Patents

Literature

62results about How to "Good comprehensive performance index" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

High-temperature-resistant heat-insulation paint and preparation method thereof

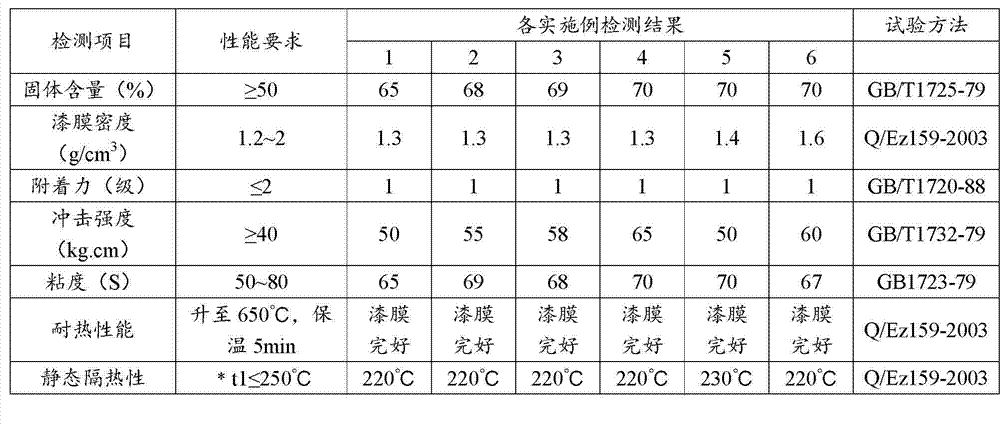

The invention relates to high-temperature-resistant heat-insulation paint and a preparation method thereof and belongs to the technical field of materials. The paint is used for heat-insulation protection of spacecrafts. The paint comprises, by weight, 25-35 parts of epoxide resin modified organic silicon resin containing nano particles, 10-20 parts of polybenzimidazole, 5-10 parts of high-temperature-resistant inorganic nonmetal compounds, 20-30 parts of high-temperature-resistant fillers, 1-3 parts of curing agents and 5-27 parts of solvents. The paint is high-temperature resistant, low in thermal conduction, high in shock resistance, low in density, good in bonding capacity, good in comprehensive performance index and capable of guaranteeing strength and rigidity of structural materials under the high temperature condition and meeting harsh requirements of aviation and space fields.

Owner:SHANDONG LIAOCHENG QILU SPECIAL PAINT

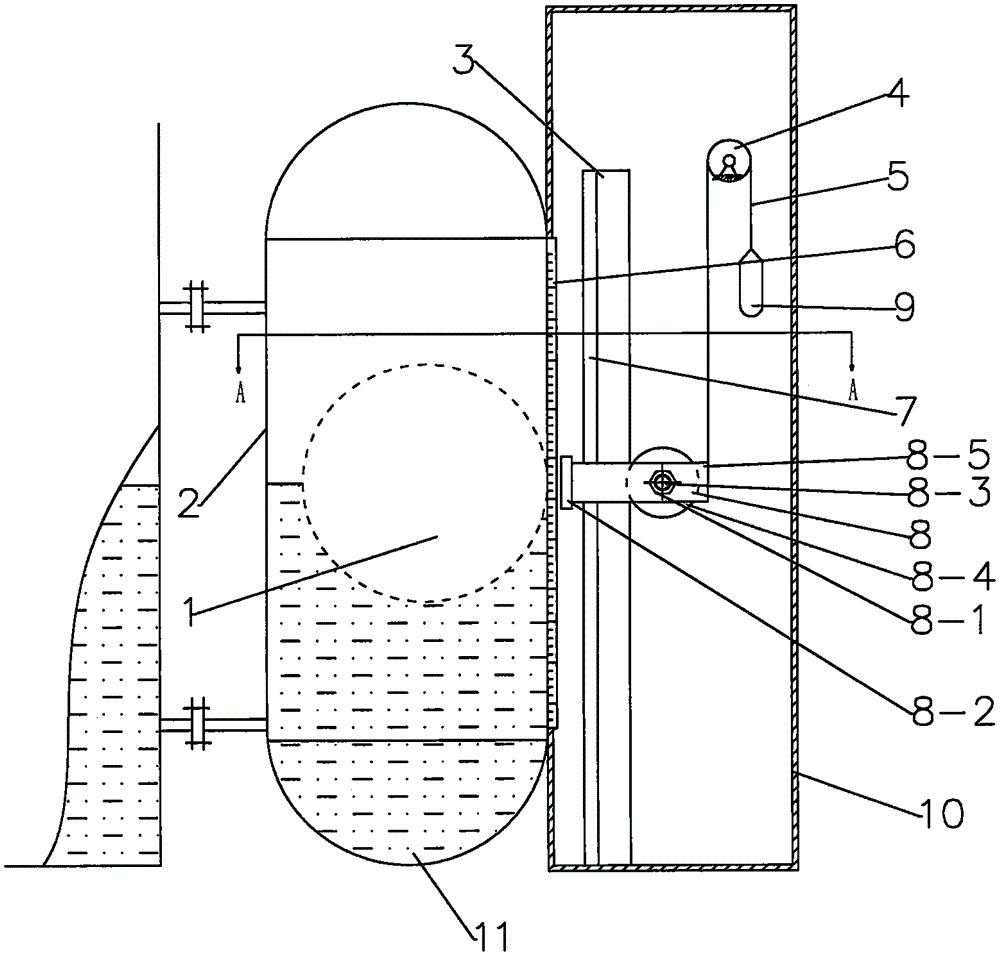

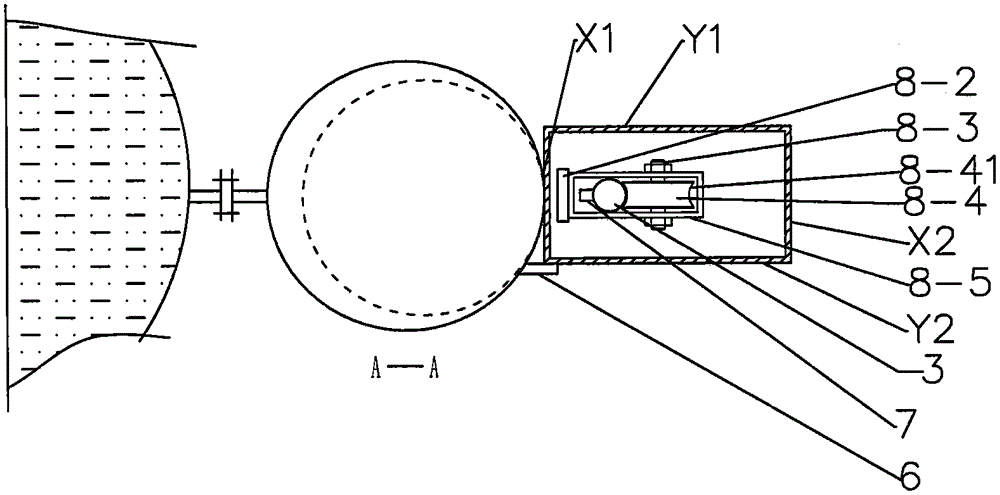

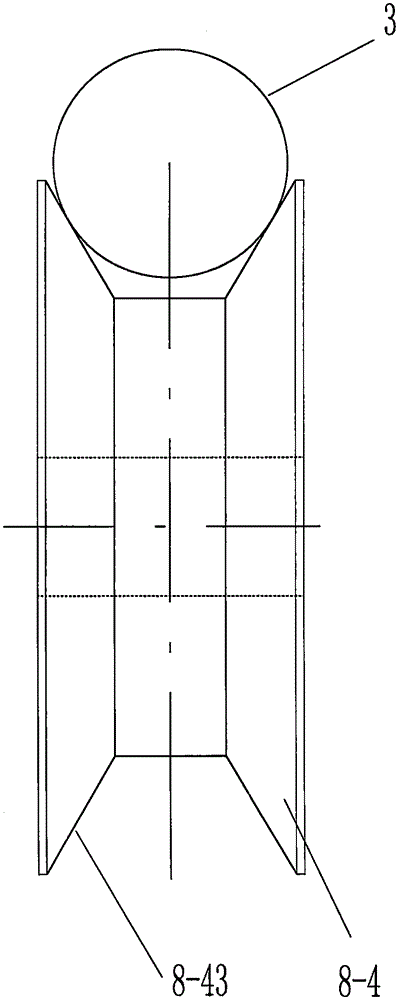

Space extensible catopter device

InactiveCN101224793AStable supportHigh storage rateCosmonautic power supply systemsAntenna adaptation in movable bodiesEngineeringArea density

