Thick steel plate having excellent low-temperature strain aging impact property and manufacturing method therefor

A technology of strain aging and impact characteristics, applied in the field of thick steel plate and its manufacturing, which can solve the problems of reduced toughness, increased cold deformation, and reduced use environment temperature, and achieves excellent yield strength and excellent low temperature strain aging. The effect of impact characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0063] Hereinafter, the present disclosure will be described more specifically through examples. However, the following examples should be considered in a descriptive sense only and not for purposes of limitation. The scope of the invention is defined by the appended claims, and modifications and changes may be reasonably inferred therefrom.

[0064] (Example)

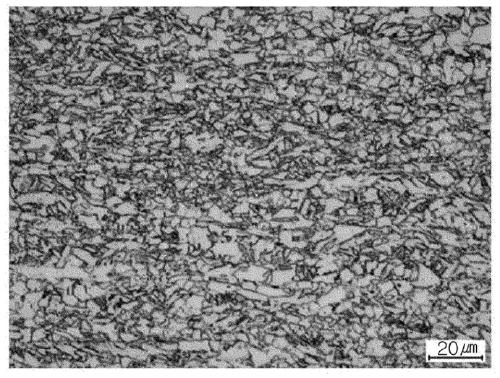

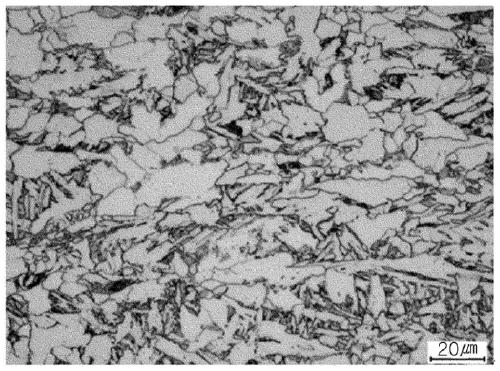

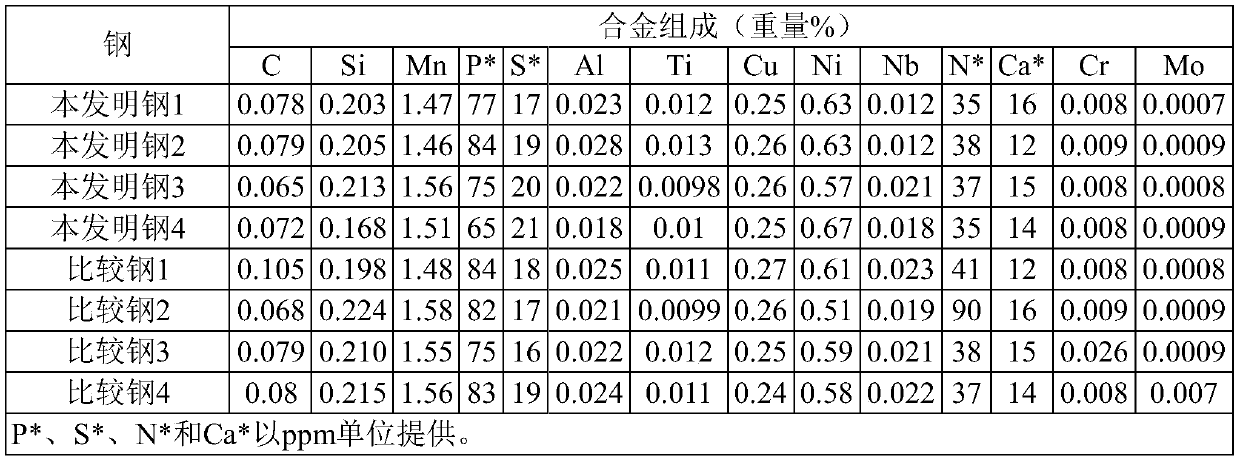

[0065] After preparing molten steel having the alloy composition shown in Table 1, a continuous casting operation was used to produce billets. The billets were reheated, hot rolled and cooled under the conditions shown in Table 2 to produce thick steel plates. After measuring the microstructure and mechanical properties of the thick steel plates thus prepared, the results are shown in Table 3 below.

[0066] [Table 1]

[0067]

[0068] [Table 2]

[0069]

[0070] [table 3]

[0071]

[0072] As can be seen from Tables 1 to 3, in the case of Examples 1 to 5 of the present invention satisfying the alloy com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com