Oceanography engineering module integral hoisting method

An overall hoisting and marine engineering technology, applied in the directions of loading/unloading, transportation and packaging, ship parts, etc., can solve the problems of complicated technical preparation, huge materials used for towing tooling, and high cost, so as to avoid the amount of tooling and reduce Reduce shipbuilding costs and improve the effect of effective lifting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

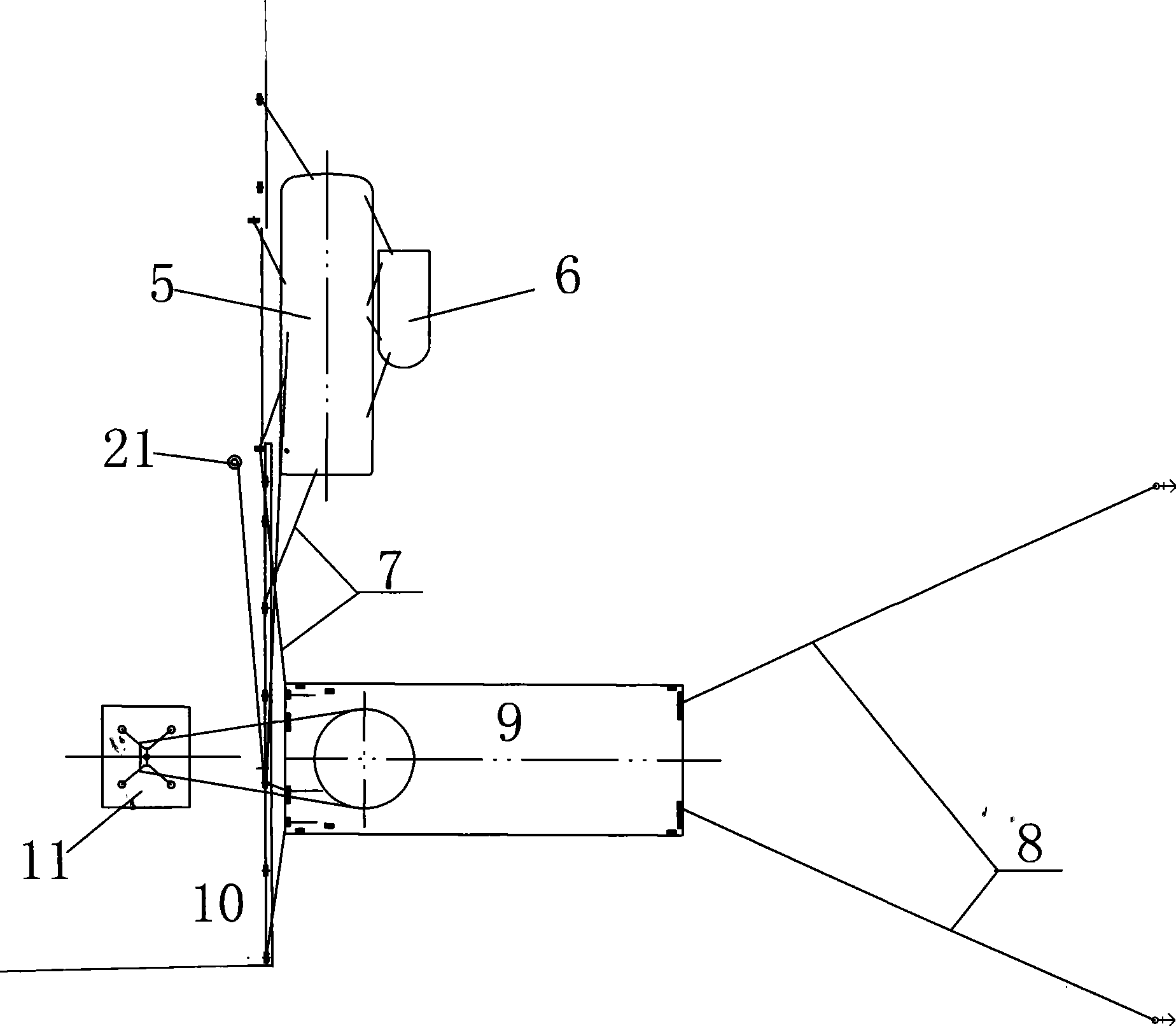

[0023] The overall hoisting method of the marine engineering module of the present invention mainly adopts floating cranes and special hanging beams. First, the large-scale modules are hoisted from the land to the barge, and the barge is used to transfer the modules to the deep water area where the main ship system to be built is moored. Ballasting, lowering the freeboard height, and then hoisting the modules from the barge to the main hull allows for the lifting of larger modules with the height of a smaller floating crane.

