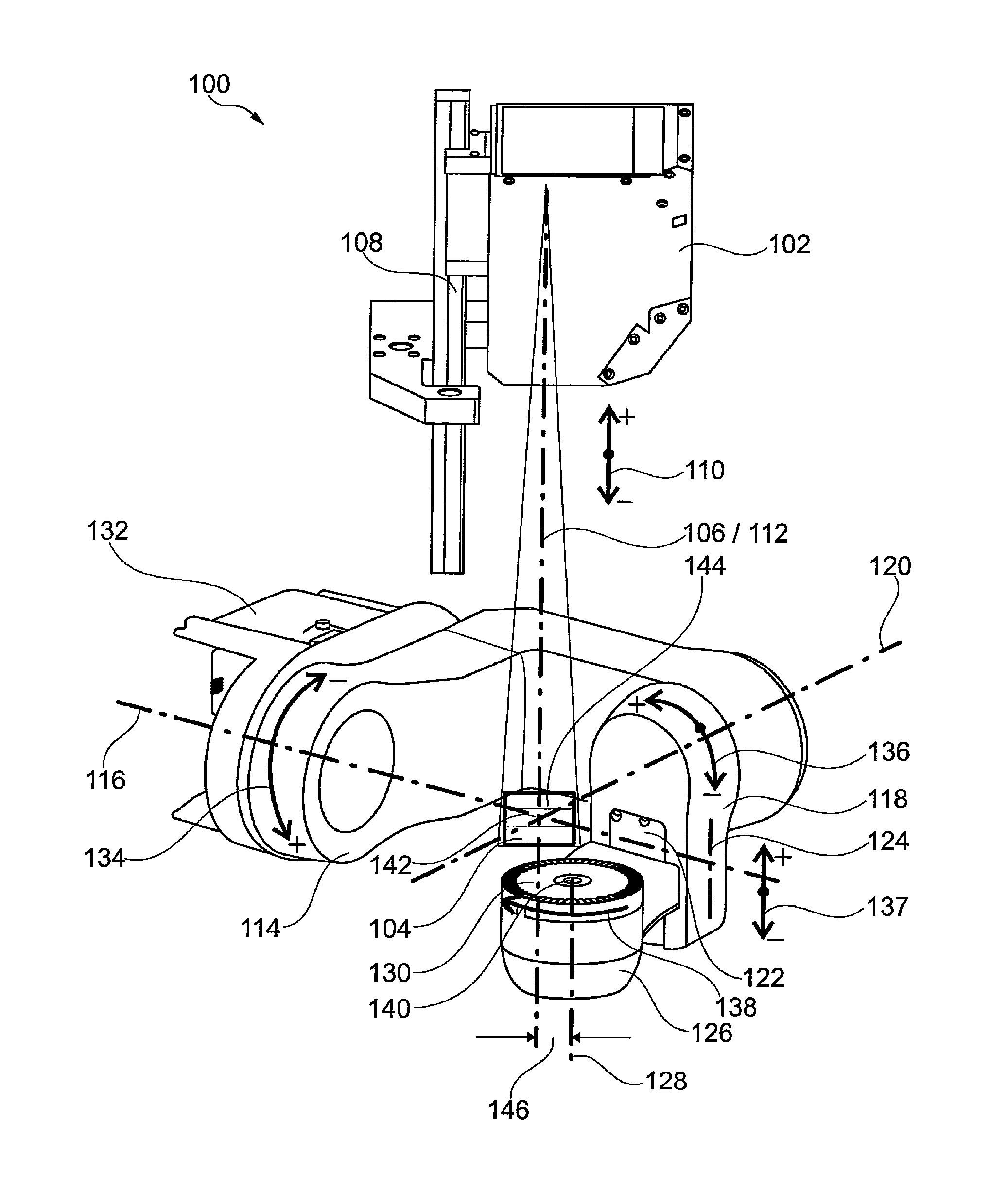

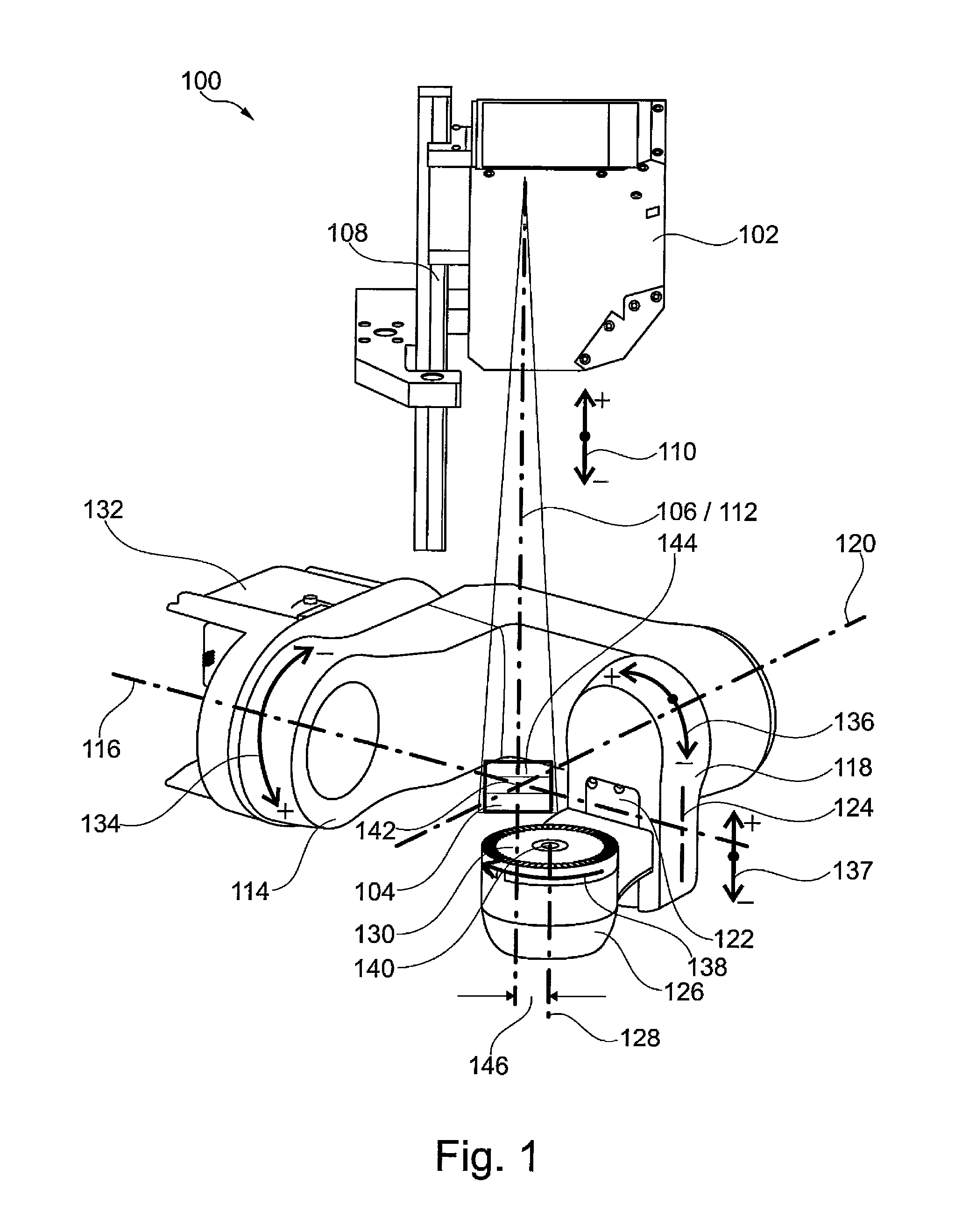

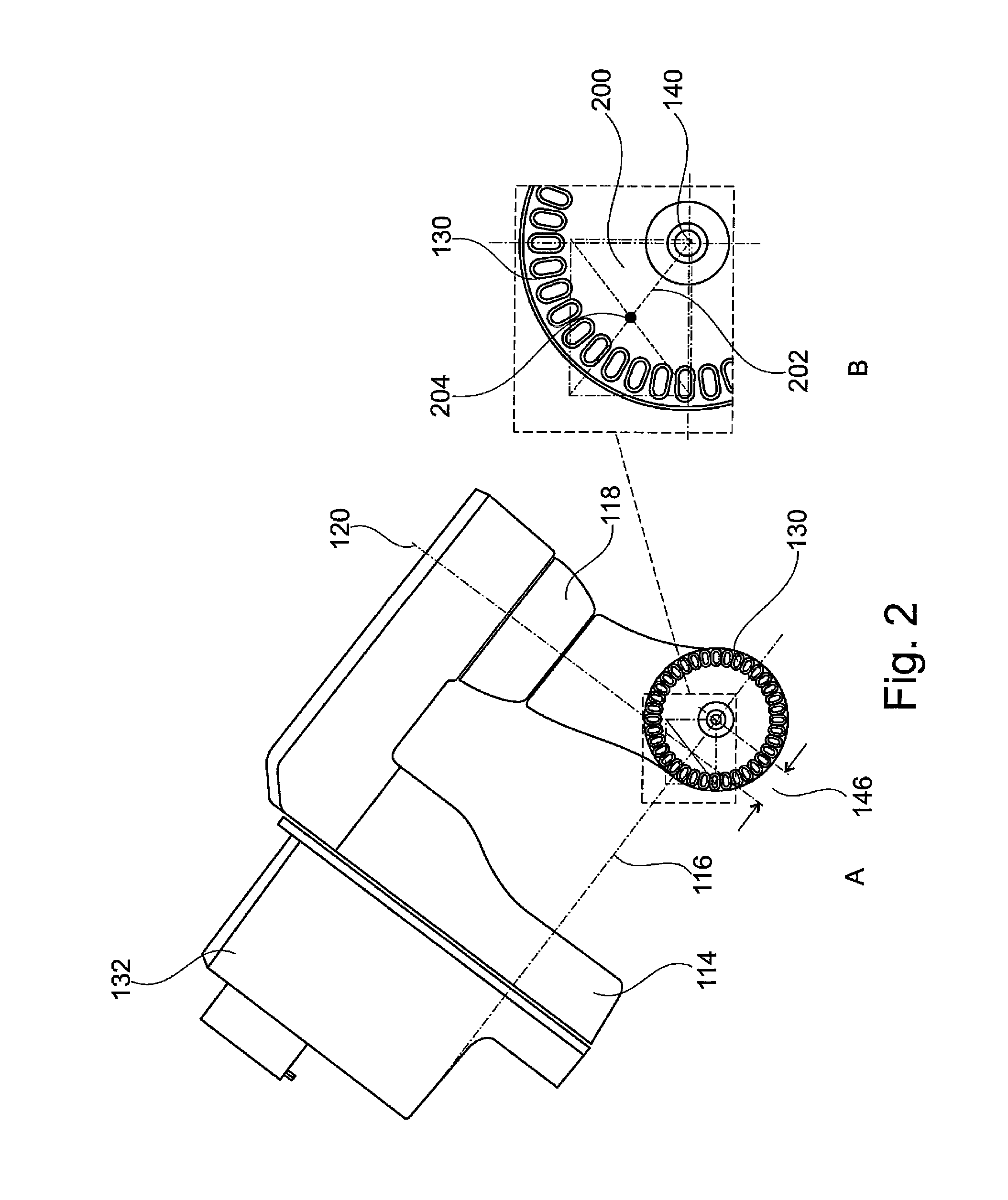

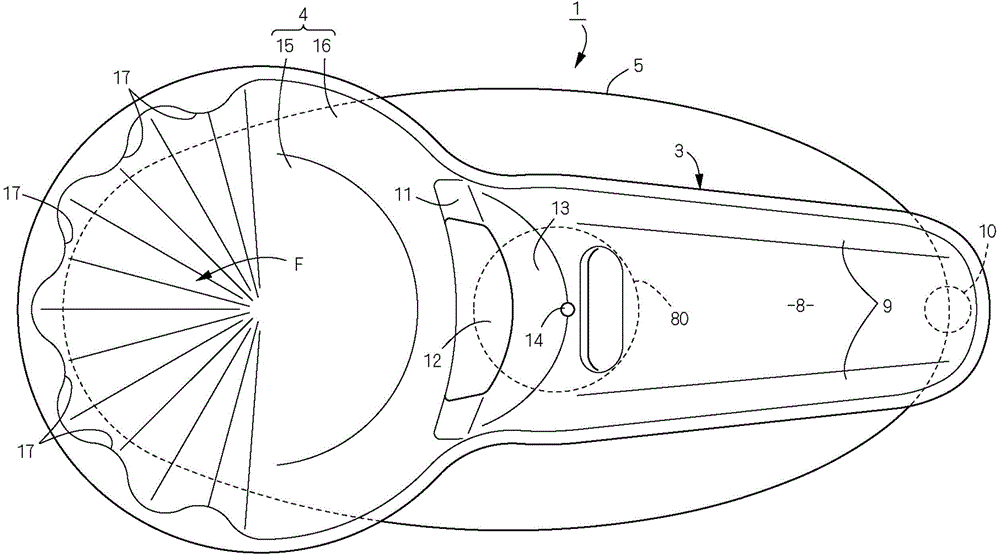

Extraoral dental scanner

ActiveUS20160008111A1Big free spaceEasy to measureImpression capsUsing optical means3d imageOptical axis

An extraoral dental scanner for three-dimensional capture of the surface of a dental shaped part (300) with a 3D measuring camera (102) having an optical axis (106), wherein the means for the machine-controlled relative positioning of the 3D measuring camera (102) and the dental shaped part (300) are embodied in such a way that the means for taking up and positioning the dental shaped part (300) can be moved into a parking position outside a region that can be captured optically by the 3D measuring camera (102), with a work plate (708) for manually positioning the dental shaped part (300) in the measurement volume (144) of the 3D measuring camera (102), wherein the work plate (708) is aligned perpendicularly to the optical axis (106) and wherein the work plate (708), as viewed from the 3D measuring camera (102), is arranged behind the means for taking up and positioning the dental shaped part (300), makes it possible to record uninterrupted 3D image data with very short recording times both by automatic and by manual positioning of dental shaped parts of different sizes and embodiment variants.

