Patents

Literature

94 results about "Boat building" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shaft, rudder system mounting process of ten-thousand-ton grade special multipurpose vessel

The invention discloses a mounting process for shaft and rudder systems of a 10,000-ton class special multipurpose vessel, which comprises the following steps: a. before the vessel is launched, a center line of the shaft system and a center line of the rudder system are determined; b. a stern tube is positioned and poured with epoxy, the vessel is launched after a waterproof close board is arranged; and c. a screw shaft, a propeller, a tiller and a rudder blade are arranged. Through adopting the way, the mounting process for shaft and rudder systems of the 10,000-ton class special multipurpose vessel overcomes the inconvenience that the screw shaft, the propeller, the tiller and the rudder blade of the vessel are all placed on a slipway for installation before the vessel is launched in the prior art, and makes the vessel launch after the shaft line and the ruder line are determined and checked, thereby saving time for preparing the screw shaft, the propeller, the tiller and the rudder blade of the vessel, shortening the construction cycle of the vessel, improving the utilization rate of the longitudinal slipway for a ship-building unit to construct the vessel, and reducing the production cost.

Owner:JIANGDONG SHIPYARD CHINA NAT CHANGJIANG SHIPPING COOPERATION

Oceanography engineering module integral hoisting method

The invention discloses a method used for realizing the integral lifting of marine engineering modules in the marine engineering field. After the module is constructed integrally, the invention makes use of floating cranes, barges and special crane beams to realize the integral lifting of modules on water by regulating the sea gauge of a main hull. Compared with the similar technology, the invention has the following advantages that the preparation of special crane beams can reduce the length of lifting cables so as to enhance the effective lifting height of floating cranes; and the adopting of the floating crane to lift the modules to the barges can avoid the use of a plurality of fittings used for conveying so as to reduce the cost. Simultaneously, the deep water is adopted to moor the main ship so as to ballast the main hull and reduce the height of the freeboard and then the high lifting capability of the floating crane is enhanced and the shipbuilding cost is reduced finally.

Owner:DALIAN SHIPBUILDING IND

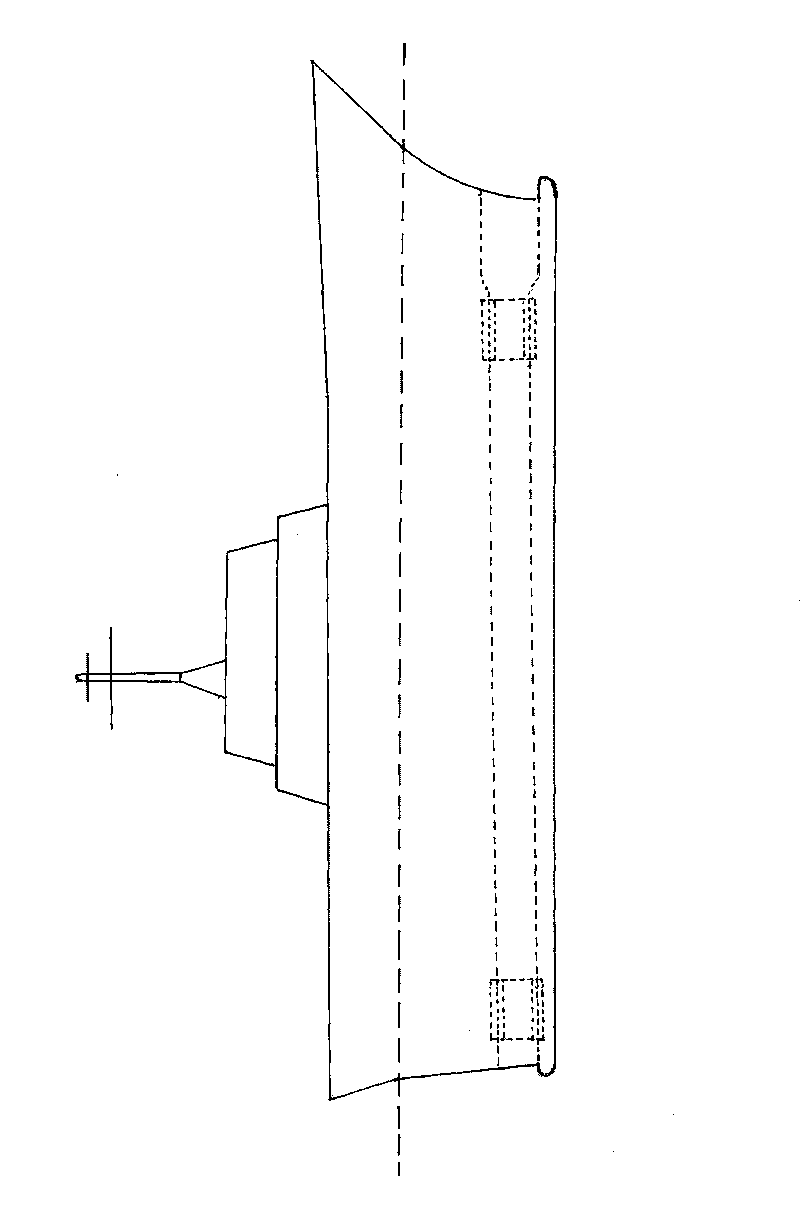

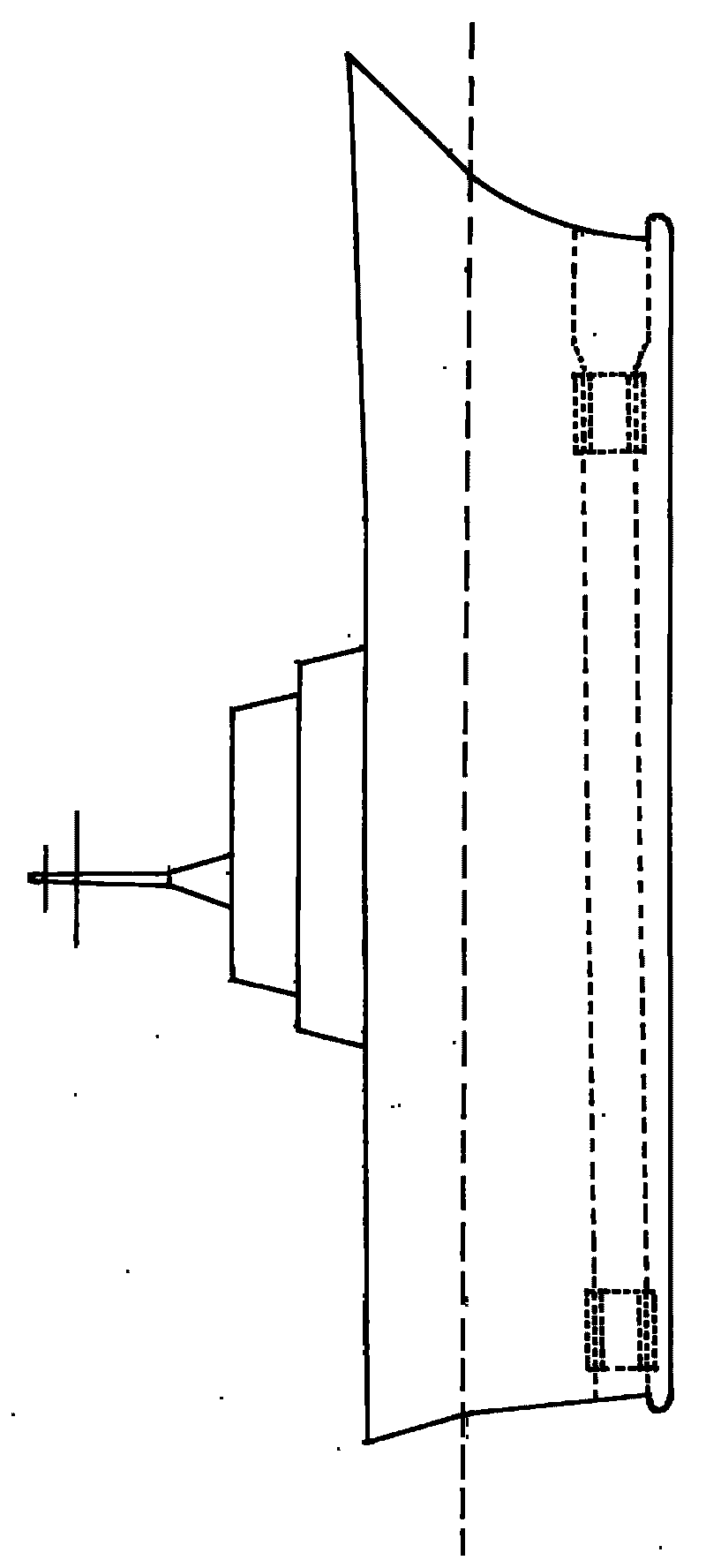

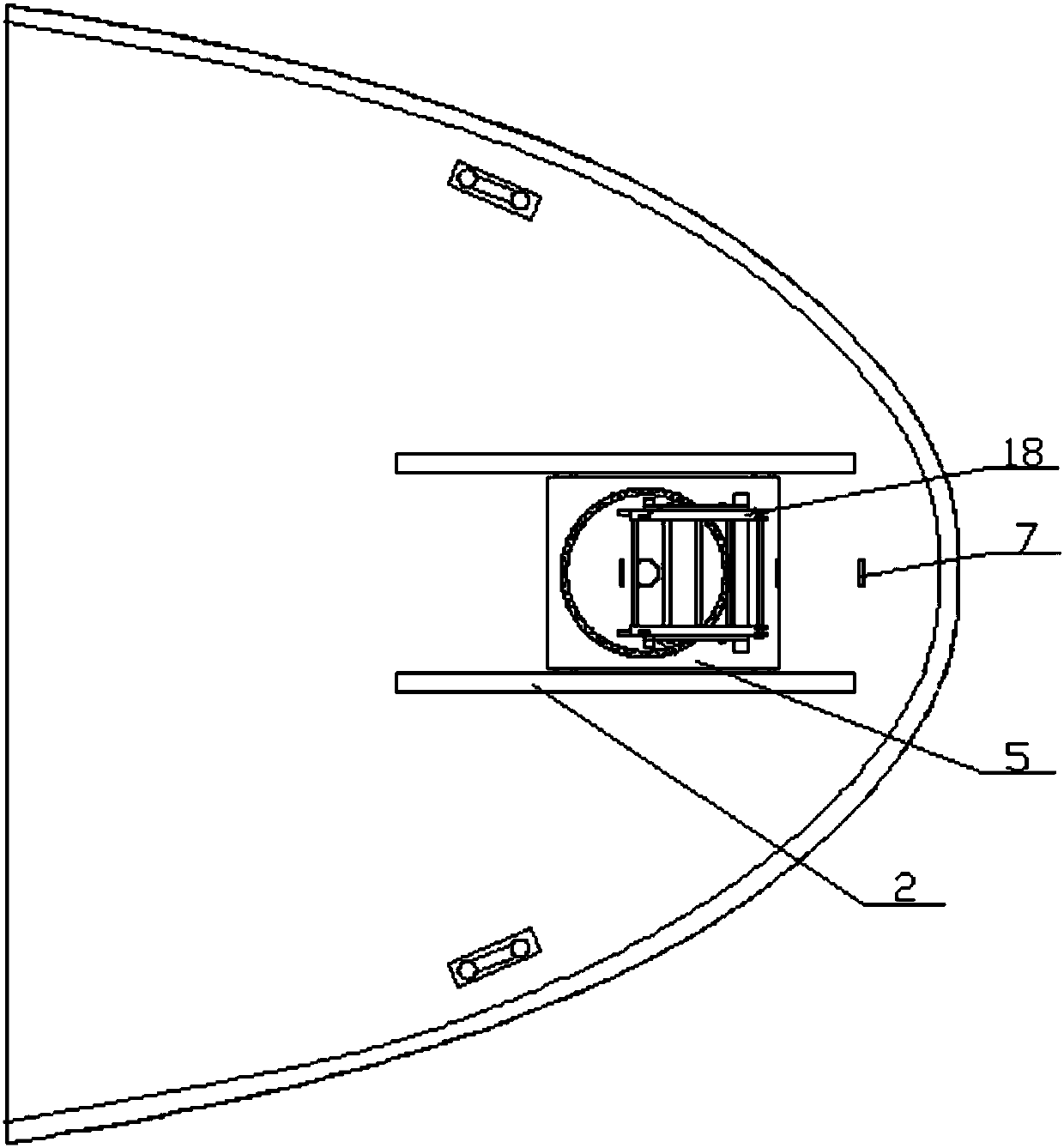

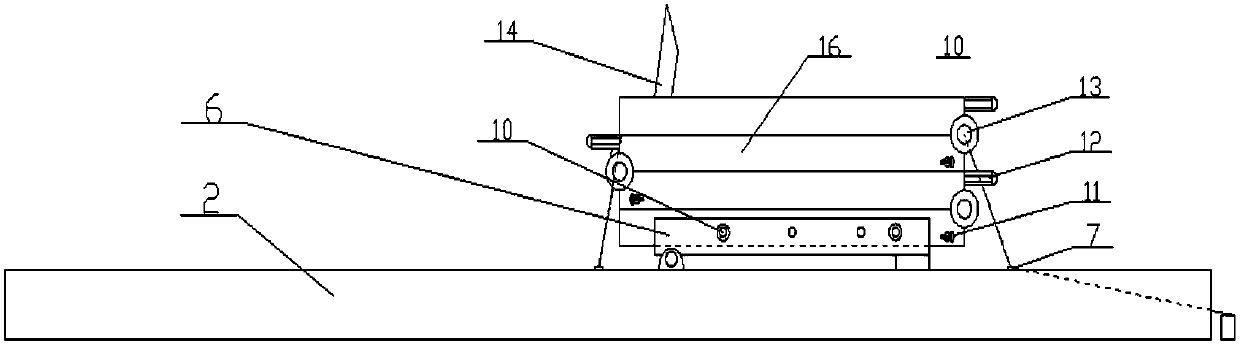

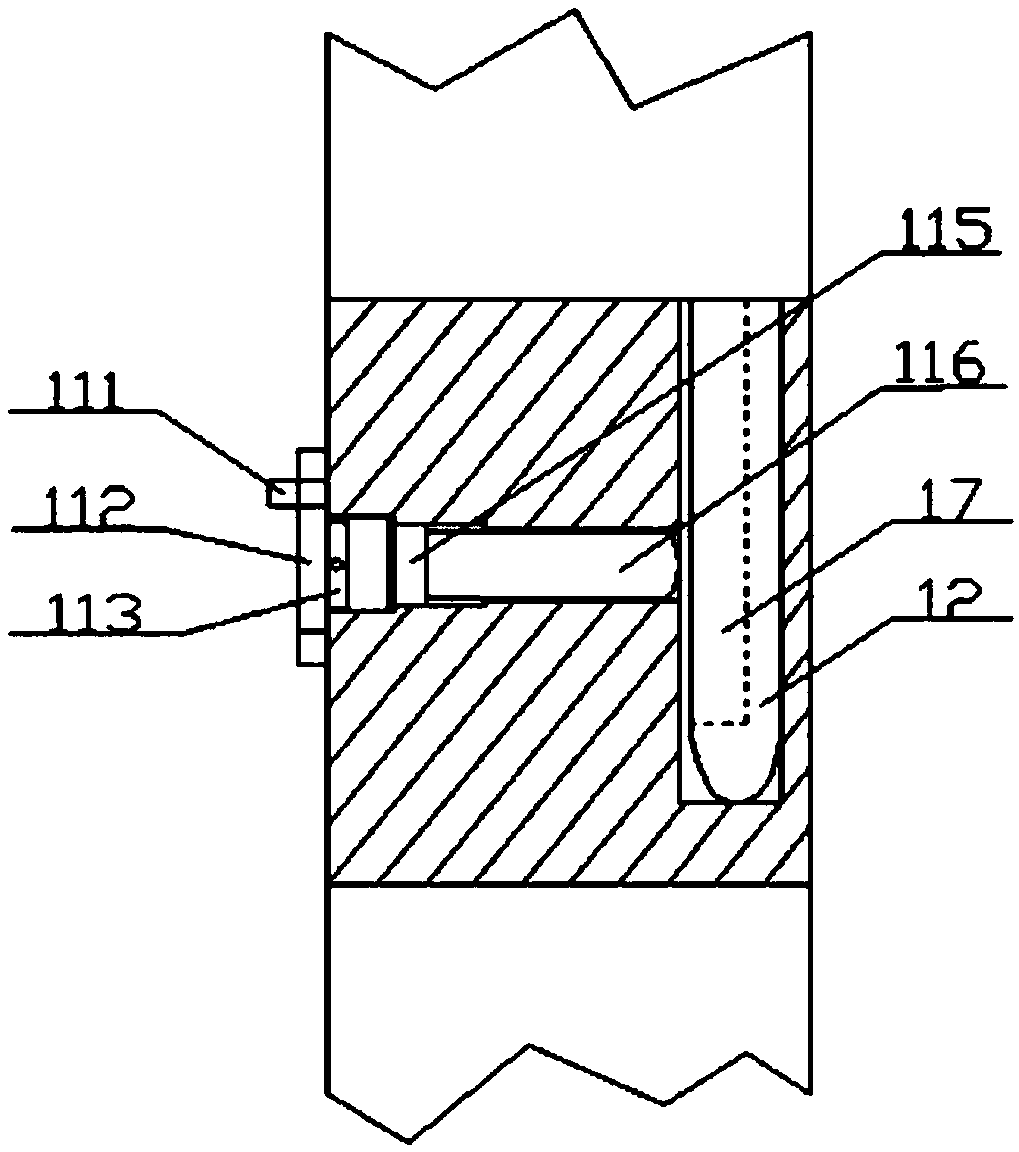

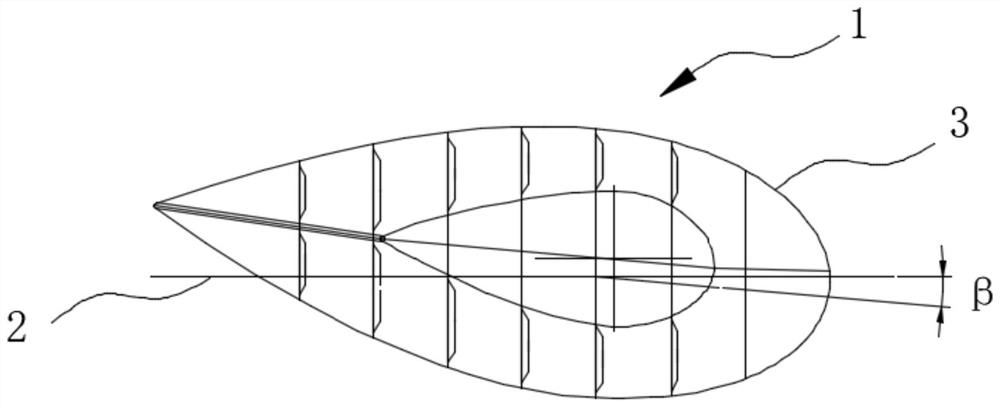

Vehicular bulbous bow integral-replacing process

ActiveCN103192952AShorten docking periodReduce labor intensityVessel partsStructural engineeringMechanical engineering

The invention discloses a vehicular bulbous bow integral-replacing process and belongs to the technical field of ship repair and construction. By sectionally prefabricating and assembling a new bulbous bows and cutting an old bulbous bow, the vehicular bulbous bow integral-replacing process mainly includes steps of marking a positioning line, a datum line and a guide line on a dock bottom surface, arranging and adjusting a docking block, additionally arranging lifting buttresses on two sides of a bow portion, integrally packing the old bulbous bow and the new bulbous bow, disposing a split positioning machine and accurately centering, positioning and folding. The vehicular bulbous bow integral-replacing process has the advantages that docking period is shortened to 15 days from existing 30-40 days; prefabricating and assembling of the new bulbous bow are realized in a machine room, engineer quality and construction accuracy can reach novel shipbuilding level; operation is convenient, reliable and quick, alignment speed and accuracy are greatly increased, workload is greatly reduced, and labor intensity and labor cost are reduced; occupation time of shipyard equipment and facilities is short, and production cost of replacement of the bulbous bow is reduced. The vehicular bulbous bow integral-replacing process can be widely used for the fields of ship repair and construction.

