Method for hoisting bow anchor gear hydraulic pipes of supertanker

A hoisting method and ultra-large technology, applied to ship parts, transportation and packaging, ships, etc., can solve the problems of shortened construction time, tight schedule, and difficult installation of bow windlass hydraulic pipes, so as to shorten the docking period and improve construction environmental effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

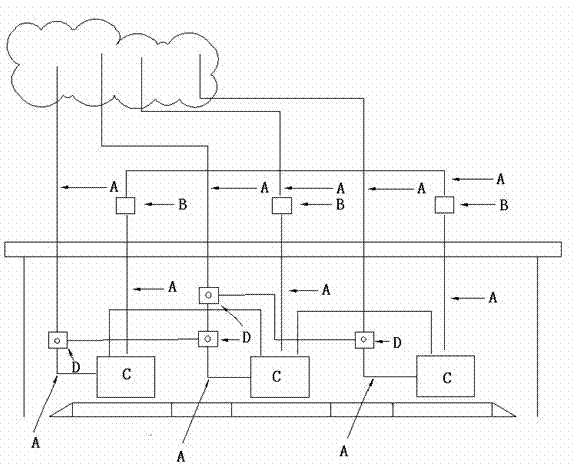

[0020] Below we will further elaborate on the present invention in combination with the accompanying drawings and specific embodiments.

[0021] In the present invention, the hydraulic pump unit of the bow windlass is first set out and positioned according to the position and size on the ship in the infield, and then the design drawings are subdivided to make the hydraulic pipes of the bow windlass into an independent unit form, and the installation position of the hoist is confirmed by contacting the construction method , After the unit construction is completed, it will be hoisted as a whole when the general section is hoisted.

[0022] The hoisting method of the hydraulic pipe of the windlass at the bow of the ultra-large oil tanker of the present invention specifically includes the following steps:

[0023] The first step is production preparation: 1) Disassemble and refine the designed drawings before starting construction, and hand them over to the designer for con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com