Owner:DENTSPLY SIRONA INC

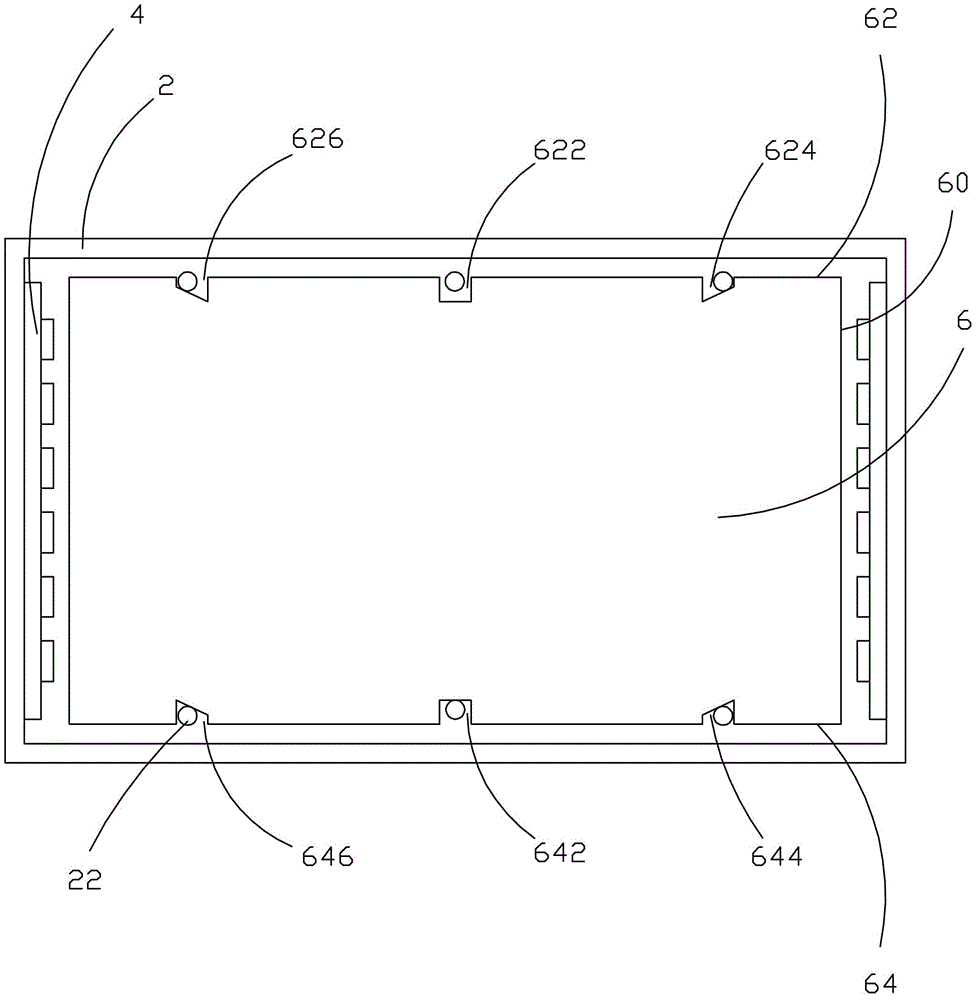

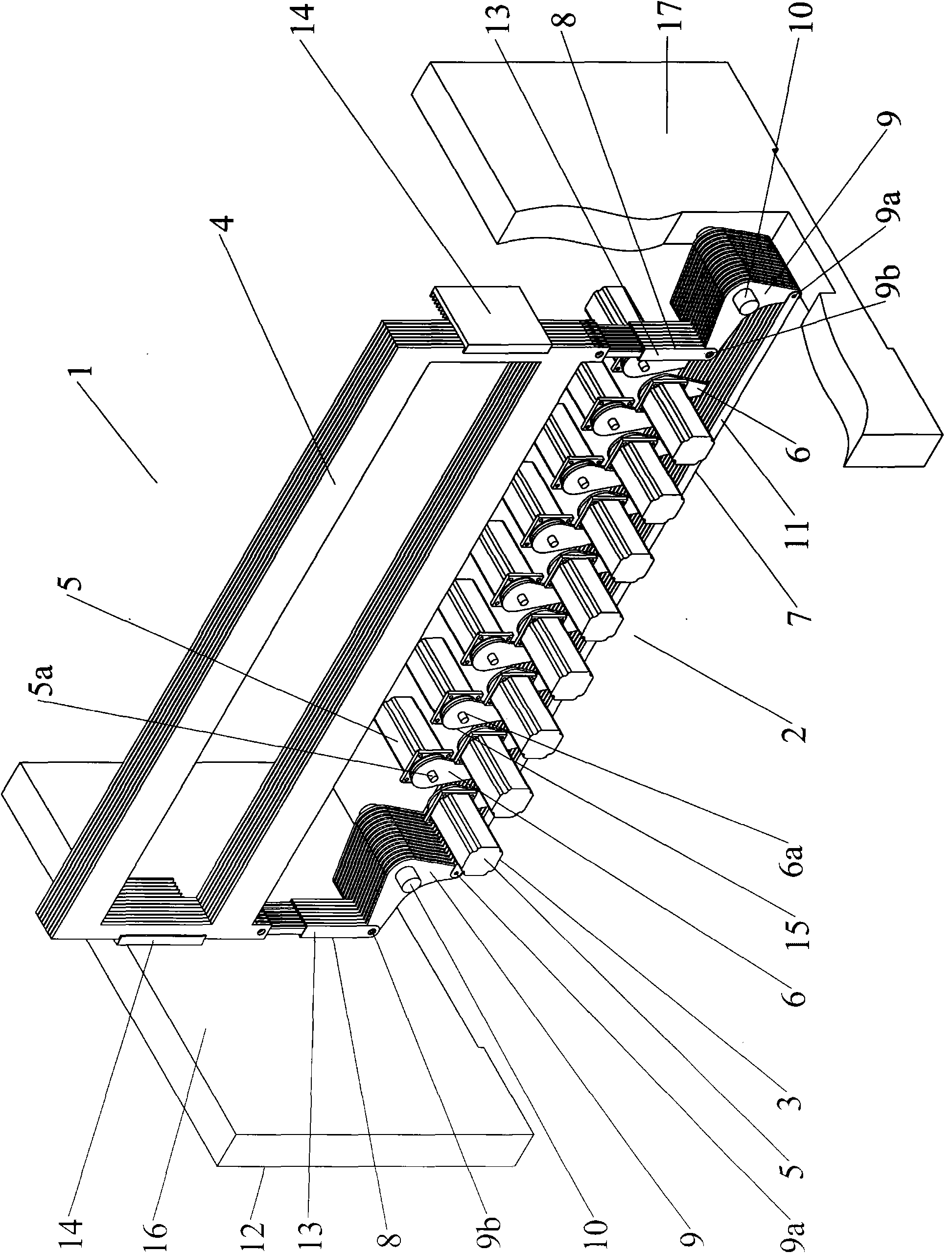

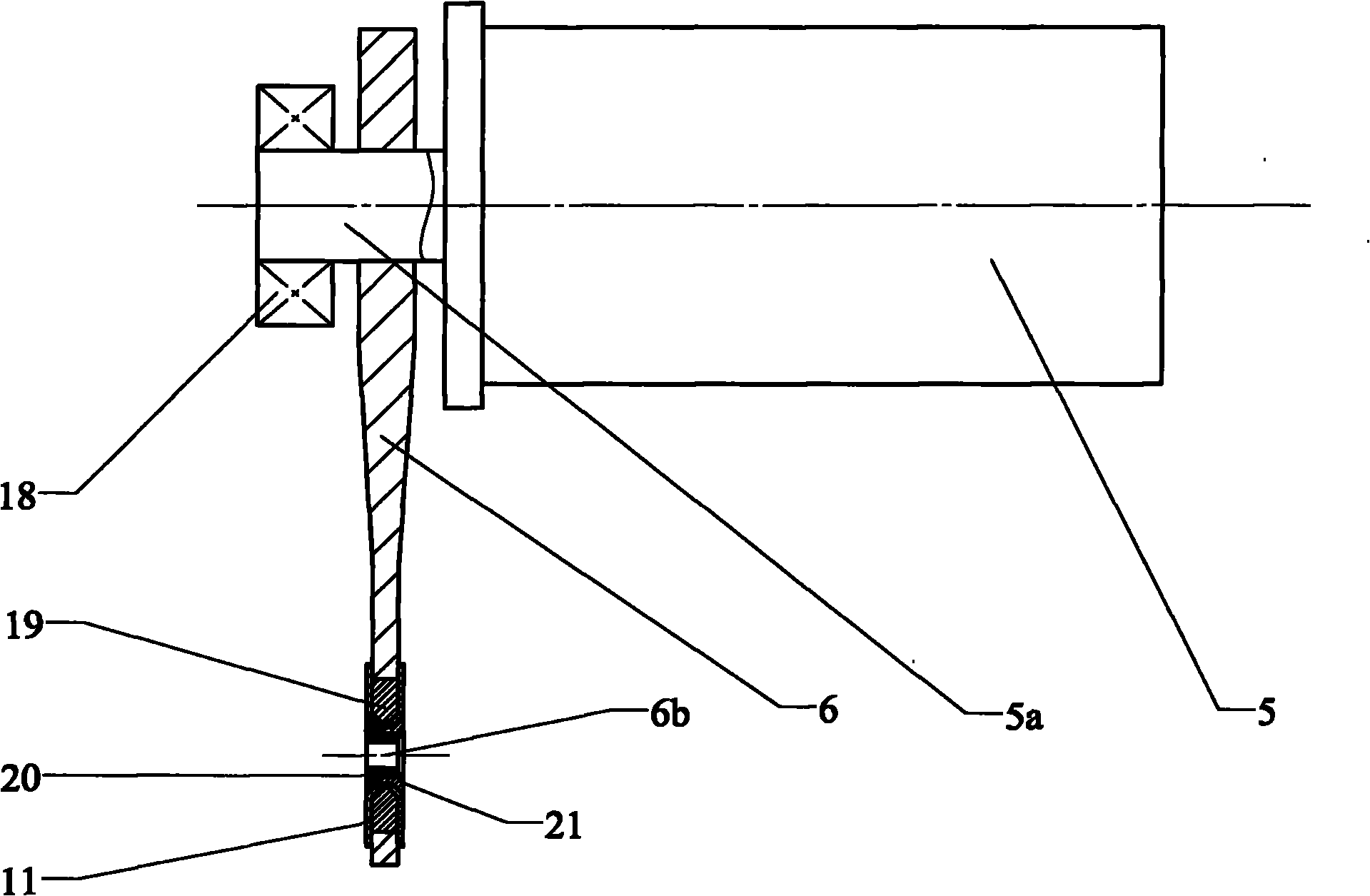

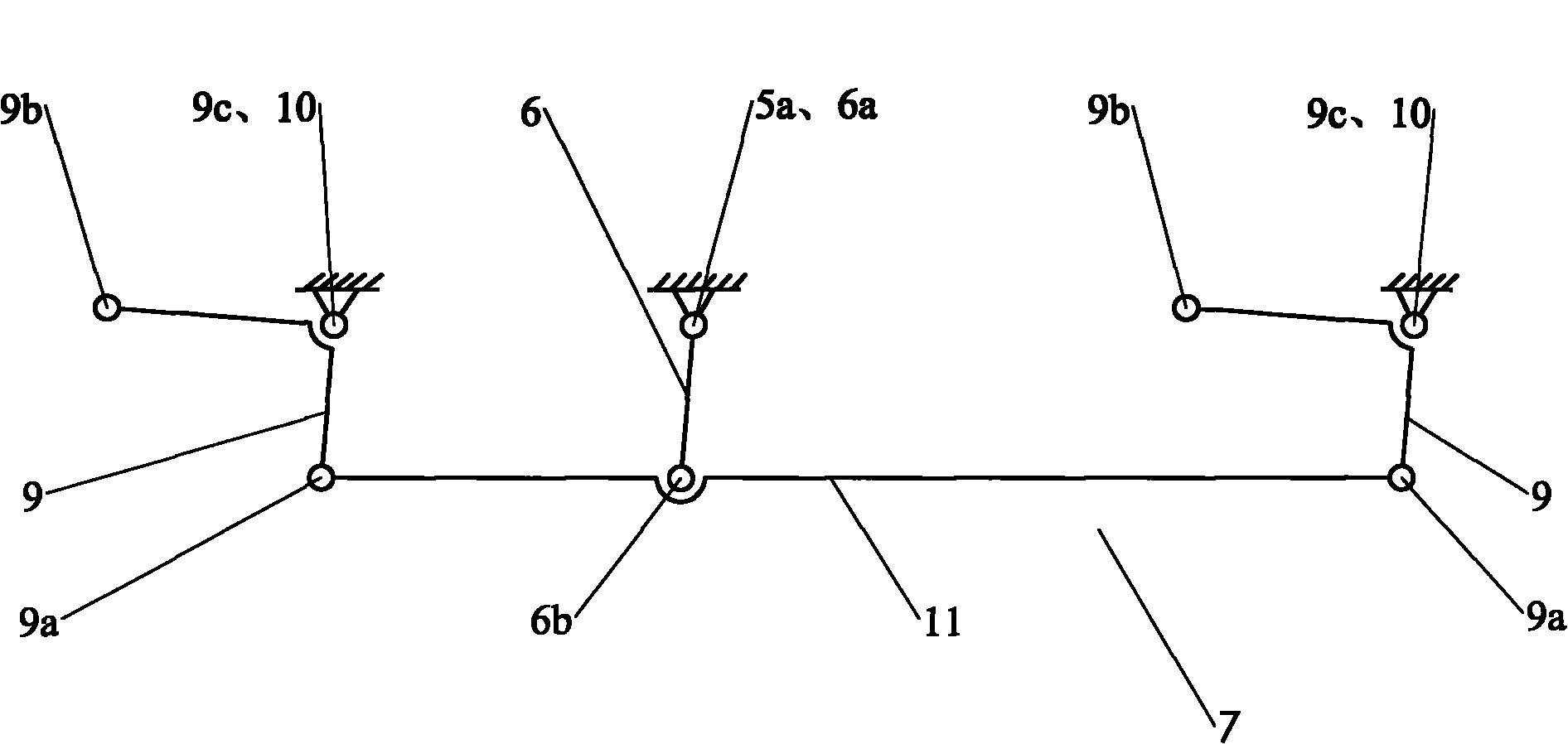

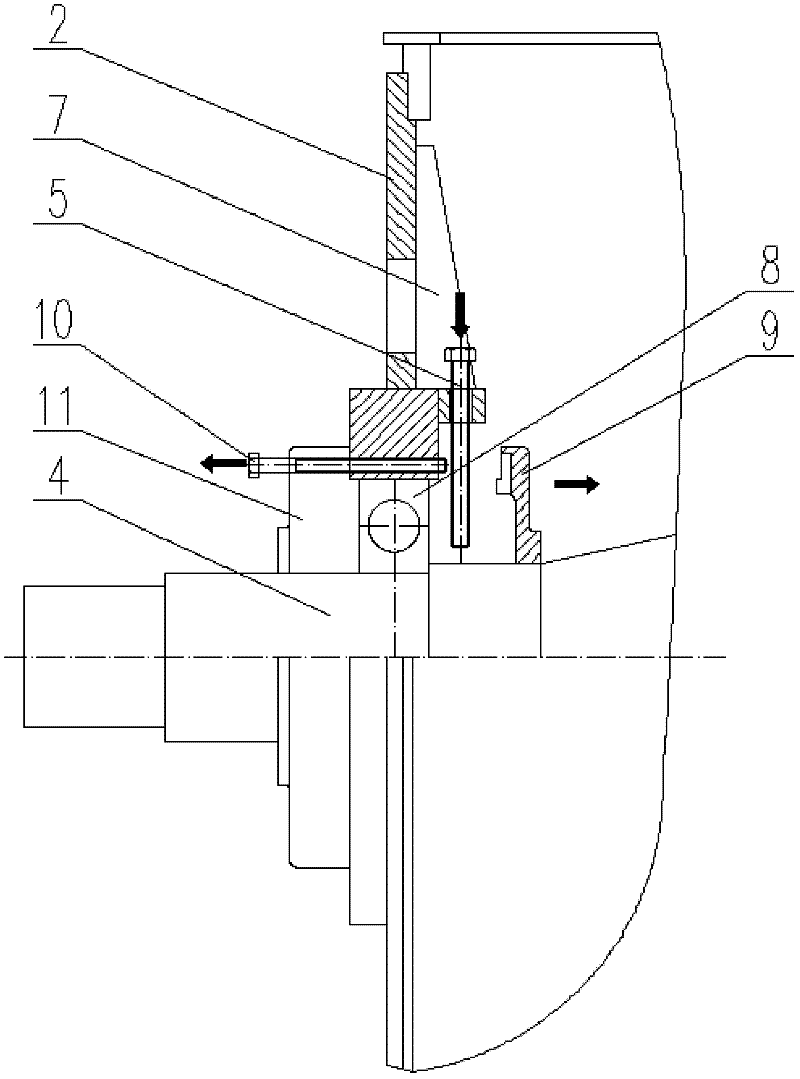

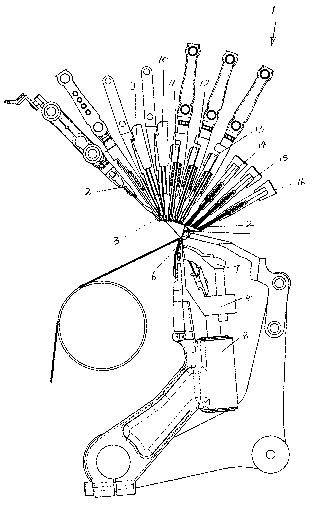

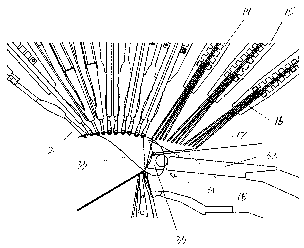

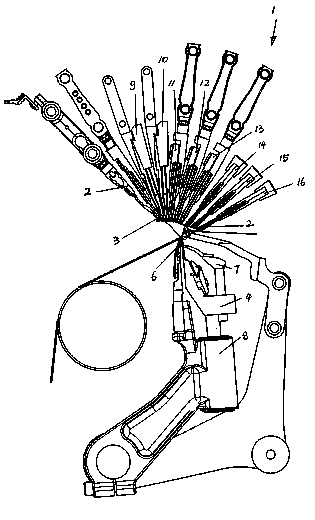

Shedding device of weaving machine

InactiveCN101922076AEasy to driveSolve problems that are longed to be solved but not solvedLoomsOther shedding mechanismLinear motionElectric machine

The invention discloses a shedding device of a weaving machine, which adopts an electric machine to independently drive each heald frame. The device comprises a plurality of sets of driving mechanisms (3) for driving heald frames (4). The driving mechanisms (3) comprise electric machines (5), driving swing arms (6) and parallelogram linkages (7). The output ends of the driving swing arms are hinged with connecting rods (11) of the parallelogram linkages (7), the driving swing arms (6) and side links (9) are not only of the same length but also are parallel to each other. The electric machines (5) drive the driving swing arms (6), the output ends of the driving swing arms drive the connecting rods (11), and the connecting rods (11) transmit the driving power to the side links (9) at the left sides and right sides of the parallelogram linkages (7) so as to enable the heald frames (4) to complete reciprocating linear motion. In the invention, the driving mechanisms (3) do not occupy any space expect that of a weaving machine rack (12), so that the weaving machine (1) occupies obviously reduced space, the sizes of the driving mechanisms (3) are uniform and only electronic setting is required to adjust heald frame (4) stroke.