Owner:QINGDAO BEIHAI SHIPBUILDING HEAVY IND CO LTD

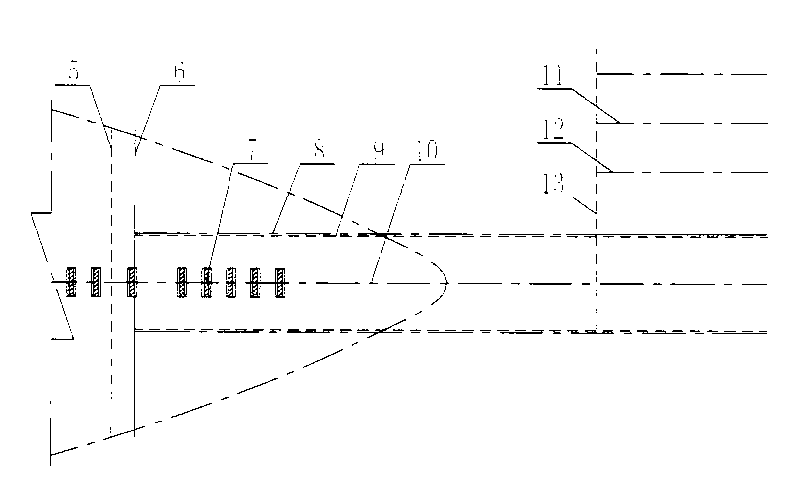

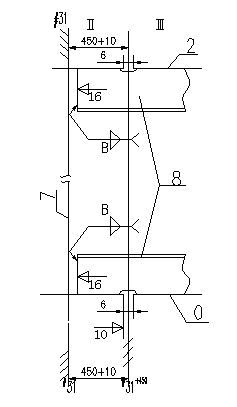

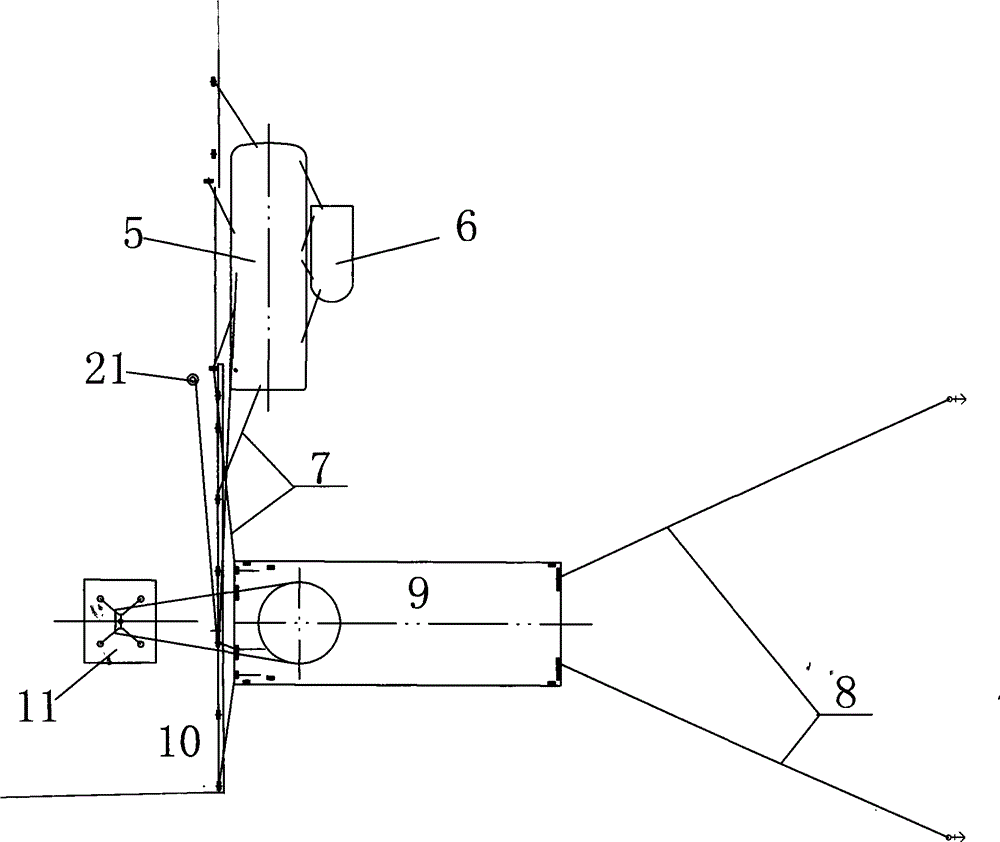

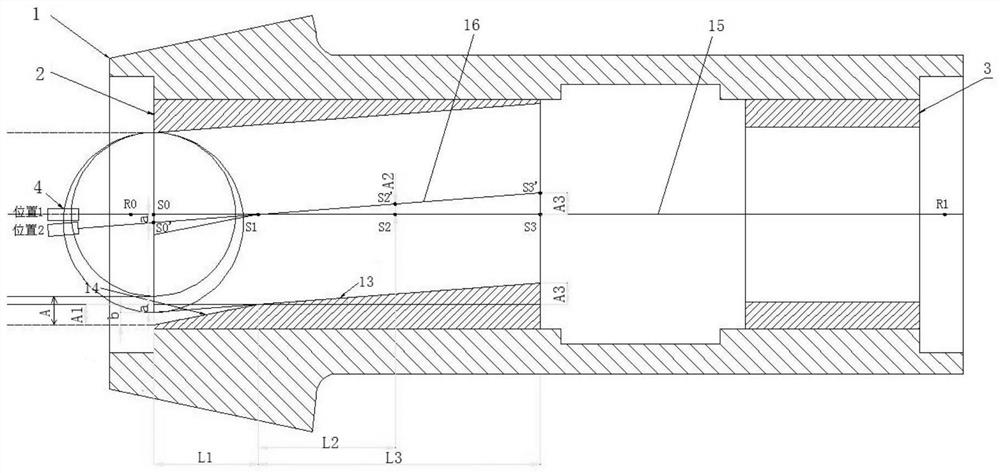

Process for shafting and rudder system installation of multi-purpose ship

InactiveCN107640282AShorten the construction periodShorten the timeVessel partsPropellerBuilding unit

The invention discloses a process for shafting and rudder system installation of a multi-purpose ship. The process includes a step a of determination of a shafting center line and a rudder system center line before ship launching; a step b of stern tube positioning and epoxy casting, installation of a waterproof closure plate and ship launching; and a step c of installation of a tail shaft, a propeller, a rudder stock and a rudder blade. The process for shafting and rudder system installation of the 10000-ton special multi-purpose ship is in such a mode such that the problem that in the priorart, the ship tail shaft, the propeller, the rudder stock and the rudder blade must be all complete on a shipway before the ship launching to be installed, so that inconvenience is caused is solved; after the shafting and the rudder system are determined and undergo inspection on the shipway, the ship launches, the time of preparing the ship tail shaft, the propeller, the rudder stock and the rudder blade is saved, the ship building cycle is shortened, the utilization rate of a longitudinal slipway of the ship built by a ship building unit is improved, and the manufacturing cost is reduced.

Owner:南通如港船舶配套机械有限公司

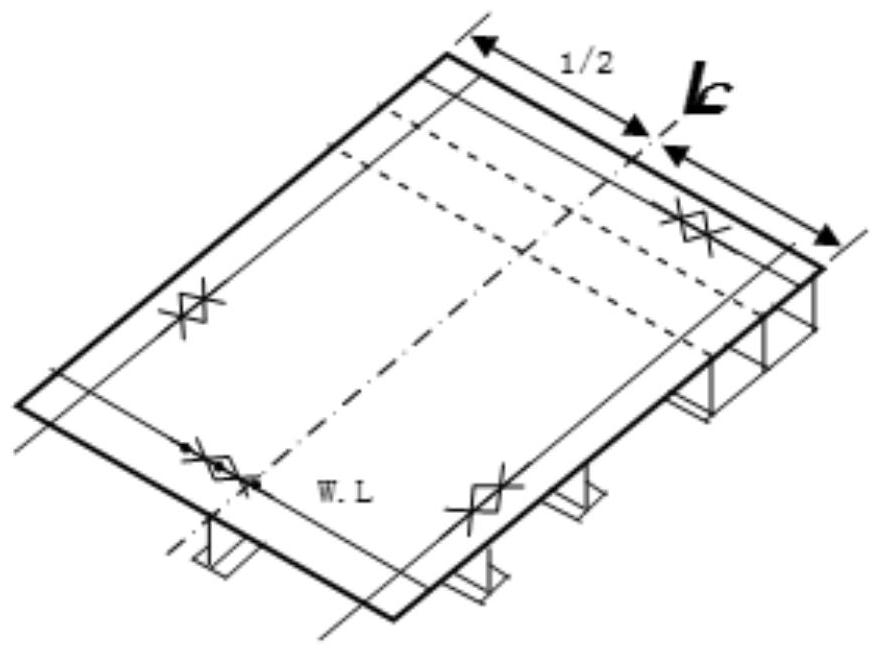

Technology for reducing allowance cutting during ship building

The invention relates to a technology for reducing allowance cutting during ship building. In the technology, a hull is firstly divided into a plurality of general sections for building; and the general sections are gathered up. The invention is characterized in that in the step of lofting and baiting of parts, section allowance, slipway allowance, compensation dosage and material cutting are additionally and respectively placed once on a deck, a strake, a longitudinal bone, a rib, an enforced bone, a wall plate and other structures of each typical node according to section splicing or section butt joint and other different forms; in the step of the whole building of the general sections, when the joint of one of two general sections is provided with a transversal bulkhead, the two general sections adopt a splicing form, and the general section without the transversal bulkhead is inserted with the general section with the transversal bulkhead for carrying out sintered ceramsite liner welding; and when the joint of the two general sections are not provided with the transversal bulkhead, the two general sections adopt a sintered ceramsite liner welding butt joint form. The invention can determine the size of parts once, and improve the precision of parts manufacturing, thereby avoiding on-site secondary cutting quantity, and providing guarantee for general section construction; and the procedures are shifted forward, thus reducing slipway working capacity and waste backflow volume, shortening building ship period and reducing building ship cost.

Owner:WUCHANG SHIPBUILDING IND

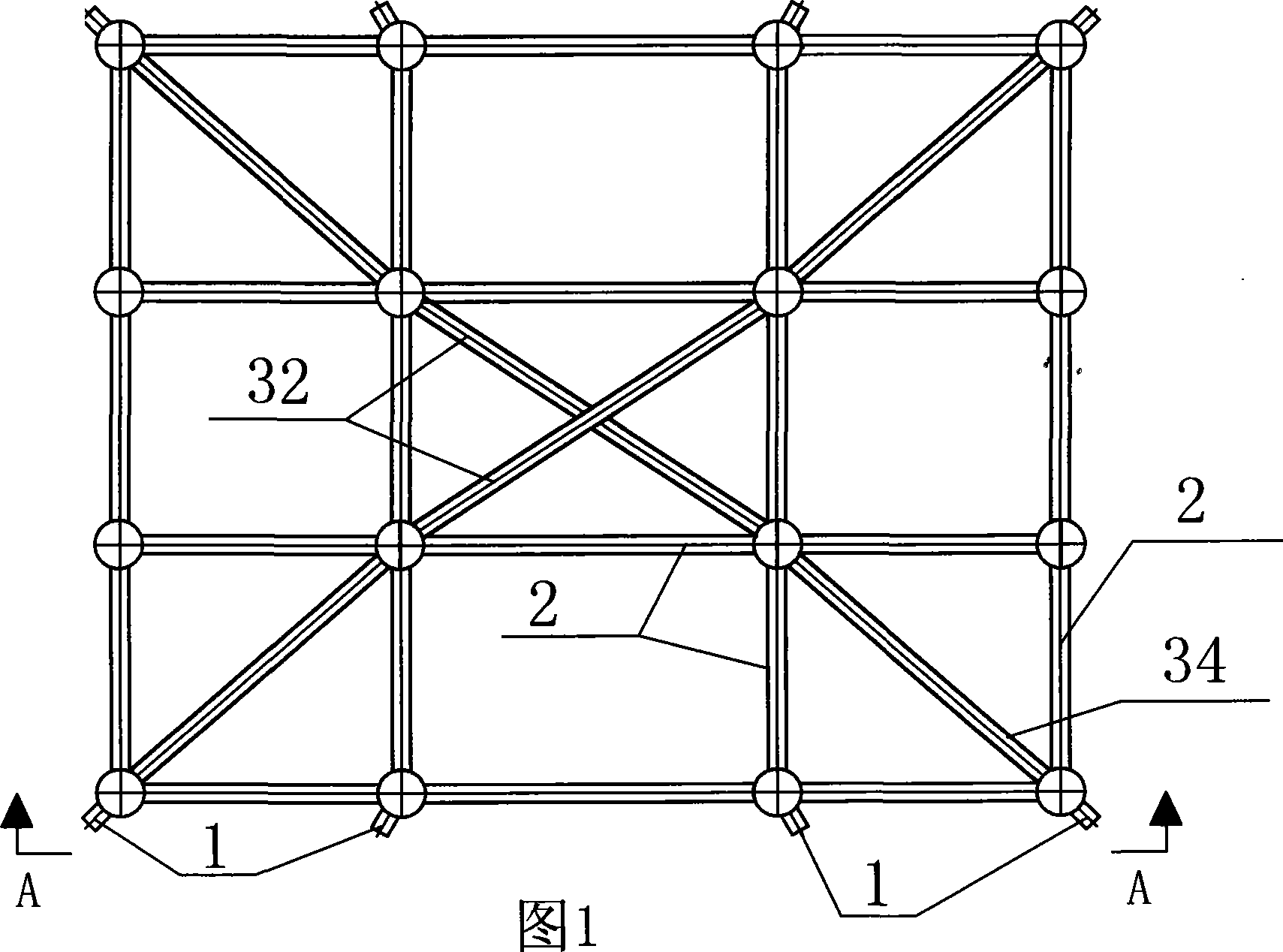

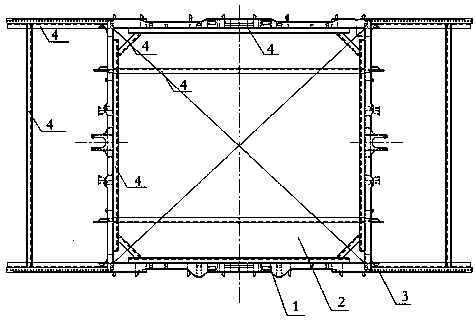

Integrated land leveling construction method for translation type hatch cover system of large ocean-going bulk cargo ship

InactiveCN110877677AImprove work efficiencyMeet the requirementsWaterborne vesselsBulk cargoLine tubing

The invention discloses an integrated leveling construction method for a translation type hatch cover system of a large ocean-going bulk cargo ship. The integrated leveling construction method comprises the following steps: 1, manufacturing a special jig frame on a foundation flat ground; 2, splicing a hatch coaming steel structure on the special jig frame, 3, pre-assembling a hydraulic power pipeline and a cable system on the foundation flat ground, 4, installing the hatch cover on the hatch cover steel structure; 5, installing a reinforcing plate on the hatch cover system, hoisting the hatchcover system to a deck to be assembled, assembled and welded, and fixing a pre-assembled hydraulic power pipeline and a cable system to the hatch cover system and the deck through clamping sleeves. The construction environment coefficient, the construction safety coefficient, the construction production efficiency and the productivity are all improved. A great effect is achieved on preassembly maximization of modern shipbuilding enterprises, the shipbuilding period is shortened, the process precision is guaranteed, and the requirements of ship inspection and shipowners are met.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

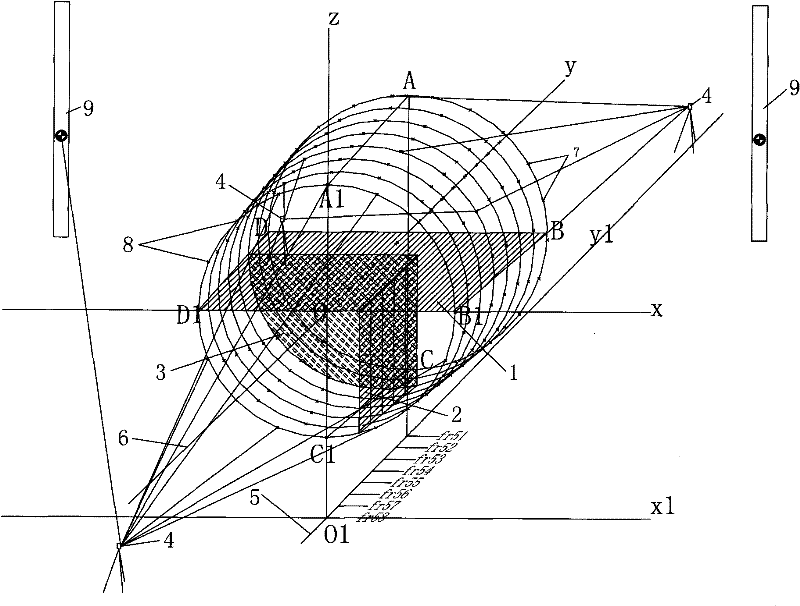

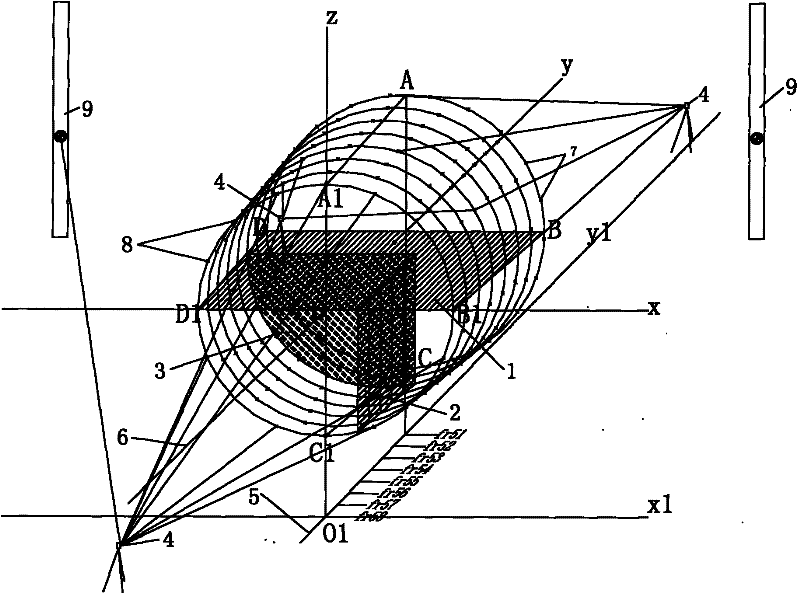

Application method of electronic total station apparatus to ellipticity of submarine

InactiveCN102331238ASpeed up modernizationAccurate measurement accuracyUsing optical meansTheodoliteElectric machinery

The invention discloses a method for measuring the ellipticity of a submarine. An electronic total station apparatus is applied to the field for finishing the measurement of the ellipticity of the whole submarine pressure resisting body, wherein the measuring precision can accurately reach 0.5mm. The electronic total station apparatus is matched with a laser transit for accurately positioning and measuring a submarine body tail shaft, an engine seat, a propulsion motor seat, a sonar support seat and other devices. According to the method, the precision of 1mm before welding and 3mm after welding, which is obtained by positioning sectioned erection of a hull passing in Jin can be reached. The method achieves qualitative leap for accelerating modern construction of Chinese navy and propelling the precision shipbuilding.

