Vehicular bulbous bow integral-replacing process

A bulbous bow and vehicle-mounted technology, which is applied to ship components, ships, transportation and packaging, etc., can solve the problems of complicated assembly operations, long docking period, segmented middle group, etc., and reduce labor intensity and labor cost of workers , Short time occupation, easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

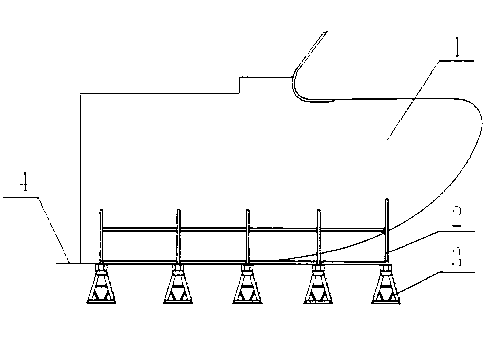

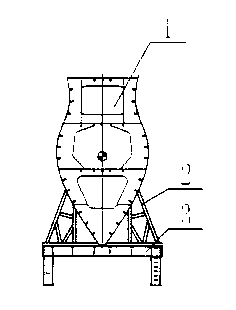

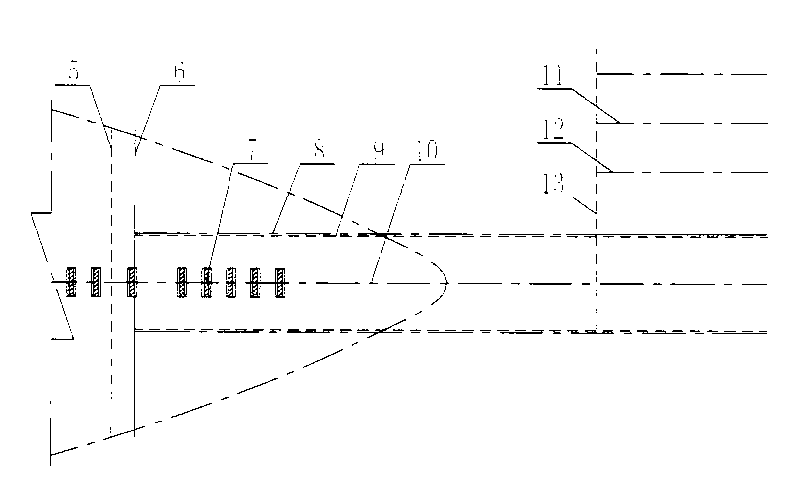

[0030] This embodiment is illustrated by the bulbous bow renewal of the Maersk company "Boston" container ship. Replace the old bulbous bow with a new bulbous bow that is straight, thinner and smaller in size, so that the ship can obtain less sailing resistance at the same speed, so as to reduce the power of the main engine, reduce the fuel consumption of the main engine, and reduce the shipping cost. cost purposes. The entire bulbous bow renewal is carried out by the vehicle-mounted bulbous bow overall renewal process, including the segmental prefabrication of the new bulbous bow and the middle group, the cutting of the old bulbous bow, the drawing of positioning lines, reference lines and guide lines on the bottom of the dock, and the docking The layout of the pier is adjusted, and elevated buttresses are added on both sides of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com