Owner:赵斯伟

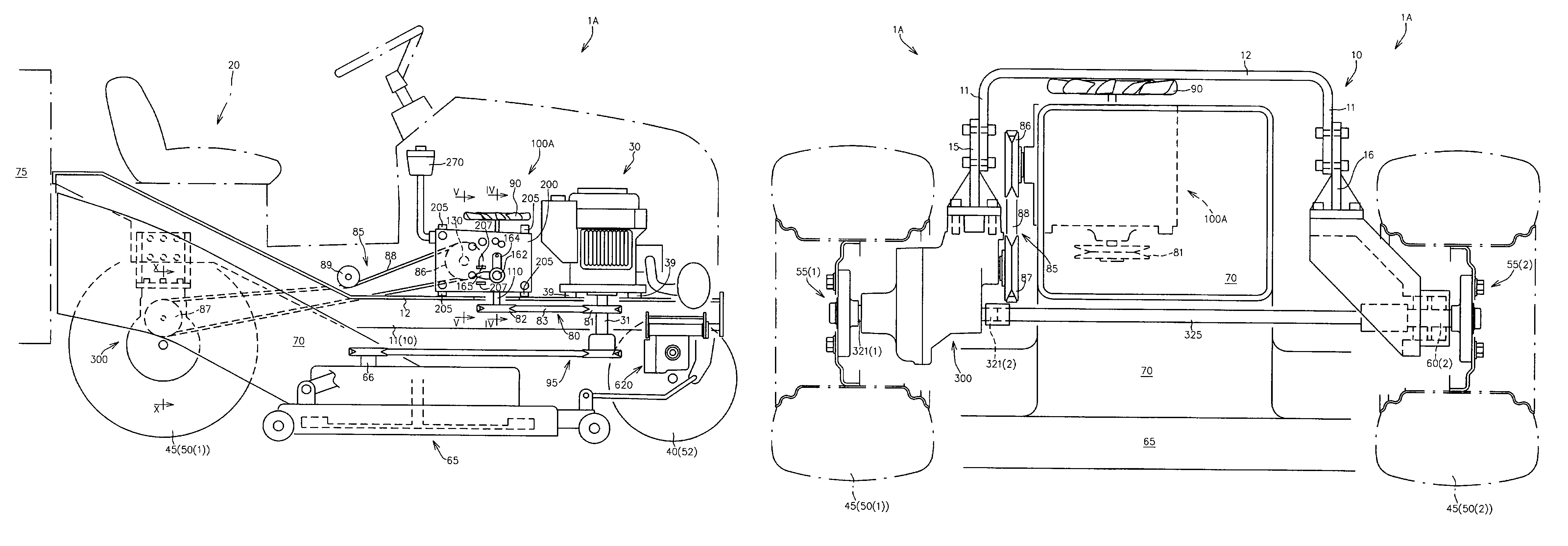

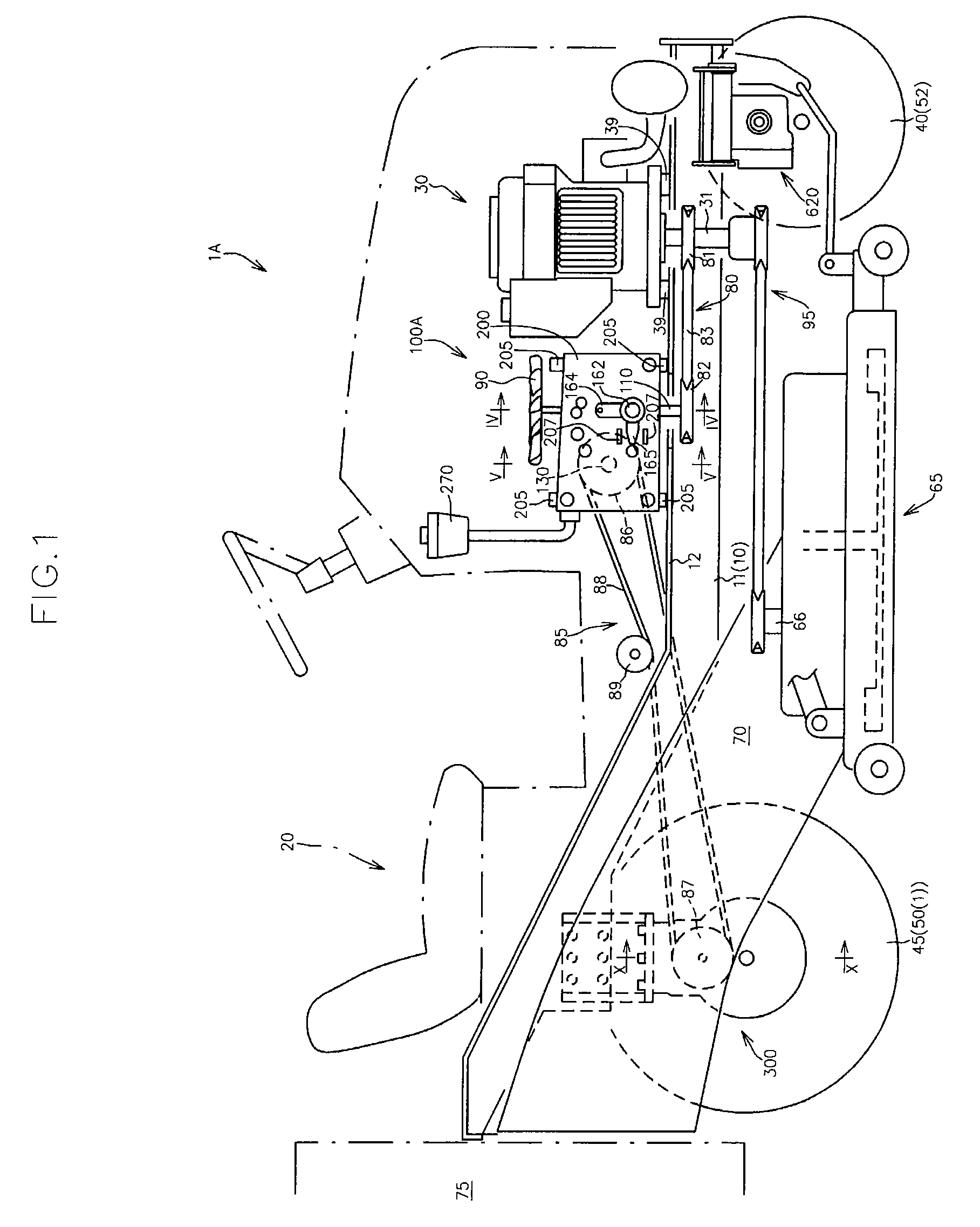

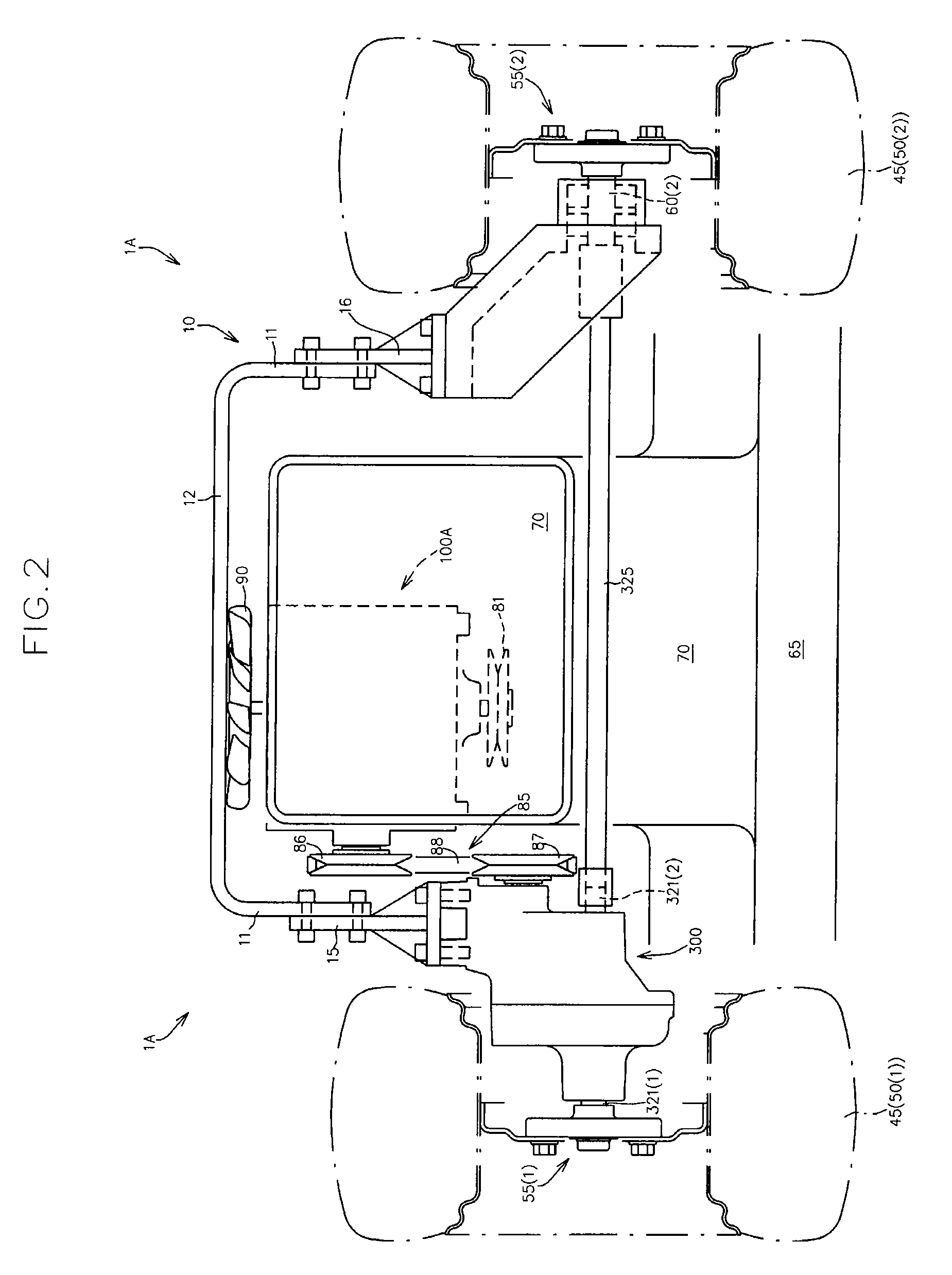

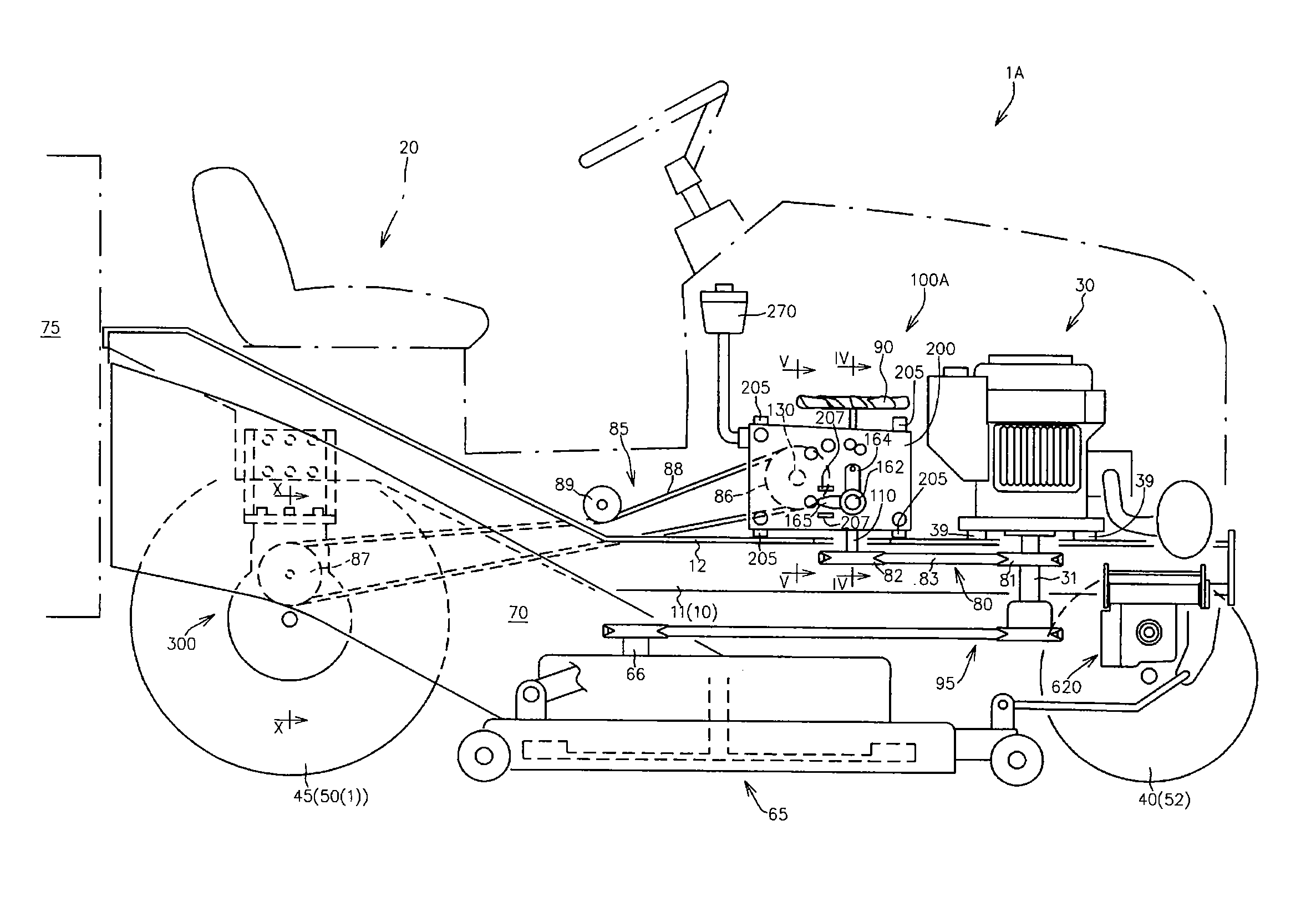

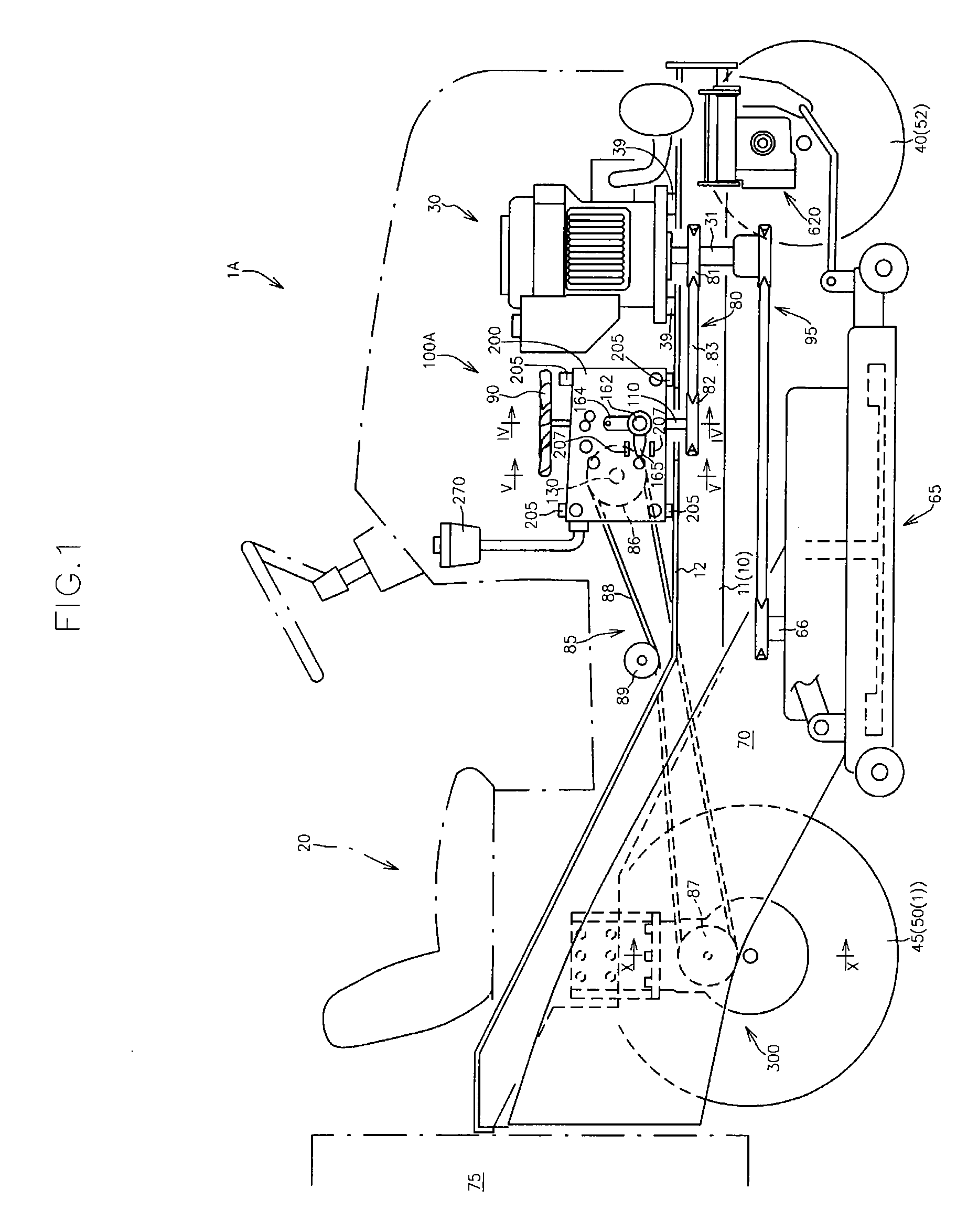

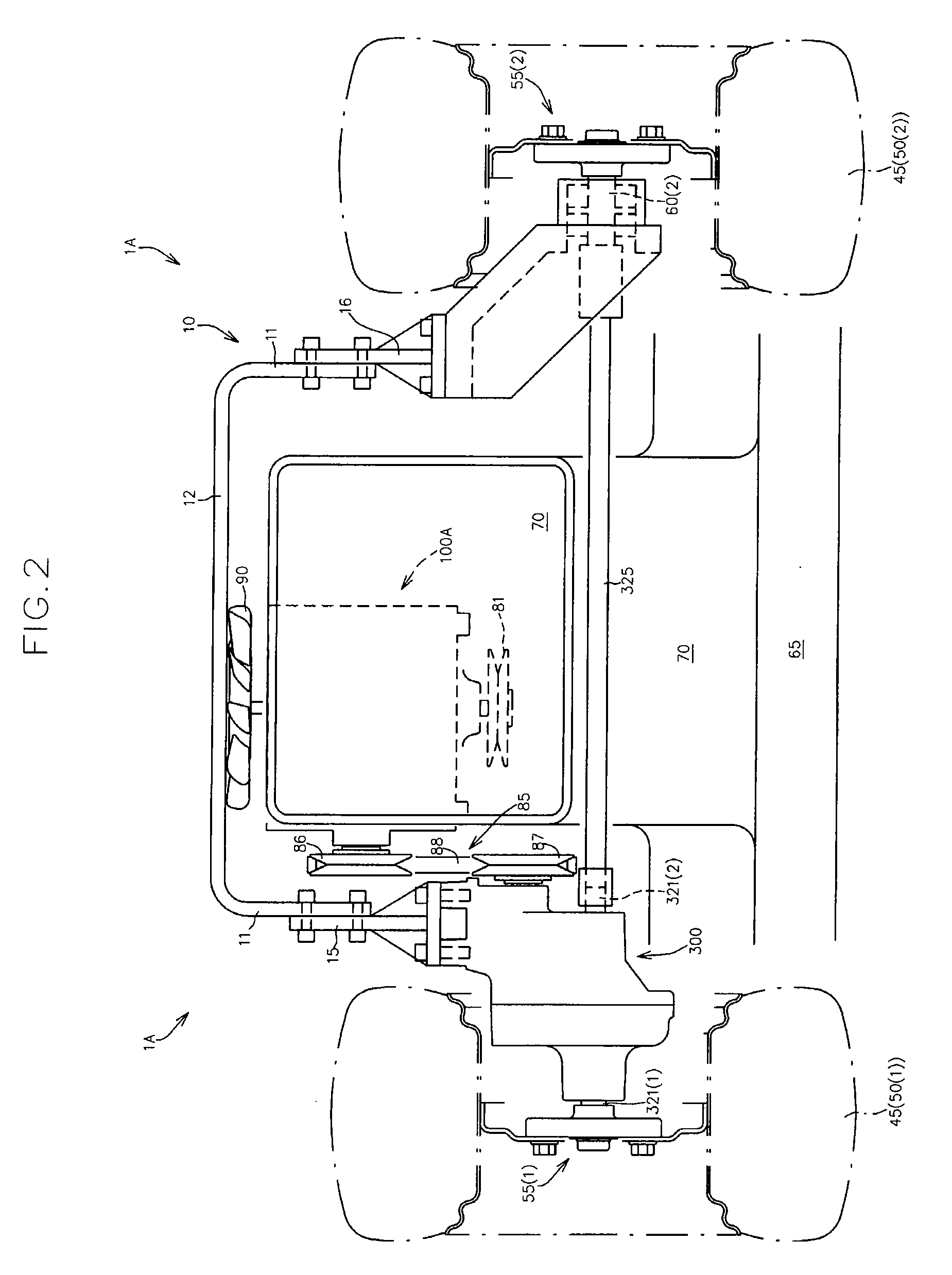

Working vehicle and HST unit

Owner:KANZAKI KOKYUKOKI MFG

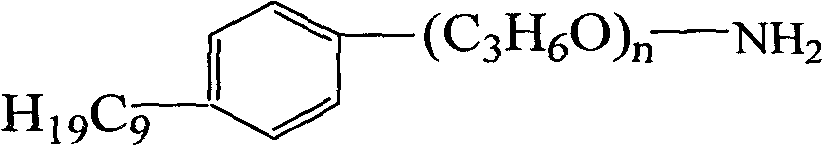

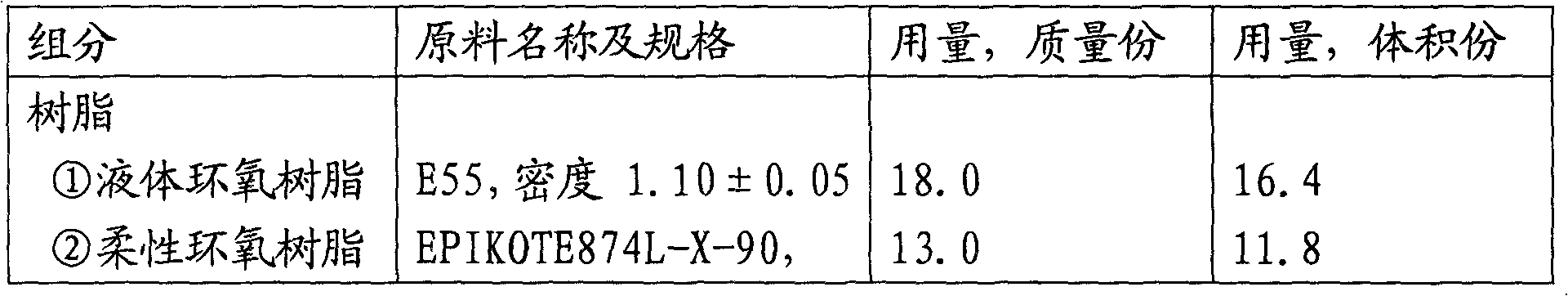

High solid constituent epoxy coating composition

ActiveCN102634261AGood flexibilityImprove compatibilityAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention relates to a high solid constituent epoxy coating composition. The mass ratio of A component to B component is 100:20 in parts. 25-33 parts of resin, 50-60 parts of pigment and padding, 1-3 parts of assistants and the balance of organic solvent are contained in 100 parts of the A components by mass. 6-10 parts of polyamide, 3-5 parts of cashew nut oil modified amine, 3-5 parts of chain extender and the balance of solvent are contained in 20 parts of the B components by mass. The content of volatile organic compound (VOC) of the coating composition is less than or equal to 250g / L. The resin in the A component is a compound of epoxy resin E51, or E 55, or F51 and flexible epoxy resin, and the flexible epoxy resin accounts for 33-66%. 25 DEG C viscosity of the polyamide in the B component is less than 20000mPa.S, and the chain extender is nonylphenol polyether amine containing end primary amine. The combined property of the high solid constituent epoxy coating composition is superior to that of the existing high solid constituent epoxy coating and traditional epoxy anti-corrosion coating.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST +2

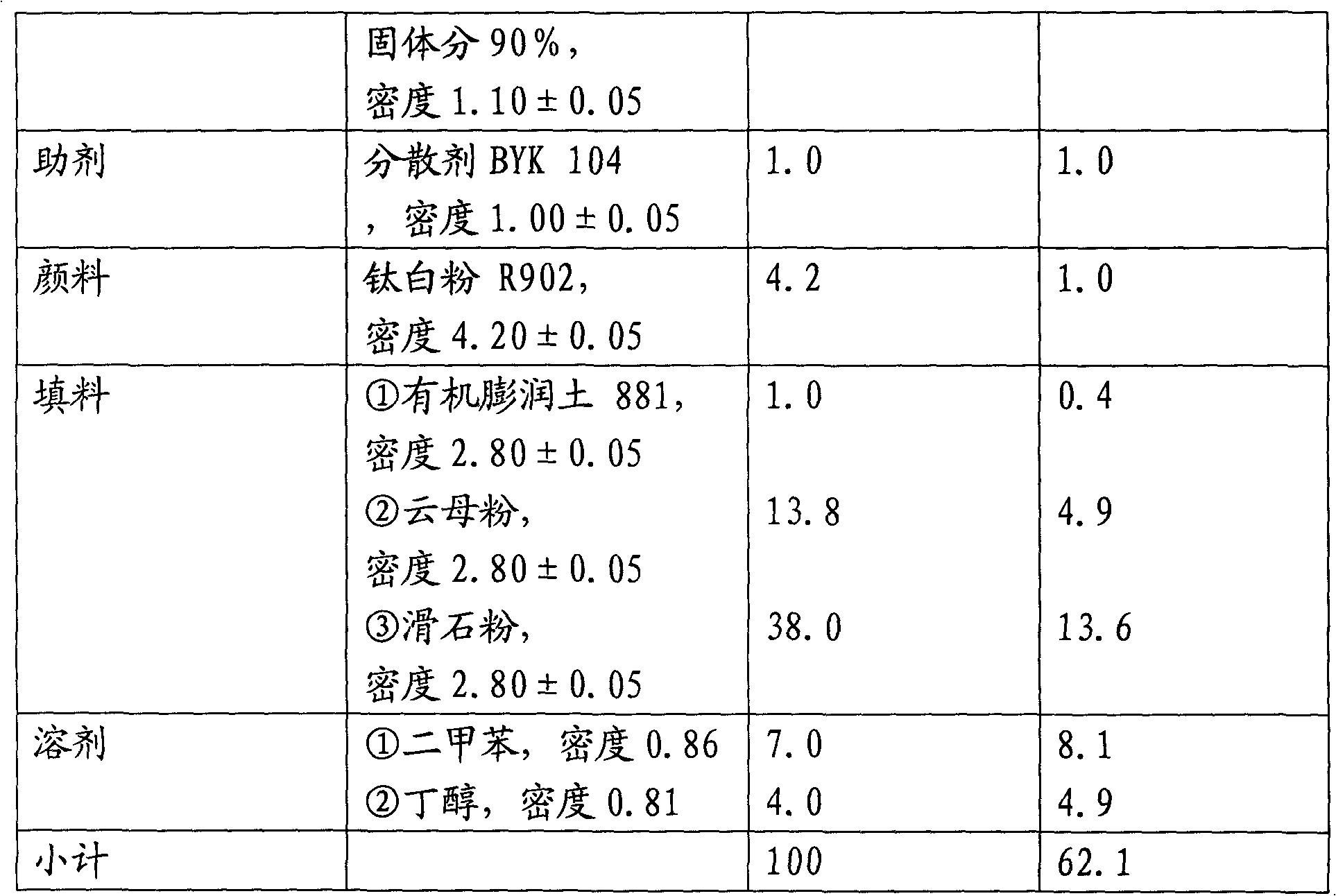

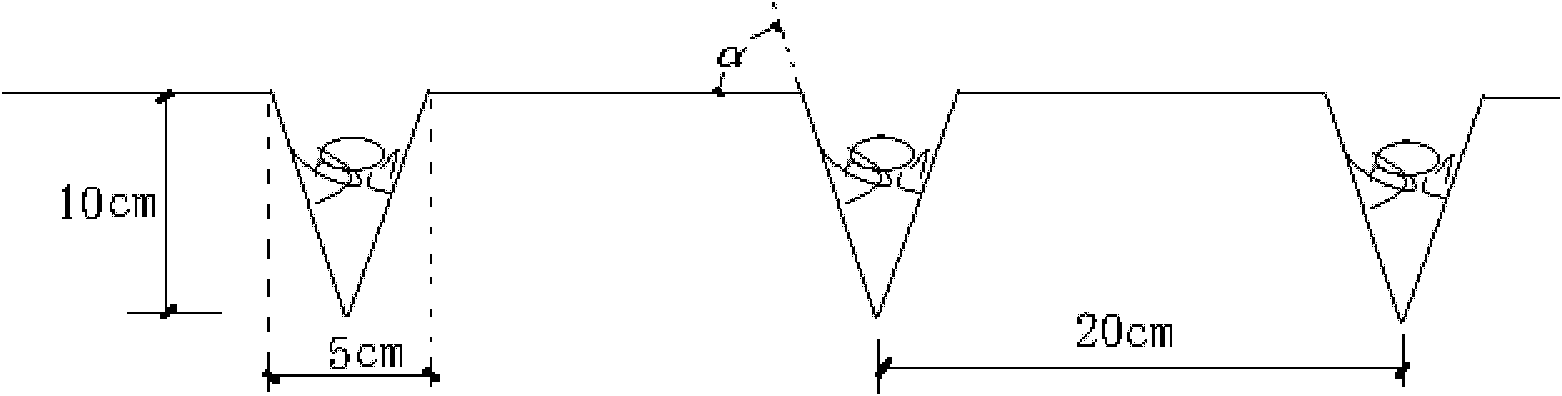

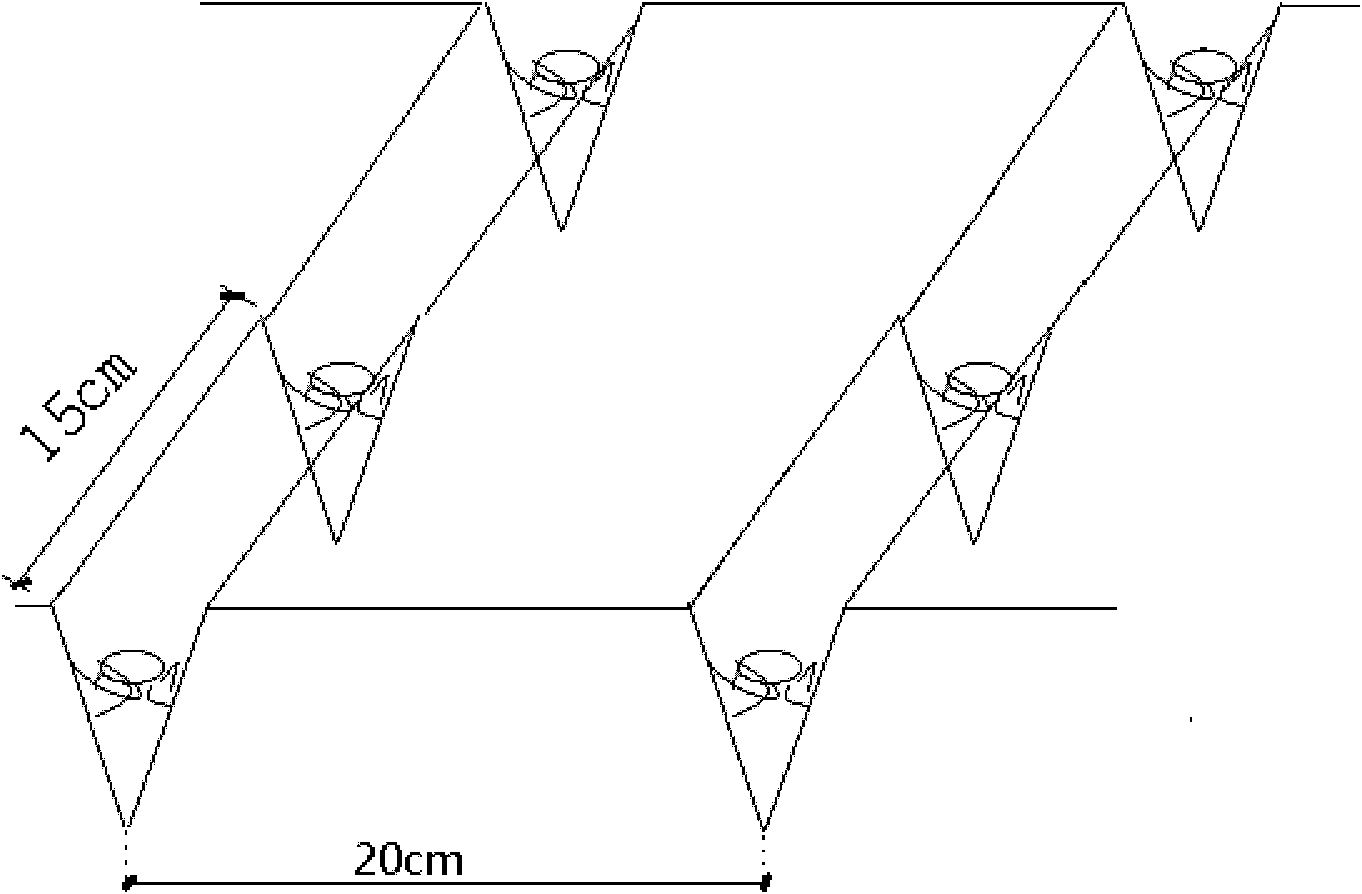

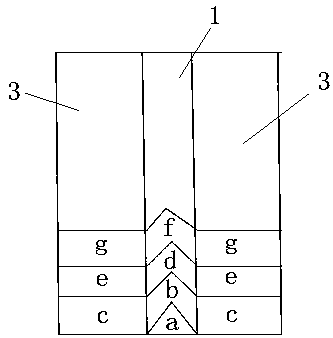

Cultivation method for rice direct dibble seeding in wedged ditches

InactiveCN102550348AIncrease profitIncrease temperatureFertilising methodsRice cultivationSystem stabilityDitch

The invention discloses a cultivation method for rice direct dibble seeding in wedged ditches, which belongs to the field of rice cultivation. In order to solve the problem that yield potential of high-yield high-quality varieties is difficult to fulfill by existing cultivation methods, the cultivation method for rice direct dibble seeding in wedged ditches includes the steps: firstly, tilling soil, namely performing no turning or irrigation after preceding harvesting, and digging a field to obtain a plurality of ditches, wherein row spacing between each two adjacent ditches is 18-22cm, each ditch in a triangular shape is wide end up, each ditch is 5-20cm deep and 3-6cm wide, two sides of each ditch are slopes relative to the horizontal plane, and an included angle between each slope and the horizontal plane is 40 DEG-70 DEG; secondly, post-treating rice seeds; thirdly, performing base fertilizer application, direct dibble seeding, and irrigation; and fourthly, performing field management. The traditional ploughing is replaced with wedging, so that farming intensity is reduced, interference to soil is lowered, energy sources are saved, labor is reduced, seeds for use are few, soilwater retention capacity is high, soil system stable is high, fertilizer utilization rate is high, root system growth environment is improved, and cost reducing, yield increase and efficiency enhancement are achieved.

Owner:HUNAN AGRICULTURAL UNIV

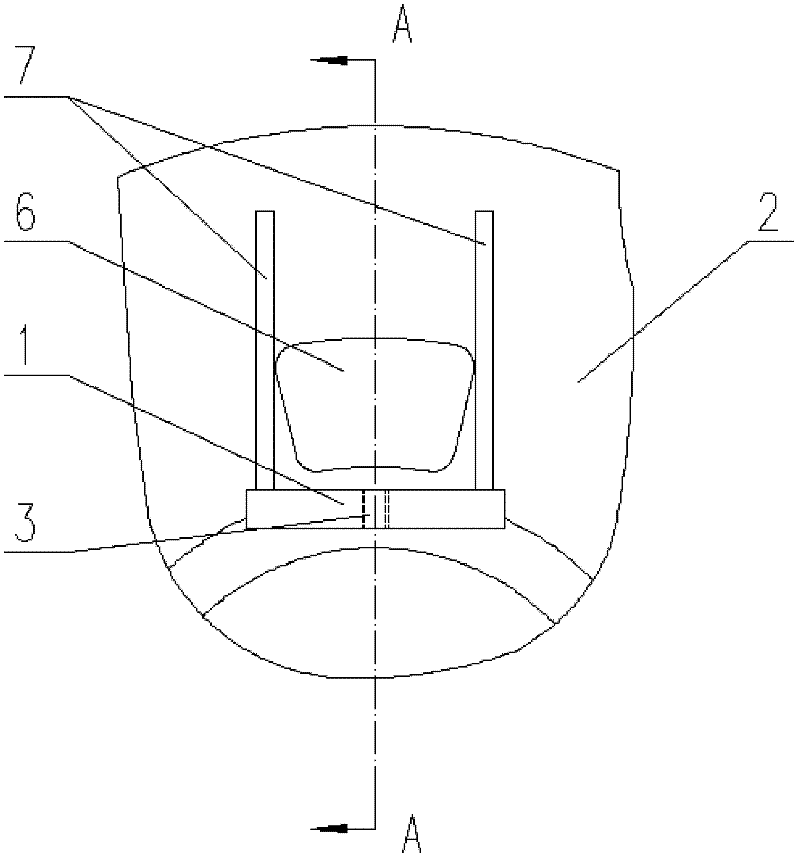

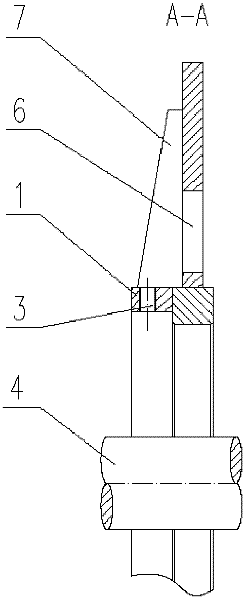

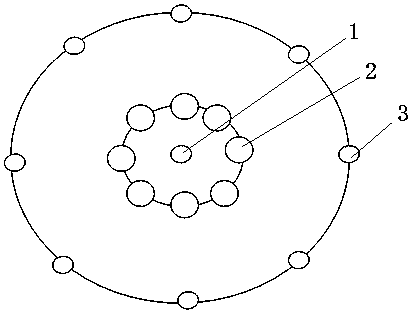

Alignment support device for rotor of permanent-magnetic wind power generator and rotor bearing replacement method

ActiveCN102570680ASimple structureEasy to operateManufacturing dynamo-electric machinesSupports/enclosures/casingsSuction forceStructural engineering

The invention discloses an alignment support device for a permanent-magnetic wind power generator. The alignment support device comprises at least three alignment support parts. Each alignment support part comprises a support plate and a support bolt, wherein the support plate is fixedly arranged on an end cover of the generator; a threaded hole is formed in the support plate, and penetrates through the support plate along the radial direction of a rotating shaft of the generator; the bolt is arranged on the threaded hole; and the bottom end of the bolt can contact the outer surface of the rotating shaft of the generator. A certain number of bolts fix the rotor by taking the end cover of the generator as a support to make the rotor always in an acting force balanced state, so that the rotor is prevented from being attracted onto or colliding with a stator under the action of gravity and magnetic attraction force in operation such as the replacement of a rotor bearing and the like; compared with the prior art in which the stator and the rotor are supported by stainless steel wedged cushion blocks, the rotor support device adopting the bolts has a simple structure, and is convenientto assemble and disassemble; and the bolts have small volumes, so that a large operating space can be provided for subsequent procedures.

