Transformer substation hoisting device with adjustable hoisting arm

A hoisting device and substation technology, applied in cranes and other directions, can solve the problems of laborious operation and unadjustable boom length, and achieve the effect of strong applicability and manpower saving

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

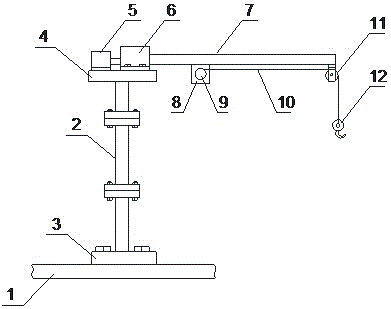

[0018] Such as figure 1 As shown, the present invention provides a hoisting device for a substation with an adjustable boom, which includes a base 1, a support body 2, a telescopic drive mechanism 5, a fixed seat 6, a boom 7, a motor 8, a rotating roller 9, a suspension rope 10, and a fixed pulley 11 and hook 12, the bottom of the support body 2 is set on the base 1, the boom 7 is horizontally set above the support body 2, the top of the support body 2 is provided with a top plate 4, and the telescopic drive mechanism 5 and the fixed seat 6 are fixed on the top plate 4, the fixed seat 6 is provided with a slider, and the telescopic part of the telescopic drive mechanism 5 is connected with the slider; Set on the mounting lug; the motor 8 is fixedly connected to the boom 7, and the output shaft of the motor 8 is connected to the rotating roller 9 through a coupling; one end of the suspension rope 10 is wound on the rotation roller 9, and the other end of the suspension rope 10 ...

Embodiment 2

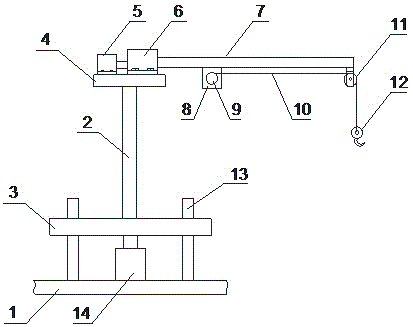

[0024] Such as figure 2 As shown, the structure of this embodiment is basically the same as that of Embodiment 1, the difference is that the support body 2 of this embodiment is a whole, the support base 3 at the bottom of the support body 2 is a square plate structure, and the base 1 is provided with four A guide column 13, the center of the four guide columns 13 is provided with a jack 14, the support base 3 is arranged on the four guide columns 13, and the support base 3 can move up and down along the guide column 13 under the action of the jack 14. This embodiment is different from the lifting method adopted by the support body of embodiment 1. This embodiment uses the jack 14 to realize the lifting of the support body 2, and does not need manual disassembly to increase or decrease the number of segments of the support body 2, so that the operation is more convenient and flexible .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com