Enhanced LNG tanker offloading in shallow waters

a technology of lng tanker and shallow water, which is applied in the direction of container discharging from pressure vessels, special dispensing means, coastline protection, etc., can solve the problems of sudden increase in chain tension, increased cost of platform that is large enough to carry such gas heating and pumping systems, and increased cos

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

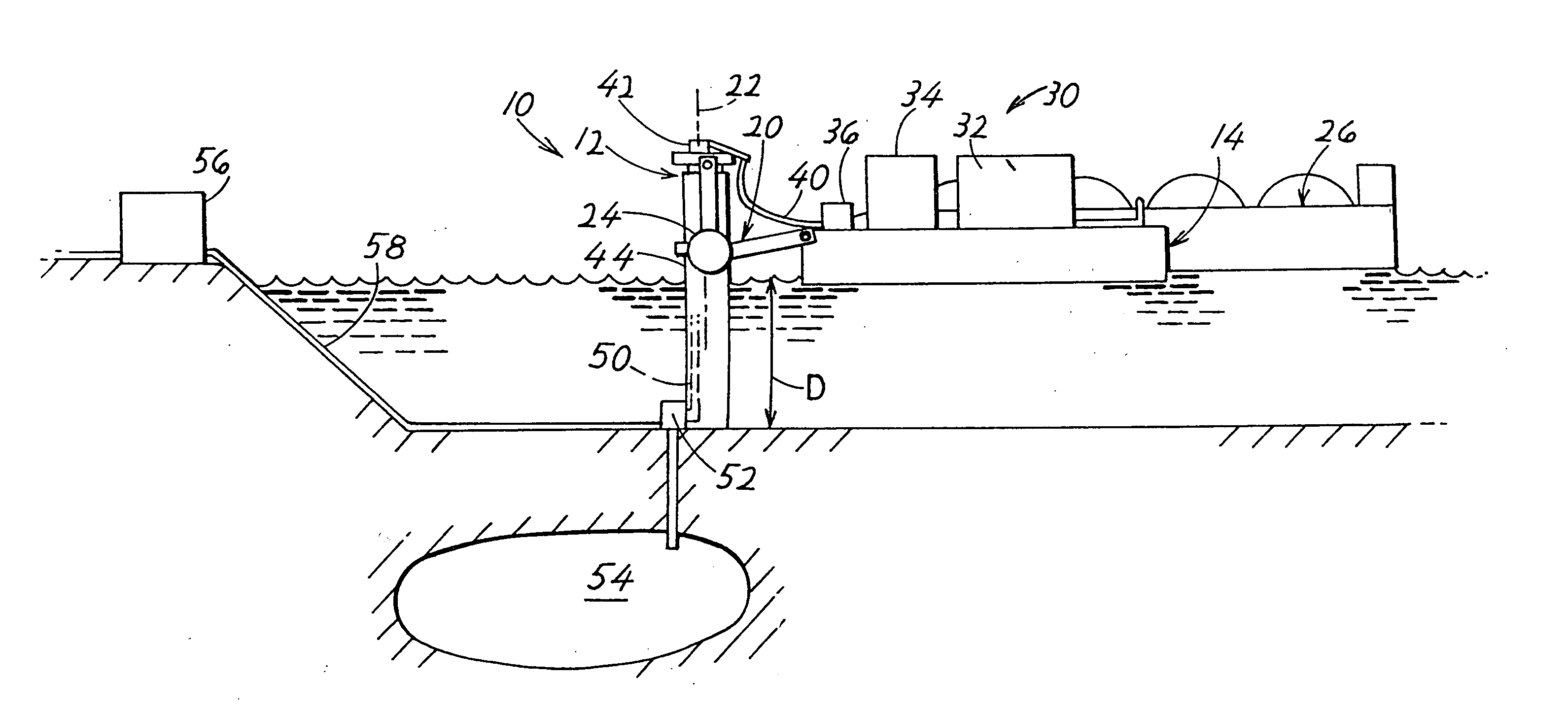

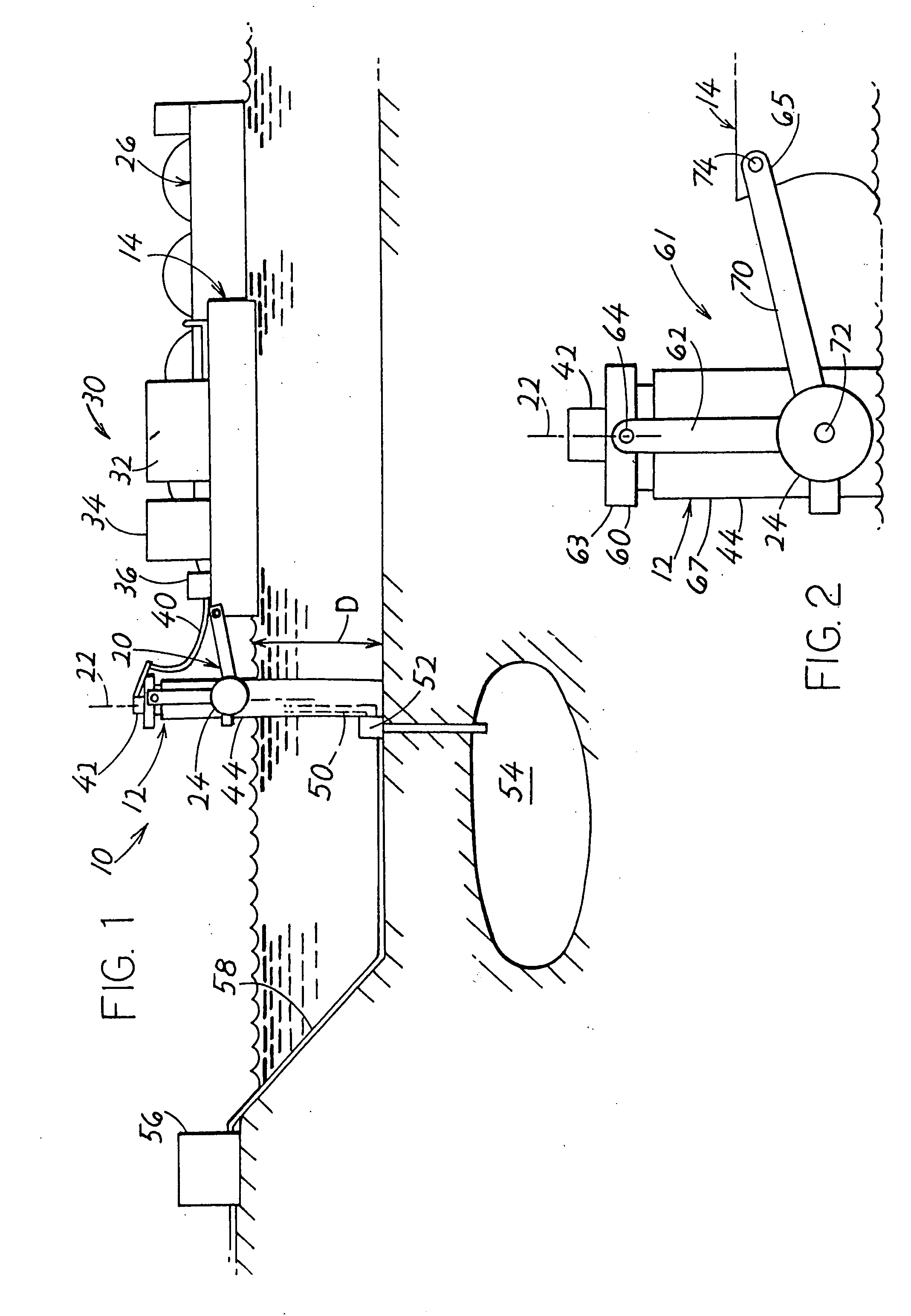