Owner:DONGFANG ELECTRIC MACHINERY

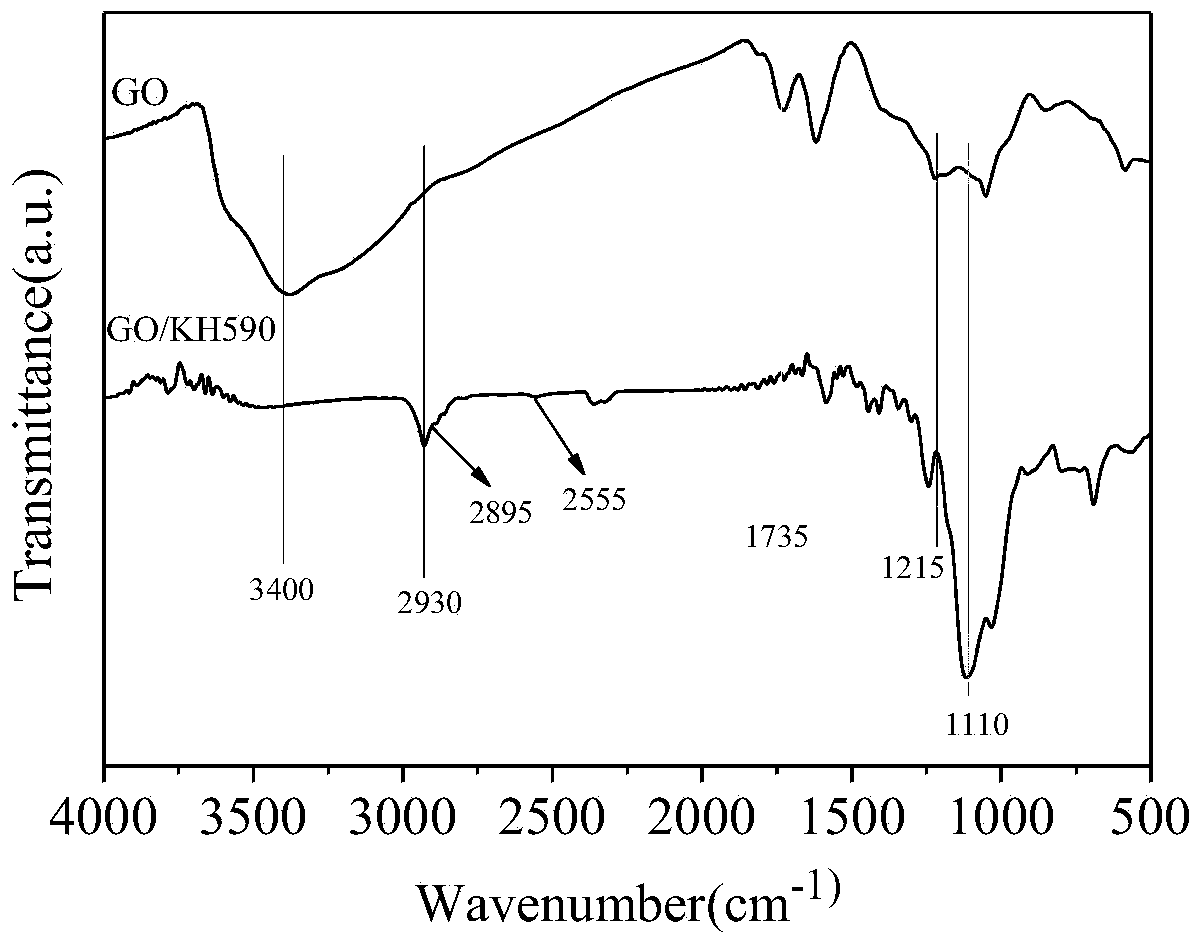

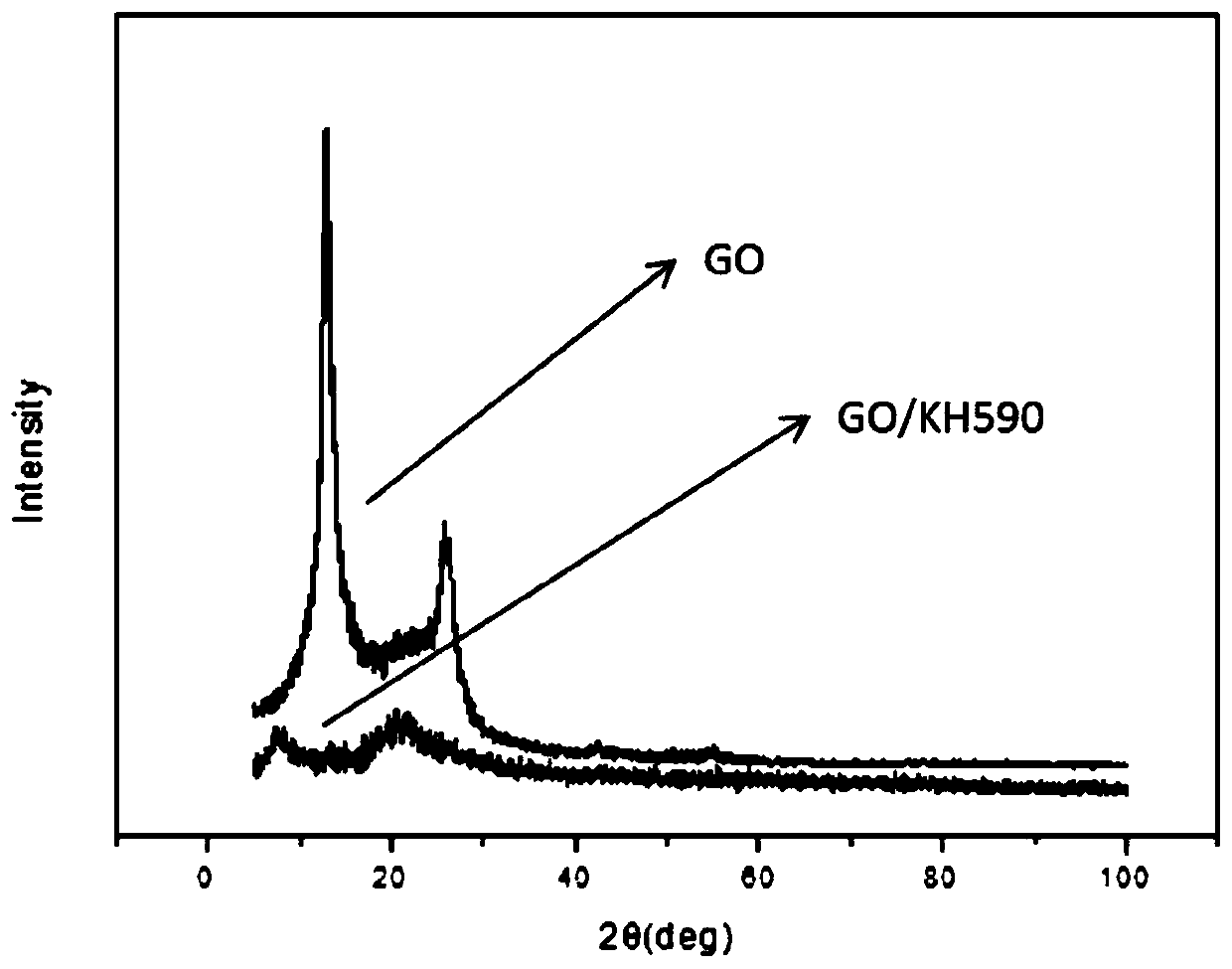

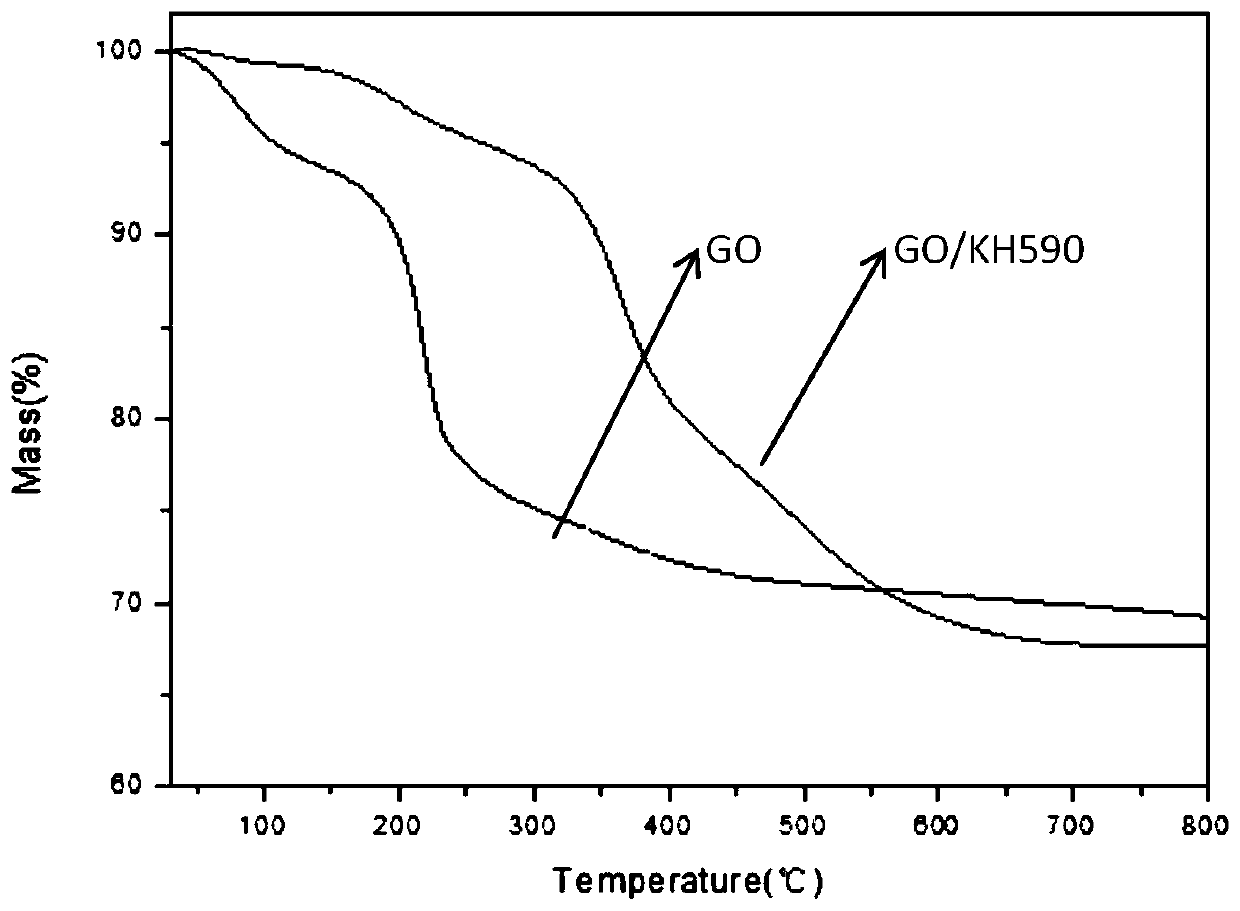

Graphene modified nitrile rubber and preparation method thereof

ActiveCN110343299ASolve the problem of poor high and low temperature resistanceImprove mechanical propertiesNitrile rubberPolymer science

The invention belongs to the technical field of graphene rubber composite materials, and provides a graphene modified nitrile rubber and a preparation method thereof. The graphene modified nitrile rubber is prepared from the following components in parts by weight: 70-90 parts of a nitrile rubber, 10-30 parts of a modified graphene oxide-carboxyl nitrile rubber master batch, 1.5-2 parts of a vulcanizing agent, 0.5-2.0 parts of a vulcanizing accelerator, 3-5 parts of a vulcanizing activator, 1-3 parts of a plasticizer, 1-2 parts of an antioxidant and 20-30 parts of fillers; and the modified graphene oxide-carboxyl nitrile rubber master batch is prepared from the modified graphene oxide and further prepared from carboxyl nitrile rubber latex, wherein mercapto-siloxane after hydrolysis reactswith the graphene oxide by being subjected to dehydration synthesis, and the modified graphene oxide is obtained. Through the technical scheme, the problem of poor high and low temperature resistanceof the nitrile rubber in the prior art is solved.

Owner:石家庄贝克密封科技股份有限公司 +1

Photosensitive composition for volume hologram recording, volume hologram recording medium using same, method for manufacturing volume hologram recording medium, and hologram recording method

InactiveCN104246626AKeep HardnessBig free spaceRecord information storageRecord carrier materialsChemical compoundPolymer

The present invention addresses the problem of providing a photosensitive composition for volume hologram recording from which a volume hologram recoding medium that shows suppressed cure shrinkage and suppressed cracking in hologram recording (hologram formation) can be formed. The photosensitive composition for volume hologram recording according to the present invention is characterized by comprising: an alicyclic epoxy compound (A) represented by formula (I), a hot acid generating agent (B), a radical-polymerizable compound (C), a radical polymerization initiator (D), and at least one kind of an epoxy compound (E) selected from the group consisting of a compound represented by formula (1), an epoxidized fatty acid ester and an epoxidized product of a conjugated diene-type polymer.