Owner:NANTONG YAOSHENG STEEL STRUCTURE

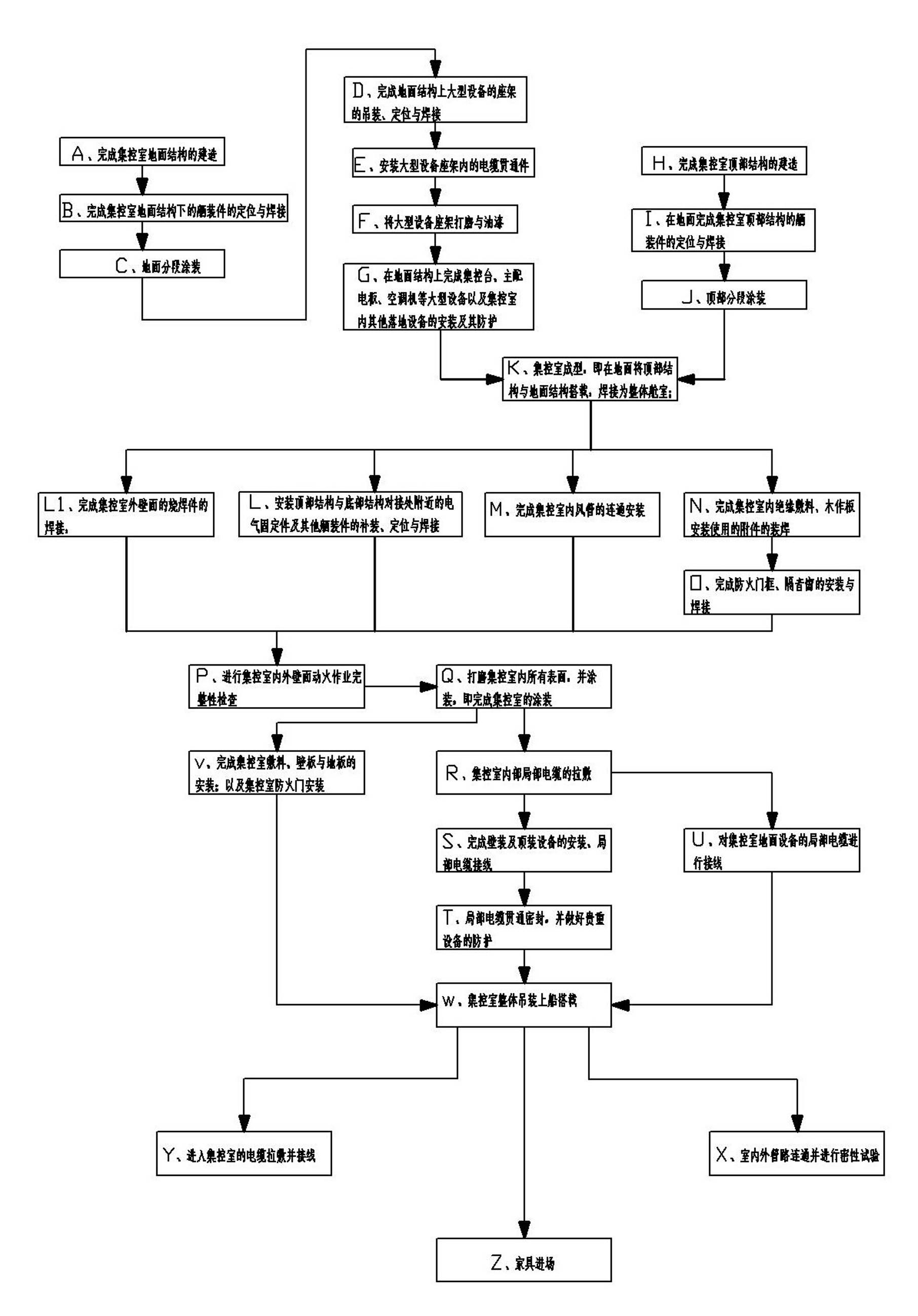

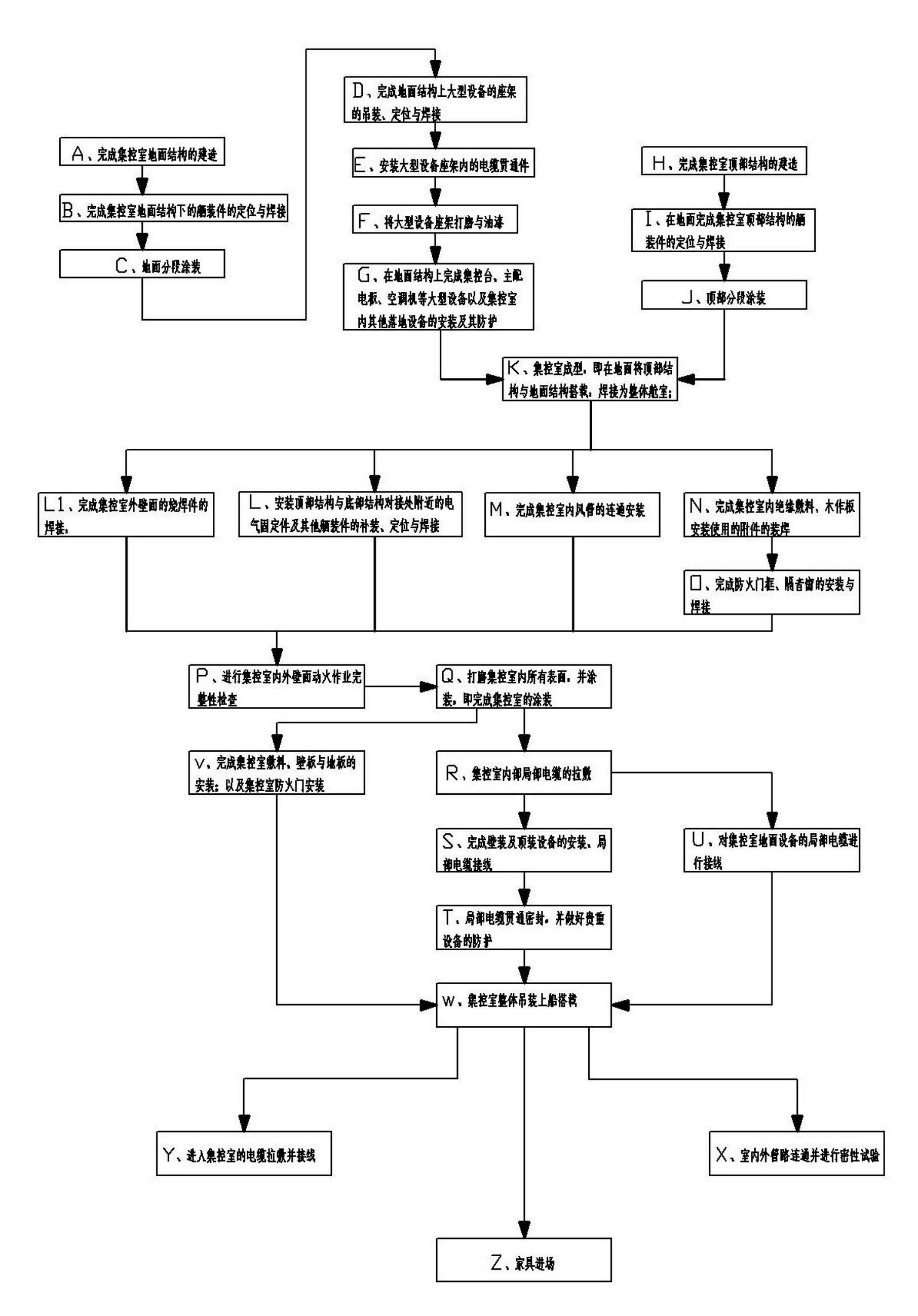

Building process for ship central control room

The invention discloses a building process for a ship central control room. The building process comprises the following steps of: respectively building a ground structure and a roof structure of the central control room; mounting and welding fittings on the ground structure and the roof structure of the central control room; mounting floor type large equipment on the ground structure, mounting the ground structure and the roof structure and welding the ground structure and the roof structure into a whole cabin; finishing hot work, such as complementary welding, for all the fittings of the connecting parts of wall surfaces; polishing and coating all the outer surfaces in the central control room; and finishing all mounting works of electric mounting, mechanical mounting and room mounting of the central control room. According to the building process for the ship central control room, all the fitting project (electric mounting, mechanical mounting and room mounting) mounting works of the central control room are finished before the central control room structure is mounted on a ship and an engine cabin is formed, so the workload after the central control room is mounted on the ship is greatly reduced, the whole period for building a dock (a ship platform) is shortened, and the ship building efficiency and the lean ship building capability of a shipyard are improved.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

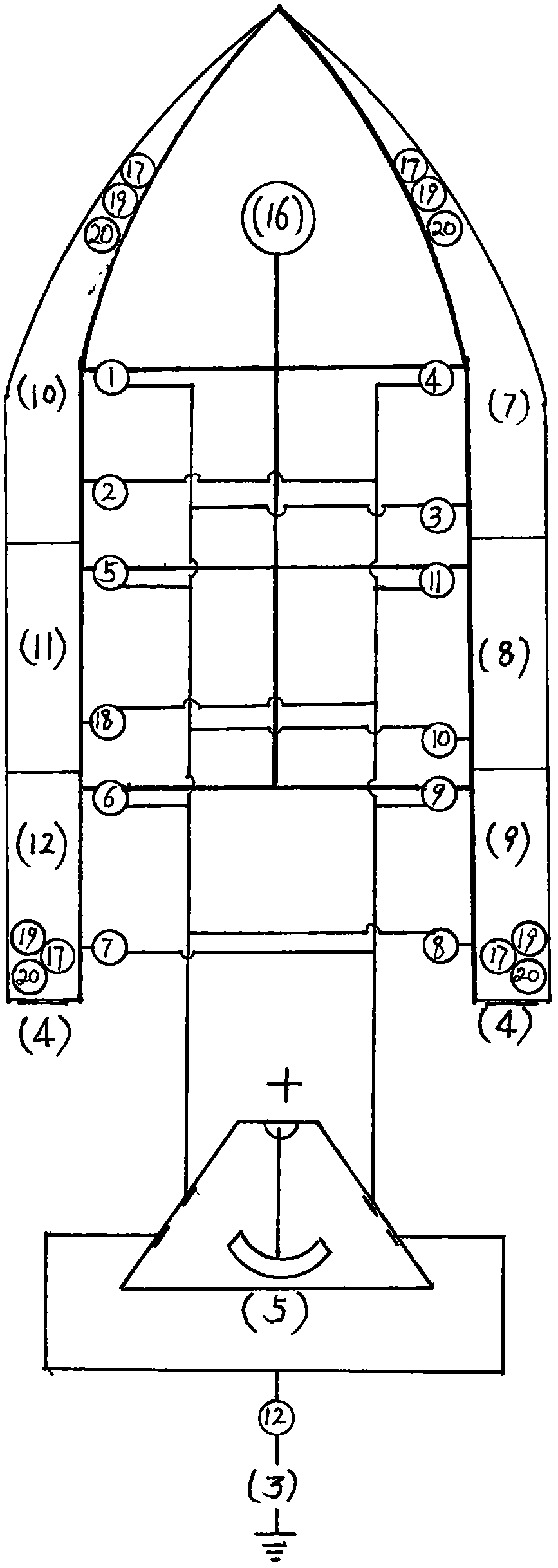

Water-swallow ship form

The invention relates to a technique for a 'water-swallow ship form' design, which belongs to the field of shipbuilding, and is suitable for manufacturing ships of which the prows have certain draughts during advancing, but is not suitable for manufacturing the ships of which the prows have shallow draughts during advancing, such as speed boats, small-sized yachts, wooden boats and the like. The 'water-swallow ship form' design is an effective method for reducing the water resistance for a boat during advancing. The basic principle of the 'water-swallow ship form' design is that the inner part below a draught part of a ship is designed and manufactured with a water flow pipeline with a larger front part and a smaller rear part, and a water flow accelerator is arranged in the pipeline. Thus, when the ship moves forwards, a part of water in front of the prow is smoothly swallowed into the water flow pipeline, and the water is accelerated by the water flow accelerator and flows backwards. The water flow is accelerated for one time even more times and is finally spurted out at a high speed from an outlet of the water flow pipeline below the stern. Therefore, the swallowed water not only reduces the resistance to the ship during advancing, but also plays a role in driving the ship forwards and becomes the main power for driving the ship to move forwards. Although the water flow pipeline occupies certain space in the lower part inside the ship, the ship obtains the power for moving forwards and accelerates the advancing speed of the ship while reducing the water resistance. Obviously, the advantages far outweigh the disadvantages.

Owner:王久泉

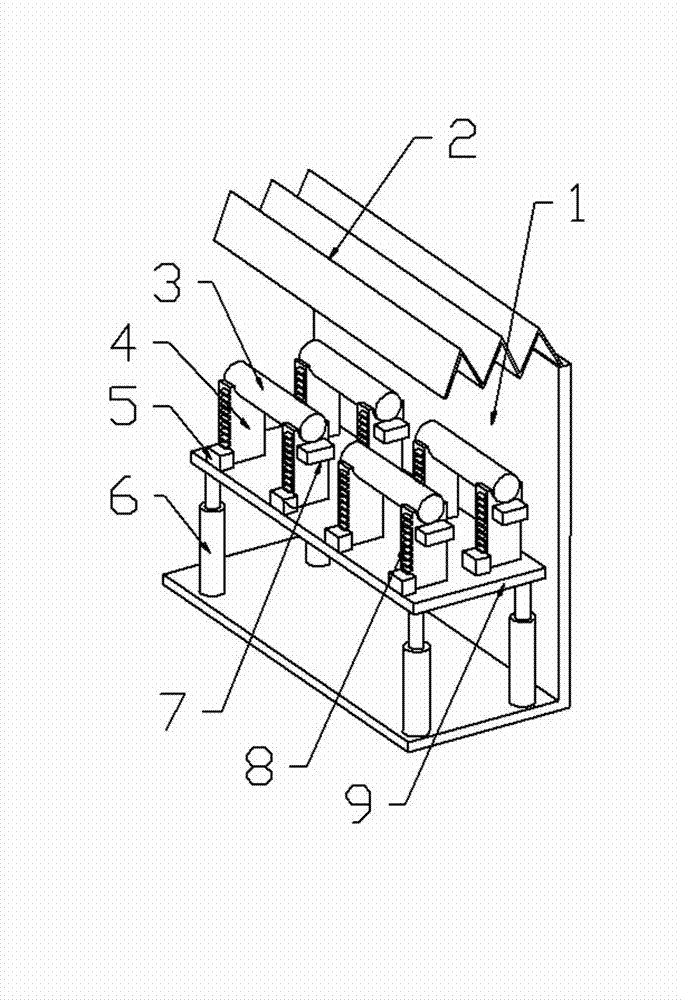

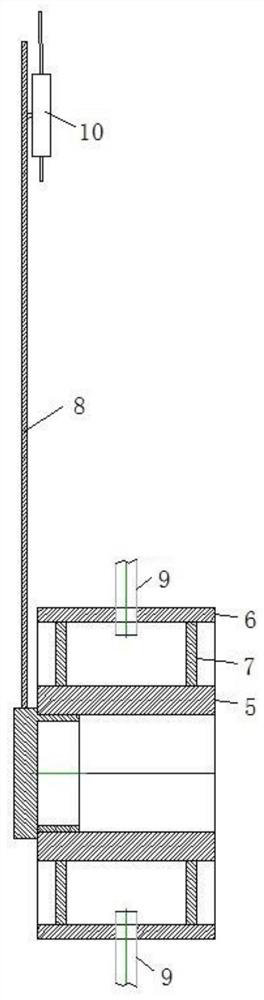

Offshore wind-power maintenance buffer landing and berthing device and application method thereof

PendingCN107914830AEnsure stabilityIncrease flexibilityCargo handling apparatusPassenger handling apparatusElectricityMarine engineering

The invention provides an offshore wind-power maintenance buffer landing and berthing device and an application method thereof. The offshore wind-power maintenance buffer landing and berthing device includes a base and a landing ladder, wherein the base is mounted on a ship bow deck, and the bottom of the landing ladder is fixed to the base; folding or straightening of all ladder beams, sequentially hinged end to end, of the landing ladder is achieved, and a joint end of every two connected ladder beams is provided with a corresponding locking device and a corresponding buckling device. According to the offshore wind-power maintenance buffer landing and berthing device and the application method thereof, a ship bow does not need to abut against a berthing pile at the bottom of a draught fan, so that the situation is avoided that when a maintenance ship sails under relatively bad sea conditions, the ship bow is damaged because the ship bow collides with the berthing pile due to environmental elements; when used, the landing ladder is locked through the locking devices and the buckling devices, and the stability of the landing ladder is ensured, wherein the locking devices are matched with the buckling devices; at the same time, by fixing a gear on the base and a hinge device on the gear, a direction facing the berthing pile is changed at any time; through a bottom sliding rail,the front and rear positions of the base can also be changed, and the flexibility is good, so that it is unnecessary for the maintenance ship to sail the ship bow in an assigned direction facing the berthing pile, time and labor are saved, and the ship bow only needs to get close to an abutting pile.

Owner:JIANGSU UNIV OF SCI & TECH

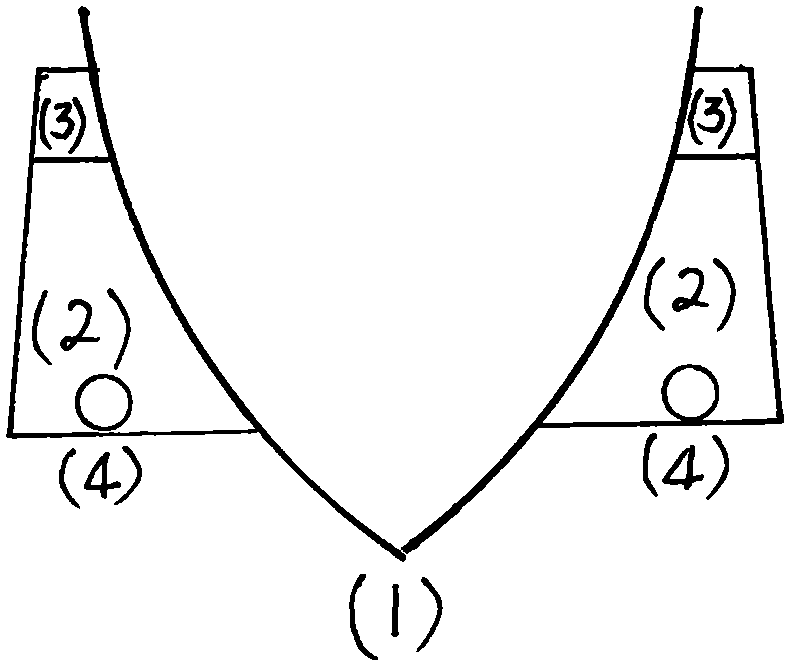

Dual-wall permanent floating ship

PendingCN107776842AImprove stabilityStrong wind resistanceHull bulkheadsVessel safetyWater leakageMarine engineering

The invention discloses a dual-wall permanent floating ship, and belongs to novel ship developing and manufacturing. Due to the fact that a ship body is not stable and is inclined and water enters theship body, shipwrecks happen frequently. Currently, ships are made of steel and must sink when the ships are inclined and water enters the ships or the ships leak water to a certain degree. The dual-wall permanent floating ship can never sink and solves the problems that the ship is not stable and is inclined, capsize and sink or shipwrecks are caused. The dual-wall permanent floating ship is characterized in that the ship bottom is a V-shaped sharp bottom, and the gravity center can be effectively lowered; the two side walls are air cushion type inclination adjusting cabins, and the buoyantcenters can be increased; an intelligent inclination monitoring controller can adjust the inclination of the ship body in a full-time and all-directional mode, and it is ensured that the ship is balanced and stable and is prevented from capsizing or sinking; pressure sensors are arranged inside inclination adjusting cabins at the four corners of the ship and can monitor that loading is balanced ornot; an emergency circumstance monitoring controller is arranged for monitoring the situation of non-inclined water leakage, slow sinking and any shipwreck risk; when inclination adjusting is not valid, a lifesaving program can be automatically started, all water in the inclination adjusting cabins is drained, and the inclination adjusting cabins are made into floating cabins; meanwhile, a lifesaving air bag restraint system is rapidly turned on, the ship floats and cannot sink, and the security of the ship and all persons is ensured.

