Bearing frame

A load-bearing frame and support frame technology, applied in the field of load-bearing frames, can solve the problems of long load-bearing frame, low utilization rate of gantry crane, poor loading accuracy, etc., and achieve the effect of simple structure, strong adjustability and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The embodiments of the present invention will be described with reference to the drawings. In the drawings of the specification, elements with similar structures or functions will be represented by the same element symbols. The drawings are only used to facilitate the description of various embodiments of the present invention, and are not intended to be an exhaustive description of the present invention, nor are they intended to limit the scope of the present invention.

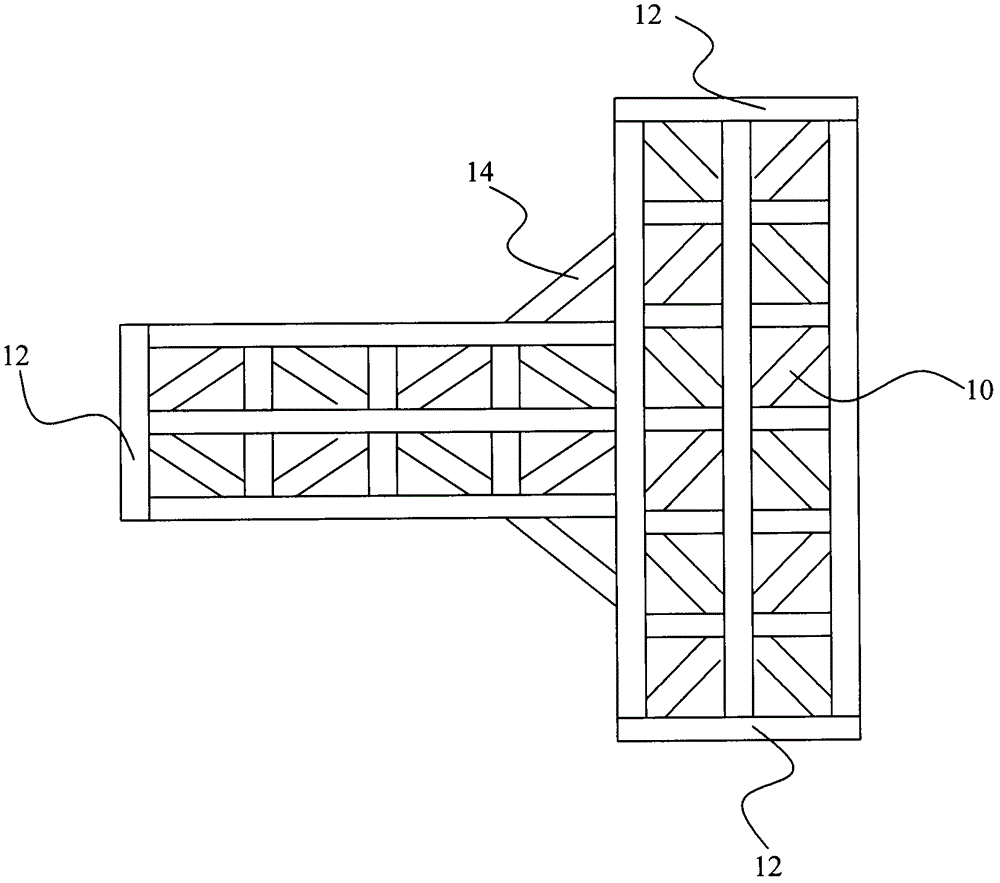

[0020] figure 1 Shows a top view of the platform under one embodiment. In this embodiment, the platform 10 is formed by welding angle irons, and has a "T" shape as a whole, with lining plates 14 arranged at the corners. The platform 10 is provided with three side panels 12 so that the platform 10 can stand on the ground.