Owner:DAICEL CHEM IND LTD

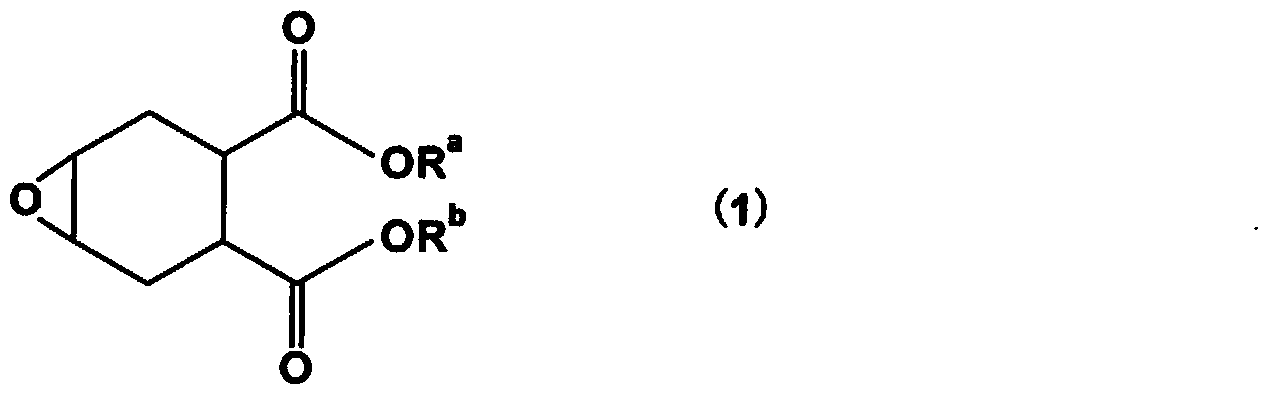

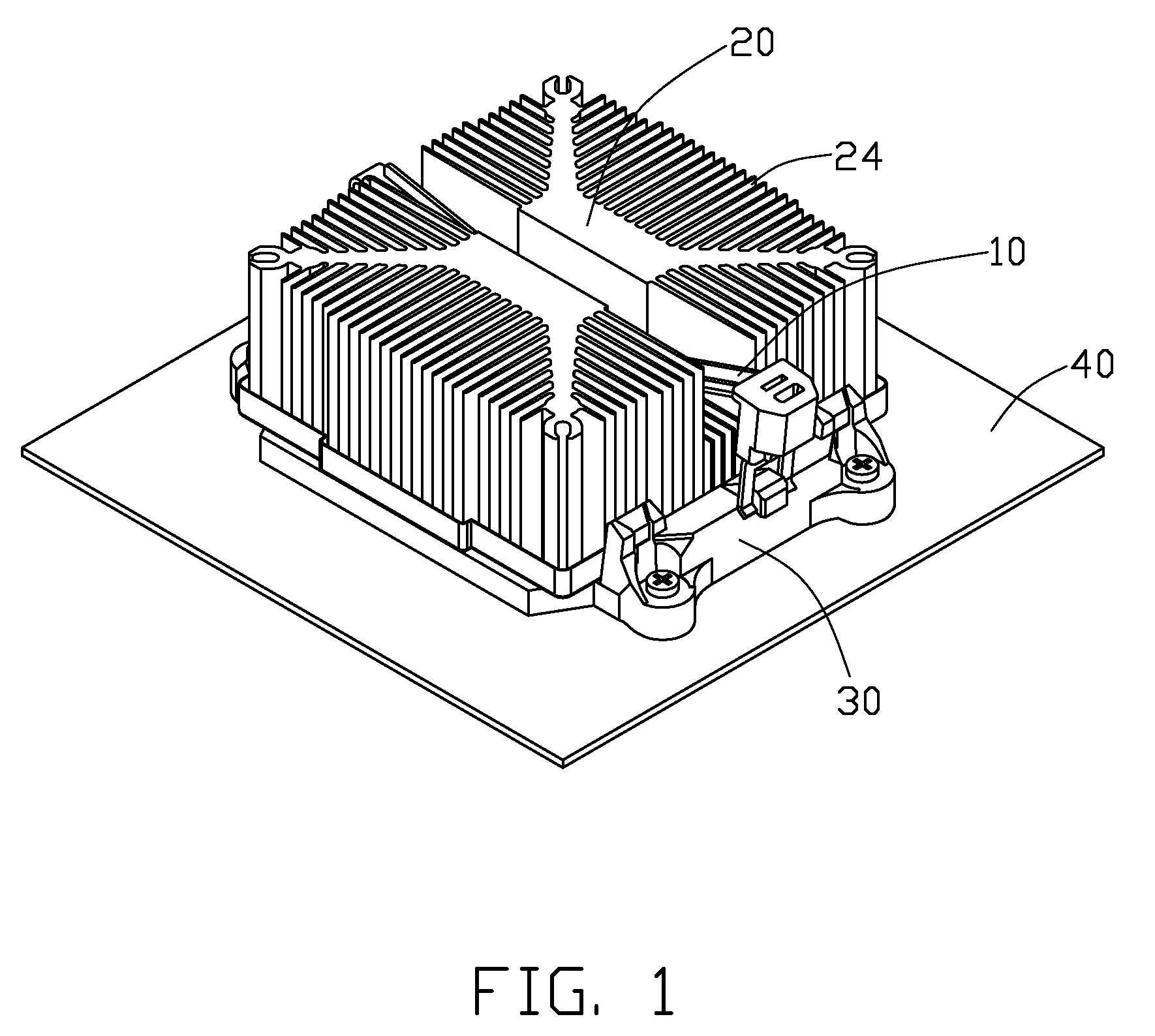

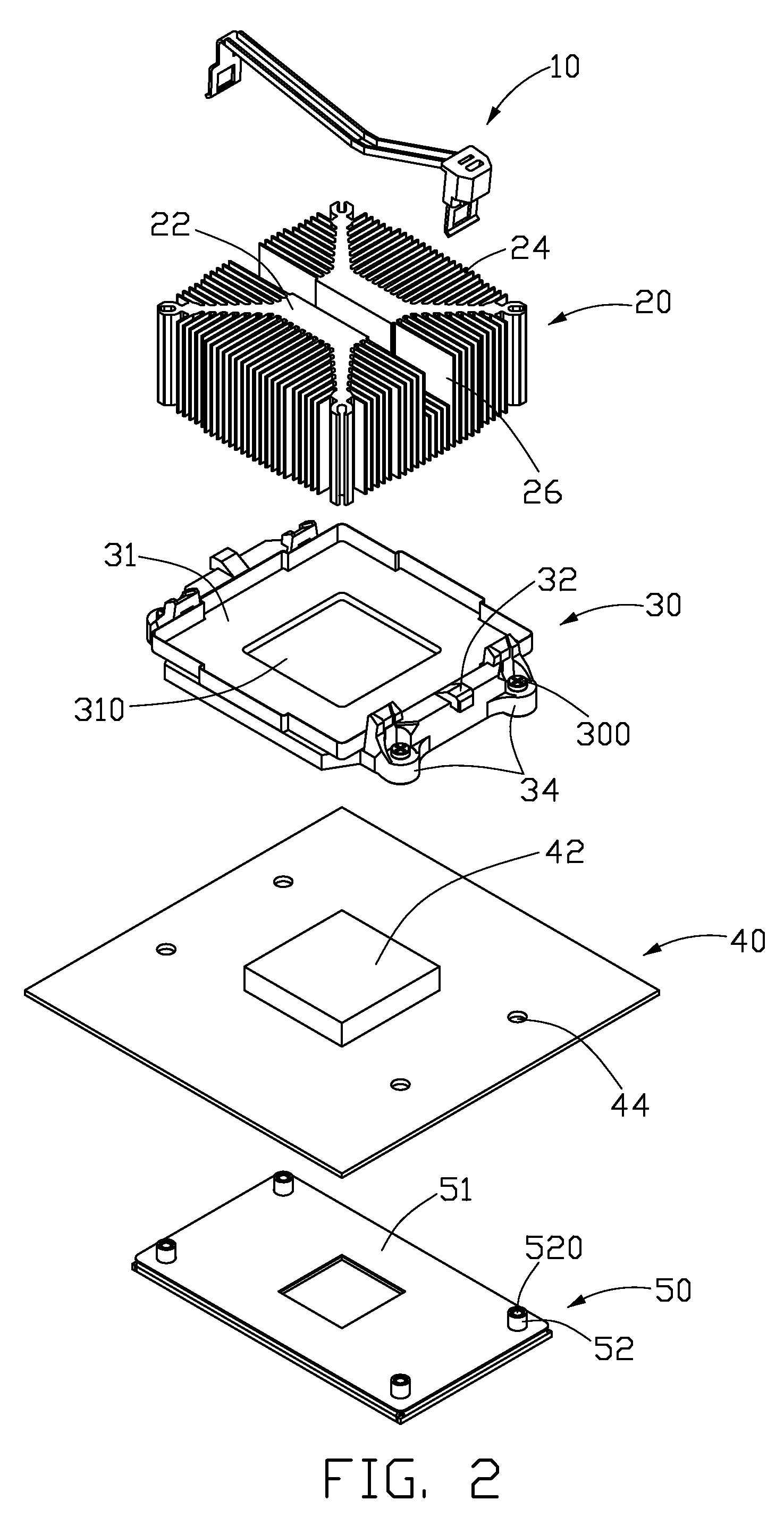

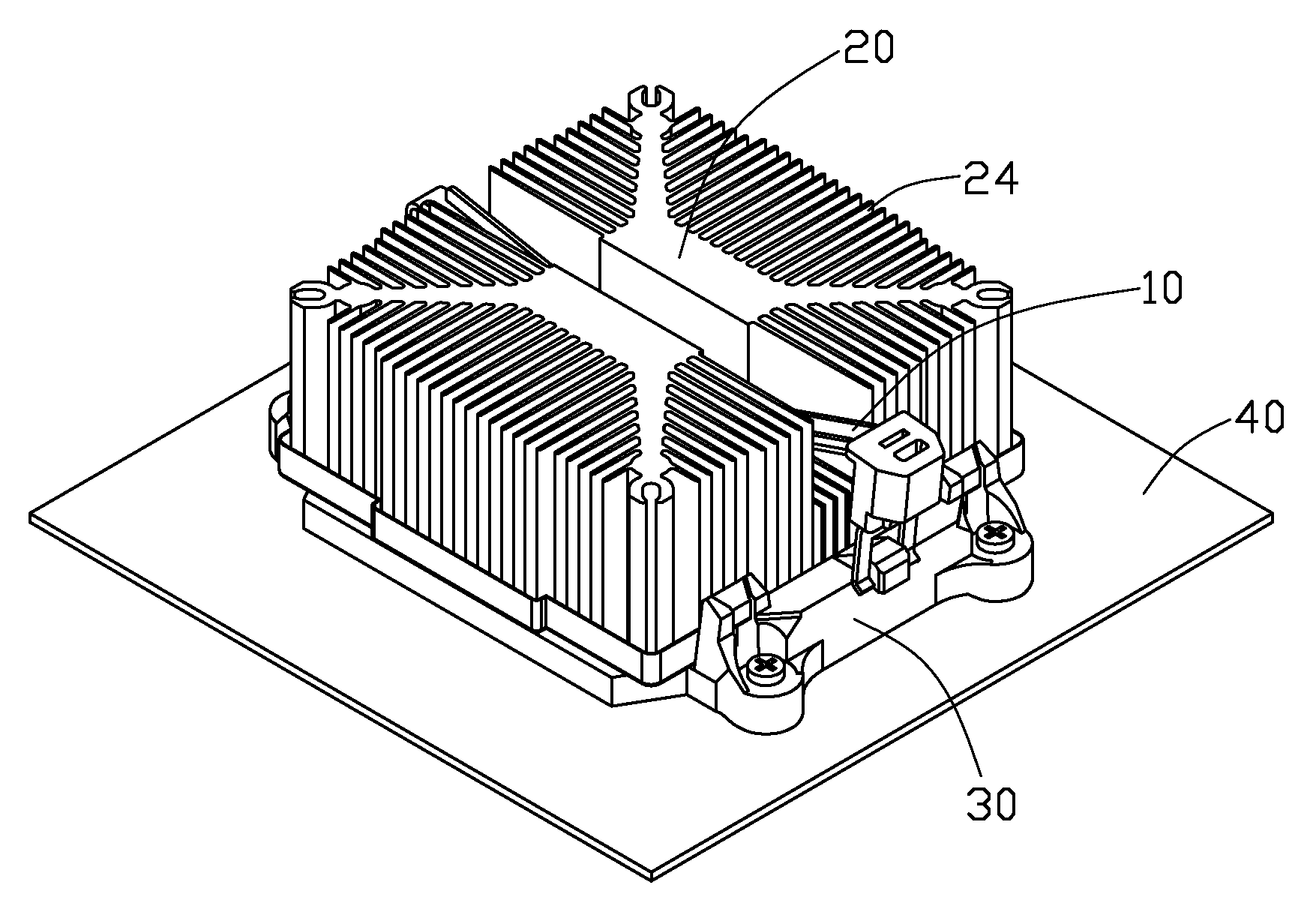

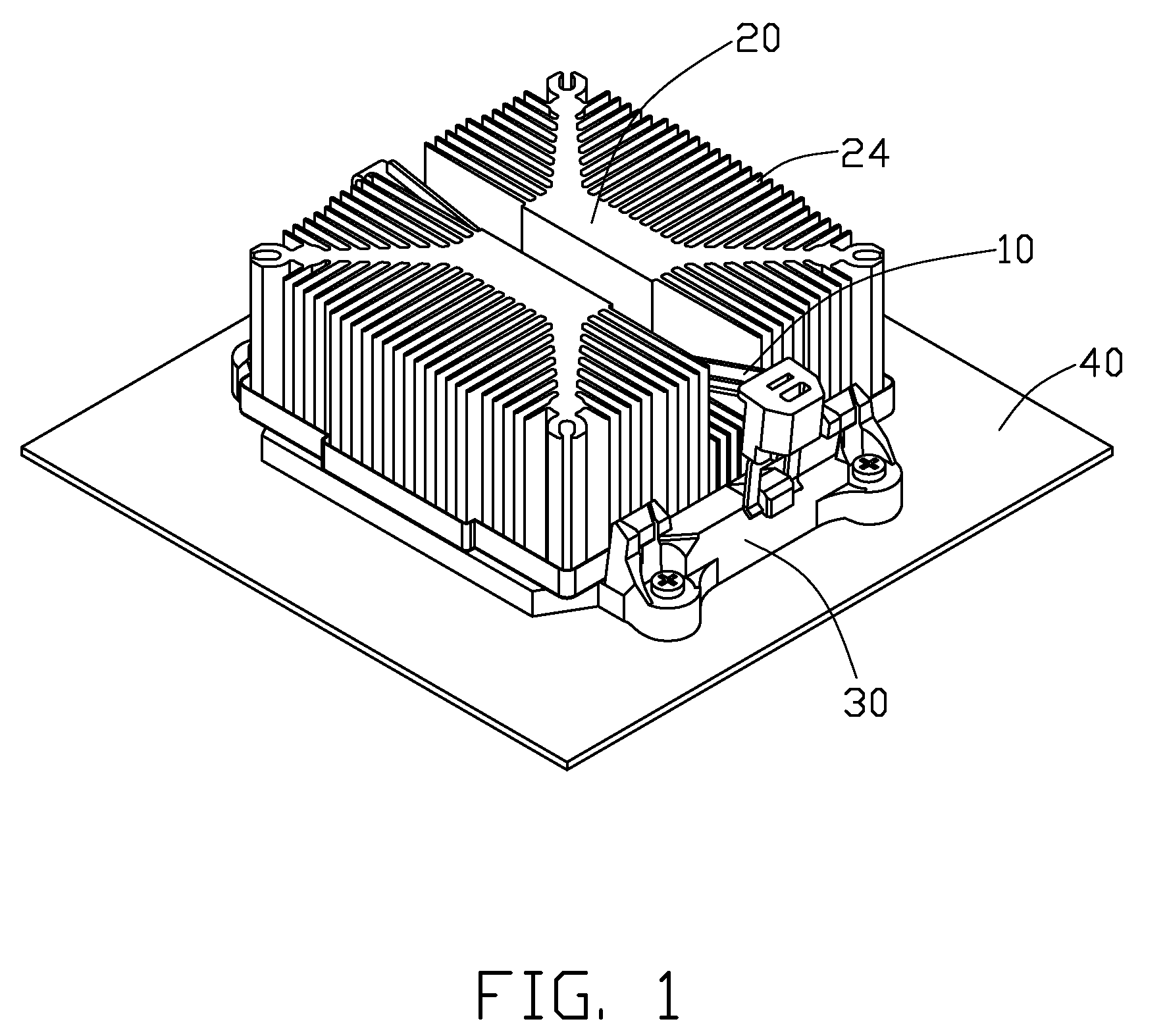

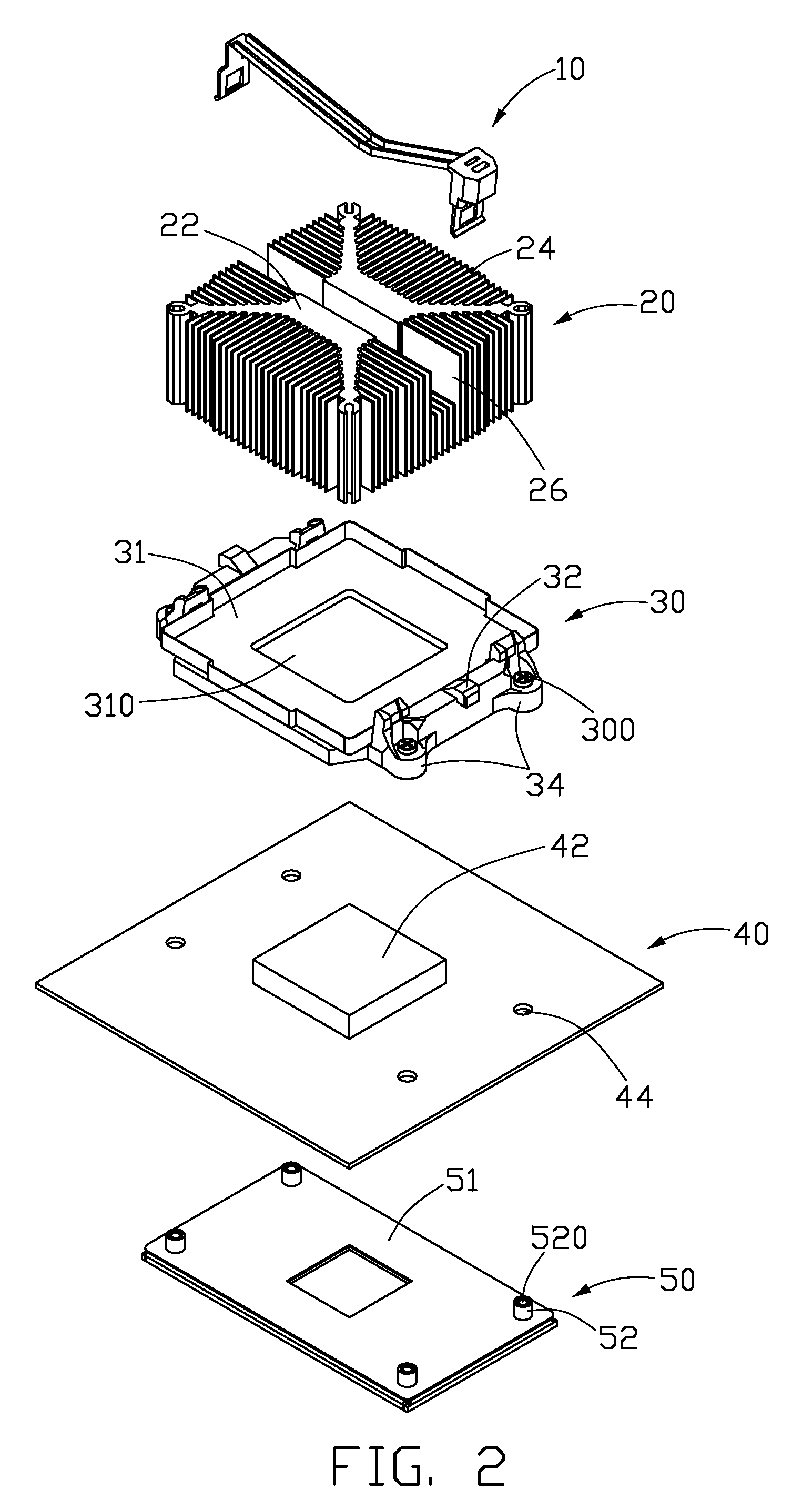

Heat sink fastening assembly

InactiveUS7433194B2Low costEasy to fixSnap fastenersSemiconductor/solid-state device detailsEngineeringHeat spreader

A heat sink fastening assembly includes a fastener comprising a latching member and an operating member. The latching member includes a pressing part, a first latching leg and a second latching leg bent downwards respectively from two opposite ends of the pressing part. The operating member has a coping and a sidewall extending downwards from an edge of the coping. The sidewall defines two locking slots engaging with the first latching leg and an elastic rib extending downwards from the coping and engaged with the first latching leg of the latching member for inhibiting any movement of the operating member in a direction along the locking slot of the sidewall.

Owner:HON HAI PRECISION IND CO LTD +1

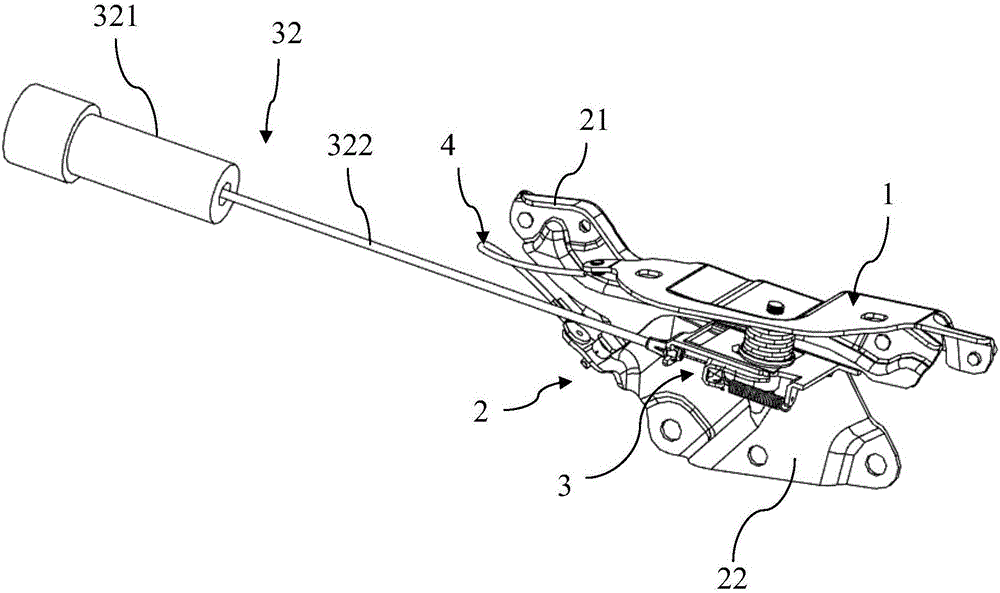

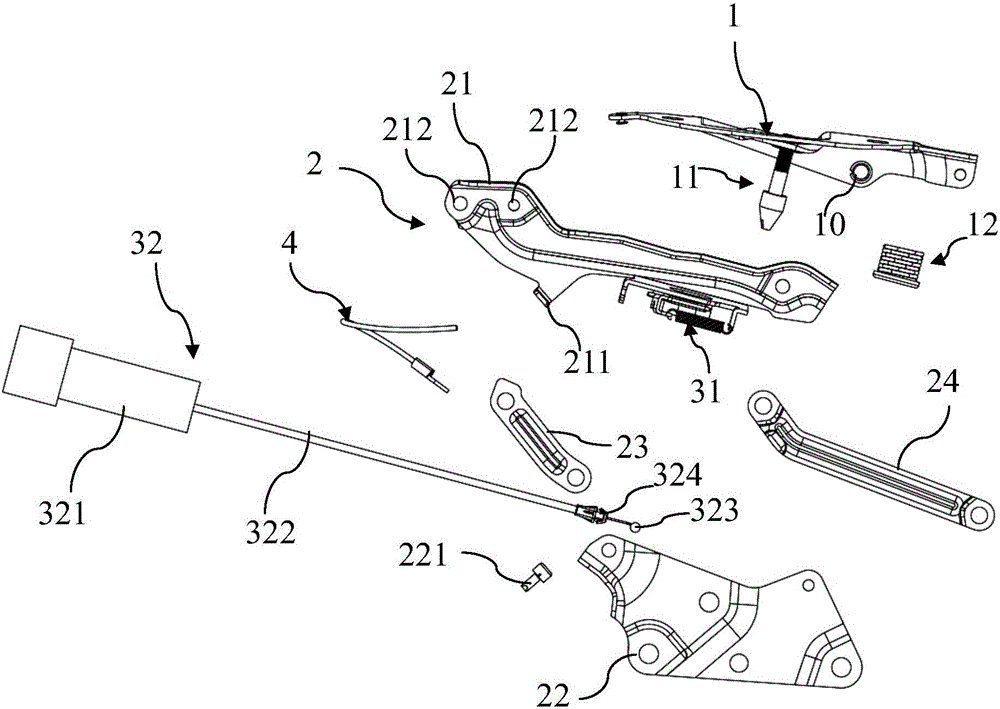

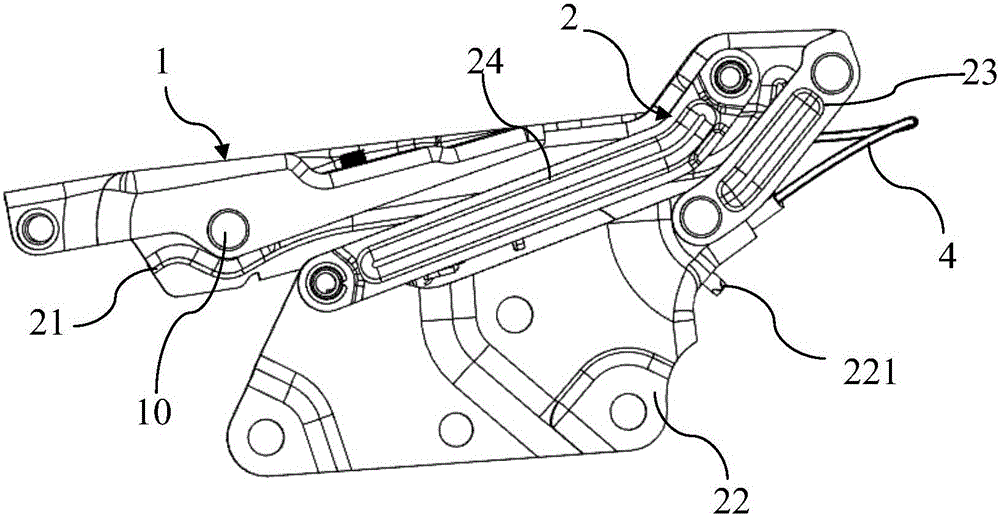

Connecting assembly for connecting engine hood and car body

ActiveCN105151129ABig free spaceAvoid damagePedestrian/occupant safety arrangementSuperstructure subunitsMechanical engineeringHinge angle

The invention discloses a connecting assembly. The connecting assembly comprises an upper connecting rod piece and a four-connecting-rod hinge structure. The four-connecting-rod hinge structure comprises a lower connecting rod piece, one end of the upper connecting rod piece is hinged to the lower connecting rod piece through a hinge shaft, and the upper connecting rod piece has a locking state and an upspring state. A lock pin is arranged on the upper connecting rod piece and provided with a clamp groove and a preloaded spring. A mounting plate is arranged on the lower connecting rod piece and extends upwards to form a matching hole. A clamp plate is hinged to the position, at one side of the matching hole, of the mounting plate, the position, close to one side of the matching hole, of the clamp plate extends to form a clamping portion, and an open portion is formed on the wall of the matching hole. A drive assembly used for driving the clamp plate to rotate is arranged on the mounting plate, and the clamping portion and the clamp groove can match or be separated along with rotation of the clamp plate. When the clamping portion and the clamp groove match, the lock pin is locked in the matching hole, and the upper connecting rod piece is in the locking state. When the clamping portion and the clamp groove are separated, the lock pin is separated out of the matching hole, and the upper connecting rod piece is in the upspring state.

Owner:SAIC GENERAL MOTORS +1

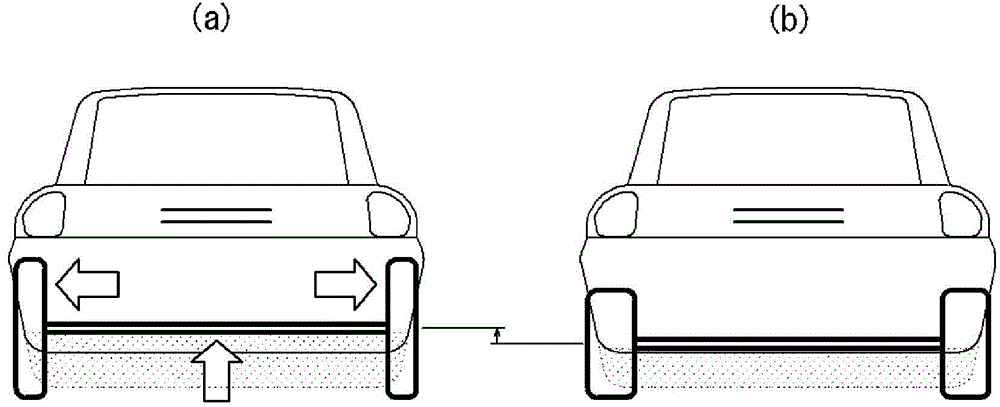

Working Vehicle and HST Unit

The working vehicle includes an axle unit that has a differential gear device, an axle case, an axle input shaft and first and second main output shafts, and an HST unit that has a hydraulic pump main body, a hydraulic motor main body, a capacity adjustment mechanism, an HST case, a pump shaft and a motor shaft, an HST input shaft, and an HST output shaft, wherein the axle unit is directly or indirectly supported by the vehicle frame so as to be positioned close to a first main driving wheel in a state where the axle input shaft extends in a vehicle widthwise direction, wherein the HST unit is directly or indirectly supported by the vehicle frame at a position away from the axle unit in a state where the HST output shaft extends in the vehicle widthwise direction, and wherein the HST output shaft and the axle input shaft are operatively connected to each other through an endless type transmission member.

Owner:KANZAKI KOKYUKOKI MFG

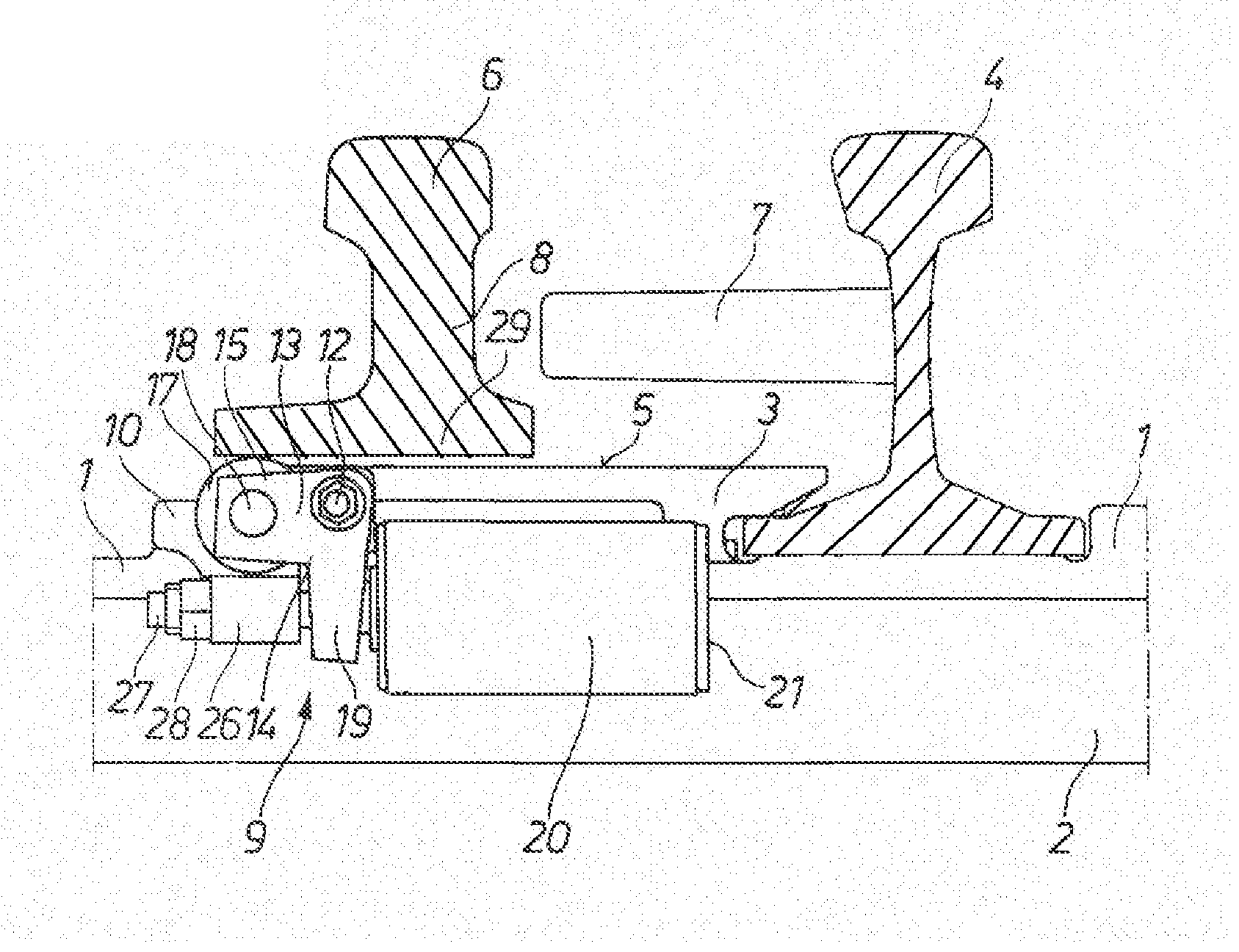

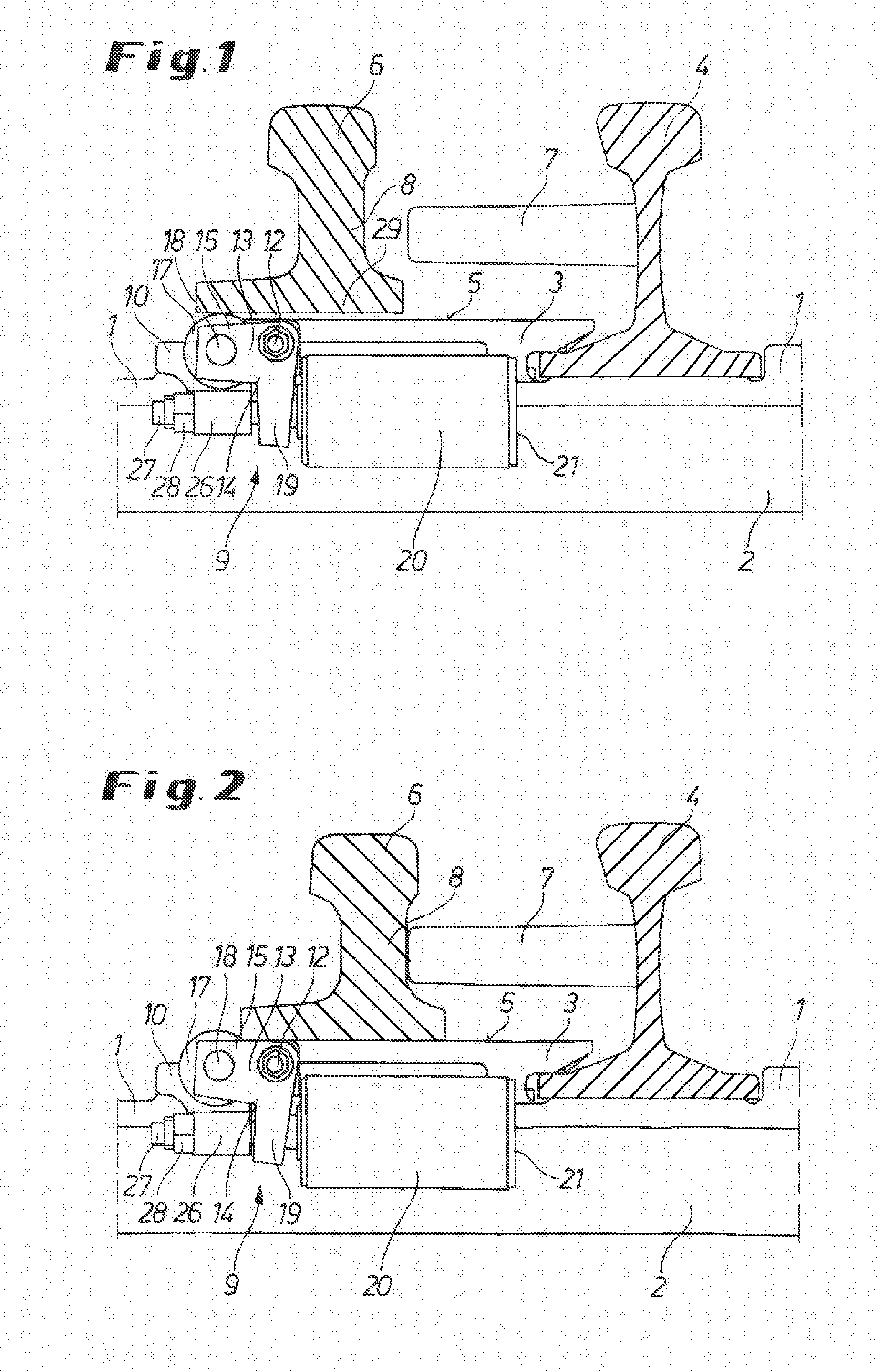

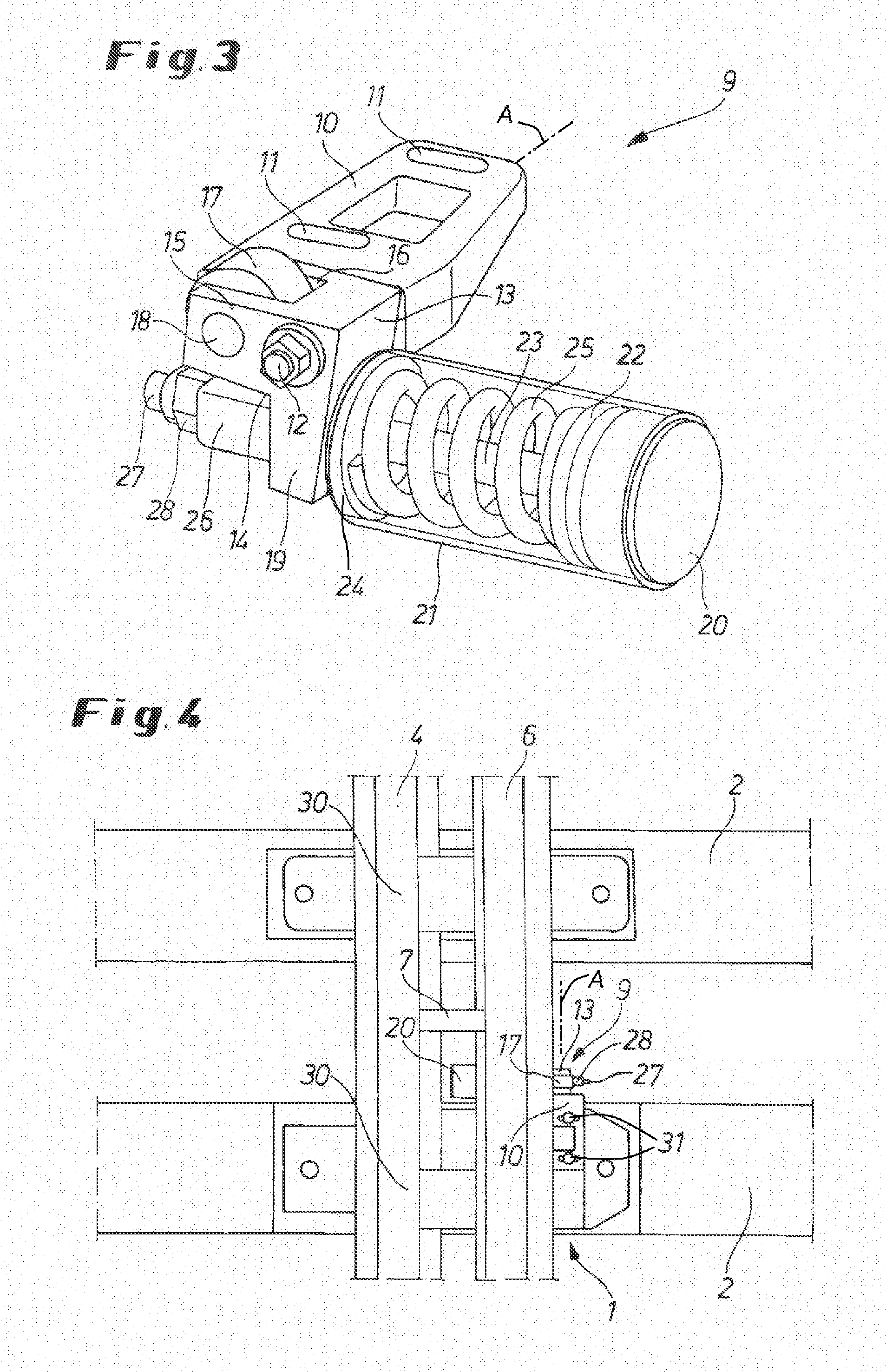

Roller support for the point rail of a railroad switch

A point rail is shiftable transversely on an upper face of a rail base plate between an engaged position bearing on a longitudinally extending and fixed stock rail and a disengaged position spaced transversely of the stock rail. A roller assembly has a mounting plate securable to the rail base plate, a roller support pivotal about a support axis on the rail base plate, a roller carried on the roller support, and a spring biasing the roller upward with a predetermined spring force into a lift position with the roller projecting upward past the upper face for supporting the point rail on the roller. Thus this assembly supports the point rail and, in the engaged position, presses it against the support cleats and the stock rail and it is an integral part of one of the rail base plates.

