Automatic transmission

An automatic transmission, free technology, applied in the direction of vehicle gearbox, transmission element, transmission device, etc., can solve the problems of deterioration of transmission efficiency and large friction loss, to improve the freedom of configuration and design, reduce friction loss, improve Effects of setting degrees of freedom

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

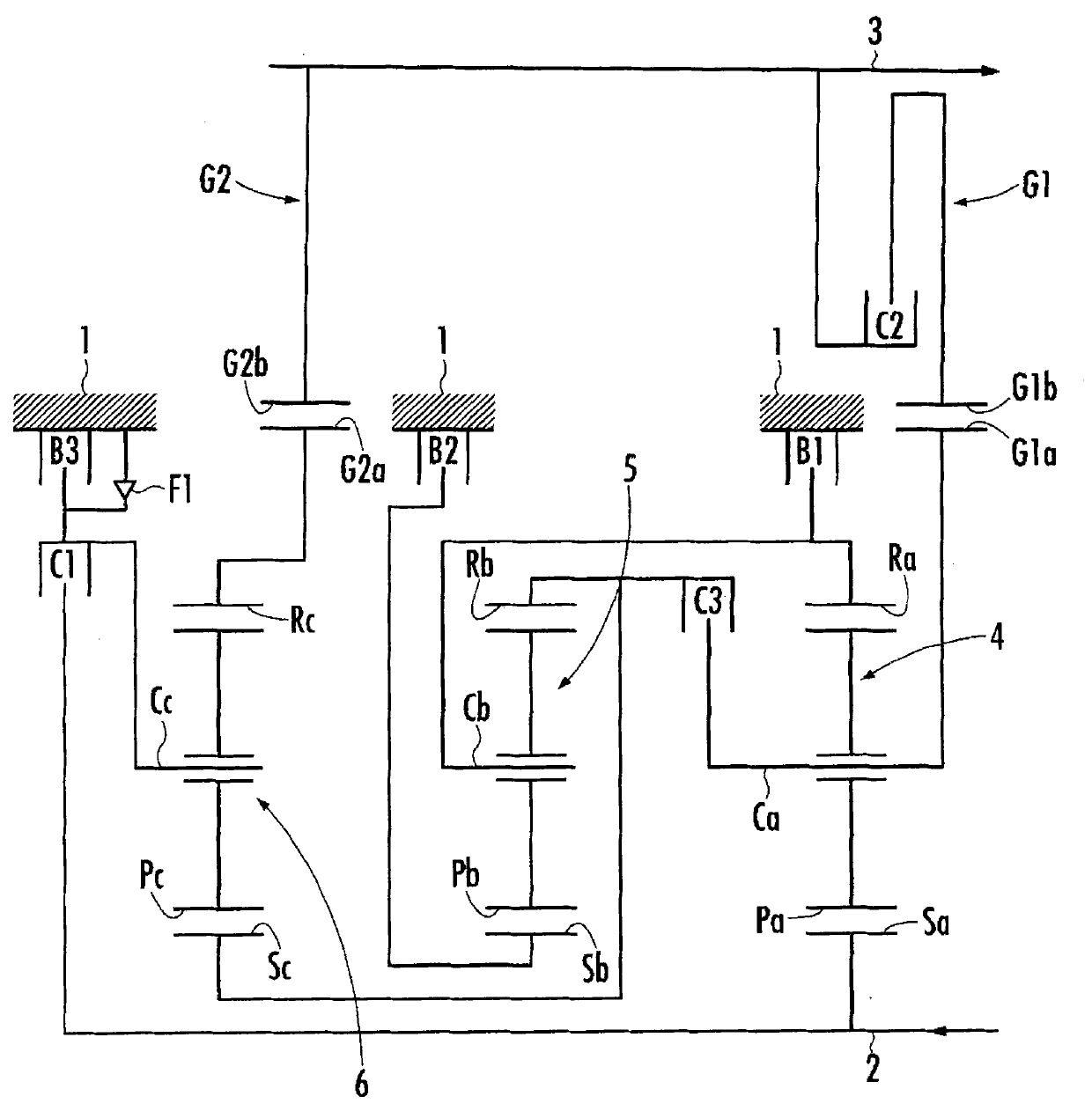

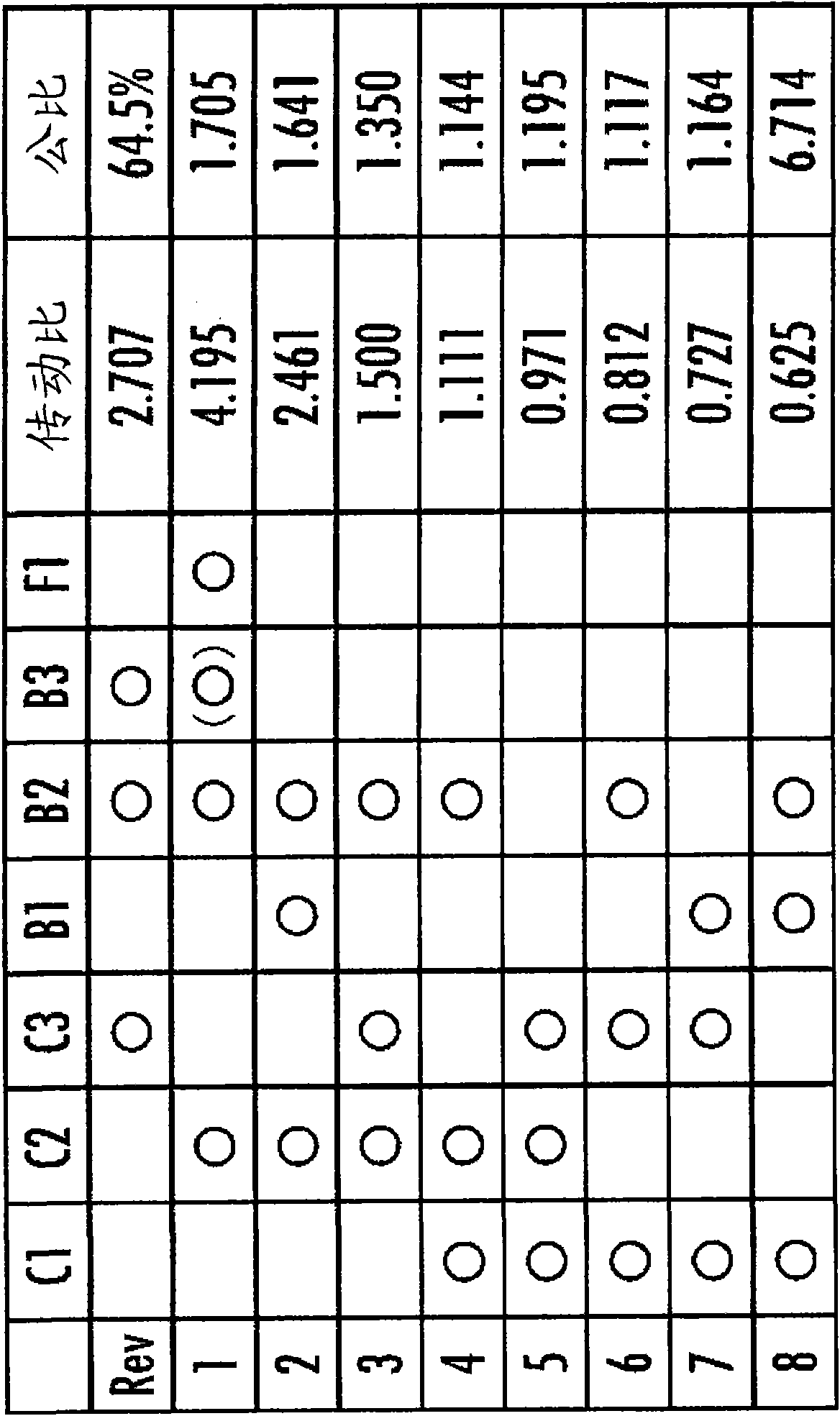