Owner:曹伟华 +2

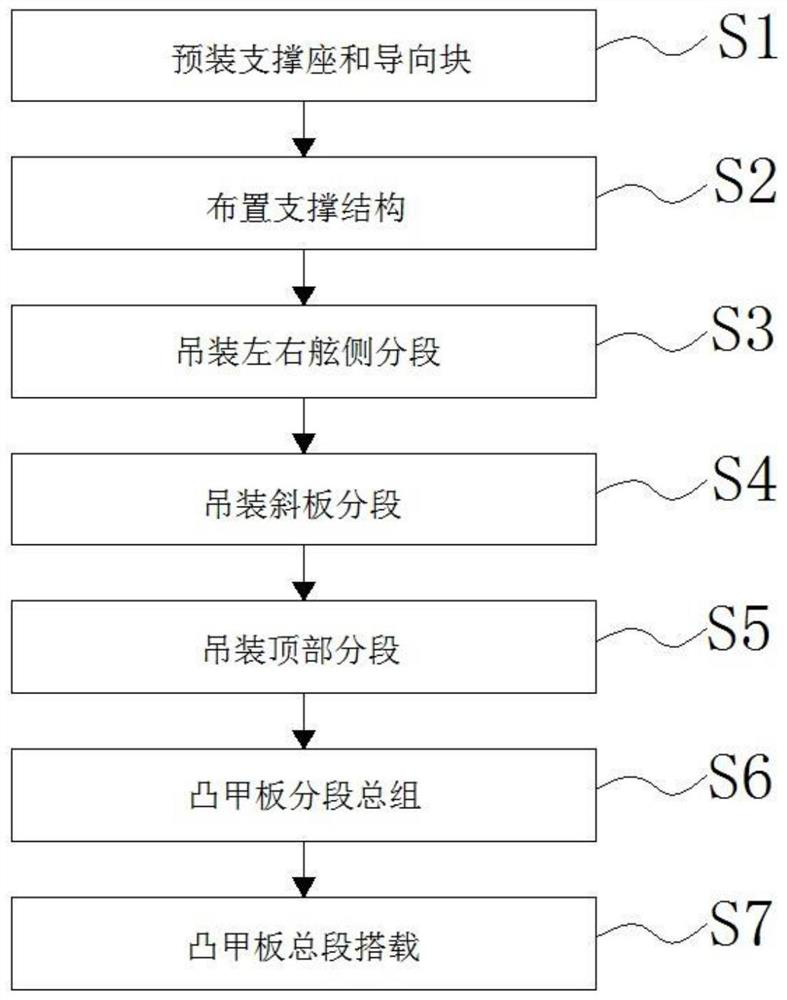

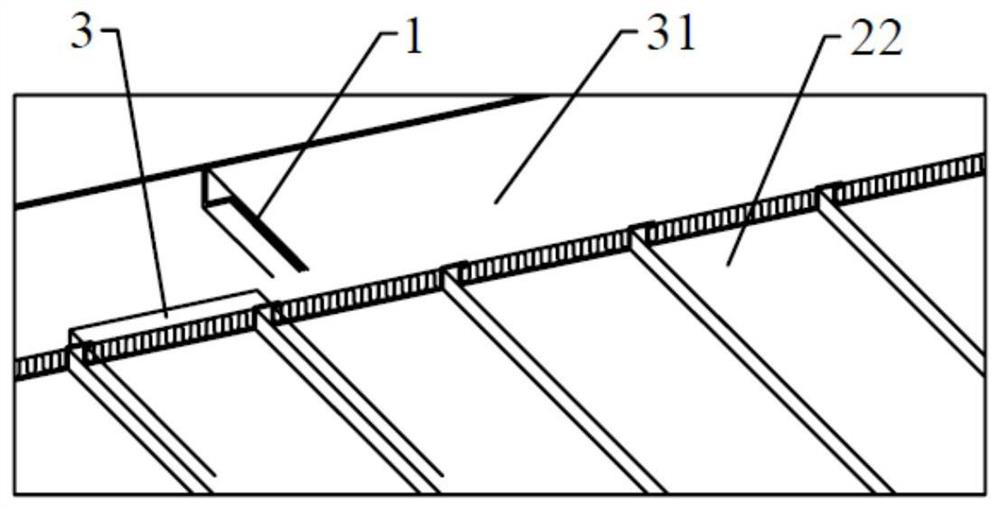

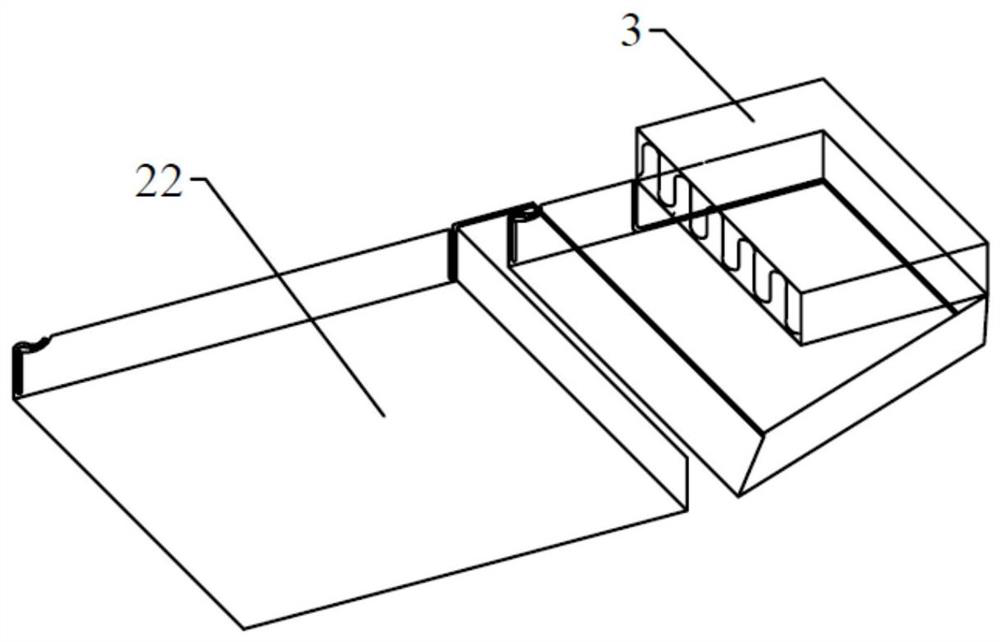

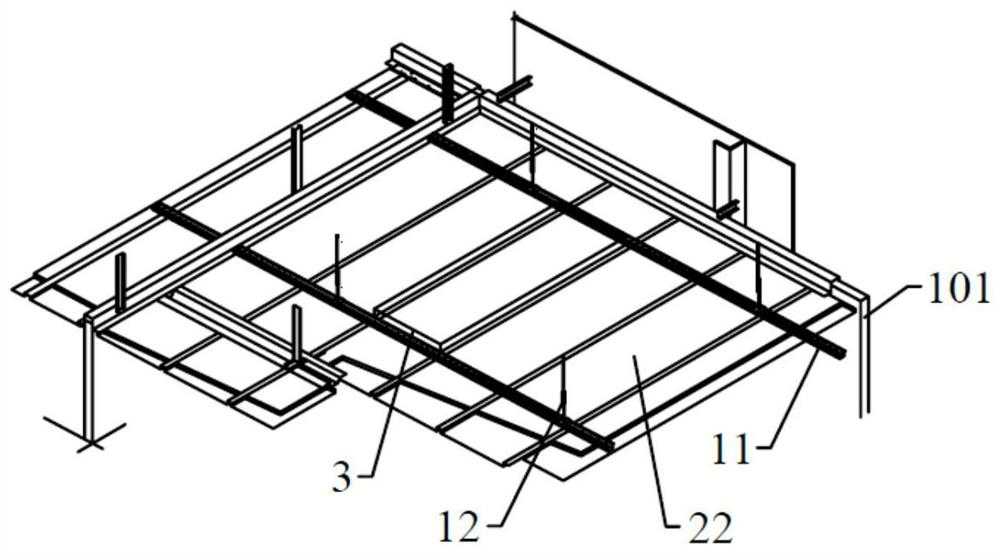

Mounting method of convex deck assembly

The invention provides a convex deck assembly mounting method. The method mainly comprises the steps that a supporting base and a guide block are preassembled; arranging a supporting structure; hoisting the left and right broadside sections; hoisting the inclined plate subsections; hoisting the top section; the convex deck is assembled in a segmented mode; according to the invention, the full utilization of site resources and crane resources is realized, the working procedure of the convex deck structure with higher construction difficulty is completed on the platform in advance, the workload of a follow-up dock is reduced, the rapid construction of the liquefied gas carrier is realized, and the shipbuilding efficiency is improved.

Owner:JIANGNAN SHIPYARD GRP CO LTD

Passenger cabin deck structure and ship

PendingCN113715958ALow costReduce weightHull decksHull panellingsMarine engineeringMechanical engineering

The invention relates to the technical field of ships, and discloses a passenger cabin deck structure and a ship. The passenger cabin deck structure comprises a steel deck, a ceiling and a rock wool board, and no fireproof layer is arranged on the steel deck; the ceiling is arranged below the steel deck; and the rock wool board is arranged on the side, close to the steel deck, of the ceiling, a preset distance is formed between the rock wool board and the steel deck, and an air layer is arranged within the preset distance. The fireproof layer arranged on a steel deck in the prior art is omitted, the fireproof layer cost and the labor cost are reduced, and the weight and the work amount of the steel deck are reduced; and the ceiling is arranged below the steel deck, the rock wool board is arranged above the ceiling, and the rock wool board and the steel deck are arranged at the preset interval, so that it is guaranteed that the rock wool board and the air layer have the good fireproof effect, meanwhile, the ceiling is easy to lay, the rock wool board only needs to be placed on the ceiling, construction operation is easy, and construction cost is low. The labor cost is saved, and meanwhile the shipbuilding period can be guaranteed.

Owner:GUANGZHOU SHIPYARD INTERNATIONAL LTD

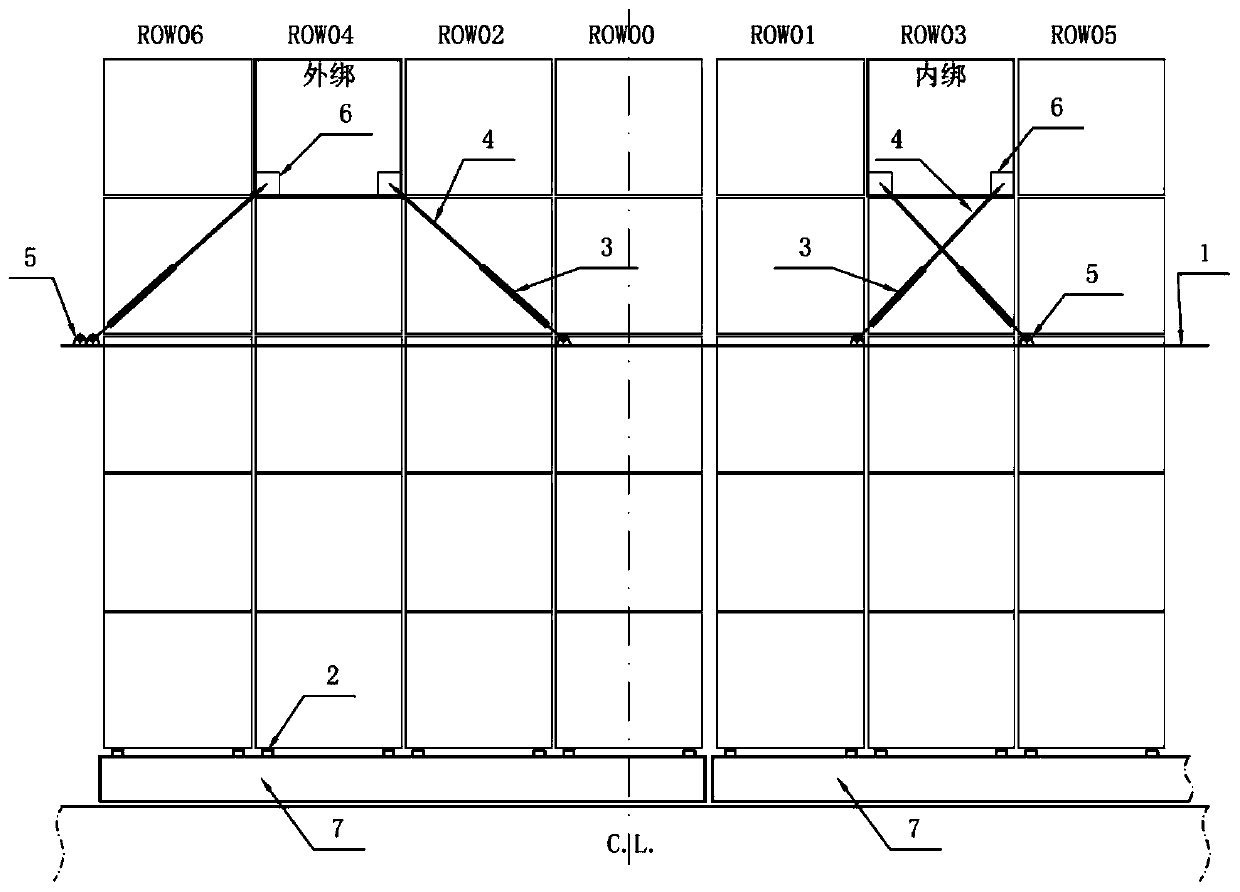

Real ship inspection method for container ship binding system

ActiveCN110674555AVerify reliabilityGuaranteed reliabilityGeometric CADVessel designingStructural engineeringBoat building

The invention discloses a real ship inspection method for a container ship binding system, and the method comprises the following steps: building a binding system three-dimensional model, and calculating a theoretical binding length; then measuring three-dimensional positioning of the binding eye plate by a real ship so as to calculate error values of the binding eye plate in three directions, andcalculating to obtain the change amount of the binding length; measuring the allowance of the original turnbuckle through a binding model; calculating the final turnbuckle allowance by using the original turnbuckle allowance and the actually measured binding length change amount; and finally, judging whether the allowance of the turnbuckle meets the requirement or not according to the standard, and adjusting and guiding the direction and the distance of the binding eye plate which does not meet the requirement. According to the method, material cost expenditure is avoided, only less labor hours are consumed, a dock or wharf crane is not occupied, shipbuilding cost expenditure is greatly reduced, and meanwhile the reliability of a binding system is guaranteed through the final result.