Owner:SCHWIHAG

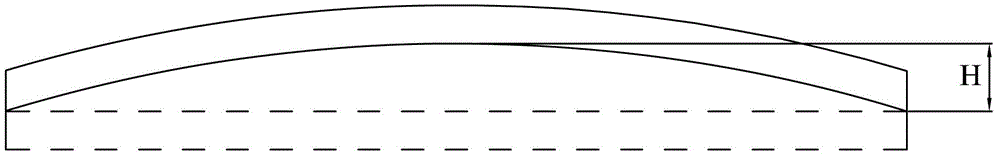

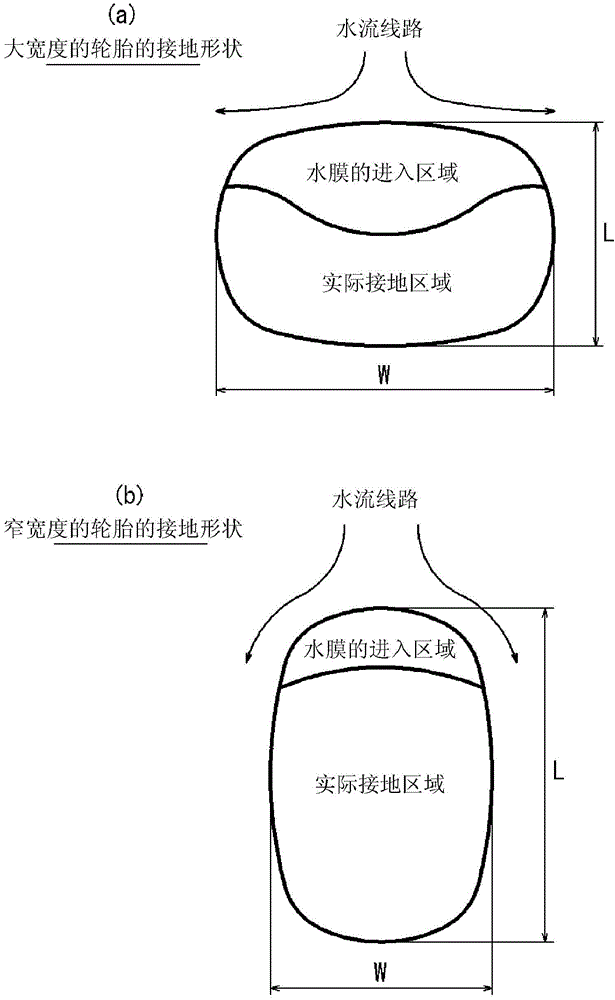

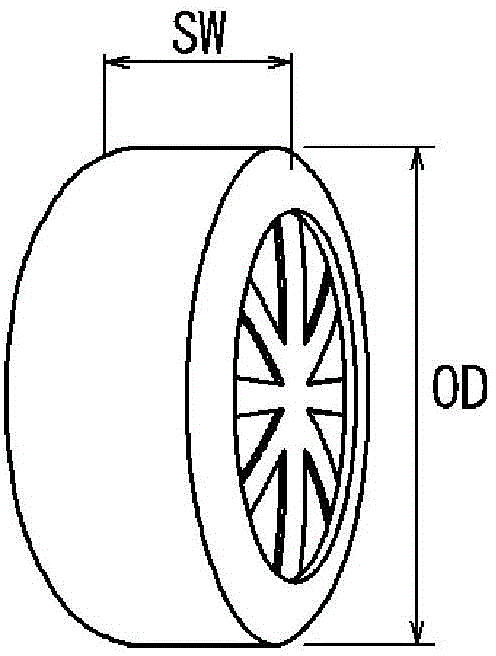

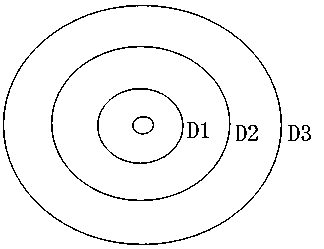

Pneumatic radial tire for passenger car and method for use thereof

InactiveCN104010836AImprove fuel economyImprove driving performanceSpecial tyresTyre tread bands/patternsGround contactGroove width

An object of the present invention is to adequately control relationship between a cross sectional width SW and an outer diameter OD of a pneumatic radial tire for a passenger vehicle. Specifically, a ground contact surface 1 of the tread of the pneumatic radial tire for a passenger car of the present invention is provided with either, as a groove, only at least one main groove 2a extending in the tread circumferential direction or, as grooves, only the main groove 2a and at least one auxiliary groove 2b other than the main groove, wherein the auxiliary groove has a groove width ‰¤ 2 mm in a tread widthwise region and a negative ratio of the main groove 2a is in the range of 12% to 20% (inclusive of 12% and 20%).

Owner:BRIDGESTONE CORP

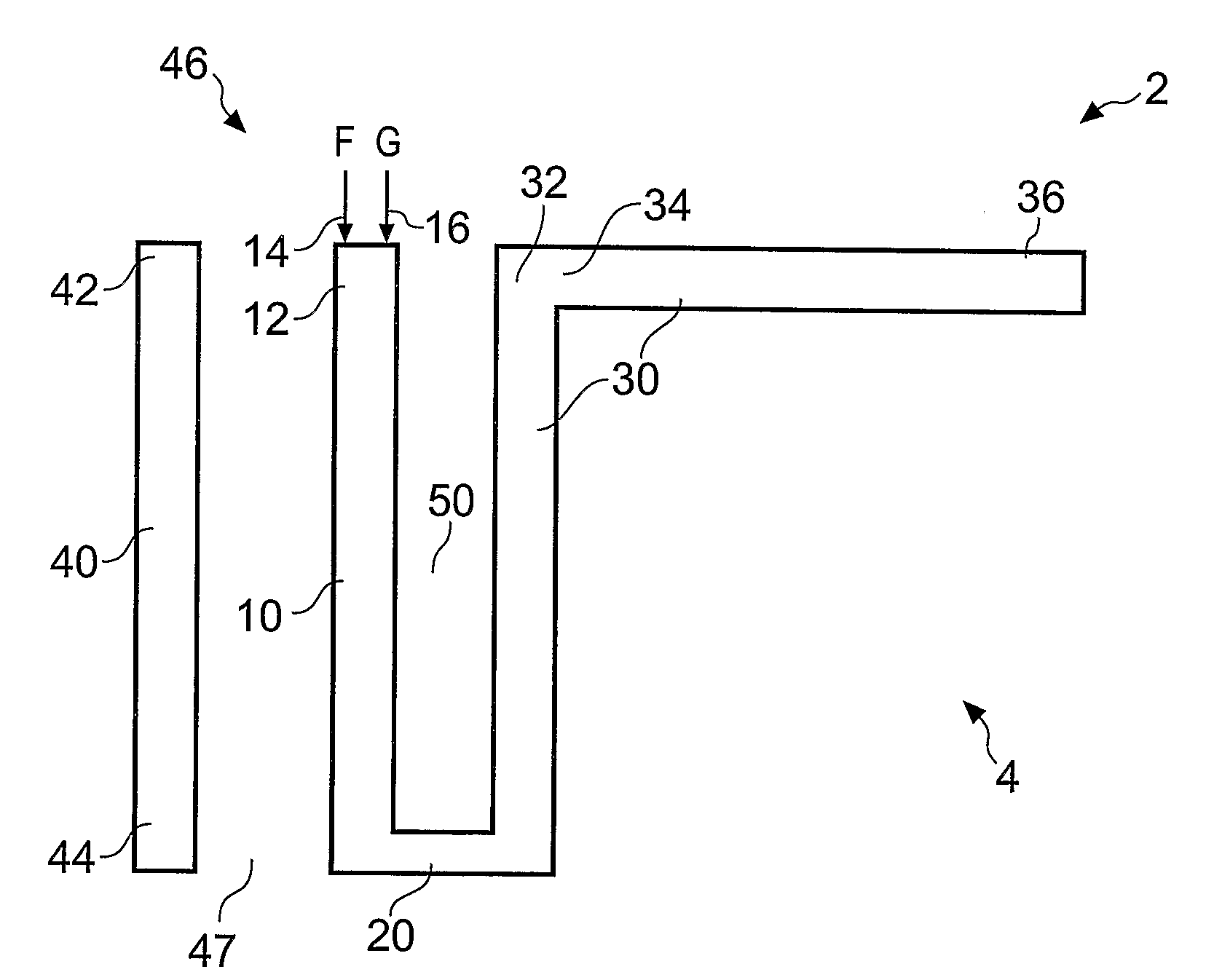

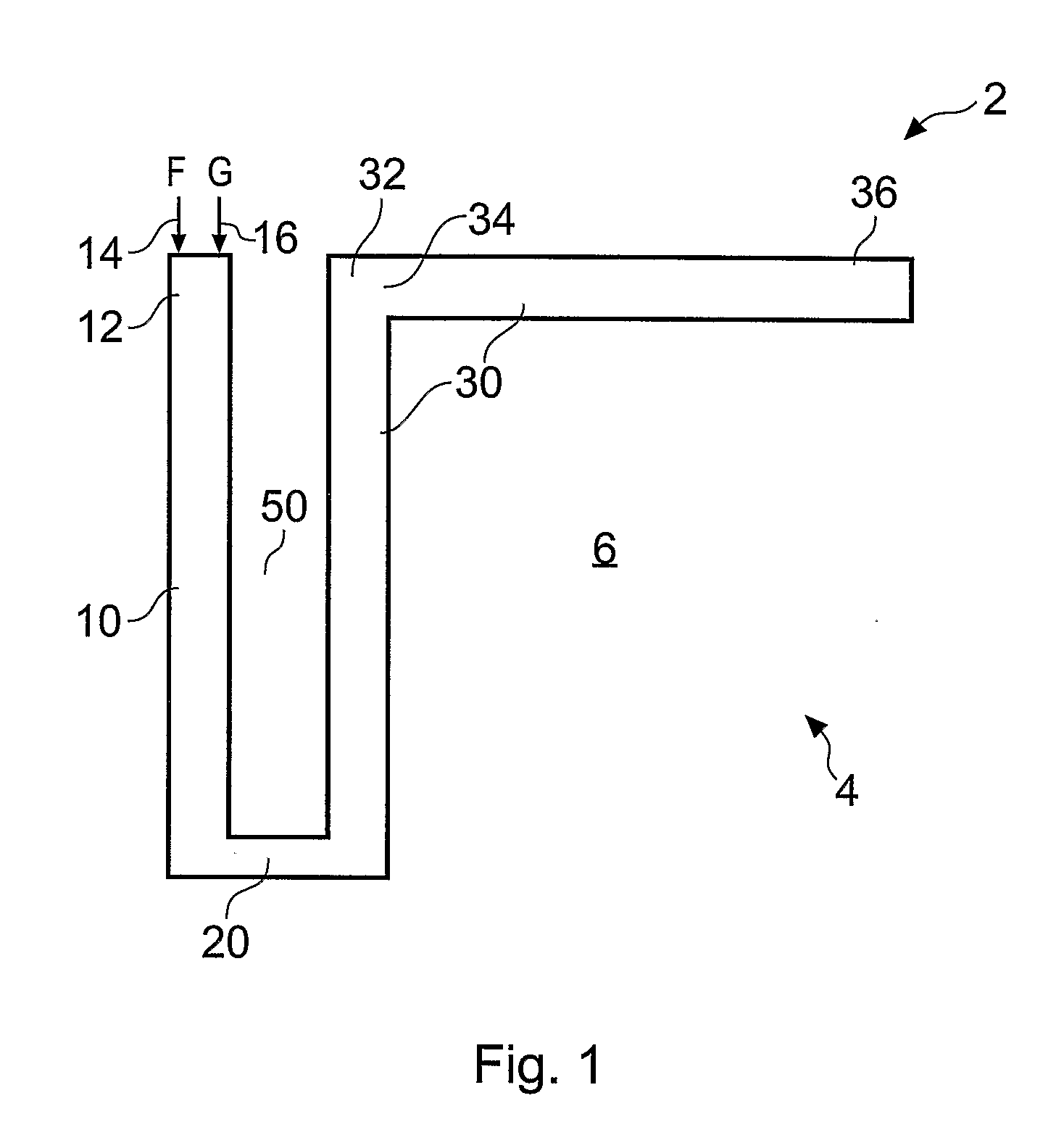

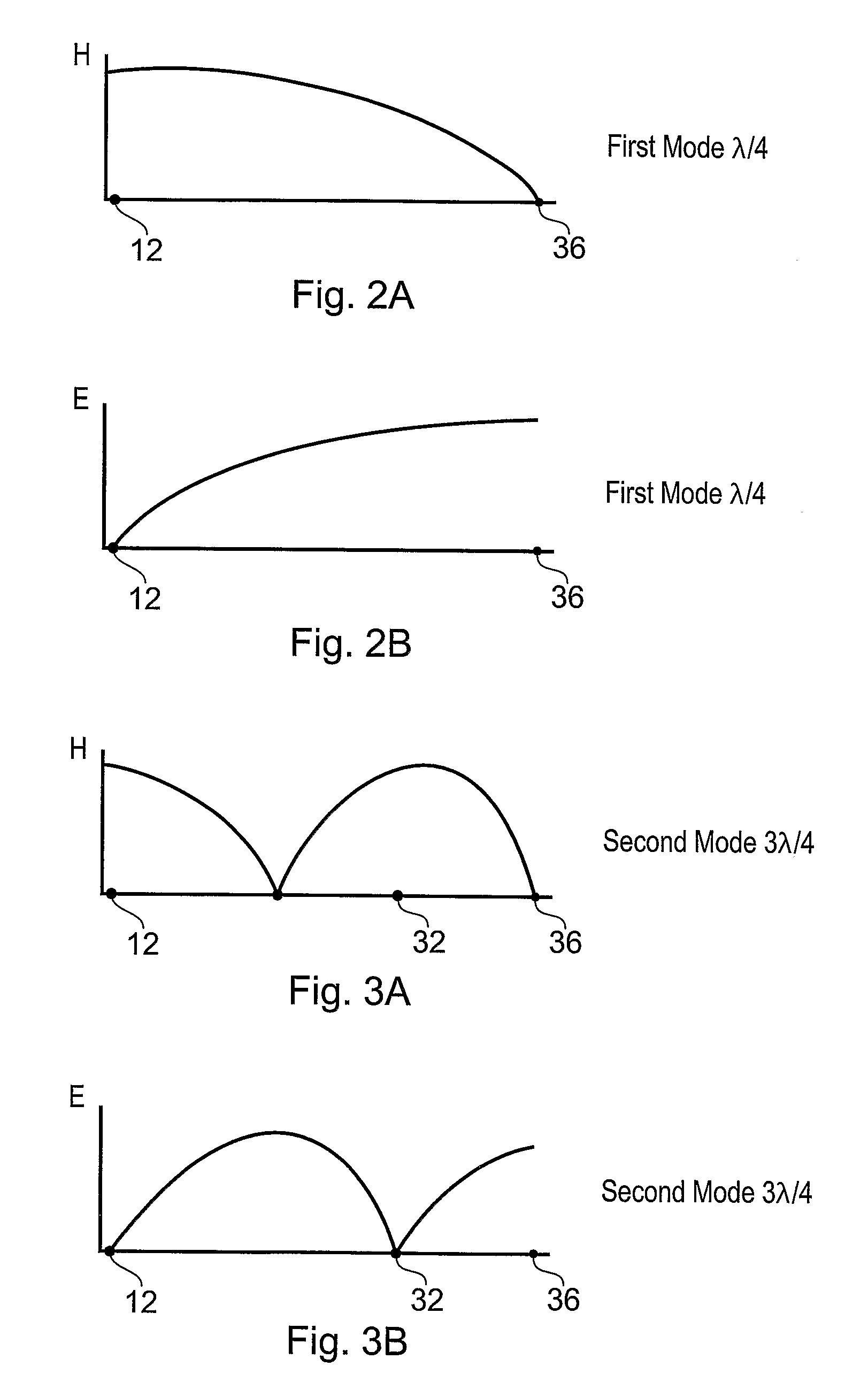

Antenna

InactiveUS20080278379A1Improving Impedance MatchingEnhanced radiationSimultaneous aerial operationsRadiating elements structural formsAntenna elementNarrow gap

An antenna having a first resonant mode and a second resonant mode and including an antenna element, the antenna element including a first portion; a second portion; and at least one bend between the first portion and the second portion, wherein a first part of the first portion opposes a second part of the second portion across a narrow gap and, in use, a maximum of current density for the second resonant mode is at or adjacent each of the first part of the first portion and the second part of the second portion.

Owner:NOKIA CORP

Heat sink fastening assembly

InactiveUS20080151507A1Low costEasy to fixSnap fastenersSemiconductor/solid-state device detailsEngineeringHeat spreader

A heat sink fastening assembly includes a fastener comprising a latching member and an operating member. The latching member includes a pressing part, a first latching leg and a second latching leg bent downwards respectively from two opposite ends of the pressing part. The operating member has a coping and a sidewall extending downwards from an edge of the coping. The sidewall defines two locking slots engaging with the first latching leg and an elastic rib extending downwards from the coping and engaged with the first latching leg of the latching member for inhibiting any movement of the operating member in a direction along the locking slot of the sidewall.

Owner:HON HAI PRECISION IND CO LTD +1

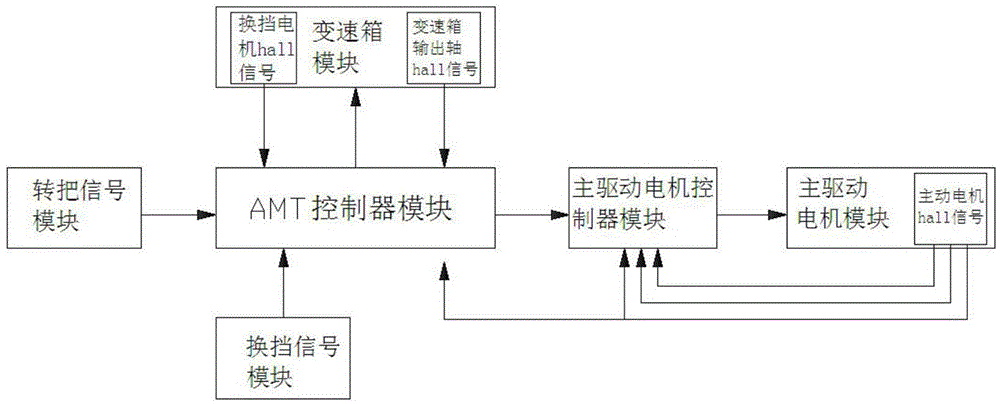

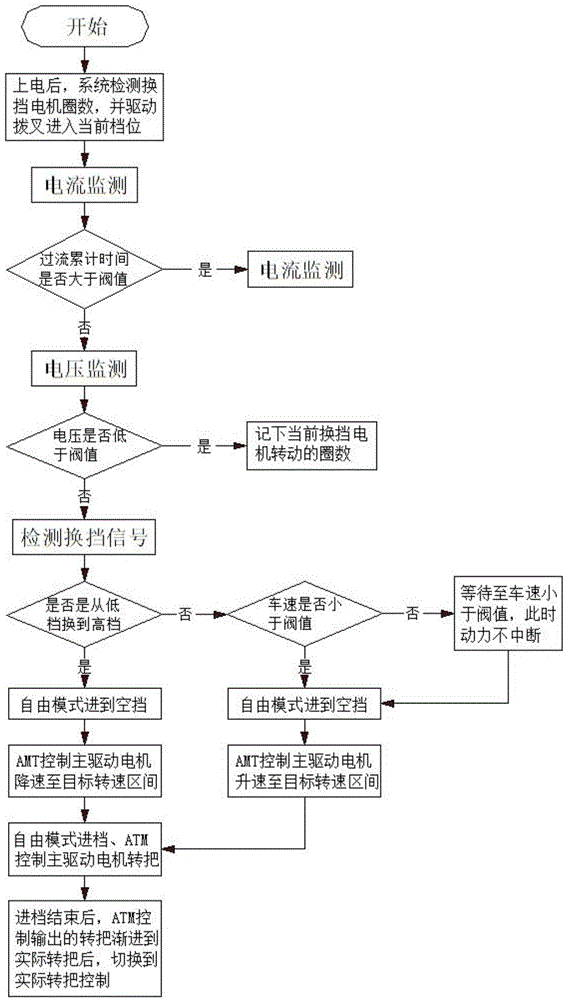

Electric vehicle shift-by-wire control system and control method thereof

ActiveCN104534081AImprove riding performanceExtend your lifeGearing controlDriver/operatorControl system

The invention provides an electric vehicle shift-by-wire control system. The control system comprises an ATM control module, a steering signal module, a gear shifting signal module, a speed changing box module, a main drive motor module and a main drive motor controller module. The signal output end of the steering signal module, the signal output end of the gear shifting signal module and the signal output end of the speed changing box module are connected with the signal input end of the ATM control module. The signal output end of the ATM control module is connected with the main drive motor module through the main drive motor controller module. The smoothness of steering switching is improved. A gear shifting switch is continuously and rapidly shifted, a gear shifting motor does not respond, and the misoperation of a driver is avoided. The counter potential impact of the gear shifting motor is reduced, the electromagnetism abrasion of the motor is greatly reduced, and the service life of the motor is prolonged.

