Water-borne epoxy composite-containing emulsified asphalt cold-recycling agent and preparation method thereof

A water-based epoxy emulsion and emulsified asphalt technology, which is used in building structures, building components, building insulation materials, etc., can solve the problems of poor storage stability, easy demulsification, and high temperature of finished products, achieve low equipment requirements, and avoid brittleness. The effect of cracking and wear resistance improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

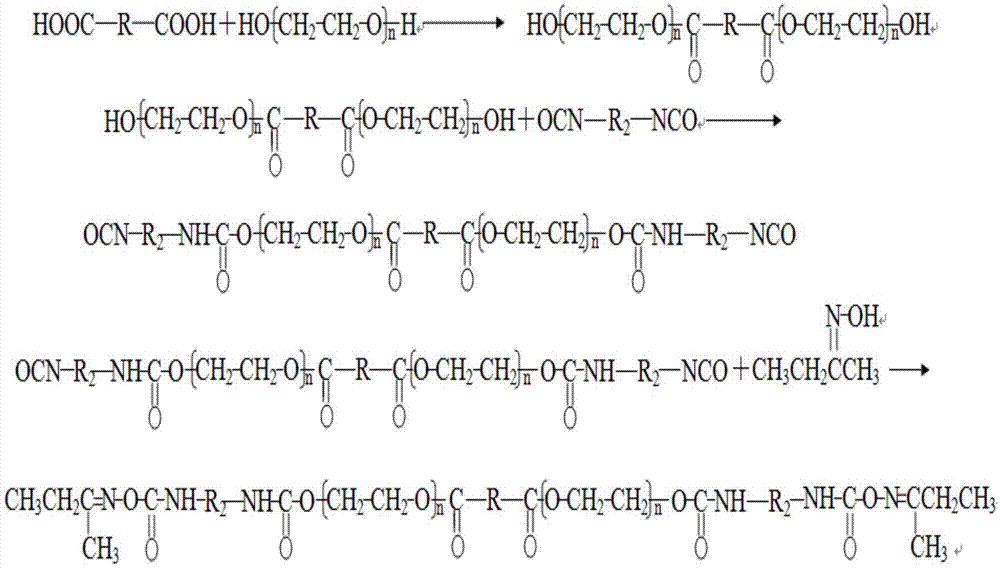

[0031] 1. Synthesis of blocked waterborne polyurethane:

[0032] The first step is to prepare polyester polyol; after evacuating PEG-1000 to remove water, add adipic acid and p-toluenesulfonic acid (catalyst, 1% of the total mass), and react at 80-90°C for 3 hours to obtain terminal hydroxyl groups Polyester polyol; Second step, prepare end isocyanate group prepolymer; With above-mentioned polyester polyol and TDI (N 2 protection) in the presence of dibutyltin dilaurate catalyst (accounting for 1% of the total mass), react at 70-80°C for 2.5h; the molar ratio of adipic acid, PEG-1000 and TDI is 1:2:2.5; Three steps, the preparation of end-blocking type waterborne polyurethane; The above-mentioned terminal isocyanate group prepolymer (N 2 protection) by adding a certain amount of methyl ethyl ketone oxime and reacting at 70-80°C for 1.5h to obtain a blocked water-based polyurethane.

[0033] 2. Preparation of waterborne epoxy compound:

[0034]Utilize the shear mixing equipm...

Embodiment 2

[0042] 1. Synthesis of blocked waterborne polyurethane:

[0043] The first step is to prepare polyester polyol; vacuumize PEG-1500 to remove water, add succinic acid and p-toluenesulfonic acid (catalyst, 1% of the total mass), react at 80-90°C for 3.5h, and obtain terminal Hydroxyl polyester polyol; second step, prepare terminal isocyanate group prepolymer; above-mentioned polyester polyol and MDI (N 2 protection) in the presence of stannous octoate catalyst (accounting for 1% of the total mass), react at 70-80°C for 2h; the molar ratio of the succinic acid, PEG-1500 and MDI is 1:2.1:3; the third step, The preparation of end-blocking type waterborne polyurethane; The above-mentioned terminal isocyanate group prepolymer (N 2 protection) by adding a certain amount of methyl ethyl ketone oxime and reacting at 70-80°C for 2 hours to obtain a blocked water-based polyurethane.

[0044] 2. Preparation of waterborne epoxy compound:

[0045] Utilize the shear mixing equipment with w...

Embodiment 3

[0053] 1. Synthesis of blocked waterborne polyurethane:

[0054] The first step is to prepare polyester polyol; after vacuumizing PEG-2000 to remove water, add phthalic anhydride and p-toluenesulfonic acid (catalyst, 1% of the total mass), and react at 80-90°C for 4 hours to obtain Hydroxyl-terminated polyester polyol; second step, prepare terminal isocyanate group prepolymer; above-mentioned polyester polyol and liquefied MDI (N 2 protection) in the presence of dibutyltin dilaurate catalyst (accounting for 1% of the total mass), react at 70-80°C for 2h; the molar ratio of phthalic anhydride, PEG-2000 and liquefied MDI is 1:2.1:2.5 ; the third step, the preparation of end-blocking type water-based polyurethane; the above-mentioned terminal isocyanate group prepolymer (N 2 protection) by adding a certain amount of methyl ethyl ketone oxime and reacting at 70-80°C for 2 hours to obtain a blocked water-based polyurethane.

[0055] 2. Preparation of waterborne epoxy compound:

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

| stability | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com