Owner:NANTONG COSCO KHI SHIP ENG

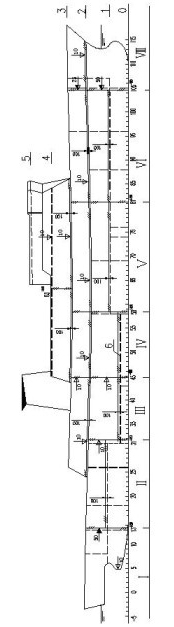

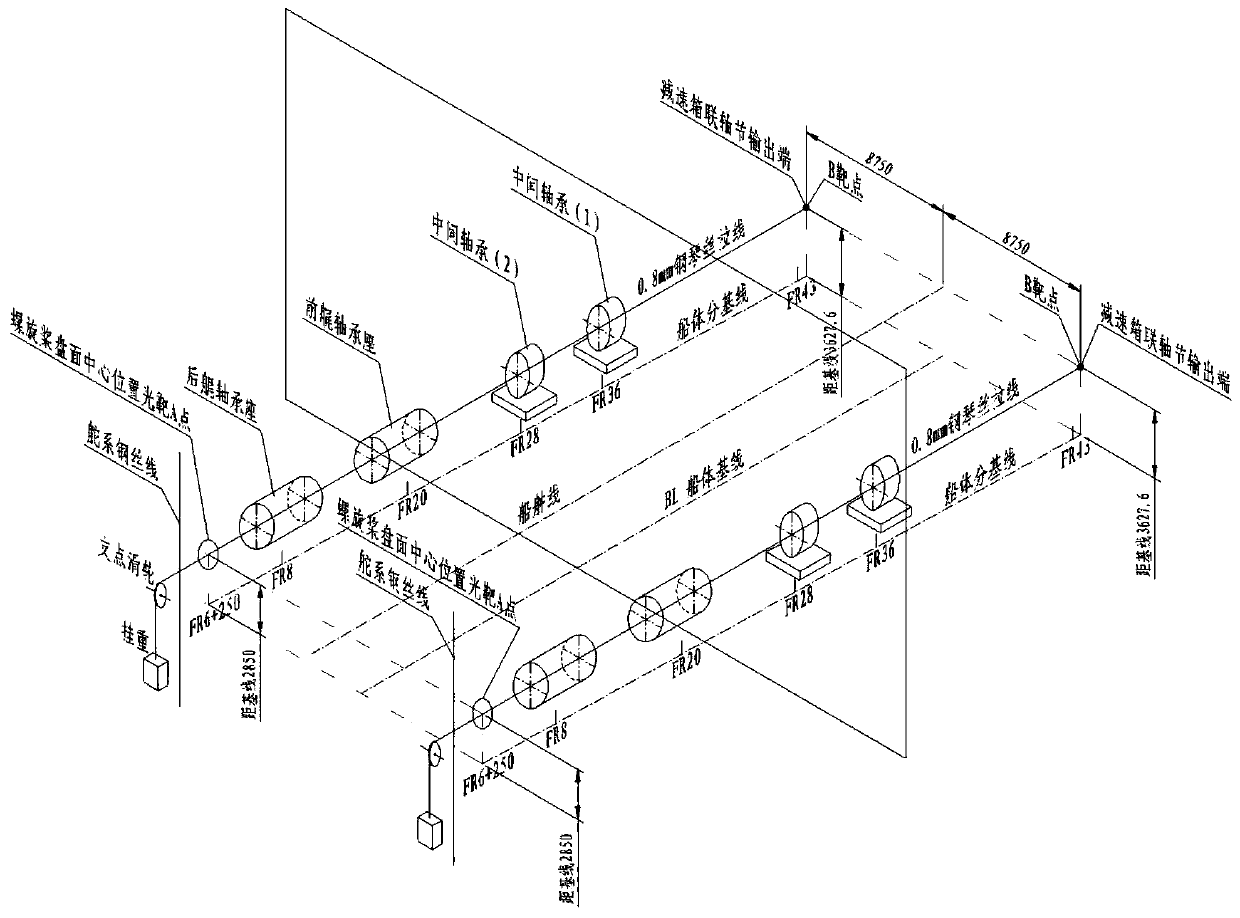

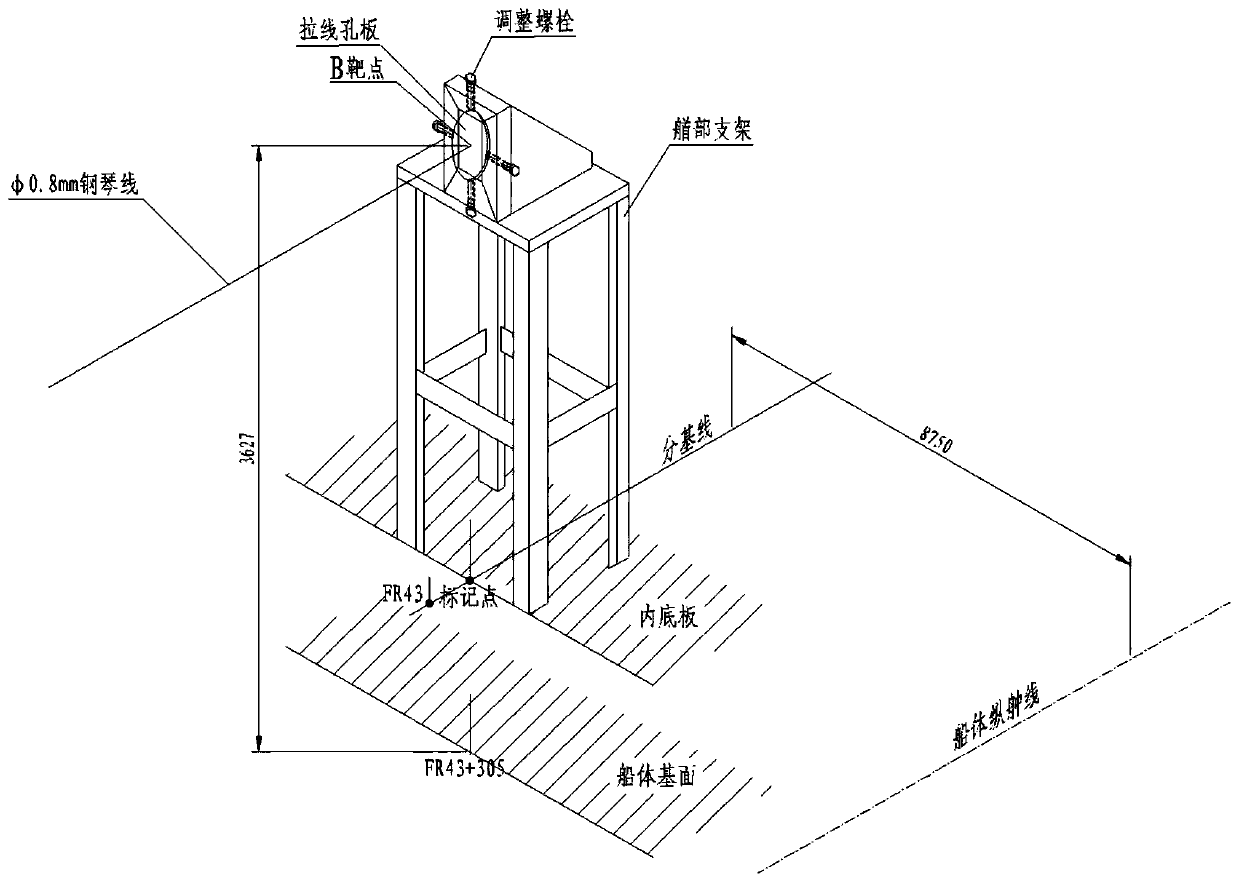

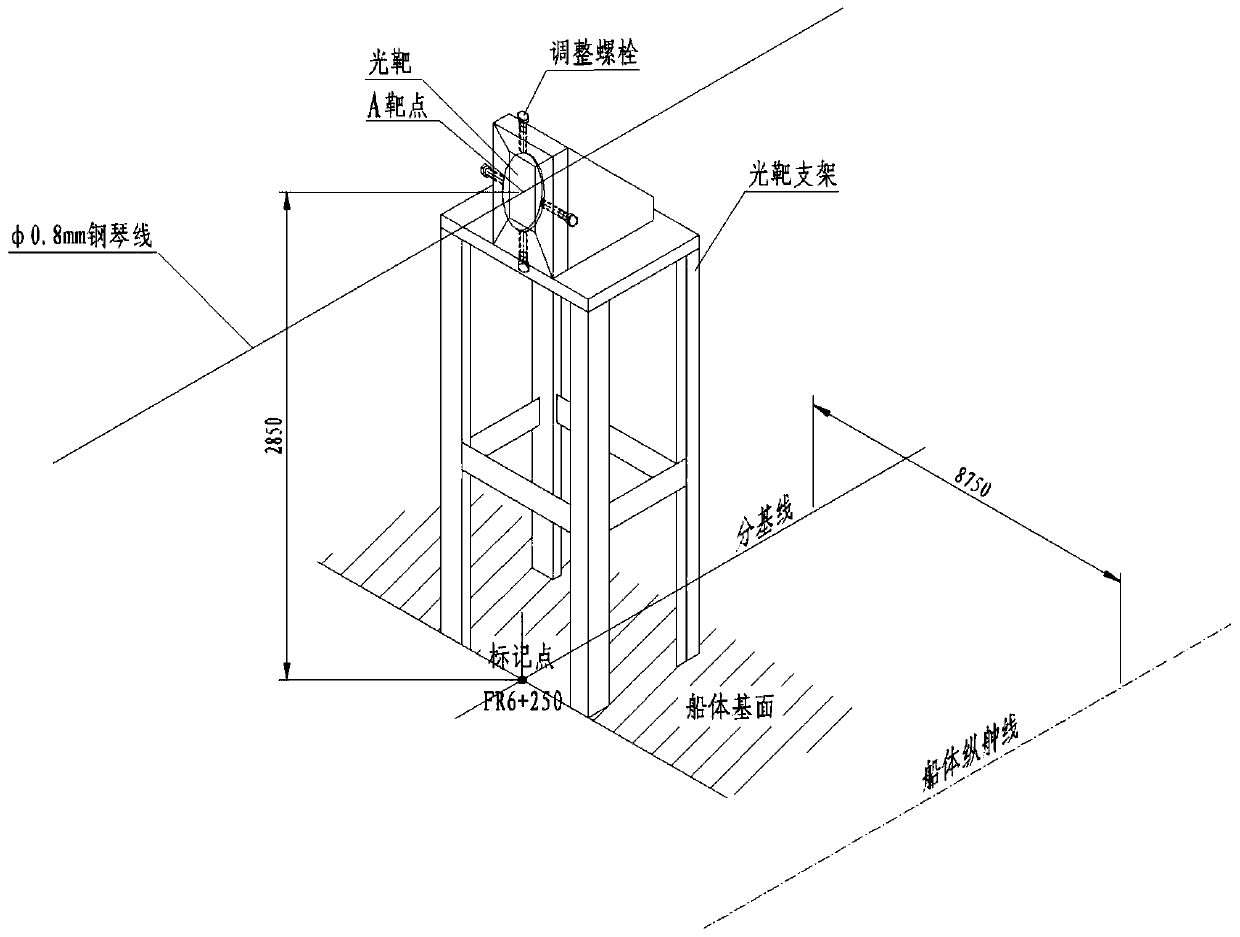

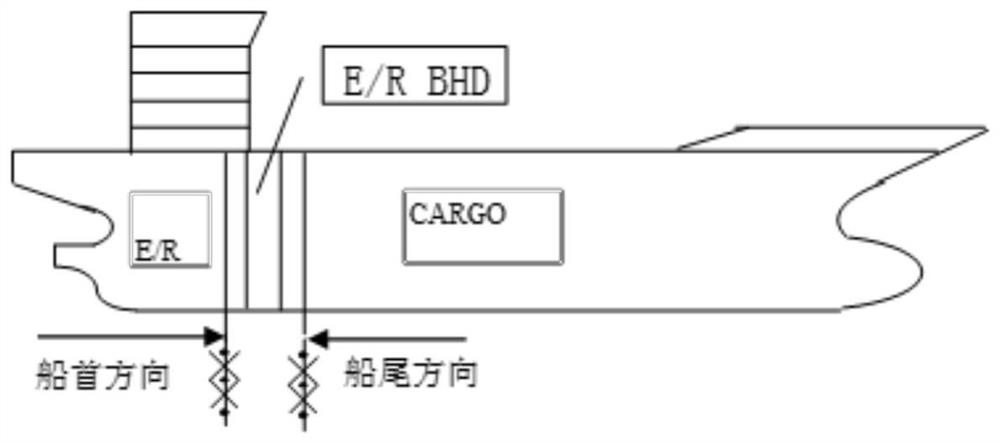

Ship shafting adjusting method

InactiveCN111071404AImprove accuracyImprove the construction processWaterborne vesselsEngineeringHull

The invention provides a ship shafting adjusting method. The method comprises the following steps: 1, determining a theoretical shafting center line, and finding out bow and stern points for determining the theoretical shafting center line on a left board and a right board by adopting a steel wire drawing method; 2, measuring a stern target point A in a shafting line, and measuring the stern target point A on the left and right sides of an FR-1 rib position and a plumb line of a hull plate by taking a hull sub-baseline as a reference; 3, measuring a shafting midline bow reference point B, andmeasuring the shafting midline bow reference point B at the measurement mark point of the ship body baseline surface. The method has the beneficial effects that in the whole shipbuilding process, thedata accuracy of each link can be effectively improved, so that the shipbuilding process is improved, the efficiency is improved, the cost is reduced, and meanwhile, the shipbuilding quality is ensured.

Owner:YIU LIAN DOCKYARDS SHEKOU LTD +1

Oceanography engineering module integral hoisting method

ActiveCN101417693BShorten the lengthIncreased lifting capacityVessel partsLoading/unloadingFreeboardLightering

The invention discloses a method used for realizing the integral lifting of marine engineering modules in the marine engineering field. After the module is constructed integrally, the invention makes use of floating cranes, barges and special crane beams to realize the integral lifting of modules on water by regulating the sea gauge of a main hull. Compared with the similar technology, the invention has the following advantages that the preparation of special crane beams can reduce the length of lifting cables so as to enhance the effective lifting height of floating cranes; and the adopting of the floating crane to lift the modules to the barges can avoid the use of a plurality of fittings used for conveying so as to reduce the cost. Simultaneously, the deep water is adopted to moor the main ship so as to ballast the main hull and reduce the height of the freeboard and then the high lifting capability of the floating crane is enhanced and the shipbuilding cost is reduced finally.

Owner:DALIAN SHIPBUILDING IND

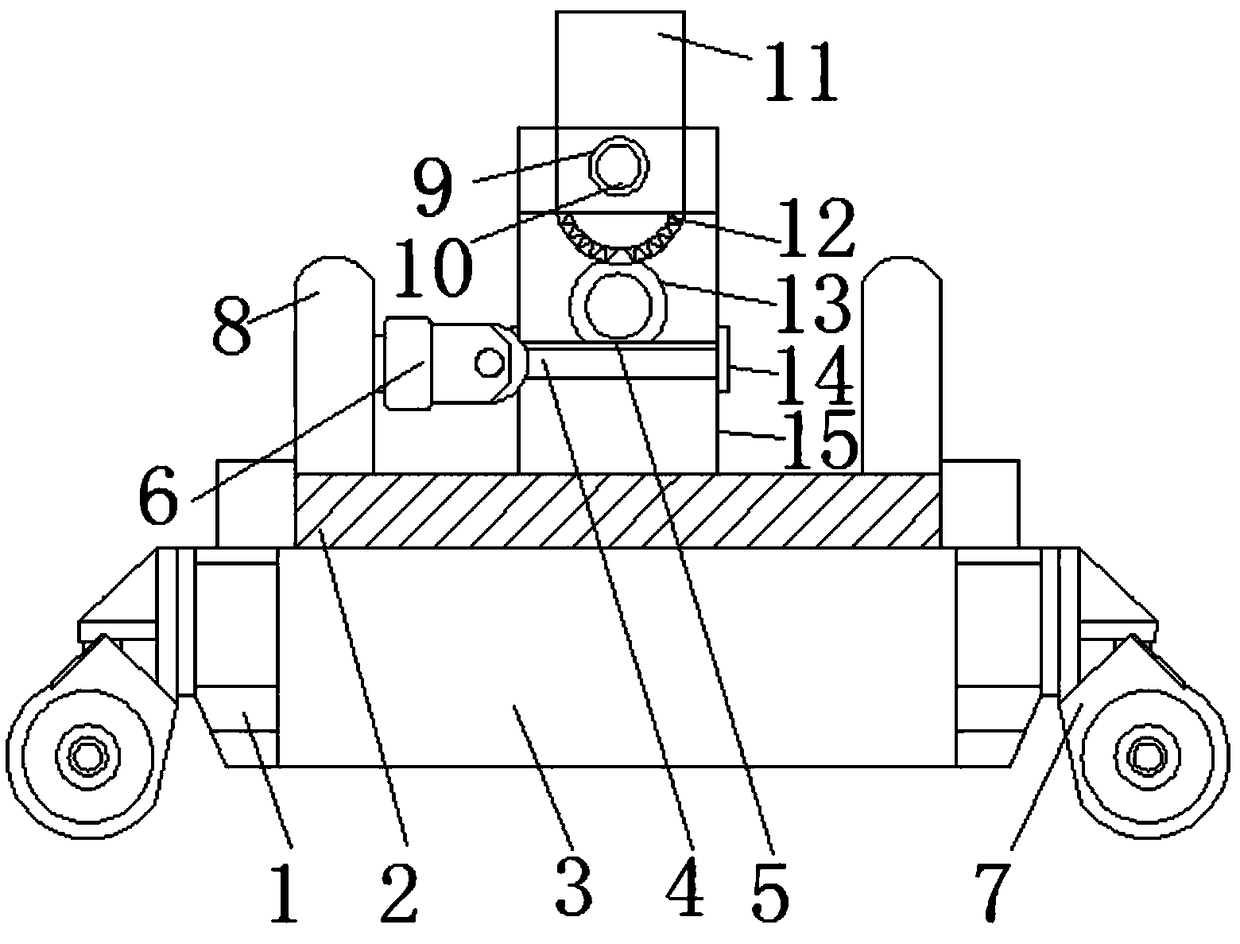

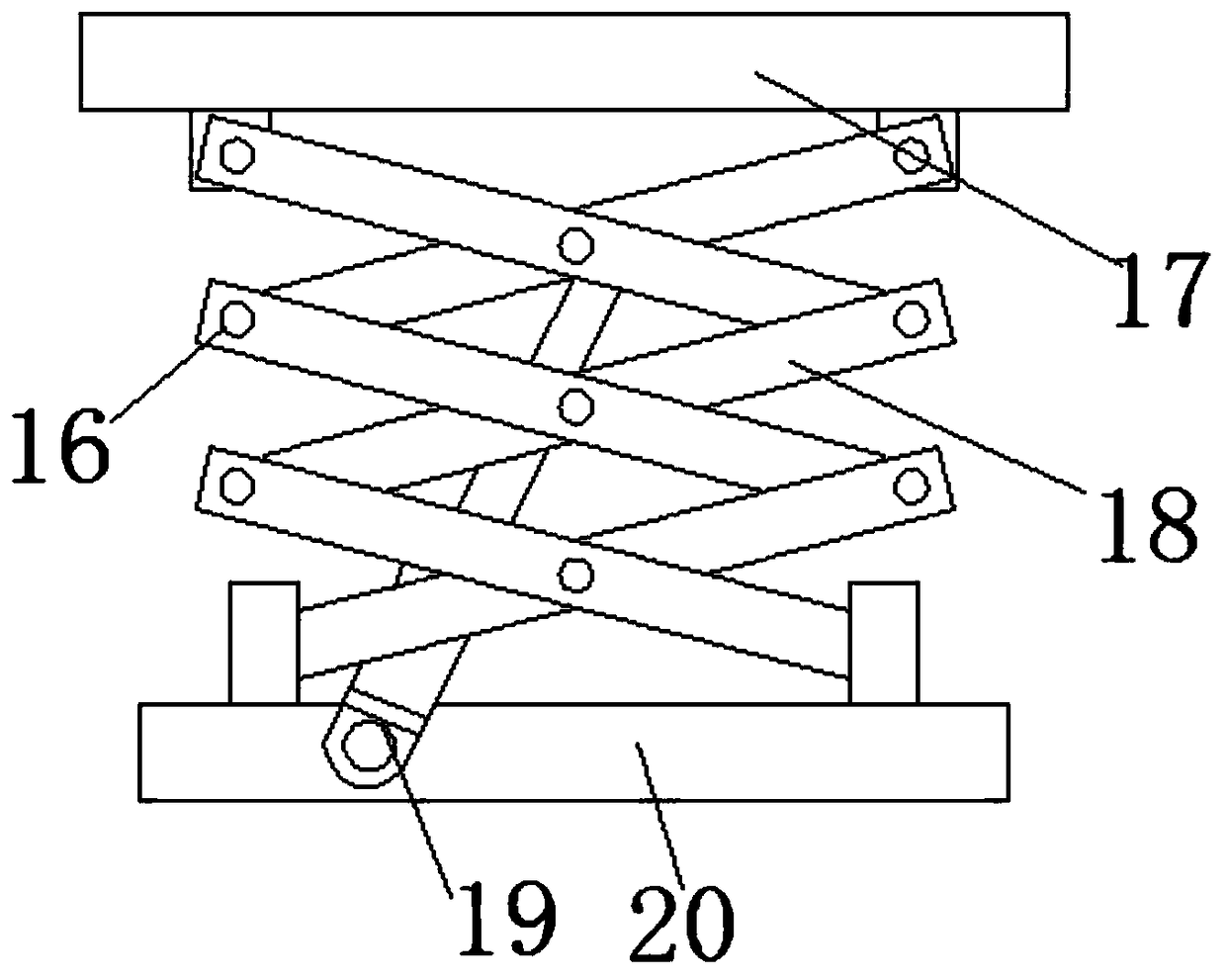

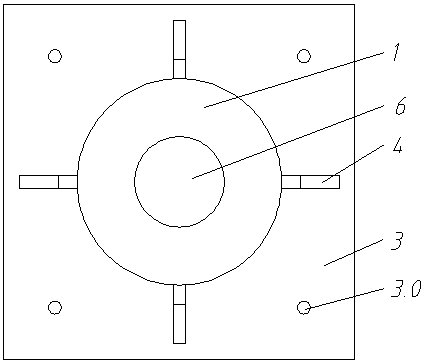

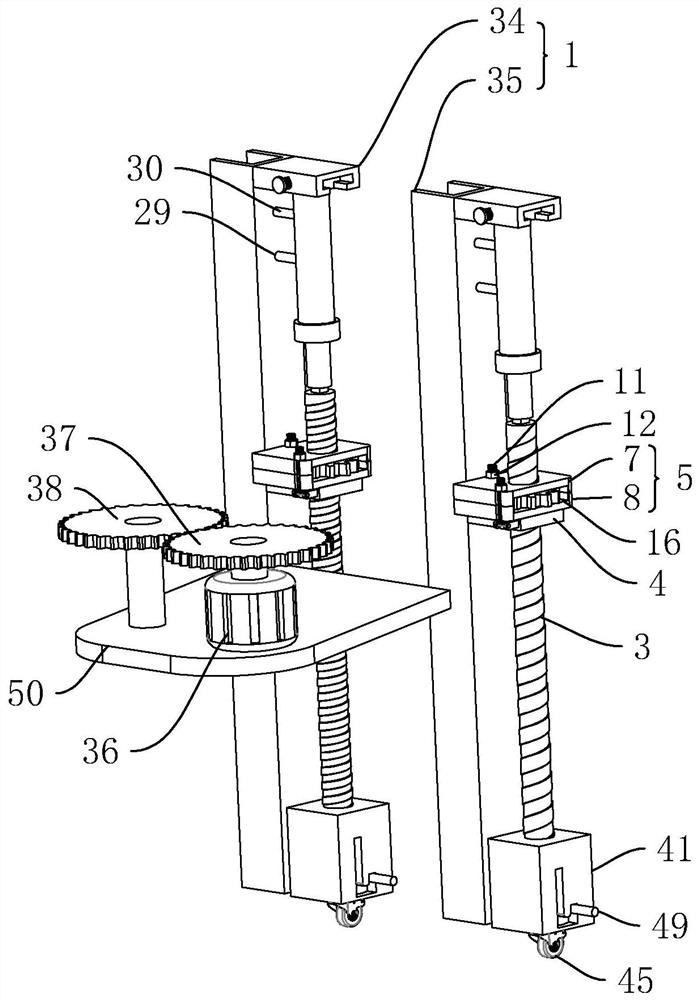

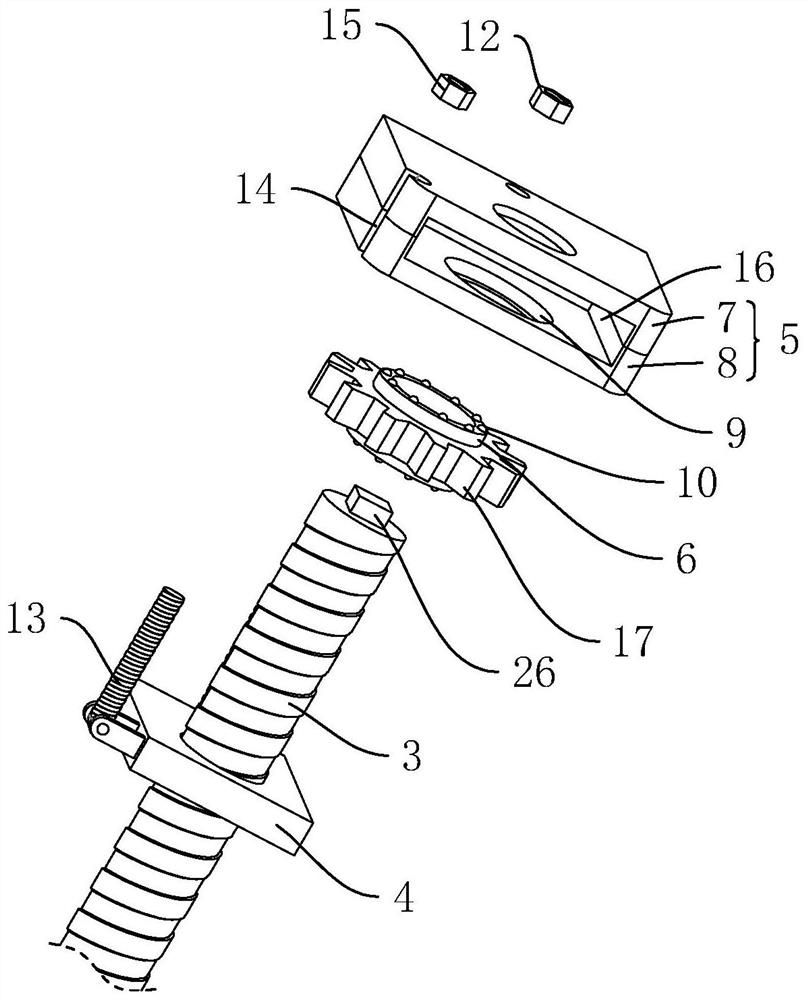

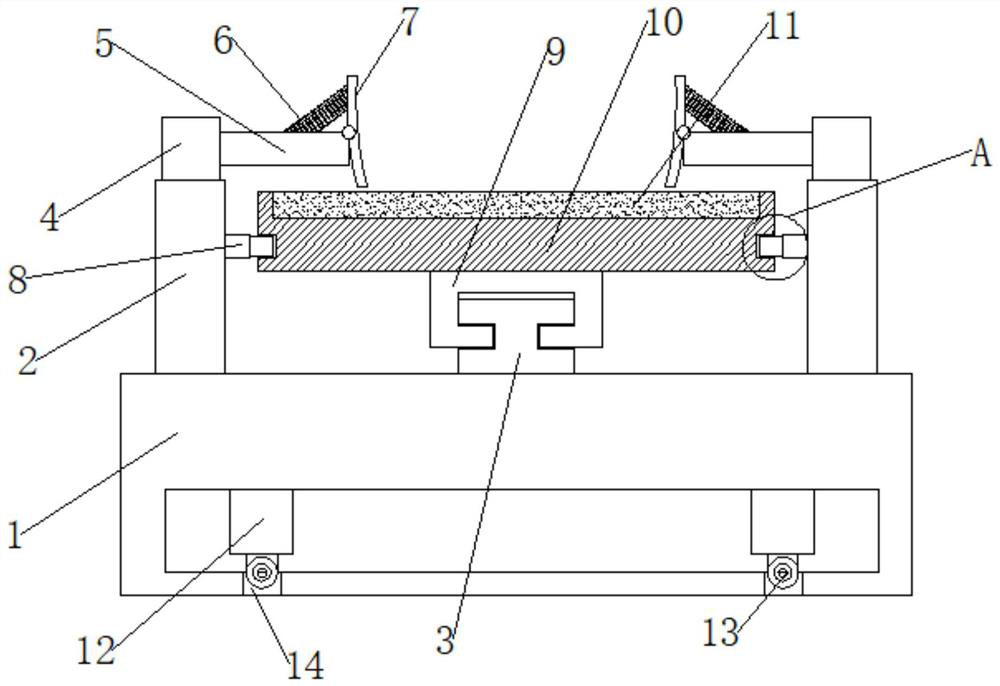

Mold frame adjusting seat for boat building

InactiveCN108909979AEasy to adjust and moveEasy to operateDry-dockingSlipwaysHydraulic cylinderPulp and paper industry

The invention discloses a mold frame adjusting seat for boat building. The mold frame adjusting seat comprises an installation seat, wherein the interior of the installation seat is fixedly connectedwith a hydraulic lifting platform, the bottom end of the hydraulic lifting platform is horizontally fixedly provided with a bottom plate, the top end of the hydraulic lifting platform is provided witha top plate, movable rods are alternately arranged between the top plate and the bottom plate, the middle of the top plate is provided with an installation frame, two sides of the installation frameare symmetrically provided with a fixed plate, the inner side of the fixed plate is horizontally provided with a first hydraulic cylinder, one end of the first hydraulic cylinder is connected with anangle adjusting rod, a gear strip is integrally molded on the upper end surface of the angle adjusting rod, a first adjusting gear is arranged above the gear strip, and a second adjusting gear is arranged between the first adjusting gear and the gear strip. By virtue of the angle adjusting rod and the first adjusting gear, the first hydraulic cylinder controls the movement of the angle adjusting rod along the horizontal direction, so that the angle of a supporting rod is changed by virtue of the first adjusting gear engaged with the second adjusting gear, and the adjusting precision can be improved.

