Guide bar structure in warp knitting machine, knitting machine and thread guide set

A warp knitting machine and yarn guide technology, applied in the field of warp knitting machines, can solve the problems of inability to avoid each other and the limitation of pattern design, and achieve the effect of simple structure and rich pattern design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

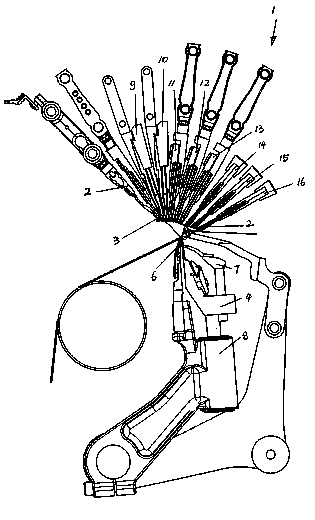

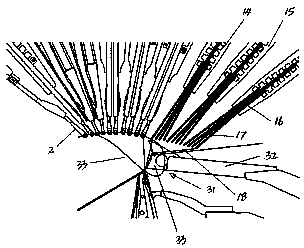

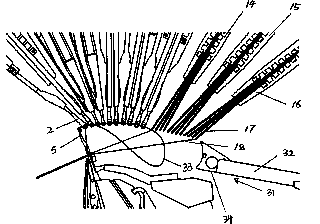

[0026] figure 1 The warp knitting machine 1 shown has a bottom bar 2 with a plurality of yarn guide needles 3 continuously arranged in a direction perpendicular to the paper surface. A needle bed 4 is also provided with knitting needles 5. A knock-off comb 6 is provided adjacent to the knitting needle 5. A needle core bed 7 works with knitting needles 5. The needle bed 4 is guided by a guide device 8.

[0027] The structure and working method of this type of warp knitting machine have been widely known, and will not be described further here.

[0028] In addition to bottom bar 2, there are other bars, bar one 9 and bar two 10. In addition, a plurality of horizontal shifting rows are provided, such as horizontal shifting row one 11, horizontal shifting row two 12, and horizontal shifting row three 13. These horizontal shifting rows can be constructed in the form described in, for example, Chinese Patent CN02127580.

[0029] In addition, the warp knitting machine 1 also has other t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com