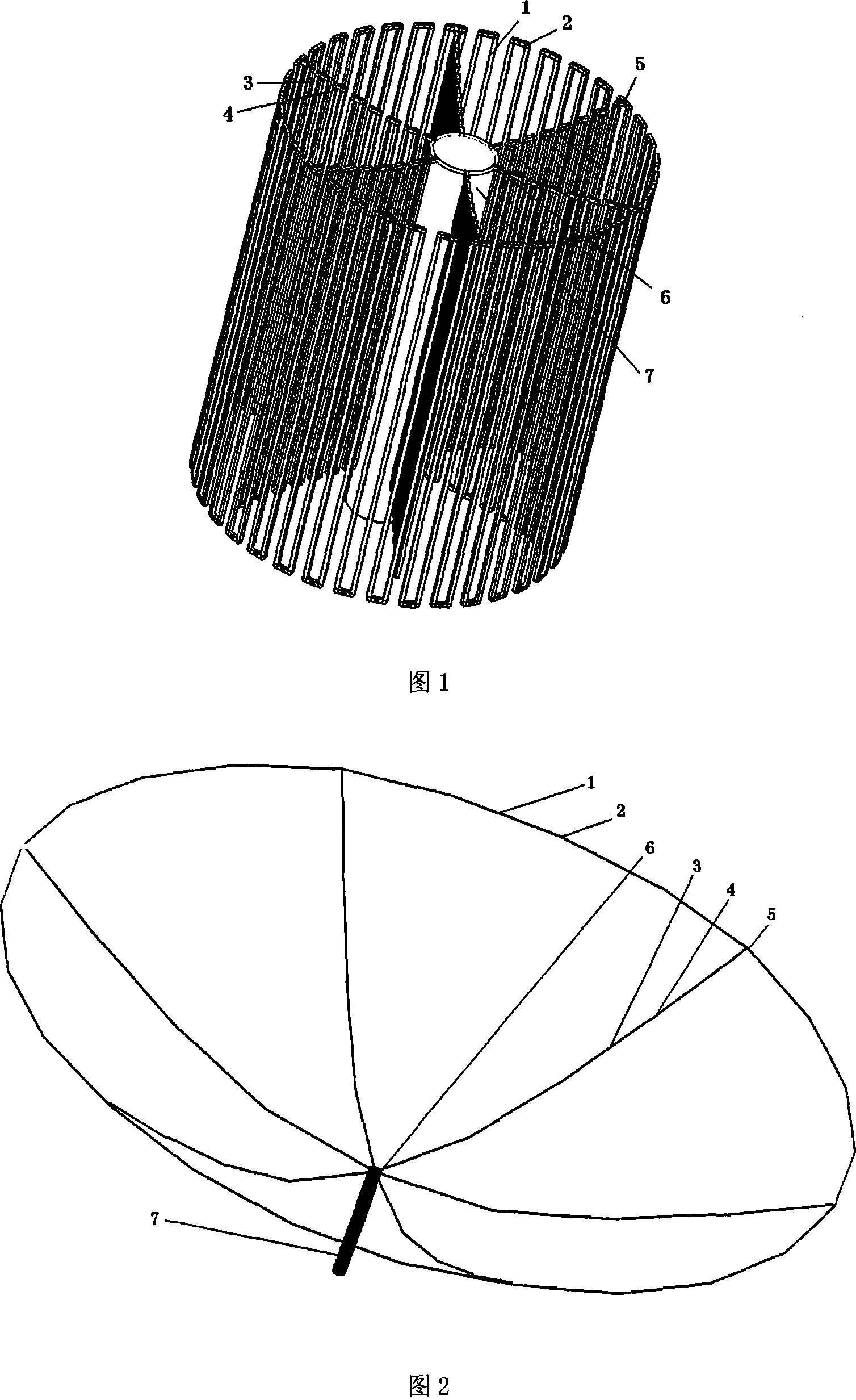

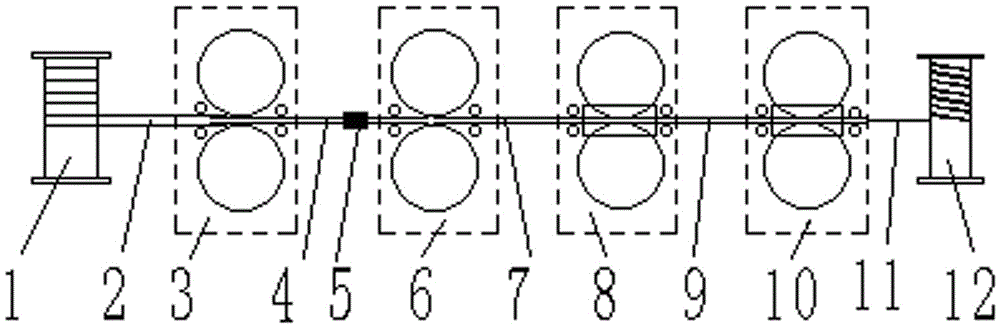

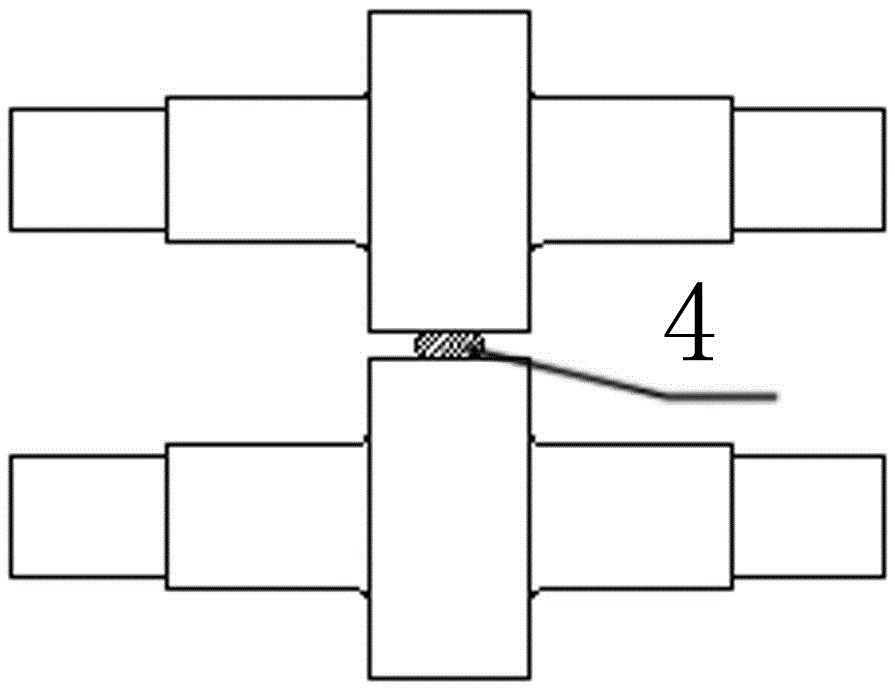

The invention discloses a device that can stretch the reflection plane in space, which includes a foldable ring pole, a foldable rib pole and a plurality of connection joints, wherein, every two foldable ring poles (1) are connected by a ring pole connection joint (2) to form a furling and stretching ring structure; every two foldable rib poles (3) form a furling and stretching rib structure by a rib pole connection joint (4); one end of the rib structure is connected with the ring structure by a ring rib connection joint (5) and the other end is connected with a central ribbed tube connection joint (6) to form a whole rigid body; the ring pole connection joint and the rib pole connection joint drives, locks and controls the foldable ring pole to stretch from the vertical furled state to the horizontal stretched state and controls the foldable rib pole to stretch from the vertical furled state to the expected curve proximity state. The invention has low area density, high structural precision and large holding rate and can be used for the ground or space as a reflector or a collector.

Owner:XIDIAN UNIV

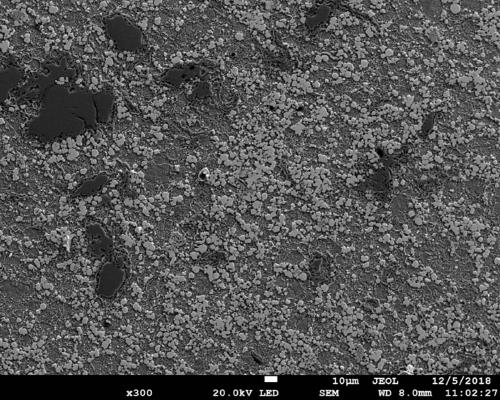

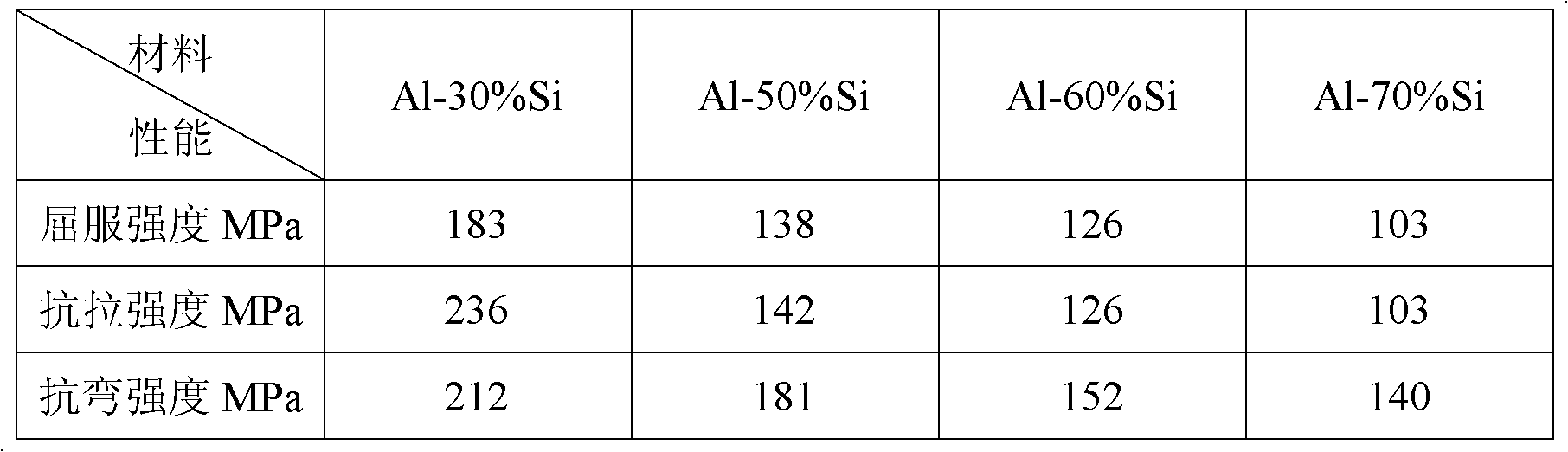

Process for preparing silumin electronic package materials

InactiveCN1877821AImprove featuresImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSiluminMaterials processing

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) proceeding ball grinding disposal for Al-Si alloy powder at 5-15:1 percentage for 8-32 h; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