Owner:芜湖籁余新能源科技有限公司

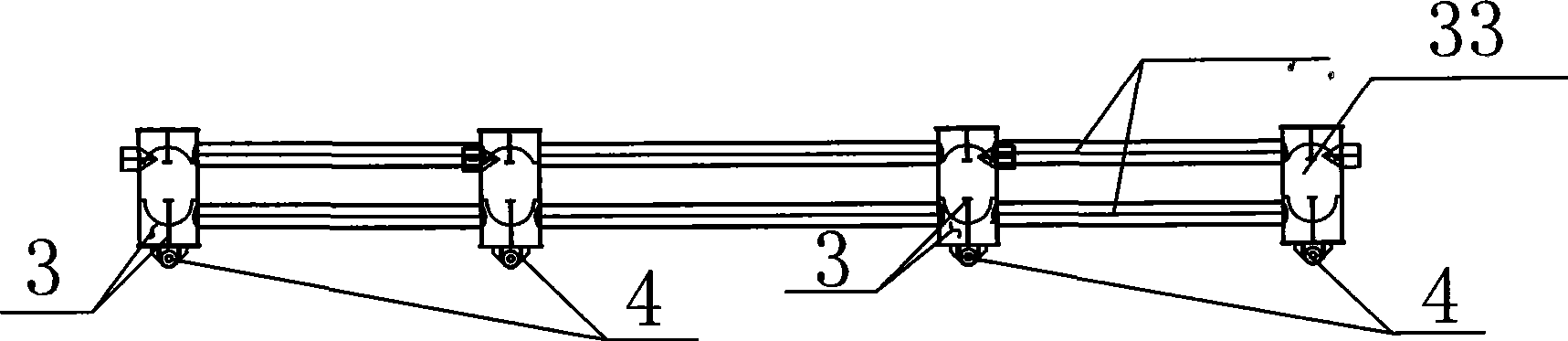

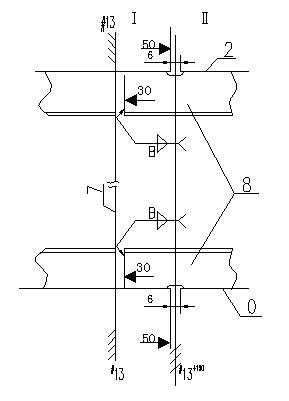

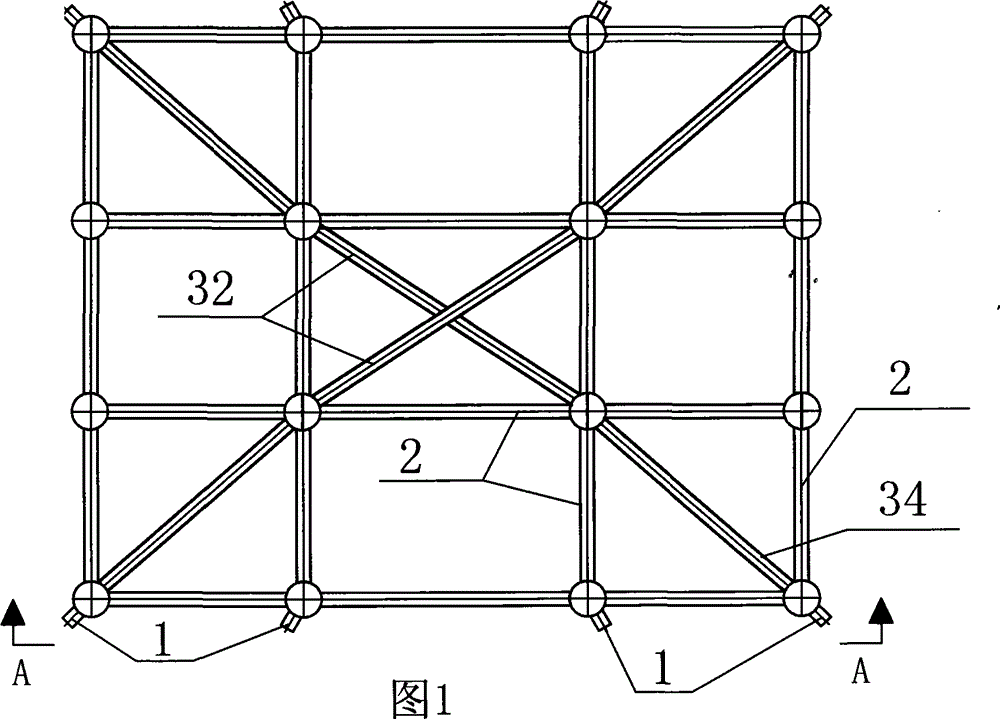

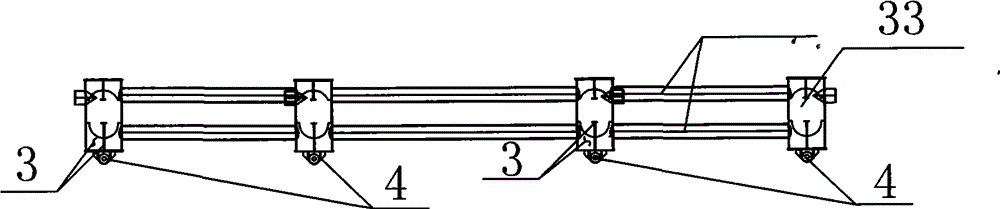

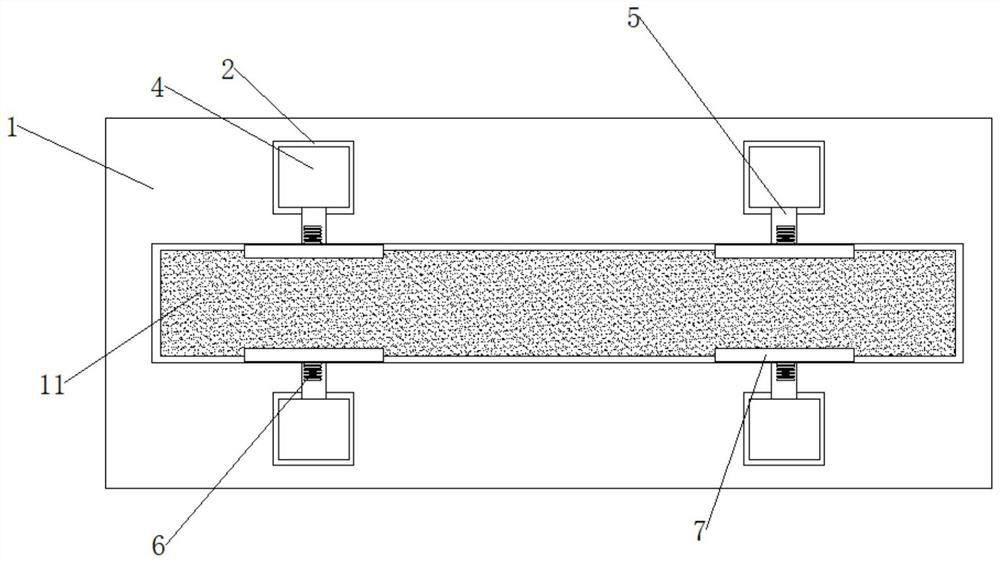

Slipway unified reference establishing method and device

ActiveCN110836664AEliminate cumulative errorsHigh measurement accuracyMeasuring points markingControl engineeringReference device

The invention provides a slipway unified reference establishing method and device. The slipway unified reference device used for various working conditions and spaces of shipway stage construction inthe technical field of shipbuilding is divided into three types including an A-type device, a B-type device and a C-type device. According to the invention, a slipway unified reference device is adopted, so that multiple measurement transfer errors caused by too far measurement are eliminated; a good foundation is laid for establishing a high-precision temporary reference under the shielding condition, and multiple measurement transfer errors caused by shielding are eliminated. According to the invention, the established slipway unified reference can effectively eliminate accumulated errors ofa digital measurement system caused by station transfer, the application range of the measurement system is widened, the system does not need to be modified, the device is simple, convenient and practical, installation and operation are easy, the measurement precision of various advanced digital measurement systems can be effectively improved, a powerful guarantee is provided for high-precision measurement and construction of ships, and the slipway unified reference establishing method and device have wide market prospects and are suitable for eliminating the transfer errors.

Owner:渤海造船厂集团有限公司

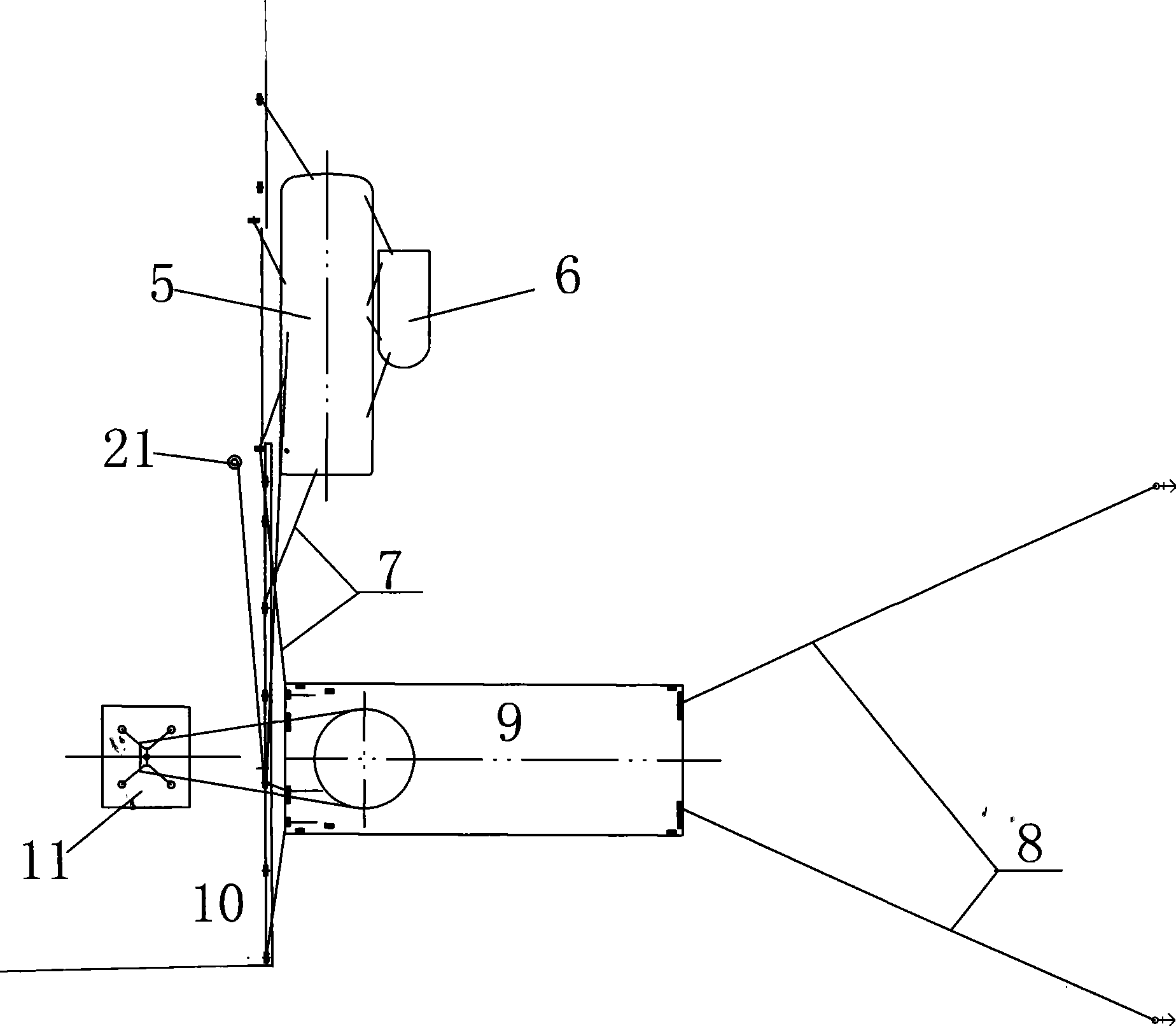

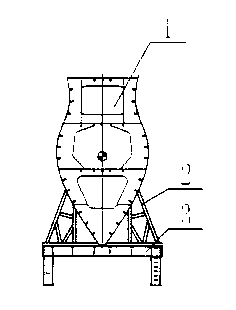

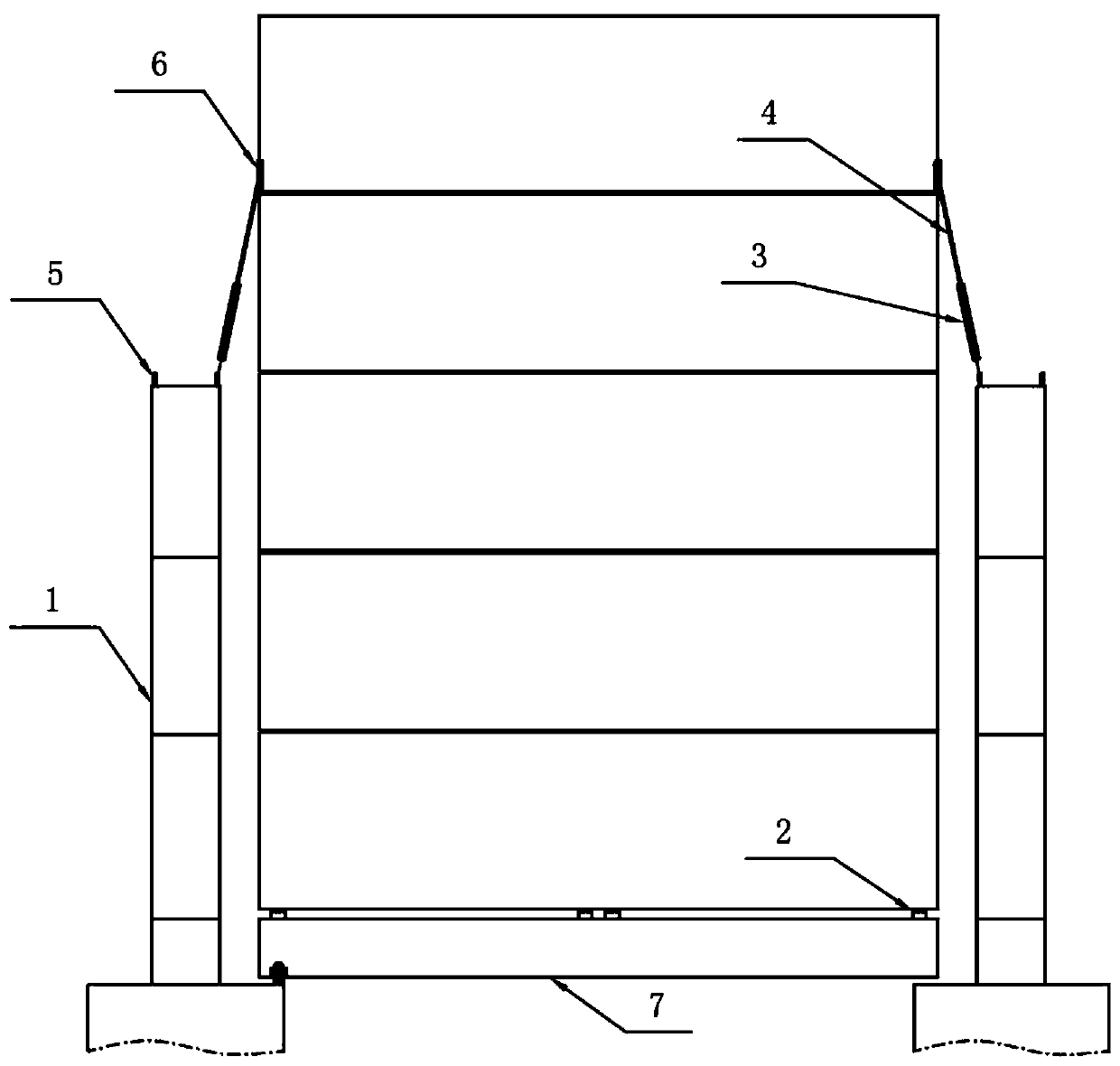

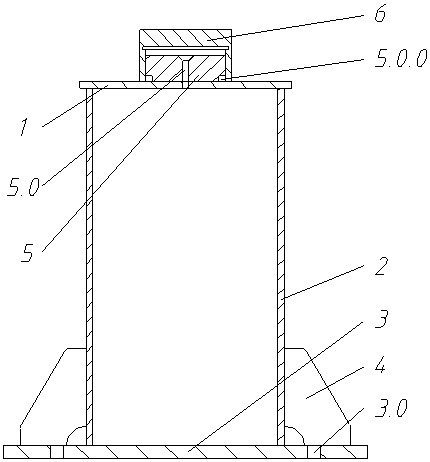

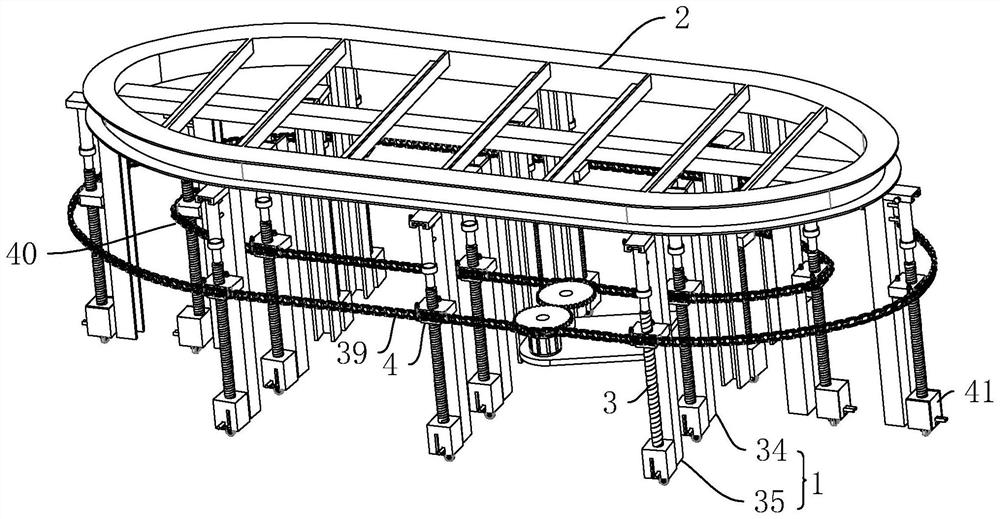

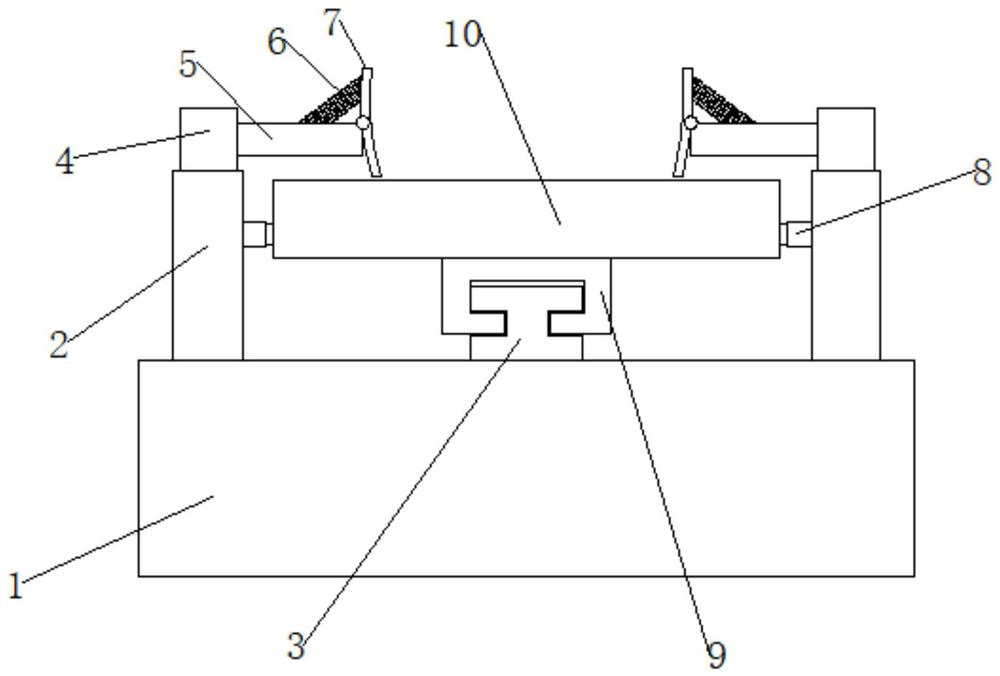

Dock for manufacturing submarines

InactiveCN103112559AConvenience to workImprove product qualityDry-dockingHydraulic cylinderEngineering

The invention relates to a dock for manufacturing submarines, belonging to the technical field of ships. The dock comprises a dock main body, a camouflage cover, rolling shafts, support posts, gear motors, hydraulic cylinders, rotating motors, racks and a division plate, wherein the division plate is mounted at the bottom of the dock main body through the four hydraulic cylinders; the four groups of support posts are mounted on the division plate; the rolling shafts are mounted at the upper parts of the support posts, and are connected with the rotating motors beside the support posts; the support posts are provided with the racks, and the racks cooperate with the gear motors to achieve the lifting of the support posts; the camouflage cover is arranged at the top of the dock main body and is formed by articulating a plurality of flat toughened glass, and 3M films are adhered to the inner layers of the toughened glass while steel wire nets are adhered to the inner layers of the toughened glass; and the division plate has a steel box girder structure to increase the structural strength. The dock adopts an open way to manufacture the submarines, so that various advanced ship building equipment can be used, and at the same time, the submarines can be rotated freely during the manufacture, thereby facilitating the work of workers and improving the manufacturing quality.

