Patents

Literature

354 results about "Lightering" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Lightering (also called lighterage) is the process of transferring cargo between vessels of different sizes, usually between a barge and a bulker or oil tanker. Lightering is undertaken to reduce a vessel's draft in order to enter port facilities which cannot accept very large ocean-going vessels. Lightering can also refer to the use of a lighter barge for any form of short-distance transport, such as to bring railroad cars across a river. In addition, lightering can refer to the process of removing oil or other hazardous chemicals from a compromised vessel to another vessel to prevent oil from spilling into the surrounding waters.

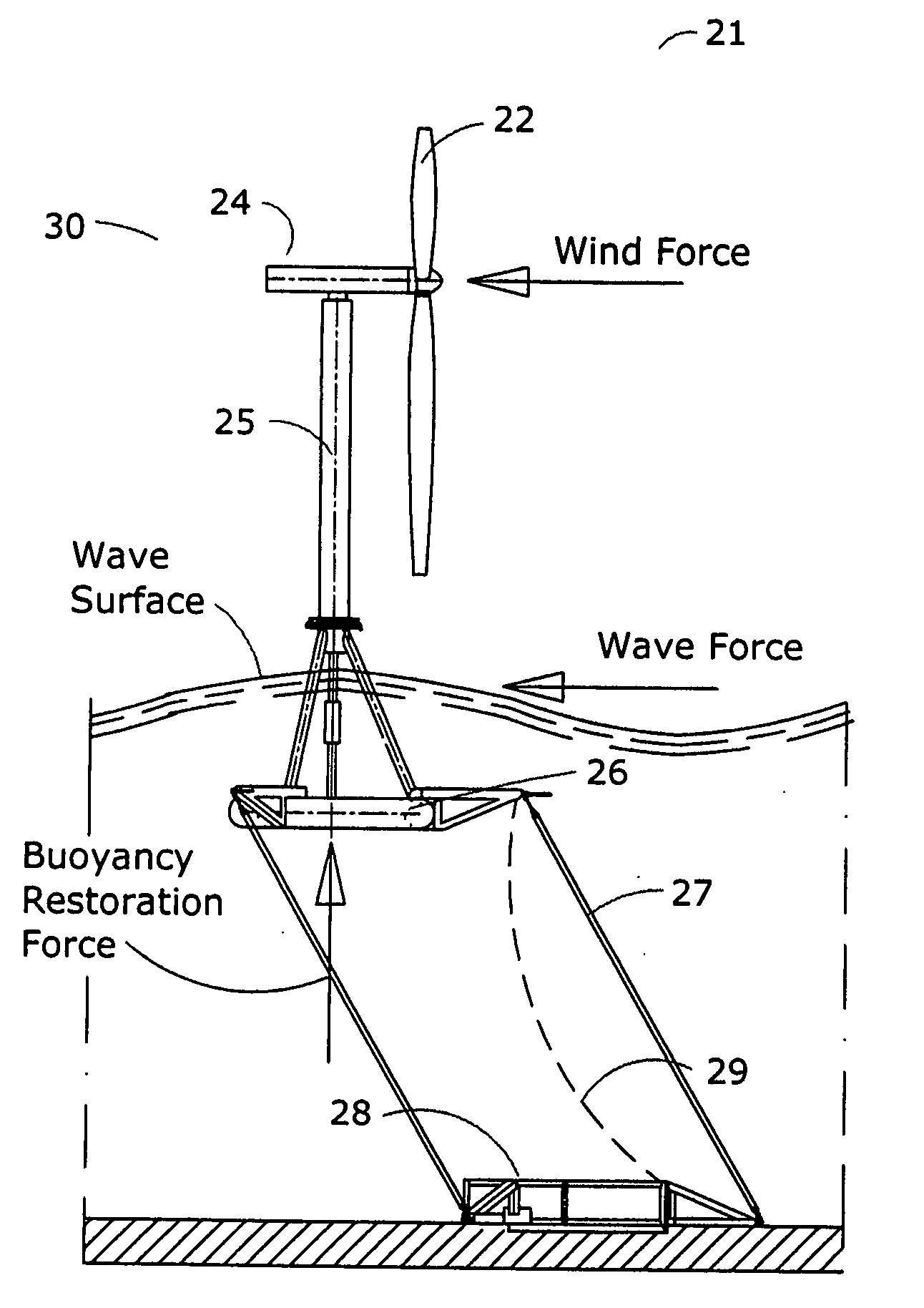

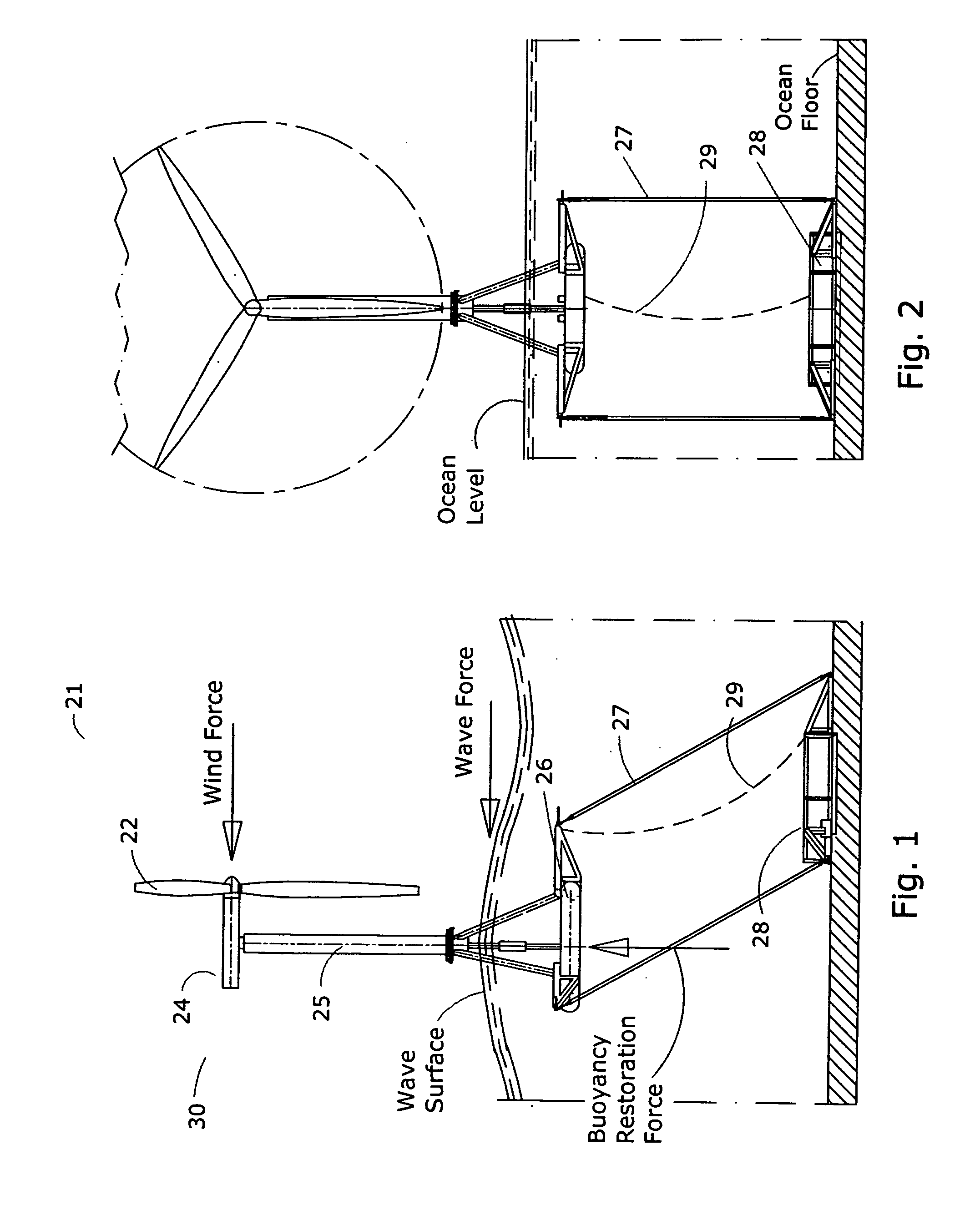

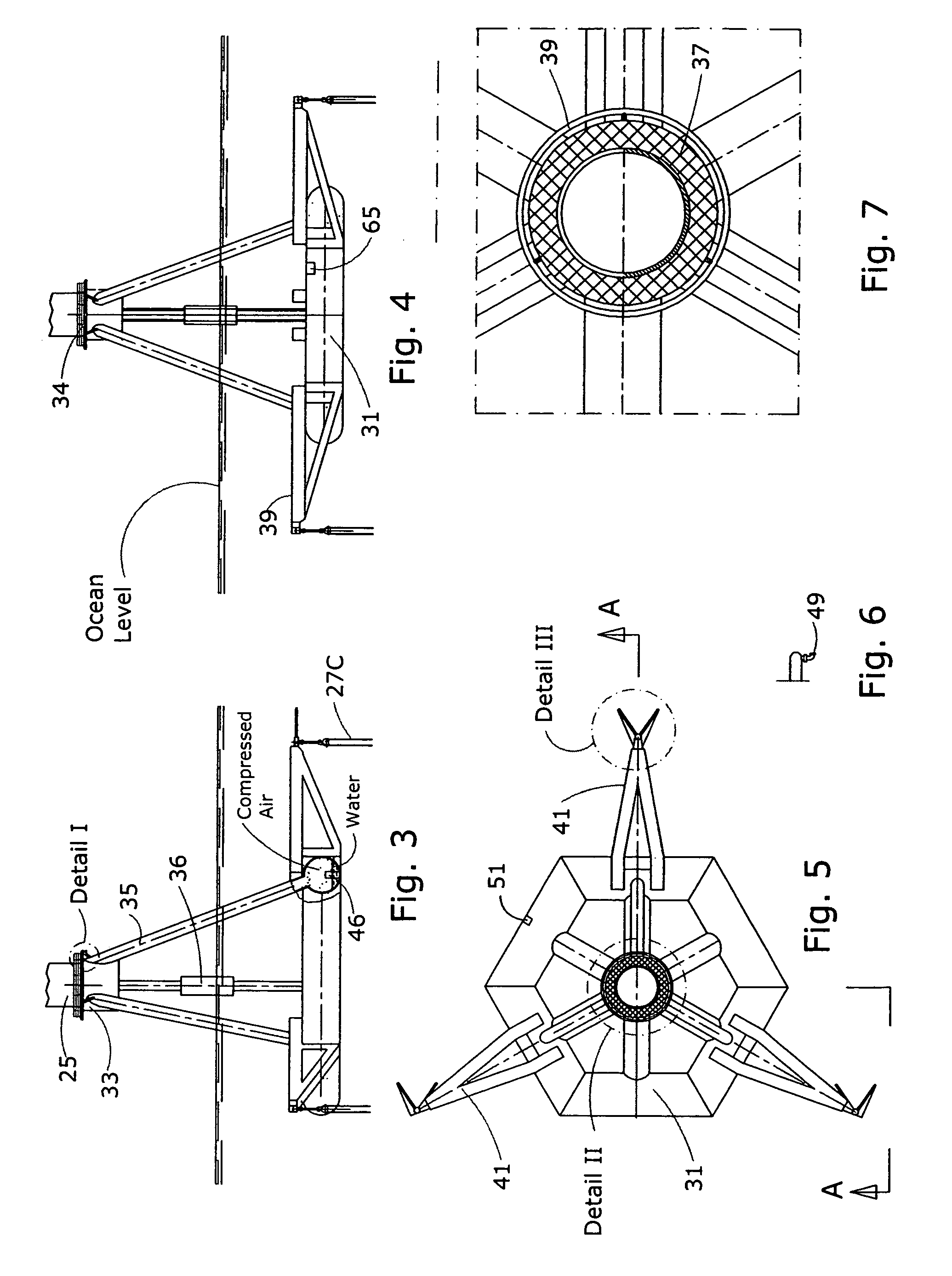

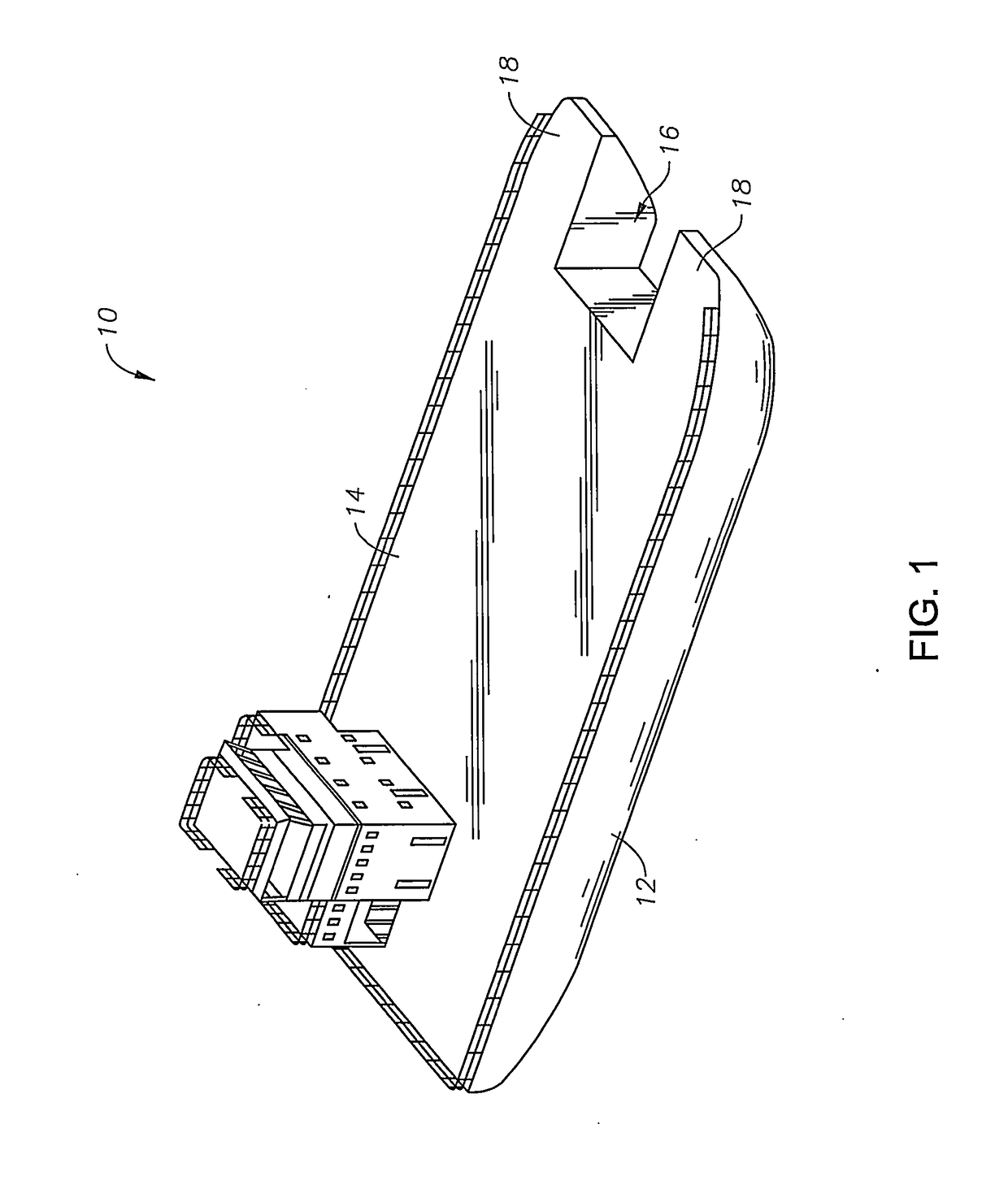

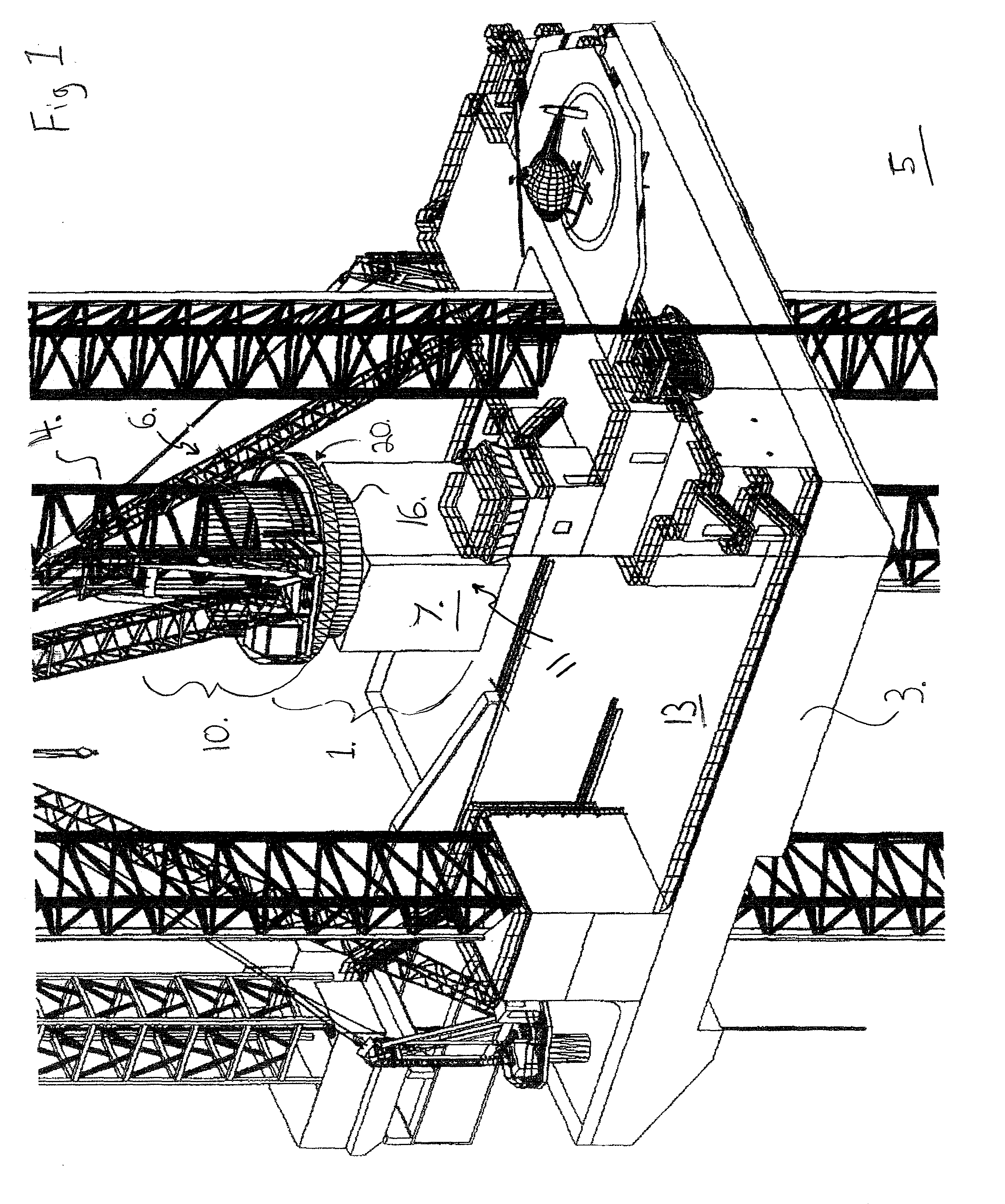

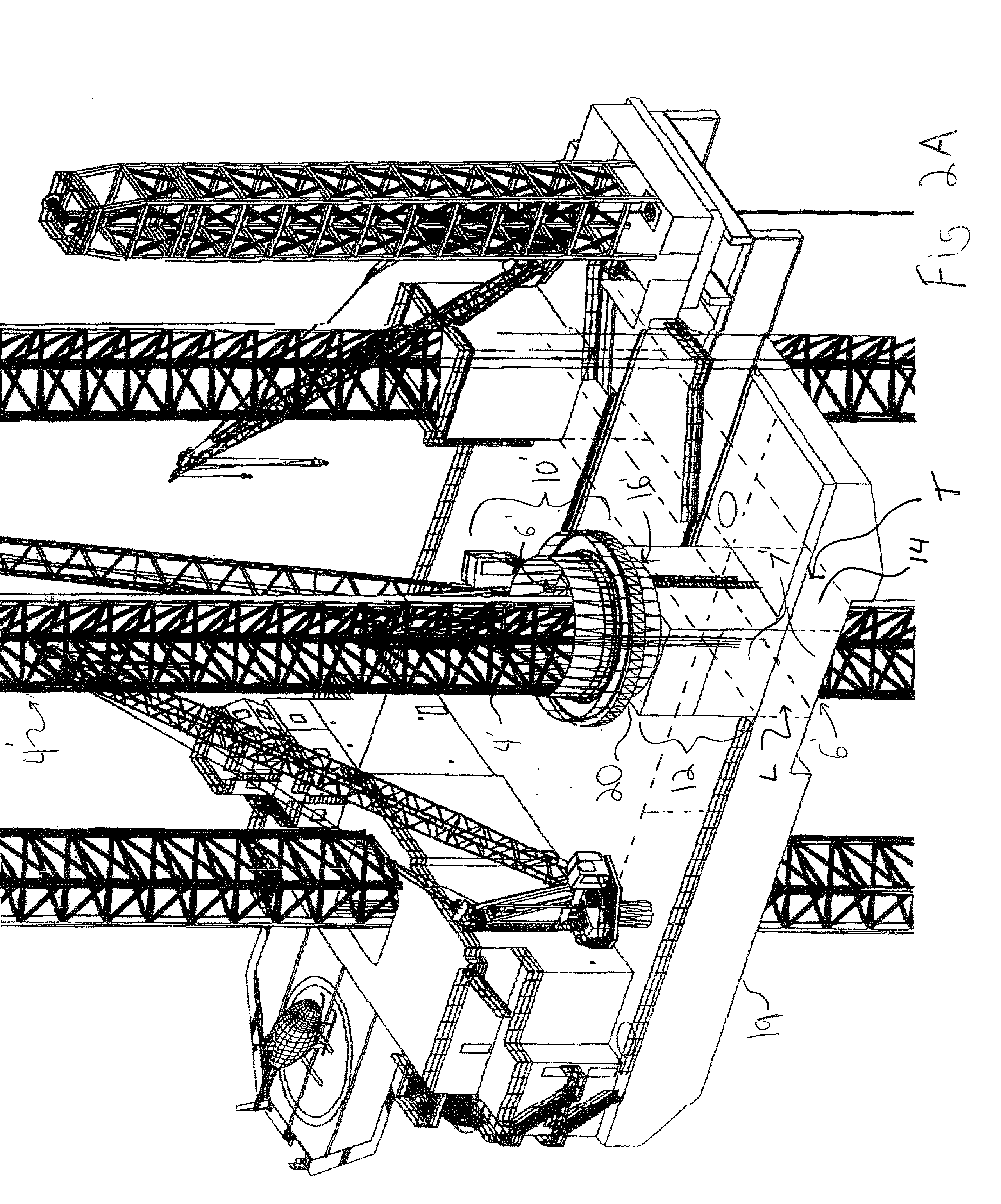

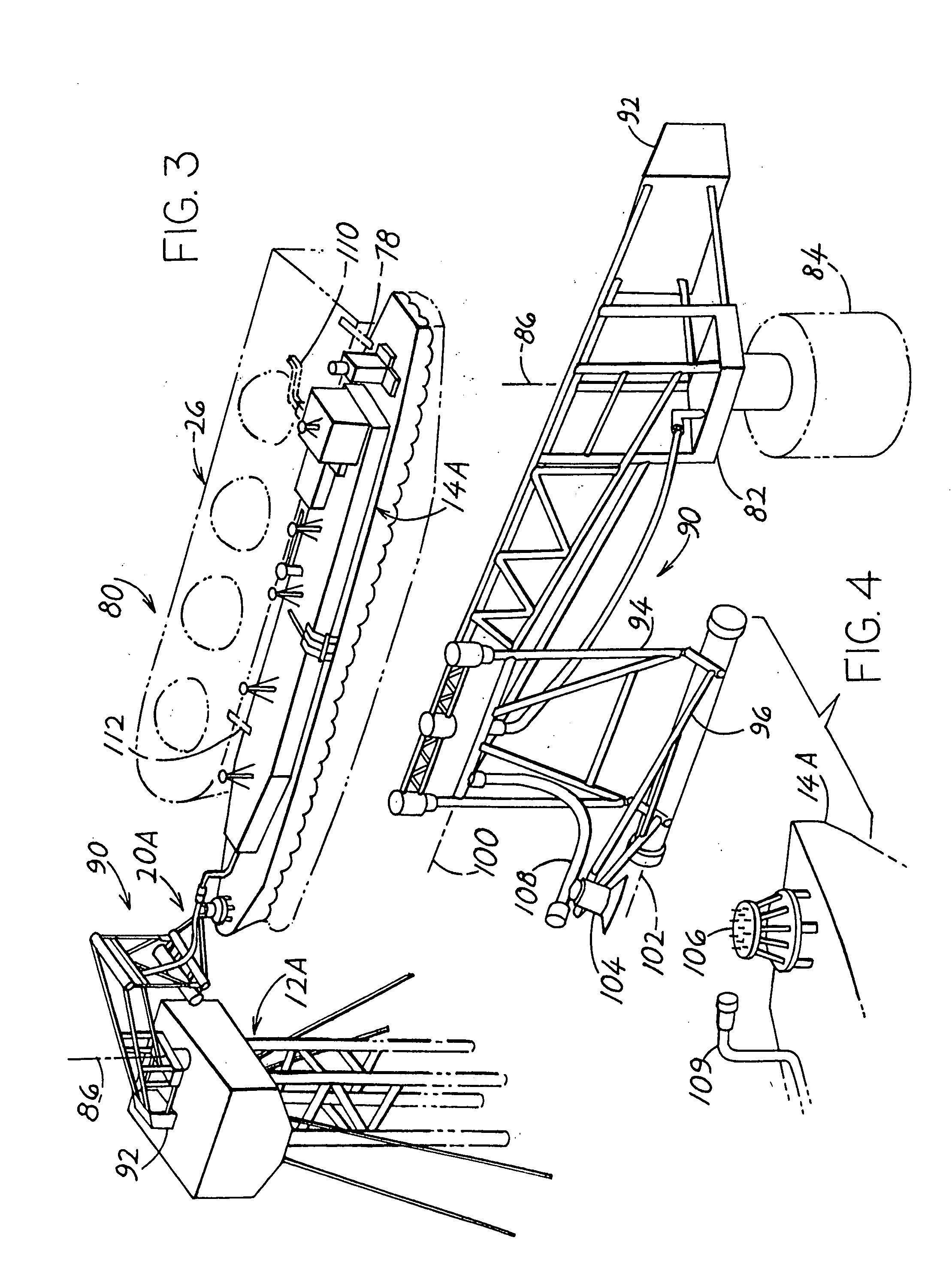

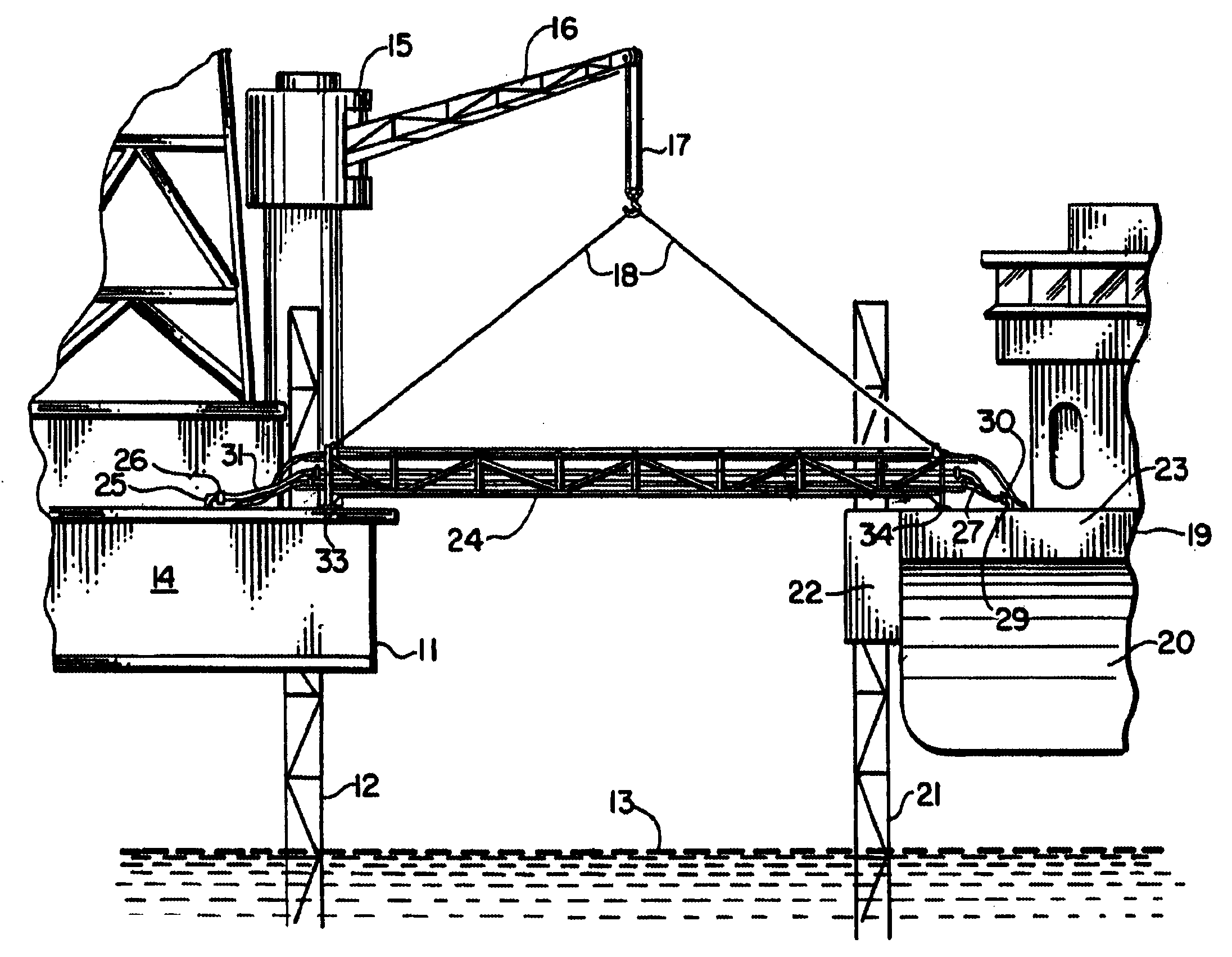

Assembly, transportation and installation of deepwater windpower plant

InactiveUS20080240864A1Reduce installationShorten assembly timeWind motor assemblyWind motor supports/mountsOcean bottomBuoy

A deepwater windpower plant (DWP) has a tension leg-type floating platform with an evacuable base for adjusting its buoyancy for installation at ocean depths ranging from 40 meters up to 1.5 kilometers and more. The DWP has a typical offshore wind turbine assembled close to shore which is then towed to a desired installation site on the ocean, and held in place by a gravity anchoring base (GAB), to which an evacuable portion or space of the DWP platform is anchored. The GAB has upwardly extending mooring tethers and a power cable which are brought to the ocean surface by attached buoys. The GAB is sunk to the ocean floor at the installation site under controlled conditions so that the GAB lands flat on the ocean floor. As the GAB sinks to the ocean floor, the mooring tethers and power cable are pulled to the surface by their respective buoys. The GAB is loaded with heavy ballast material that can be dropped from barges on the ocean surface into the upwardly open GAB below the barges.

Owner:DEEPWATER WIND

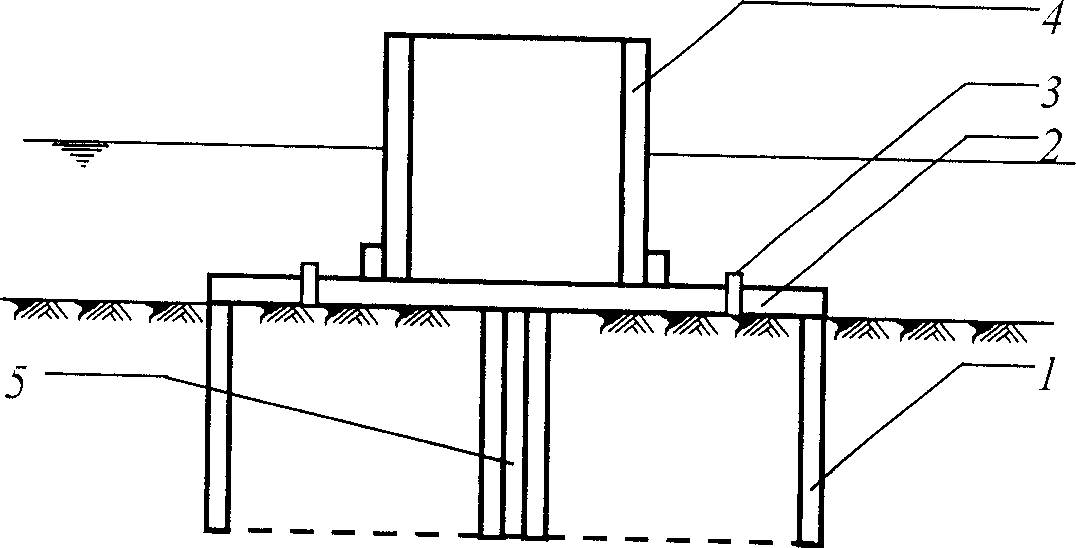

Maritime air float hauling and positioning sinking mounting method for soft-foundation box-cylinder type infrastructure

InactiveCN1730842ALocating sinking equipment is simpleEasy constructionCaissonsEngineeringLightering

The present invention is the marine air floatation hauling and locating and depositing installation process of case and barrel shaped foundation structure for soft soil. The construction process includes inflating the case and barrel shaped foundation structure in water for it to float and hauling to the installation site; locating in the floating state; deflating for deposition via controlling the deflation speed and amount to control the deposition speed and inclination; pumping out air from the structure and applying pressure for further deposition; pumping out water from the structure for further deposition until pumping out all water inside the structure and completing the installation. The said process needs no large hoisting and transportation apparatus, and is simple, controllable and low in cost.

Owner:TIANJIN UNIV

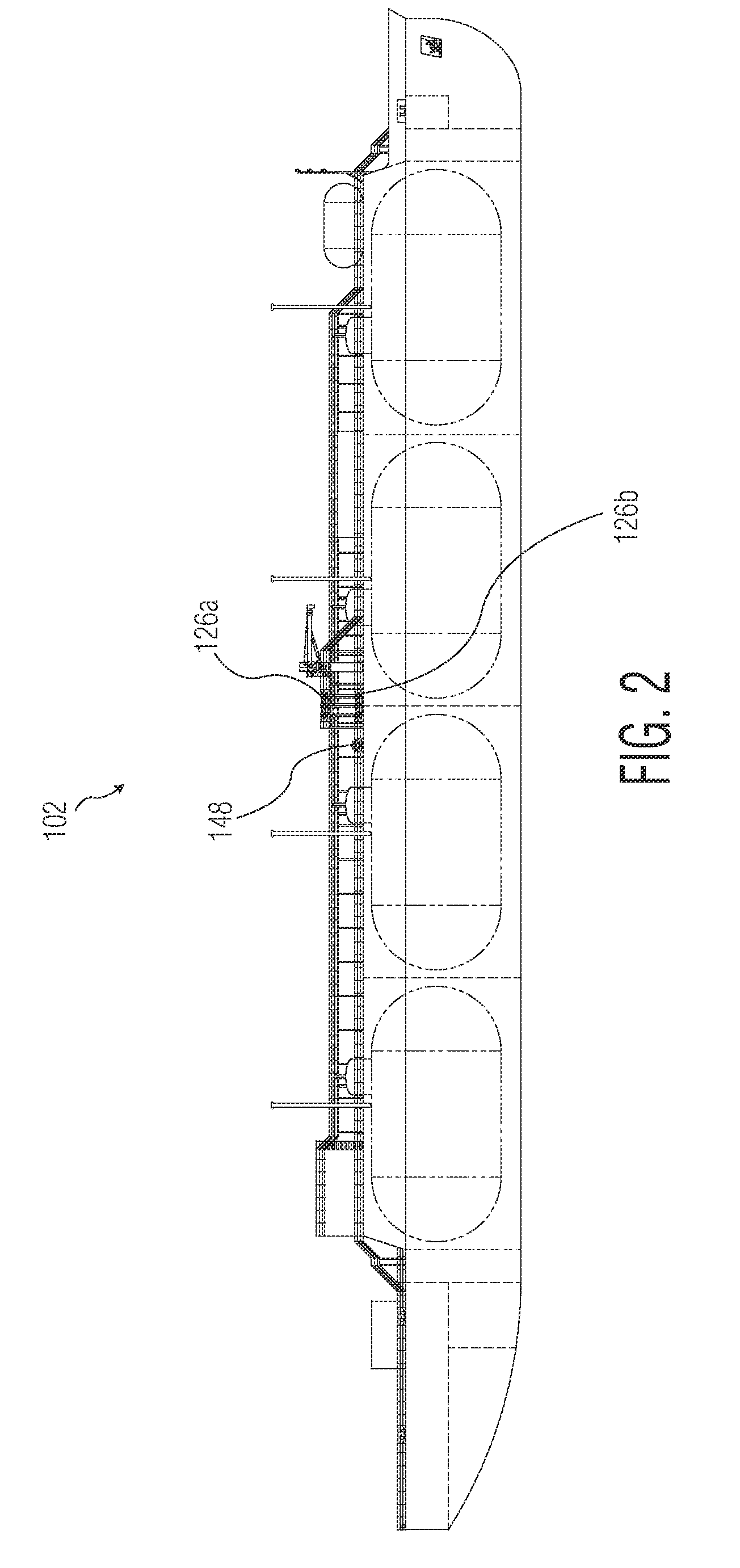

Articulated Tug and Barge Arrangement for LNG Storage, Transportation and Regasification

InactiveUS20120324910A1Easy to operateEliminate needContainer filling methodsGas handling applicationsLighteringSeawater

Articulated tug and barge arrangements and methods for transportation, storage and regasification of liquefied natural gas (LNG) aboard barge units and for ballasting the barge units are provided. A barge unit includes a type C tank for the containment of LNG under pressure and a regasification unit fluidly coupled to the type C tank for regasification of LNG aboard the barge unit for offloading natural gas. The barge unit is adapted for loading LNG directly from a liquefaction plant, for transporting LNG by operatively coupling to a tug unit, as well as for storing LNG at a destined off board facility, and for fueling a floating power production facility. The arrangements and methods provide a transport terminal ring. The arrangements and methods provide for the circulation of seawater through the regasification unit and into ballast tanks for ballasting of the barge unit while offloading natural gas.