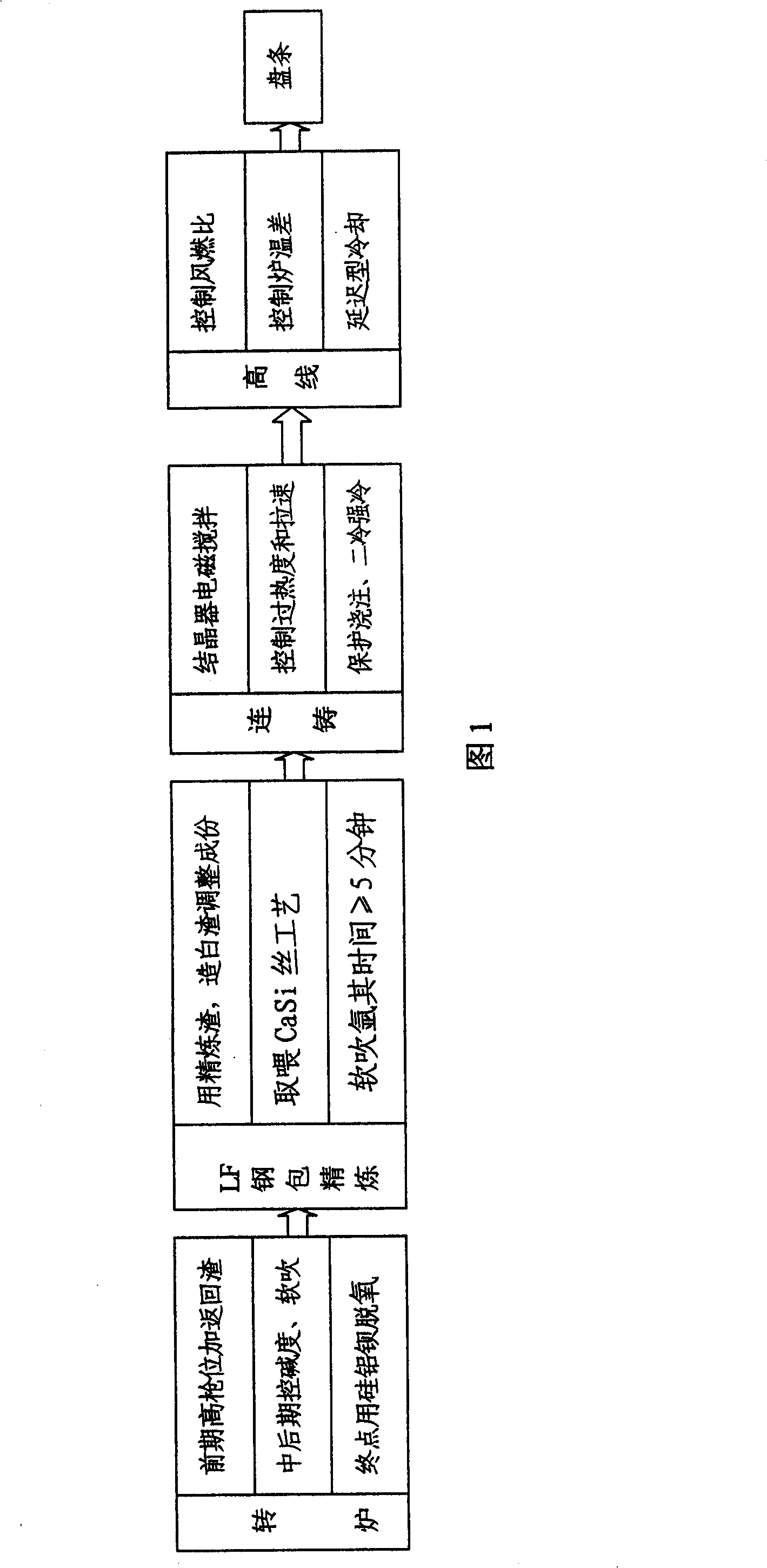

Wire rod for prestressed concrete steel stick and manufacturing process

InactiveCN101245433AGood comprehensive performance indexReduce the probability of wire breakageRoll mill control devicesMetal rolling arrangementsAlkalinityWire rod

The invention relates to a novel steel wire rod and a manufacturing technique thereof. A prestressed steel bar used as the distributed steel of tubular piles is a new product developed in recent years, and the raw material thereof, namely, the steel wire rod, has no special steel and production technique; the controls for the components and performances, etc. of the steel wire rod are different, which results in larger fluctuation thus bringing the producers and the users more difficulties; therefore, the novel steel wire rod and the manufacturing technique thereof are invented. The components of the novel steel by weight percentage are: 0.28-0.34 percent of C, 0.70-1.10 percent of Si, 1.10-1.50 percent of Mn, less than or equal to 0.025 percent of S, less than or equal to 0.025 percent of P, less than or equal to 0.25 percent of Ni, less than or equal to 0.25 percent of Cr and less than or equal to 0.20 percent of Cu; the adopted technique is converter - ladle furnace (LF) refining - continuous casting - highline mill; in the converter process, high lance height is adjusted, returned slag by the converter is added in the front period, and the alkalinity is controlled in the middle and late period; stirring is done under soft blowing before the end of the process, and then deoxidation by adopting SiAlBa is carried out; in the ladle furnace (LF) refining process, reductive white slag is adopted, the CaSi wires are fed and before finishing the refining, and soft argon blowing is done; in the continuous casting process, the degree of superheat and the casting speed of the molten steel are controlled and casting is preformed under whole course protection; in the rolling process, the delayed cooling technique is adopted. The novel steel wire rod, when in use, the control range of the components is narrow, therefore, the fluctuation of adjacent batches is small; the performance of the novel steel wire rod is stable, and the aberration thereof is small.

Owner:TIANJIN IRON & STEEL GRP

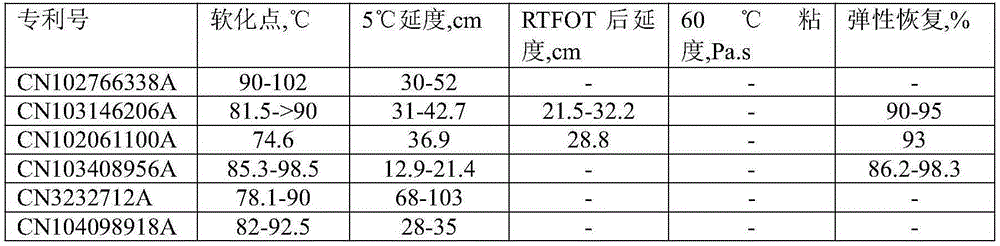

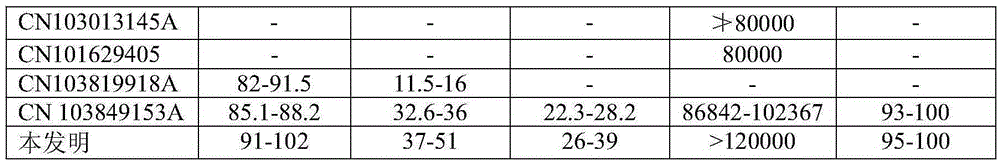

High temperature storable high viscosity and high elasticity modified asphalt and preparation method thereof

ActiveCN106800787AWide variety of sourcesEasy to promote and applyBuilding insulationsWaste rubberAging resistance

Owner:PETROCHINA CO LTD

Preparation method for sodium alginate-nano silicon dioxide compound film

The invention discloses a preparation method for a sodium alginate-nano silicon dioxide compound film. Through a series of technical means of performing in-situ compounding on sodium alginate and nano silicon dioxide, performing ultrasonic defoaming treatment before film casting, increasing the concentration of sodium alginate by step control in a preparation process, controlling addition time and speed of hydrochloric acid and the like, so that nano silicon dioxide is ideally dispersed in a reaction system, an agglomeration phenomenon is avoided, and the sodium alginate / nano silicon dioxide film which is compact in structure, colorless, transparent, airtight, high in quality, degradable, good in waterproof performance and strong in ultraviolet-proof capability, has comprehensive performance indexes and is suitable for food packaging is prepared. Compared with the prior art, the preparation method has the characteristics of simple and easily controlled process, low preparation cost and the like.