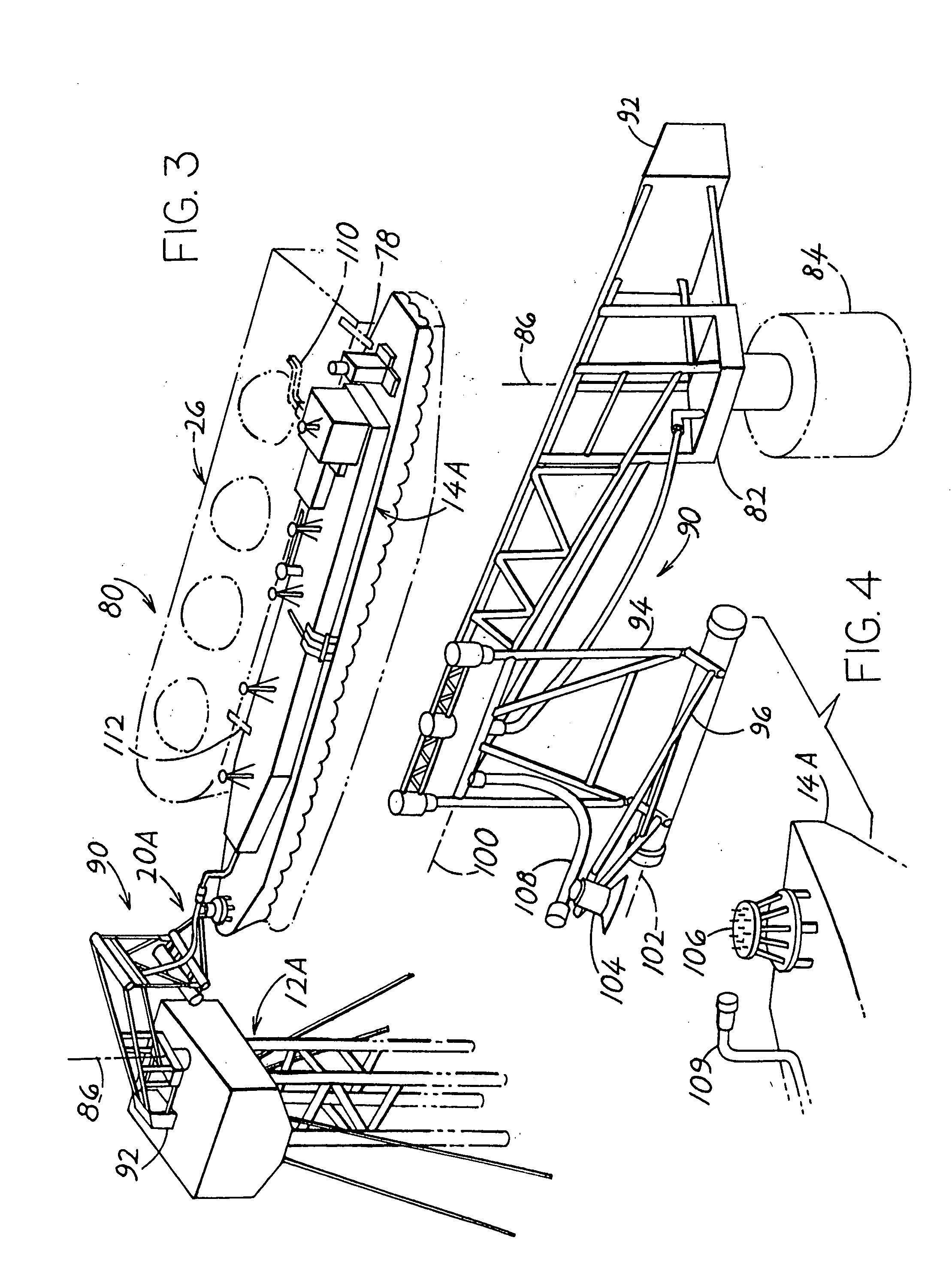

[0020]FIG. 1 illustrates an offloading / injection system 10 for shallow water, in which a moderate cost fixed tower 12 is used in conjunction with a floating and weathervaning structure in the form of a barge 14. A yoke 20 which can rotate around the tower axis 22, allows the floating and weathervaning barge to drift a limited distance away from the tower and urges the barge back towards the tower, as with counterweights 24. Thus, the barge can weathervane, to head in different directions with changes in winds, waves and currents and can move slightly away and back towards the tower to minimize the forces resulting from large waves. A tanker 26 is moored directly to the barge and weathervanes with it.

[0021] The tanker carries cold hydrocarbons that are cooled well below 0° C., and which must be heated to at least 0° C. before they can be pressurized and flowed though a pipeline to shore. The most common type of such cold hydrocarbons is LNG (liquified natural gas) which has been coo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com