Owner:WALLER MARINE

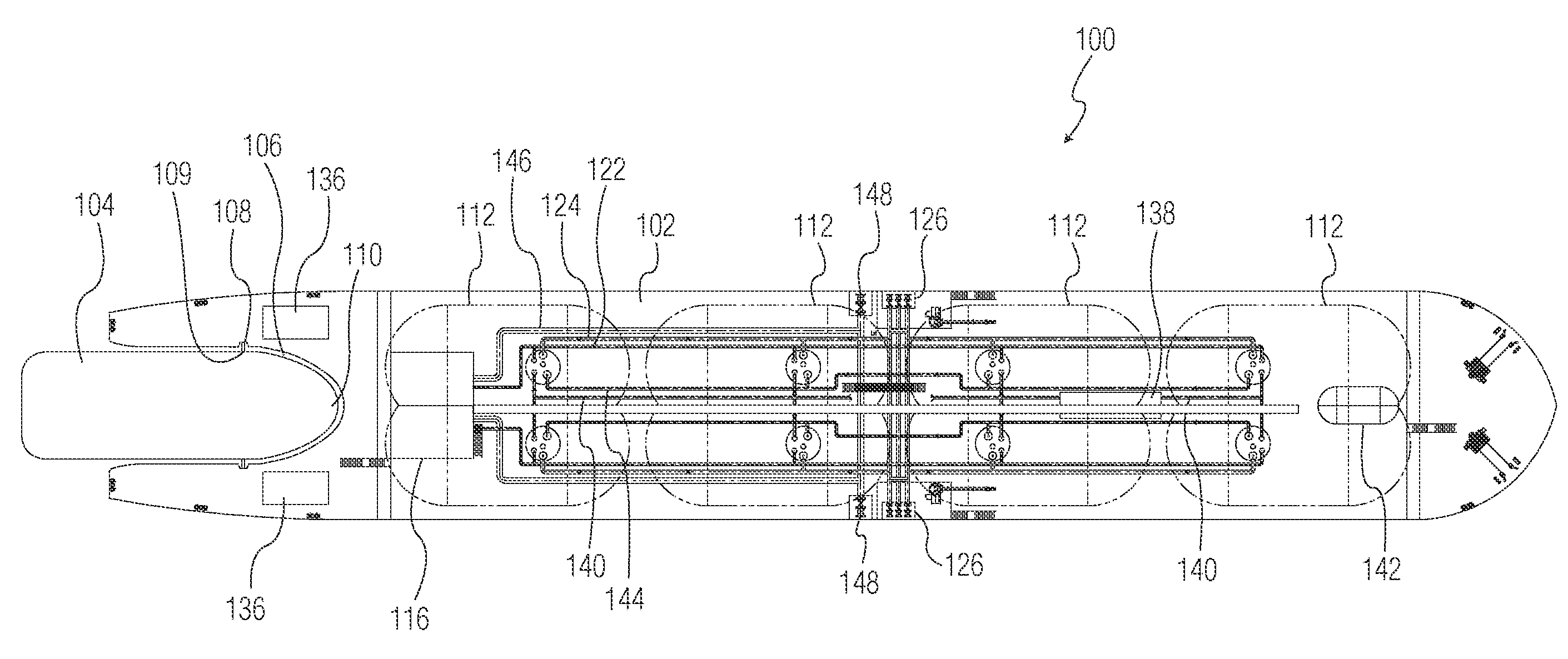

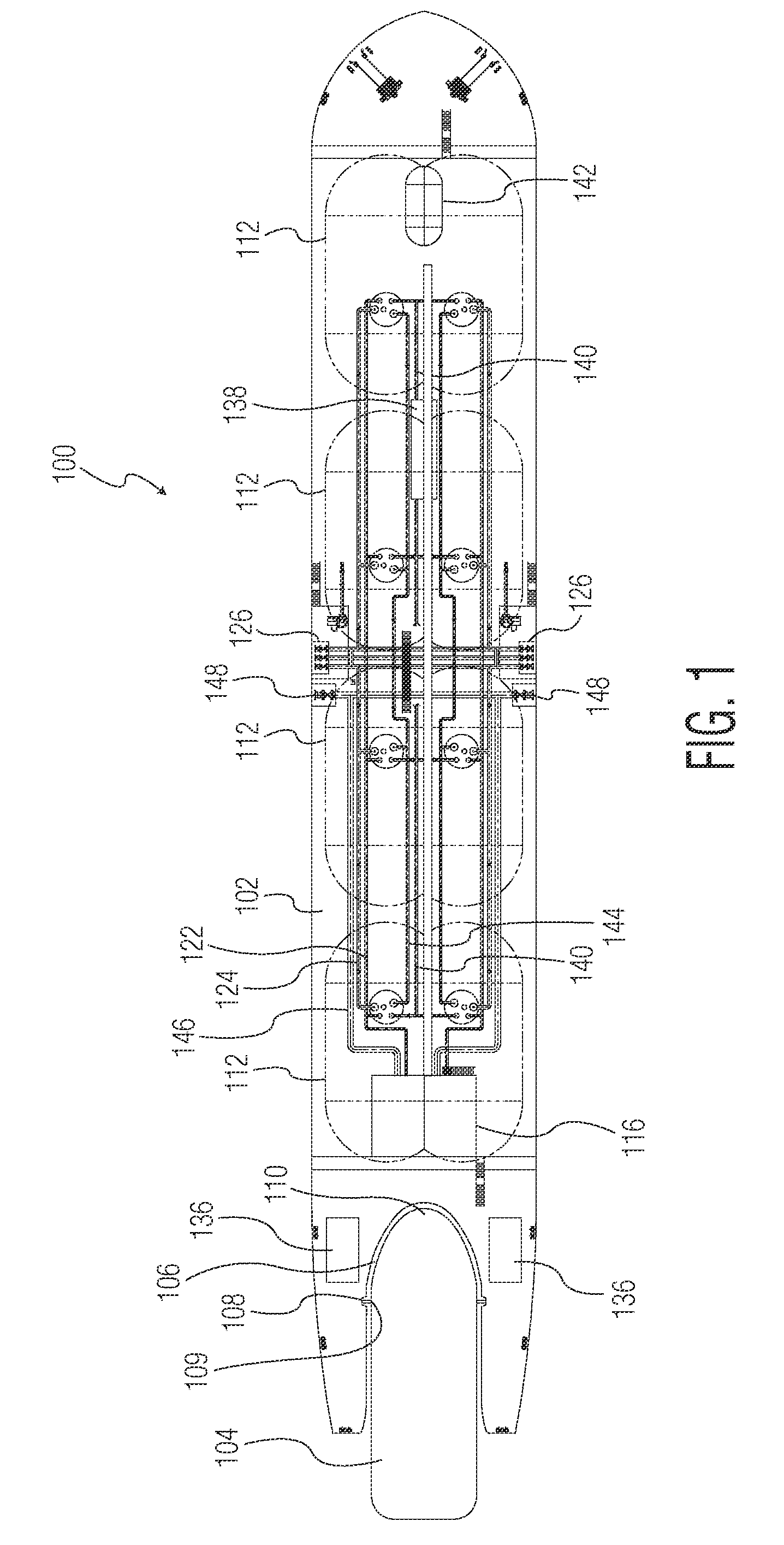

Lng Transportation Vessel and Method For Transporting Hydrocarbons

A vessel for transporting liquefied natural gas is provided. The vessel generally includes a gas transfer system for on-loading and off-loading natural gas to and from the vessel at essentially ambient temperature. The vessel further includes a gas processing facility for selectively providing liquefaction and regasification of the natural gas. The vessel also includes a containment structure for containing the liquefied natural gas during transport. The vessel may be a marine vessel or a barge vessel for transporting LNG over water, or a trailer vessel for transporting LNG overthe-road. A method for transporting LNG is also provided, that provides on-loading of natural gas onto a vessel, condensing the natural gas, storing the gas on the vessel in liquefied form, transporting the gas to an import terminal, vaporizing the gas, and off-loading the gas at the terminal.

Owner:BOWEN RONALD R +3

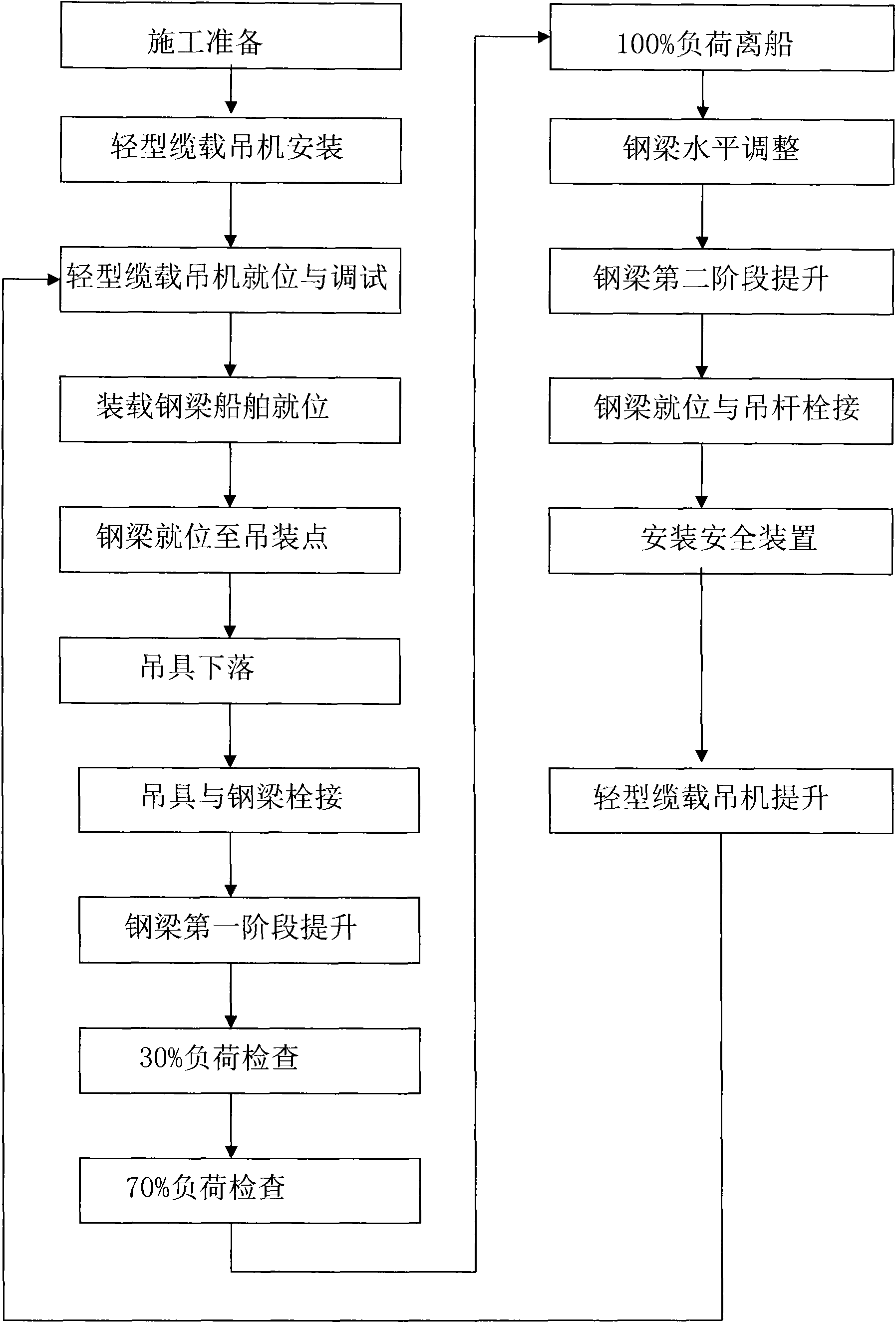

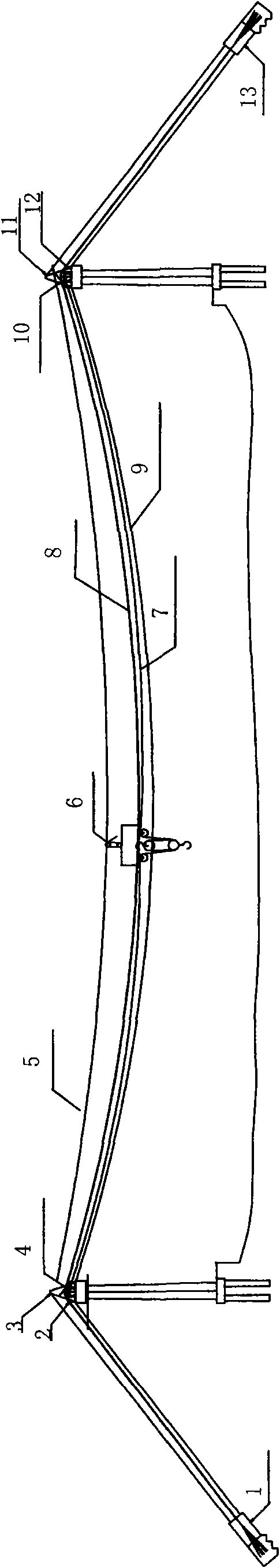

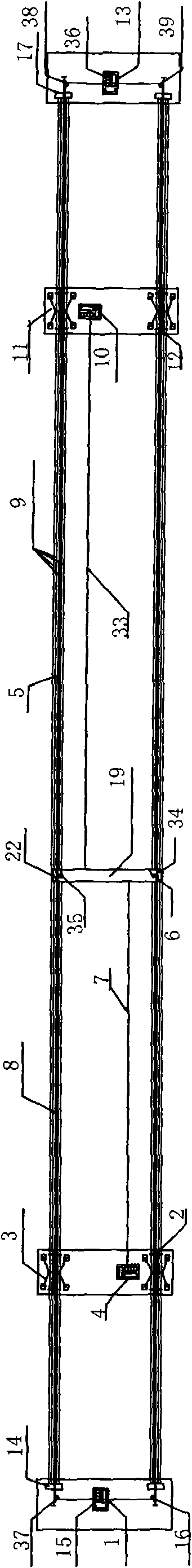

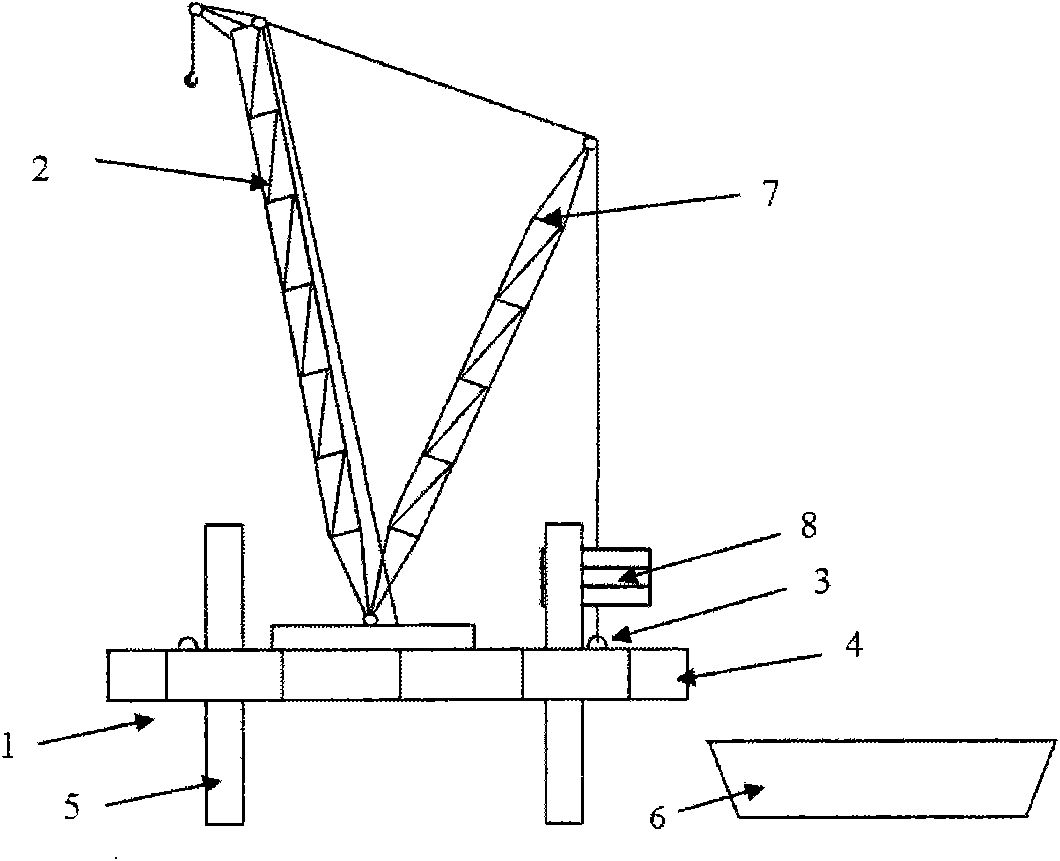

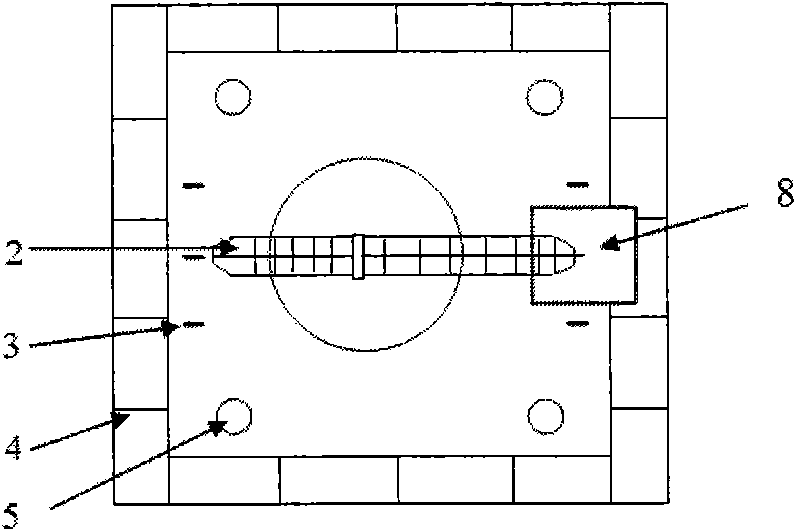

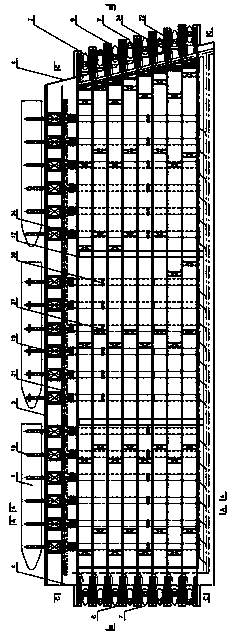

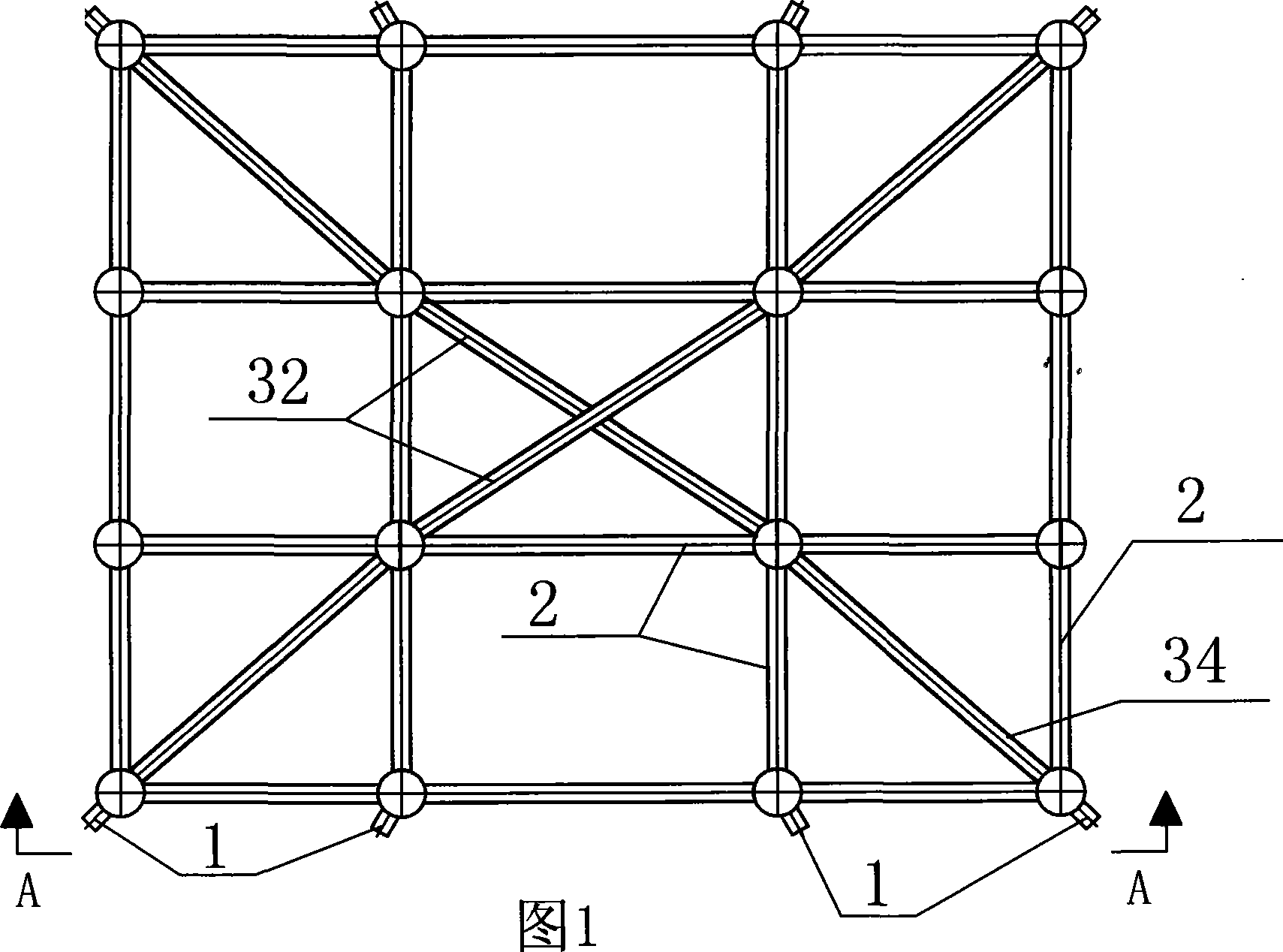

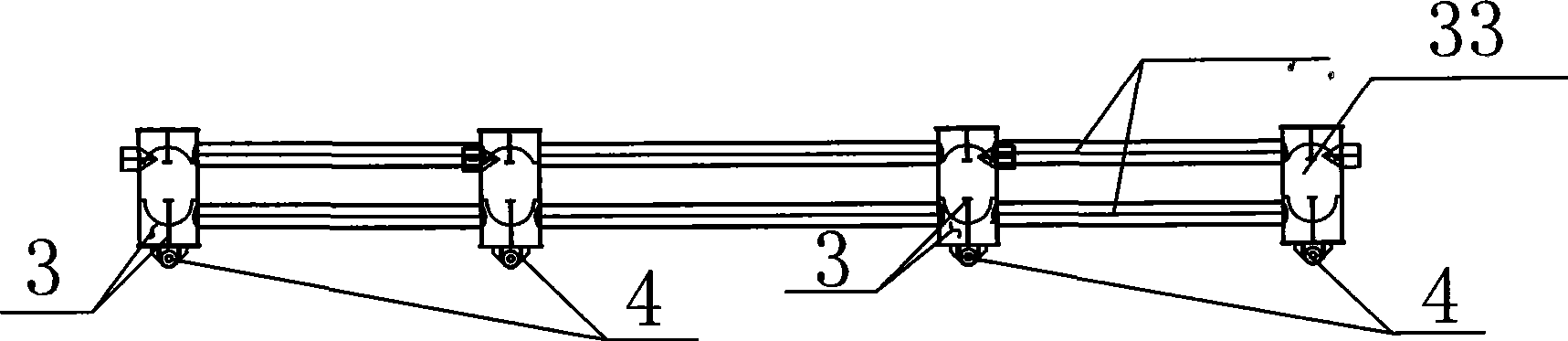

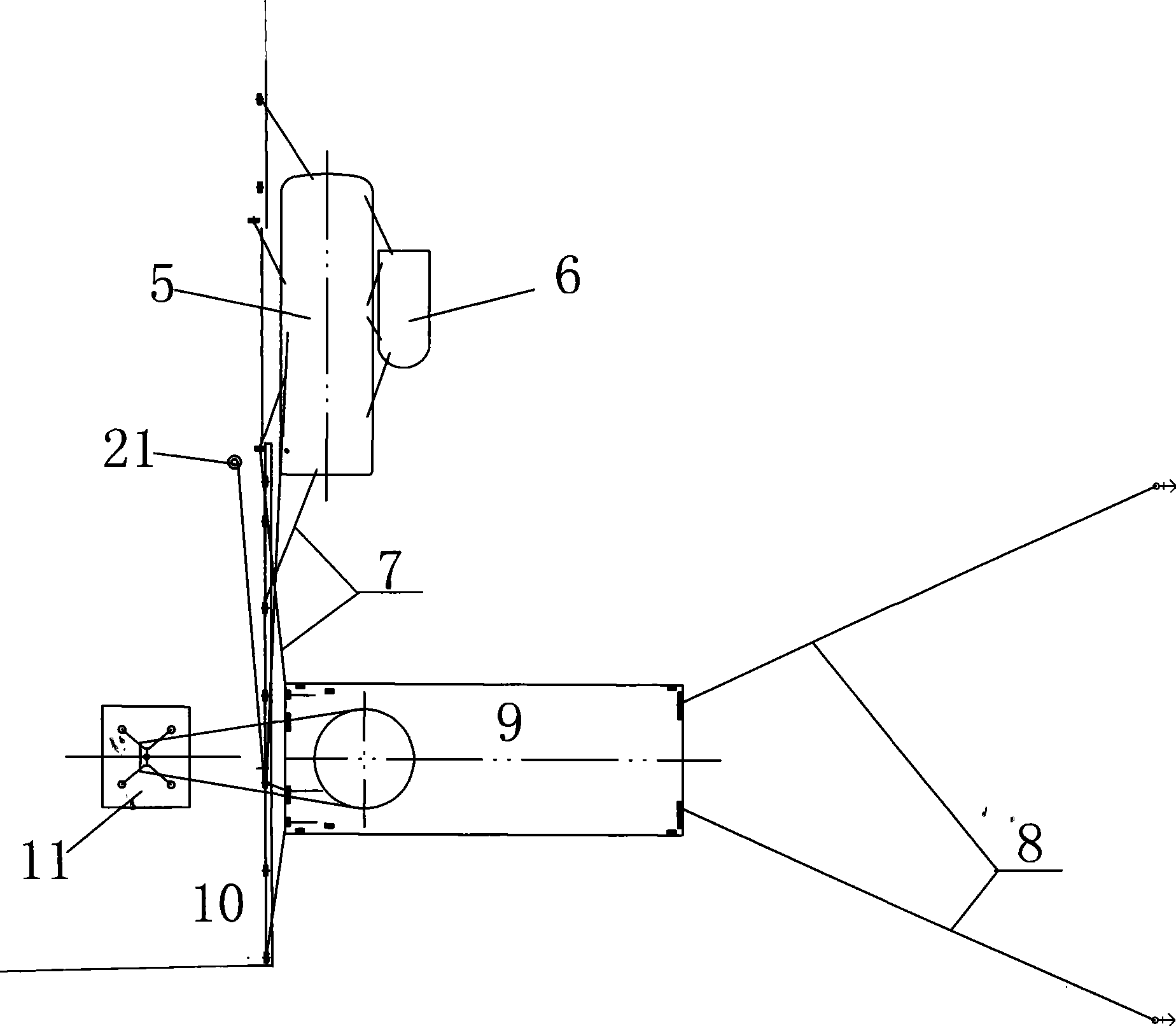

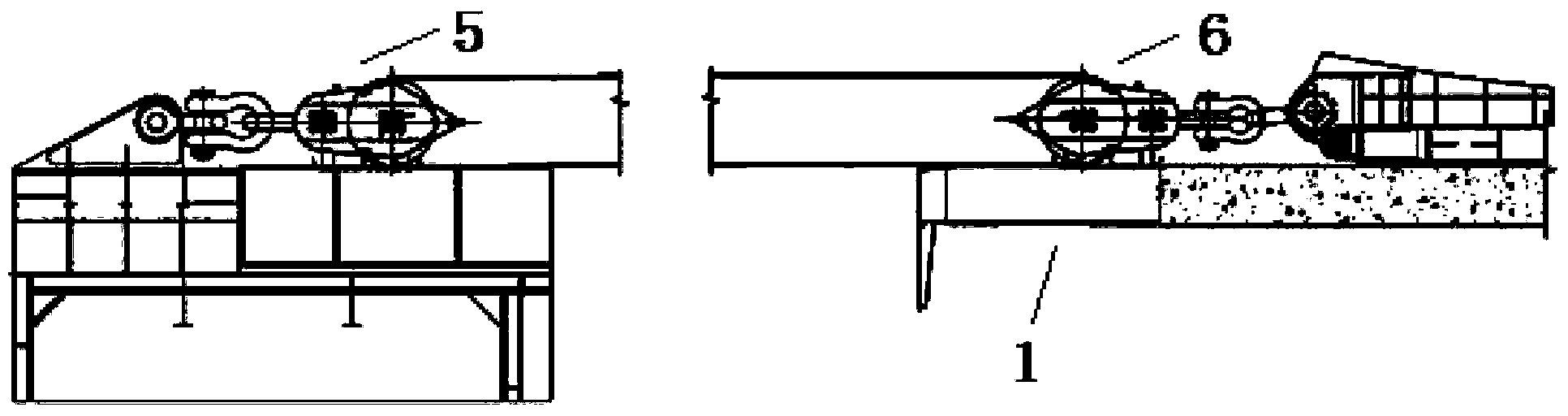

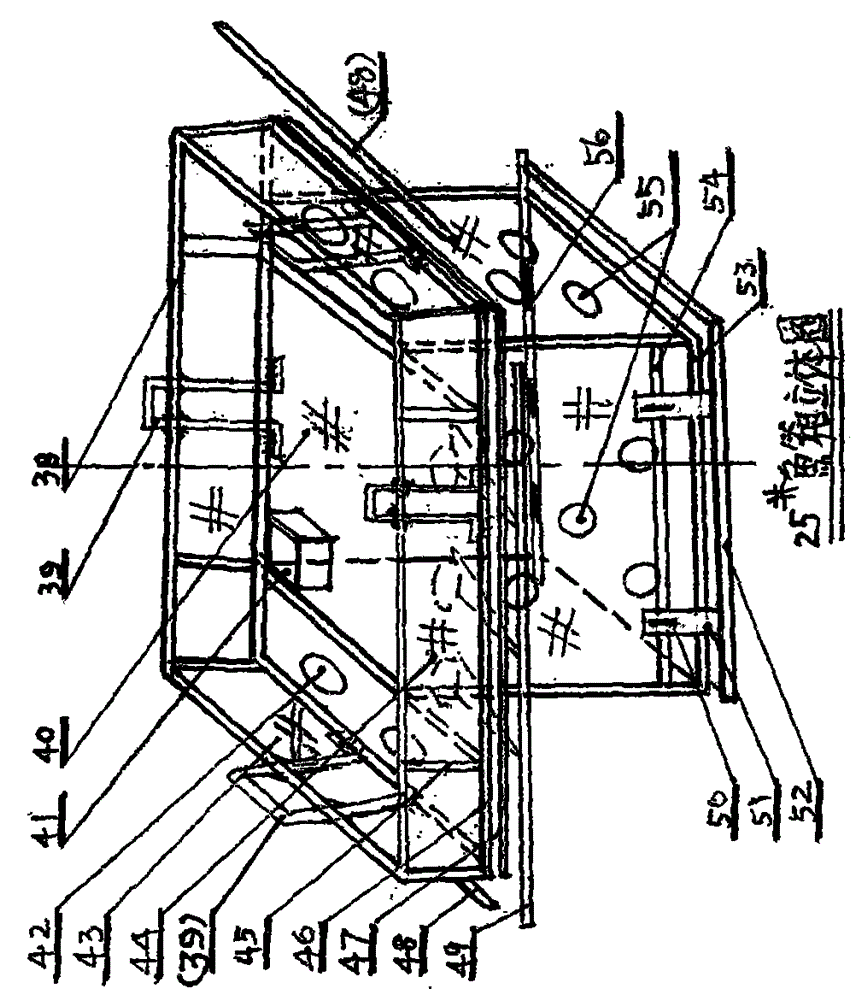

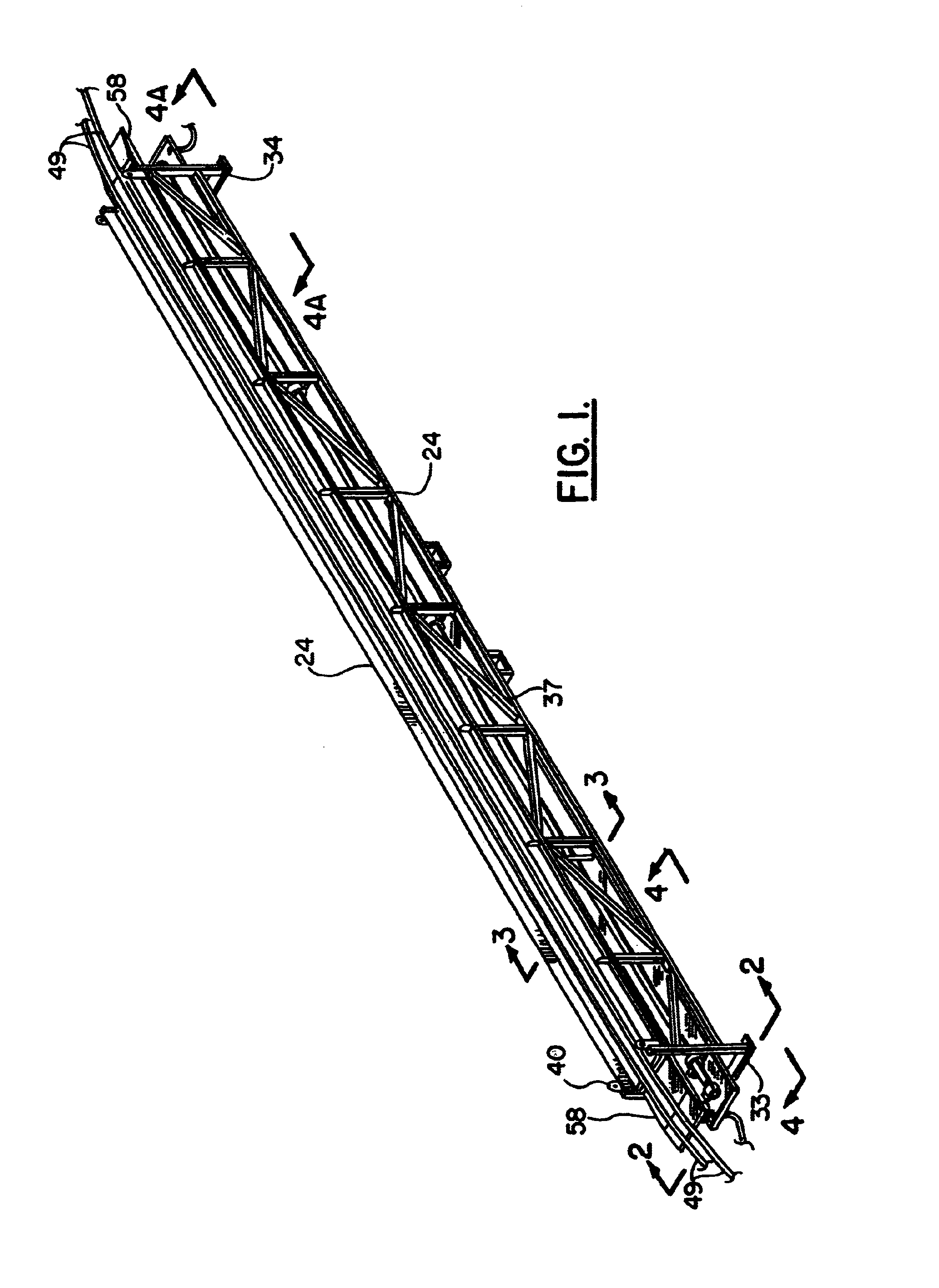

Process method for construction of steel-structured suspension bridge and light type cable carrying crane specially used in same

InactiveCN101684639AReduce weightSimple structureSuspension bridgeBridge erection/assemblyStructural engineeringLightering

The invention provides a process method for the construction of a steel-structured suspension bridge and a light type cable carrying crane specially used in the same, wherein the process flow comprises the steps of construction preparation, assembly of the light type cable carrying crane, the positioning and debugging of the light type cable carrying crane, the positioning of a ship carrying steelbeams, the lifting of the steel beams up to the hoisting point, the descent of a lifting device, the bolting connection of the lifting device and the steel beams, the first stage lifting of the steelbeams, the 30-percent load detection, the 70-percent load detection, the 100-percent load detection, the horizontal adjustment of the steel beams, the second stage lifting of the steel beams, the positioning of the steel beams and boiling connection of a lifting rod, the assembly of a security device, the lifting of the light type cable carrying crane, the movement positioning of the light type cable carrying crane; and the special light type cable carrying crane consists of a load-bearing mechanism, a load-lifting mechanism, a traveling mechanism, an anchoring mechanism and a weight-balancing beam. The process method and the special light type cable carrying crane have the advantages of light weight, simple structure, easy processing, convenient assembly and disassembly, no waterway occupation, big free space brought to transport barges and waterway traffic, high flexibility and maneuverability, high lifting speed, low construction cost, low labor intensity of workers and the suitability for the construction of the suspension bridge.