Owner:QINGDAO UNIV

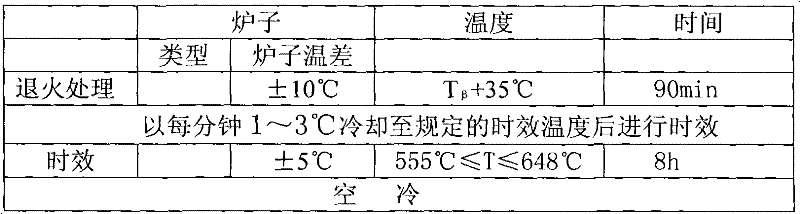

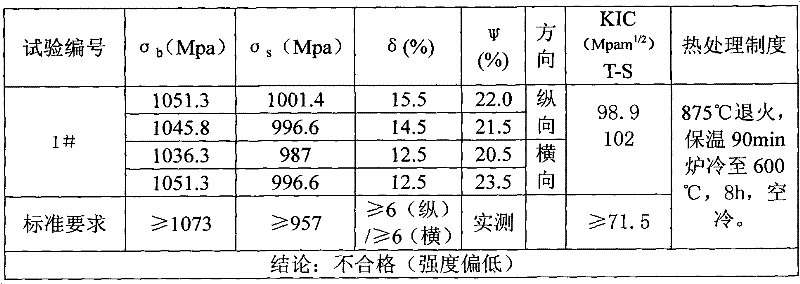

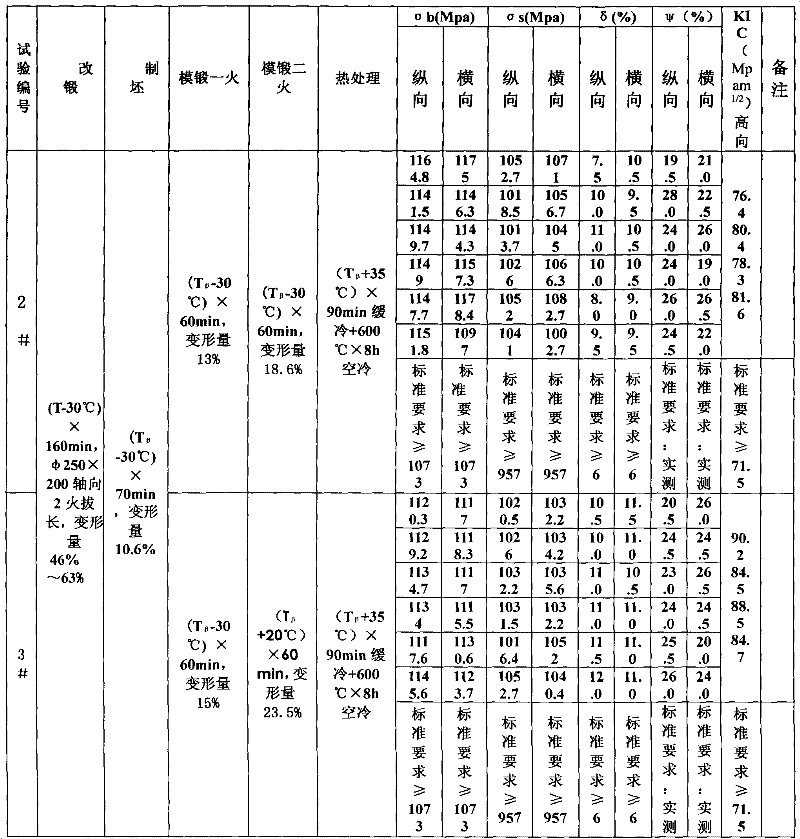

Hot working method for improving structure property of Ti5553 titanium alloy

The invention discloses a hot working method for improving structure property of Ti5553 titanium alloy, which comprises the steps of: firstly, performing two-phase region re-forging (alpha equiaxial+ beta transformation) on a titanium alloy blank; and then, performing beta forging on the re-forged blank (the beta forging is a forging method of heating above phase transformation point); and finally, performing beta thermal treatment to primarily form a fine and dense net basket structure after the re-forging operation; and a fine flaky alpha phase inversion in beta crystal grain and a fine, disperse and discontinuous alpha phase inversion at the crystal boundary are generated during the final beta thermal treatment process to improve the comprehensive structure property of the beta titanium alloy. By means of the heating re-forging in two-phase region (alpha equiaxial+ beta transformation) and the beta forging, nucleation energy and broken crystal structures formed by relatively large deformation quantity lay a good foundation for improving the flaky alpha phase inversion and the granular beta phase inversion in the successive beta thermal treatment, so as to obtain a member with uniform, fine and dense structure and good comprehensive performance indexes.

Owner:SHAANXI HONGYUAN AVIATION FORGING

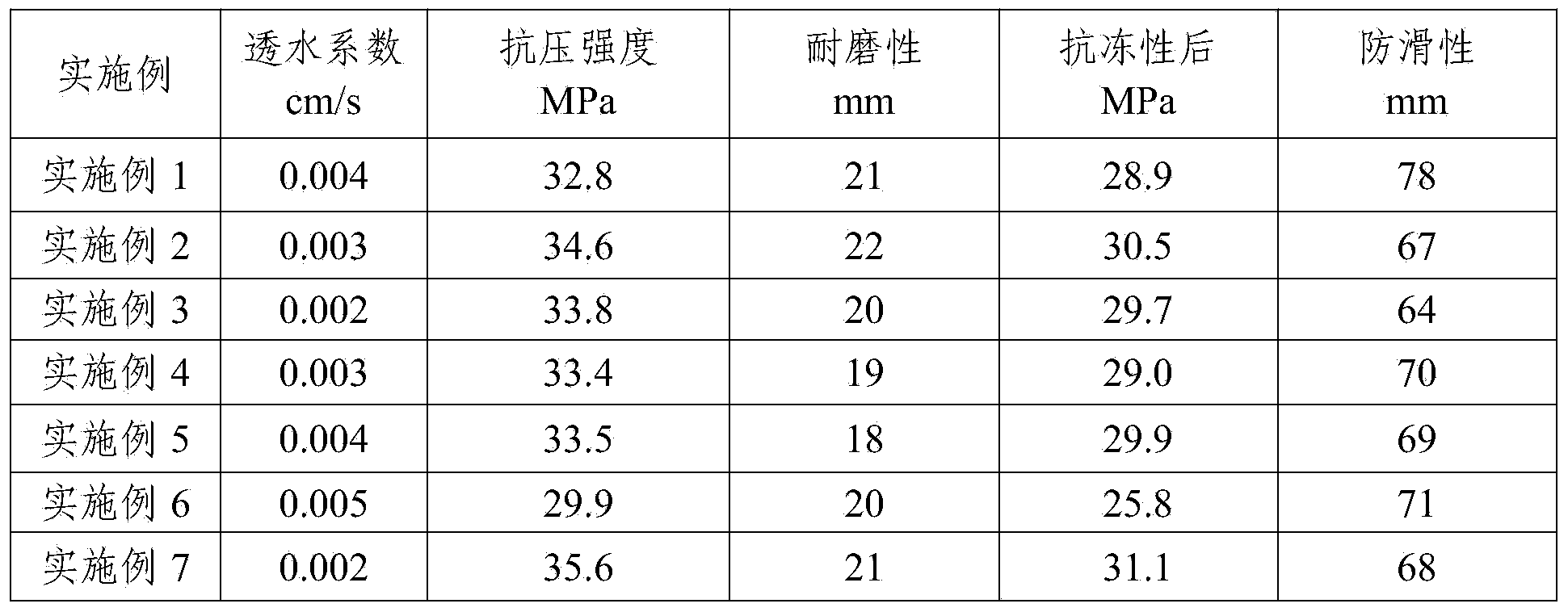

Ferro-nickel slag water permeable brick for pavements and preparation method of water permeable brick

ActiveCN104163596AEfficient resource utilizationSolve intractable problemsSolid waste managementBrickResource utilization

The invention relates to the technical field of building materials and particularly relates to a ferro-nickel slag water permeable brick for pavements and a preparation method thereof. A great deal of ferro-nickel slag is mixed into the adopted raw materials, so that the resource utilization of the ferro-nickel slag is remarkable, the treatment cost is reduced, a problem that the ferro-nickel slag is difficult to treat is effectively solved, and the environmental pollution is reduced; a modifier gypsum is introduced, so that part of a gel material can be effectively substituted by virtue of active ferro-nickel slag micro powder; by controlling the total mixing amount of the ferro-nickel slag in the water permeable brick to be over 75% and adding an activator, the breaking strength and the compressive strength as well as various indexes of the prepared ferro-nickel slag water permeable brick for pavements are guaranteed, the national comprehensive utilization industrial policy of the waste resources are fulfilled, and a great deal of the ferro-nickel slag can be treated, and thus the production cost and the energy consumption are reduced.

Owner:贵州省建筑材料科学研究设计院有限责任公司 +1

Process for preparing silumin electronic package materials

InactiveCN1877823AImprove performanceImprove interface binding stateSemiconductor/solid-state device detailsSolid-state devicesSiluminFree cooling

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) placing Al-Si alloy powder in the resistance stove at 250-450 deg.c for 8-32 h; cooling naturally; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

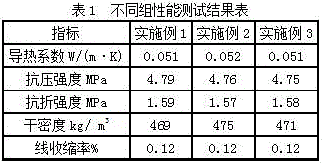

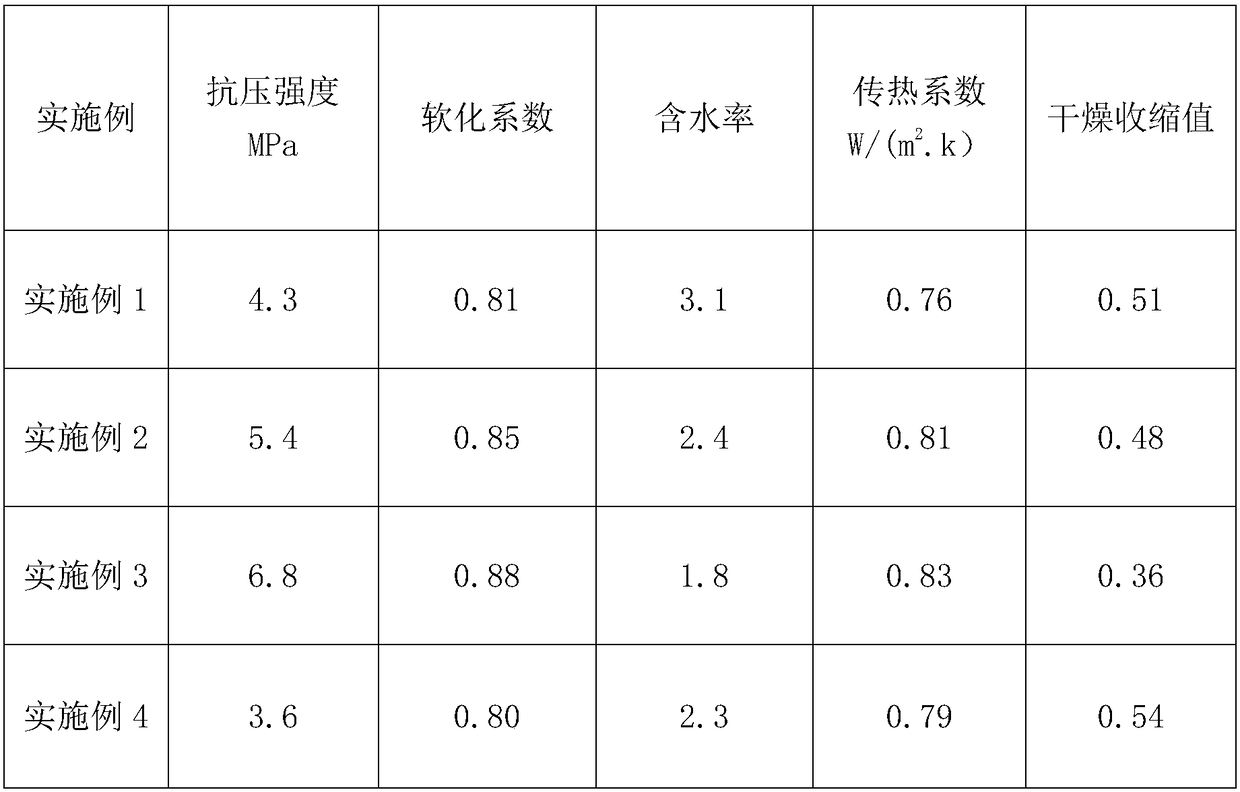

Novel energy-saving thermal insulation mortar and preparation method thereof

The invention relates to novel energy-saving thermal insulation mortar, which is prepared from the following components in parts by weight: 45 to 53 parts of ordinary Portland cement, 8 to 10 parts of wollastonite, 6 to 8 parts of vermiculite power, 12 to 15 parts of ceramic polished waste residue, 15 to 18 parts of vitrified light hollow microsphere, 8 to 10 parts of fly ash hollow cenosphere, 4 to 6 parts of alumina bubble, 2 to 3 parts of lignin fibre, 2 to 3 parts of polyvinyl alcohol fibre, 1 to 1.5 parts of sucrose fatty acid ester, 4 to 5 parts of hydroxypropyl guar gum, 1 to 1.5 parts of sodium dehydroacetate, 2 to 3 parts of strontium carbonate and 3 to 4 parts of poly carboxylic acid water reducing agent. The novel energy-saving thermal insulation mortar disclosed by the invention is prepared by adopting a special formula and an optimized proportion; waste, such as the ceramic polished waste residues, is utilized, and an excellent comprehensive performance index is achieved; the novel energy-saving thermal insulation mortar is ensured to have an unexpected thermal insulation effect and a crack resistance effect, and is very suitable for various building thermal insulation projects with high requirements.