Owner:ZHEJIANG OCEAN UNIV

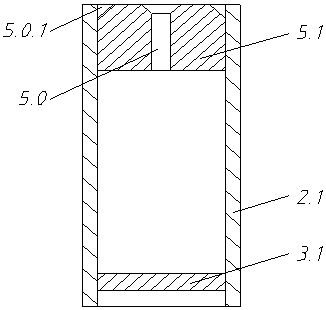

Reverse shipbuilding jig frame structure

ActiveCN112937799AHeight adjustablePrevent rotationDry-dockingSlipwaysClassical mechanicsScrew thread

Owner:JIAXING JINJIA SHIPBUILDING CO LTD

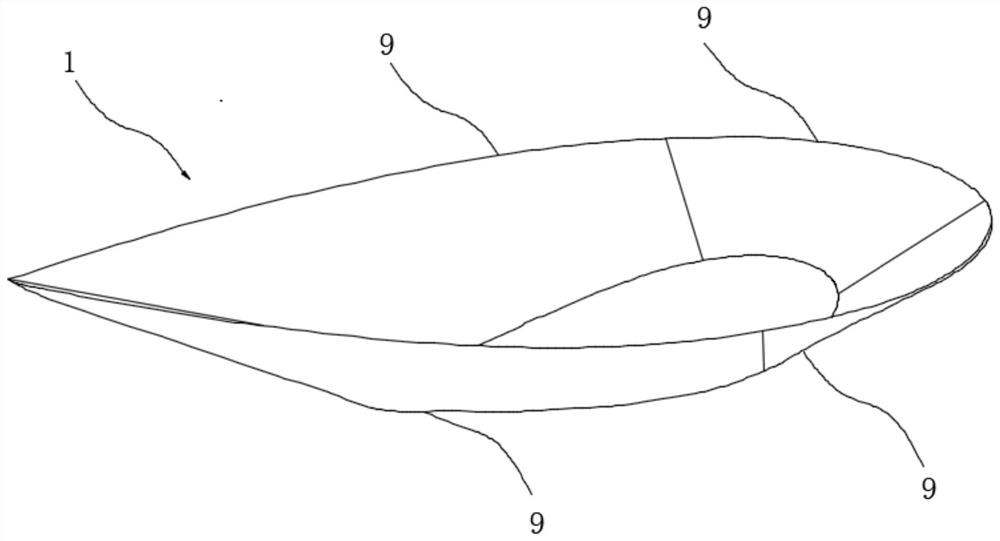

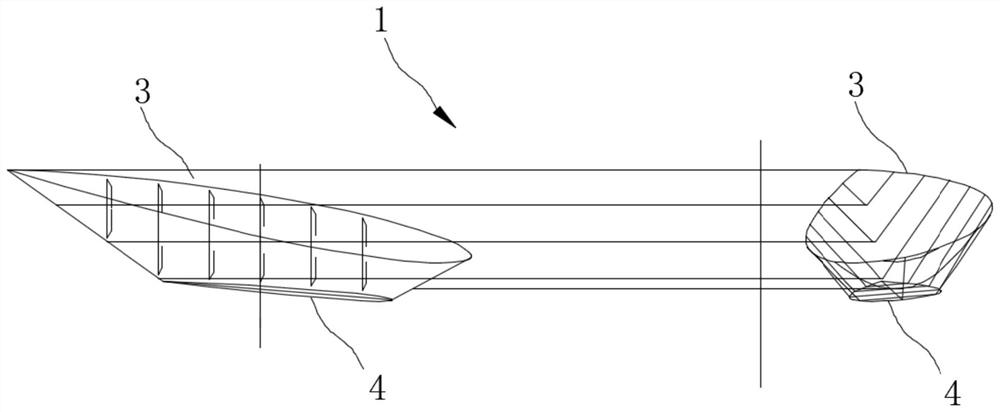

Modeling and lofting method for ship fairing

ActiveCN113148054AAccurate installation dataManufacturing Design SpecificationGeometric CADWatercraft hull designStructural engineeringHull

The invention discloses a modeling and lofting method for a ship fairing, which comprises the following steps of: according to upper end sample line data and lower end sample line data provided in a molded line graph of the fairing, performing interpolation processing on the fairing, acquiring molded value data at each gear of rib position, and performing optimization processing on an area which is not smooth enough; importing the data into curved surface modeling software, and establishing an upper end sample line stretching curved surface and a lower end sample line stretching curved surface of the fairing; intersecting the upper end sample line stretching curved surface of the fairing with the outer plate surface of the ship body of the ship to obtain the upper end boundary of the curved surface of the fairing; intersecting the lower end sample line stretching curved surface of the fairing with the lower end sealing plate surface of the fairing to obtain the lower end boundary of the fairing curved surface; and establishing the curved surface of the air guide sleeve, and completing modeling and lofting of the curved surface of the air guide sleeve. The method solves the problem of inaccurate modeling and lofting in the design and production of the fairing, improves the production efficiency of the design and production of the fairing, and belongs to the technical field of shipbuilding production design.

Owner:CSSC HUANGPU WENCHONG SHIPBUILDING COMPANY

Auxiliary device for ship launching

The invention discloses an auxiliary device for ship launching, and relates to the technical field of ships, the auxiliary device comprises a base, the top of the base is provided with a supporting column and a sliding rail, the top of the supporting column is provided with an air cylinder, and the output end of the air cylinder is connected with a clamping block through a piston rod. During shipbuilding, a ship body is placed on a sponge cushion, the ship body cannot be abraded through the sponge cushion, the ship body is supported through a placing table, the ship body is limited and fixed under the action of an electric push rod and a limiting groove, and then the ship body cannot slide out; and secondly, by starting an electric push rod, the electric push rod shrinks, so that the electric push rod is separated from the interior of a limiting groove, a placement table is moved again, a sliding block drives the placement table to move, the ship is pushed into water, the problem that the ship is inconvenient to move is effectively solved, and the use performance is good.

Owner:中国船舶集团广西造船有限公司

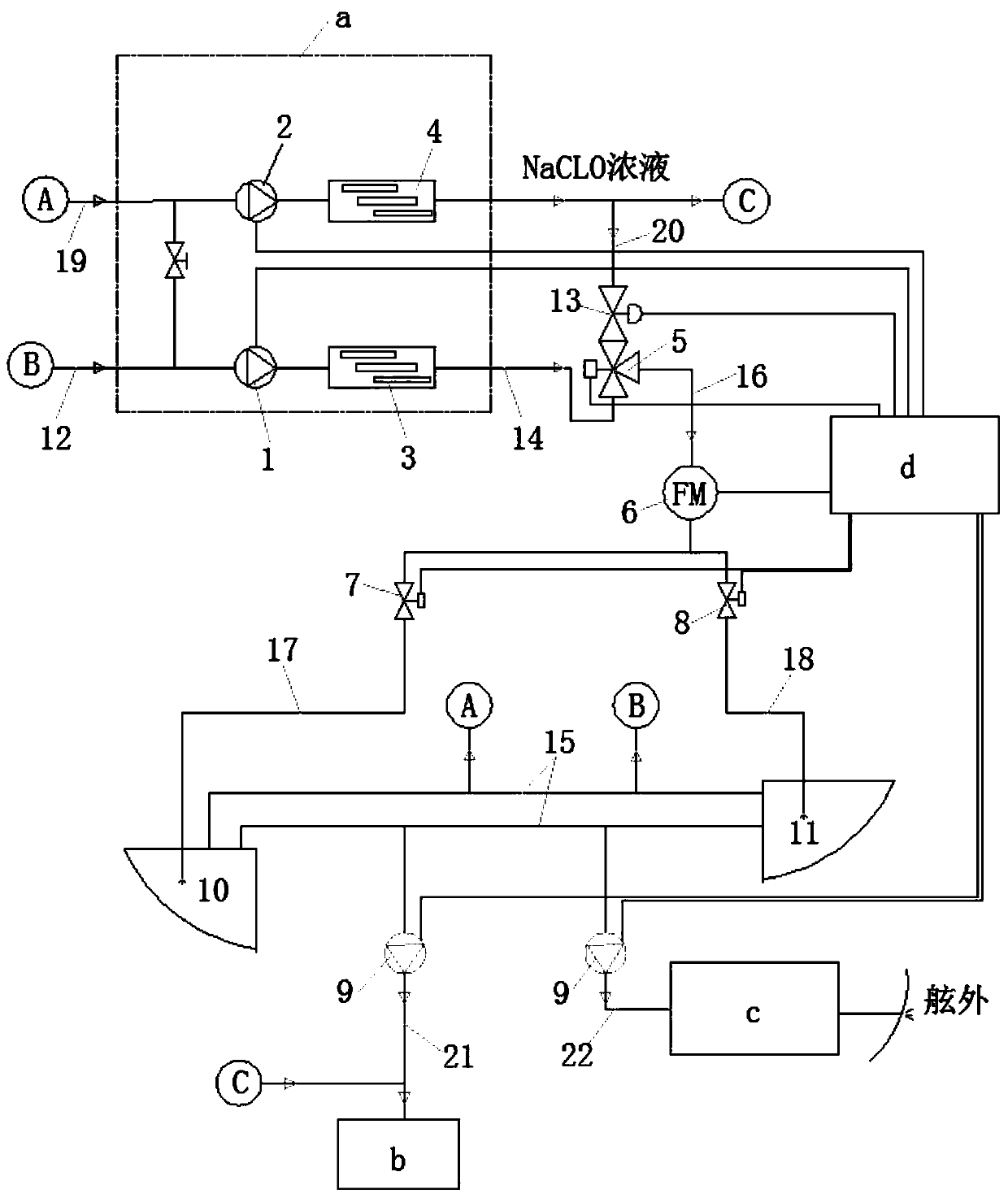

System for treating cabin seawater pipe microorganisms by ballast water device and ship

PendingCN110902775ASave spaceImprove utilization efficiencyAuxillariesSeawater treatmentMicroorganismElectrolysis

The invention discloses a system for treating cabin seawater pipe microorganisms by a ballast water device and a ship, the system comprises the ballast water treatment device, a sea chest, a ballast tank, cabin equipment and a control box, the ballast water treatment device comprises two groups of electrolysis mechanisms which operate in parallel, and the electrolysis mechanisms are respectively afirst electrolysis mechanism and a second electrolysis mechanism; the first electrolysis mechanism is connected with a water outlet pipeline through a first water conveying pipe, and the water outletpipeline is connected with the sea chest; the second electrolysis mechanism is connected with a second water conveying pipe and the ballast tank, the second water conveying pipe is communicated witha switching valve, and the ballast tank and the cabin equipment are both connected with a seawater header pipe on the sea chest. By reasonably arranging the pipelines in the system, a sodium hypochlorite solution generated by electrolysis of the ballast water treatment device can treat the microorganisms in the ballast tank and a cabin seawater pipe at the same time, a cabin marine organism prevention device does not need to be installed on the ship, and the shipbuilding cost is reduced.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

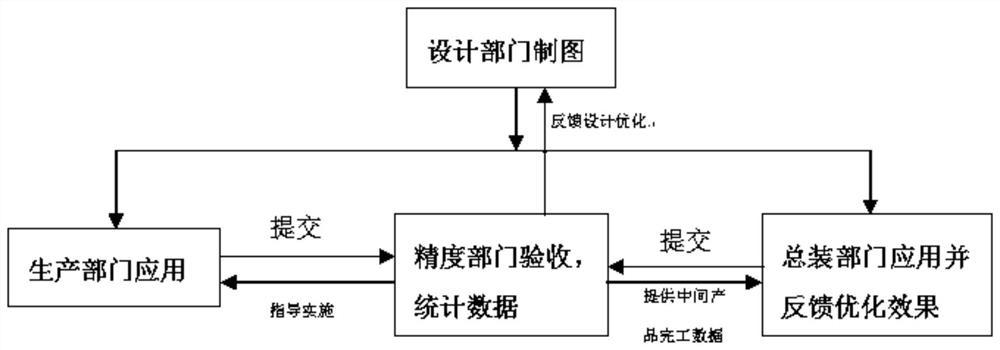

Shipbuilding precision control method utilizing unilateral datum

The invention discloses a shipbuilding precision control method utilizing unilateral datum, which comprises the following steps that: a datum line is arranged on a datum edge of the unilateral datum from the beginning of a blanking stage, the datum line is from the beginning of butt joint of parts to the end of carrying, and the datum line is used for a long time and is a datum for realizing butt joint line shipbuilding; when a ship body works, all parts are assembled or segmented, lineation is carried out on a unified datum according to the same size, and the lineation is used as a datum which is set for guiding field operation personnel to ensure that a good ship body is manufactured in the assembling and total assembling / carrying stage. Unilateral datum construction application standardization is achieved through design, production, inspection and feedback design improvement, and the construction technology is formed. According to the method, the unified datum of the whole ship is improved, a previous cross curve shipbuilding process method is replaced, the serious phenomenon of the repairing and cutting rate caused by margins existing all around in the past is improved, meanwhile, the repairing and cutting process is moved forwards, the original groove retention rate is increased, the dock tool opening rate is reduced, and cost reduction and gain are achieved.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

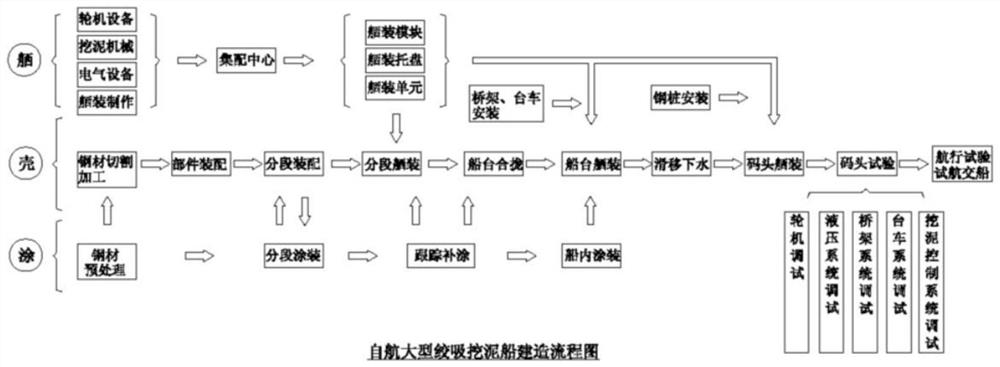

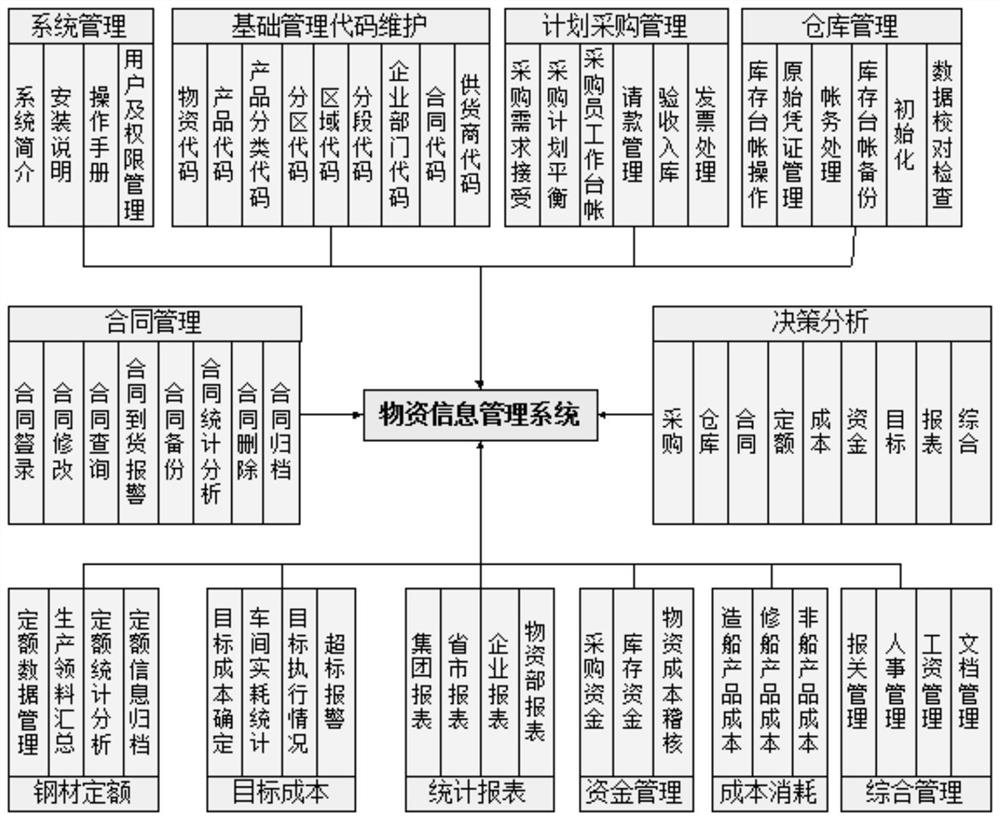

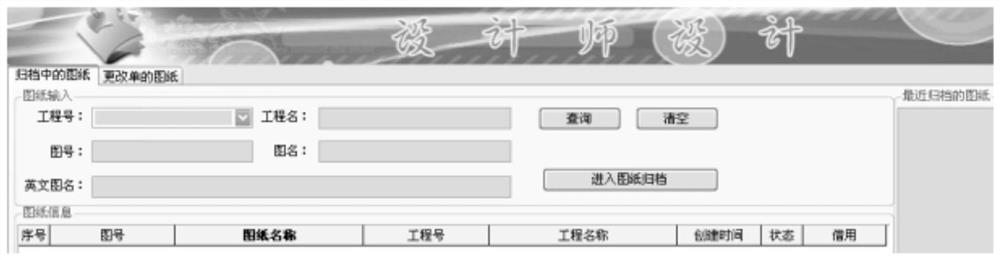

Large cutter suction dredger construction method

InactiveCN111667140AImprove product qualityLow costGeometric CADResourcesGeneral assemblyConstruction engineering

The invention relates to the technical field of cutter suction dredger construction. The invention further discloses a construction method of the large cutter suction dredger. The system comprises a large self-propelled cutter suction dredger construction process flow, a general assembly shipbuilding system technical center for providing technical support, a hierarchical project management organization mechanism, a ship material information management system and an electronic drawing file management system, according to the large self-propelled cutter suction dredger construction technologicalprocess, intermediate product specialized cooperation reasonable in layout needs to be established, shell, outfitting and coating operations are integrally carried out at the same time, a general assembly shipbuilding system technical center providing technical support establishes an ocean engineering and ship product database, design cost management is carried out, and equipment is arranged in advance to issue an equipment ordering list. According to the construction method of the cutter suction dredger, by establishing the construction technological process of intermediate product specialized cooperation reasonable in layout, social resources of domestic and overseas shipbuilding matching capacity are fully utilized, and strength is concentrated to be engaged in final assembly production with the goals of improving the product quality, reducing the cost and shortening the shipbuilding period as the target.