Owner:CHINA FIRST METALLURGICAL GROUP

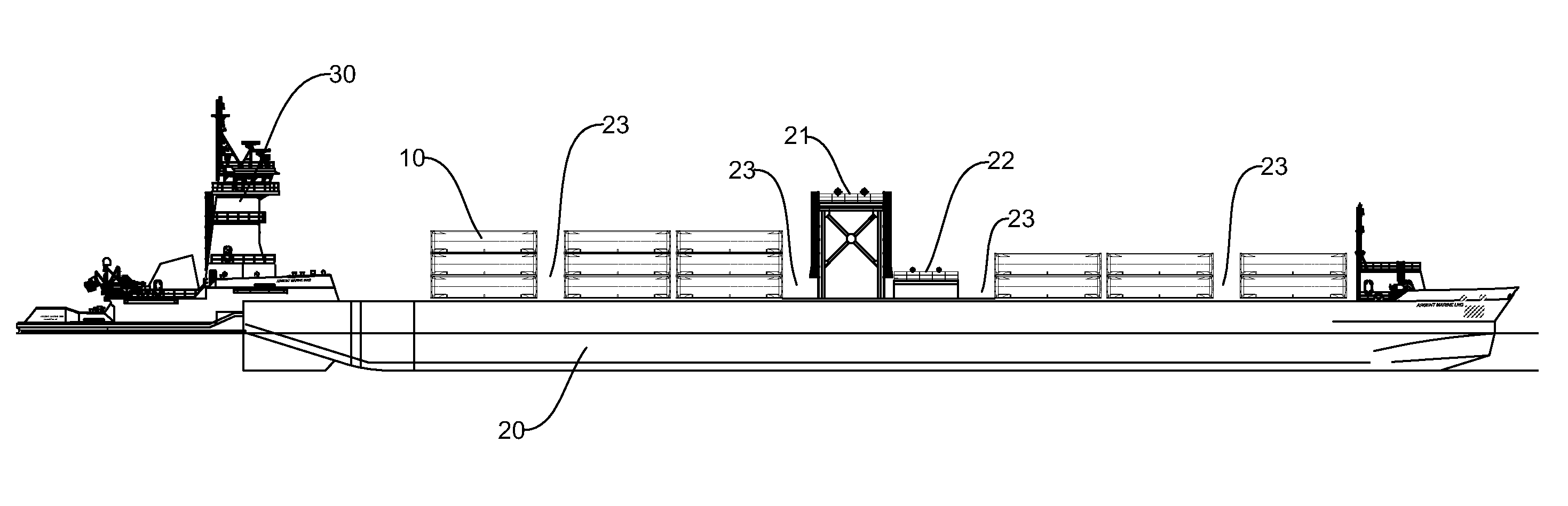

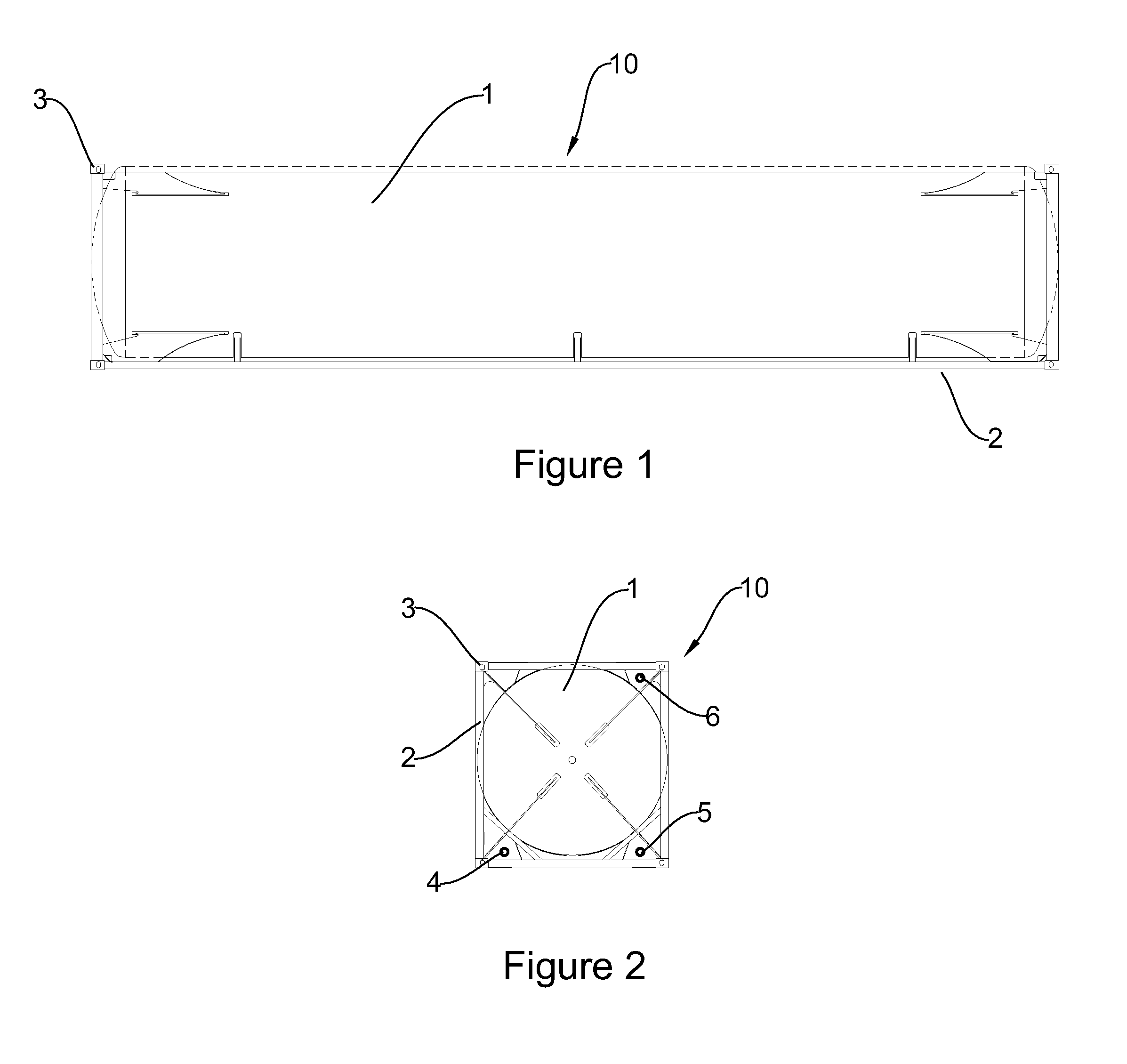

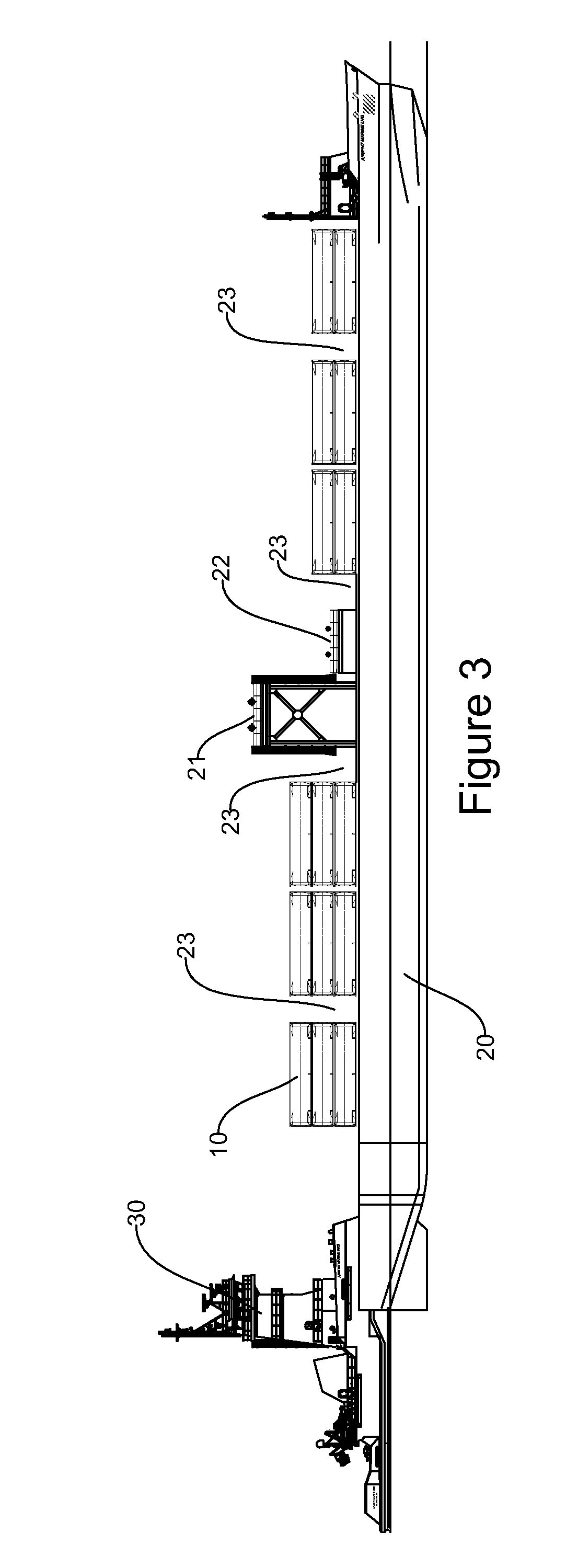

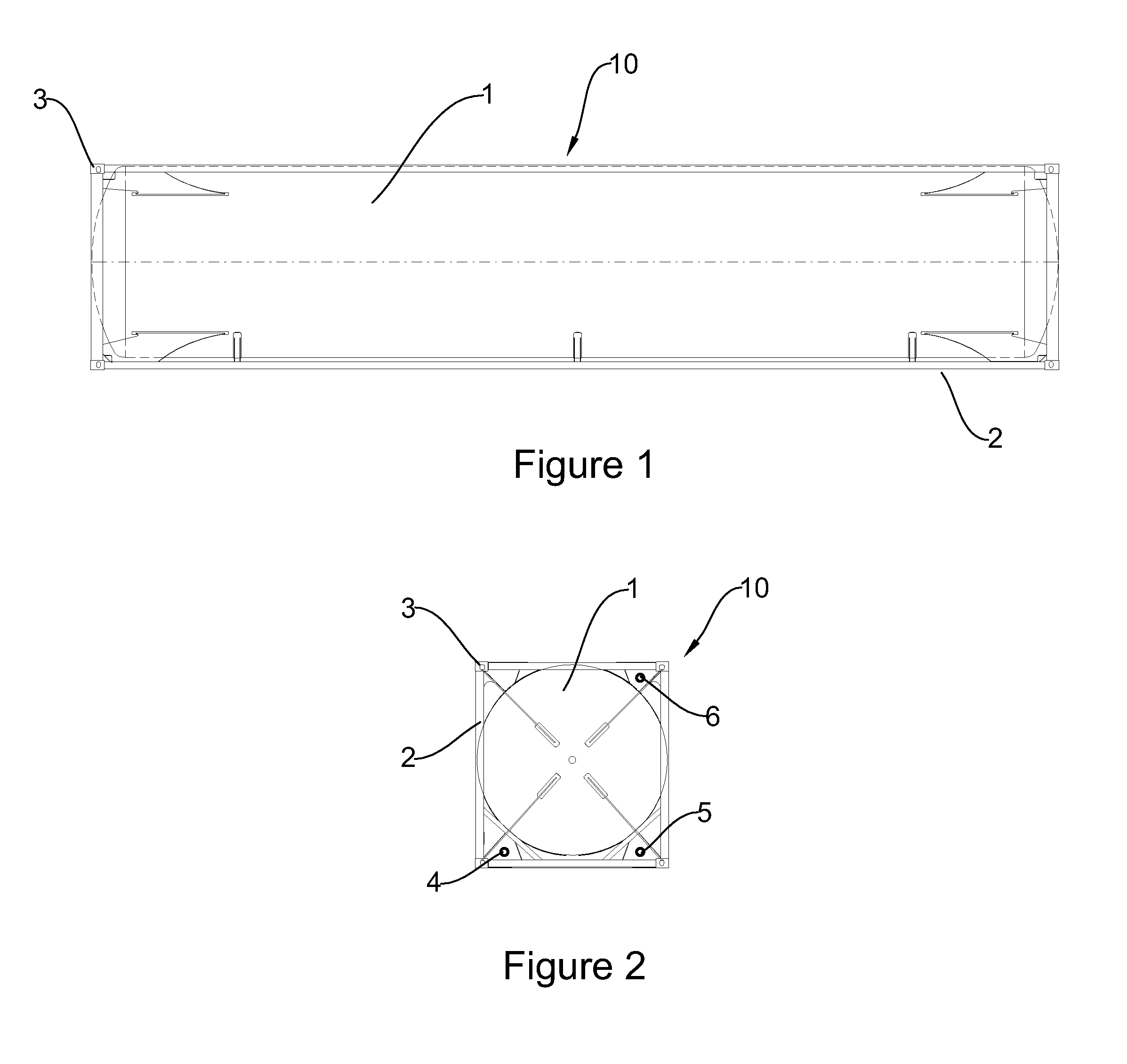

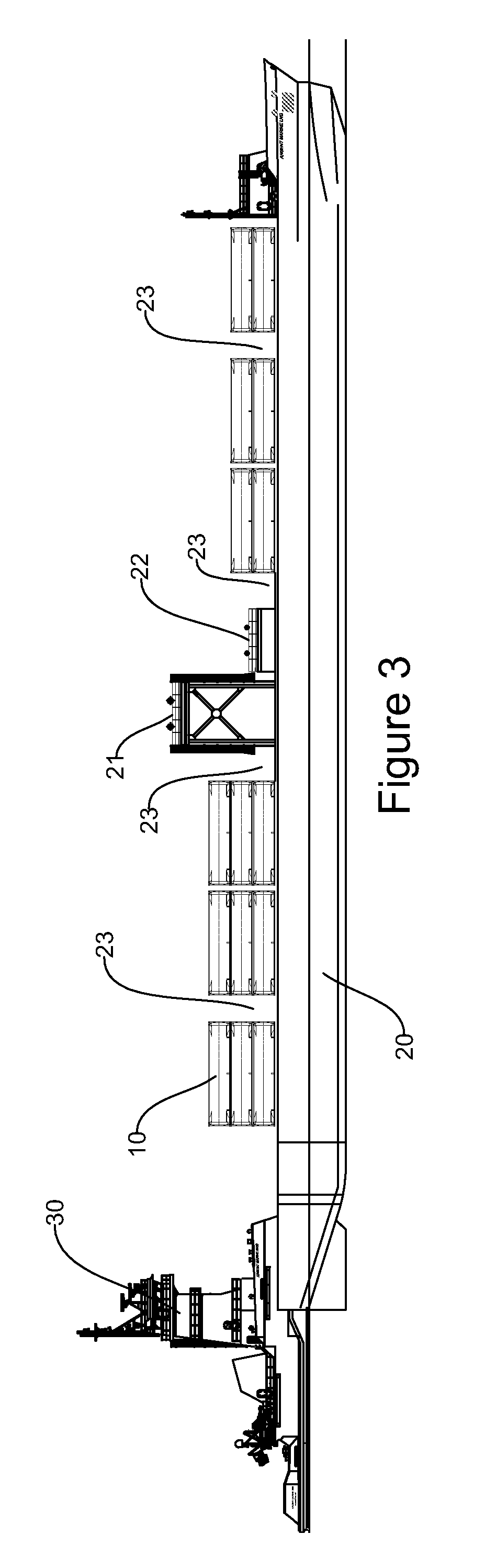

System and method for containerized transport of liquids by marine vessel

ActiveUS20120137955A1Efficient loadingSafely berthingLarge containersGaseous engine fuelsLiquid tankInterconnection

A marine vessel, and a system and method of using the marine vessel, to facilitate the introduction of bulk liquid commodities, such as LNG, into the established and extensive worldwide intermodal transportation system, which is based on containerized shipments. The marine vessel is a specialized vessel, of either ship or barge form, that is capable of holding a large number of ISO-sized intermodal LNG tanks and is configured so as to have at one and the same time characteristics of both a tanker vessel (e.g., a gas carrier) and a container vessel. The intermodal LNG tanks connect to a piping system of the marine vessel and are thereby interconnected in such a manner that allows the interconnected intermodal LNG tanks to behave as if they constitute a typical LNG vessel bulk liquid tank to facilitate efficient loading at a typical marine LNG terminal The containerized intermodal LNG tanks are capable of discharging liquids to a marine terminal as if in a bulk mode, or of being disconnected from the common interconnection system to allow lift-off discharge of the intermodal LNG tanks at a typical cargo container port so that the intermodal LNG tanks can enter the existing intermodal transportation system for further distribution to the end user by other marine vessels, over-the-road truck, or by rail.

Owner:ARGENT MARINE MANAGEMENT

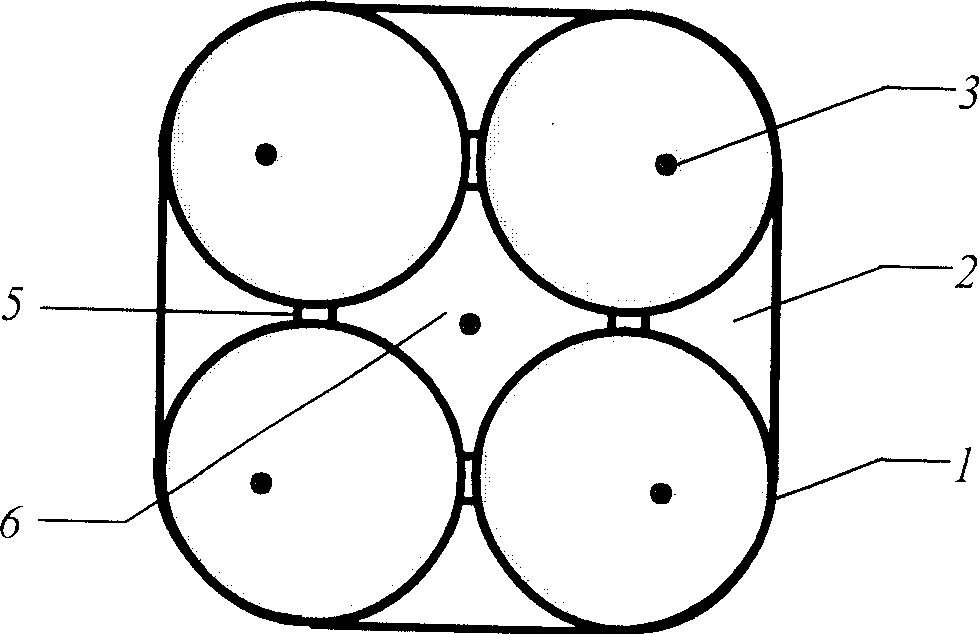

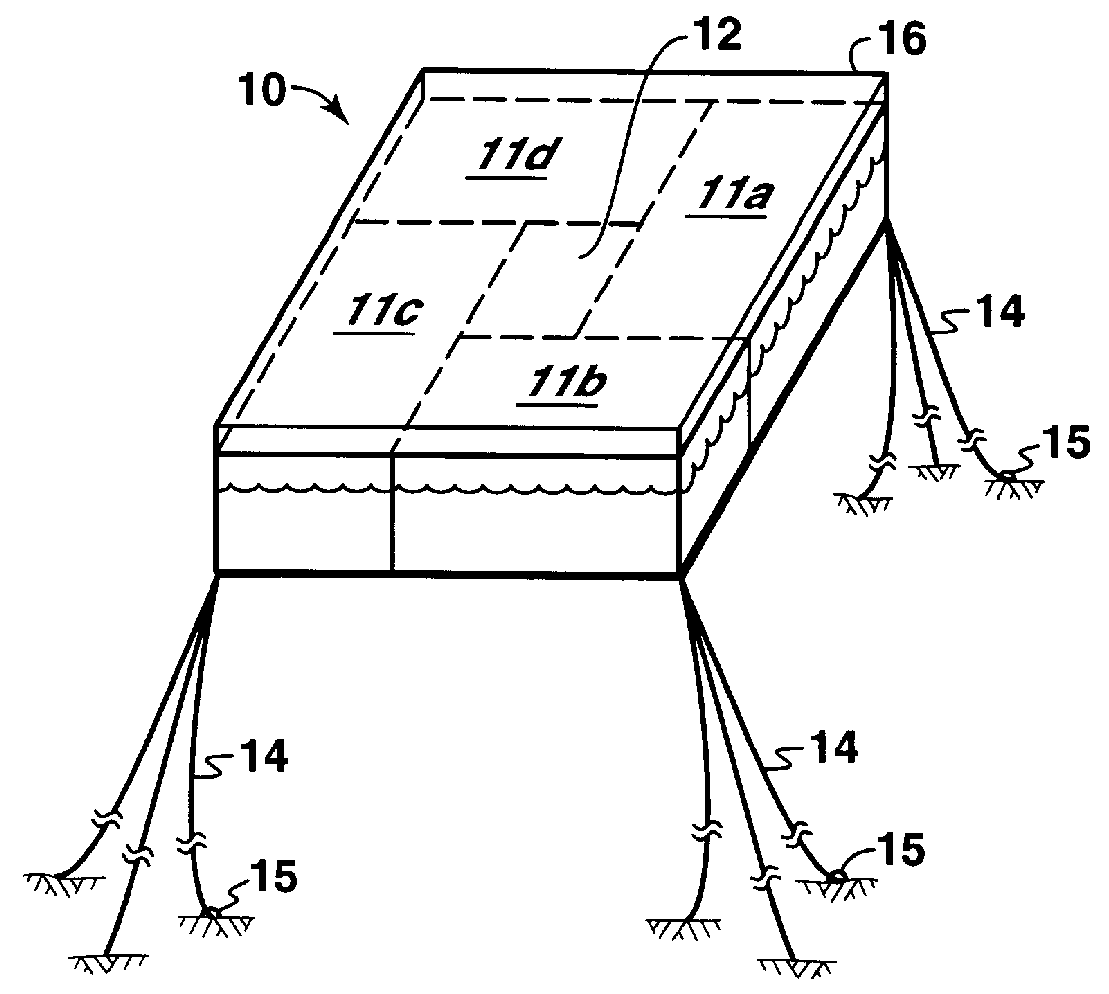

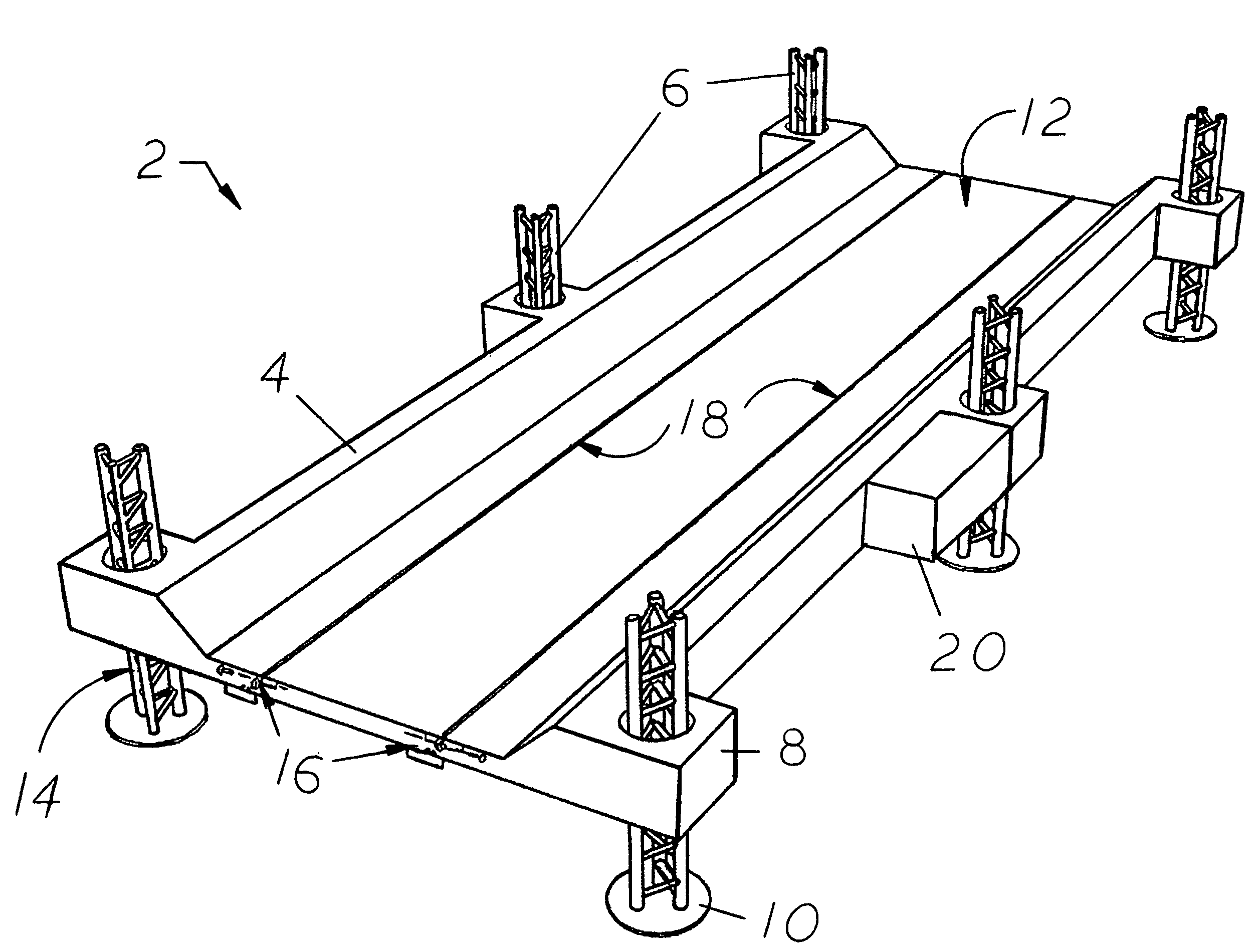

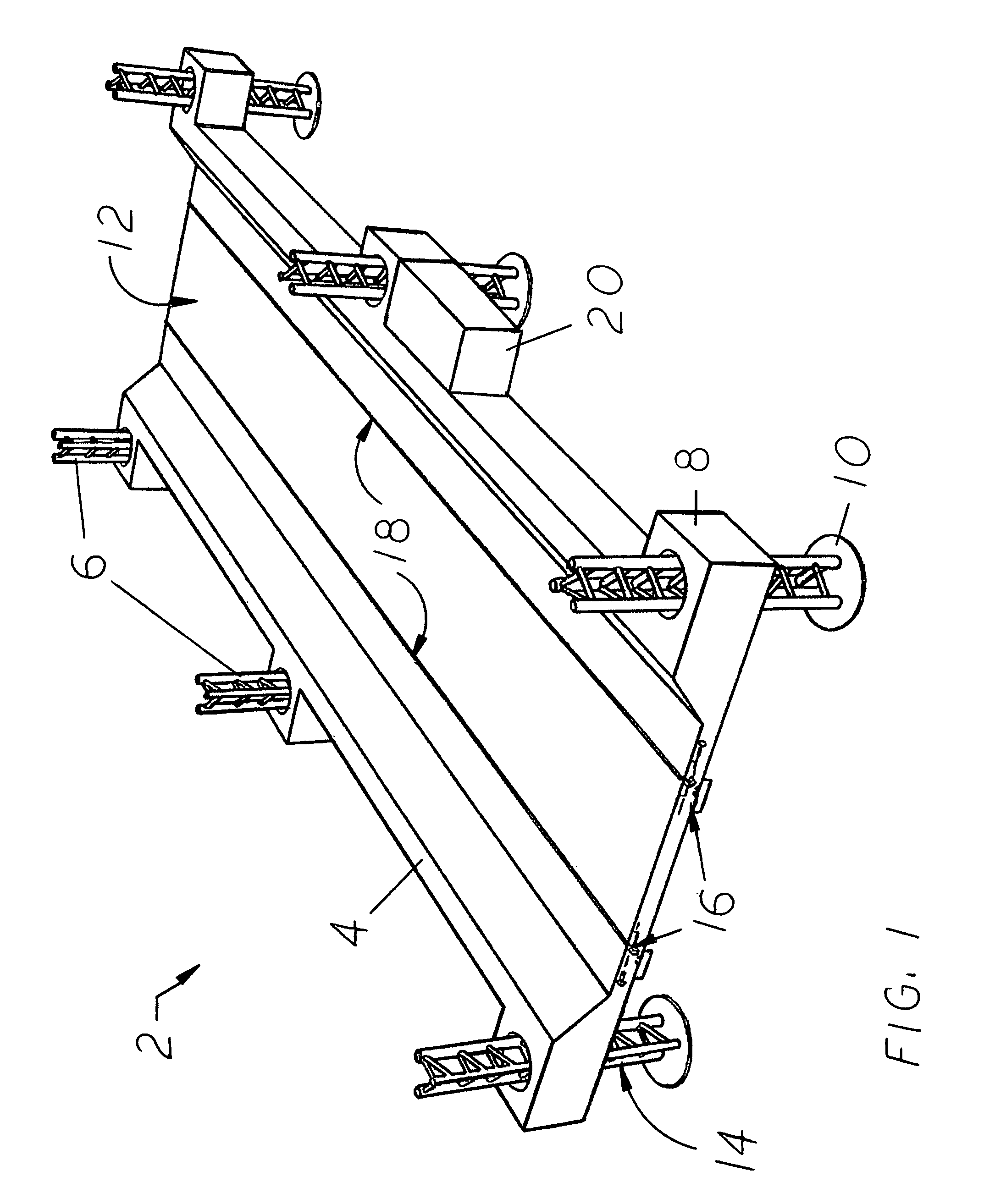

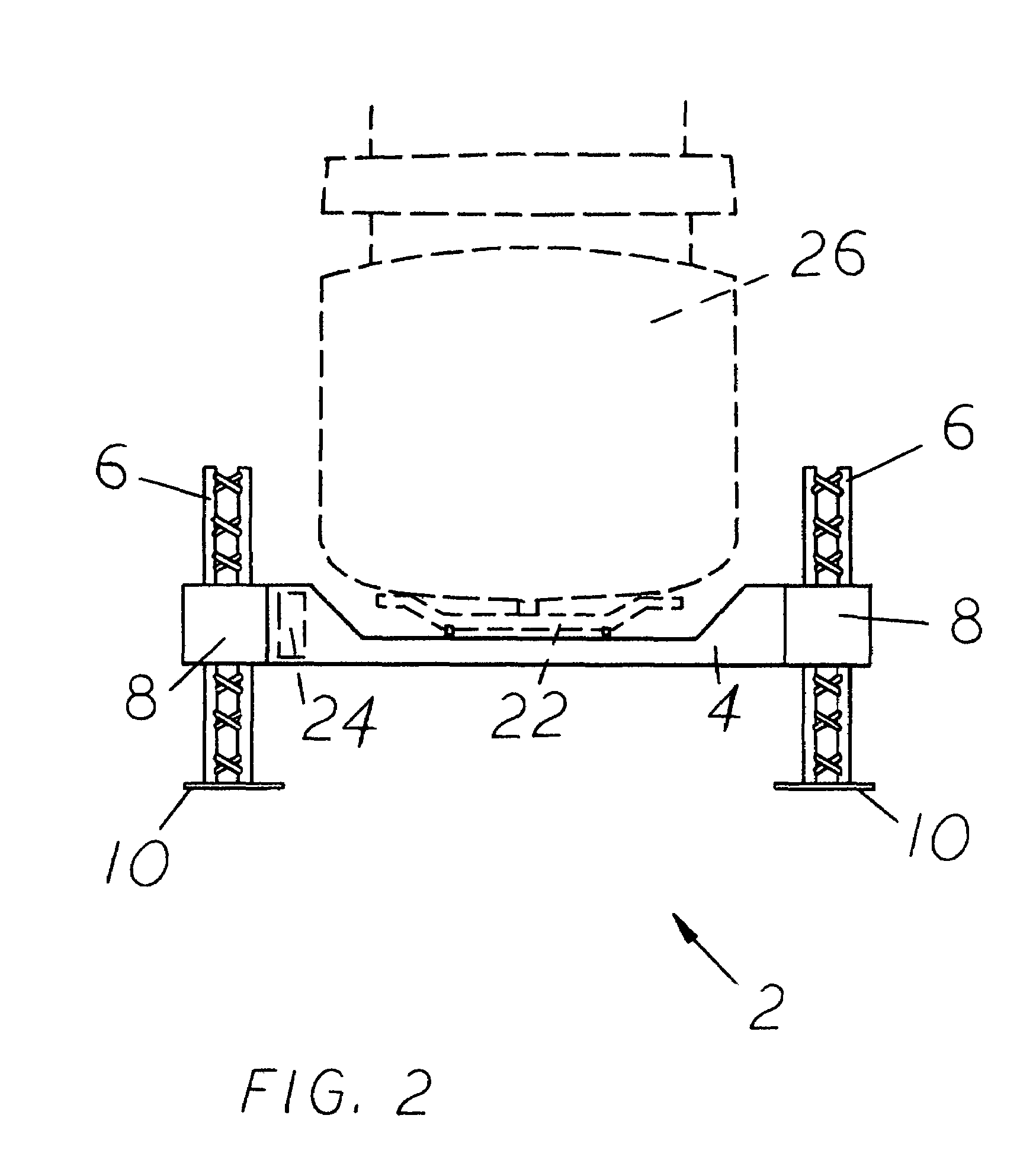

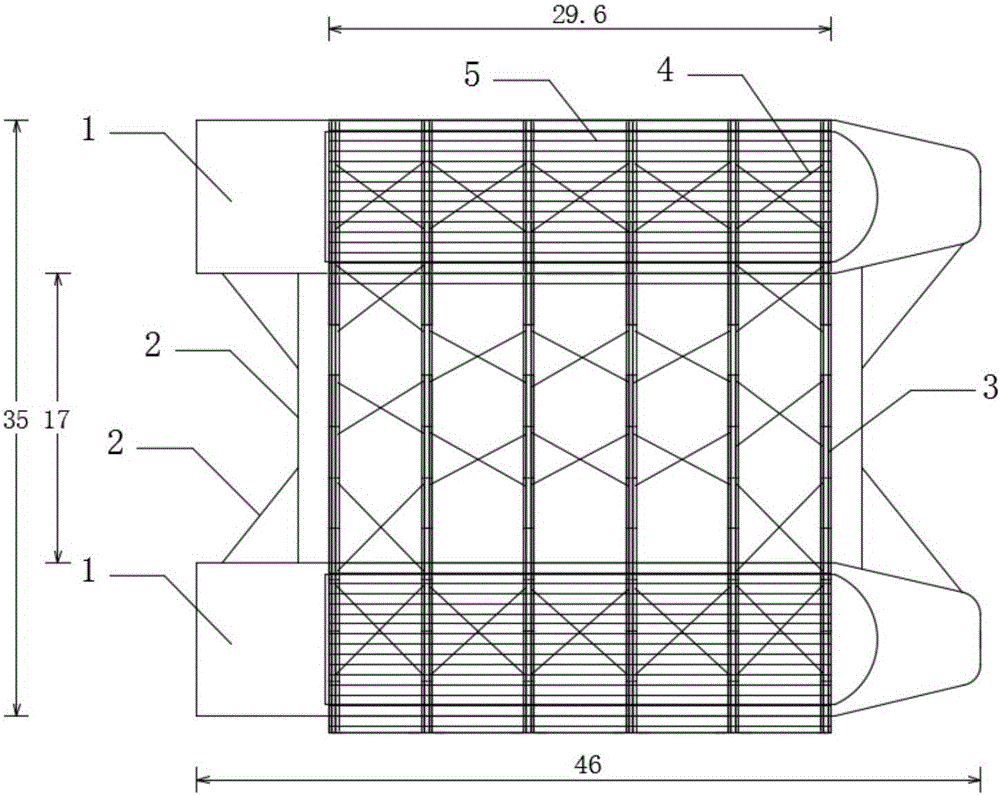

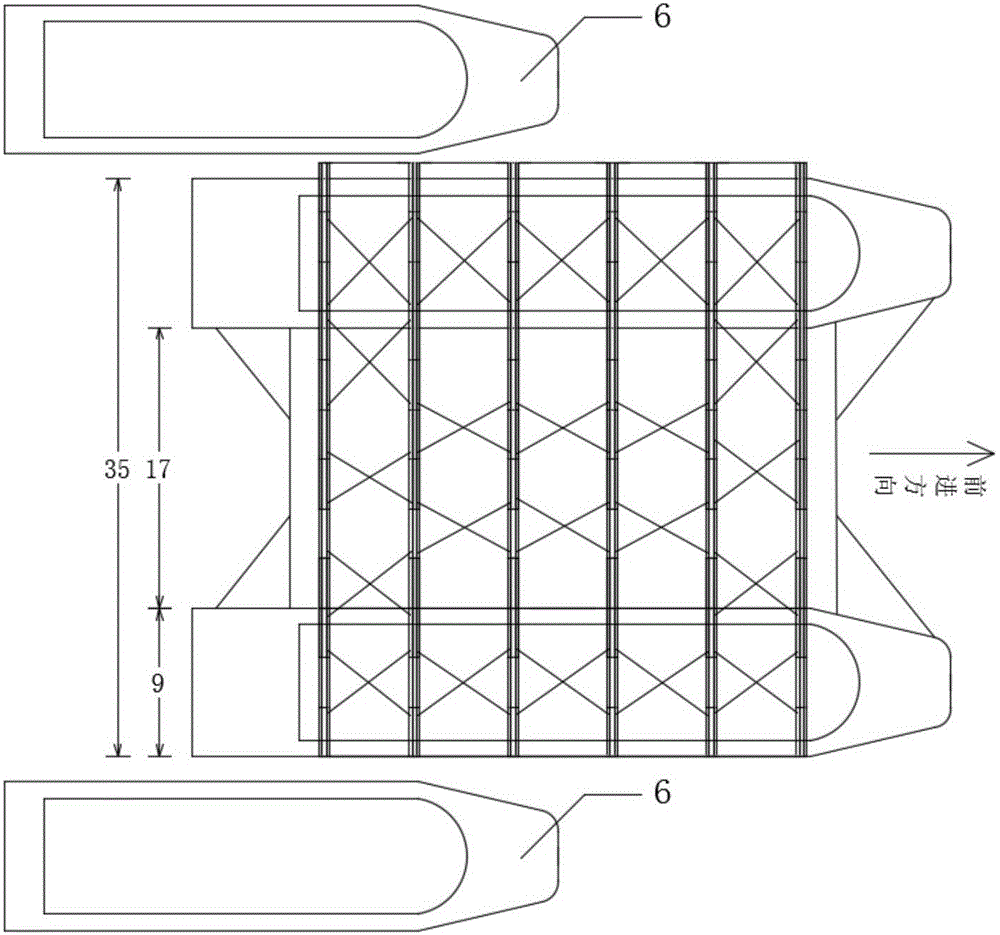

Floating barge-platform and method of assembly

InactiveUS6125780AIncreases the draft of the platformReduce areaVessel partsHulls from prefabricated subunitsBuoyancyBARGE

A stable floating barge-platform for offshore operations and a method for assembling same. The barge-platform is assembled from a plurality of substantially identical, buoyant modules, all of which have substantially the same outer configuration. The buoyant modules are constructed onshore and transported to an offshore location where they are positioned and connected together to form the platform. When connected, an opening will be present through the center of the platform. This opening reduces the bottom area of the platform and accordingly substantially reduces the wave forces on the platform.