Owner:东莞市鑫燕建筑节能材料有限公司

Ball float type liquidometer with vernier display

ActiveCN105277258AIncrease stiffnessGuaranteed measurement accuracyLevel indicators by floatsFloat chamberRolling-element bearing

The invention relates to a ball float type liquidometer with vernier display. The ball float type liquidometer comprises a ball float chamber and a ferromagnetic spherical floating ball arranged therein, a vernier outside the ball float chamber, a calibrated scale and a vernier guide rail. The vernier comprises magnetic steel, a frame and a rolling system which is horizontally fixed and sleeved in the frame; the rolling system comprises rolling wheels which are provided with radial grooves along a circumferential surface, rolling bearings and shafts; the magnetic steel is disposed between the ball float chamber and the frame and is fixed outside one side surface close to the ball float chamber on the frame, and the magnetic pole of the magnetic steel is right oriented towards the floating ball; the vernier guide rail is sleeved in the frame and is disposed between the magnetic steel and the rolling system; and the rolling system enables the rolling wheels to roll vertically along the vernier guide rail at groove positions through a magnetic coupling force between the magnetic steel and the floating ball. The ball float type liquidometer is simple and scientific in structure, reliable in application performance, easy to manufacture and low in cost, reduces defects in the prior art and effectively meets needs in correlation fields.

Owner:DALIAN JIAXIN ELECTROMECHANICAL INSTR CO TD

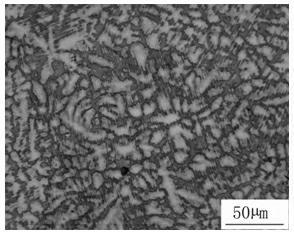

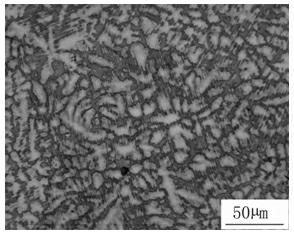

Process method for preparing magnesium alloy through electro-slag remelting

Owner:SOUTHEAST UNIV

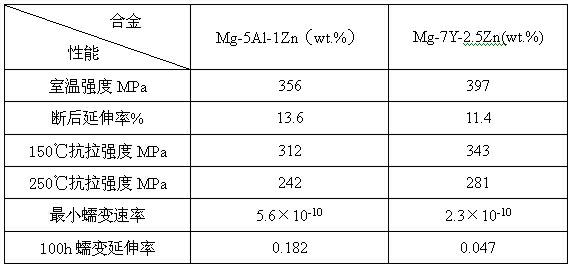

Antibacterial PP spun-bonded non-woven fabric and preparation method thereof

InactiveCN113106633AImprove antibacterial propertiesImprove breathabilityConjugated synthetic polymer artificial filamentsNon-woven fabricsPolymer sciencePolyethylene glycol

The invention discloses an antibacterial PP spun-bonded non-woven fabric and a preparation method thereof. The antibacterial PP spun-bonded non-woven fabric is prepared from the following raw materials in parts by weight of 55 to 65 parts of polypropylene, 30 to 37 parts of an ethylene-methyl methacrylate copolymer, 16 to 20 parts of polyethylene glycol monomethyl ether, 2 to 4 parts of maleic anhydride grafted polypropylene, 3 to 4.2 parts of large-aperture hollow silicon dioxide nanoparticles, 2.6 to 3.2 parts of nano silver-loaded titanium dioxide and 5 to 8 parts of a filler. The antibacterial PP spun-bonded non-woven fabric disclosed by the invention is good and lasting in antibacterial effect, high in air permeability, large in moisture-absorbing constant, high in water absorption rate, good in moisture-absorbing and air-permeable performance, good in skin-friendly performance and high in use comfort level; and in addition, the antibacterial PP spun-bonded non-woven fabric is high in breaking strength, good in mechanical property, good in durability, excellent in comprehensive performance index, good in comprehensive use performance and wide in market application prospect.

