One-time well completion method through VCR method

A one-off, high-well technology, applied in blasting and other directions, can solve problems such as the inability to form the center of the pilot tunnel, the inability to complete the blasting of the wellbore, and the blockage of the middle and upper blasting, and achieve high explosive utilization, good well-forming effect, and high-efficiency well-forming

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] This embodiment discloses a one-time well forming method of the VCR method, comprising the following steps:

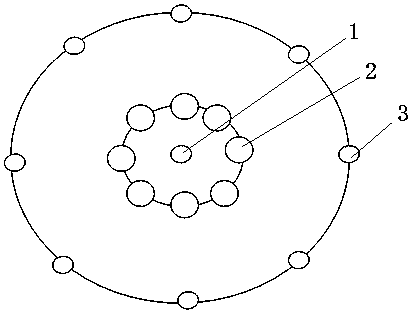

[0028] a. Drill a center hole 1 at the center of the raised well face of the proposed well, and then drill a compensation hole 2 around the center hole 1 and a peripheral hole 3 around the center hole 1 in sequence. The compensation hole 2 and the peripheral hole 3 are both in line with the center Hole 1 is vertically parallel (eg figure 1 shown).

[0029] In this step, preferably, the diameters of the central hole 1 and the peripheral hole 3 are both 80 mm, and the diameter of the compensation hole 2 is 120 mm. The distance between the peripheral hole 3 and the central hole 1 is 800mm, the distance between any two adjacent peripheral holes 3 is 1500mm, and the distance between the compensation hole 2 and the central hole 1 is 300mm.

[0030] In this step, the central hole 1, the compensation hole 2 and the peripheral hole 3 are all drilled and formed at one t...

Embodiment 2

[0040] This embodiment discloses a one-time well forming method of the VCR method, comprising the following steps:

[0041] a. Drill a center hole 1 at the center of the raised well face of the proposed well, and then drill a compensation hole 2 around the center hole 1 and a peripheral hole 3 around the center hole 1 in sequence. The compensation hole 2 and the peripheral hole 3 are both in line with the center Hole 1 is vertically parallel (eg figure 1 shown).

[0042]In this step, preferably, the diameters of the central hole 1 and the peripheral hole 3 are both 100 mm, and the diameter of the compensation hole 2 is 150 mm. The distance between the peripheral hole 3 and the central hole 1 is 1200mm, the distance between any two adjacent peripheral holes 3 is 1800mm, and the distance between the compensation hole 2 and the central hole 1 is 3500mm.

[0043] b. The central hole 1 and the peripheral hole 3 are charged with explosives in sections, and two adjacent sections of...

Embodiment 3

[0046] This embodiment discloses a one-time well forming method of the VCR method, comprising the following steps:

[0047] a. Drill a center hole 1 at the center of the raised well face of the proposed well, and then drill a compensation hole 2 around the center hole 1 and a peripheral hole 3 around the center hole 1 in sequence. The compensation hole 2 and the peripheral hole 3 are both in line with the center Hole 1 is vertically parallel (eg figure 1 shown).

[0048] In this step, preferably, the diameters of the central hole 1 and the peripheral hole 3 are both 90 mm, and the diameter of the compensation hole 2 is 130 mm. The distance between the peripheral hole 3 and the central hole 1 is 1000mm, the distance between any two adjacent peripheral holes 3 is 1650mm, and the distance between the compensation hole 2 and the central hole 1 is 400mm.

[0049] b. The central hole 1 and the peripheral hole 3 are charged with explosives in sections, and two adjacent sections of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com