Ship flat ground construction method

A construction method and flat ground technology, applied to ships and other directions, can solve problems such as huge investment and increased construction costs, and achieve the effects of improving construction quality, reducing costs, and improving weld quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0065] This embodiment takes the Yangtze River 130m bulk carrier as an example to illustrate:

[0066] A method for building a ship on flat ground, comprising the following steps:

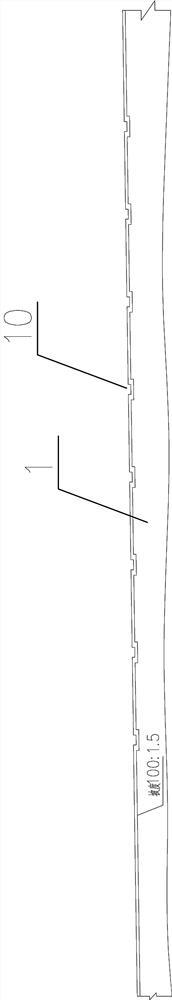

[0067] 1. For the hardened slope-level slipway, the slope ratio of the slope slipway is 100:1.5, and the slipway area is 25*180m.

[0068] The straightness error of the slipway is less than 1%, and the flatness error is less than 3mm. The hardened flat slipway is made of 30# reinforced concrete, and the bottom layer of the concrete is prefabricated with an anti-seepage layer, so that the bottom plate of the ship does not produce soda when welding on the slipway.

[0069] With such a 100:1.5 slope hardened slipway, the ship can be built by the flat construction method. The total length of the cargo hold of a 130m bulk carrier is 100m, and it is a flat-bottom, double-bottom and double-hulled ship.

[0070] 2. Assembling of the bottom of the ship: According to the plane size of the bottom of the ship...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com