Owner:福建澳杰无纺布科技有限公司

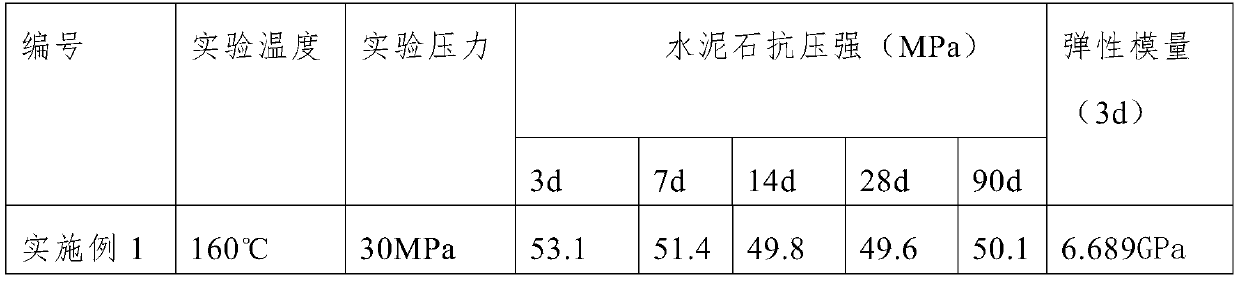

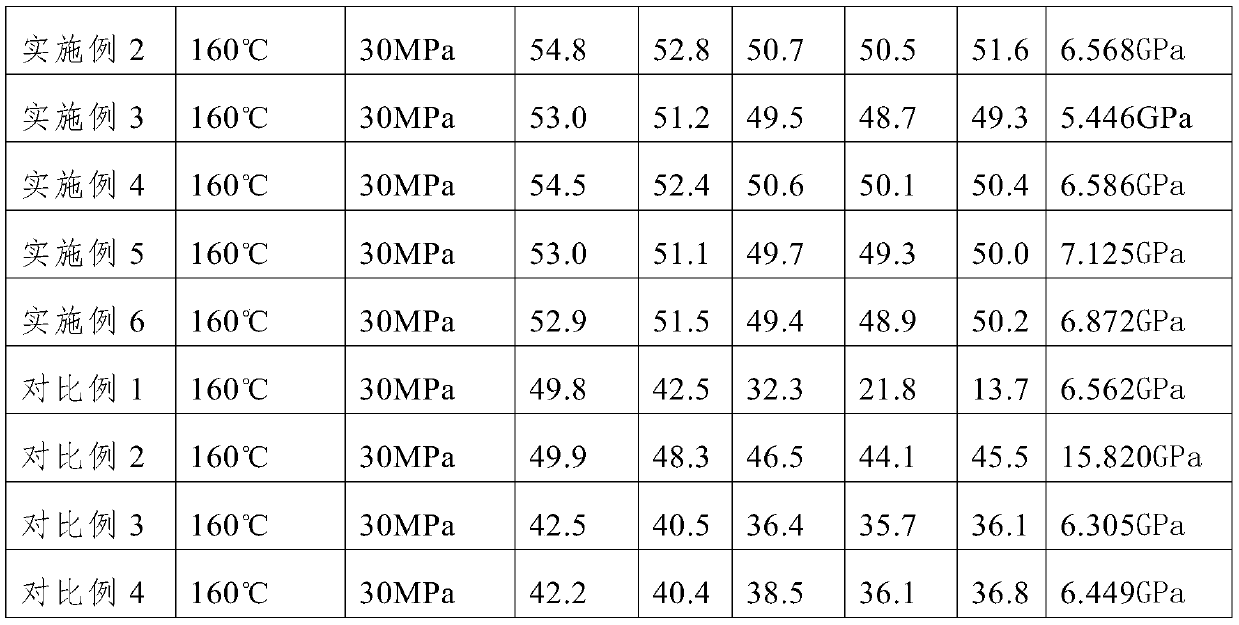

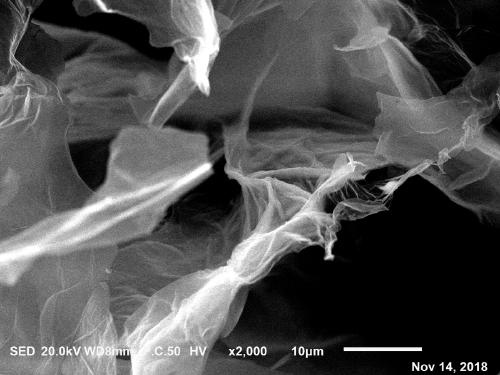

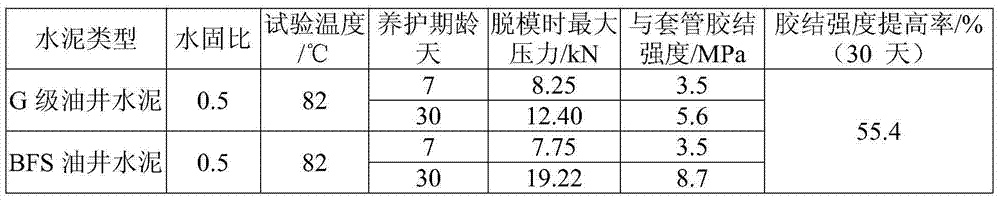

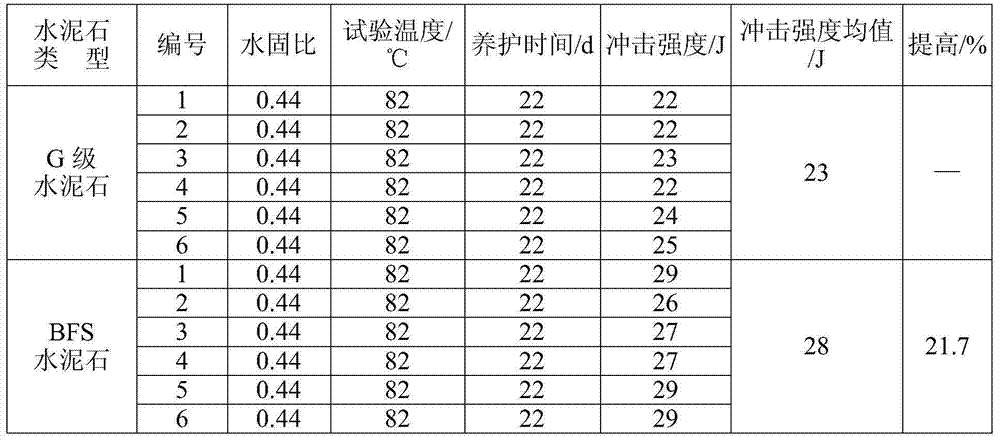

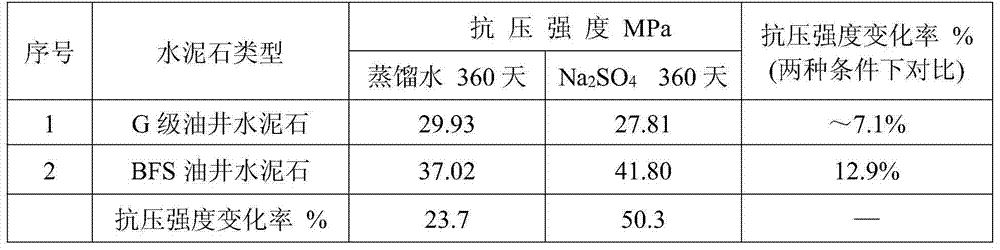

Well cementation oil well cement composition and preparation method thereof

ActiveCN111362656AGood comprehensive performance indexGood practical engineering application effectSolid waste managementCarbon fibersFirming agent

The invention relates to a well cementation oil well cement composition. The oil well cement composition comprises the following components in parts by mass: 50-60 parts of clinker, 5-10 parts of an anti-strength declining agent, 4-8 parts of a brittleness-reducing toughening agent, 2-5 parts of a high-temperature reinforcing agent, 10-20 parts of BFS and 0.5-4 parts of a dispersing agent. The anti-strength declining agent is prepared by mixing wollastonite micro-powder and metakaolin according to a ratio of 1: 4, the brittleness-reducing toughening agent is one or more of high-elastic-modulusPVA fibers, low-elastic-modulus polypropylene fibers, calcium sulfate whiskers, carbon fibers and waterborne epoxy resin containing a curing agent, the high-temperature reinforcing agent is nano SiO2sol, and the dispersing agent is an APC dispersing agent. The invention is used for solving the problem that the strength of the well cementation cement paste is easy to quickly decline and age in ahigh-temperature hydrothermal environment, and can obviously enhance the impact resistance of the cement, enhance the toughness, reduce the brittleness and improve the rheological property of the cement paste.

Owner:BAODING BAOXING OIL FIELD CEMENTING MATERIAL MFG

Graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material and preparation method thereof

InactiveCN110172632AMeet the use requirementsImprove performanceUltrasonic dispersionCopper–tungsten

The invention relates to a graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material. A preparation process comprises the following steps of uniformly mixing copper aluminumalloy powder, tungsten powder, chromium powder and cuprous oxide powder for standby application; adding ultrasonically dispersed graphene oxide into pre-mixed powder and transferring the mixture to aball-milling tank to be ball-milled; then freezing and drying the mixture; and carrying out vacuum hot press sintering to obtain the graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material. According to the graphene oxide enhanced dispersed copper-tungsten-chromium electric contact material, by adding the graphene oxide into the copper aluminum tungsten chromium mixedpowder for vacuum hot press sintering, an internal oxidization process is simplified. The defects that the affinity and the interface bonding force of graphene and a copper matrix are poor and the electric conducting ability of the graphene oxide is poor are overcome, and the graphene oxide reduced in a vacuum high-temperature condition improves the comprehensive performance of the dispersed copper-tungsten-chromium electric contact material. In addition, the experimental process is simple, small in energy consumption, obvious in performance improvement, high in production efficiency and easyfor industrial production.

Owner:HENAN UNIV OF SCI & TECH

Steel plate with yield strength of 390MPa for building structure, and production method

The invention discloses a steel plate with the yield strength of 390MPa for a building structure, and a production method. The steel plate is prepared from, by mass, 0.10-0.18% of C, 1.20-1.55% of Mn, 0.10-0.30% of Si, 0.02-0.04% of Al, at most 0.01% of S, at most 0.18% of P, at least 0.020% of V, at least 0.010% of Ti, at least 0.015% of Nb and the balance Fe and inescapable impurity elements. The production method comprises a smelting process, a continuous casting process, a heating process, a rolling process and a cooling process, wherein in the continuous casting process, a continuous casting machine with the dynamic soft / heavy reduction technique is adopted for casting. The components are matched according to different steel plate thicknesses, and the efficient utilization of alloy elements is realized. Meanwhile, the production method has the aid of the soft / heavy reduction technique of continuous casting for production, the surface and core quality of the steel plate is stabilized, and the comprehensive performance index of products is good. The thickness range of the produced steel plate is 10-100mm, the fluctuating value of the yield strength is at most 8MPa, and the plate thickness effect is eliminated.

Owner:TANGSHAN IRON & STEEL GROUP +1

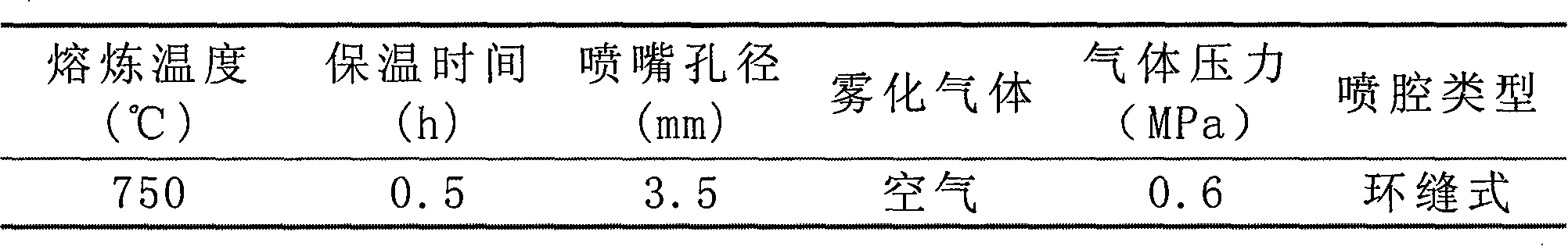

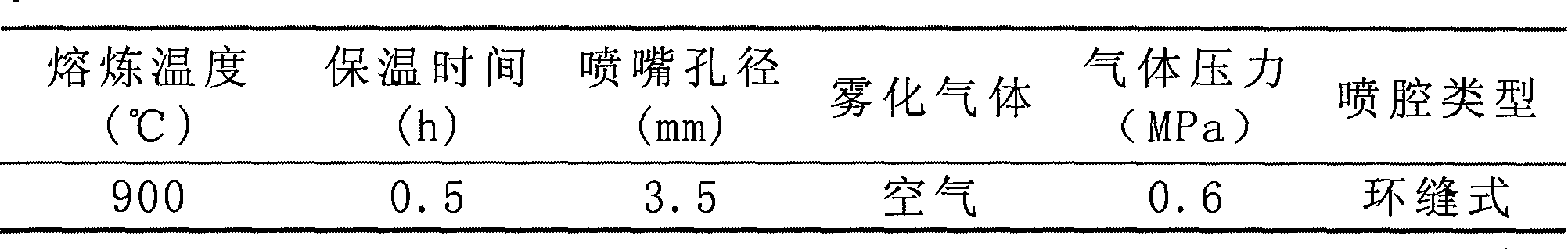

Preparation process of light electronic packaging material

InactiveCN102134650ASmall coefficient of thermal expansionGood mechanical propertiesSemiconductor/solid-state device detailsSolid-state devicesAluminiumSmelting process

The invention discloses a preparation process of a light electronic packaging material which consists of aluminum and silicon, wherein the content of silicon in mass percent is 30-80% and the balance is aluminum. The process comprises the steps of: mixing the aluminum and the silicon and then placing the mixture in a vacuum induction furnace for smelting at a temperature of 800-1300 DEG C so as to obtain a consumable electrode bar; loading in an electric slag furnace for electric slag smelting, wherein the work voltage of the electric slag furnace is 20-40V, the work current is 1-10kA, the arc strike block is a pure aluminum block and the arc strike slag is CaF2; adding electric slag which is thermally insulated for 4-8h at a temperature within 500-800 DEG C in the smelting process, wherein the addition of the electric slag is 3-4% of the quality of the consumable electrode bar and the electric slag consists of 20-30% of Na3A1F6, 25-35% of NaC1 and 45-55% of KC1 in mass percent; and annealing the aluminum-silicon cast ingot which is rapidly solidified by a water cooling crystallizer for 3-5h at a temperature within 325-375 DEG C after the smelting of the electric slag.

