High temperature storable high viscosity and high elasticity modified asphalt and preparation method thereof

A modified asphalt, storage-resistant technology, applied in the direction of building insulation materials, building components, buildings, etc., can solve the problems of weak van der Waals force, complex production process, and lack of extensive application, and achieve a wide range of sources and easy promotion and application. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

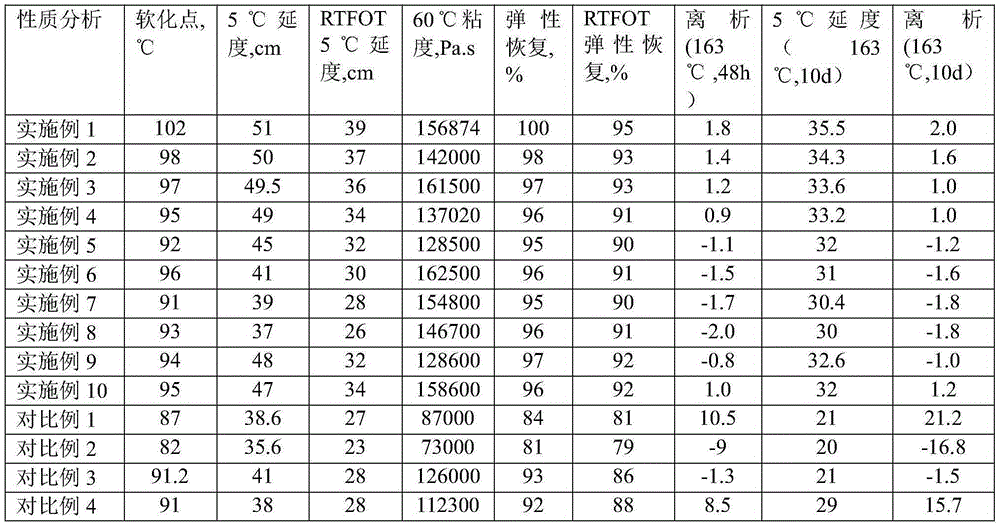

[0042] Example 1

[0043] The high-viscosity and high-elastic modified asphalt is composed of the following components by weight: 100 parts of SK asphalt with a penetration of 100dmm, 8 parts of 40-mesh waste rubber powder, 6 parts of SBS, with a weight average molecular weight of 80,000, 3 parts of EVA , its vinyl acetate content is 15%, melt index is 180g / 10min, 0.5 part of aluminum-zirconium coupling agent, 0.5 part of minus four-line extraction oil, 0.5 part of elemental sulfur, 1.5 part of N-phenyl-β-naphthylamine, high The viscoelastic modified asphalt is prepared according to the following process:

[0044] S1: Mix 4 parts of waste rubber powder, 6 parts of SBS, 3 parts of EVA, 0.5 part of coupling agent, and 0.5 part of compatibilizer to prepare a blend of waste rubber powder / SBS / EVA in an internal mixer. Pelletizing to obtain waste rubber powder / SBS / EVA blended pellets.

[0045] S2: heat 100 parts of base asphalt to a flowing state, heat up to 190°C, turn on the hig...

Example Embodiment

[0048] Example 2

[0049] The high-viscosity and high-elastic modified asphalt is composed of the following components: 100 parts of Esso asphalt, whose penetration is 97dmm, 9 parts of 50-mesh waste rubber powder, 5.5 parts of SBS, whose weight average molecular weight is 88,000, 2.5 parts of EVA, its Vinyl acetate content of 30%, melt index of 120g / 10min, 1 part of aluminum-titanium composite coupling agent, 0.5 part of catalytic cracking slurry extraction oil, 0.5 part of phosphoric acid, 1.0 part of 2,2,4-trimethyl-1,2 - Dihydroquinoline.

[0050] The difference between the preparation process and steps of high-viscosity and high-elasticity modified asphalt and Example 1 is that the amount of waste rubber powder used in step S1 is 4 parts, the shear rate in step S2 is 5000r / min, the shearing temperature is 180°C, and the shearing temperature is 180°C. For 50 minutes, in step S3, blend A is heated to 190° C., and the reaction is stirred for 120 minutes. , and its properti...

Example Embodiment

[0051] Example 3

[0052] The high-viscosity and high-elasticity modified asphalt is composed of the following components: 100 parts of Liaohe asphalt, whose penetration is 93dmm, 10 parts of 60-mesh waste rubber powder, 5 parts of SBS, whose weight average molecular weight is 91,000, 2.5 parts of EVA, its acetic acid Ethylene content is 28%, melt index is 130g / 10min, 0.5 part of aluminum-zirconium coupling agent, 1 part of aluminum-titanium composite coupling agent, 1 part of coking wax oil extraction oil, 0.5 part of polyphosphoric acid, 0.5 part of 6-ethoxy base-2,2,4-trimethyl-1,2-dihydroquinoline.

[0053] The difference between the preparation process and steps of high-viscosity and high-elasticity modified asphalt and Example 1 is that the amount of waste rubber powder used in step S1 is 5 parts, the shear rate in step S2 is 5500r / min, the shearing temperature is 185 ° C, and the shearing temperature is 185 °C. For 50 minutes, in step S3, blend A is heated to 190° C., ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com