Sifting device

A filter device and filter rod technology, which is applied in the direction of filter separation, filter screen, fixed filter element filter, etc., can solve the problem of inaccurate geometry of filter slits, inaccurate relative attachment, dispersion of filter slit or gap width, etc. problem, to achieve reliable and precise orientation, and permanent connection, reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

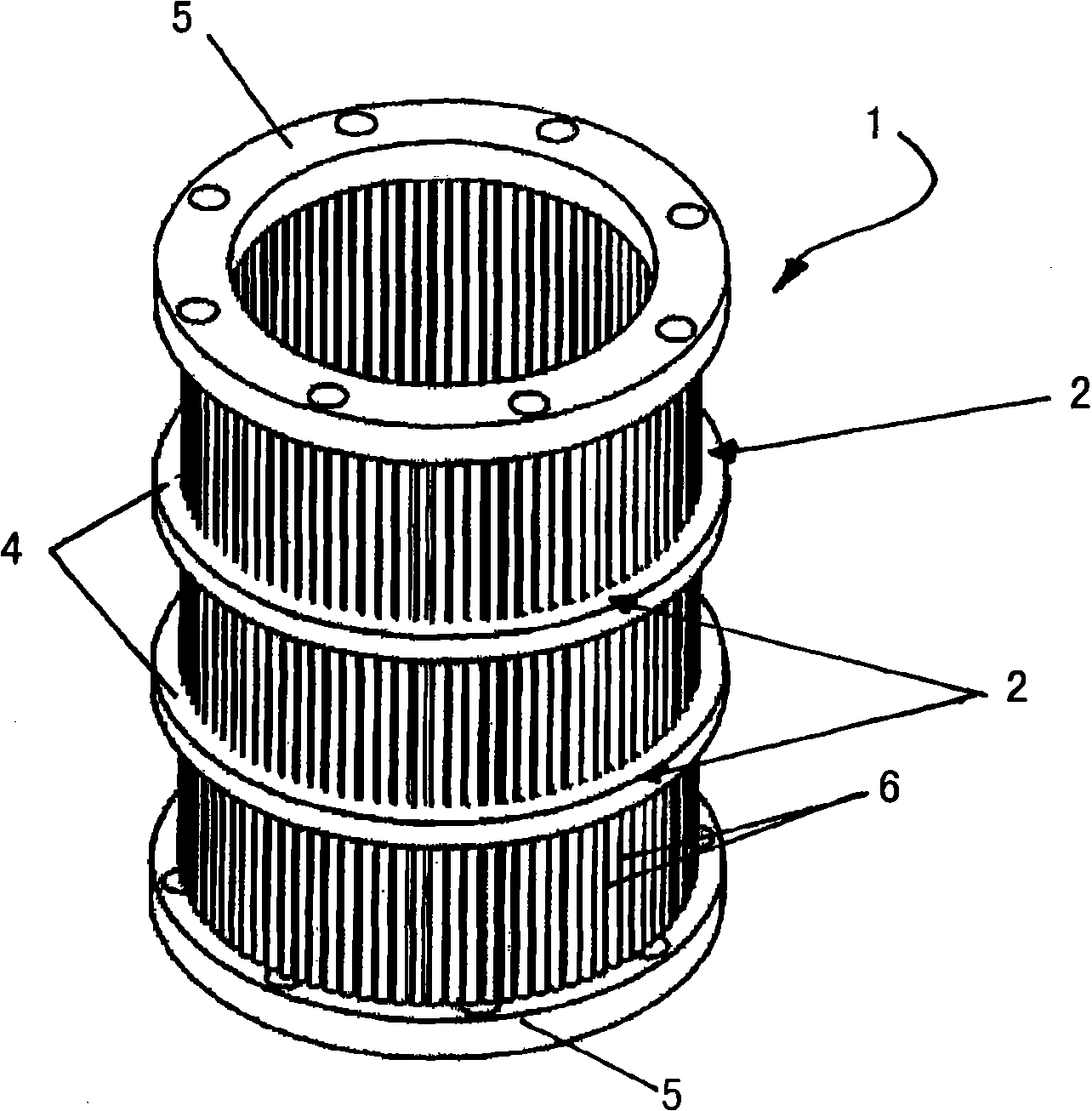

[0026] figure 1 A cylindrical filter basket 2 is shown representing a preferred exemplary embodiment of a filter device, which is generally designated with reference numeral 1 . It will be appreciated that the filter device 1 of the present invention can also be constructed as a filter plate. Said filter device 1 comprises supports 3 , which in the illustrative example are formed as support rings 4 . Furthermore, so-called end flanges 5 are provided in the axial end regions of the filter device 1 . Inserting the filter rod 6 into the corresponding receiving cutout of the support 3 forms a corresponding filter slit or filter gap between the head regions of the filter rod 6 . exist figure 1 Such rod filter baskets are schematically shown in and are known in the art.

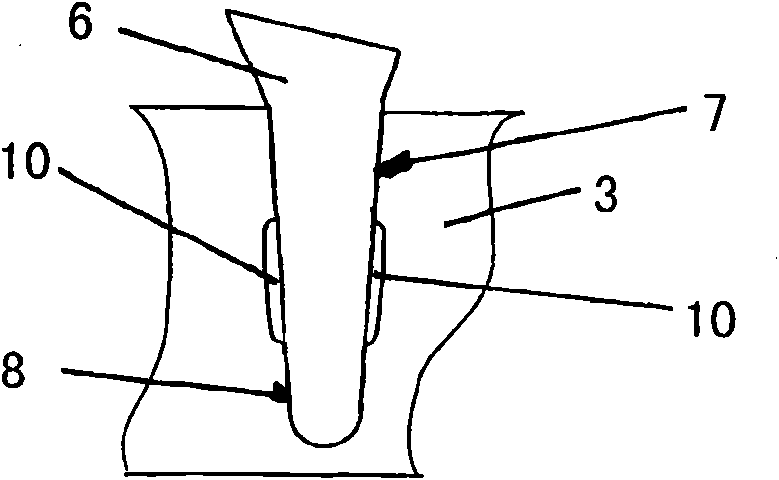

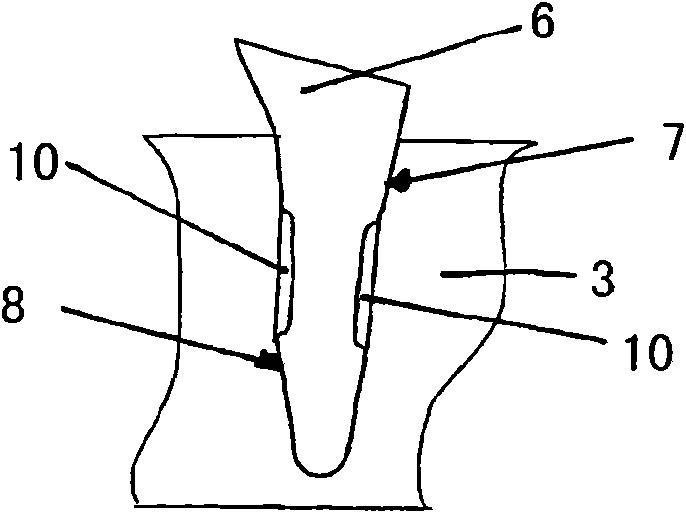

[0027] as by Figures 1 to 10 As can be seen, the filter device according to the invention is designed with pockets 10 located between each support 3 and each associated filter rod 6, at least on the supports ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com