Owner:SOUTHEAST UNIV

Preparation method of acrylate-modified polyurethane aqueous dispersion body and application thereof

InactiveCN107722187AHigh transparencyReduce distractionsPaints with free metalsHardnessColor changes

The invention relates to a preparation method of an acrylate-modified polyurethane aqueous dispersion body and application thereof, and belongs to automobile coating series. The invention discloses the polyurethane aqueous dispersion body and the preparation method of the acrylate-modified polyurethane aqueous dispersion body. The acrylate-modified polyurethane aqueous dispersion body fully combines the advantages of acrylics and polyurethanes and has excellent performance on water resistance, solvent resistance, hardness, adhesion and other aspects, the appearance of paint film has metal texture, the color change performance along with angles is high, the total VOC emission can be reduced by 2 / 5, and the acrylate-modified polyurethane aqueous dispersion body is environmentally friendly, capable of saving energy, high in operability, convenient to popularize and apply and broad in market prospect.

Owner:广东华斓汽车材料研究院

BFS oil well cement

The invention discloses a BFS oil well cement. The BFS oil well cement comprises BFS and clinker, wherein a weight ratio of the BFS to the clinker is 20: 100 to 40: 100. The BFS comprises the following raw materials by weight: 38 to 46% of CaO, 36 to 42% of SiO2, 7 to 20% of Al2O3, 4 to 13% of MgO, 0.2 to 1% of Fe2O3, 0.1 to 1% of MnO and 1 to 5% of SO3. The clinker comprises the following raw materials by weight: 61 to 64% of CaO, 20 to 23% of SiO2, 3 to 6% of Al2O3, 1 to 3% of MgO, 3 to 6% of Fe2O3 and 3% of SO3. According to the invention, a part of the special raw material BFS is employed, a great number of simulation tests under different well depth conditions are carried out, and finally, an optimal composition range is determined; the structural characteristics and chemical activity of the raw material are made full use of, and every performance index is well balanced; thus, the overall performance index of the BFS oil well cement is obviously better than the overall performance index of G-grade oil well cement, and the BFS oil well cement has good effect in practical engineering application and exerts obvious improvement effect on well cementation quality.

Owner:BAODING BAOXING OIL FIELD CEMENTING MATERIAL MFG

Machining method of trapezoid-section special-shaped steel wire

The invention provides a machining method of a trapezoid-section special-shaped steel wire. Preliminary drawing is performed on a steel wire rod through a die to form a machining bus, wherein the diameter of the machining bus is 0.25-0.30 time of the perimeter of the trapezoid-section special-shaped steel wire; and continuous multi-pass rolling is performed on the prepared machining bus through arolling mill to prepare a flat steel wire, wherein the thickness of the flat steel wire is 1.05-1.15 times of the size of the upper bottom side of the final trapezoid-section special-shaped steel wire. The flat steel wire with a similar trapezoid section is produced in the flat roller cold rolling stage, the machining efficiency is high, and product performance is stable. Then, through die drawing, the semi-finished large-specification trapezoid-section special-shaped steel wire with excellent comprehensive performance indexes and meeting the use requirements of auger blades is produced through size settling. Since the steel wire obtained through drawing forming is quite small in deformation, high-speed production can be carried out, die consumption is low, and the steel wire is accurate in size control, smooth and natural in appearance and free of flash. The machining method is low in production cost, high in production efficiency and stable in finished product performance.

Owner:江阴法尔胜异型金属材料有限公司

Preparation method of oxide ceramic particle enhanced Cu-based composite material

ActiveCN111996408AGood comprehensive performance indexSimple processOxide ceramicAmmonium metatungstate

The invention relates to an oxide ceramic particle enhanced Cu-based composite material and a preparation method thereof, and belongs to the field of composite materials. Aluminum nitrate (or zirconium nitrate), cupric nitrate and ammonium metatungstate are adopted as raw materials to prepare a solution with the certain concentration, and the solution is evenly mixed, a composite powder precursoris prepared through a whirlwind spray drying method, and an Al2O3-WO3-CuO mixed powder is obtained through roasting; and then after Al2O3-WO3-CuO is reduced through high-purity hydrogen, Al2O3-doped copper-tungsten composite powder is obtained, and the composite powder is subjected to vacuum hot-pressing sintering to prepare the Al2O3 ceramic particle enhanced Cu-based composite material, whereinZrO2-WO3-CuO mixed powder can also be used for obtaining ZrO2, and the effect of the ZrO2-WO3-CuO mixed powder is the same as the effect of Al2O3. The technological process is simple, and the preparedAl2O3 ceramic particle enhanced Cu-based composite material is uniform in component, fine and uniform in crystal particle, ultra low in impurity content and good in comprehensive performance index, can be used for harsh working conditions where power receiving, high temperature, abrasion and corrosion interact, is suitable for large-scale industrial production and has wide industrial applicationprospects.

Owner:HENAN UNIV OF SCI & TECH

Method for forming irregularly-shaped steel wire with S-shaped cross section

InactiveCN105537266AGood comprehensive performance indexMeet the use requirementsMetal rolling arrangementsMetallurgyLower upper

The invention discloses a method for forming an irregularly-shaped steel wire with an S-shaped cross section. The method comprises the following steps: a, taking a round steel wire as a raw material, primarily rolling the round steel wire into a first flat steel wire with parallel upper and lower upper surfaces by using upper and lower rollers of a first rolling machine; b, threading the first flat steel wire into a sensing ring for heating in front of an inlet end of a second rolling machine, and subsequently rolling the flat steel wire into a second flat steel wire with a trench in an opposite angle of the upper surface and the lower surface by using the upper and lower rollers of the second rolling machine; c, after cooling the second flat steel wire, further rolling the cooled second flat steel wire by using the upper, lower, left and right rollers of a third rolling machine, and obtaining a third flat steel wire with a cross section having the shape and the size approximate to those of an irregularly-shaped steel wire finished product with a S-shaped cross section; d, finely trimming and shaping the third flat steel wire by using the upper, lower, left and right rollers of a rolling mold, and obtaining the irregularly-shaped steel wire finished product with the S-shaped cross section. Due to multiple continuous rolling procedures of hot rolling first and cooling rolling later, the irregularly-shaped steel wire with the S-shaped cross section, which is excellent in comprehensive property indexes, can meet the use requirements of a flexible compound hose anti-pressure armor layer, and is small in amount of procedures, low in cost and high in production efficiency, can be formed.

Owner:中钢集团郑州金属制品研究院股份有限公司

Preparation method of magnesium alloy steering wheel skeleton

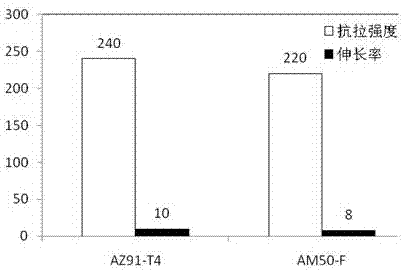

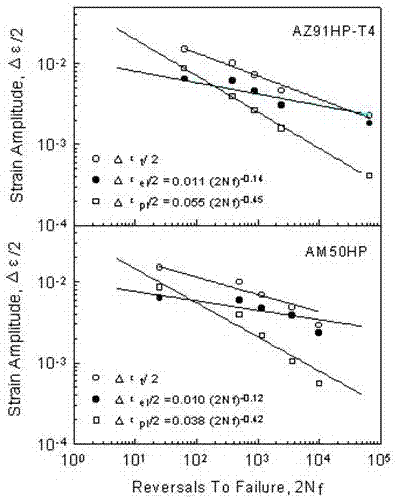

The invention discloses a preparation method of a magnesium alloy steering wheel skeleton, and belongs to the technical field of materials. The preparation method is characterized in that an AZ91-F magnesium alloy and a preparation technology in which solution treatment is carried out after vacuum die-casting forming are mainly adopted to replace an AM50-F / AM60-F magnesium alloy and a preparationtechnology in which thermal treatment cannot be carried out after non-vacuum die-casting forming, wherein the die-casting pouring temperature is 670 DEG C to 690 DEG C, the mold temperature is 200 DEGC to 220 DEG C, the mold filling speed is 80 m / s, the solidification pressure is 70 MPa, the vacuum degree of a mold cavity is 5 KPa, the solid solution heating temperature is 415 DEG C, the heat preservation time is 8 h, and the cooling method is air cooling. Compared with an AM50-F / AM60-F magnesium alloy steering wheel skeleton, an AZ91-T4 magnesium alloy steering wheel skeleton has the advantages that the static tensile strength is improved by 20 MPa, the elongation is improved by 9%, the transition fatigue life under the condition that R equal to minus 1 is improved by 80% to 100%, and the AZ91-T4 magnesium alloy steering wheel skeleton has relatively long strain fatigue life at high strain amplitude.