Owner:CHINA MERCHANTS HEAVY IND SHENZHEN +1

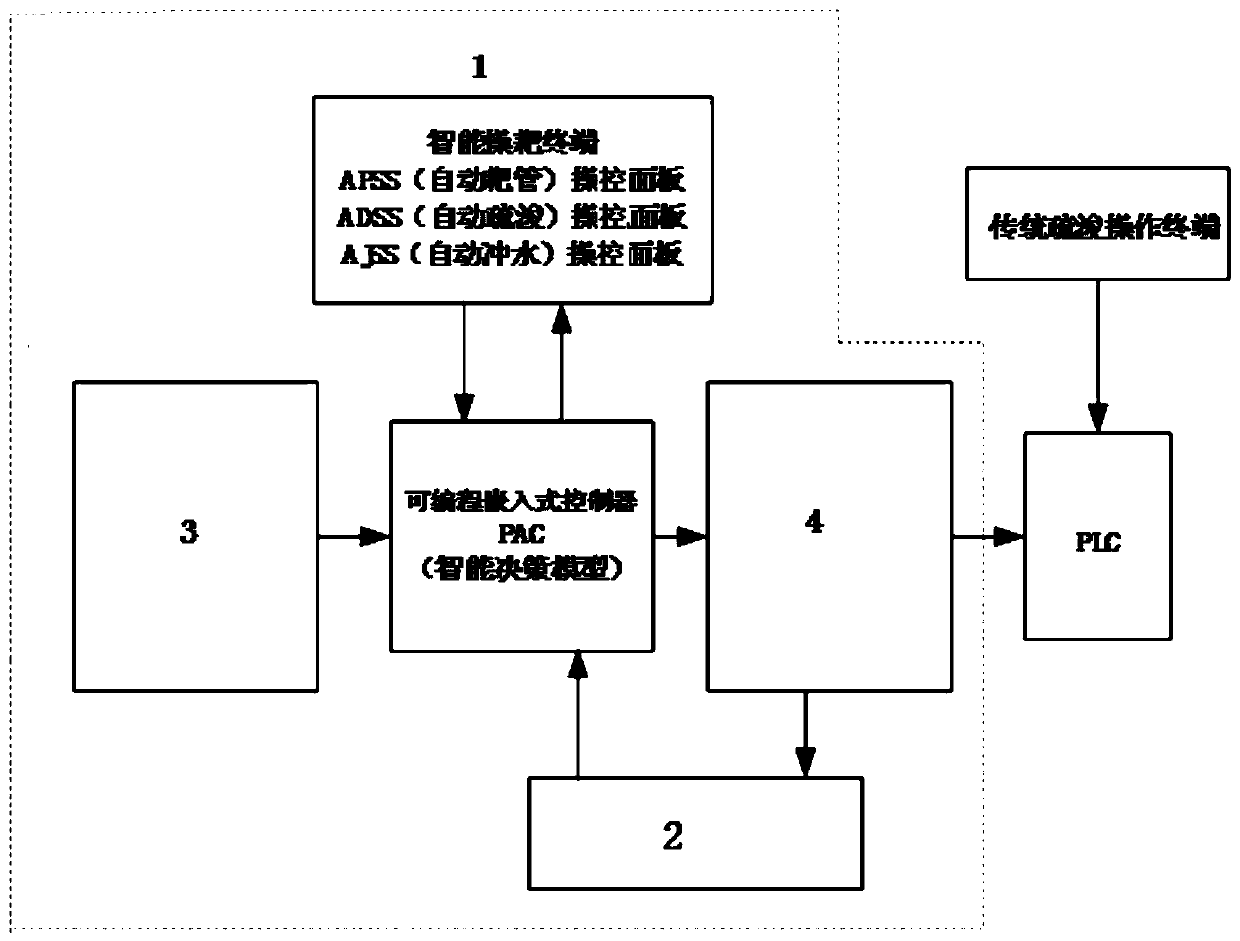

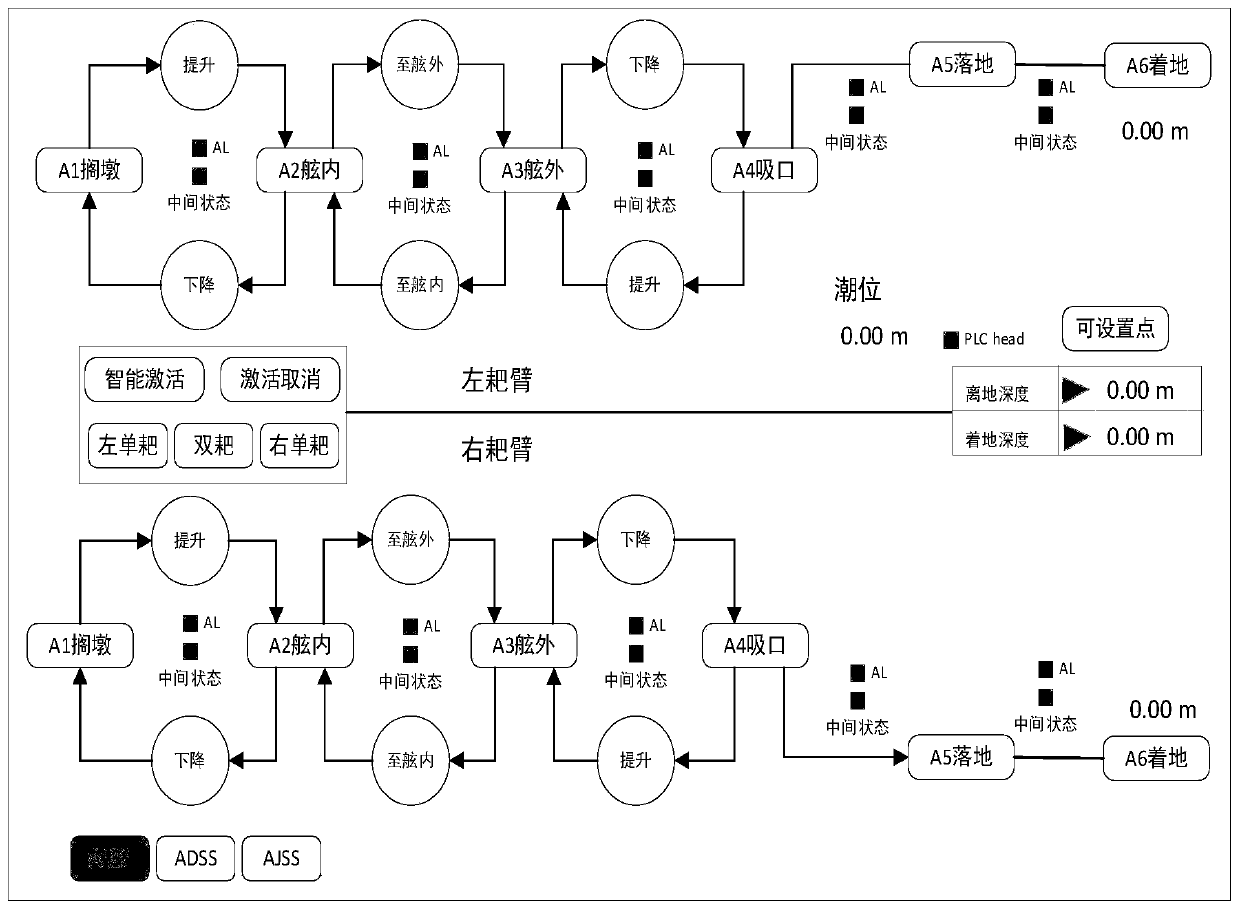

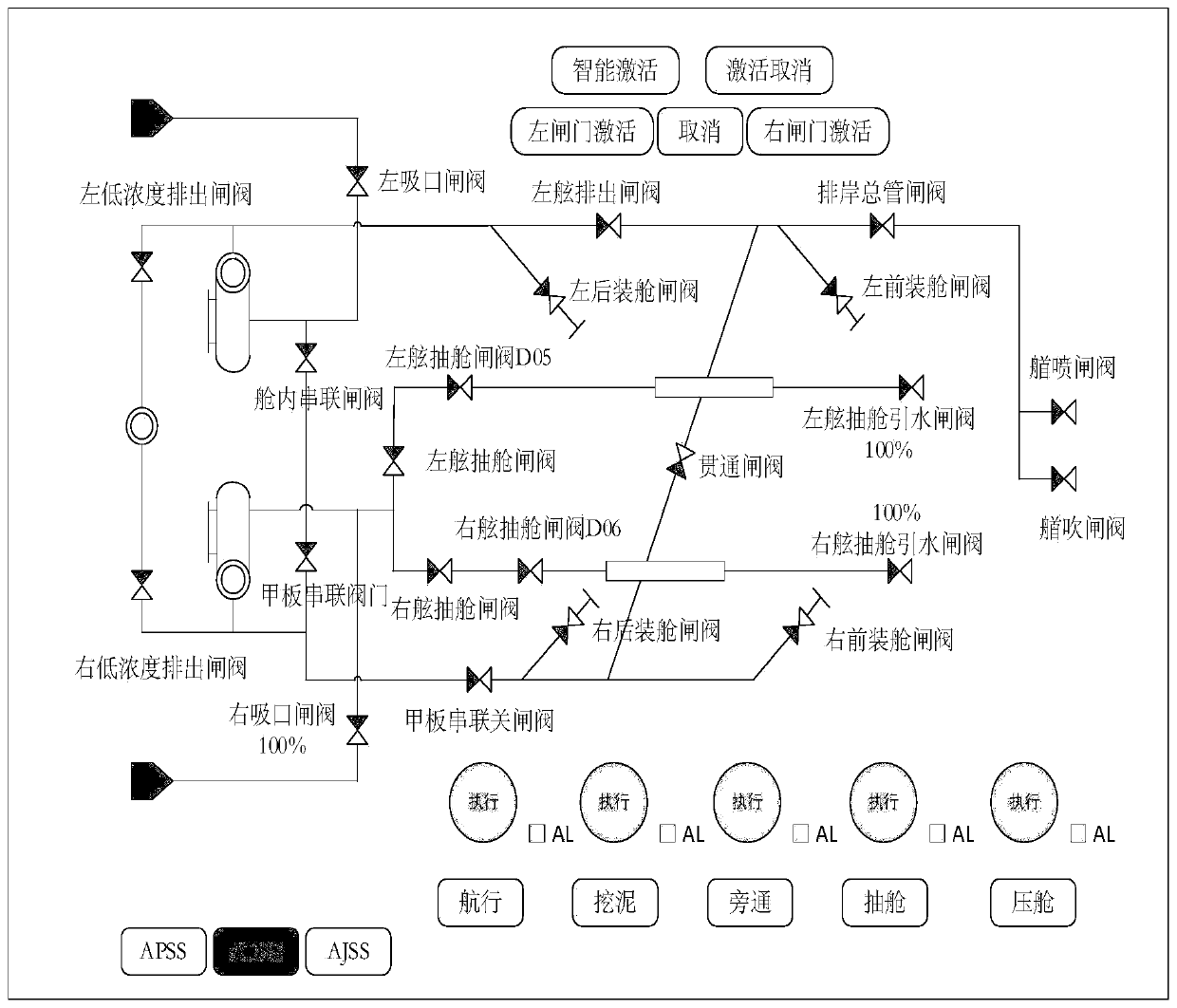

Automatic dredging optimization control system of trailing suction hopper dredger

ActiveCN111485591AEnsure safetyGuaranteed adaptabilityMechanical machines/dredgersTotal factory controlInformation sharingControl system

The invention provides an automatic dredging optimization control system of a trailing suction hopper dredger. The automatic dredging optimization control system comprises a programmable embedded controller (PAC), an intelligent trail operating terminal, an intelligent dredging monitoring interface, a data acquisition module and an output instruction module, wherein the intelligent trail operatingterminal, the intelligent dredging monitoring interface, the data acquisition module and the output instruction module are connected with the PAC. According to the automatic dredging optimization control system, various complex control process sequences can be conveniently and quickly activated by one key through an intelligent control terminal, the overall efficiency of construction operation isimproved, the automatic dredging level is improved, the adaptability of construction to the operation environment is improved, seamless joint and information sharing with an existing trailing suctionhopper dredger control system PLC can be achieved, the mutual interaction switching function also can be completed, operation is flexible, easy and convenient, and the automatic dredging optimizationcontrol system can be used for application demonstration of newly-built ships, upgrading and transformation of old ships and the like, has the wide market application and popularization value, and has very ideal technical effects and practical value for further improving the automation and intelligence levels of an integrated control system of the trailing suction hopper dredger at the same time.

Owner:CCCC GUANGZHOU DREDGING +1

Method and ship for stopping flooding of ship cabin

ActiveCN104843152ANot easy to enter waterImprove impact resistanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesClassical mechanicsPolystyrene

The invention relates to the technical field of shipbuilding, in particular to a method and a ship for stopping flooding of a ship cabin. The method includes filling expandable polystyrene foam filler into the ship cabin. Since the expandable polystyrene foam filler is light and non-absorbable, flooding into the ship cabin is well stopped by the foam filler and the ship cannot sink when the ship cabin is burst and encounters accidents, and finally safety performance of the ship is improved.

Owner:天津新龙桥工程塑料有限公司

Method for measuring dual slope of stern tube rear bearing

ActiveCN111678499ASolve the problem of double slopeEasy to operateMachine bearings testingIncline measurementStructural engineeringMechanical engineering

The invention discloses a method for measuring dual slope of a stern tube rear bearing. The method is simple to operate and convenient in construction, solves the problem of how to detect the dual slope of the stern tube rear bearing of an existing ship, and can meet the shipbuilding precision. In some cases, the method can be expanded and used in the situation of measuring the inclination of inner holes of stern tube rear bearings after other stern tube rear bearings are assembled.

Owner:HUDONG ZHONGHUA SHIPBUILDINGGROUP

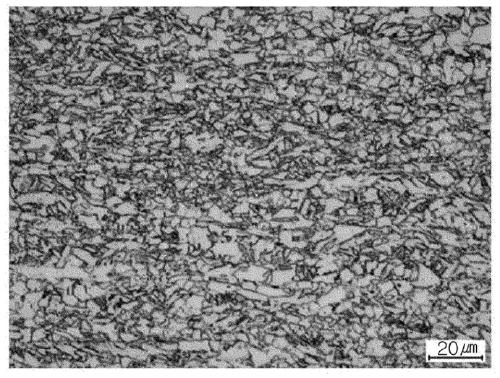

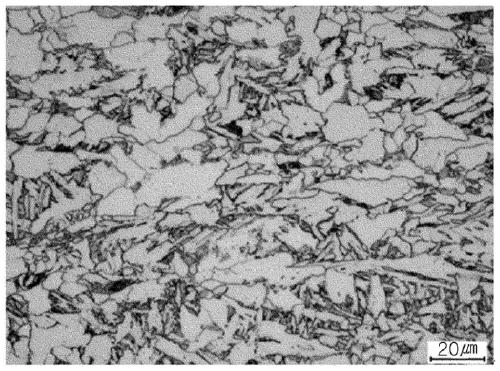

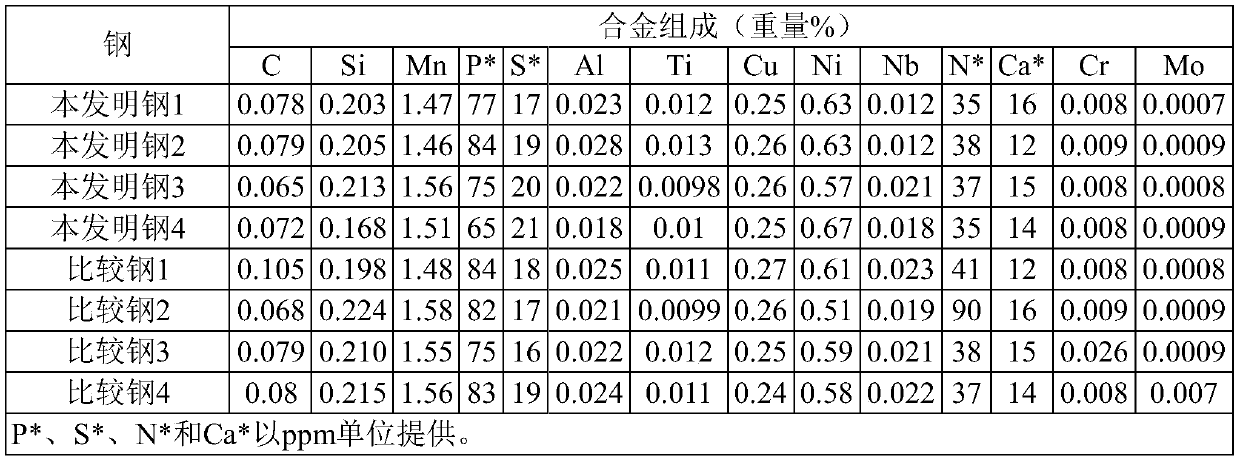

Thick steel plate having excellent low-temperature strain aging impact property and manufacturing method therefor

ActiveCN111225987AExcellent low temperature strain aging impact propertiesHigh yield strengthMarine structureBoat building

The present invention relates to a thick steel plate superior in low-temperature strain aging impact properties and a manufacturing method therefor and, more particularly, to a thick steel plate thatis usable as a material in ship building, marine structures, and the like and which has excellent low-temperature strain aging impact properties and a method for manufacturing the same. An embodimentof the present invention provides a thick steel plate having excellent low-temperature strain aging impact properties, the steel plate comprising, by weight: 0.04-0.1% of C; 0.05-0.4% of Si; 1.0-2.0%of Mn; 0.01% or less of P; 0.003% or less of S; 0.015-0.04% of Al; 0.005-0.02% of Ti; 0.35% or less (0 exclusive) of Cu; 0.05-0.8% of Ni; 0.003-0.03% of Nb; 0.002-0.008% of N; 0.0002-0.0050% of Ca; 0.009% or less of Cr; 0.0009% or less of Mo; and a balance of Fe and other inevitable impurities, with the microstructure thereof including 95% by area or greater of ferrite 10 um or less in average grain size, and a manufacturing method therefor.

Owner:浦项股份有限公司

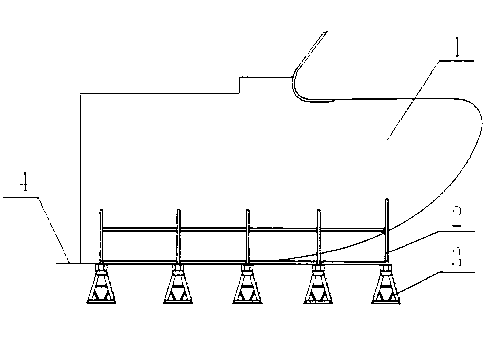

Ship flat ground construction method

ActiveCN114802641AShorten the construction periodImprove build qualityWaterborne vesselsTransverse grooveStern

A ship flat ground construction method comprises the steps that a slipway is built on the flat ground, a plurality of transverse grooves are formed in the plane of the slipway, and air bags are installed in the transverse grooves; welding of the bottom plate of the whole ship is completed in a fragmentation assembly welding mode; the center line of the bottom plate of the whole ship is calibrated by adopting a direct line pulling and marking method, and then the position line of each component is calibrated; welding of the inner bottom plate is completed by adopting a fragmentation assembly welding method, the inner bottom plate is connected with the double-layer bottom framework, and installation of the double-layer bottom is completed; when the inner bottom plate is assembled and welded, the shipway on the two sides of the inner bottom plate is assembled with the shipway on the left side and the shipway on the right side of the inner bottom plate; assembling, welding and painting the front bulkhead, the middle bulkhead and the rear bulkhead of the cargo hold while assembling the left and right side ultra-long blocks; the bow and the stern of the whole ship are manufactured in a segmented mode at the same time, then the whole ship is integrally folded to be formed, outfitting assembling is conducted, and finally the head segment and the tail segment are sequentially assembled; and main and auxiliary machines and the superstructure are hoisted on the ship. The shipbuilding construction period can be shortened, the shipbuilding cost is reduced, and the shipbuilding quality is improved.

Owner:宜昌一凡船舶设计有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com