Light frame type rear torsion beam test device and design method thereof

A test device and frame-type technology, which is applied in the field of light-weight frame-type rear torsion beam test devices, can solve problems such as uneconomical, difficult to ensure size, and large processing volume, so as to reduce its own weight, save production consumables, and have a large free space. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

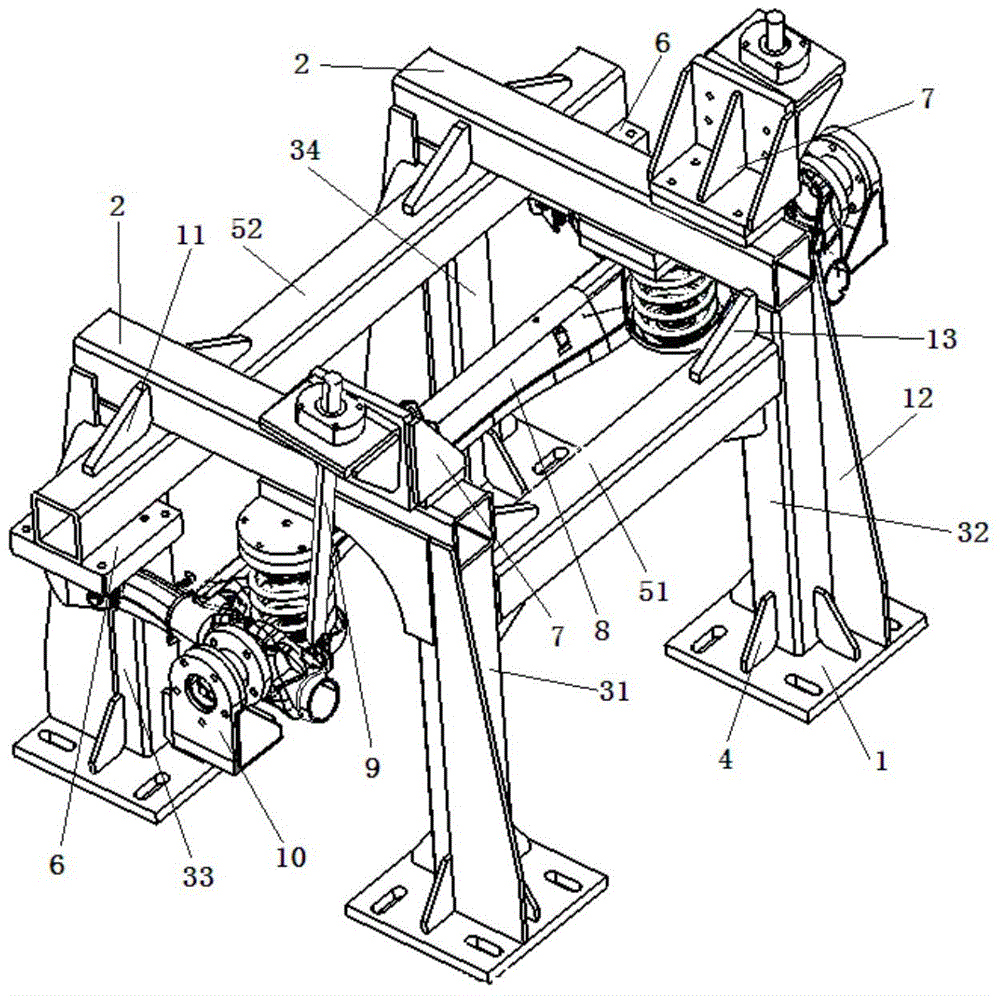

[0014] The present invention will be described in detail below in conjunction with accompanying drawing: figure 1 As shown, the present invention includes a bracket mounting plate 1, a column made up of a first column 31, a second column 32, a third column 33, and a fourth column 34, a beam made up of a first beam 51, a second beam 52, and a vertical beam. Beam 2, the support mounting plate 1 is fixed on the bottom end of the column, the first reinforcement block 4 is welded between the support mounting plate 1 and the column; the four columns are distributed in a rectangular shape, and the vertical beam 2 respectively fixed on the first column 31, the third column 33 and the second column 32, the fourth column 34, between the first column 31, the second column 32 is fixed with the first beam 51, the third column 33, A second crossbeam 52 is fixed between the fourth column 34 and the vertical beam 2, and the two ends of the second crossbeam 52 extend between the two vertical b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com