Owner:SHENYANG POLYTECHNIC UNIV

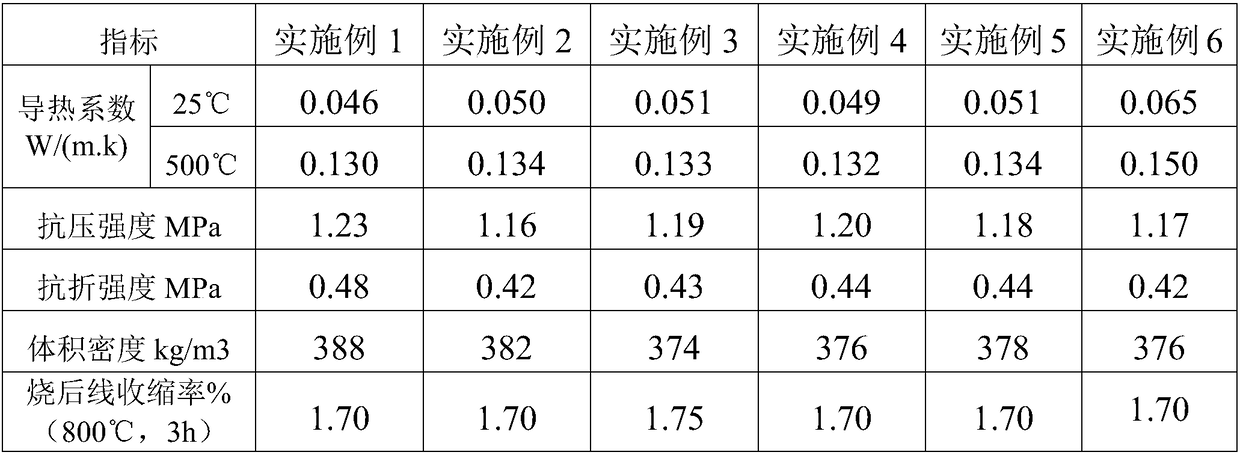

Thermal insulation mortar with lower thermal conductivity coefficient and preparation method thereof

The present invention discloses a thermal insulation mortar with a lower thermal conductivity coefficient and belongs to the technical field of building materials. The thermal insulation mortar is prepared from the following raw materials: 250-350 parts of silicate cement, 180-240 parts of river sand, 160-240 parts of construction waste residues, 120-170 parts of talc, 10-20 parts of asphalt, 30-80 parts of thermal insulation aggregate, 6-9 parts of mineral wool, 8-12 parts of lignocellulose, 3-8 parts of a water resistant agent and 3-5 parts of an admixture. The thermal insulation aggregate is composed of expanded perlite and hollow glass micro-beads in a weight ratio of 1:(0.1-0.3). The hollow glass micro-beads are compounded with the expanded perlite and mineral wool. The prepared thermal insulation mortar has a thermal conductivity coefficient obviously lower than that of thermal insulation mortar compounded by the expanded perlite and mineral wool, and also has higher strength andhigher use value.

Owner:芜湖市颂晖商贸有限公司

Copper-based composite material and preparation method thereof

ActiveCN110257664AGood comprehensive performance indexSimple processMaterials preparationNuclear radiation

The invention relates to a copper-based composite material and a preparation method thereof, and belongs to the field of metal and composite materials thereof. The copper-based composite material comprises the following components of, in percentage by weight, 3%-18% of W, 0.5%-5% of B4C, and the balance copper. The preparation method comprises the following steps of firstly, selecting high-purity Cu powder, W powder and B4C powder, and weighing the Cu powder, the W powder and the B4C powder by adopting a high-precision balance, and carrying out vacuum ball milling for 2 h-8 h; secondly, filling the mixed powder into a mold made of heat-resistant steel, and then putting the mold into a vacuum hot-press sintering furnace for hot-pressing sintering forming, wherein the sintering temperature is 950 DEG C-1030 DEG C, the sintering pressure is 50 MPa-60 MPa, the heat and pressure preservation time is 1 h-3 h, and the vacuum degree is 10<-3> Pa; finally, carrying out cooling along with the furnace after the sintering is completed. The copper-based composite material preparation method has the advantage of being simple in process, and the prepared copper-based composite material has good comprehensive performance and can be used in strict working conditions of power receiving, abrasion, corrosion and nuclear radiation interaction, thus having a very wide application prospect and popularization value.

Owner:HENAN UNIV OF SCI & TECH

Phosphogypsum-based steel mesh frame composite wallboard and preparation method thereof

PendingCN109180215AEfficient resource utilizationSolve difficult-to-use problemsCeramicwareResource utilizationSlurry

The invention discloses a phosphogypsum-based steel mesh frame composite wallboard, and relates to the technical field of building materials. The wallboard includes phosphogypsum powder, mineral powder, activated mineral powder, cement, quicklime, a foaming agent, an admixture, a steel mesh frame and fiberglass mesh. The preparation method comprises the following steps: firstly placing the steel mesh frame into a mold for standby, then weighing the phosphogypsum powder, the mineral powder, the activated mineral powder, the cement, the quicklime and the foaming agent and stirring and mixing uniformly, adding water into the admixture, adding the admixture into the above mixture and stirring to form a mixed slurry; pouring the mixed slurry into the mold for moulding, demolding the formed product and cutting, laying the fiberglass mesh, and spraying a cement paste protective layer onto the broadside so as to obtain the phosphogypsum-based steel mesh frame composite wallboard. The preparedphosphogypsum-based steel mesh frame composite wallboard has advantages of effective resources utilization, good stability, high compressive strength, durability and good water resistance.

Owner:兴义市黔城商品混凝土有限公司

Process for preparing silumin electronic package materials

InactiveCN100411157CImprove featuresImprove performanceSemiconductor/solid-state device detailsSolid-state devicesSiluminMaterials processing

The invention discloses a making technology of high-silafont electronic packing material, which comprises the following steps: A) preparing powder: blending industrial pure aluminum and high-pure silicon at 6-8.8:4-1.2 percentage to prepare Al-Si alloy powder; B) proceeding ball grinding disposal for Al-Si alloy powder at 5-15:1 percentage for 8-32 h; C) loading oxide alloy powder in the pure aluminum; proceeding squeezing disposal on the 300-500 ton hydrostatic machine through forward squeezing pattern; keeping temperature at 400-520 deg.c for 0.5-2 h for Al-Si alloy powder before squeezing; placing each squeezing mould in the heat stove at 10-21 squeezing rate to preheat at 200-400 deg.c; squeezing to produce the product. The invention can improve heat conductivity, airtightness and tensile strength obviously, which keeps low expansion coefficient.

Owner:CENT SOUTH UNIV

Process method for preparing magnesium alloy through electro-slag remelting

The invention discloses a process method for preparing magnesium alloy through electro-slag remelting, which comprises the following steps of: mixing raw materials for preparing the magnesium alloy, and smelting at the temperature of between 800 and 900DEG C under the protection of SF6 and CO2- gases in a crucible to prepare a consumable electrode bar; filling in an electroslag furnace for electroslag smelting, wherein the working voltage is 25-40V, the working current is 0.8-5kA, an arc strike block is a pure aluminum block, arc strike slag is CaF2, the protective gases are SF6 and CO2- gases, the electroslag material kept at the temperature of between 700 and 850DEG C for 6 to 8 hours is added in the smelting process, the adding amount of the electroslag material is 3 to 4 percent of the mass of the consumable electrode bar, and the electroslag material comprises the following components in percentage by mass: 5 to 15 percent of CaO, 5 to 20 percent of Al2O3, 10 to 30 percent of MgOand the balance of CaF2; and performing annealing treatment on a magnesium alloy ingot which is quickly consolidated by a water cooled crystallizer at the temperature of between 500 and 525DEG C for 3 to 5 hours, and machining to obtain the finished product.

Owner:SOUTHEAST UNIV

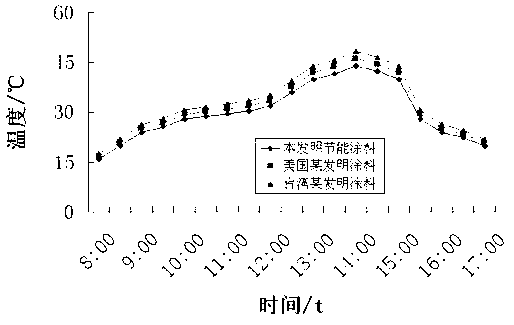

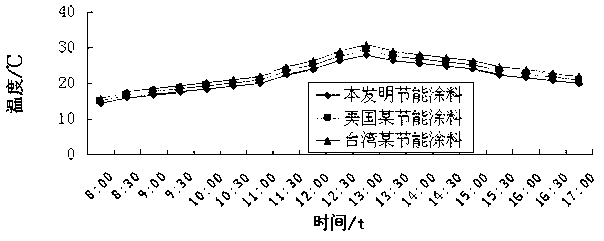

Building outer wall solar heat reflecting energy-saving coating and preparation method thereof

InactiveCN102993851AReduce the temperatureIncrease reflectionReflecting/signal paintsCelluloseTriple superphosphate

The invention discloses a building outer wall solar heat reflecting energy-saving coating which consists of the following components in parts by mass based on 100 parts: 10-15 parts of water, 0.5-1.5 parts of dispersing agent, 0.1-0.5 part of wetting agent, 0.1-0.5 part of antifoaming agent, 0.05-0.15 part of preservative, 0.05-0.15 part of pH regulator, 1-3 parts of propylene glycol, 0.05-0.15 part of cellulose, 5-15 parts of triple superphosphate, 10-30 parts of titanium dioxide, 40-60 parts of emulsion, 4-6 parts of film forming aid, 0.3-0.7 part of mould inhibitor and 0.1-0.5 part of thickening agent. The building outer wall solar heat reflecting energy-saving coating disclosed by the invention can effectively reduce the surface temperature of the outer wall and the indoor environment temperature, reduce the energy consumption of a building, save cost and increase economic benefits.

Owner:BEIJING ORIENTAL YUHONG WATERPROOF TECH CO LTD +1

Super-soft and super-fluffy spun-bonded non-woven fabric and preparation method thereof

ActiveCN112095230AImprove anti-oxidative aging performanceGood anti-ultraviolet aging performanceConjugated synthetic polymer artificial filamentsNon-woven fabricsLow-density polyethylenePolyurethane elastomer

The invention discloses a super-soft and super-fluffy spun-bonded non-woven fabric and a preparation method thereof. The super-soft and super-fluffy spun-bonded non-woven fabric is prepared from the following raw materials in parts by weight: 55-65 parts of polyethylene glycol terephthalate, 25-32 parts of polyurethane elastomers, 7-10 parts of polyethyleneglycol adipate, 5-7 parts of linear low-density polyethylene, 9-12 parts of metallocene linear low-density polyethylene and 4-6 parts of oxidized polyethylene. According to the super-soft and super-fluffy spun-bonded non-woven fabric, on thepremise that the mechanical property and durability are guaranteed, the softness of the super-soft and super-fluffy spun-bonded non-woven fabric is far superior to that of common PET non-woven fabric, the fluffy comfort degree of the super-soft and super-fluffy spun-bonded non-woven fabric is far superior to that of the common PET non-woven fabric, the air permeability is high and good, the disability is high, and the elasticity is good; the good waterproof performance is achieved; and the comprehensive performance index is excellent, the comprehensive use performance is good, and the marketapplication prospect is wide.

Owner:FUJIAN GUAN HONG IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com