Owner:MOBIL OIL CORP

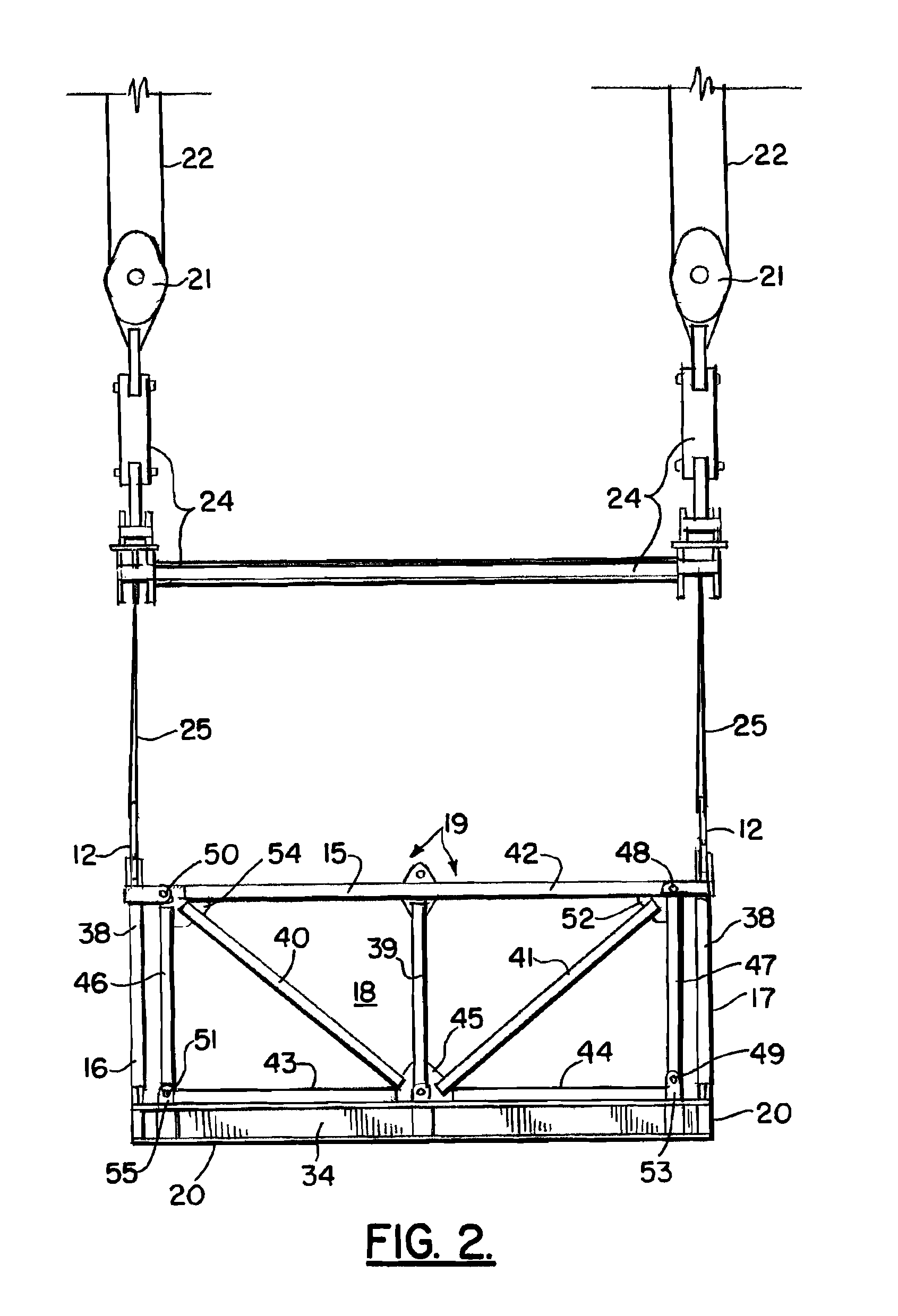

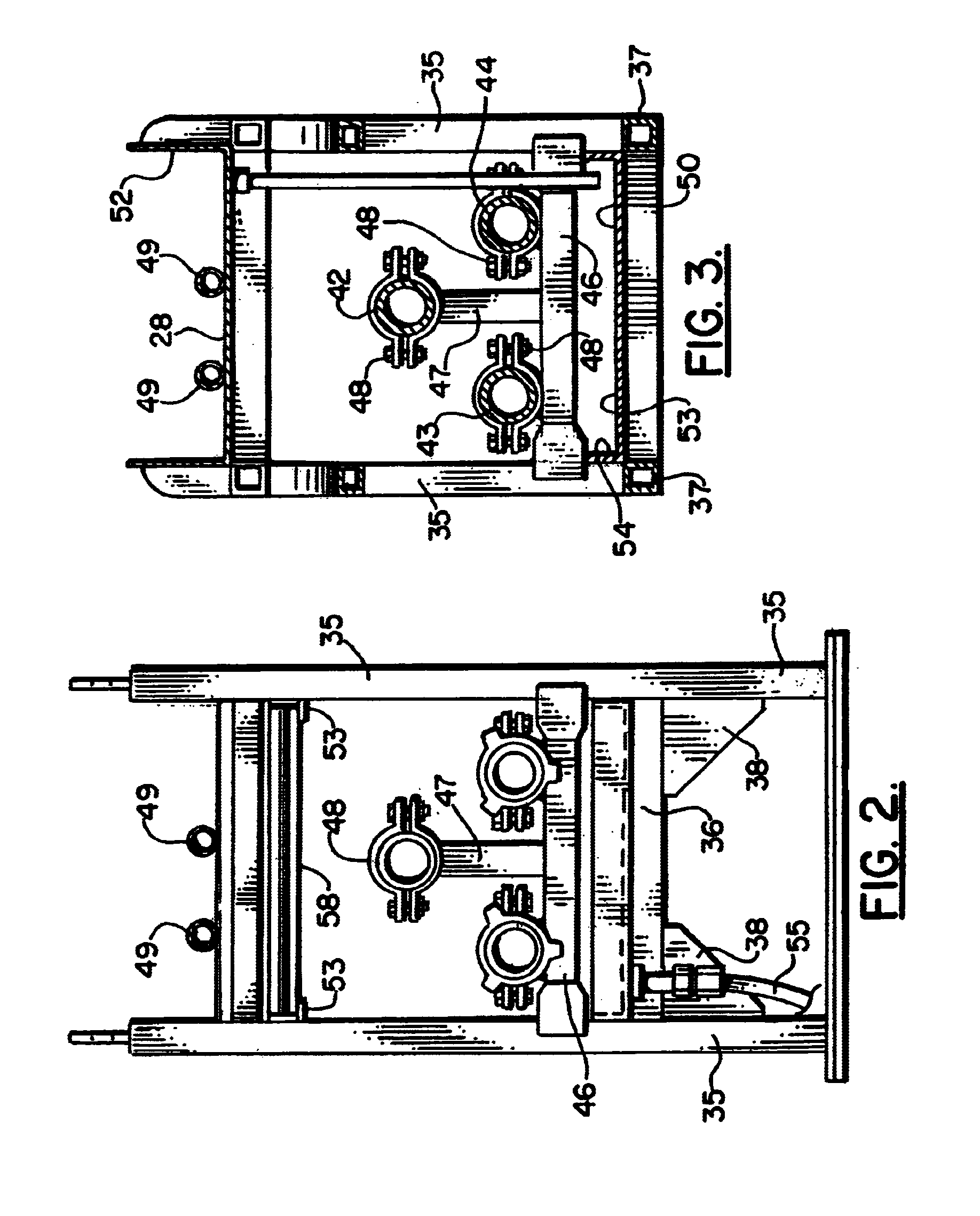

Semi-submersible dry-docking lift apparatus

A portable marine lift capable of multi-directional off-loading of yachts, ships, and other marine vessels at ground level to dry-dock them. It is compact and barge-like, and can be shared by independent shipyards, or used to expand the work area within a single port facility or shipyard. It is also self-contained when fitted with generators and / or propulsion means via add-on pods, and comprises independent platform sections joined together to meet any hull design, length and water depth. Platform sections have the ability to submerge, and may also be employed to capture and temporarily contain environmentally hazardous materials commonly produced by shipyards. In addition, the platform sections are preferably open-framed for weight savings. Computerized lifting, via multiple lift modules secured to platform sections, assures lifting of vessels in substantially level orientation. Optionally, platform sections can be configured for shallow water operation, with locking devices, and / or guides usable for off-loading railway alignment.

Owner:TAFOYA CRAIG ALLEN

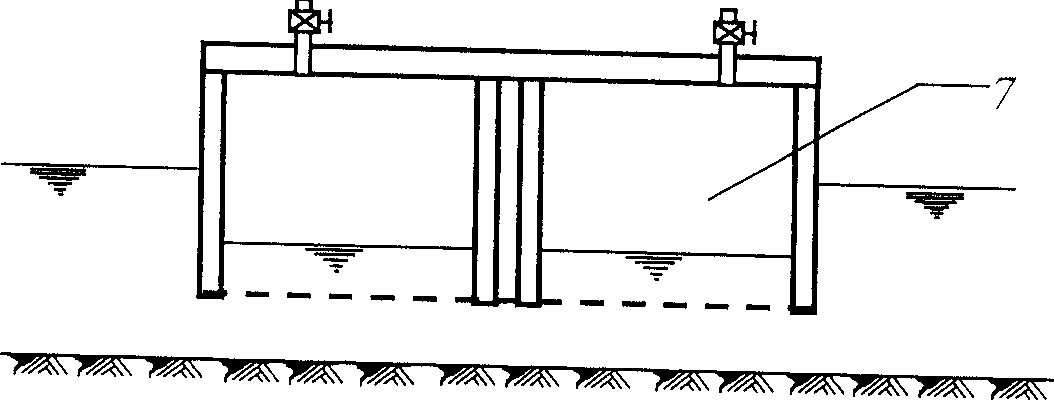

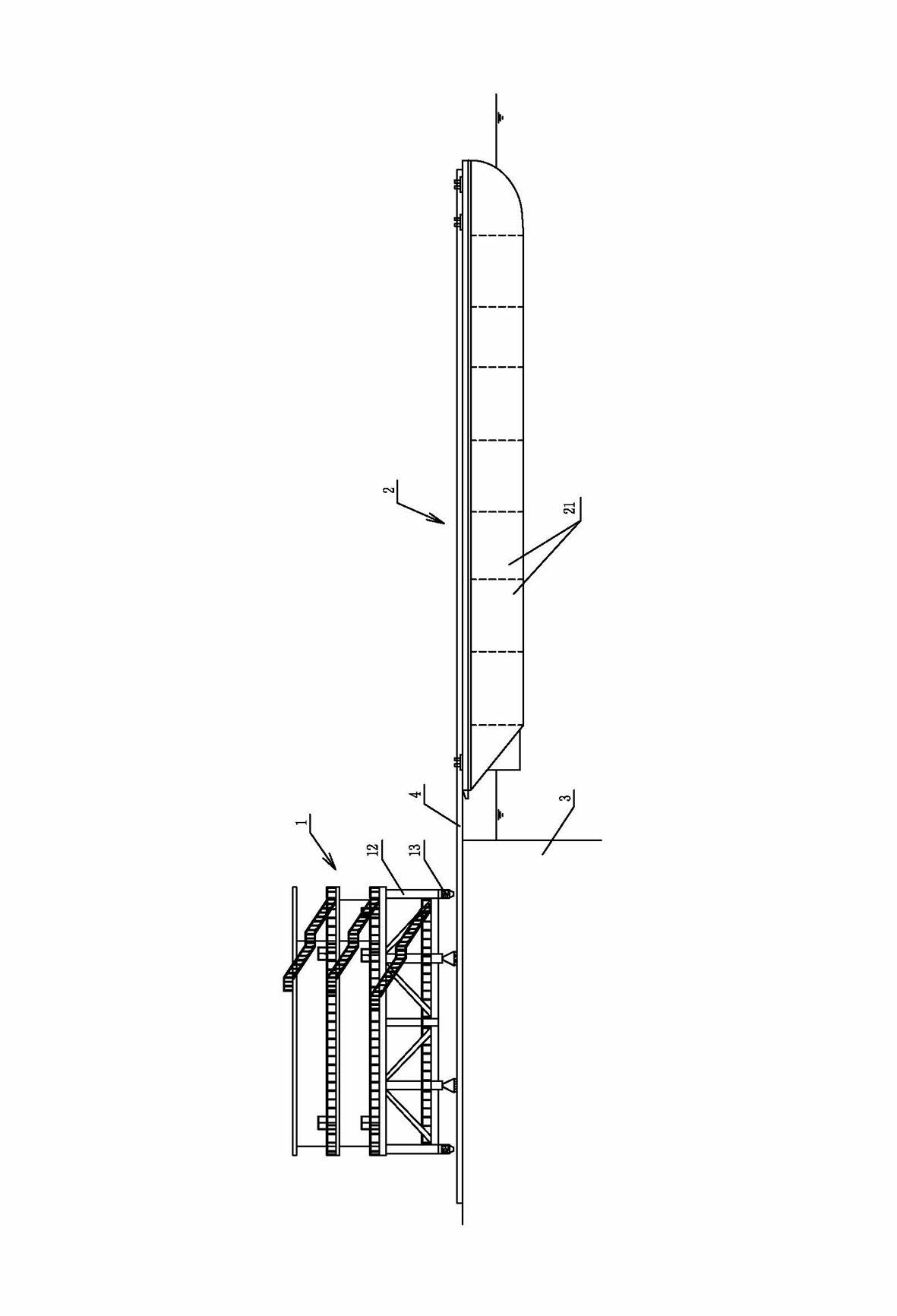

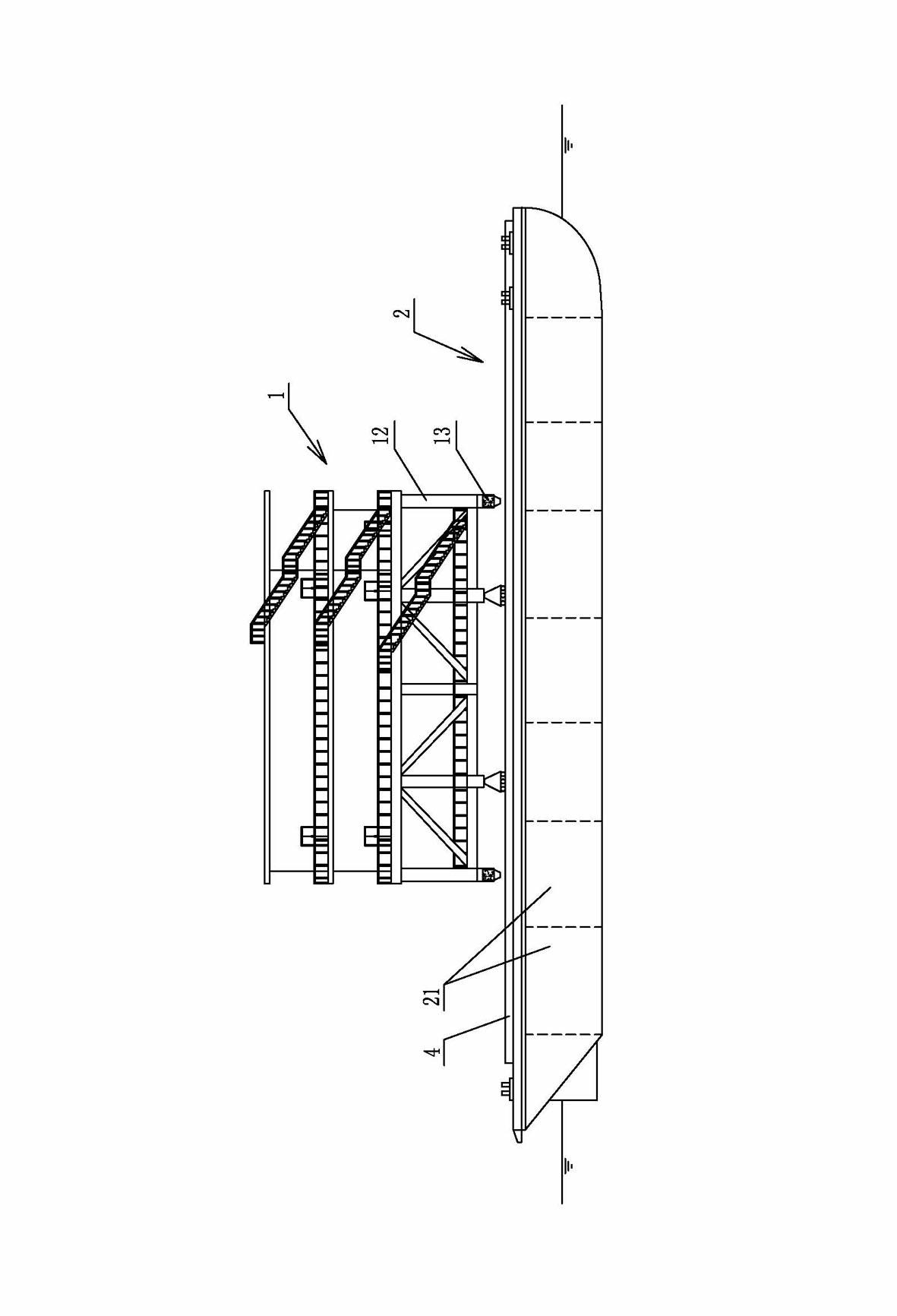

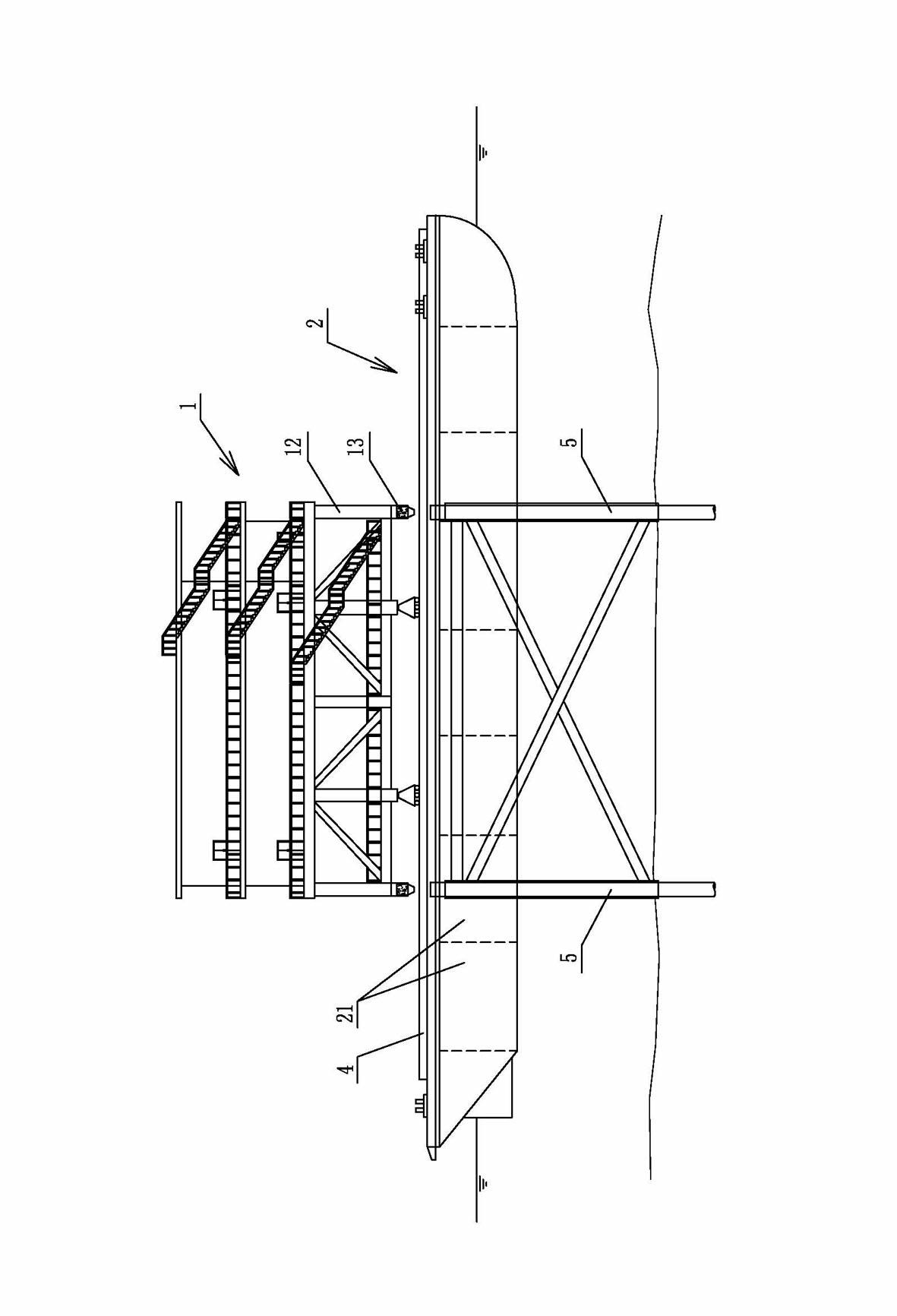

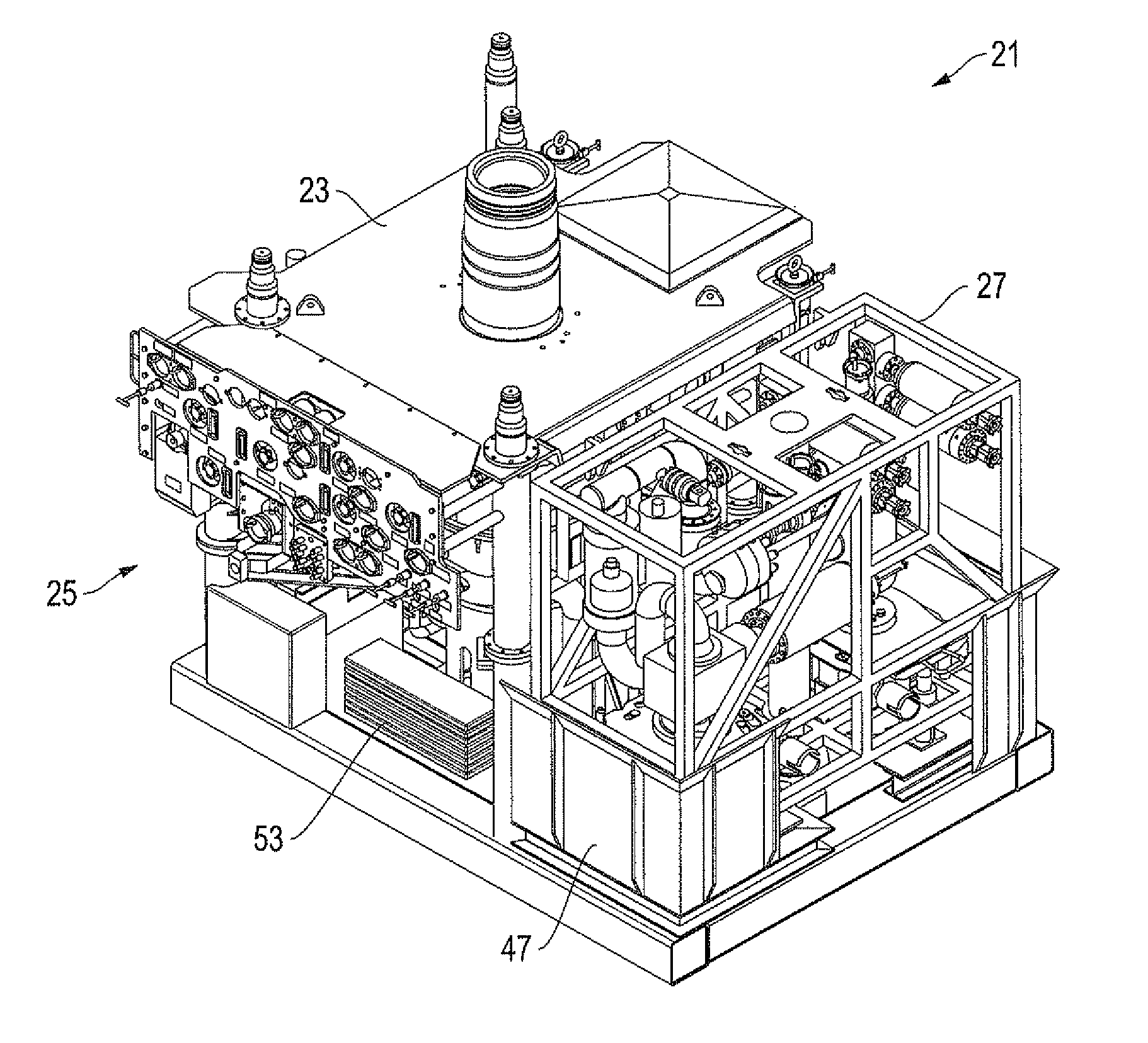

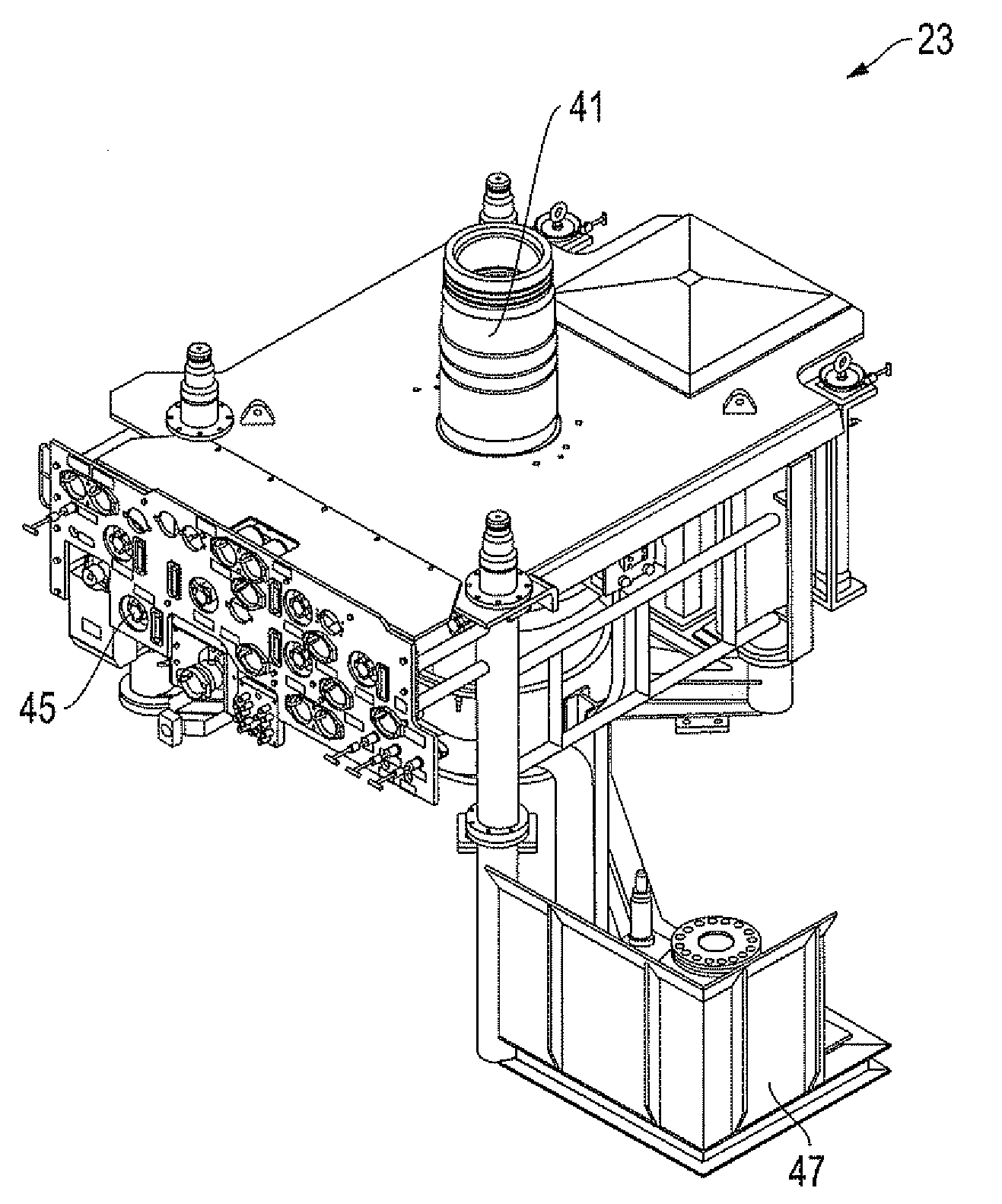

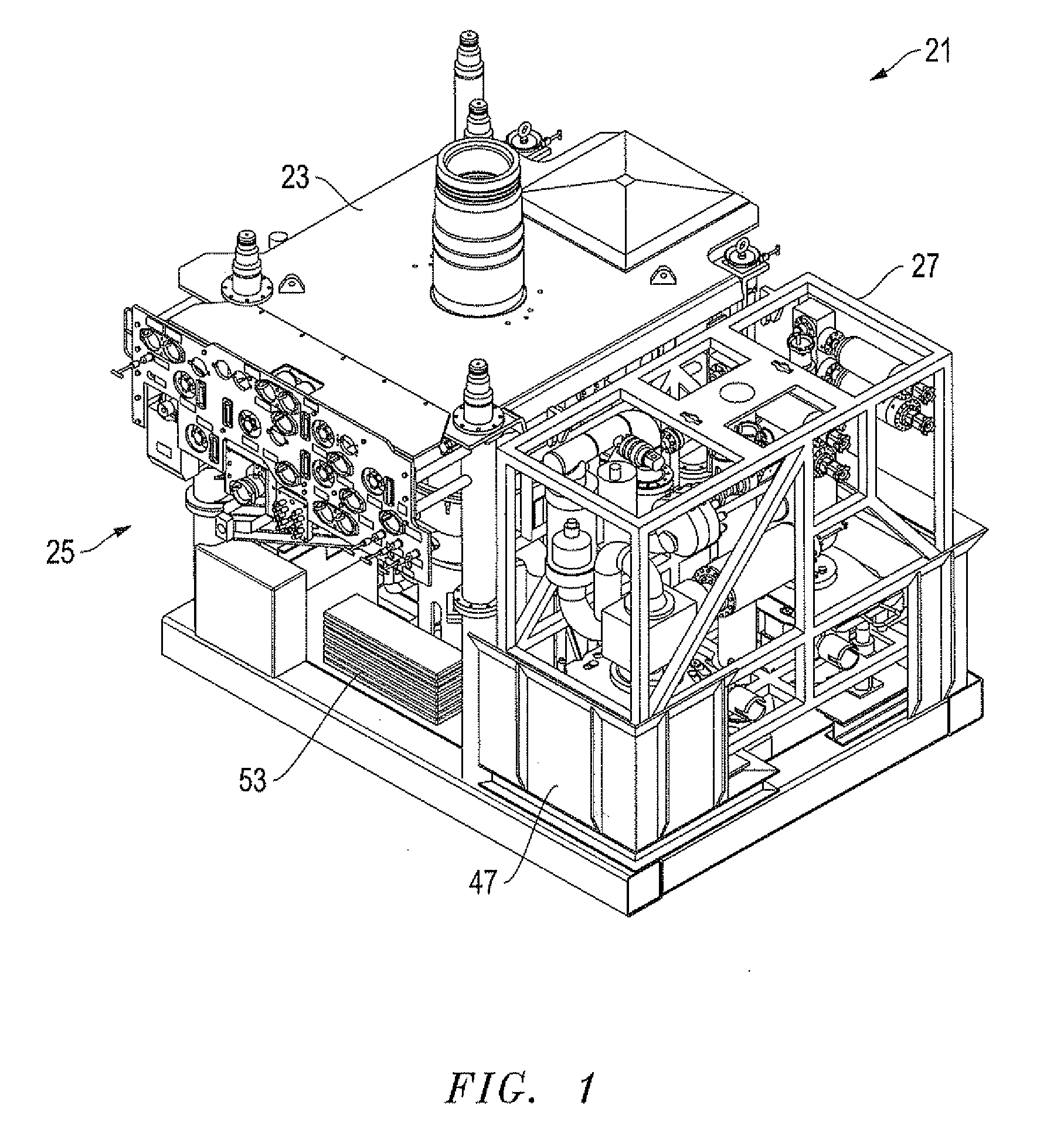

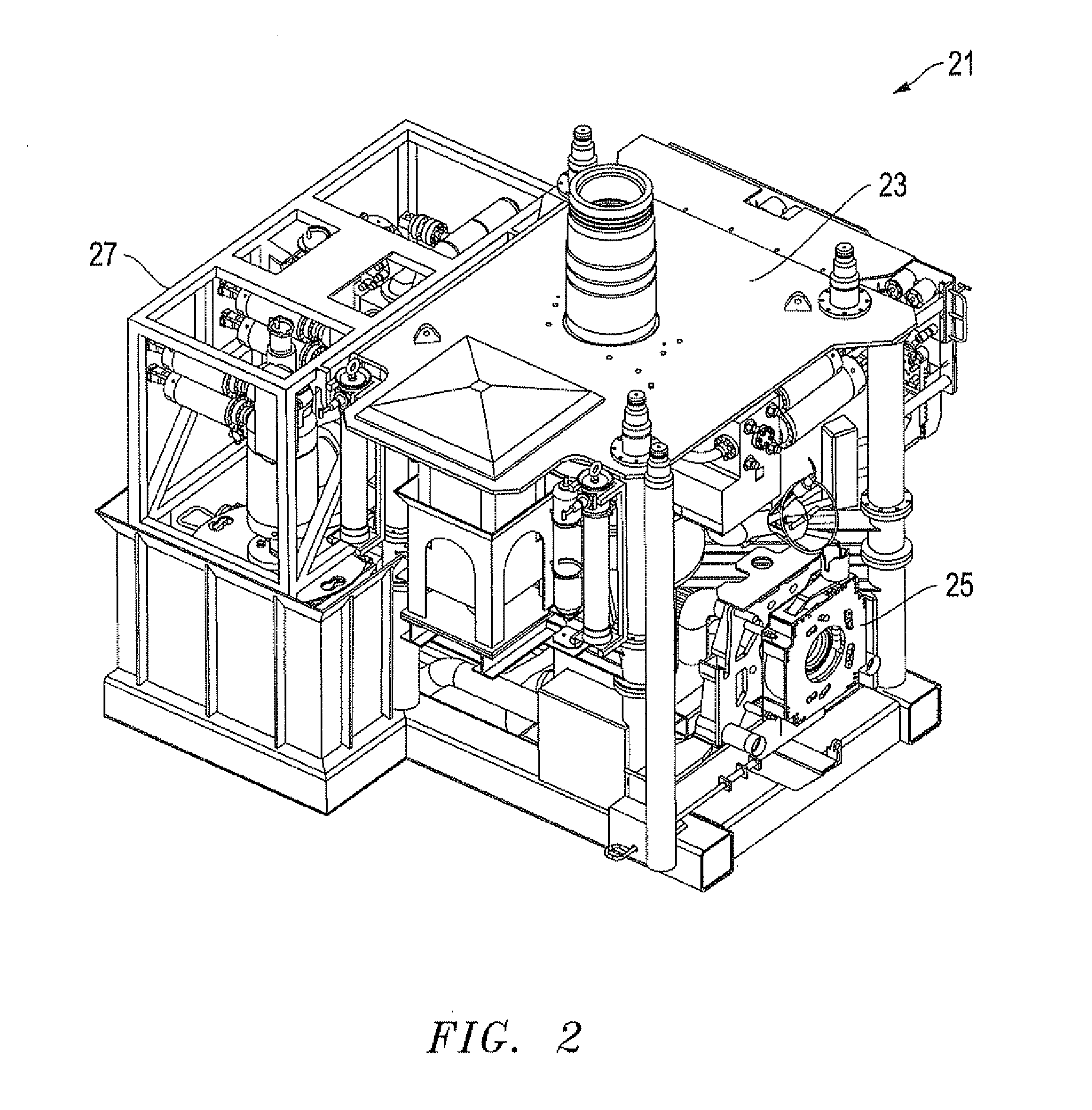

Buoyancy type mounting method for offshore boosting station

ActiveCN102587342ALower requirementFlexible scheduleArtificial islandsUnderwater structuresOffshore wind powerLightering

The invention relates to a buoyancy type mounting method for an offshore boosting station, which aims to be safe and high-efficiency, save expense and have low requirements on ship machines and equipment. The technical scheme includes that the buoyancy type mounting method for the offshore boosting station is characterized by comprising steps of a, building the offshore boosting station on the land; b, sliding the offshore boosting station on a barge, conveying the offshore boosting station to a specified mounting position, judging whether the bottom of a support of the offshore boosting station is higher than the top end of a foundation or not, executing a step d if the bottom of the support of the offshore boosting station is higher than the top end of the foundation, and executing a step c if the bottom of the support of the offshore boosting station is not higher than the top end of the foundation; c, controlling the barge to ascend; d, leading the barge to move into a gap of the middle of the foundation and positioning the barge; e, controlling the barge to descend, placing the support of the offshore boosting station on the foundation, simultaneously, leading the barge to continue descending until the barge is separated from the offshore boosting station, and then dragging the barge out from the bottom of the offshore boosting station; and f, welding the support with the foundation. The buoyancy type mounting method is applicable to the field of offshore wind power generation.

