Heat sink fastening assembly

a technology for fastening and sinks, which is applied in the direction of snap fasteners, lighting and heating apparatus, and semiconductor/solid-state device details. it can solve the problems of large free space for users to operate the handles, prone to damage other electronic components, and awkward operation of the fastener

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

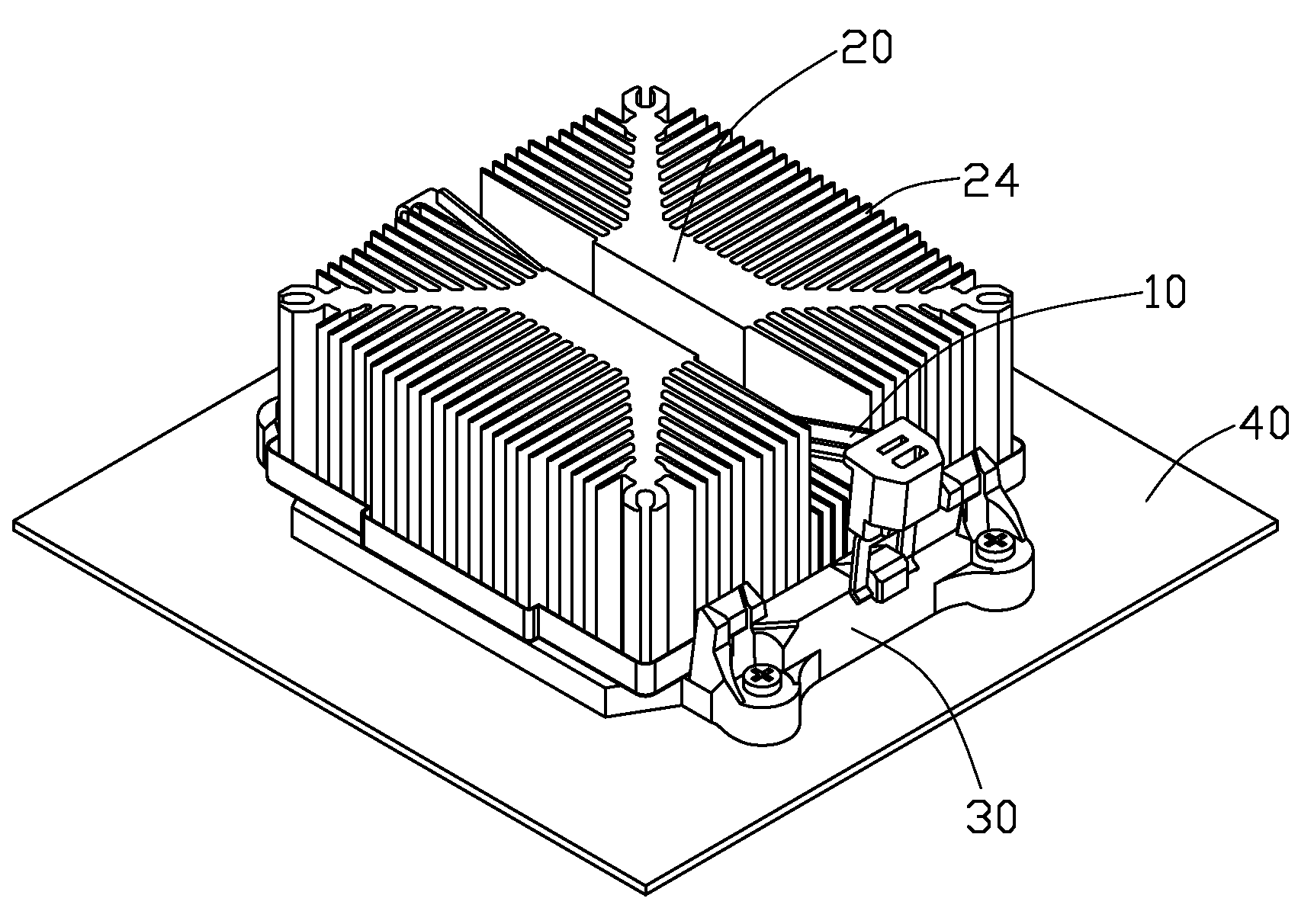

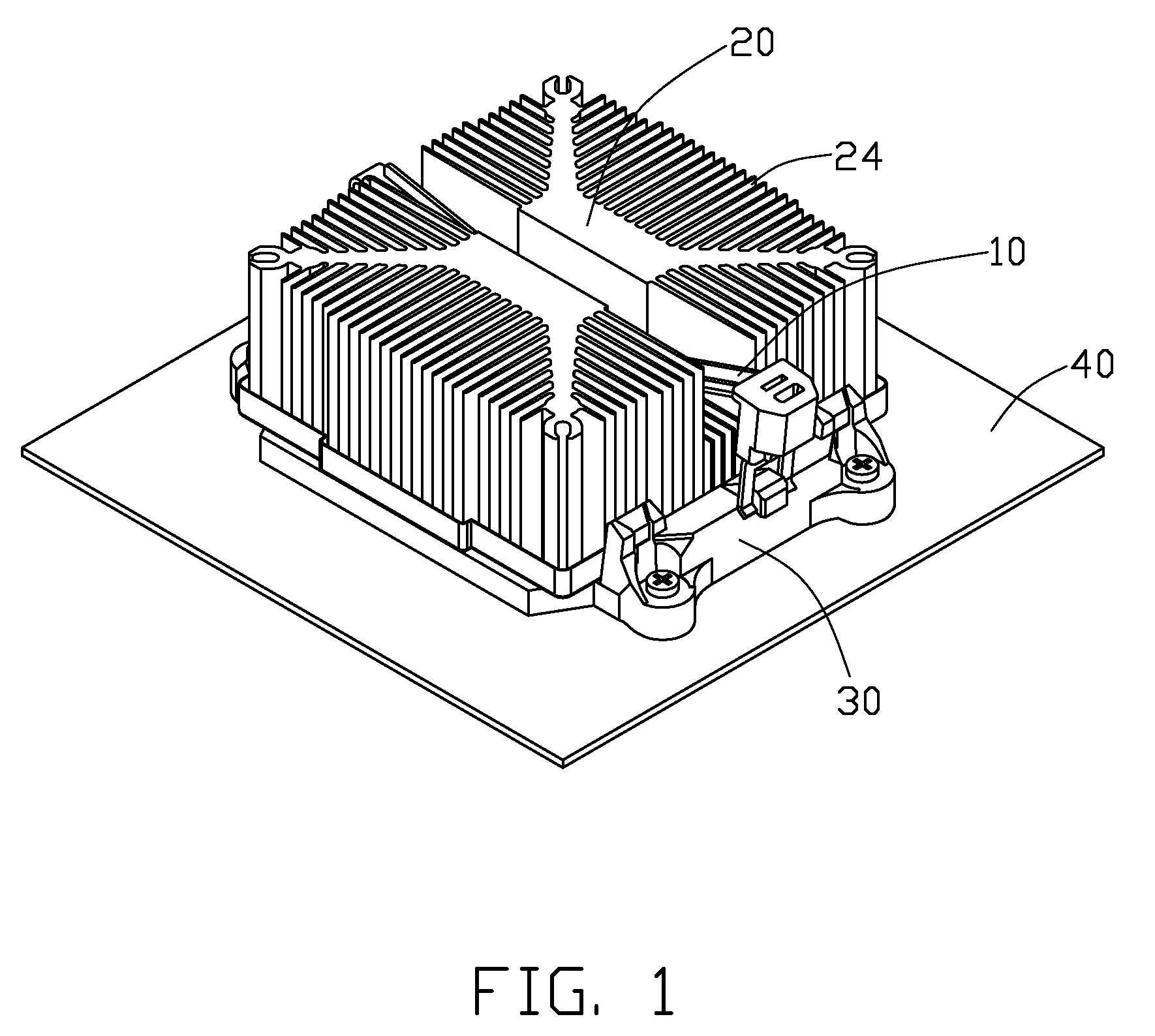

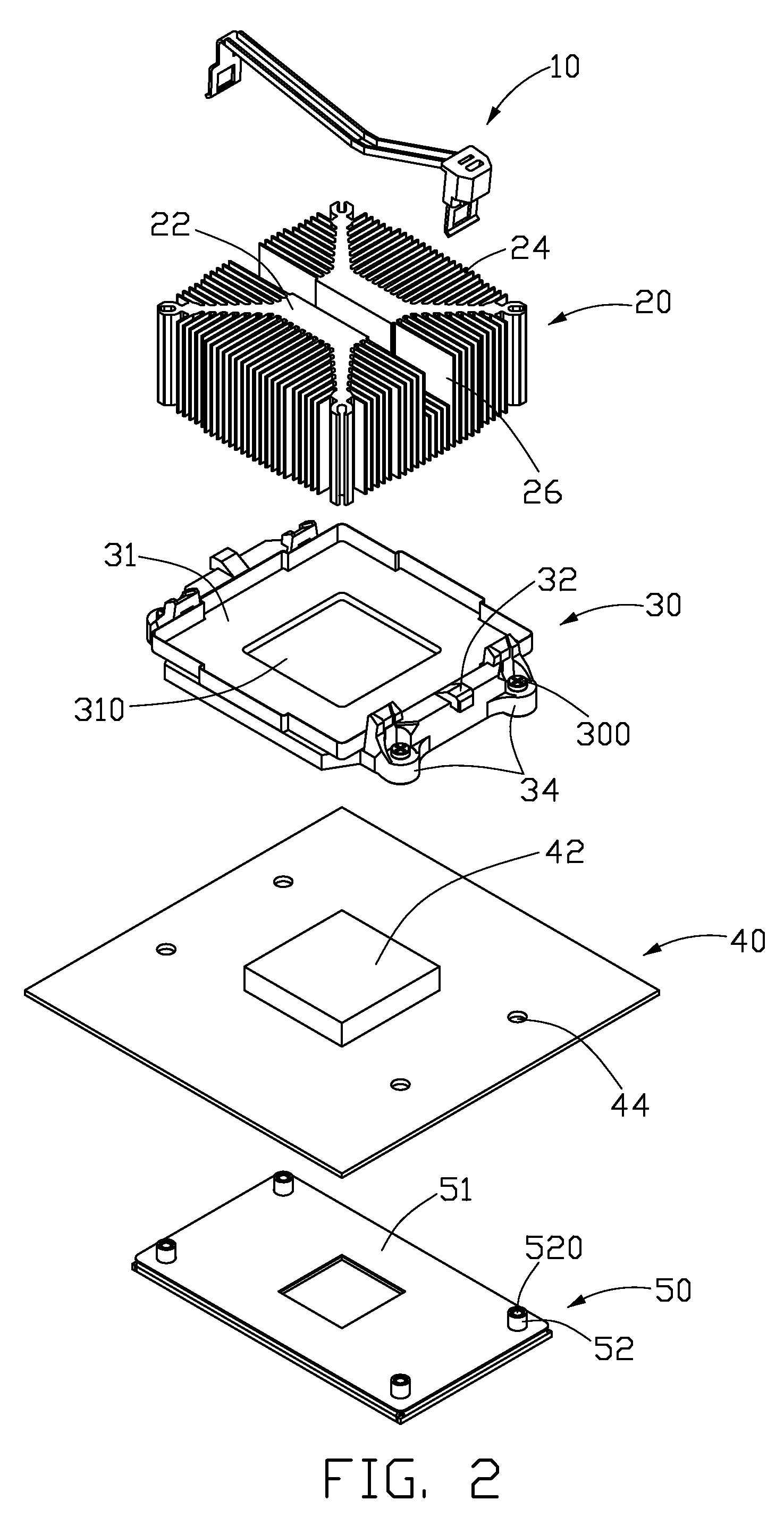

[0017]Referring to FIGS. 1 and 2, a heat sink fastening assembly in accordance with a preferred embodiment of the invention is used for attaching a heat sink 20 to a printed circuit board 40, for dissipating heat generated by a heat-generating component 42 mounted on the printed circuit board 40. The heat sink fastening assembly includes a fastener 10 for spanning over the heat sink 20 and a retention module 30 for engaging with the fastener 10 to clip the heat sink 20 therebetween. The retention module 30 is mounted on the printed circuit board 40 via a plurality of screws 300 extending through the printed circuit board 40 to engage with a back plate 50 located below the printed circuit board 40.

[0018]The back plate 50 comprises a substantially rectangular main body 51 and four posts 52 respectively extending upwardly from four corners of the main body 51. The posts 52 each define a mounting hole 520 for locking the screws 300.

[0019]The printed circuit board 40 defines four through...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com