Owner:GAOYOU SHUNDA POWER MACHINE

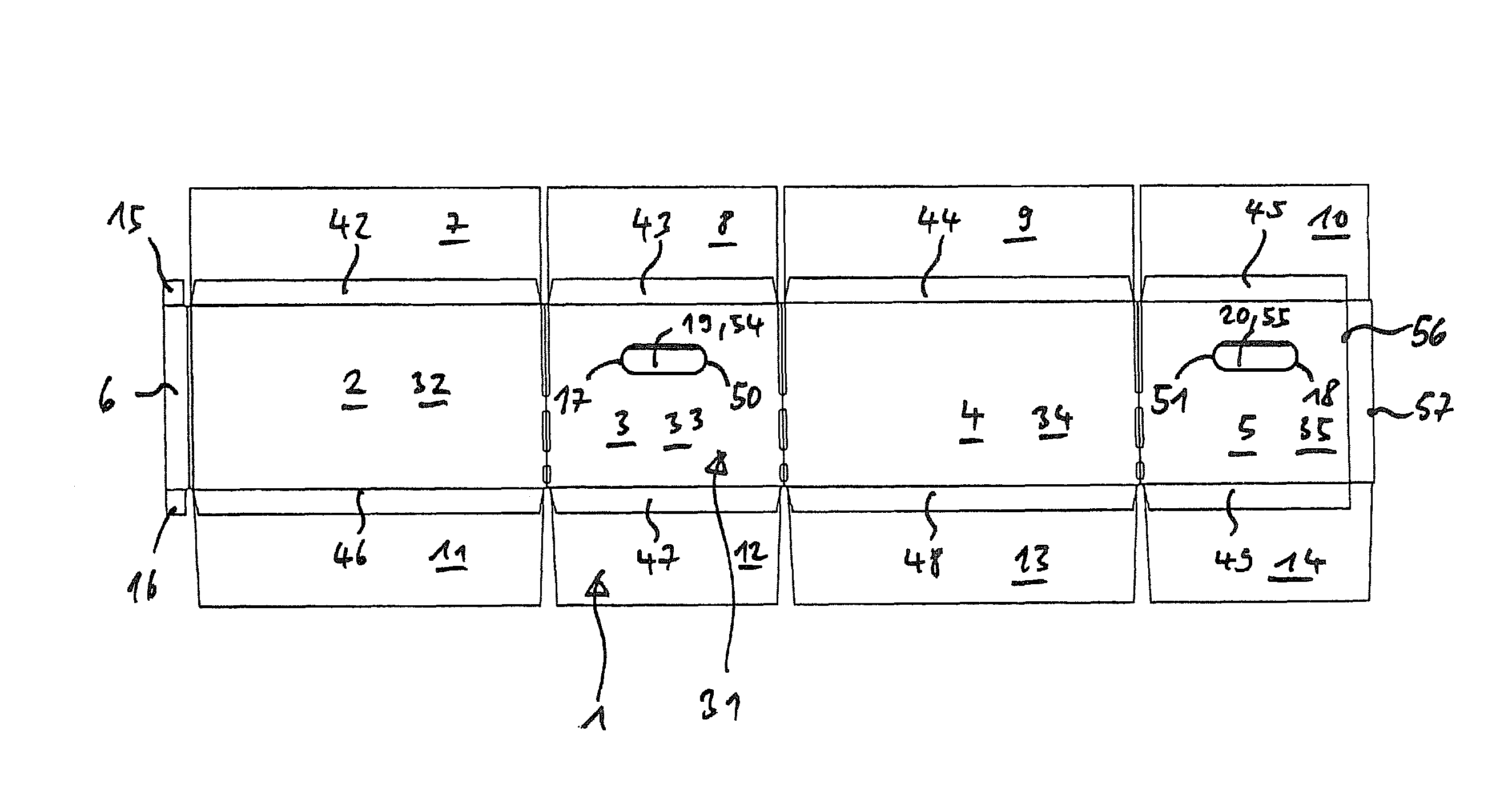

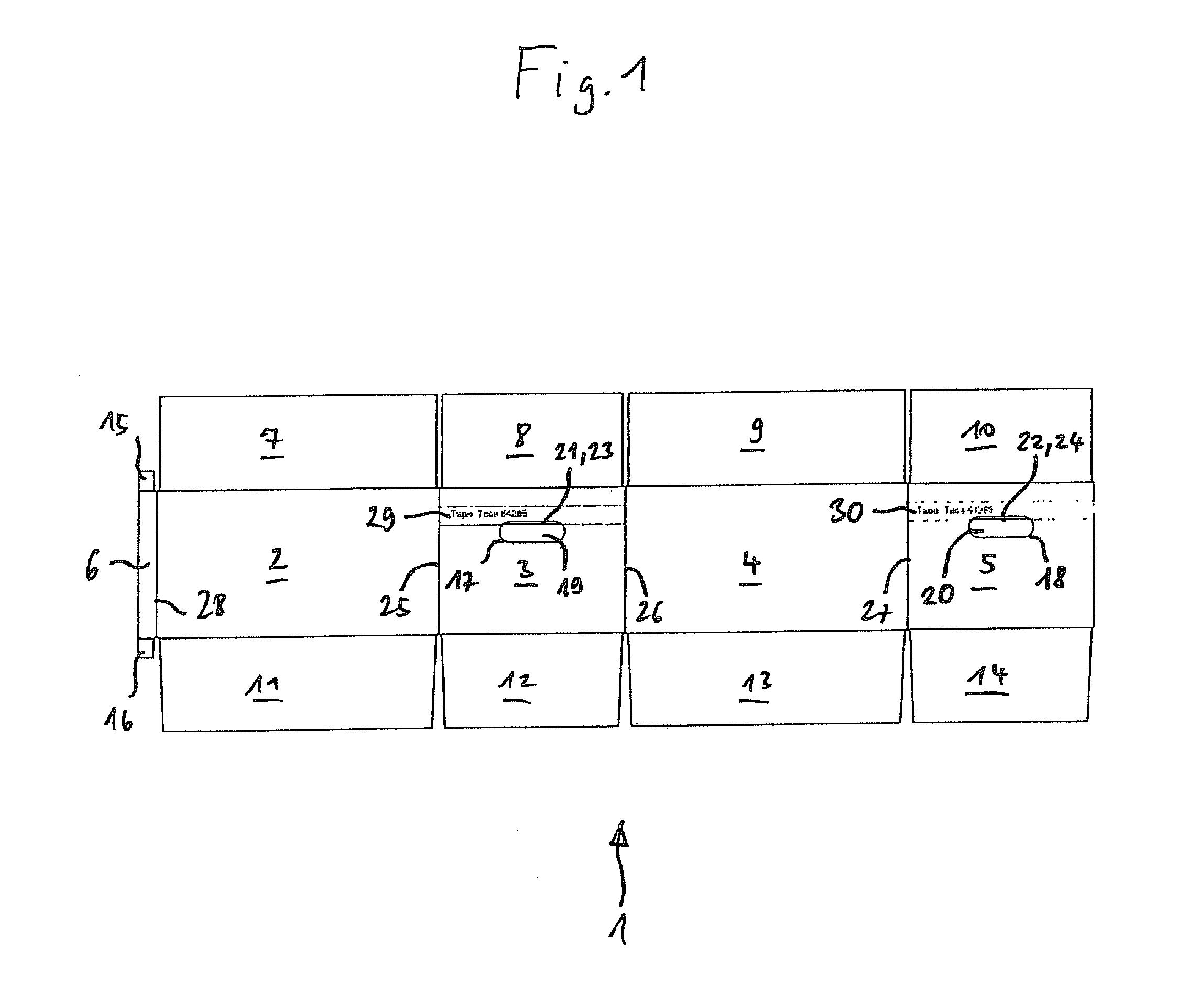

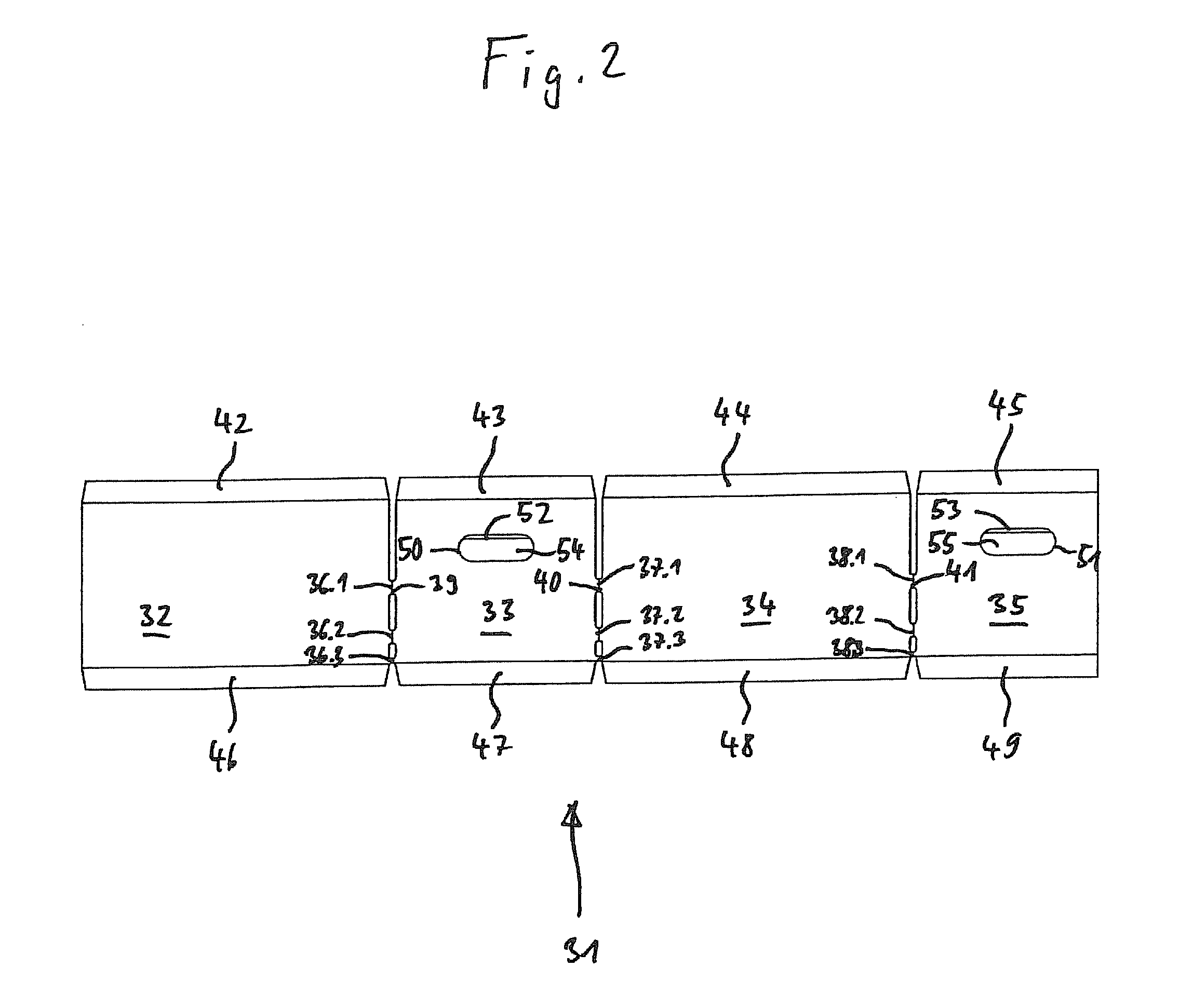

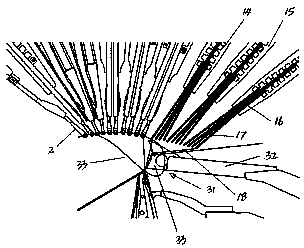

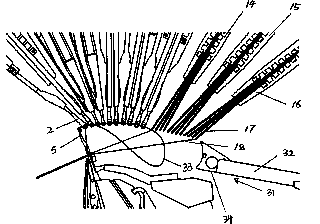

Guide bar structure in warp knitting machine, knitting machine and thread guide set

The invention relates to the technical field of a warp knitting machine, in particular to a guide bar structure in the warp knitting machine, the warp knitting machine and a thread guide set. The guide bar structure comprises at least one lateral-moving row. The lateral-moving row is provided with the thread guide set which is arranged in a common supporting device. Each thread guide row is capable of moving along a lateral-moving direction. The thread guide set is composed of at least one long belt which is arranged in the supporting device. A hole section is arranged on the lower portion of the long belt. At least one thread guide hole is formed in the hole section side by side along the lateral-moving direction. Extensions are arranged on the long belt extends along the lateral-moving direction, and extensions are arranged between the lower portion of a supporting section in the supporting device and the hole section of the thread guide hole. The guide bar structure, the warp knitting machine with the guide bar structure and the thread guide set on a guide bar all enable the existing monotonous warp knitting machine weaving to be provided with abundant pattern design, and are simple in structure.

Owner:KARL MAYER CHINA

One-time well completion method through VCR method

The invention discloses a one-time well completion method through a VCR method. The one-time well completion method comprises the following steps that a, a center hole is drilled in the center of a working face of a raise where a well is proposed to be completed, and then compensating holes and periphery holes surrounding the center hole are sequentially drilled by taking the center hole as a center; b, the center hole and the periphery holes are internally filled with explosives in a deck charge mode, and every two adjacent sections of explosives in the same hole are separated by a bulkhead;and c, the center hole is blasted firstly to expand a groove cavity, then a millisecond blasting method is utilized to conduct sectional blasting in the blasting sequence of the center hole first andthen the periphery holes, and tower blasting is formed till the whole raise is completely blasted. According to the one-time well completion method through the VCR method, one-time well completion canbe achieved by adopting the tower blasting mode, and the one-time well completion method has the advantages that the well completion effect is good and the well completion efficiency is high.

Owner:TIBET HUATAILONG MINING DEV

Folding box for receiving a group of containers

A folding box for receiving a group of containers includes a cuboid-shaped external packaging made of cardboard. The external packaging has side walls, bottom walls and top walls. The folding box also includes a lining on the inside of the external packaging at least in the corner region between the side walls, top walls and / or bottom walls.

Owner:GRAPHIC PACKAGING INT EURO NETHERLANDS

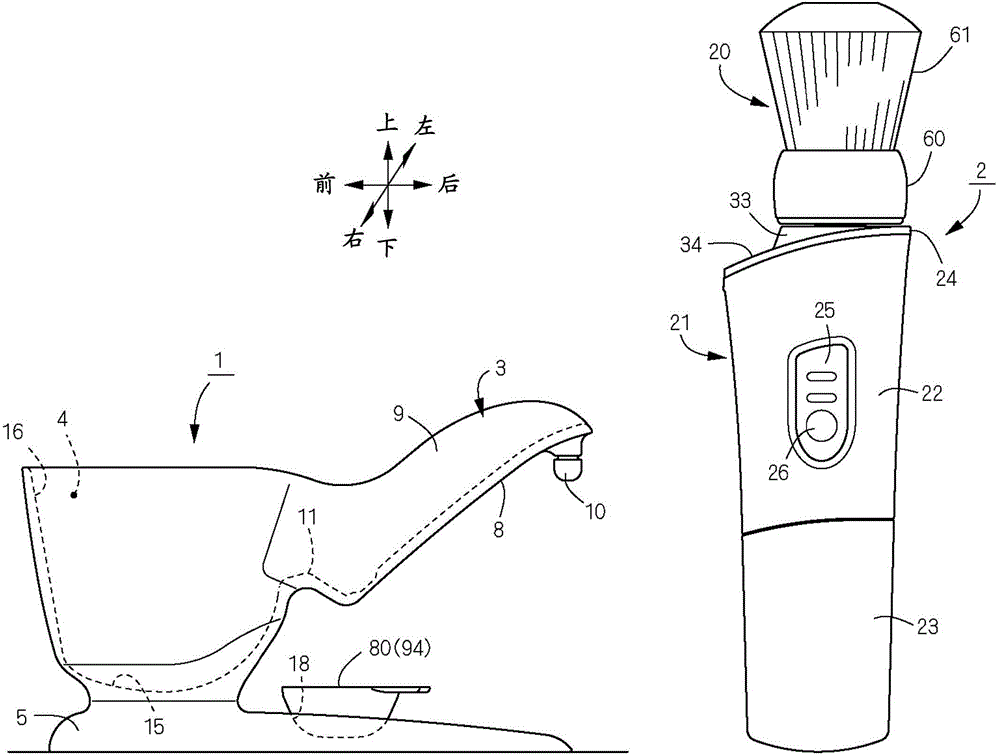

Foam maker

The invention provides a foam maker which effectively generates foaming elements to produce friction slice shaped foam blocks and can rapidly and conveniently perform coating activities. The foam maker comprises a foam making container (1) in a foam generating part (4), a stirring body (2) generated by the foam generating elements, a support (3) of a stirring gesture supporting the stirring body (2). The stirring body (2) comprises a brush (20) containing the foaming elements, a housing (21) acting as a handle and supporting the brush (20) and a driving structure to drive the housing and the brush. The stirring body can be detached and installed according to the foam container. The brush (20) comprises a base (60) supported by the main housing (21) and a brush beam (61) installed on the brush (60). The front end of the brush beam (61) is provided with a retaining convex part (78) to maintain the foaming elements.

Owner:MAXELL HLDG LTD

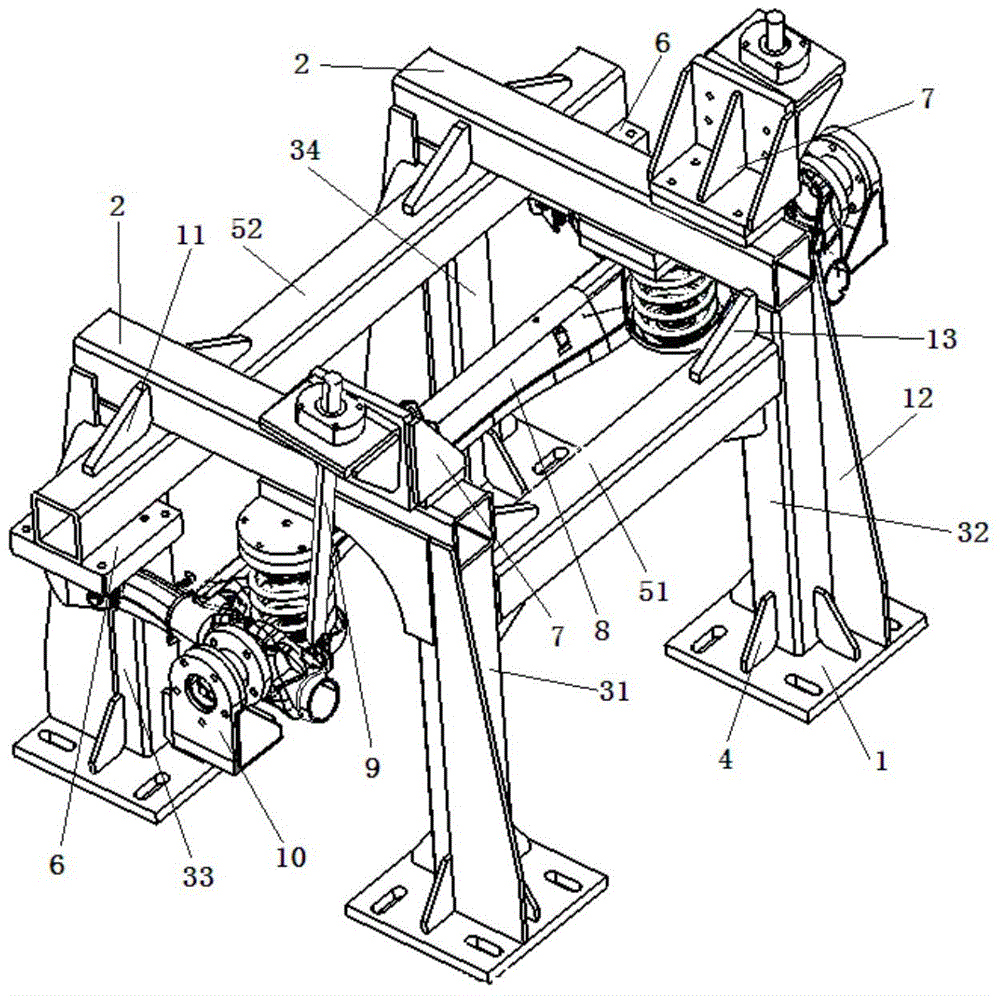

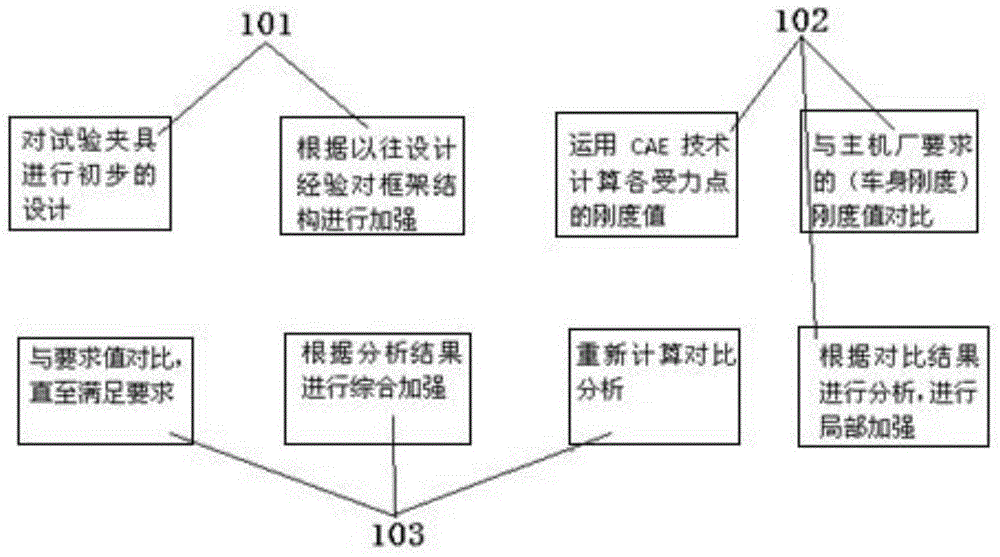

Light frame type rear torsion beam test device and design method thereof

The invention relates to a light frame type rear torsion beam test device and a design method thereof. The light frame type rear torsion beam test device comprises support mounting plates, upright columns, cross beams and vertical beams; the support mounting plates are fixed to the bottom ends of the upright columns; first reinforcing blocks are welded between the support mounting plates and the upright columns; the four upright columns are distributed in a manner that the four upright columns can form a rectangle; one vertical beam is fixed to the first upright column and the third upright column, and the other vertical beam is fixed to the second upright column and the fourth upright column; the first cross beam is fixed between the first upright column and the second upright column; the second cross beam is fixed between the third upright column and the fourth upright column; two ends of the second cross beam extend out from a space between the two vertical beams; mounting blocks are fixed to the lower parts of the two ends of the second cross beam; and a shock absorber support mounting block is fixed to the vertical beams respectively. The light frame type rear torsion beam test device of the invention has the advantages of simple structure, reliable use and short design and production cycles, and can meet requirements of test requirements.

Owner:ZHEJIANG WANXIANG SYST +1

Guide bar structure in warp knitting machine, knitting machine and thread guide set

ActiveCN103132229BRigid enoughWill not hinder each otherWarp knittingEngineeringMechanical engineering

The invention relates to the technical field of a warp knitting machine, in particular to a guide bar structure in the warp knitting machine, the warp knitting machine and a thread guide set. The guide bar structure comprises at least one lateral-moving row. The lateral-moving row is provided with the thread guide set which is arranged in a common supporting device. Each thread guide row is capable of moving along a lateral-moving direction. The thread guide set is composed of at least one long belt which is arranged in the supporting device. A hole section is arranged on the lower portion of the long belt. At least one thread guide hole is formed in the hole section side by side along the lateral-moving direction. Extensions are arranged on the long belt extends along the lateral-moving direction, and extensions are arranged between the lower portion of a supporting section in the supporting device and the hole section of the thread guide hole. The guide bar structure, the warp knitting machine with the guide bar structure and the thread guide set on a guide bar all enable the existing monotonous warp knitting machine weaving to be provided with abundant pattern design, and are simple in structure.