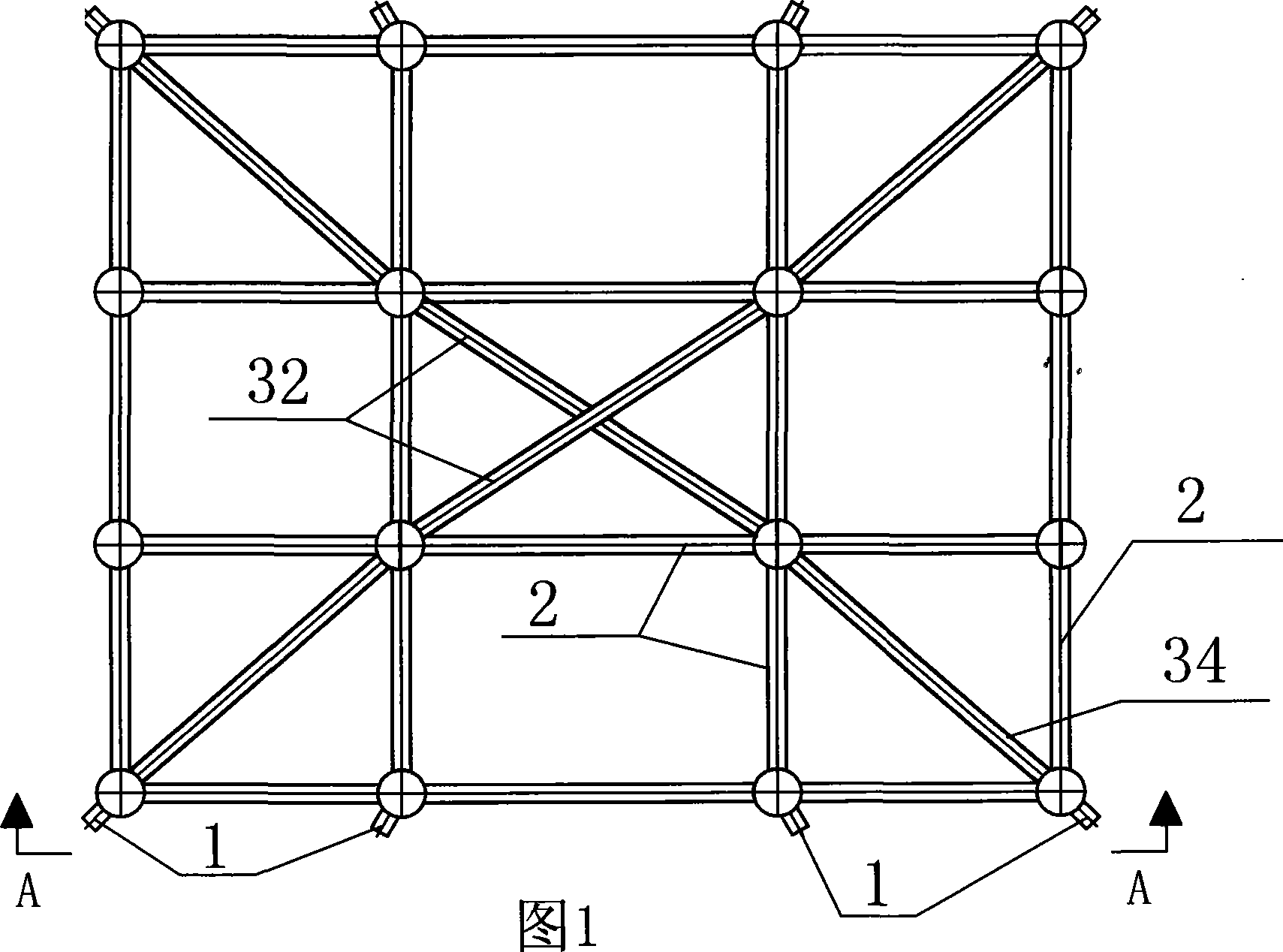

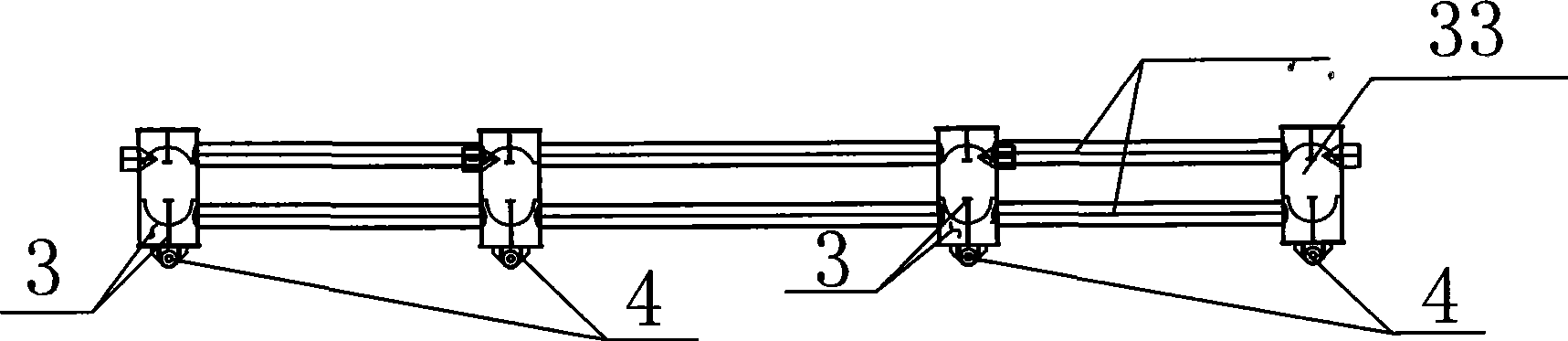

[0024] As shown in Figures 1 and 2, the structure of the special hanging beam used in the present invention includes two layers of corresponding parallel steel pipes 2 that are respectively welded and fixed into a square "grid" structure. At the intersection of each "grid", two layers of parallel steel pipes are respectively welded and fixed on a vertical steel pipe 33, and the lower end of each vertical steel pipe 33 is fixed with a suspension ring 4. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com