Owner:中电建新能源集团股份有限公司

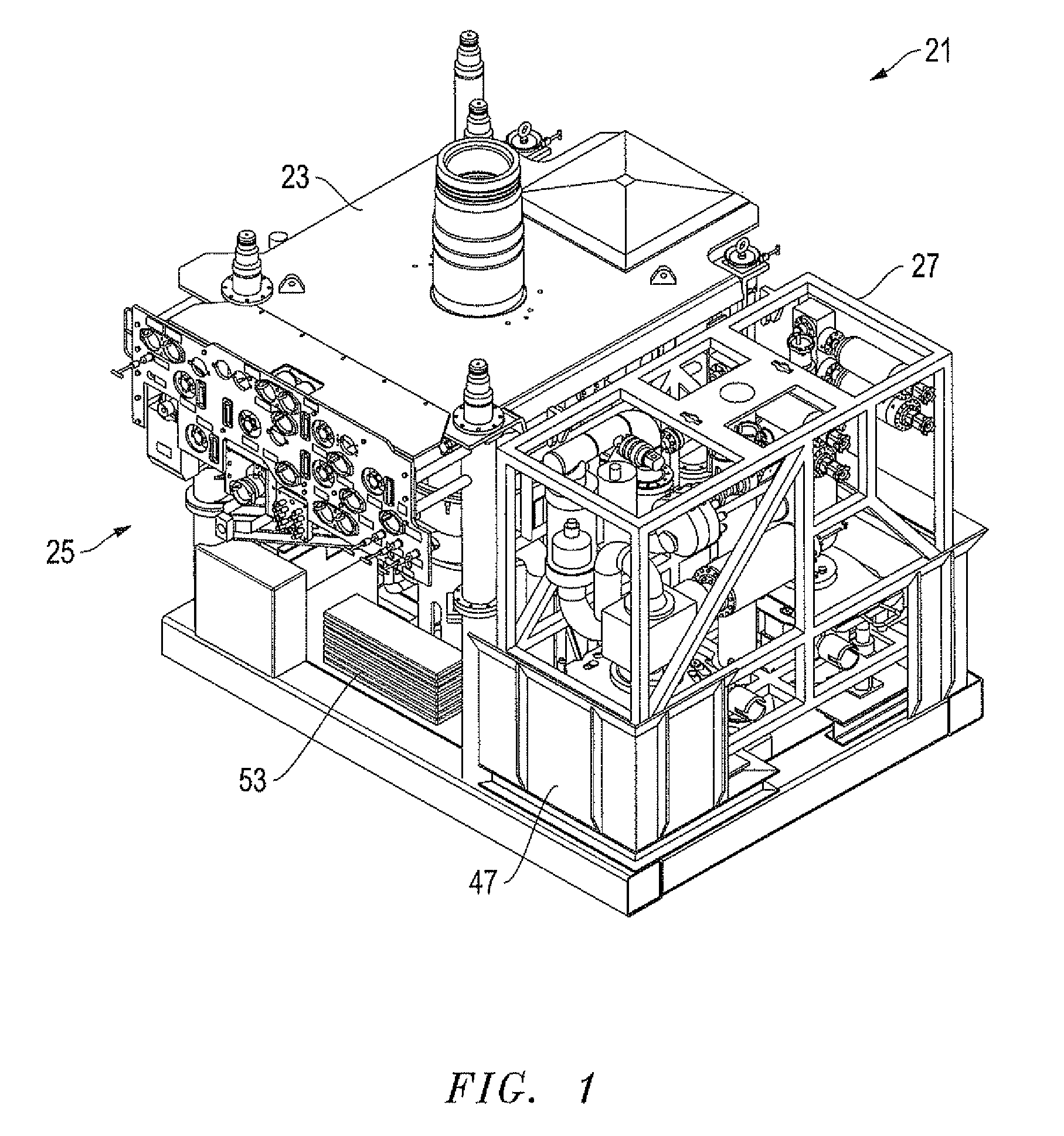

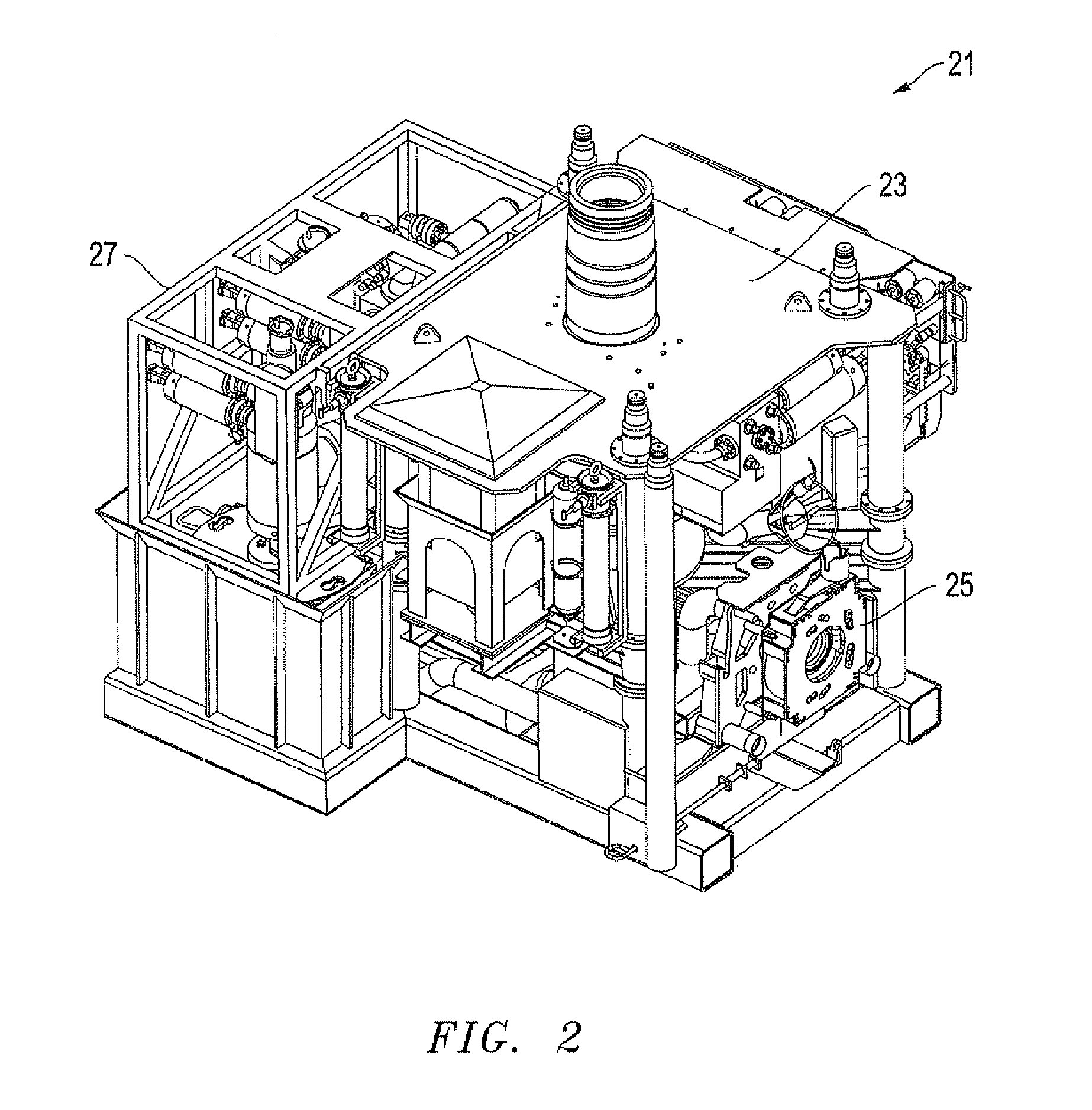

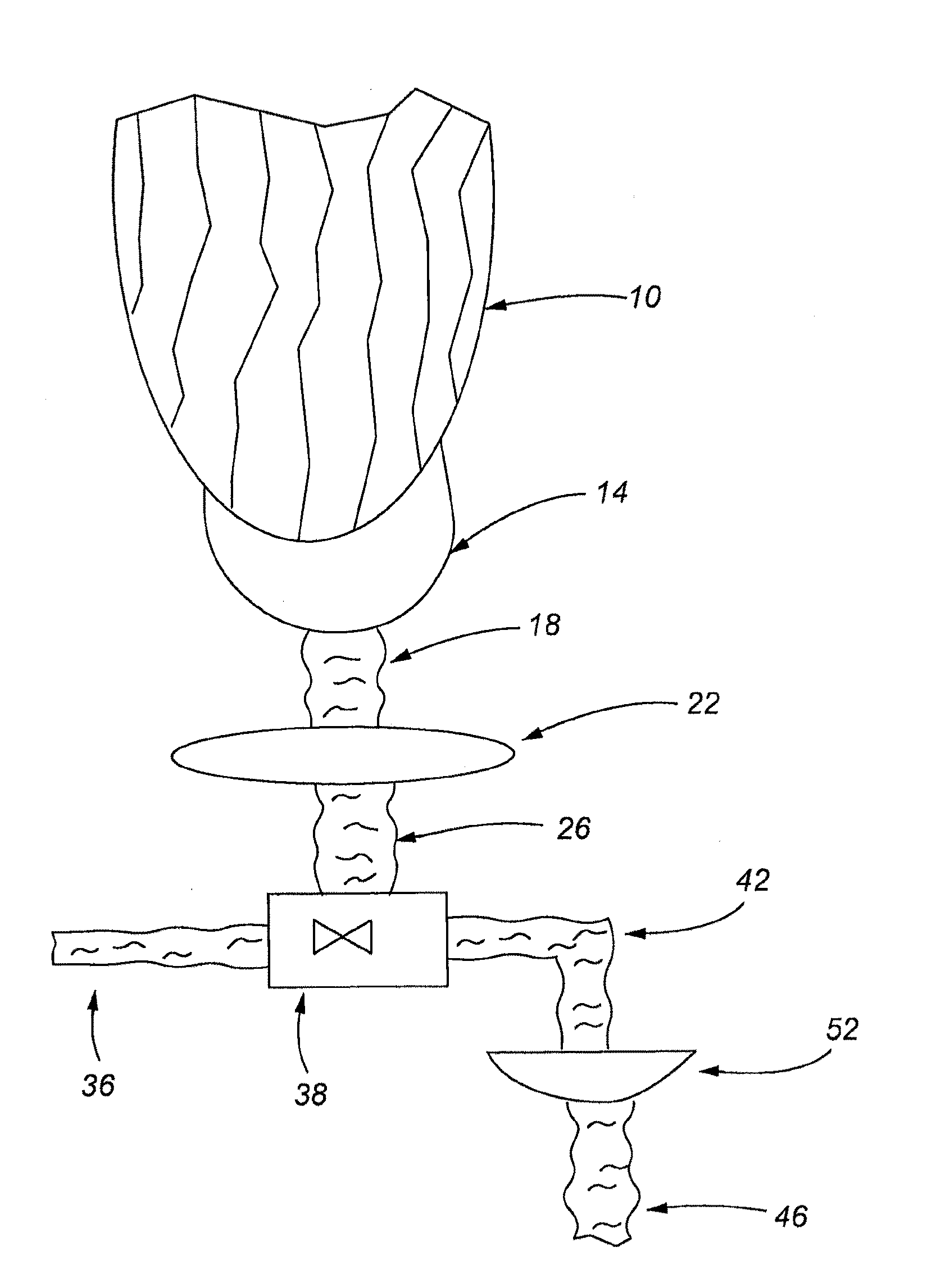

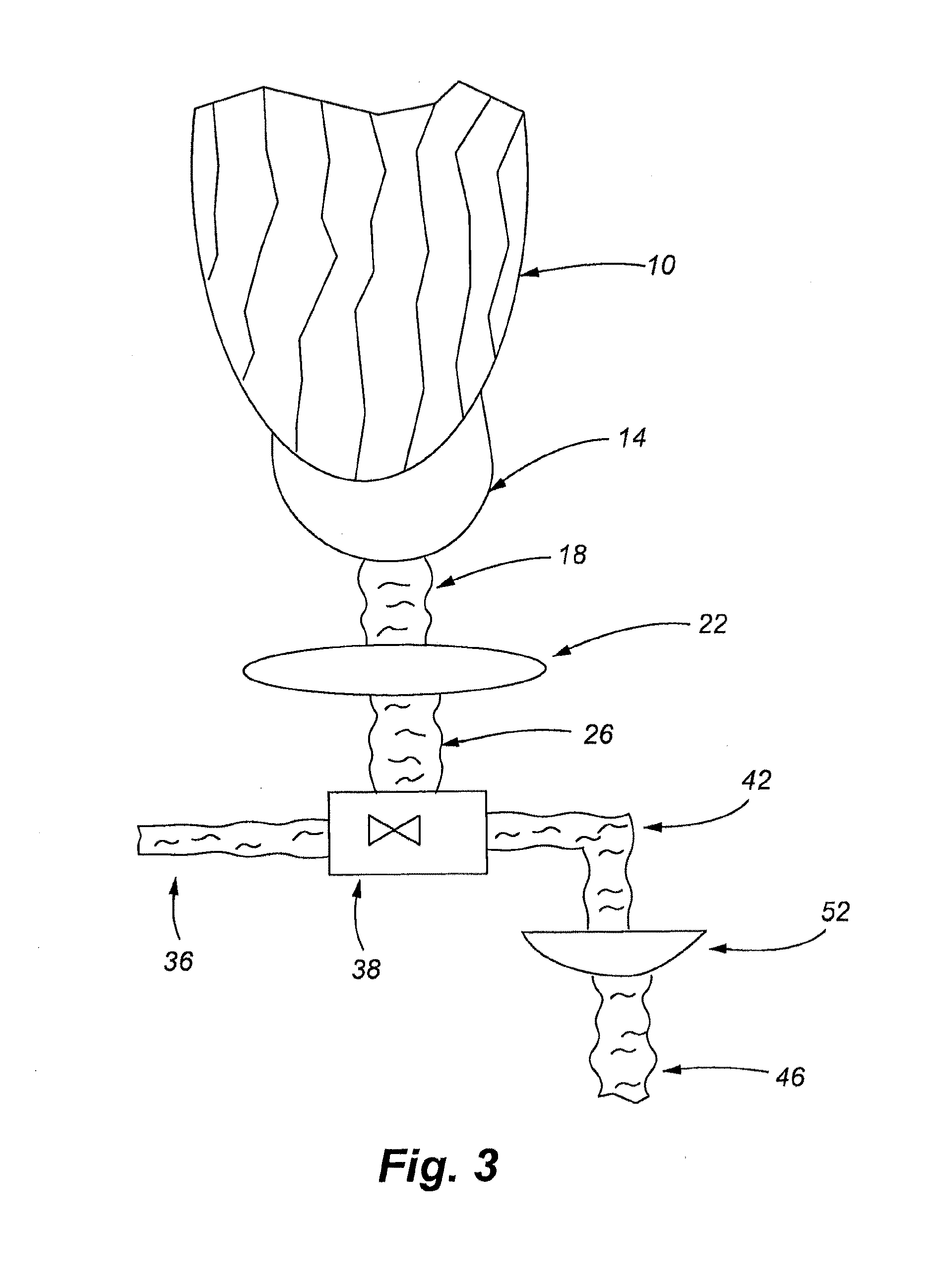

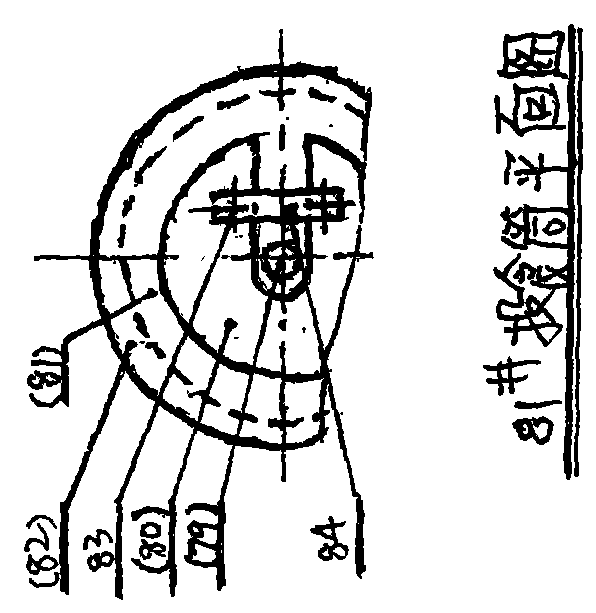

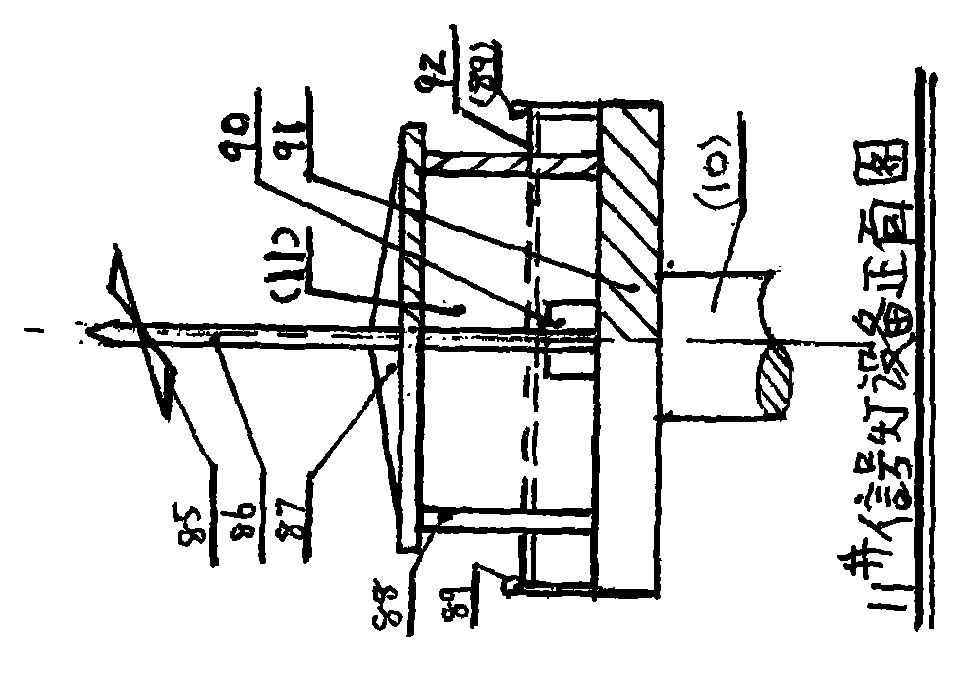

System, method and apparatus for a modular production tree assembly to reduce weight during transfer of tree to rig

A modular tree production tree assembly reduces the weight during transfer of the tree components from a barge to a production rig. The tree assembly includes an upper tree module, a lower tree module, and a choke bridge module. The upper tree module has a tree head, the lower tree module has a guidance system and ties in the flow lines to the in-field infrastructure, and the choke bridge module has the choke and instrumentation bridge to link the three components together. Prior to delivery to the rig, the components of the modular tree assembly may be joined together and tested on shore. Upon arrival at the rig, the components are individually lifted from the barge onto the rig by a crane. After the tree components are on the rig, the modular tree is reassembled and then deployed to the sea floor via the draw works.

Owner:VETCO GRAY

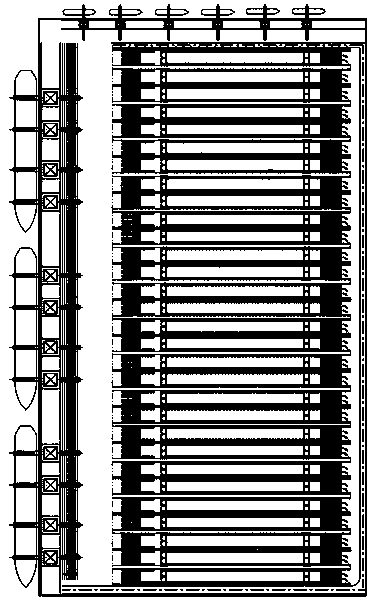

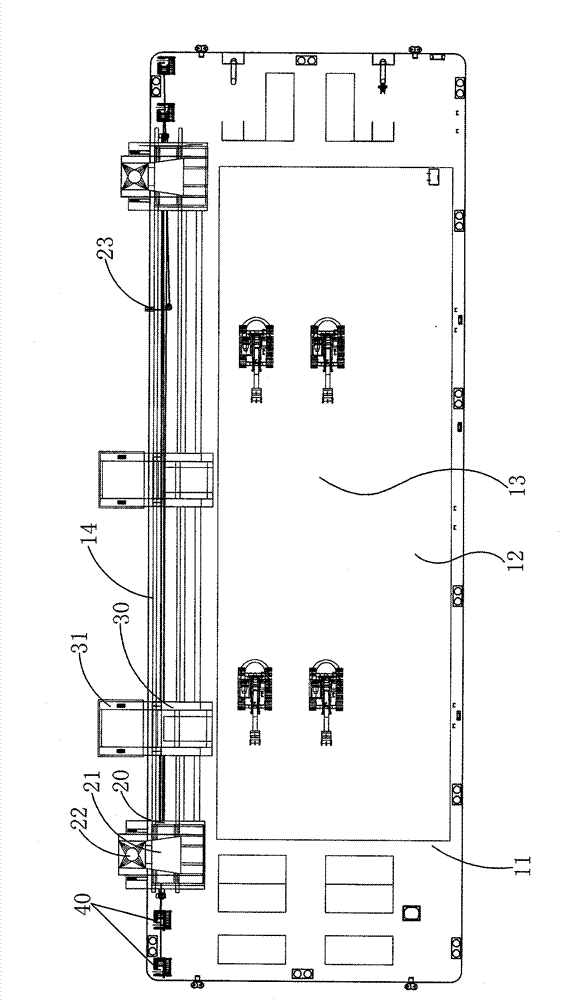

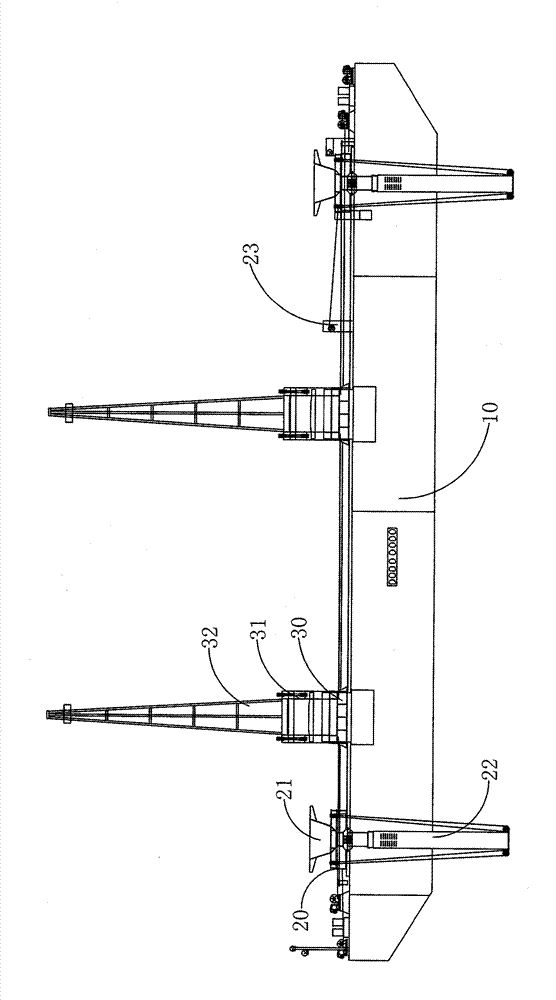

Installation equipment of above-water wind generator and construction method thereof

InactiveCN101565091ASimple structureEasy to buildWind motor assemblyWind motor supports/mountsTowerWind force

The invention provides an installation equipment of an above-water wind generator and a construction method thereof, belonging to the technical field of above-water wind power generation, comprising a hoisting ship, a transportation barge, a hoisting machine, a hoisting ring, a telescopic floating cylinder, an inflation device, a supporting leg and a lifting device, wherein four supporting legs are fixedly arranged below the hoisting ship; the circumference of the hoisting ship is fixedly provided with a plurality of telescopic floating cylinders; the hoisting machine is fixedly arranged vertically right at the center of the upper deck of the hoisting ship; 2-10 hoisting rings are symmetrically and fixedly arranged at two sides of the hoisting machines on the upper deck of the hoisting ship respectively; the hoisting rings are connected with the back rods of the hoisting machine by wire ropes; and the circumference of the transportation barge is provided with the telescopic floating cylinders and the inflation device. The installation equipment can carry out the installation operation of the marine wind power generation towel pile foundations and fans within 0.3-5m of water depth, greatly improve the installation efficiency of the marine wind power generation towers and reduce the construction cost of the marine wind power generation fields.

Owner:LICE SCI & TECH SHANGHAI

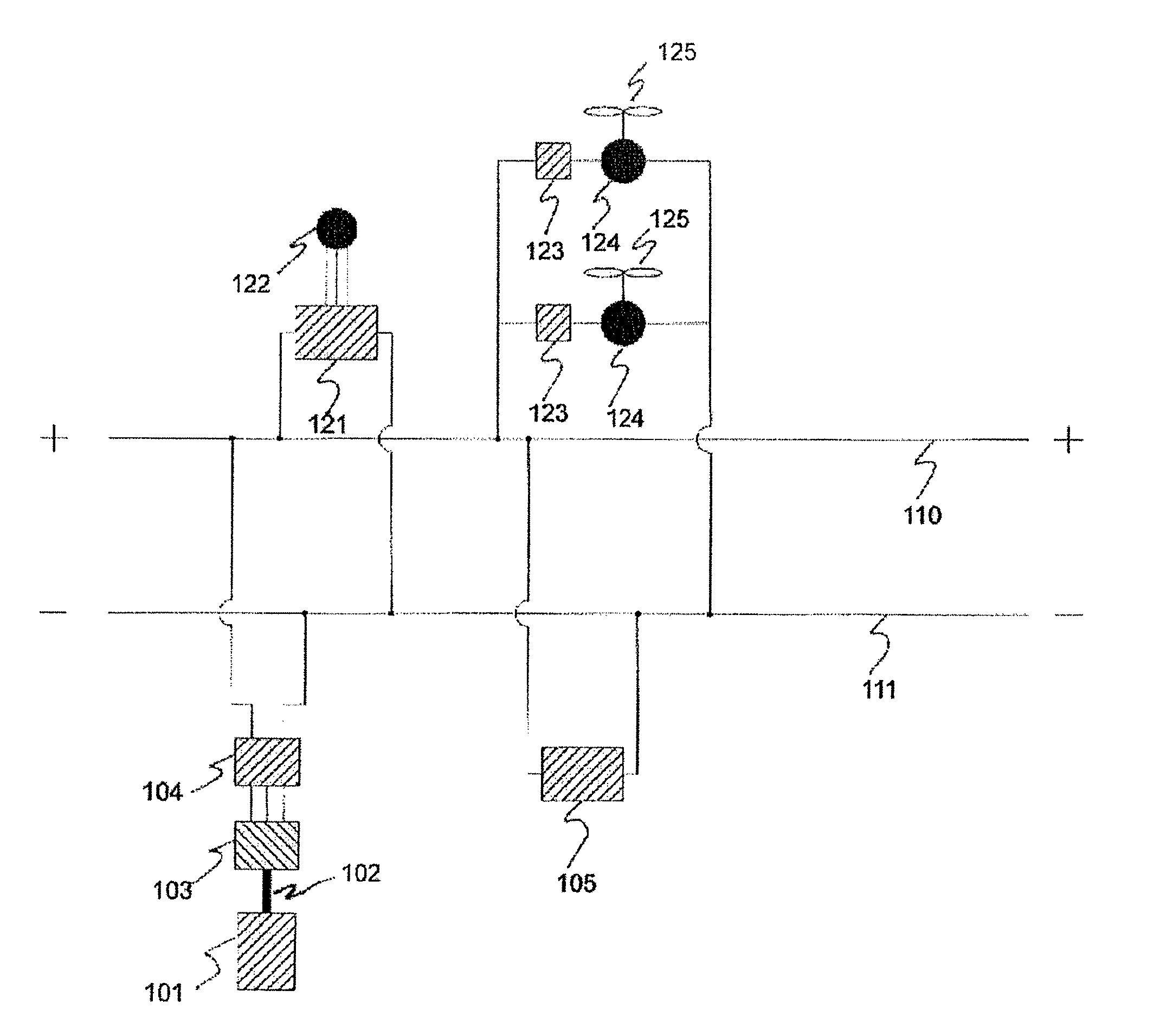

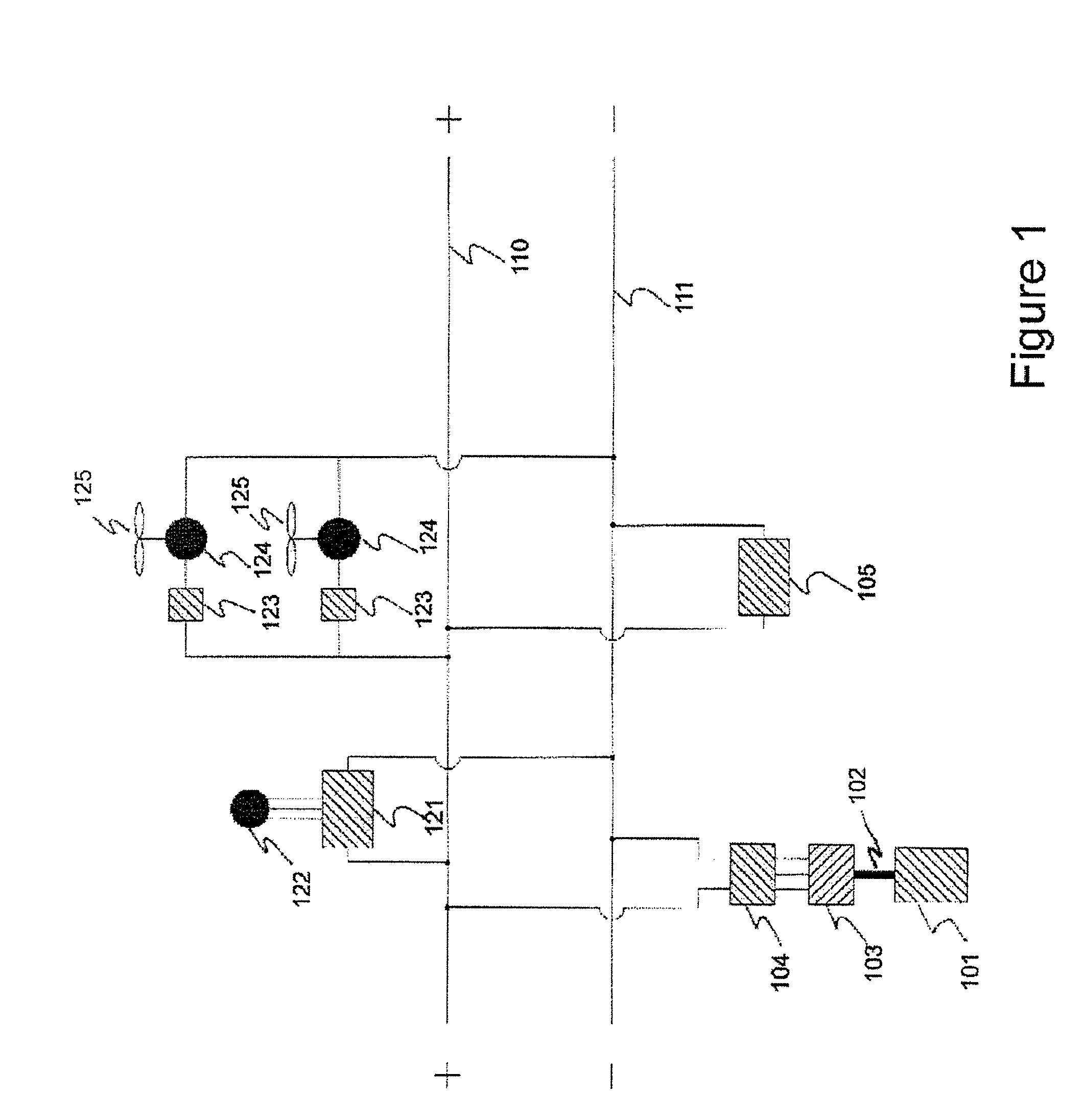

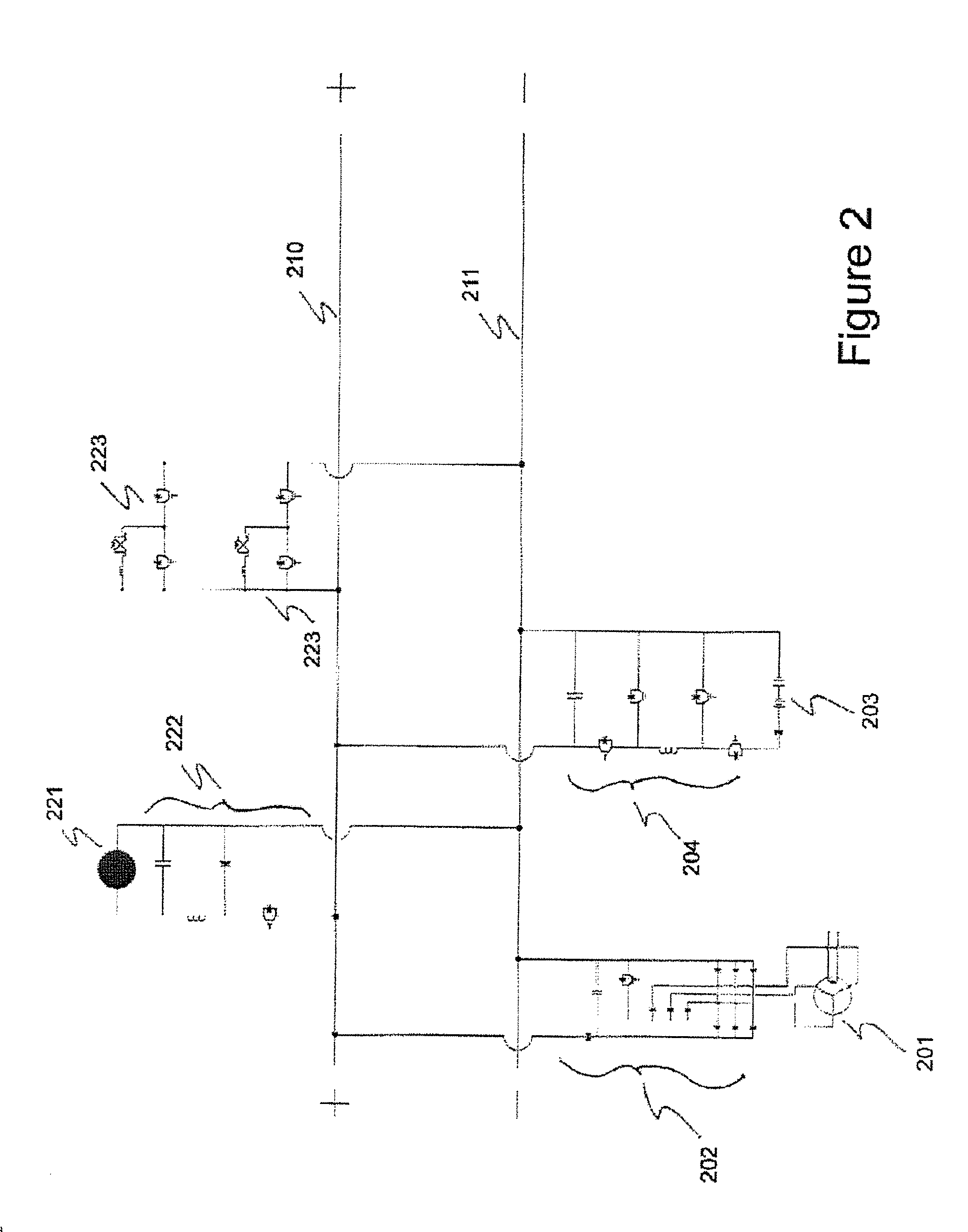

Marine power train system and method of storing energy in a marine vehicle

ActiveUS8244419B2Increase powerEmission reductionDigital data processing detailsElectric motor startersRegenerative brakeAlternator