Owner:KARL MAYER CHINA

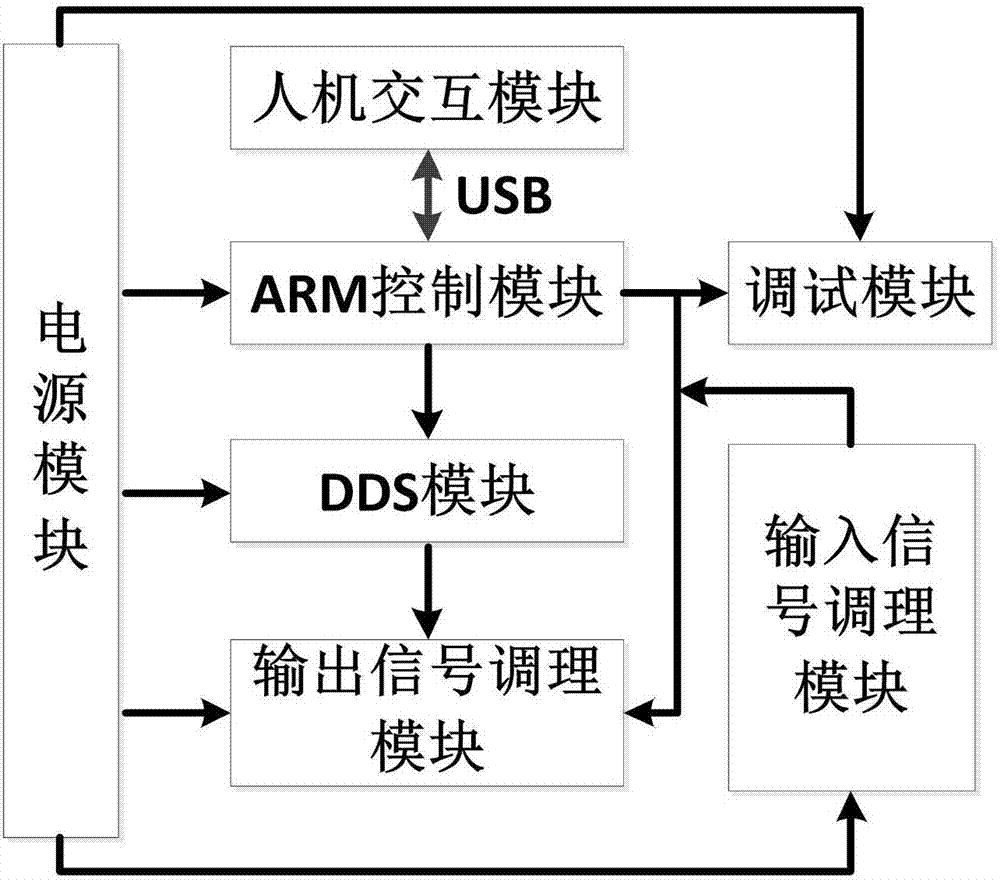

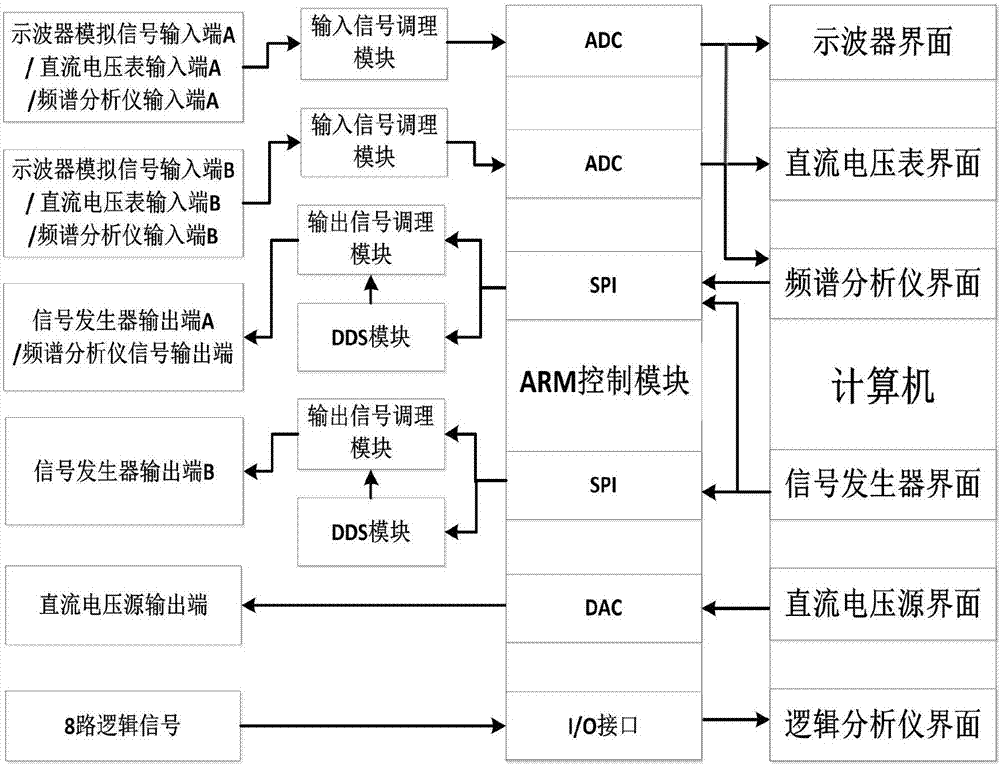

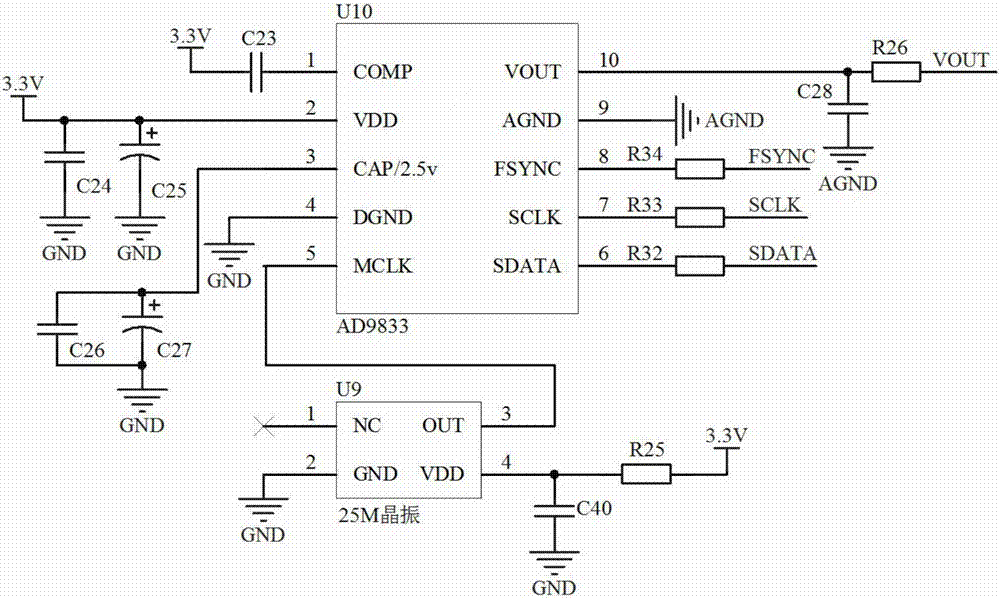

Multifunctional virtual electronic instrument

The invention discloses a multifunctional virtual electronic instrument, which comprises the functions of a digital oscilloscope, a signal generator, a DC voltage source, a DC voltmeter, a frequency characteristic analyzer and a logic analyzer. The multifunctional virtual electronic instrument comprises a human-machine interaction module, an ARM control module, an input signal regulating module, a DDS module, an output signal regulating module, a power supply module, and a debugging module. According to the instrument of the invention, the strong data processing ability of a computer is utilized; the hardware circuit size is reduced; the consumed material cost is reduced; the circuits are more integrated; and therefore, the instrument becomes portable to carry and convenient to use. The instrument further overcomes the limitation that a traditional electronic testing instrument can only be used in laboratories. Therefore, the students could use it for testing at any time and any place. The students are entitled to the largest freedom to do so, and a completely open laboratory in true sense comes into being.

Owner:NORTHEAST NORMAL UNIVERSITY

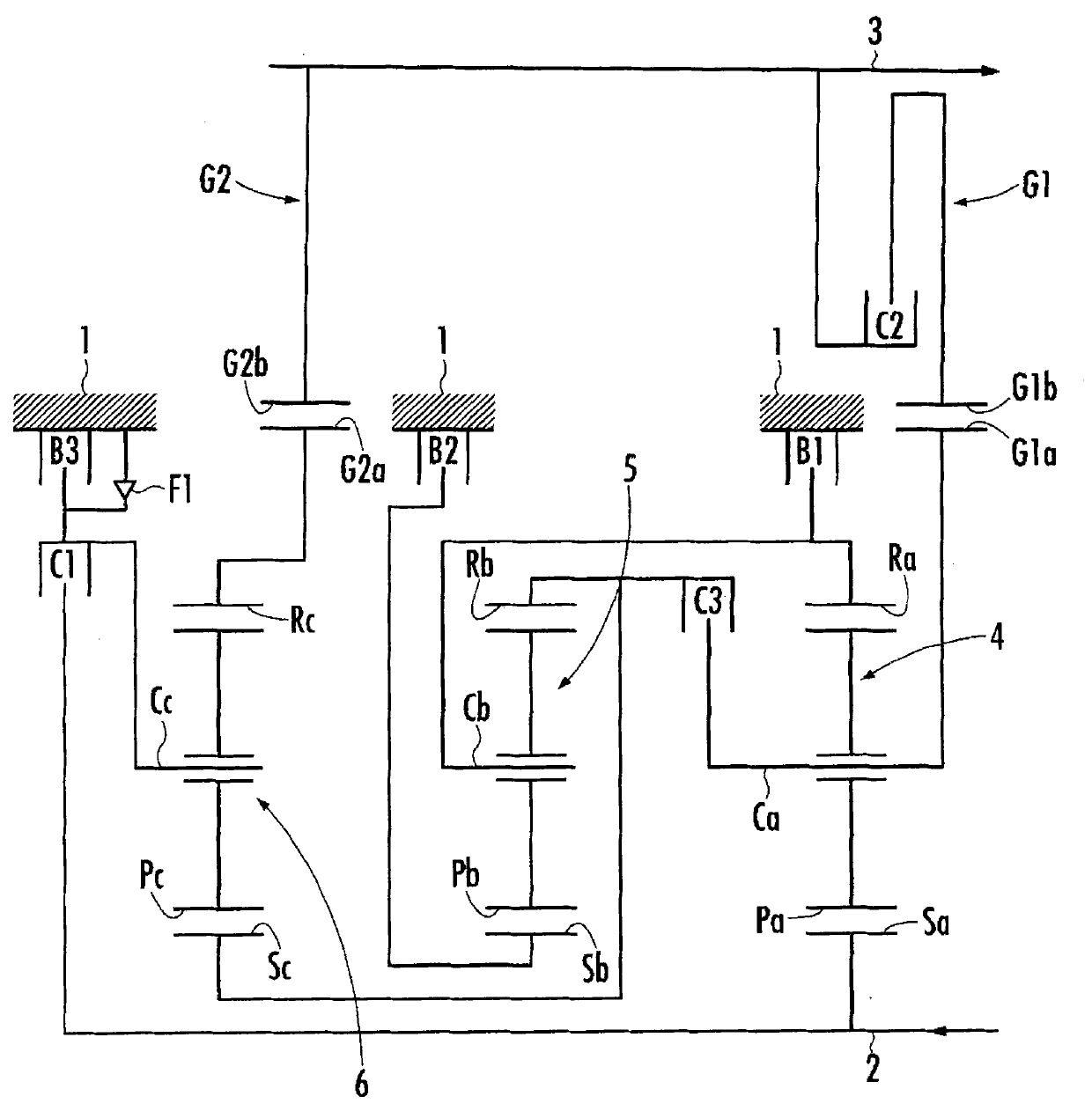

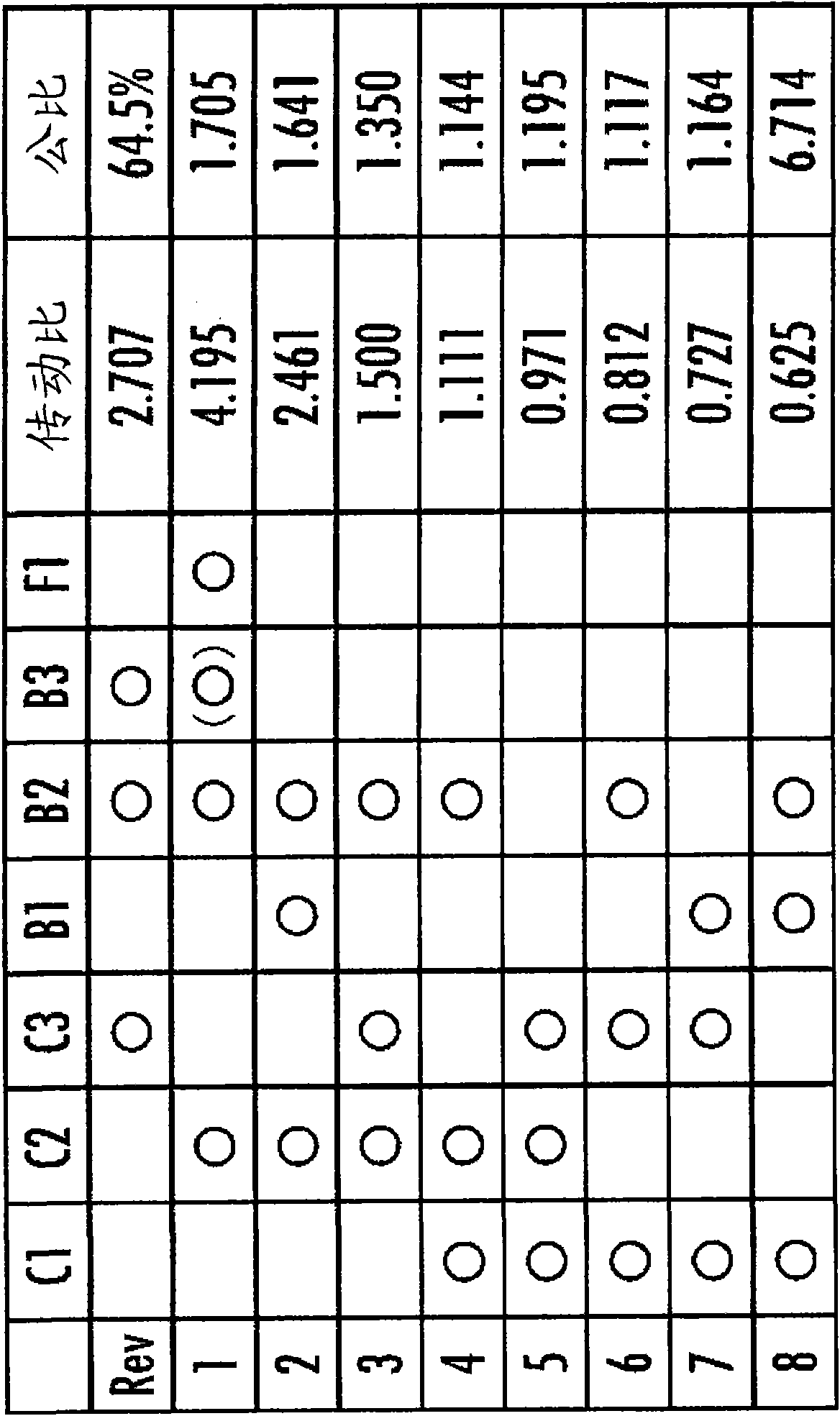

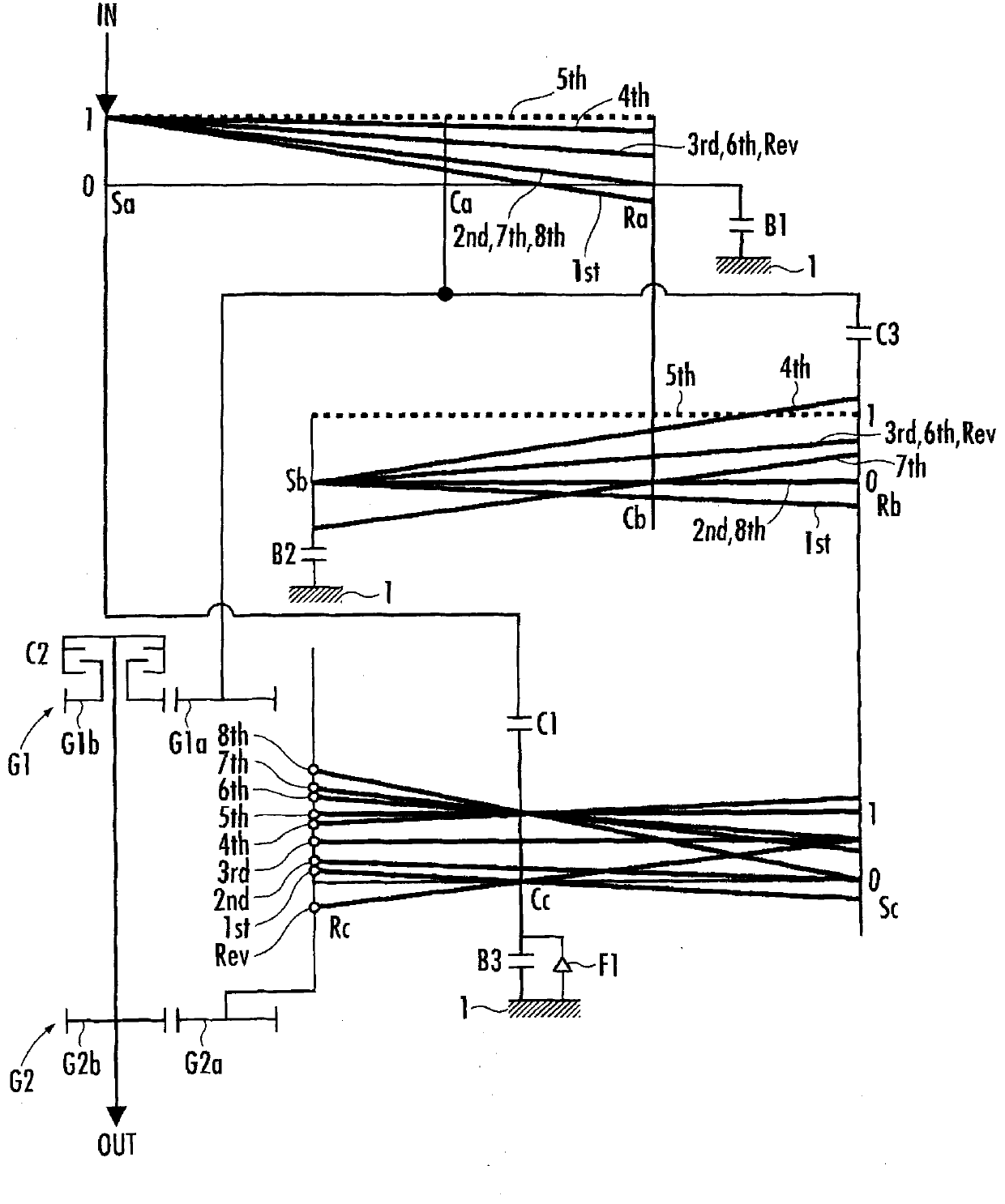

Automatic transmission

ActiveCN101907152AImprove controllabilityIncrease configuration freedomToothed gearingsTransmission elementsFriction reductionAutomatic transmission

Provided is an automatic transmission capable of reducing friction loss. A first element (Sa) is coupled with an input shaft (2), a second element Ca is coupled with a first driving gear (G1a). A first driven gear (G1b) is pivotally supported on an output shaft (3), a seventh element (Rc) is coupled with a second driving gear (G2a), and a second driven gear (G2b) is fixed to the output shaft (3).A third element (Ra) and a fifth element (Cb) are coupled to form a first coupling body, a sixth element (Rb) and a ninth element (Sc) are coupled to form a second coupling body. The automatic transmission includes a first engagement mechanism (C1) coupling the input shaft (2) and the eight element (Cc) releasably, a second engagement (C2) fixing the first driven gear (G1b) to the output shaft (3) releasably, a third engagement mechanism (C3) coupling the second element (Ca) with the second coupling body releasably, and a fourth to a sixth engagement mechanisms (B1 to B3) fixing respectively the first coupling body, a fourth element (Sb) and the eighth element (Cc) to a transmission case (1) releasably.

Owner:HONDA MOTOR CO LTD

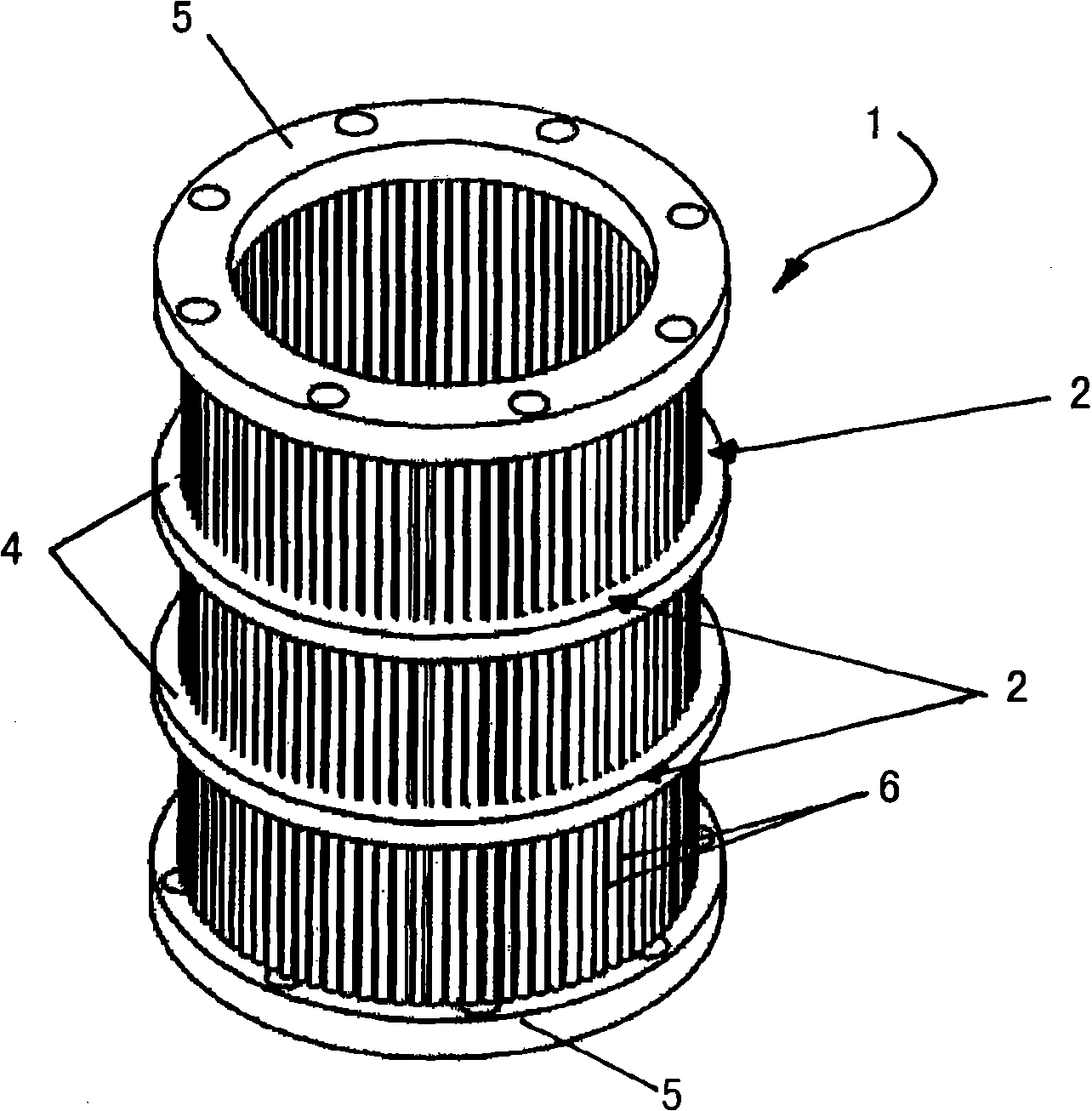

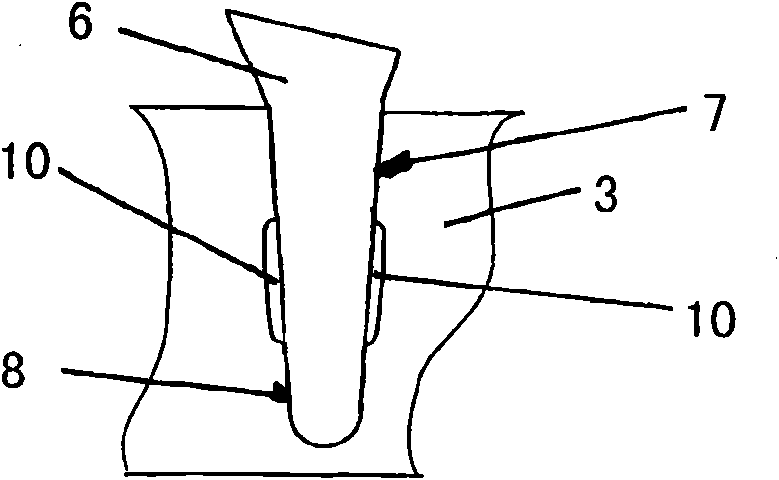

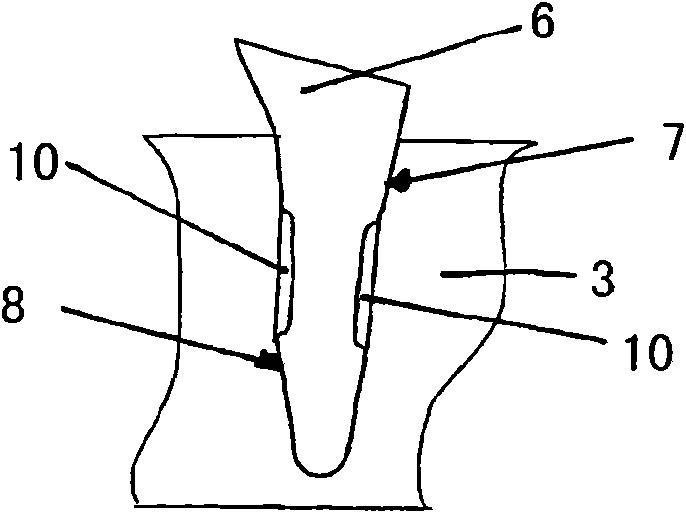

Sifting device

ActiveCN101657269AReliable and precise orientationEasy to fixSievingScreeningFilling materialsAdhesive

The invention relates to a sifting device, such as a perforated basket, a perforated cylinder or the like, in which slits or gaps are formed between sieve bars (6). The base of the sieve bars is received in receiving recesses (8) adapted to the dimensions of the base of the bars, in a carrier element (3). Said carrier element can also be a reinforcing or strengthening element, and the sieve bars (6) are permanently fixed to the respective carrier element (3). At least one pocket (10, 11) that can be filled with a filler material is provided between each carrier element (3) and each associated sieve bar (6), at least on the edge region (7) of the respective receiving recess (8). In the sifting device according to the invention, said pocket interrupts the contact surface between the outer contour of the sieve bar (6) and the inner contour of the associated receiving recess in the carrier element (3), such that a pre-determined intermediate space is formed in a targeted manner in the form of a pocket (10; 11), at least on the edge region (7). Said pocket is then filled with a homogeneous or composite filler material used as a fixing means, a constituent of said filler material being, for example, an adhesive. In this way, a permanent solid connection can be created between sieve bars (6) and carrier elements (3).

Owner:ANDRITZ FIEDLER

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com