Composite high-viscosity modified asphalt and preparation method thereof

A technology of modified asphalt with high viscosity, which is applied in building components, building insulation materials, buildings, etc. It can solve the problems of unreported segregation test of modified asphalt, high viscosity of modified asphalt at 135°C, and limited amount of SBS added. , to achieve the effects of excellent thermal storage stability, excellent high and low temperature performance, and reduced segregation tendency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Step 1: In terms of mass fraction, add 6 parts of SBS to 94 parts of 70# Zhonghai bitumen, and perform high-speed shearing at 170-190°C for 45 minutes, and the shearing speed is 3000r / min.

[0033] Step 2: Transfer the sheared modified asphalt to a high-speed disperser and stir for 150 minutes. The stirring speed is 800-900r / min. During the process, add a total of 0.15 parts of sulfur to prepare modified asphalt.

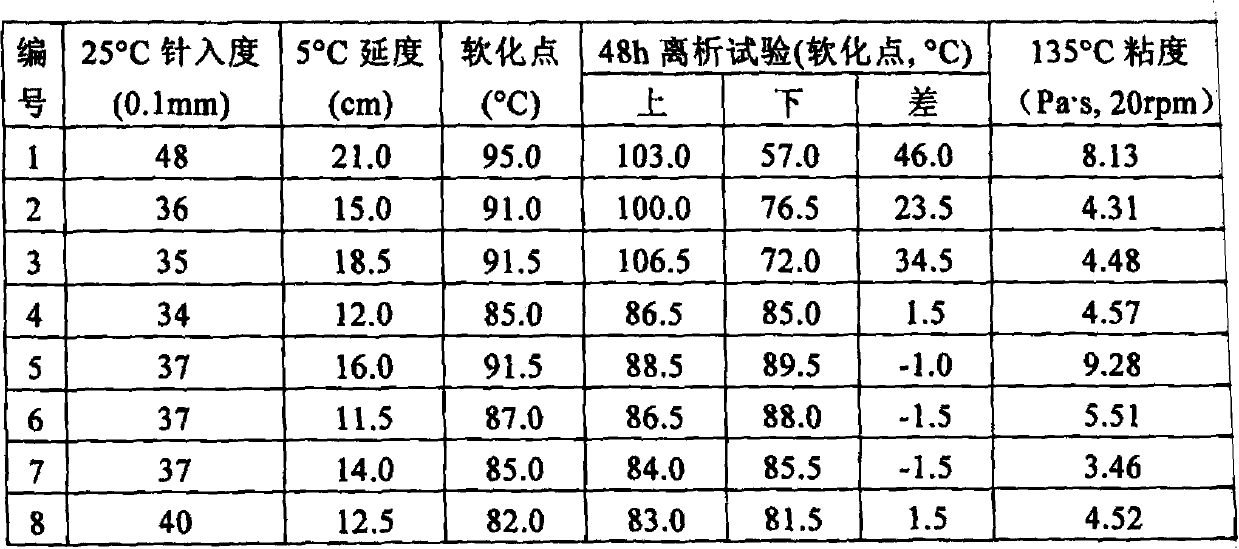

[0034] The prepared modified asphalt is numbered 1, and its properties are shown in Table 1.

Embodiment 2

[0036] Step 1: In terms of parts by mass, mix 50 parts of SBS and 50 parts of desulfurized colloidal particles evenly, and prepare SBS / desulfurized colloidal granules compound by mixing in a Hacker internal mixer, the reaction temperature is 160°C, and the rotational speed is 50r / min, the time is 10min. After blending, the modified particles are prepared by mechanical granulation.

[0037] Step 2: In terms of parts by mass, add 12 parts of modified particles to 88 parts of 70# Zhonghai bitumen, and shear at 170-190°C for 60 minutes at a high speed with a shear speed of 4000r / min.

[0038]Step 3: Transfer the sheared modified asphalt to a high-speed disperser and stir for 120 minutes at a stirring speed of 800-900 r / min to prepare a composite high-viscosity modified asphalt.

[0039] The prepared modified asphalt is numbered 2, and its properties are shown in Table 1.

Embodiment 3

[0041] Step 1: In terms of parts by mass, add 6 parts of SBS, 6 parts of desulfurized rubber particles, and 1 part of epoxy natural rubber to 87 parts of 70# Zhonghai bitumen, and shear at a high speed for 60 minutes at 170-190 ° C , The shear speed is 4000r / min.

[0042] Step 2: Transfer the sheared modified asphalt to a high-speed disperser and stir for 120 minutes at a stirring speed of 800-900 r / min to prepare a composite high-viscosity modified asphalt.

[0043] The prepared modified asphalt is numbered 3, and its properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com