Owner:MI JACK CANADA

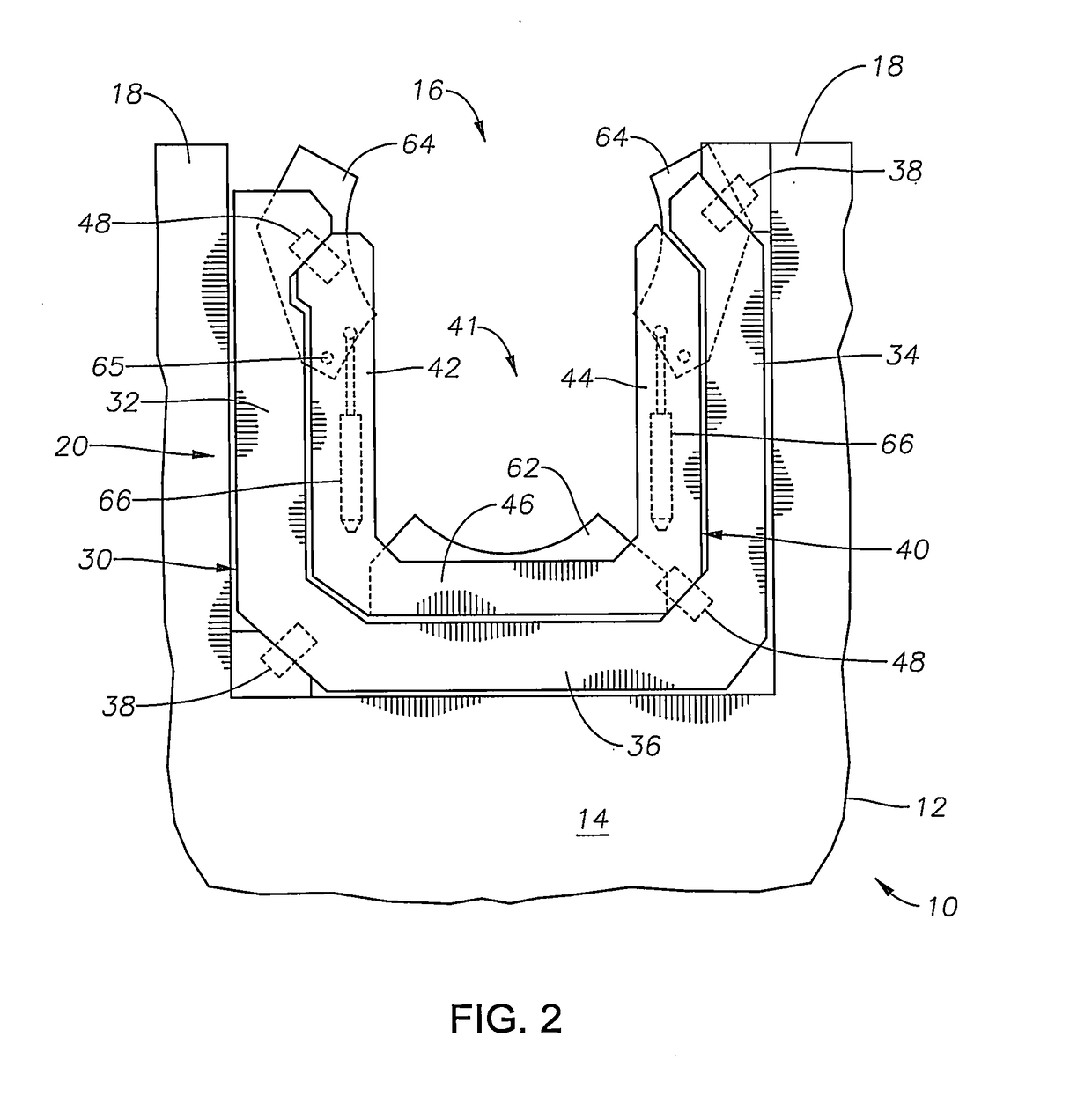

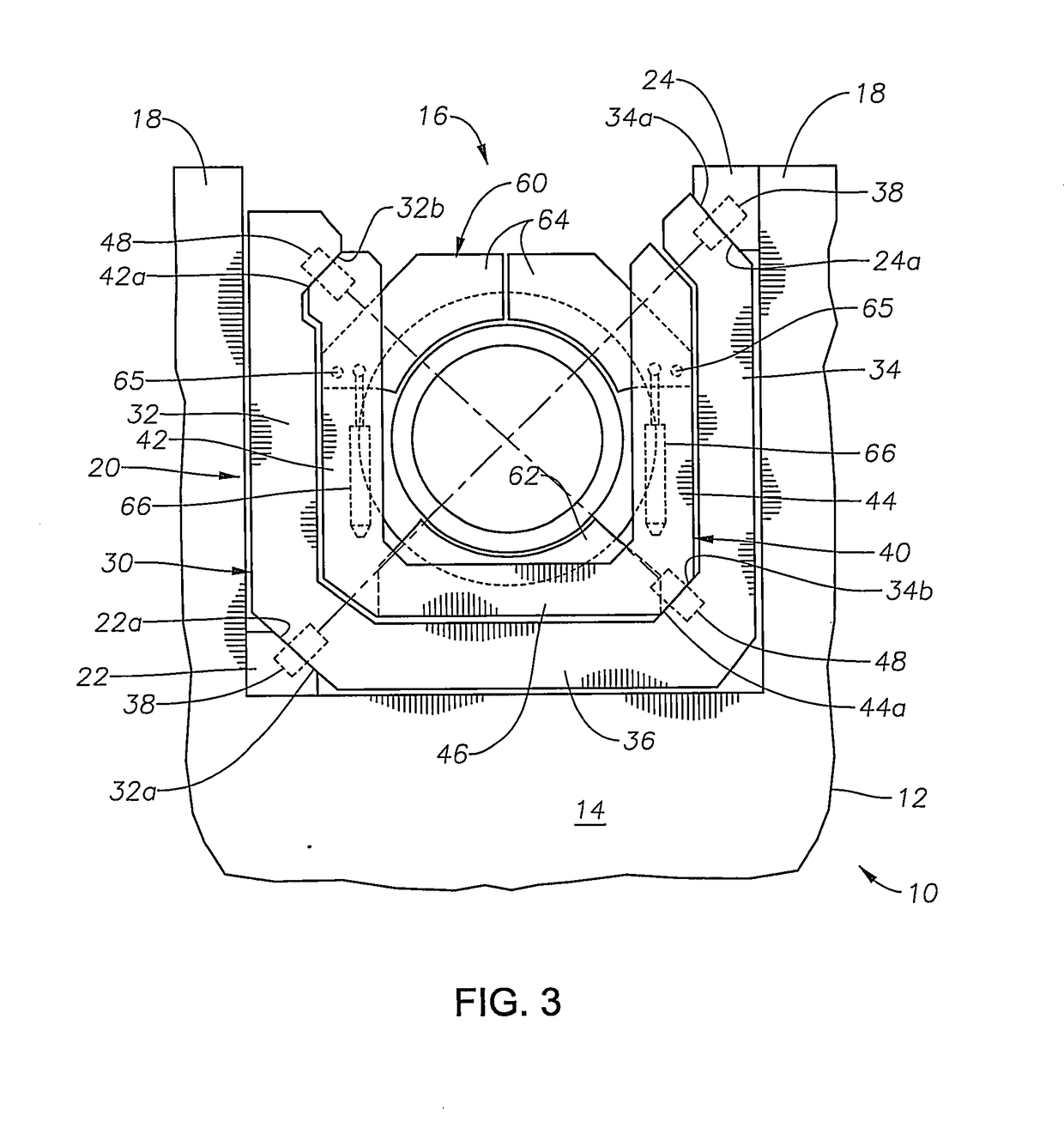

Offshore structure mating system and installation method

ActiveUS20190071830A1Isolates rollIsolates pitch motionArtificial islandsCargo handling apparatusSpar buoyMarine engineering

A system and method for mating equipment offshore to a spar buoy secured to a foundation without the use of a crane barge. The system comprises a floating vessel having a pair of forks defining a slot. A gimbal table, defining an opening, is positioned within the slot and connected to the vessel and a locking collar is mounted to the gimbal table. A mating member is attached to the spar buoy. The vessel is maneuvered to bring the spar buoy within the gimbal table opening. With the spar buoy positioned within the gimbal table opening, the locking collar is arranged and designed to releasably attach to the mating member of the spar buoy and restrict relative vertical motion between the spar buoy and the vessel while the gimbal table allows the floating vessel to roll and pitch without driving these motions into the spar buoy.

Owner:SOFEC

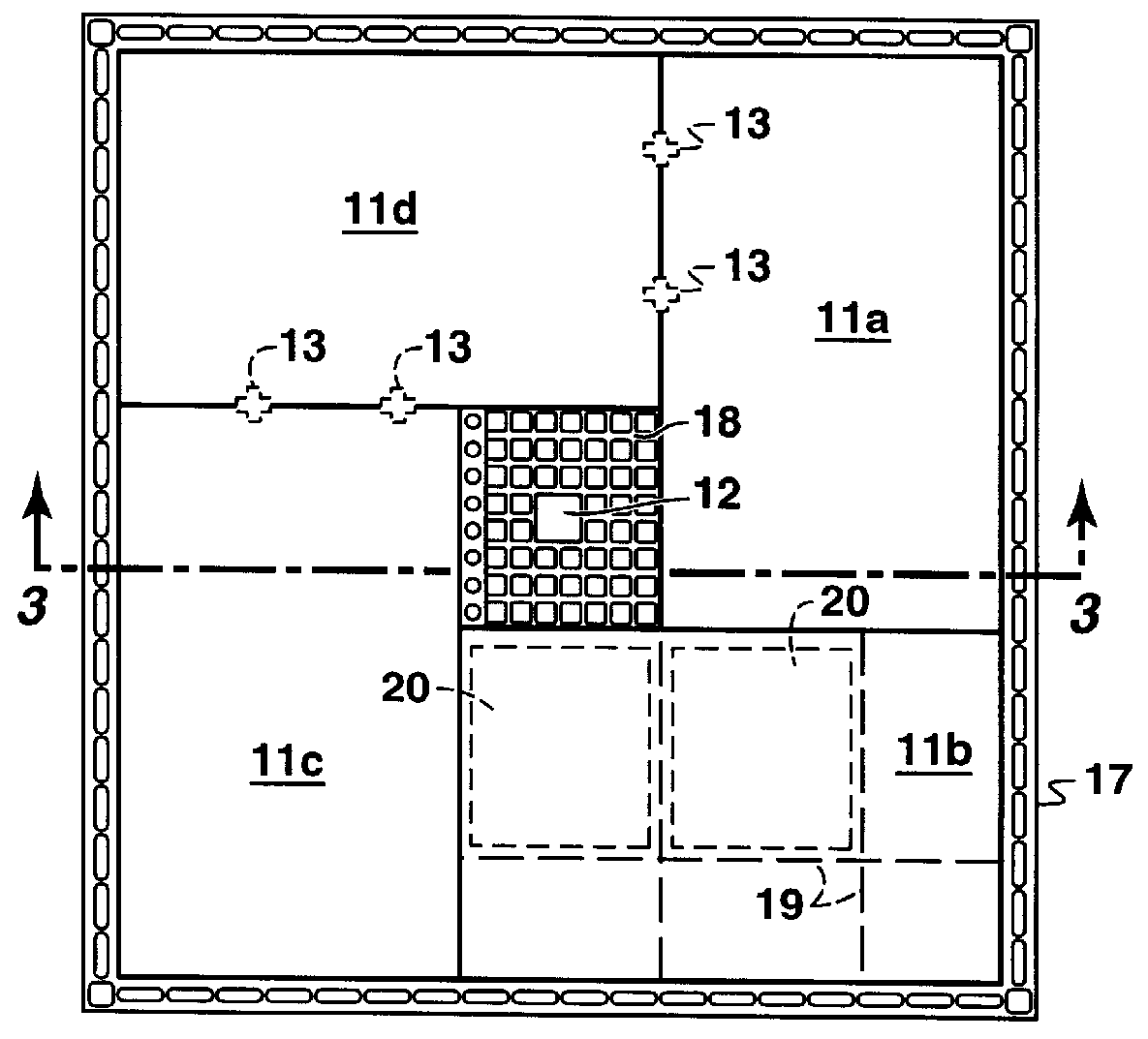

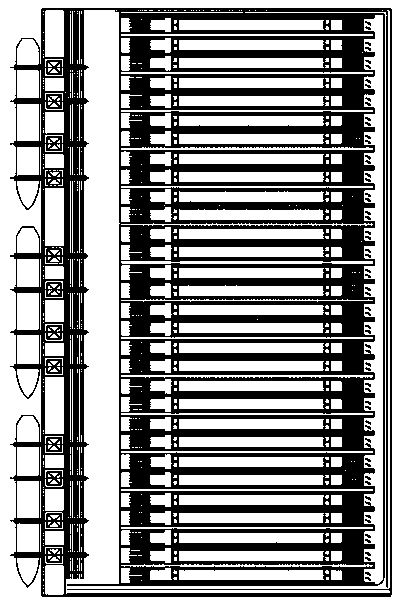

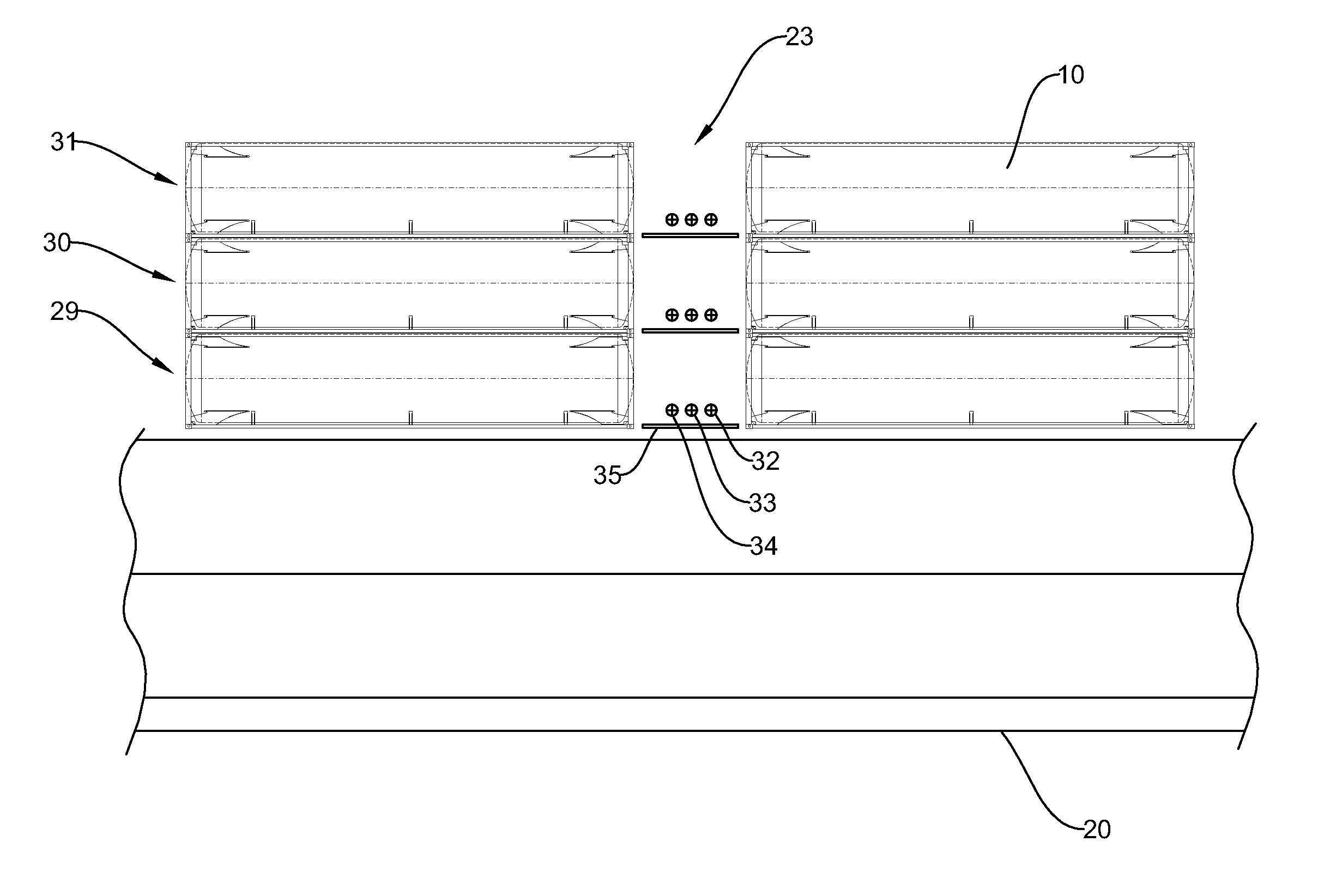

Three-dimensional general arrangement, loading and unloading process and system of automatic container wharf

PendingCN108750694AConducive to unmanned operationEasy to reachLoading/unloadingStorage devicesTransit systemControl system

The invention discloses three-dimensional general arrangement, loading and unloading process and system of an automatic container wharf. The container wharf comprises six parts: a seagoing vessel wharf, a lighter berth, a seagoing vessel wharf front edge working area, a lighter berth front edge working area, a container yard and a landside interaction area. The loading and unloading system is formed by a quay crane, a lighter loading and unloading ship overhead crane, a seagoing vessel wharf front edge three-dimensional track horizontal transportation system, a lighter berth front edge three-dimensional track horizontal transportation system and a three-dimensional automatic container yard loading and unloading system. The loading and unloading process comprises the steps of unloading a ship; loading and unloading a ship at the lighter berth; carrying out cargo concentration in a port and evacuation of cargoes from the port for a container, and loading and unloading the container; andrehandling, loading and unloading a container yard. The various function areas in general arrangement are compact in arrangement, high in land area utilization rate, short in horizontal load distance,free of interference, and low in energy consumption. The whole loading and unloading system and the process technology are mature and reliable, the control system is simple, and the cost is low.

Owner:CCCC FHDI ENG

Oceanography engineering module integral hoisting method

The invention discloses a method used for realizing the integral lifting of marine engineering modules in the marine engineering field. After the module is constructed integrally, the invention makes use of floating cranes, barges and special crane beams to realize the integral lifting of modules on water by regulating the sea gauge of a main hull. Compared with the similar technology, the invention has the following advantages that the preparation of special crane beams can reduce the length of lifting cables so as to enhance the effective lifting height of floating cranes; and the adopting of the floating crane to lift the modules to the barges can avoid the use of a plurality of fittings used for conveying so as to reduce the cost. Simultaneously, the deep water is adopted to moor the main ship so as to ballast the main hull and reduce the height of the freeboard and then the high lifting capability of the floating crane is enhanced and the shipbuilding cost is reduced finally.

Owner:DALIAN SHIPBUILDING IND

System, method and apparatus for a modular production tree assembly to reduce weight during transfer of tree to rig

A modular tree production tree assembly reduces the weight during transfer of the tree components from a barge to a production rig. The tree assembly includes an upper tree module, a lower tree module, and a choke bridge module. The upper tree module has a tree head, the lower tree module has a guidance system and ties in the flow lines to the in-field infrastructure, and the choke bridge module has the choke and instrumentation bridge to link the three components together. Prior to delivery to the rig, the components of the modular tree assembly may be joined together and tested on shore. Upon arrival at the rig, the components are individually lifted from the barge onto the rig by a crane. After the tree components are on the rig, the modular tree is reassembled and then deployed to the sea floor via the draw works.

Owner:VETCO GRAY

Methods and systems for producing, trading, and transporting water

InactiveUS20140014188A1Reduce riskQuality improvementData processing applicationsWaterborne vesselsTransport systemSalt water

Methods and systems for producing, trading, transporting, conveying, and storing non-salt water are disclosed. More specifically, methods and systems for producing, trading, transporting, and storing large quantities of water having specific characteristics are provided. Various transport systems are disclosed, including devices and methods for utilizing standard shipping containers on ships, oil tankers, barges, boats, trains, trucks, planes, and other modes of transportation. More particularly, this invention relates to delivering drinkable water to the water-poor regions of the globe using large bags or membranes in shipping containers, empty cargo holds, or empty oil tankers' cargo holds.