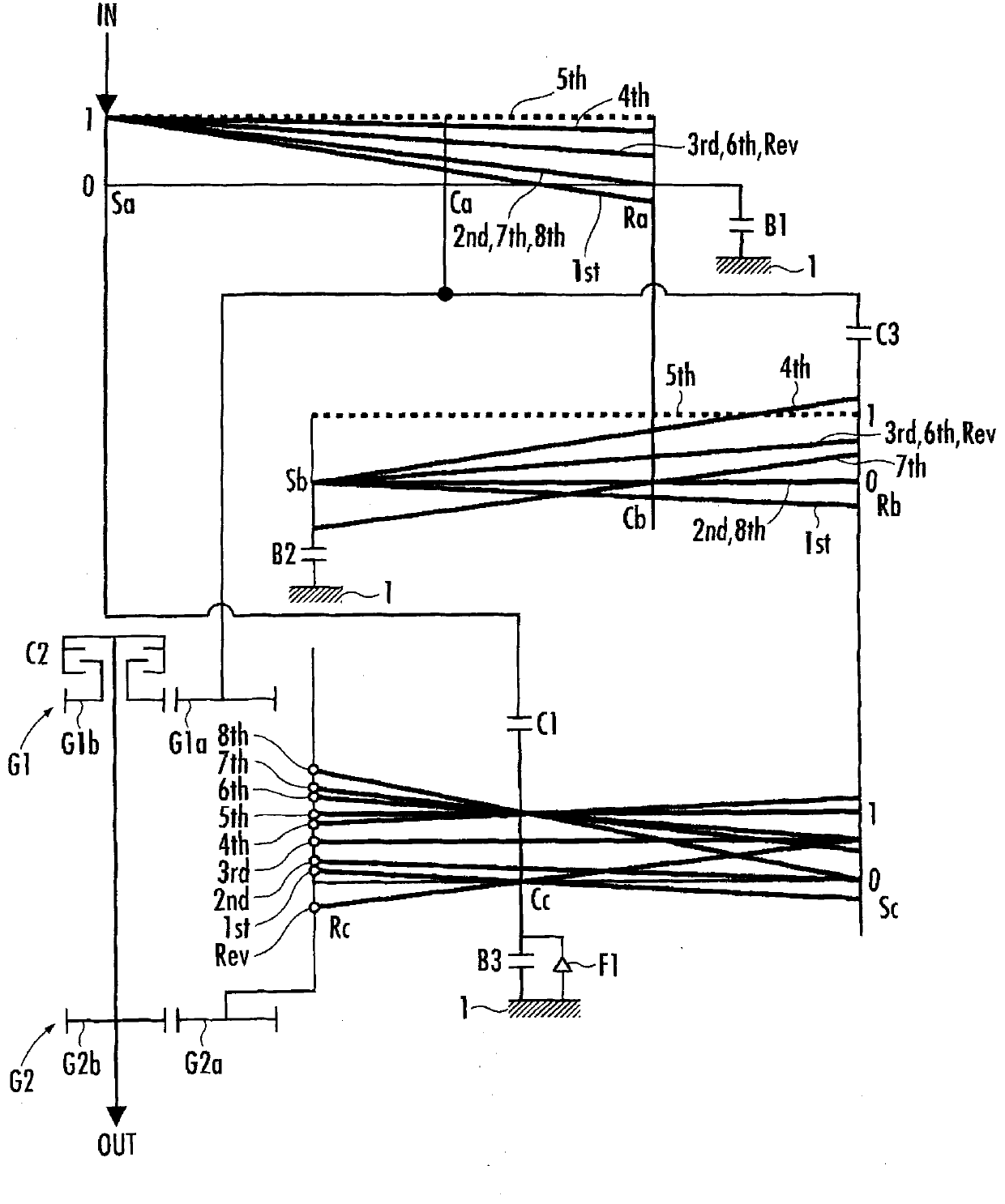

[0027] figure 1 The first embodiment of the automatic transmission of the present invention is shown. The automatic transmission of the first embodiment has an input shaft 2 and an output shaft 3. The input shaft 2 is rotatably supported in the transmission case 1 and is connected to a power source such as an engine (not shown in the figure). 3 is arranged parallel to the input shaft 2. The rotation of the output shaft 3 is transmitted to left and right drive wheels of the vehicle via a differential gear, a propeller shaft, and the like not shown in the figure.

[0028] Furthermore, in the transmission case 1 , the first planetary gear mechanism 4 , the second planetary gear mechanism 5 , and the third planetary gear mechanism 6 are arranged concentrically with the input shaft 2 . The first planetary gear mechanism 4 is composed of a single planetary gear type planetary gear mechanism, which is composed of a sun gear Sa, a ring gear Ra, and a carrier Ca. The carrier Ca is co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com