Mechanical lifting gripper

A technology of machinery and booms, applied in the field of mechanical lifting grippers, can solve the problems of manpower consumption, material resources, slow work efficiency, etc., and achieve the effect of improved work quality, high work efficiency and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention is described below in conjunction with accompanying drawing.

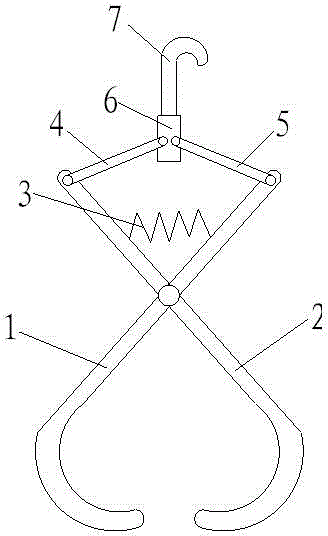

[0014] see figure 1 , a mechanical lifting gripper, including a first lifting arm 1 and a second lifting arm 2, the middle position of the first lifting arm 1 and the second lifting arm 2 is hinged, and the first lifting arm 1 and the second lifting arm The hook part of the arm 2 is in the shape of a half-moon. In actual use, the structural dimensions of the first lifting arm 1 and the second lifting arm 2 are the same. Between the first lifting arm 1 and the second lifting arm 2, a horizontally arranged spring 3 is arranged at the upper end of the hinge, and the spring 3 can keep the first lifting arm 1 and the second lifting arm 2 open when the cargo is not lifted state, the upper end of the first lifting arm 1 is hinged to one end of the first connecting rod 4, the upper end of the second lifting arm 2 is hinged to one end of the second connecting rod 5, and the first connecting rod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com