Owner:WATERS OF PATAGONIA

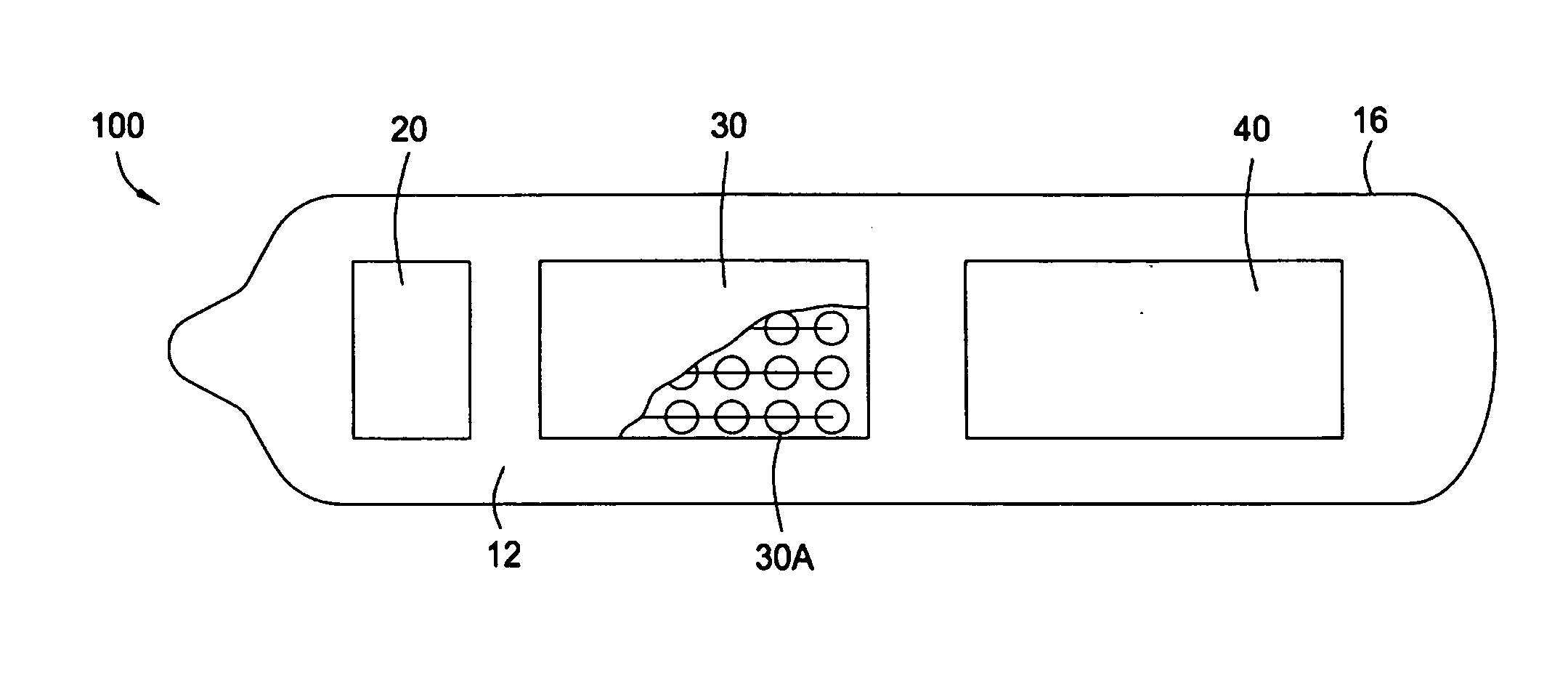

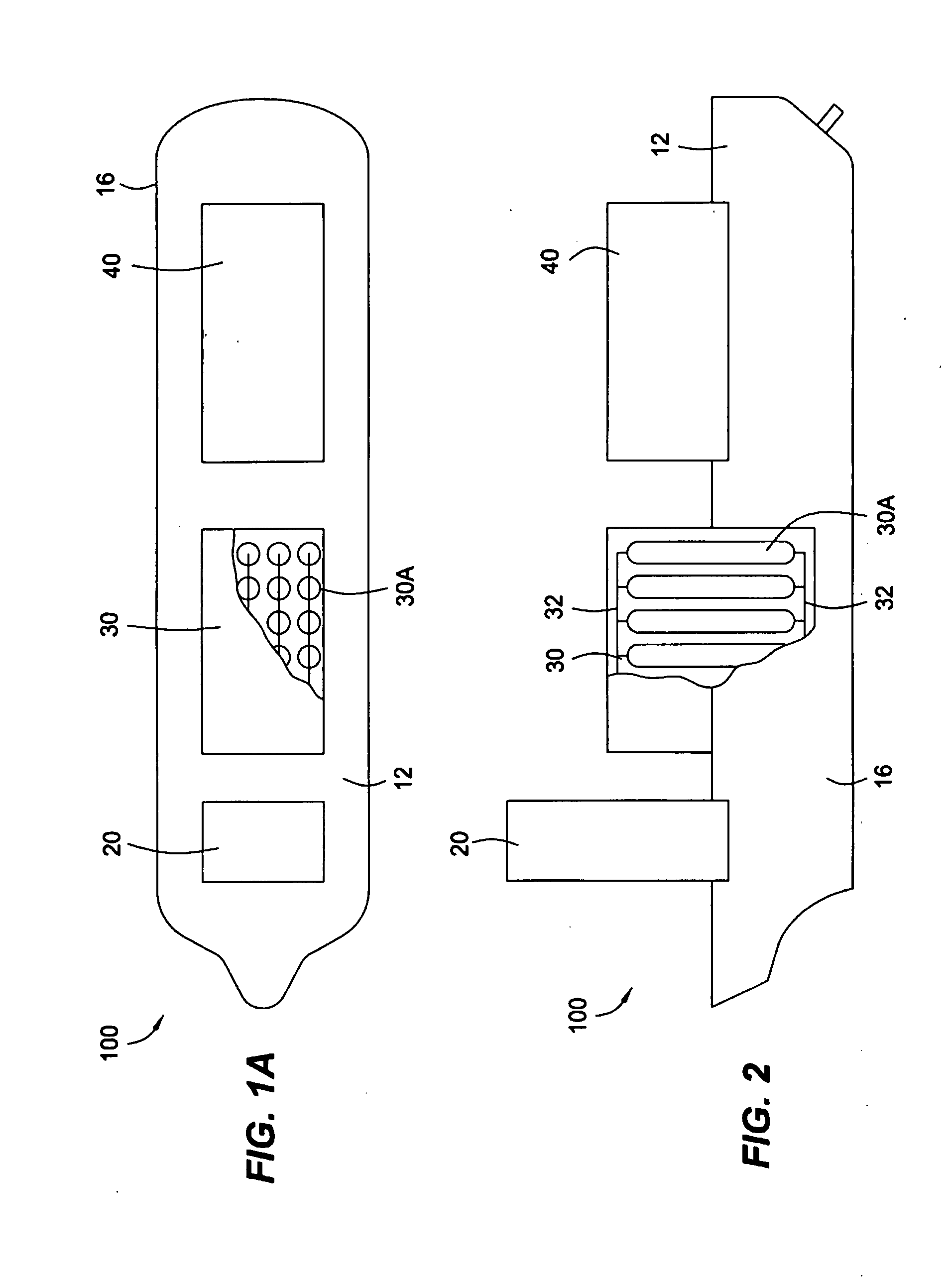

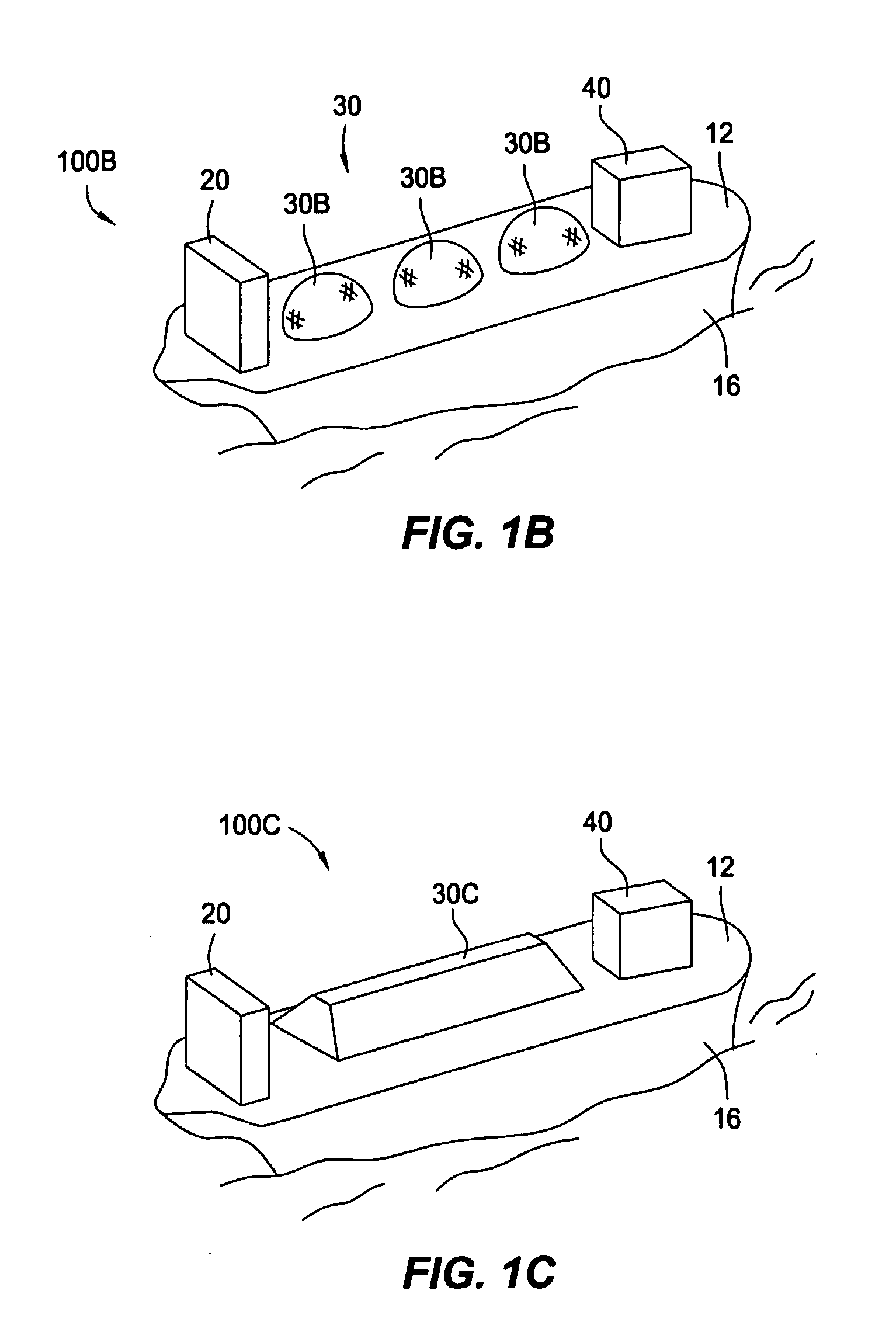

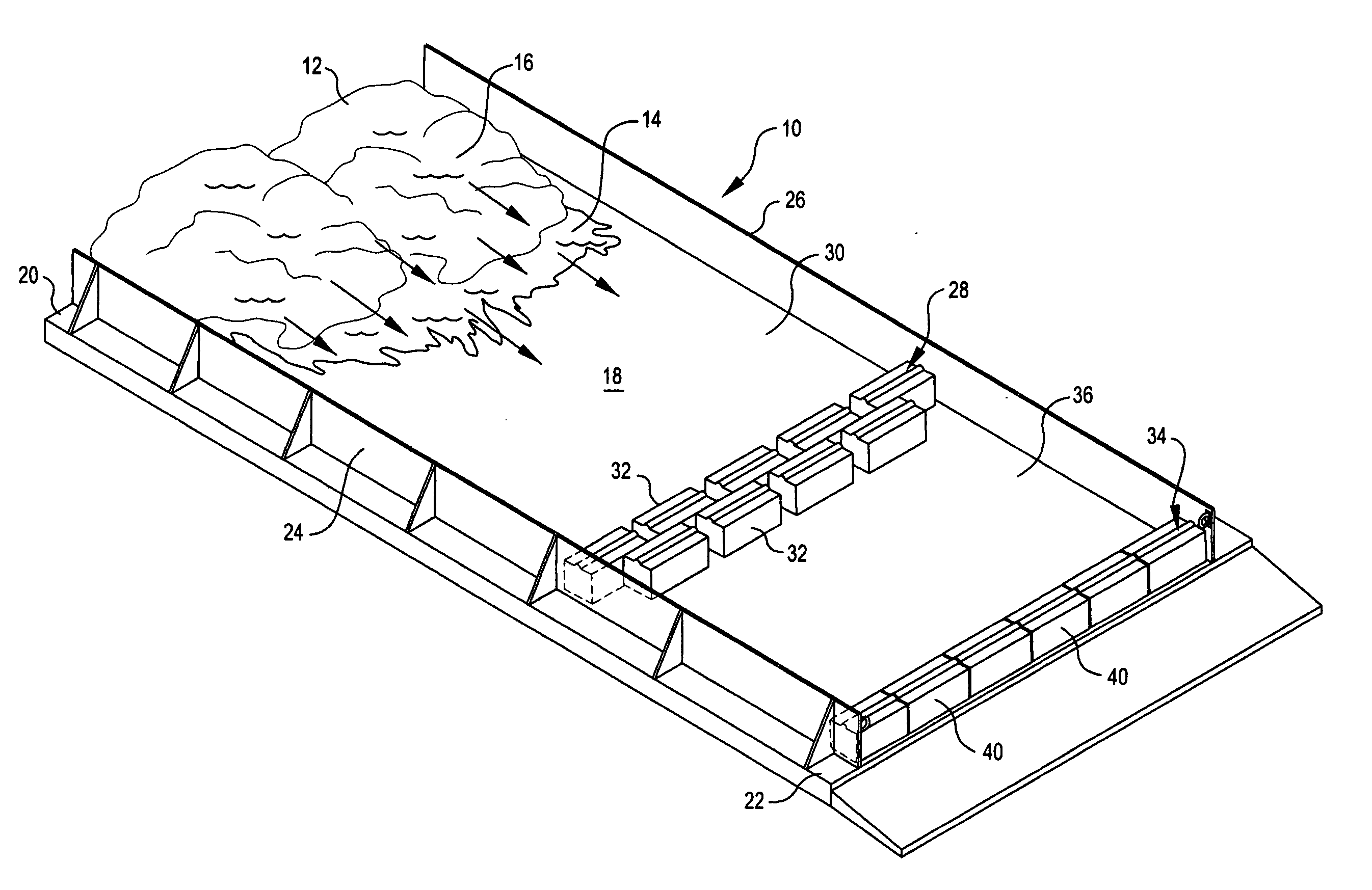

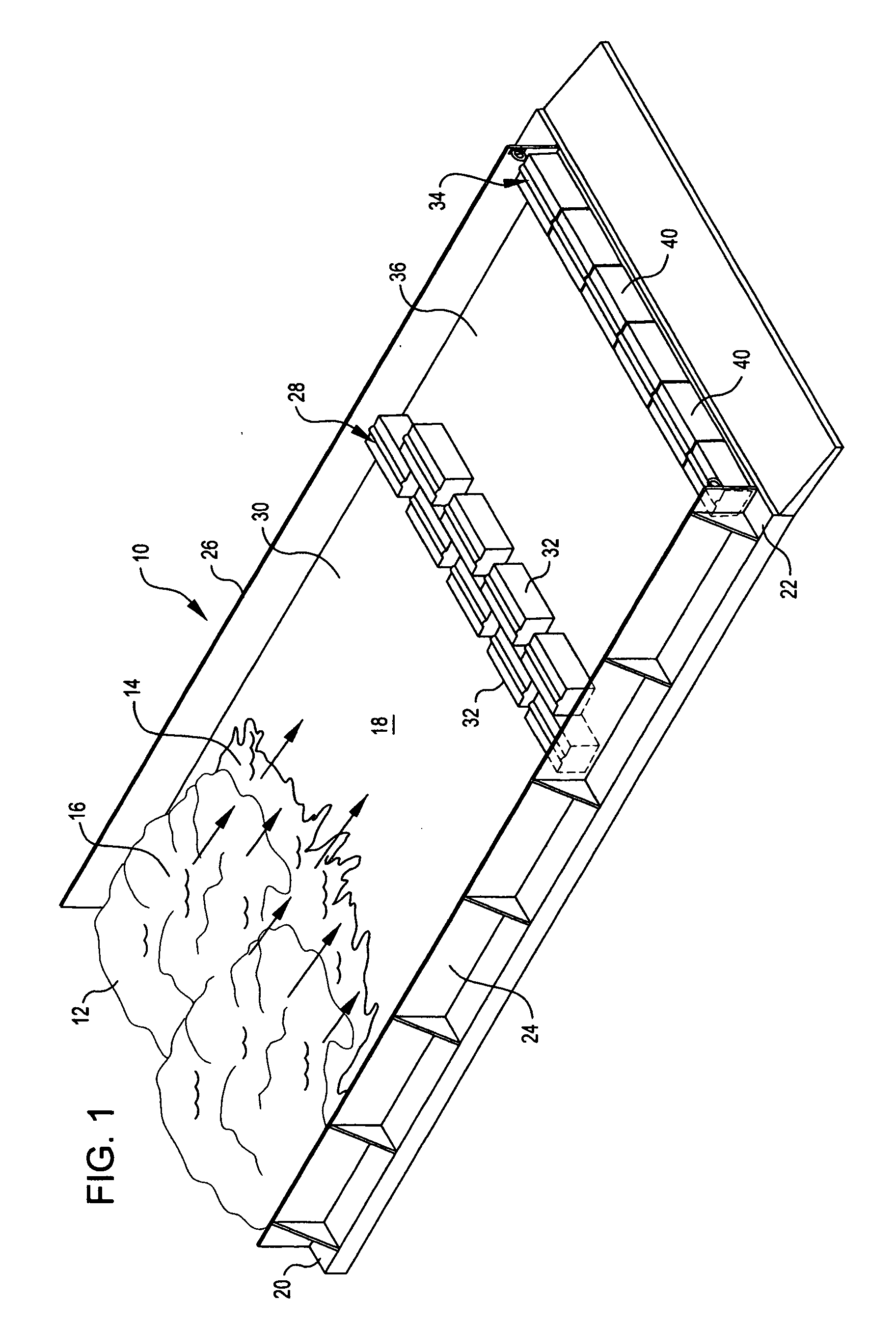

System and method for containerized transport of liquids by marine vessel

ActiveUS8375876B2Efficient loadingSafely berthingAuxillariesContainer filling methodsLiquid tankInterconnection

A marine vessel, and a system and method of using the marine vessel, to facilitate the introduction of bulk liquid commodities, such as LNG, into the established and extensive worldwide intermodal transportation system, which is based on containerized shipments. The marine vessel is a specialized vessel, of either ship or barge form, that is capable of holding a large number of ISO-sized intermodal LNG tanks and is configured so as to have at one and the same time characteristics of both a tanker vessel (e.g., a gas carrier) and a container vessel. The intermodal LNG tanks connect to a piping system of the marine vessel and are thereby interconnected in such a manner that allows the interconnected intermodal LNG tanks to behave as if they constitute a typical LNG vessel bulk liquid tank to facilitate efficient loading at a typical marine LNG terminal. The containerized intermodal LNG tanks are capable of discharging liquids to a marine terminal as if in a bulk mode, or of being disconnected from the common interconnection system to allow lift-off discharge of the intermodal LNG tanks at a typical cargo container port so that the intermodal LNG tanks can enter the existing intermodal transportation system for further distribution to the end user by other marine vessels, over-the-road truck, or by rail.

Owner:ARGENT MARINE MANAGEMENT

Method and apparatus for salvaging underwater objects

InactiveUS7908988B1Reduce necessityGood effectCargo handling apparatusSlipwaysOcean bottomLightering

A method and apparatus for removing debris from an ocean floor or seabed employs a subsea debris basket. The basket eliminates the absolute necessity of a cargo barge or any other supporting vessel that might be required to remain in a field until the objects on the ocean floor can be lifted. The present invention provides a non-weather sensitive solution. The present invention affords the safe operation in that all lifting and lowering is performed in a subsea environment next to the ocean floor or seabed. The present invention enables operation to be completed with the use of an ROV or remotely operated vehicle. The present invention provides improved offshore efficiency, less time being required to recover debris from the seabed to the underwater salvage basket or debris basket. The present invention enables the possibility of use of an A-frame or simple crane to lower debris into a subsea basket. The basket can be reused or redeployed in the field if desired. The basket may also be “reefed” in place to address the stability concerns of small debris and to minimize transit time of debris to a reef site.

Owner:VERSABAR

Method for disassembling and assembling superaqueous bridge

InactiveCN101881007ANot subject to volumeNot subject to weightBuilding repairsBridge erection/assemblyCarrying capacityEngineering

The invention discloses a method for disassembling and assembling a superaqueous bridge, which combines the buoyancy change of a barge with the waterlevel change caused by the rising and the falling of the tide level. The method can be used in a light-draft area where a floating crane can not enter, and can be effectively and safely used within the carrying capacity range of a buoyant box.

Owner:SHANGHAI SHIPYARD

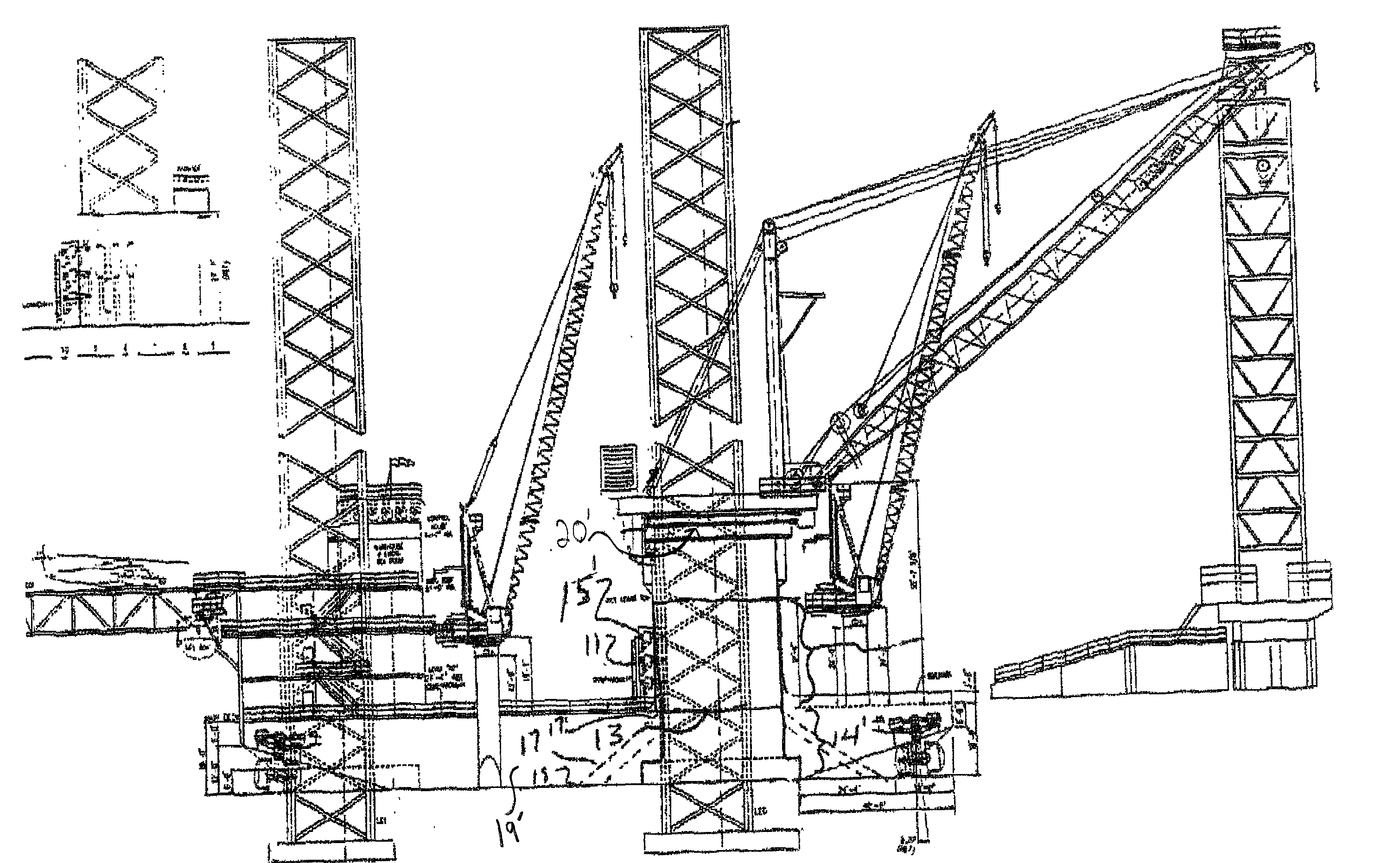

Elevated crane support system and method for elevating a lifting apparatus

InactiveUS20020079278A1Increase capacitySave spaceArtificial islandsDrilling rodsSupporting systemJackscrew

A support structure for supporting a lift crane, and in particular to a lift crane jack-up structures, including rigs, platforms, barges, boats or the like, wherein the lift crane is positioned about a leg of the jack-up structure atop the jack-house. The preferred embodiment of the present invention contemplates a system for elevating a lift crane above the deck and about the leg of the jack-up structure, without relying upon the leg for structural support. A structurally reinforced jack-house having jacking units interfacing with the leg is provided at the deck of the vessel the jack-house configured to engage and support a crane tube column upon the roof of the jack house, which crane tube column in turn has situated thereupon the lift crane. The combined jack-house / crane tube column design allows one to support a crane above the deck in a stable manner independent of the leg situated therethrough, so as to provide a superior structural support for the lift crane, while providing ample space within the jack-house for the jacking units. The combined jack-house / crane support structure thereby affords significant space savings upon deck of the platform, while providing enhanced support of the lift crane. The substructure of the vessel comprises longitudinal and transverse bulkheads intersecting to form a support cell having a perimeter, the portion of the bulkheads forming the cell extend vertically through the deck to form the walls of the jack house and support for the platform. In an alternative embodiment, a truss-type bracing assembly engages the perimeter of the support cell below deck to form a raised platform without walls.

Owner:THE LEVINGSTON

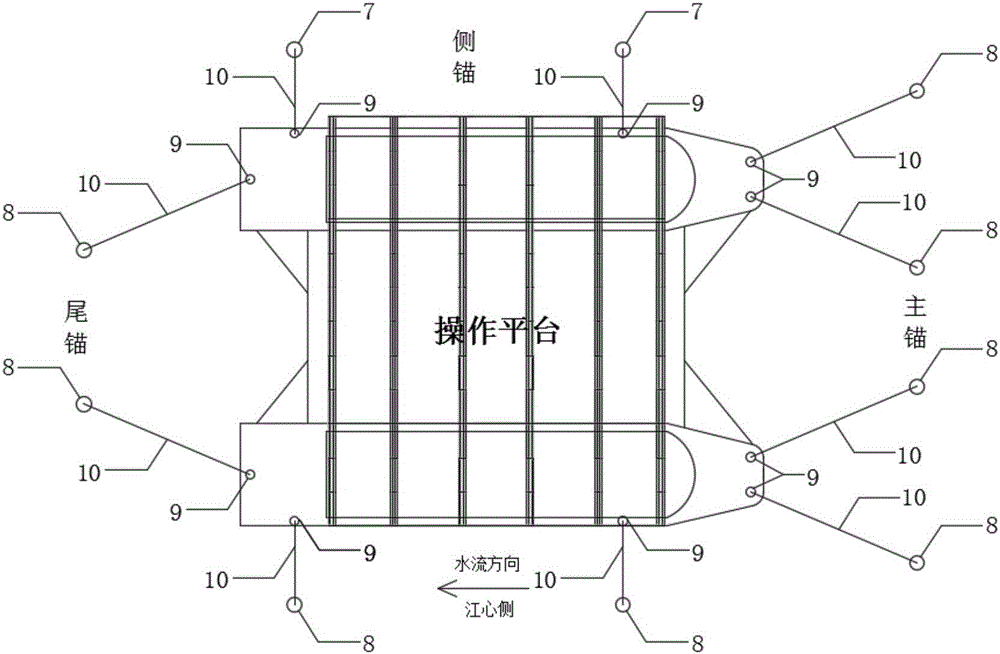

Device for underwater pile foundation construction platform convertible in floating and fixing

ActiveCN105926628AOvercoming occupied waterwayOvercome environmental problemsFoundation engineeringBasementStructural engineering

The invention discloses a device for an underwater pile foundation construction platform convertible in floating and fixing and belongs to the field of bridge construction. The device comprises a two-barge supporting device body, a shape steel beret slice combination construction platform device body, a positioning device body, a hole guiding and rock embedding device body and a system conversion device body. Two barges are parallelly connected to be the floating supporting device body, a shape steel beret slice combination construction platform is assembled on the floating supporting device body, and the floating supporting device body and the shape steel beret slice combination construction platform are fixedly connected to form an overwater floating construction platform device body; hole guiding is conducted through a percussion drill, and a pile foundation steel casing is embedded into a basement rock stratum through the percussion drill assisted with hoisting equipment and a vibration hammer; the shape steel beret slice combination construction platform above a floating platform is made to fall onto bracket supporting device bodies on the two sides of the pile foundation steel casing to complete platform system conversion by increasing the immersion depth of the two-barge supporting device body; and finally pile foundation construction is conducted. Under the conditions that the site condition is limited, waterway regulation is strict, and the geological condition is unfavorable, by using the device, the effects of being quick in starting is achieved, construction is easy and convenient, and the construction period is greatly shortened; and meanwhile, the material investment amount is small, and the cost is reduced.

Owner:THE THIRD ENG CO LTD OF THE HIGHWAY ENG BUREAU OF CCCC

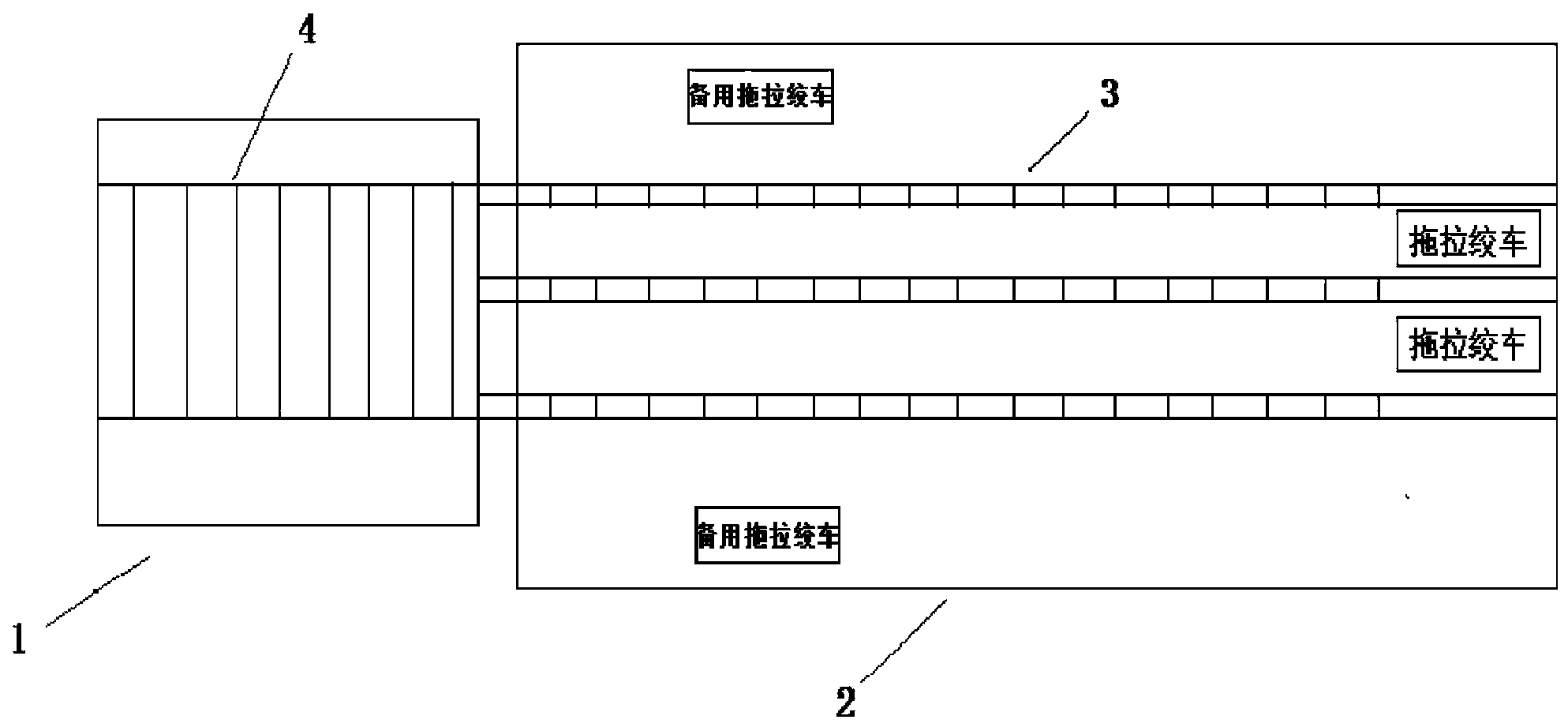

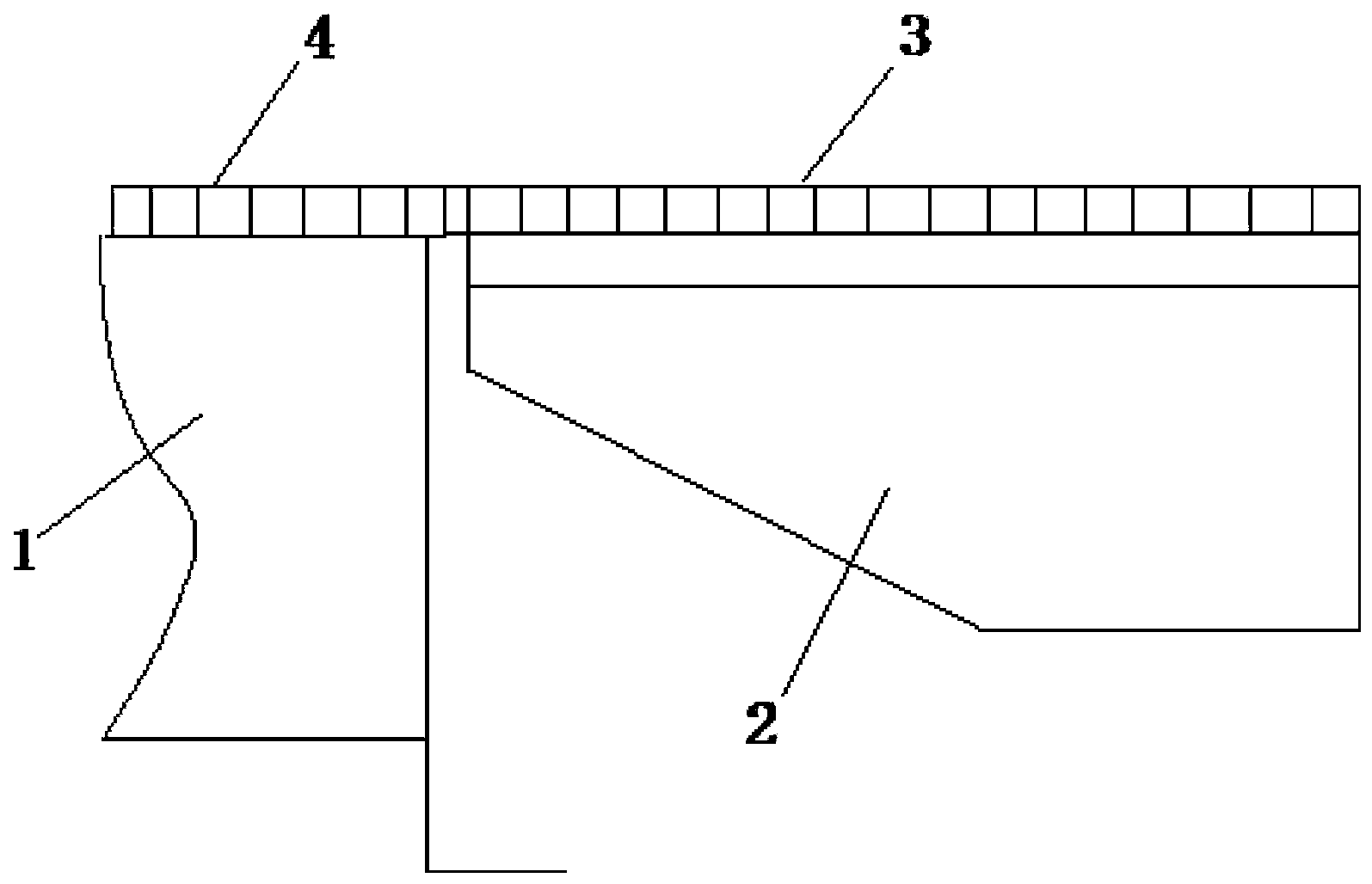

Offshore engineering vessel loading and launching system and method

ActiveCN104229099AImprove integrityImprove loading safety factorSlipwaysClassical mechanicsLightering

The invention provides an offshore engineering vessel loading and launching system and method. The system comprises a semi-submersible barge and a drag system, wherein a plurality of standby dragging winches are additionally arranged at the outer side of a barge slideway so as to be used for guaranteeing the safety in loading. The method is characterized in that the standby winches which are additionally arranged at the outer side of the barge slideway are used for dragging a main vessel body to the barge slideway from a wharf construction slideway, the barge is adjusted by discharging the water from different cabins of the semi-submersible barge, so that the horizontal dragging loading safety coefficient can be improved, the construction period is shortened, and the dragging cost is reduced.

Owner:COSCO SHIPPING SHIPYARD (NANGTONG) CO LTD +1

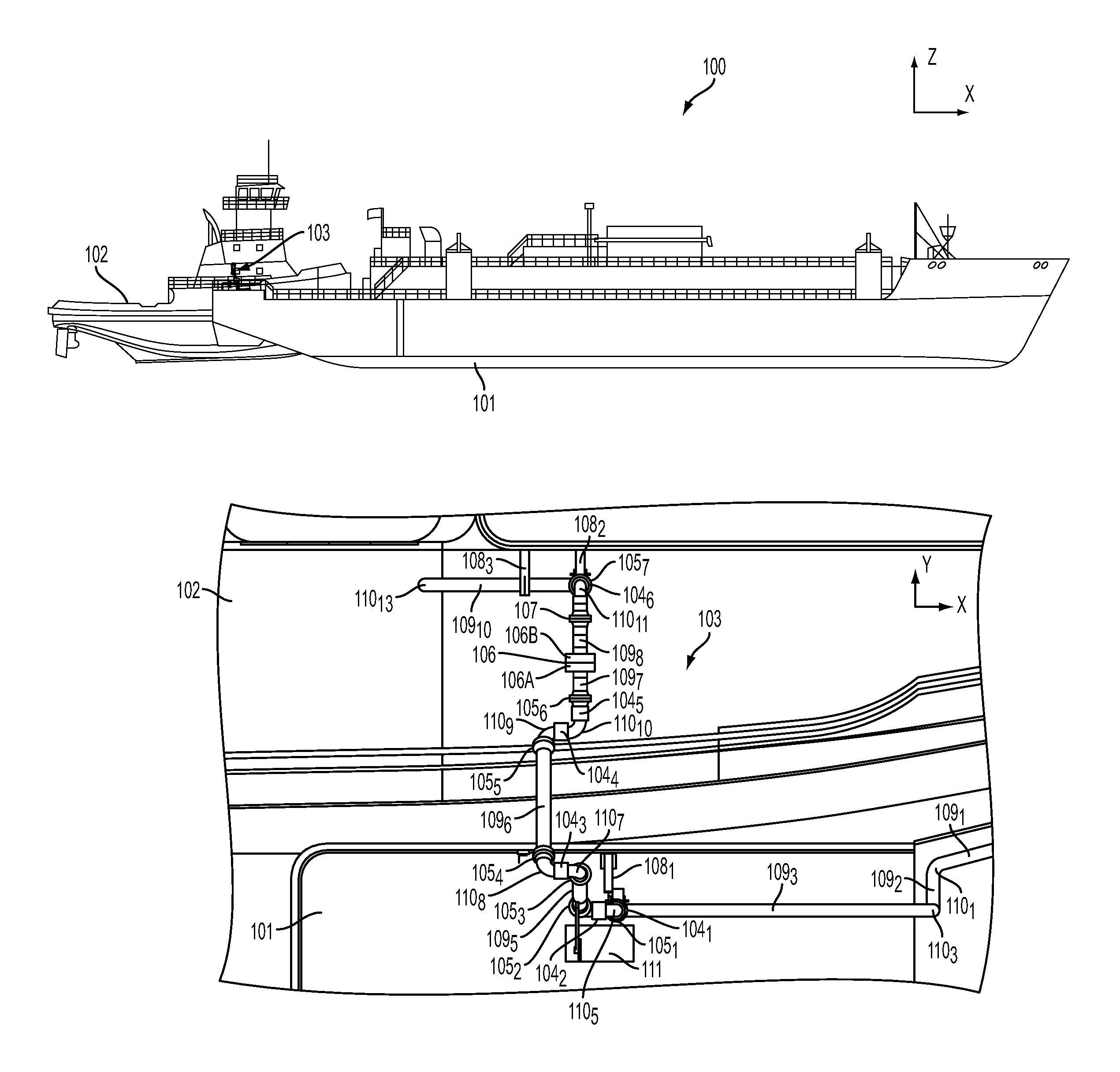

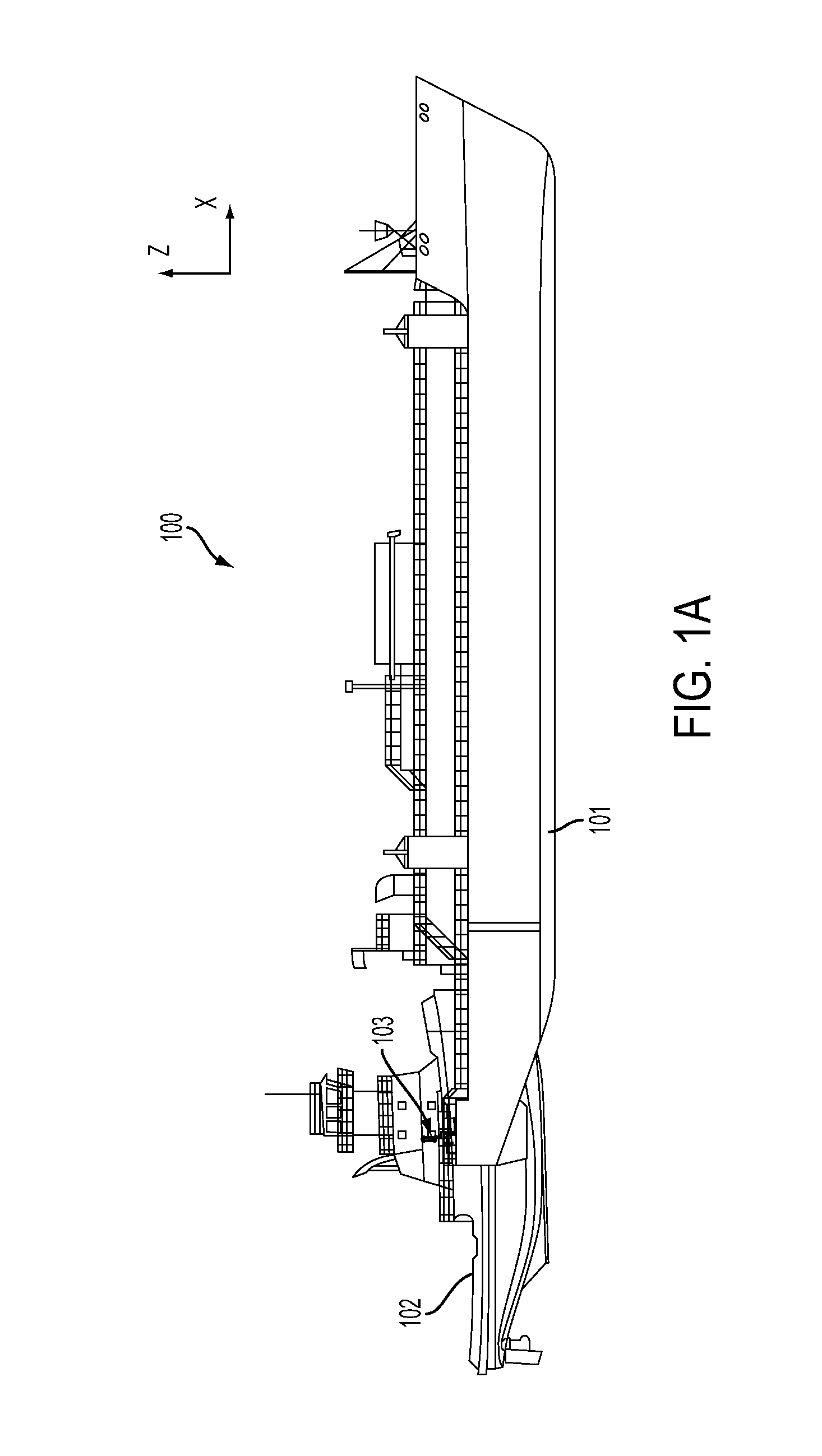

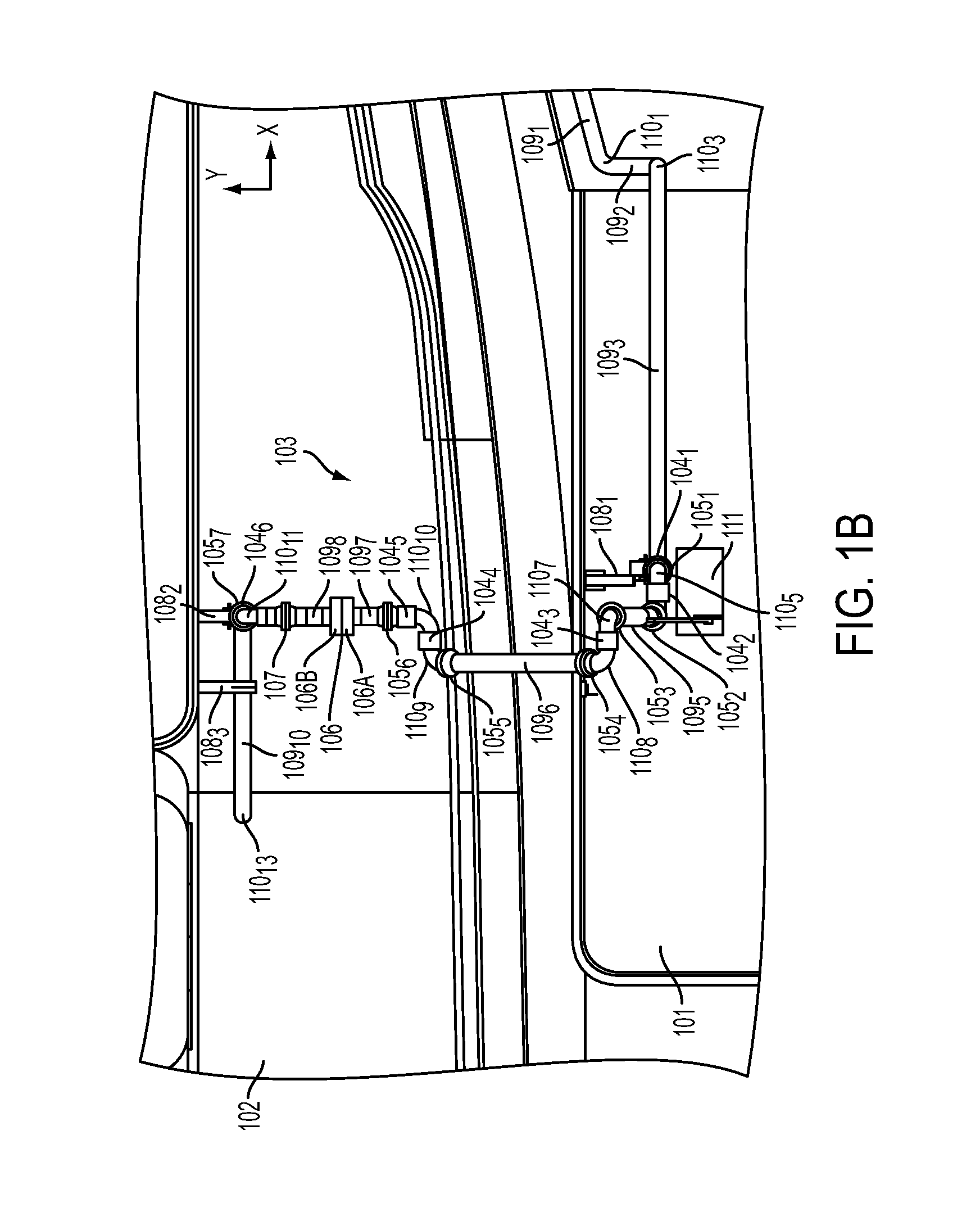

Articulated conduit systems and uses thereof for fuel gas transfer between a tug and barge

According to some aspects, a tug and barge arrangement is provided that is configured with an articulated conduit system for transferring a fuel gas (e.g., natural gas) between the tug and barge. In some embodiments, an articulated conduit system is provided that comprises a plurality of conduits fluidically interconnected by rotatable joints configured to permit positional alterations of the fluid conduits that result from differential movement between a tug and barge, such as relative vertical displacement between the tug and barge and / or relative rotation between the tug and barge about a forward-aft axis of the tug.