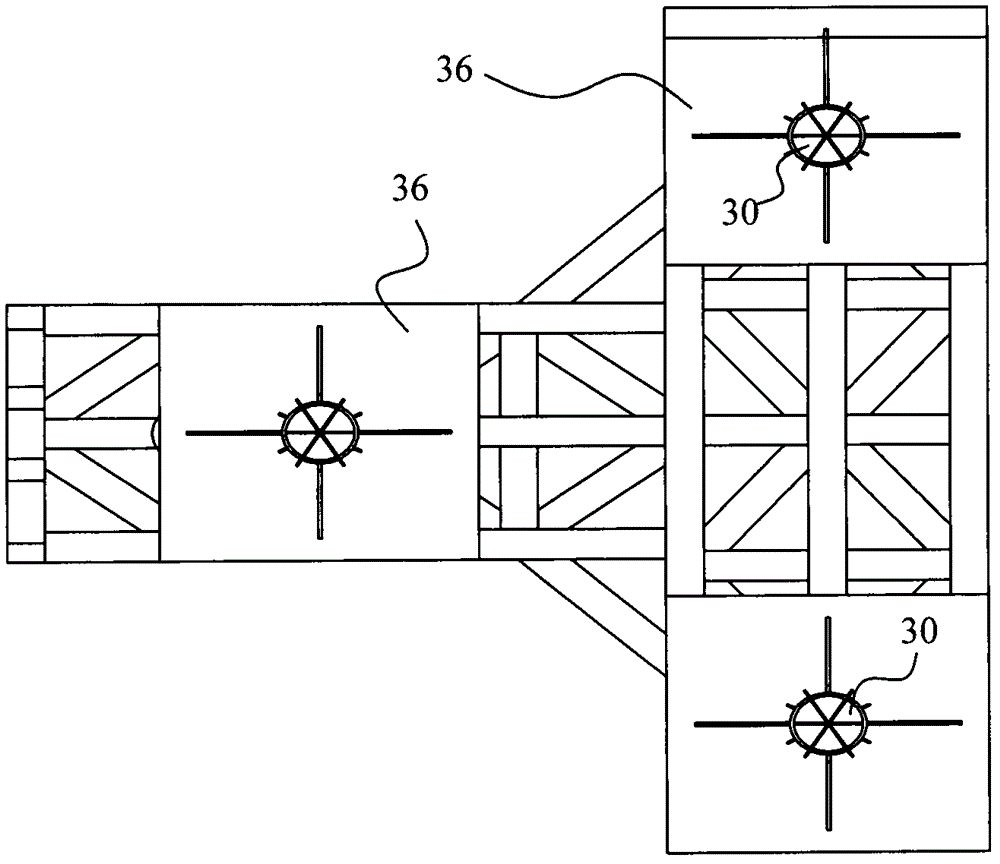

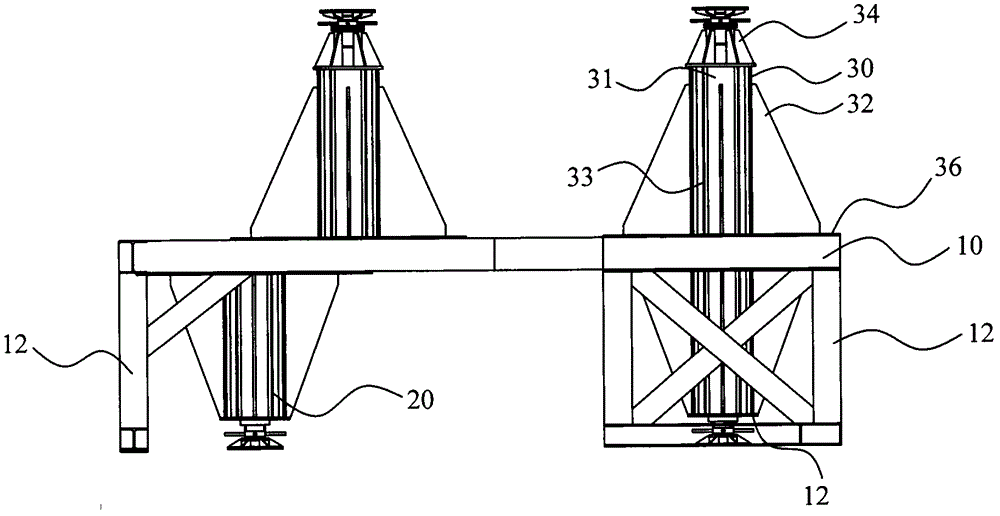

[0021] figure 2 , image 3 with Figure 4 The schematic diagram of the structure of the load-bearing frame under an embodiment of the present invention is shown together. In this emb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com