Owner:MORAN TOWING

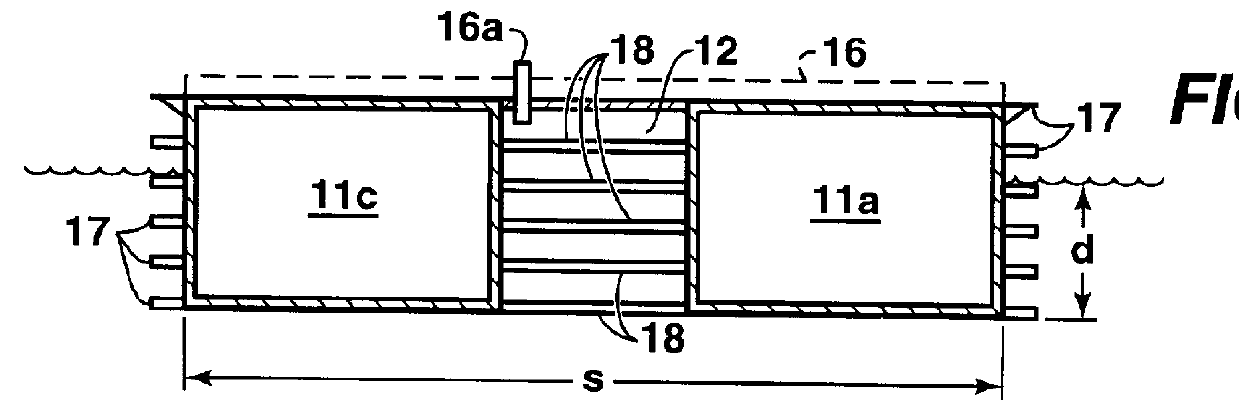

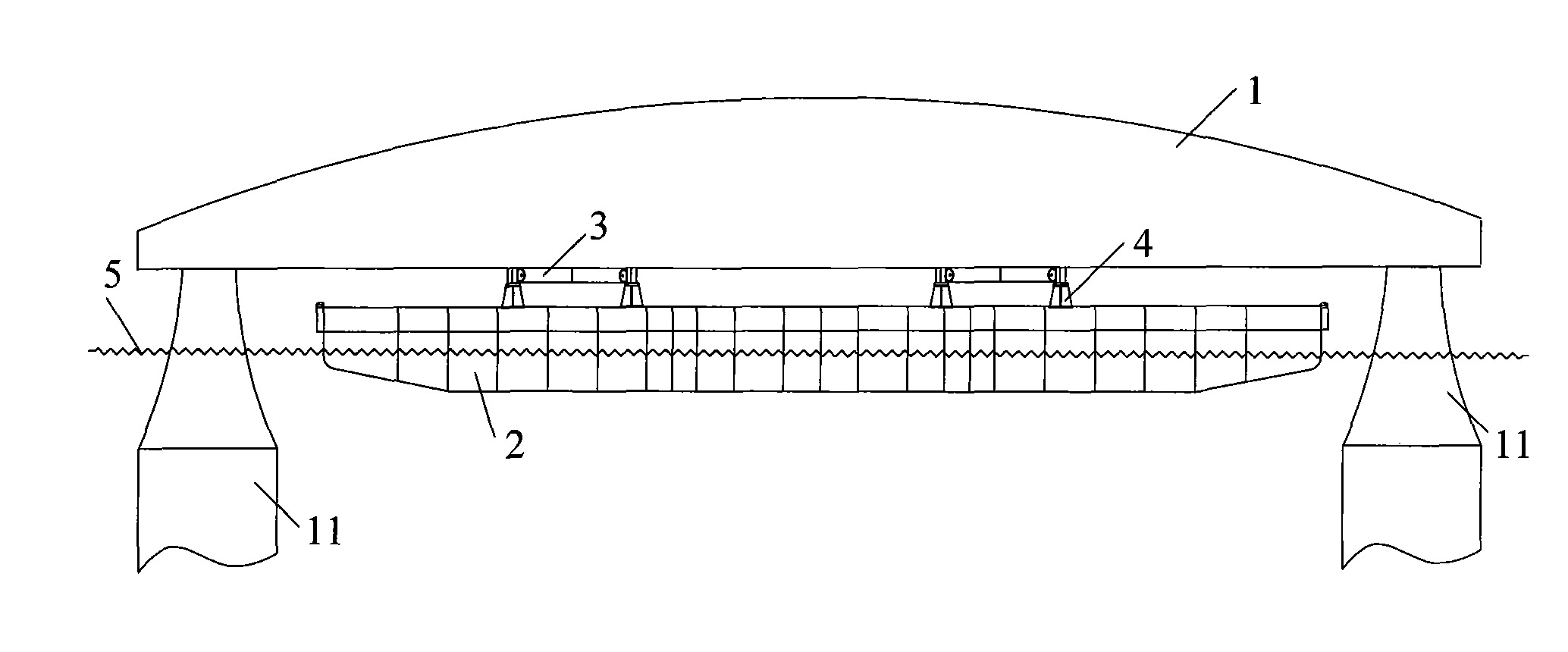

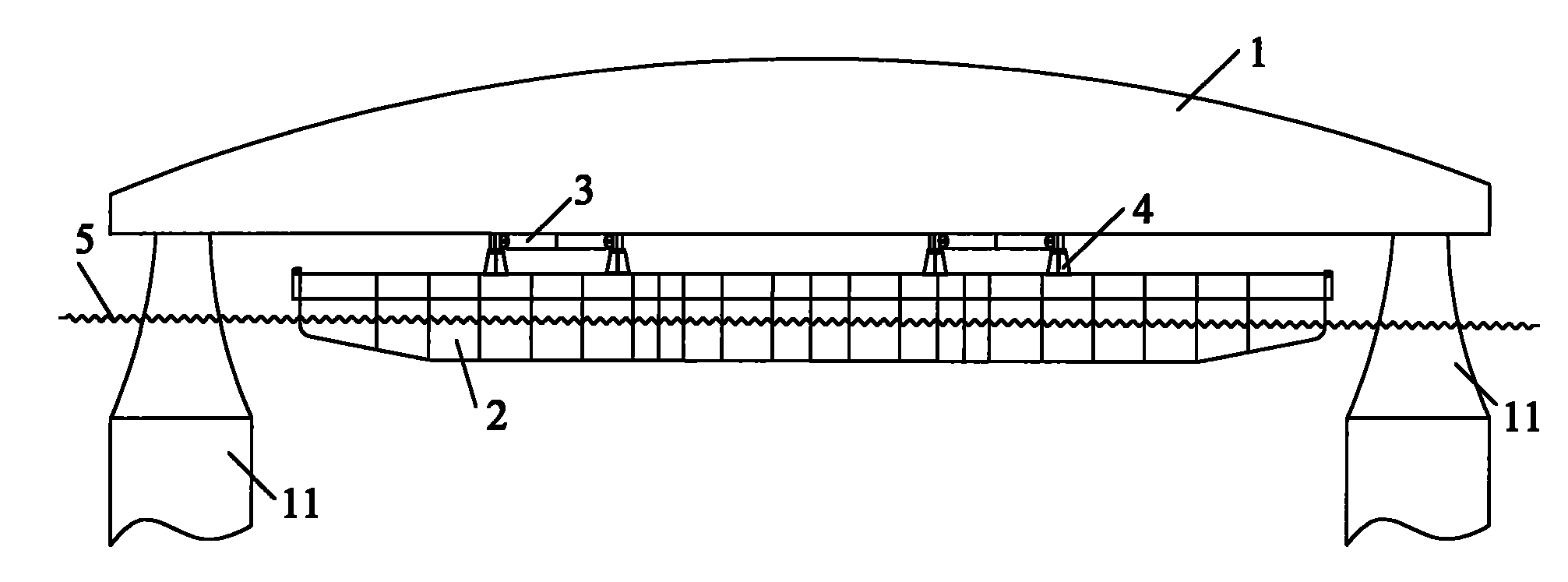

Floating wind turbine and method for installation of such floating wind turbine

InactiveCN109154280AReduce the amplitude of the vertical forceReduce pretensionWind motor supports/mountsBuoyancy meansKeelClassical mechanics

A floating wind turbine comprising a hull (1), a wind turbine (2) mounted on top of the hull (1) and a counterweight (3) suspended below the hull (1) by means of counterweight suspension means (18) isdescribed. Also a method for the installation is described. The counterweight (3) comprises one or more counterweight buoyancy tanks (17). When the internal volume of the buoyancy tanks (17) is filled with air, the total buoyancy of the counterweight (3) is close to or greater than its weight. Hereby it is capable of floating in a towing / maintenance position with moderate or no support in the vertical direction from the hull (1) or other vessels. During towing, the hull substantially has the character of a barge, substantially relying on a large waterplane area and shallow draft to maintainstability. When the buoyancy tanks (17) are partly or completely flooded with water, the counterweight (3) will sink to an installed position at a level determined by the counter- weight suspension means (18). In this position the counterweight acts as a keel, stabilizing the foundation. The counterweight suspension means (18) are separately or jointly capable of transfer- ring both forces and moments to the hull (1), thereby enabling the counterweight (3) to stabilize the hull (1) when the counterweight (3) is in its installed position.

Owner:STIESDAL OFFSHORE TECH AS

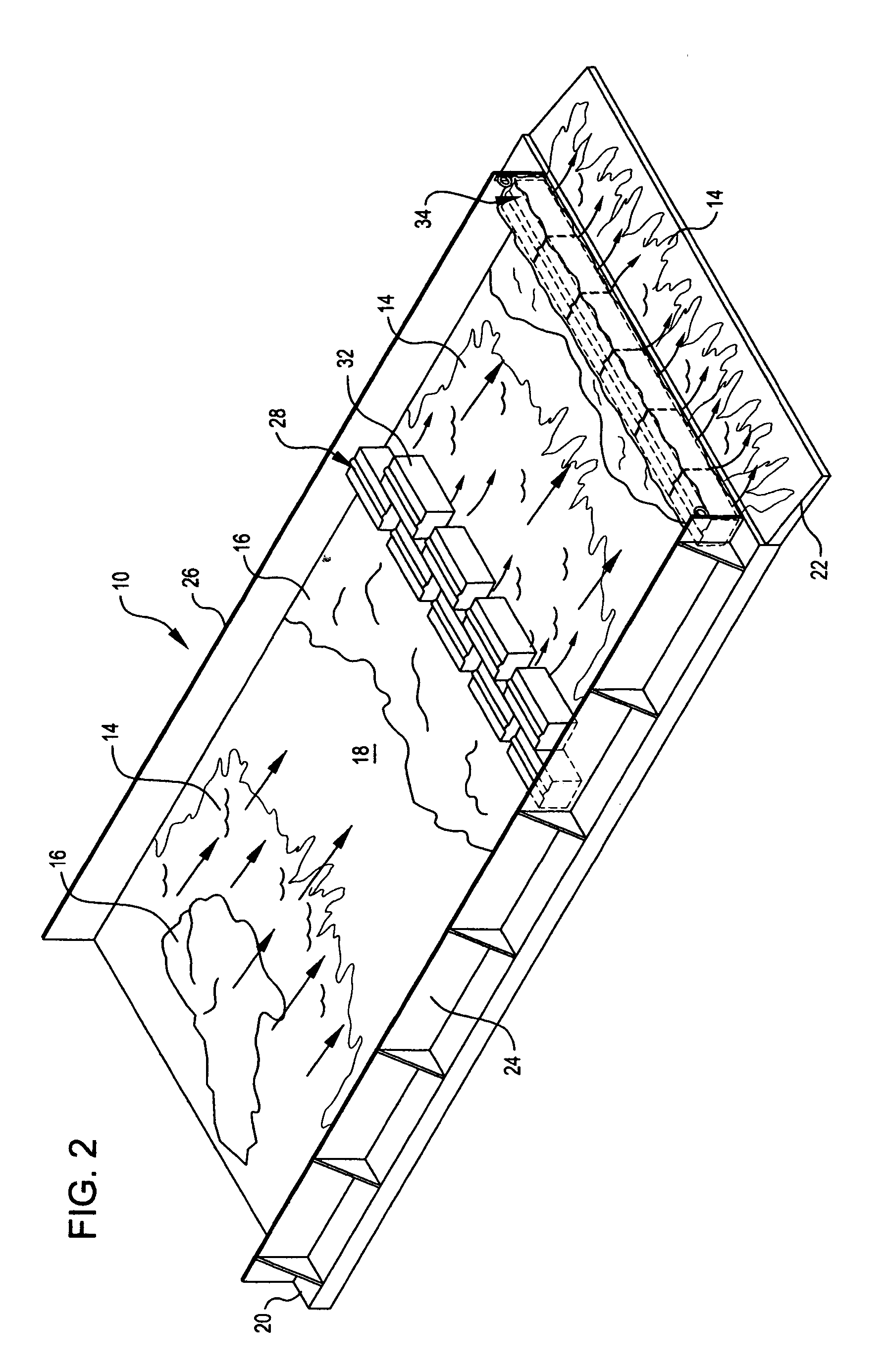

Modern intensive fast fish farm

InactiveCN104686410AClimate change adaptationPisciculture and aquariaJuvenile fishReinforced concrete

The invention discloses a modern intensive fast fish farm. The modern intensive fast fish farm is constructed on a pollution-free sea surface, and an offshore area which is 8 kilometers long and 3 kilometers wide and has a water depth of 20 to 100 meters is required. The modern intensive fast fish farm comprises a reinforced concrete foundation, bridge piers, fender piers, beams, movable fish boxes and matched steel wire mesh risers, wherein gantry cranes, reinforced concrete beams for supporting the gantry cranes, longitudinal reinforced concrete beams supported by bridge pier brackets, steel rails on the longitudinal reinforced concrete beams and portal bridge cranes capable of moving on the steel rails are arranged over water; multiple gondolas, tugboats and barges for periodically lifting feeding cylinders to feed fish food or lifting the movable fish boxes to the water surface in a layering manner and unloading fish onto the barges or the tugboats are further arranged on the water surface; after the fish is unloaded, the boxes are lifted into water again according to the sequence of the layers; in addition, multiplying farms for precious fish fries such as cods and squids are further constructed on the shore, and after being cultured to certain specifications, juvenile fish are fed into the steel wire mesh risers communicated with the movable fish boxes for being fed in the boxes.

Owner:包顺柳

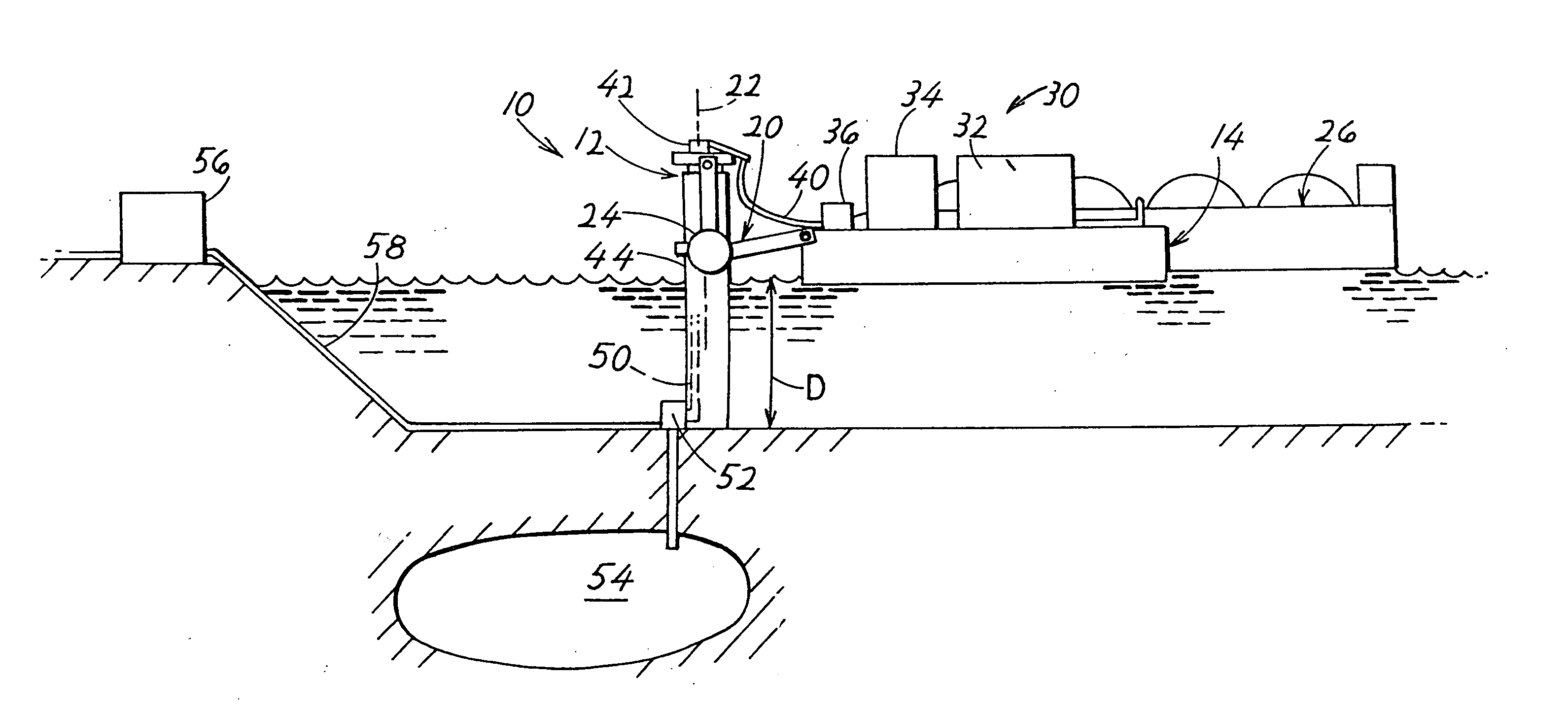

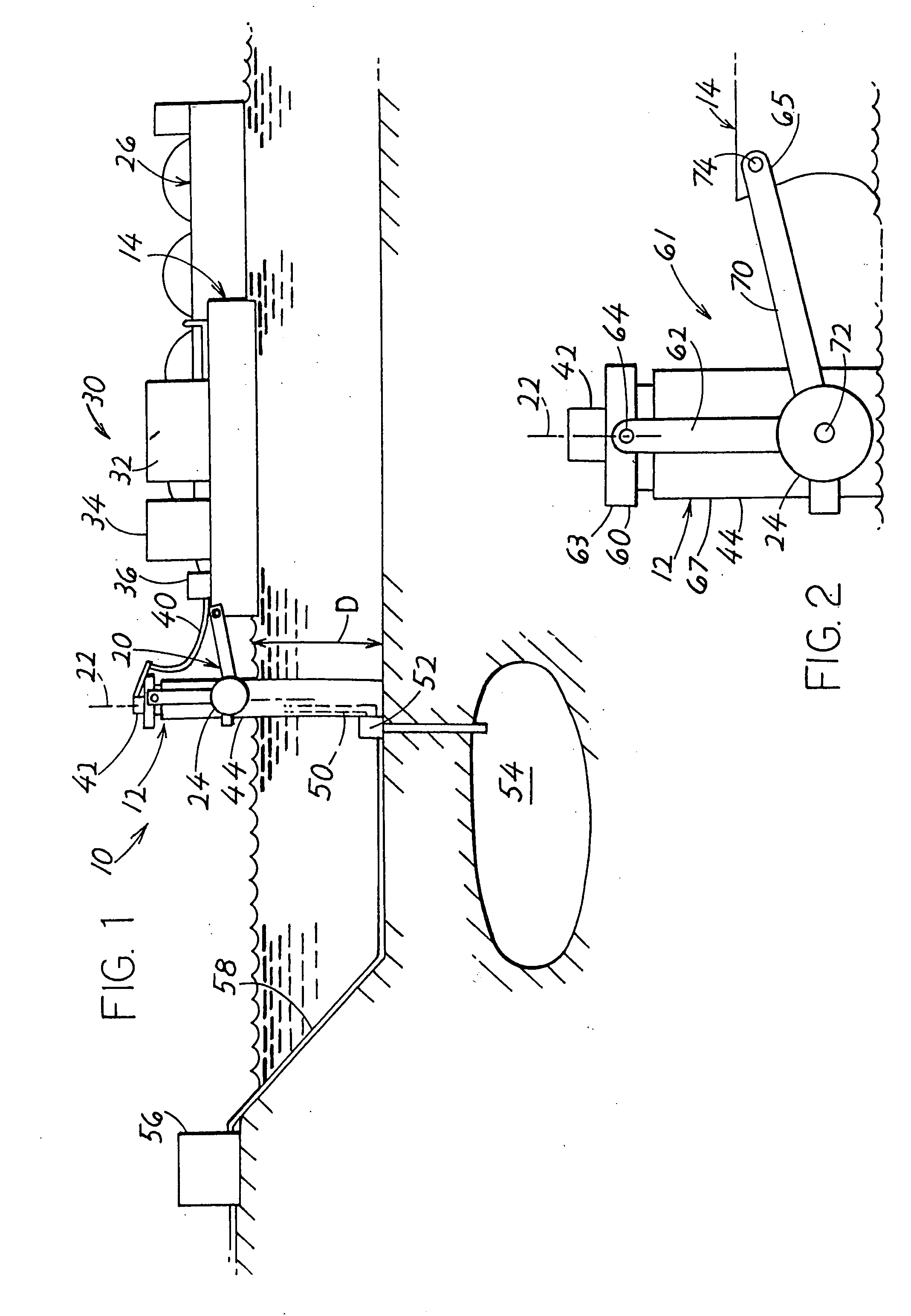

Enhanced LNG tanker offloading in shallow waters

A system for offloading LNG (liquified natural gas) from a tanker (26) in shallow waters, for regasing, or heating the offloaded LNG to produce gaseous hydrocarbons, or gas, for pressurizing the gas, and for flowing the gas to an onshore station (56), includes a structure that is fixed to the sea floor and projects above the sea surface and aids in mooring the tanker. In one system, the structure that is fixed to the sea floor is a largely cylindrical tower (12) with a mooring yoke (20) rotatably mounted on its upper end. A floating structure (14) such as a barge that weathervanes, has a bow end pivotally connected to a distal end of the yoke, so the barge is held close to the tower but can drift around the tower with changing winds, waves and currents. The tanker is moored to the tower so the barge and tanker form a combination that weathervanes as a combination. Regas and pressurizing equipment (32, 34) for heating and pressuring the LNG, and any crew quarters (36), are all located on the barge, so a low cost tower can be used. In another system, the structure is a breakwater (180).

Owner:SINGLE BUOY MOORINGS INC

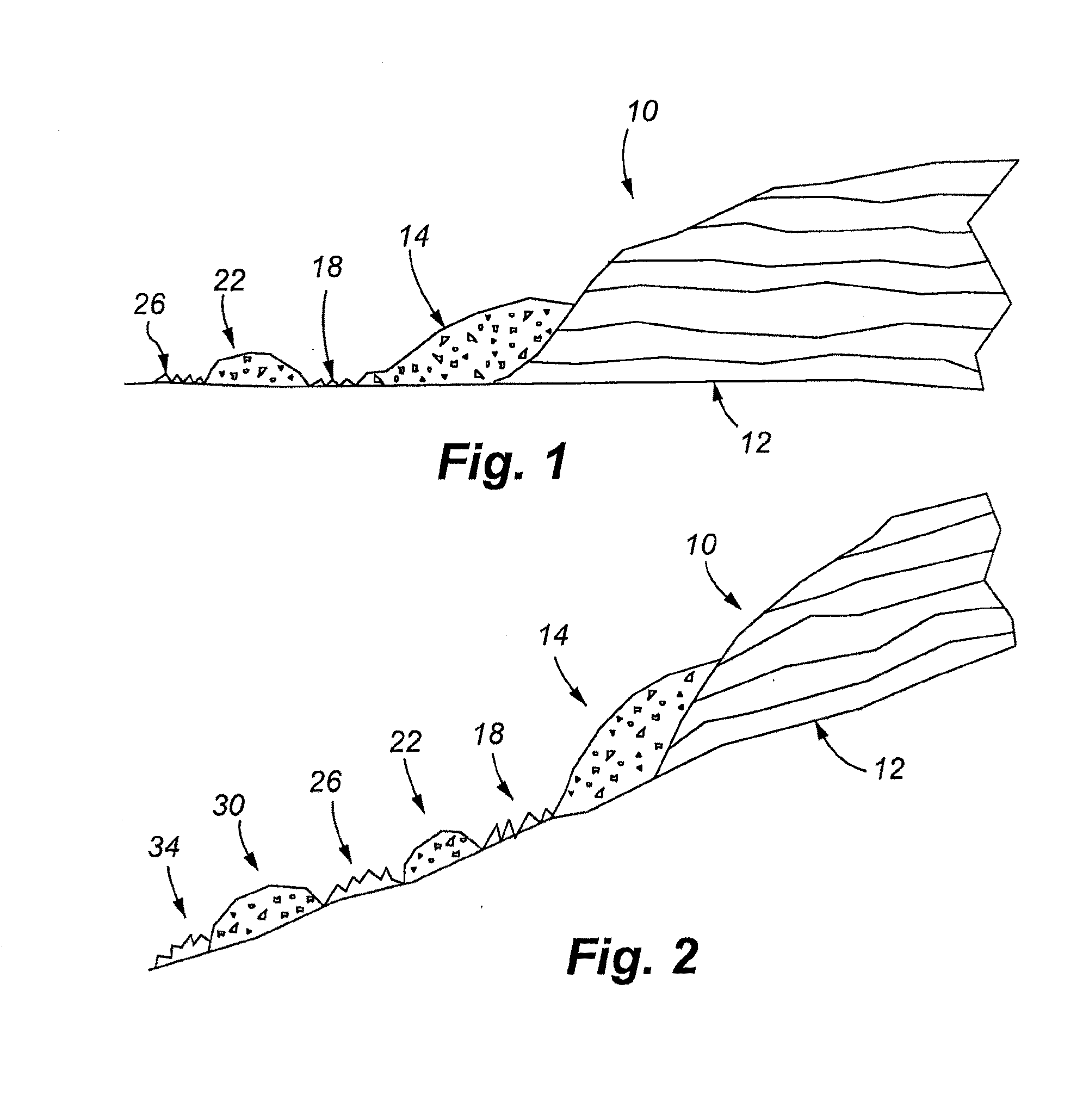

System and method of dewatering dredge spoils using sloping drain barge

InactiveUS20060162195A1Machines/dredgers working methodsTreatment with anaerobic digestion processesWater channelWater flow

An apparatus for dewatering dredge spoils includes a floating barge having a planar upper surface or deck. One end of the barge, such as the stem, is partially flooded or otherwise ballasted so that the deck slopes downwardly from the bow toward the stem. Dredge spoils removed from a waterway are deposited onto the bow where they flow down toward the stem. A plurality of concrete blocks on the deck form an attenuator that, in turn, defines one or more settling ponds on the surface of the barge. A weir across the stem of the barge forms an additional settling pond at the rear of the barge. Solids suspended in the water removed from the waterway settle out onto the deck when the dredge spoils are deposited onto the bow. Remaining solids suspended in the water deposit onto the deck as the water flows through the settling ponds. The relatively clear water that remains then flows back into the waterway off the stem of the sloped barge after passing through the settling ponds. Because the apparatus and method use materials and equipment, such as the barge and blocks, that are already likely to be on hand, the method and apparatus are particularly economical and easy to implement.

Owner:GEN CONSTR

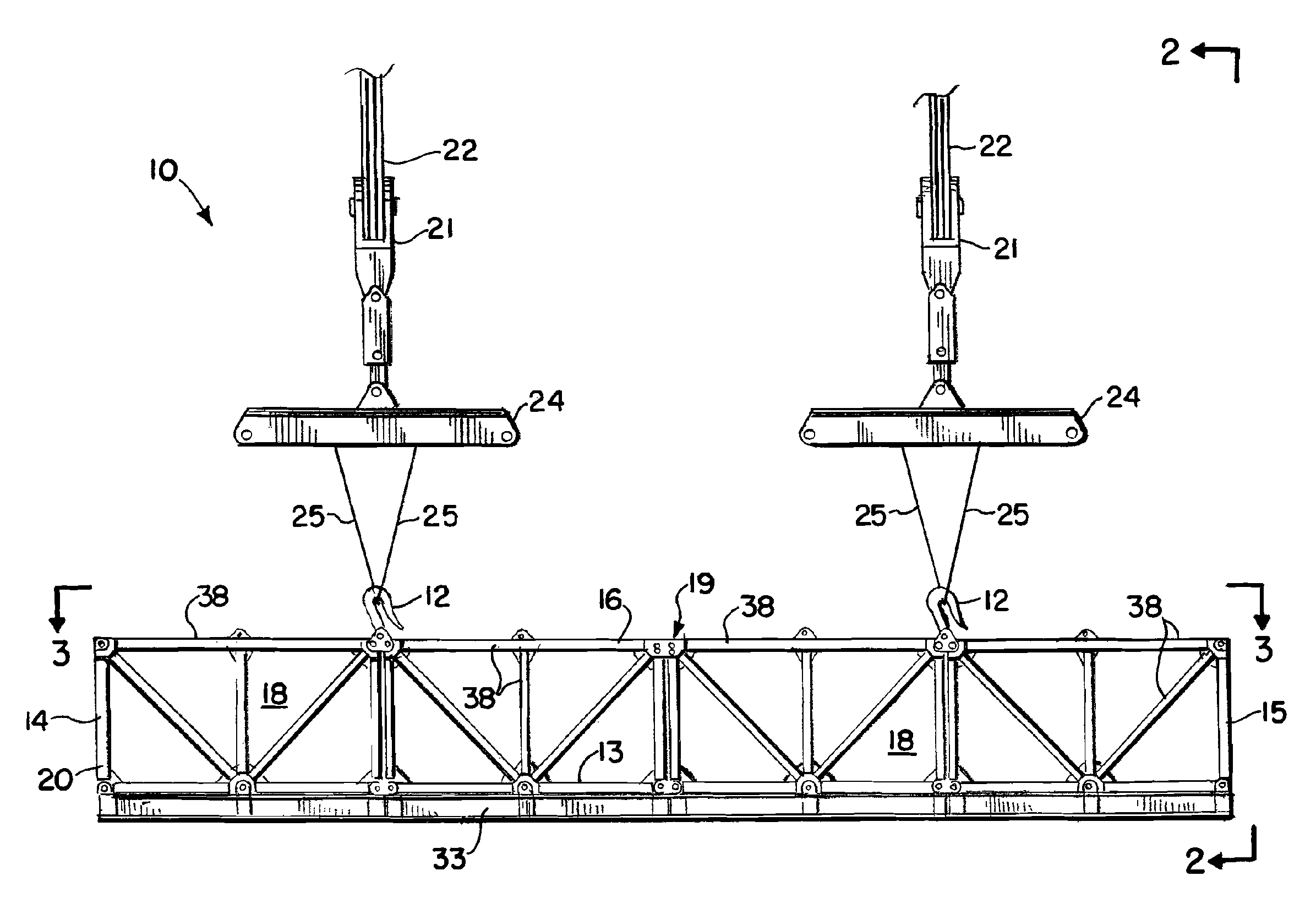

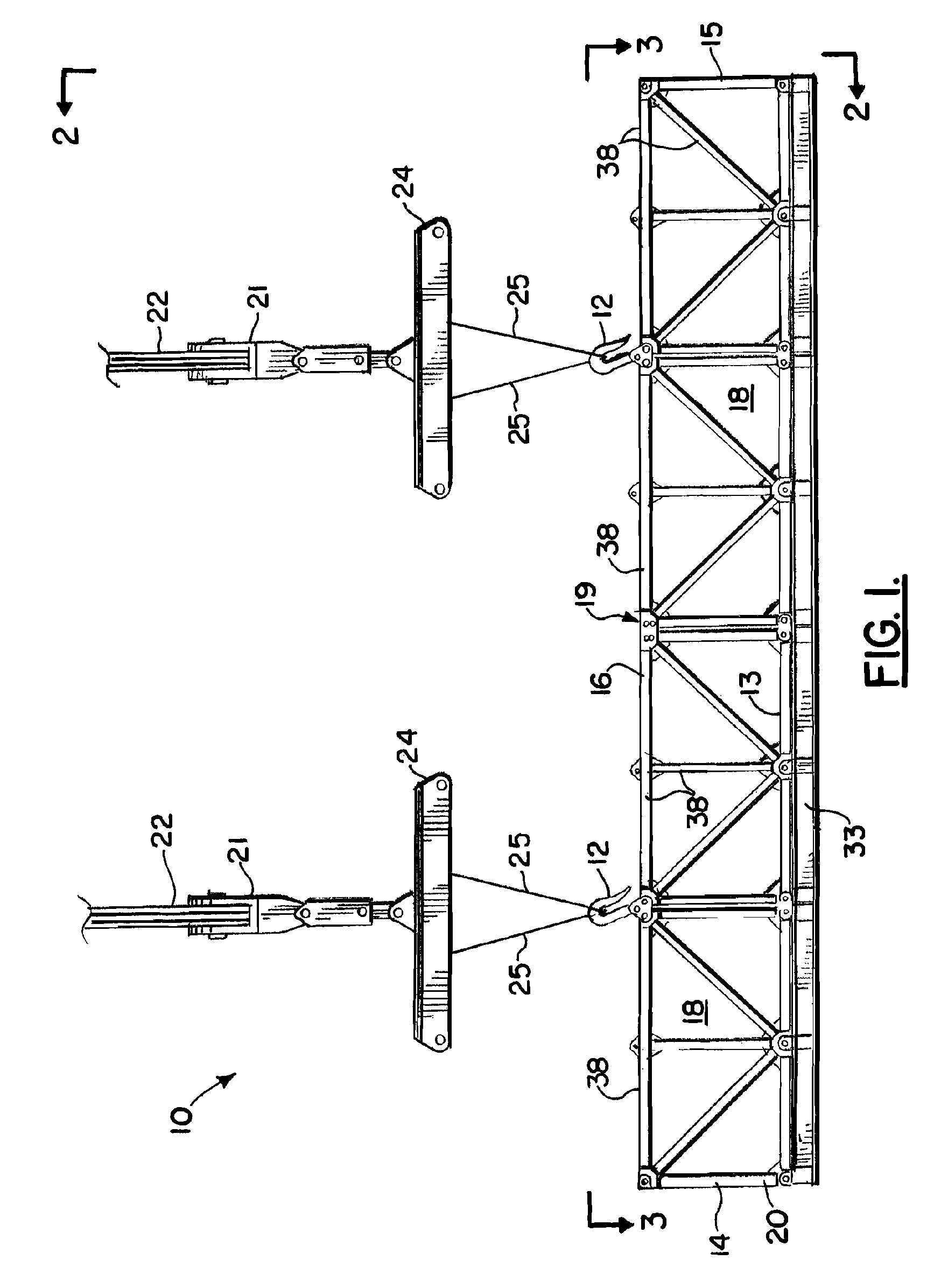

Method and apparatus for providing fluid transfer between a marine platform and a service vessel

The present invention provides a method and apparatus for fluid transfer between a fixed marine production platform and a work vessel (eg. jack up barge). The method includes positioning the work vessel next to the production platform and then adjusting the elevational position of the vessel relative to the production platform so that the deck of the production platform and the deck of the work vessel or at about the same elevational position. A bridge truss spans between the deck portions of the production platform and work vessel, the truss having interconnected truss members and a planar surface that enables flexible hoses to be supported by the truss. The truss further includes a plurality of piping spool pieces that span across the truss. Ends of the spool pieces have quick connect fittings that enable the spool pieces to be quickly connected to the piping system of the production platform and work vessel. The gap between the production platform and the work vessel are spanned with the truss. Piping systems on the production platform and work vessel are connected to the spool pieces at the quick connect fittings so that fluid transfer is enabled between the production platform and the work vessel via the spool pieces on the truss. An upper tray enables flexible hoses (eq. hydraulic hoses) to span between the work vessel and production platform.

Owner:WILLIAMSON JOHN P

Foundation construction barge for immersed tube

InactiveCN102758439AReasonable structural designReasonable layoutFoundation engineeringImmersed tubeWinch

The invention discloses a foundation construction barge for an immersed tube, which is characterized in that a rail extending in the barge direction is arranged on one side of the barge main deck; a travelling mechanism is arranged on the rail and driven by a cable winch; the travelling mechanism comprises an elephant trunk trolley and a flat rammer trolley; the elephant trunk trolley is connected with an elephant trunk system located on one side of the barge; and the flat rammer trolley is loaded with a vibratory hammer and a vibratory hammer lifting system. The foundation construction barge for the immersed tube is reasonably designed in structure, has multiple functions, and meets the engineering requirements of stone transportation, accurate riprap and hammering. The barge is highly effectively to operate, flexible and can realize the area construction requirement of a fixed point. The barge can be formed by modifying the prior ship; each device on the barge is reasonably distributed; and the barge can meet the requirements of island tunnel construction, construction safety and reliability.

Owner:CCCC FIRST HARBOR ENG +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com